Patents

Literature

52results about How to "Reduce the number of hydroxyl groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

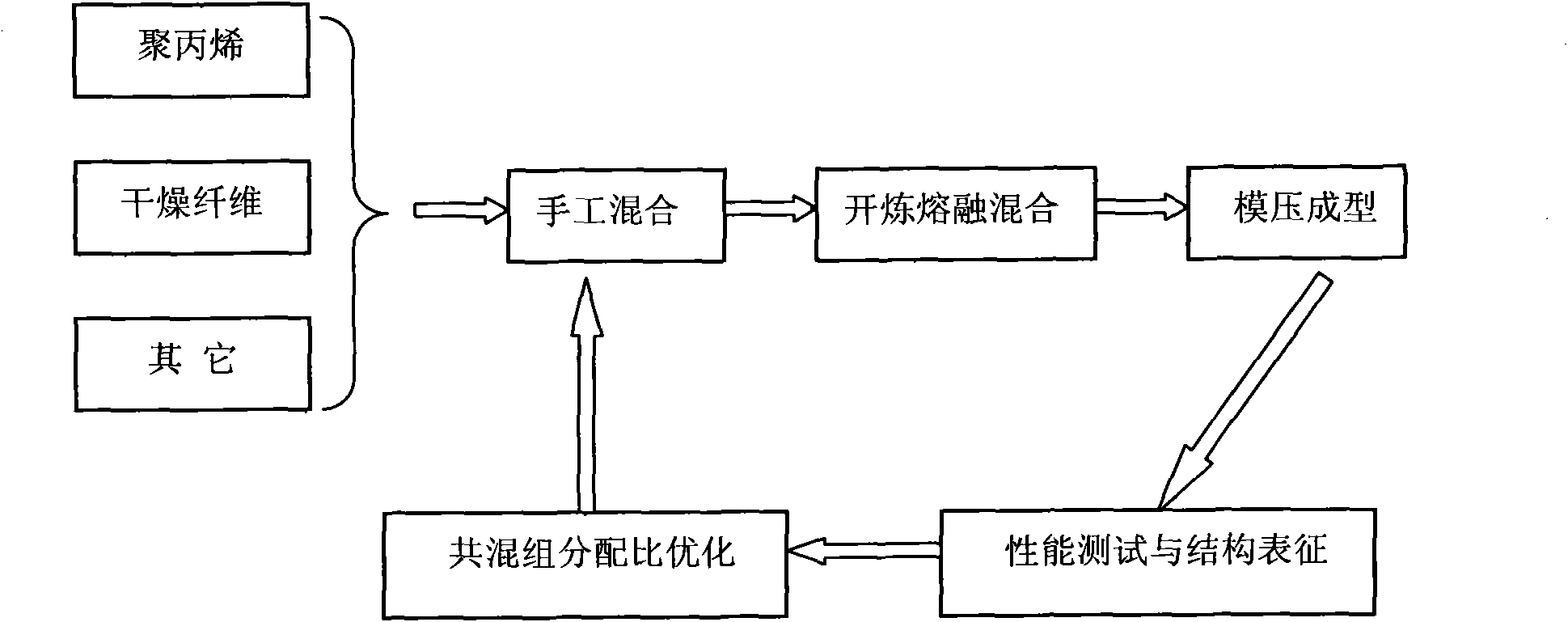

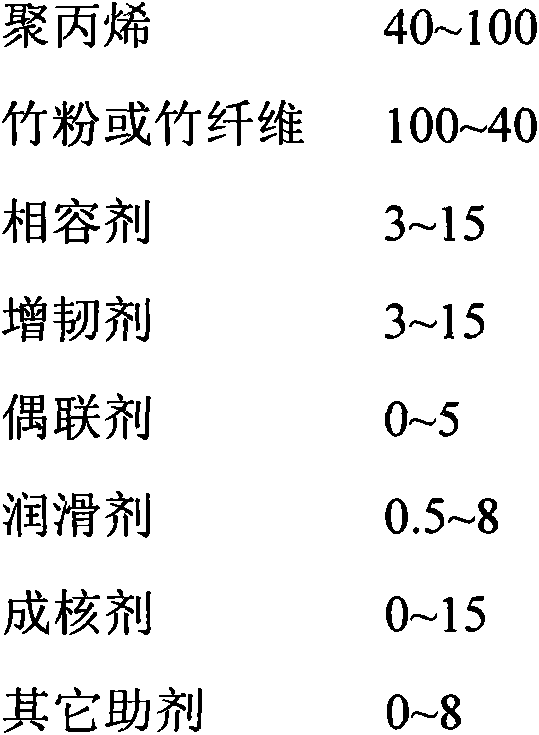

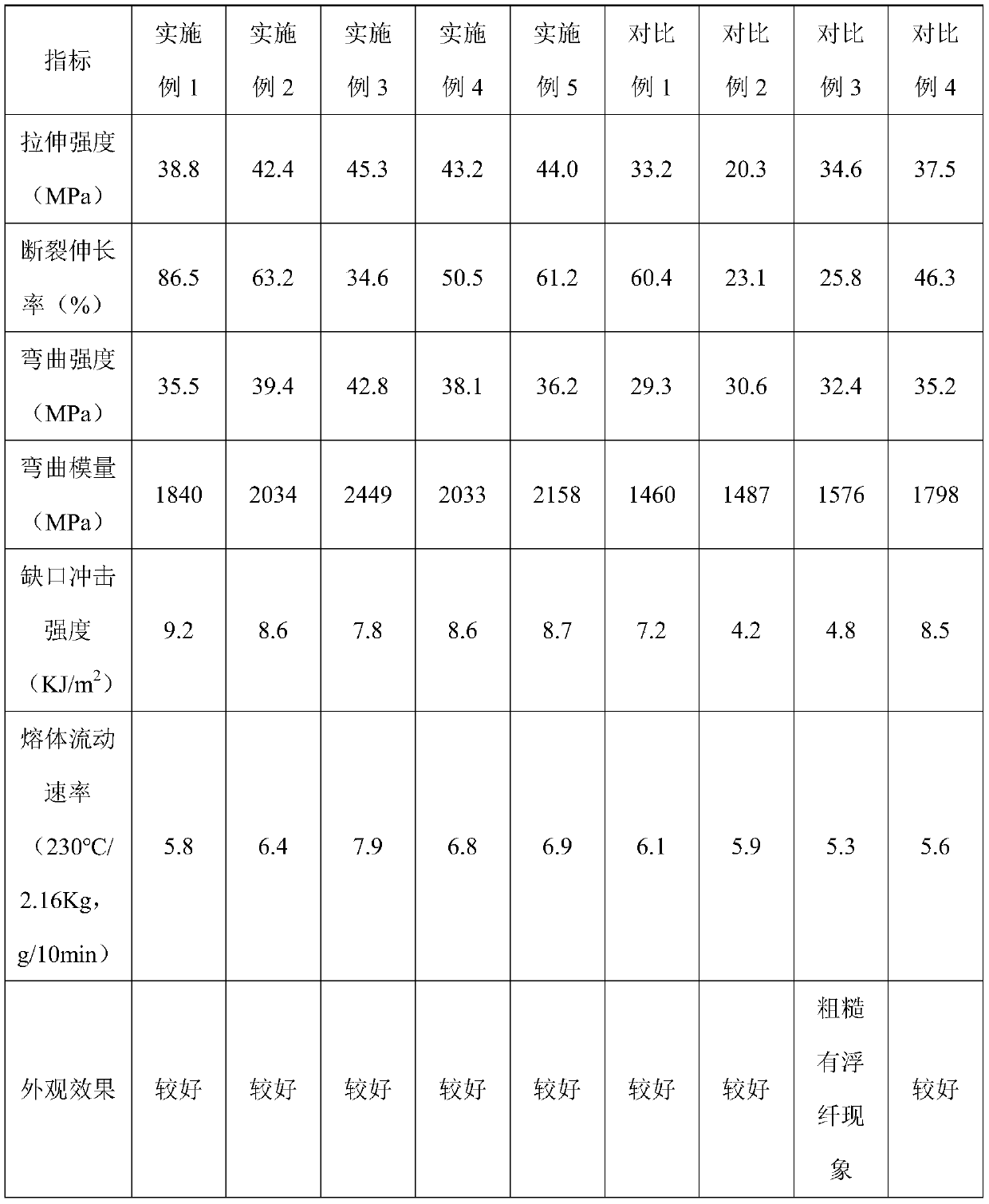

Novel bamboo-plastic composite material

