Novel bamboo-plastic composite material

A composite material, bamboo-plastic technology, applied in the field of material preparation, can solve the problems of increasing the interface adhesion between fiber and resin, reducing the impact strength of composite materials, and large shrinkage

Inactive Publication Date: 2011-11-02

EAST CHINA UNIV OF SCI & TECH

View PDF6 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are two main disadvantages of polypropylene: one is the large shrinkage rate, which leads to poor dimensional stability of the product and is prone to warping and deformation; the other is that it is easy to break at low temperature

By adding a compatibilizer, the functional groups can react, reduce the number of hydroxyl groups on the surface of the fiber, and increase the interfacial adhesion between the fiber and the resin, but the addition of the fiber will greatly reduce the impact strength of the composite material.

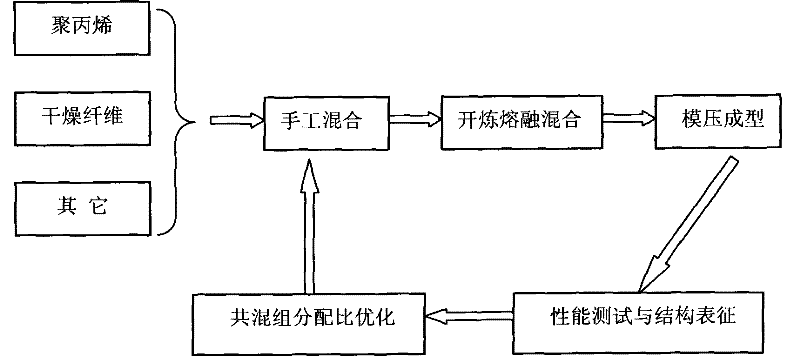

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 4

[0030]

Embodiment 8

[0035]

Embodiment 10

[0038] Comparison group:

[0039] [Example 1]

[0040] [Example 2]

[0041] [Example 3]

[0042] [Example 4]

[0043] [Example 5]

[0044] [Example 6]

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

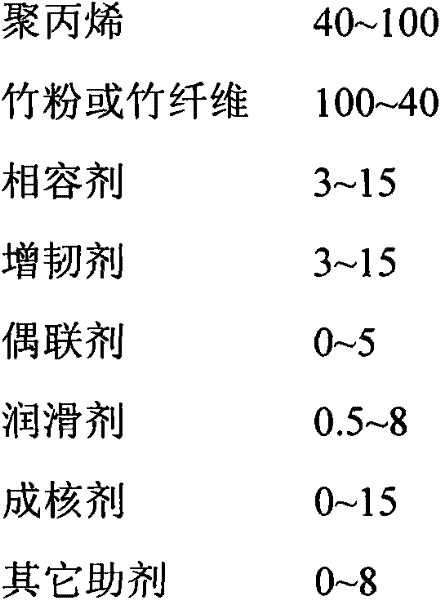

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Description

technical field [0001] The invention relates to the preparation of a novel bamboo-plastic composite material. It specifically relates to a bamboo-plastic composite material with superior mechanical properties obtained by adding reinforcement material bamboo powder (or bamboo fiber), toughening agent and other additives, which belongs to the field of material preparation. Background technique [0002] Polypropylene is a thermoplastic resin obtained by free radical polymerization of propylene monomers. According to the order of methyl groups, there are three types: isotactic polypropylene, atactic polypropylene and syndiotactic polypropylene. Industrial products are characterized by isotactic polypropylene. Propylene-based. Polypropylene has a melting temperature of about 170°C and a density of 0.90 g / cm 3 , is the lightest general-purpose plastic. It has high strength, high hardness, wear resistance, bending fatigue resistance, high heat resistance, good moisture resistance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L97/02C08L23/12C08L51/06C08L51/00C08K3/26C08K3/34C08K3/22C08K13/02

Inventor 汪济奎蔡国锋朱旭东聂亚楠田孝才郭卫红

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com