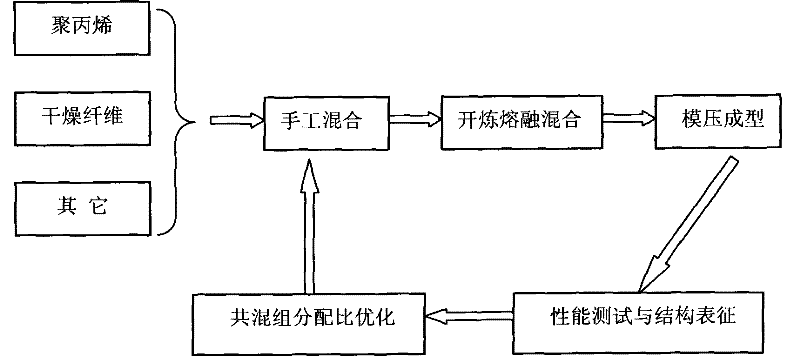

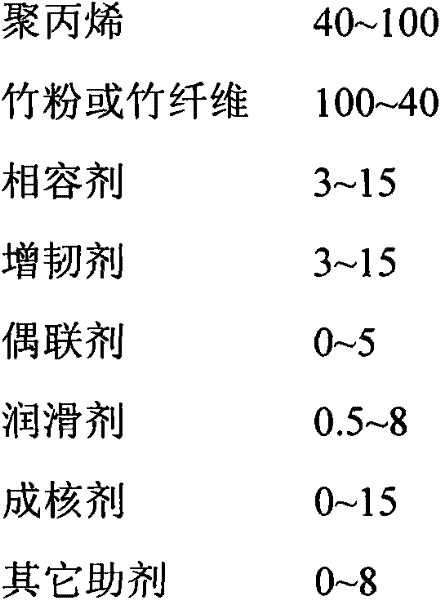

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

Laser transfer paper, and production technology thereof

ActiveCN110284372AReduce hydrophilicityReduce the number of hydroxyl groupsFlexible coversWrappersLaser patterningPaper based

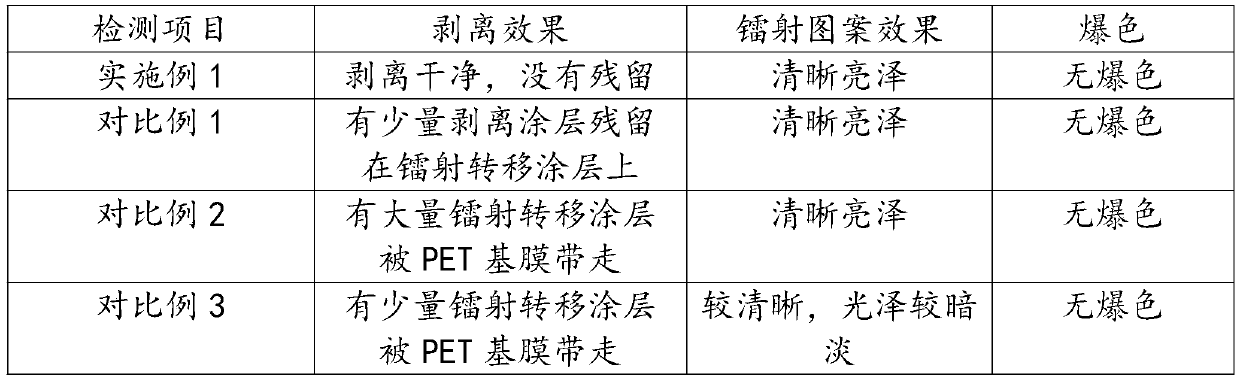

The invention discloses laser transfer paper and production technology thereof. The laser transfer paper comprises a laser transfer coating layer, laser patterns printed onto the laser transfer coating layer, an aluminizing layer used for coating the laser transfer coating layer through plating, a protective rubber layer which is used for coating the aluminizing layer and protecting a part of the aluminizing layer, and a zinc sulfide dielectric layer which is used for coating the protective rubber layer through plating; and the zinc sulfide dielectric layer is bonded with a paper base through a transfer glue. According to the laser transfer paper, the laser patterns with hollowing out effect are formed, so that the appearance effect of the laser transfer paper as packing paper is improved; the bonding capacity of a peeling coating layer with a tackifying bottom coating layer is increased, so that the stability of laser transfer film in subsequent processing process is ensured; at the same time, the surface tension of the coating layer after curing is reduced, the coating layer peeling effect is improved, and light transmission and white exposure caused by peeling of a part of the laser transfer coating layer are prevented; in laser transfer coating layer preparation process, resin system light transmission effect is improved, so that the reflective effect of the laser patterns is improved.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

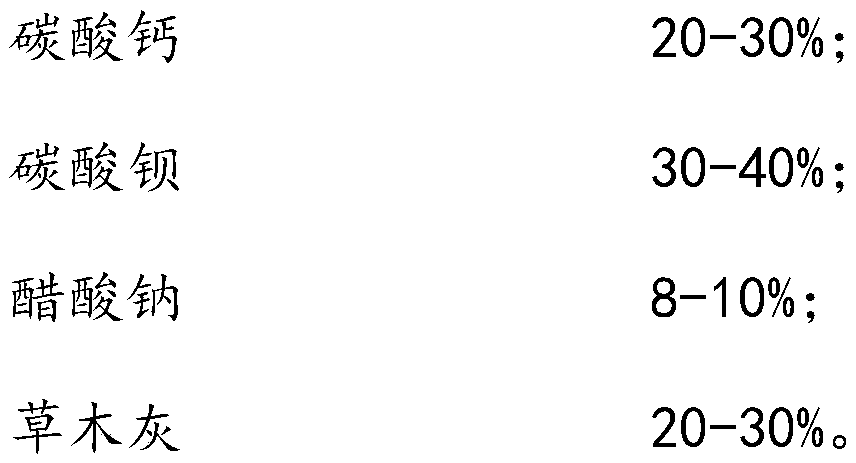

Putty powder for building inner and outer walls and preparation method of putty powder

ActiveCN106590133AEvenly distributedImprove crack resistanceFireproof paintsAntifouling/underwater paintsCellulosePolyethylene glycol

The invention provides putty powder for building inner and outer walls and a preparation method of the putty powder. The putty powder is prepared from ash-calcium, talcum powder, cement, cellulose, rubber powder, a binding agent and reinforcing powder. The reinforcing powder is formed by mixing composite powder, diatomite and calcium oxide, and the composite powder is obtained by sintering clay, silicon carbide, carbon powder and aluminum hydroxide. The binding agent is prepared from alumina micro powder, modified nanosilicon dioxide, polyethylene glycol and water. The putty powder contains the reinforcing powder and binding agent with special ingredients, when the putty powder is manufactured, the ash-calcium, the binding agent and the reinforcing powder are mixed firstly, hot water is added, the materials are stirred, part of ash-calcium is injected into a microcellular structure or adheres to the surface, then the ash-calcium is fully bonded with the cellulose and the rubber powder added later, therefore, the bonding performance between all the ingredients in the putty powder is enhanced, the anti-cracking performance and hardness of the putty powder are enhanced, and the waterproof performance of the putty powder is also improved to a certain degree.

Owner:平顶山锦亦翔墙釉科技有限公司

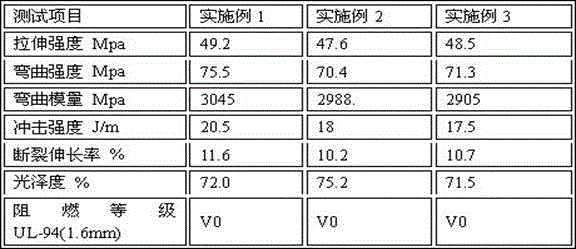

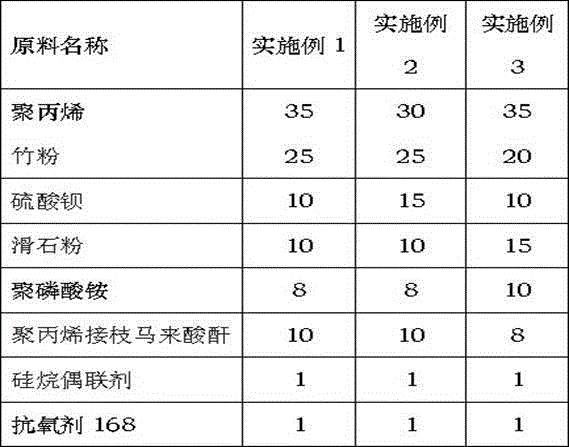

Reinforced flame-retardant bamboo-plastic composite material and preparation method thereof

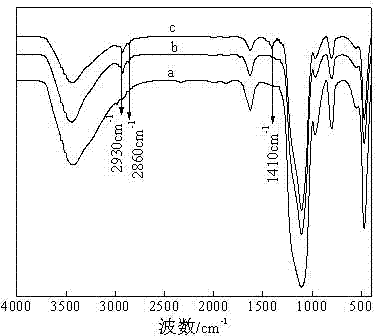

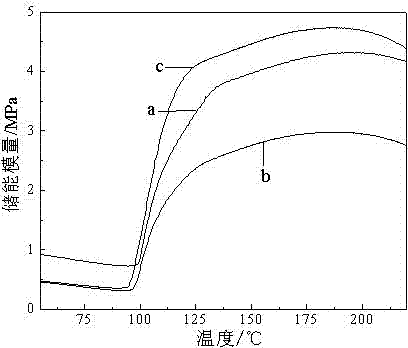

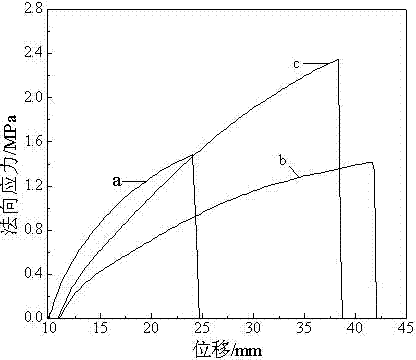

InactiveCN103333410AReduce the number of hydroxyl groupsImprove interfacial adhesionCorrosion resistantPolypropylene

The invention aims to provide a reinforced flame-retardant bamboo-plastic composite material and a preparation method thereof. The reinforced flame-retardant bamboo-plastic composite material is characterized by comprising the following components by mass percent: 35-60 percent of polypropylene, 15-40 percent of bamboo powder, 10-20 percent of barium sulfate, 10-20 percent of talcum powder, 5-10 percent of flame retardant, 2-10 percent of compatilizer, 0.5-2 percent of coupling agent and 0.1-1 percent of antioxygen. The prepared reinforced flame-retardant bamboo-plastic composite material is excellent in flame-retardant effect, favorable in surface glossiness and high in physical and mechanical strengths, is waterproof and corrosion-resistant, is a green and environmental-friendly bamboo-plastic composite material and can be widely applied in the fields of gardens, buildings, decoration and the like.

Owner:长沙达联塑料有限公司

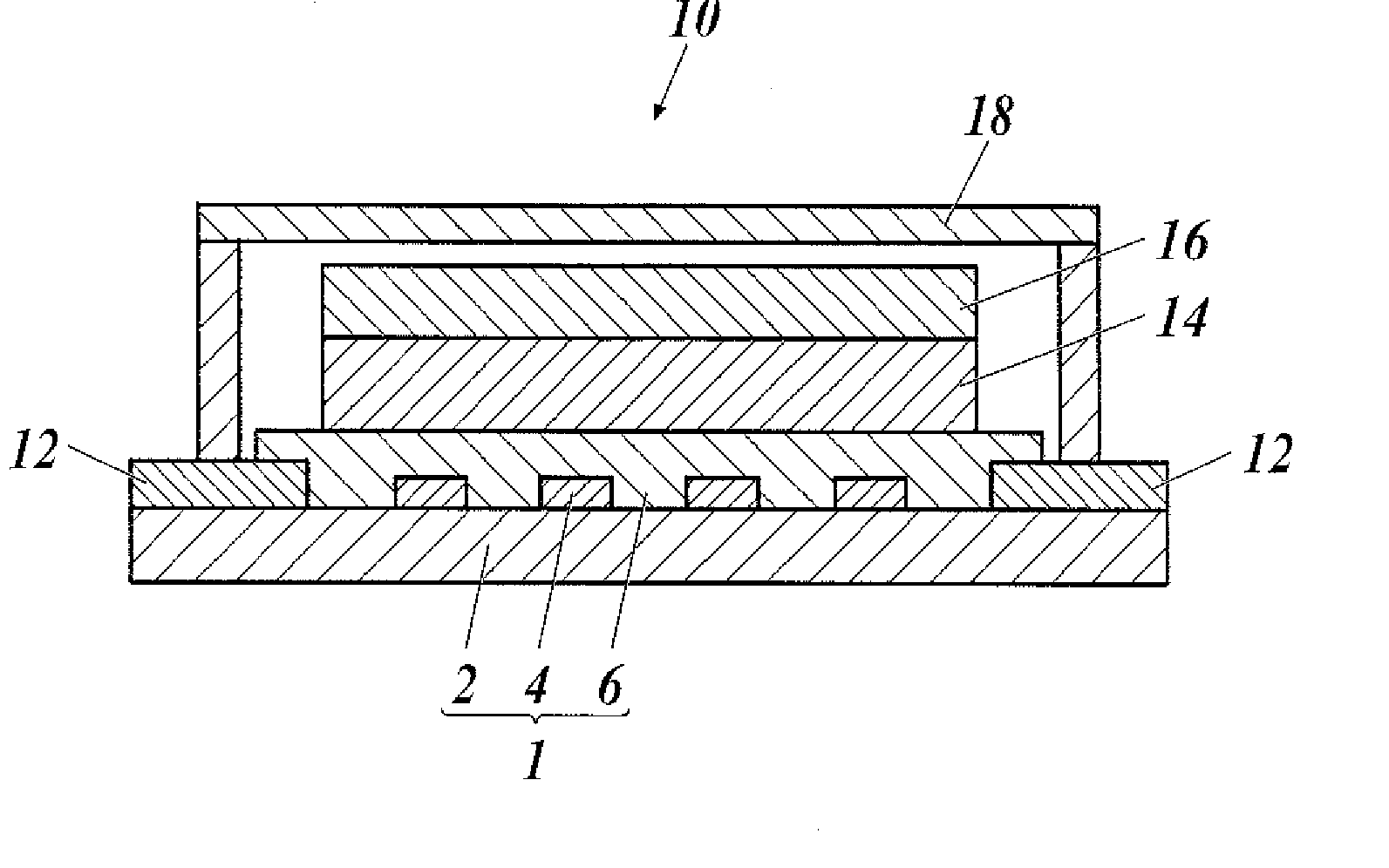

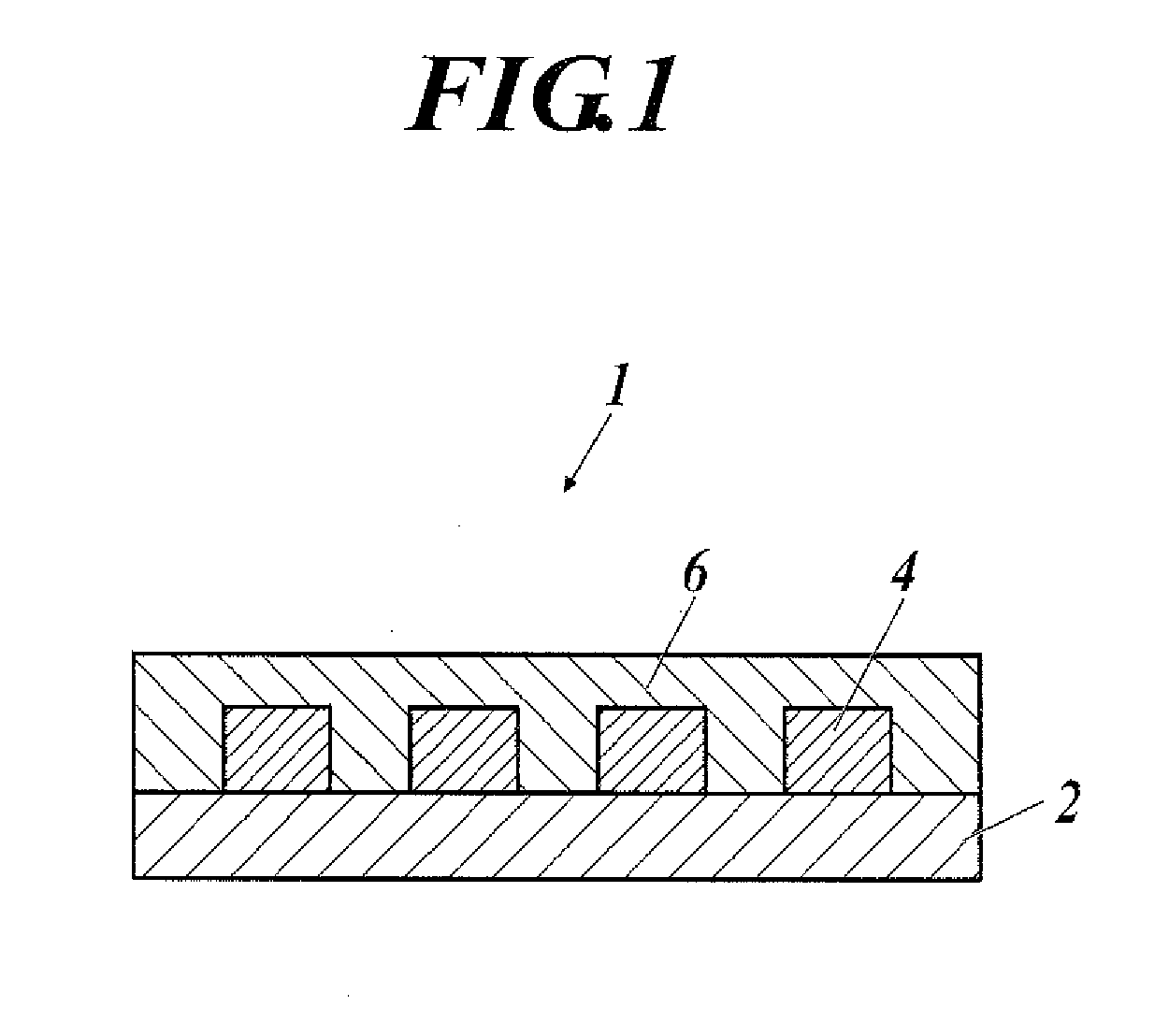

Composition for forming transparent electrode, transparent electrode, organic electronic element, and method for manufacturing transparent electrode

InactiveUS20150364713A1Prevent performanceReduce interactionFinal product manufactureSemiconductor/solid-state device detailsSolventElectrically conductive

A composition for forming a transparent electrode is to form a conductive polymer layer on a transparent substrate. The composition includes: a conductive polymer; a self-dispersing polymer dispersible in an aqueous solvent; water; a polar solvent other than water; and a glycol ether. The self-dispersing polymer is a self-dispersing polymer containing a dissociable group and having a glass transition temperature of 25° C. or more and 80° C. or less.

Owner:KONICA MINOLTA INC

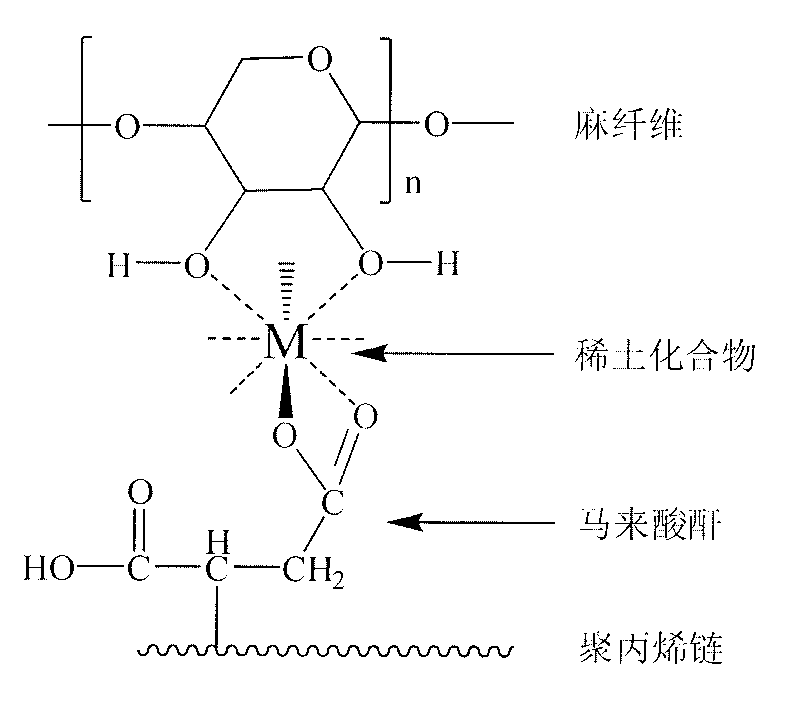

Compound modified biomass fibrilia and preparation method thereof

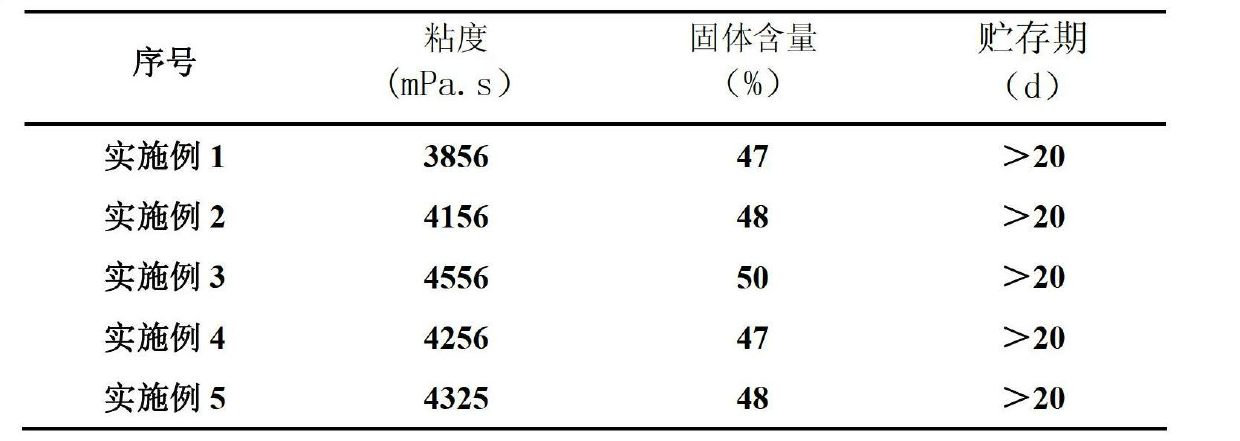

The invention relates to a compound modified biomass fibrilia and a preparation method thereof and develops a rare earth compound modified fibrilia, which is characterized in that maleic anhydride grafted polypropylene is grafted and coated on the outer surface of natural fibrilia modified by rare earth. The preparation method comprises the following steps of: impregnating the natural fibrilia in a certain rare earth solution at normal temperature or low temperature for 1-2 hours, filtering and drying; and then coating the maleic anhydride grafted polypropylene on the fibrilia treated by the rare earth by adopting an extruding method to obtain the compound modified biomass fibrilia. The compound modified method can effectively eliminate the problems of surface structural defects and impurities, change the surface polarity and the hydrophily, greatly improve the interface bonding force of the fibrilia and a polymer matrix material, can be expected to be made into a fibrilia / polymer composite material with strong interface bonding capability and excellent mechanical property and ensures that the modified natural fibrilia and a composite material thereof can be more widely applied to the field of buildings, vehicle trimmers, office furniture and the like. The modified method has the advantages of simple operation, scale, no pollution and environment friendlessness.

Owner:HUNAN UNIV +1

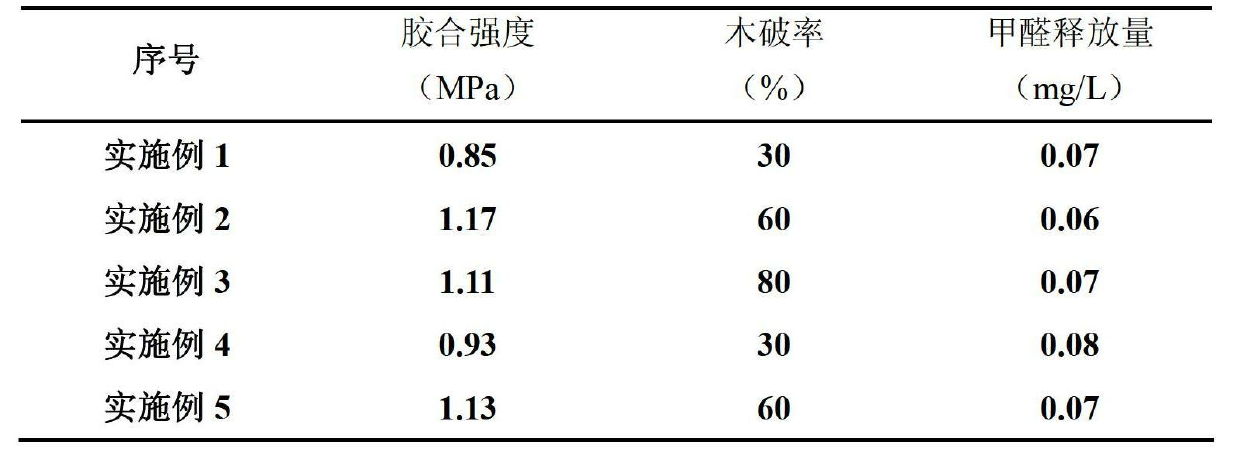

Biological oil-starch-glyoxal resin adhesive for artificial board and preparation method of biological oil-starch-glyoxal resin adhesive

InactiveCN102634298ARealize rational utilizationReduce dependenceStarch derivtive adhesivesEmulsionGlyoxal

The invention relates to a biological oil-starch-glyoxal resin adhesive for an artificial board and a preparation method of the biological oil-starch-glyoxal resin adhesive, belonging to the technical field of an adhesive of the artificial board. The adhesive is prepared by adding an additive consisting of curing agent and filler into a main agent prepared from the biological oil, mechanical activation starch, the glyoxal, oxalic acid, oxidizing agent and water. The method comprises the following steps of: preparing starch emulsion by the mechanical activation starch and water, heating and then keeping the temperature; adjusting pH to obtain acidolysis oxidized starch emulsion; adding the biological oil, adjusting pH and then adding the glyoxal; alternatively adding the oxalic acid and alkali liquor in batches until all the oxalic acid is filled, reducing the temperature and discharging to obtain the main agent; adding the curing agent and the filler into the main agent to obtain the biological oil-starch-glyoxal resin adhesive. The biological oil-starch-glyoxal resin adhesive solves the problems that the current adhesive material used by the artificial board highly depends on petrochemical resources, the environmental friendliness and the degradable performance are poor and the like, and has the characteristics of low cost, high performance and environmental friendliness.

Owner:BEIJING FORESTRY UNIVERSITY

Carrier transport material and preparation method thereof, and QLED device

ActiveCN109980099AReduce defectsSimple processSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeCharge carrier mobility

The present invention belongs to the technical field of quantum dots, especially relates to a carrier transport material and a preparation method thereof, and a QLED device. The carrier transport material comprises metal-oxide semiconductor nanocrystallines modified with an alkoxy silane coupling reagent, the structural general formula is H2NRSi(OM)3, wherein M is the metal-oxide semiconductor nanocrystalline, and R is a non-alkoxy carbon chain in the alkoxy silane coupling reagent. The carrier transport material can perform passivation of the surface of the metal-oxide semiconductor nanocrystalline for isolating from water and oxygen to reduce the negative influences of the surface defects on the hole and electron electron recombination in the quantum dots, increase the distances betweenthe metal-oxide semiconductor nanocrystallines, weaken the carrier mobility of the metal-oxide semiconductor nanocrystallines, have a carrier balance effect on the device and finally improve the luminous efficiency of the device.

Owner:TCL CORPORATION

Environment-friendly bio-oil starch adhesive and preparation method thereof

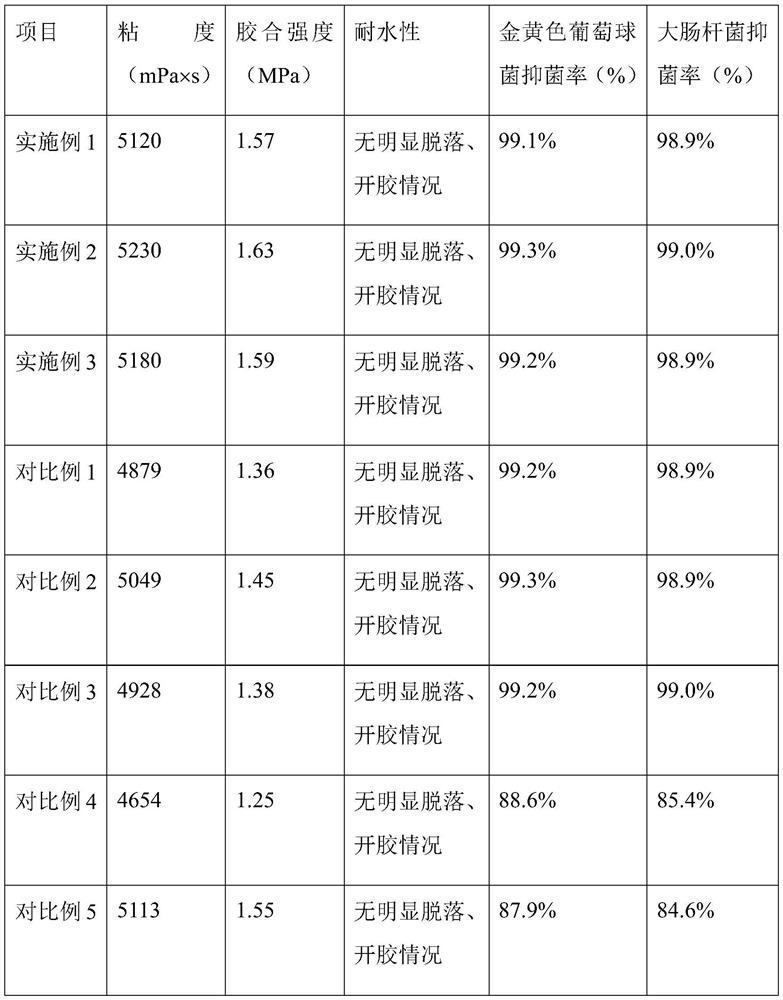

ActiveCN112375509AImprove antibacterial propertiesImprove water resistanceNon-macromolecular adhesive additivesCellulose derivative adhesivesPolyvinyl alcoholAdhesive

The invention discloses an environment-friendly bio-oil starch adhesive and a preparation method thereof. The adhesive comprises the raw materials by weight: 40-55 parts of starch, 1-1.2 parts of an oxidant, 25-35 parts of polyvinyl alcohol, 10-20 parts of acrylamide, 8-10 parts of quaternary ammonium salt chitosan, 25-30 parts of bio-oil, 6-9 parts of a curing agent, 10-12 parts of modified cellulose and 10-12 parts of modified silicon dioxide. The environment-friendly bio-oil starch adhesive and the preparation method thereof provided by the invention have the advantages that the environment-friendly bio-oil starch adhesive is simple in process design and reasonable in component proportion, the prepared adhesive not only has excellent water resistance and bonding performance, but also has excellent antibacterial property, and the practicability is greatly improved.

Owner:浙江荣禾新材料股份有限公司

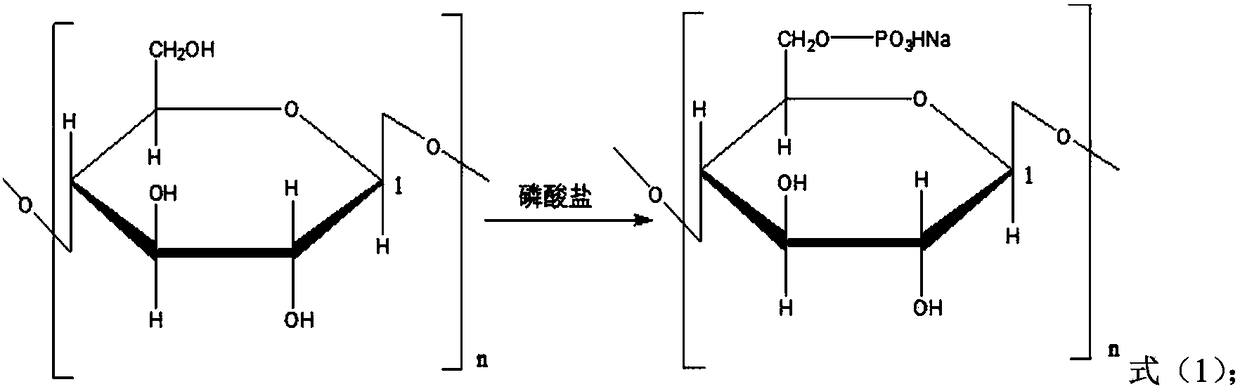

Phosphating wood and preparation method thereof

ActiveCN108407002AGood dimensional stabilityExcellent resistance to biodestructionWood treatment detailsThermal wood treatmentPhosphoric acidUrea

The invention provides a preparation method of phosphating wood. The method comprises the following steps: (1), pre-processing the wood by using alkali liquid; (2), dissolving urea and a phosphate esterification reagent into water and performing mixing to obtain reaction liquid; (3), sealing the wood obtained in the step (1) into a steeping reaction tank, vacuumizing the steeping reaction tank, then injecting the reaction liquid obtained in the step (2) into the steeping reaction tank to ensure that the wood is completely soaked, and then pressurizing to ensure that the wood is continuously soaked; (4), taking the wood obtained in the step (3) out, putting under a low-vacuum environment, and heating to carry out pre-drying and dewatering; (5), putting the wood obtained in the step (4) intoa reaction kettle, performing gradient heating under nitrogen protection so as to carry out phosphate esterification reaction, and then cooling to a room temperature in a gradient manner to obtain the phosphating wood. According to the preparation method disclosed by the invention, the dimension stability of the wood can be improved preferably, and the flame retardant performance and the biological destruction resistance of the wood are improved at the same time. The invention also provides the phosphating wood prepared by adopting the method.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation method of wear-resistant aging-resistant rubber compound filled with coupling modified wood fiber

The invention discloses a preparation method of a wear-resistant aging-resistant rubber compound filled with a coupling modified wood fiber. The method comprises the steps of mixing oxygenated black,formaldehyde and a sodium hydroxide water solution, carrying out stirring reflow reaction under the nitrogen atmosphere, filtering, water washing to be neutral, drying to the constant weight, and obtaining hydroxymethylation modified carbon black; adding a silane coupling agent into an ethanol solution, uniformly stirring and mixing, adding a wood fiber, carrying out modification treatment in water bath, taking out for air drying, drying in a drying oven, and obtaining the coupling modified wood fiber; feeding multi-functional modified natural rubber into a torque rheometer, adding zinc oxide,stearic acid, an anti-aging agent and an accelerant, mixing, adding zinc methacrylate, a coupling agent modified white carbon black, the hydroxymethylation modified carbon black and the coupling modified wood fiber, and mixing to obtain the rubber compound. By adopting the hydroxymethylation modified carbon black, the coupling modified wood fiber, and the coupling agent modified white carbon black for reinforcing, the wear-resistant aging-resistant rubber compound is prepared.

Owner:界首市鑫一龙机械设备购销有限公司

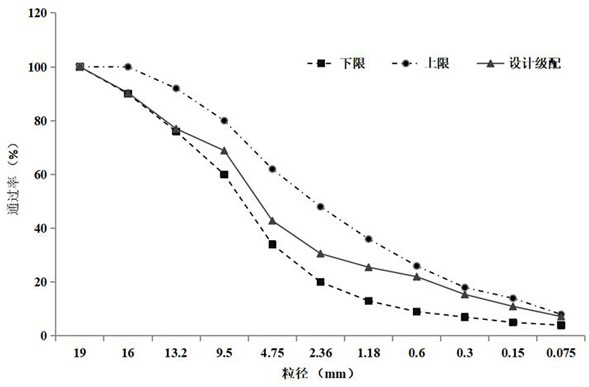

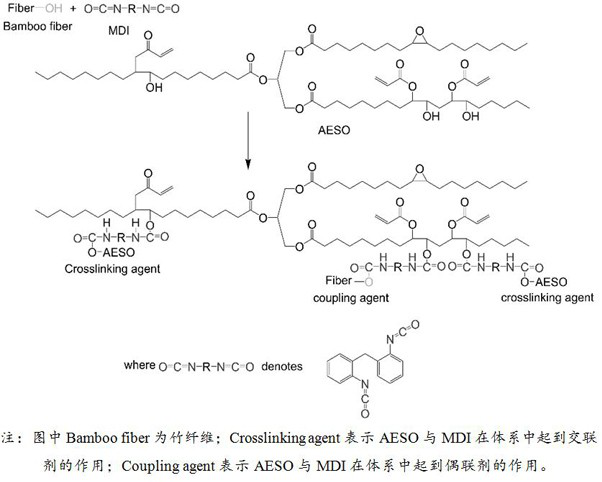

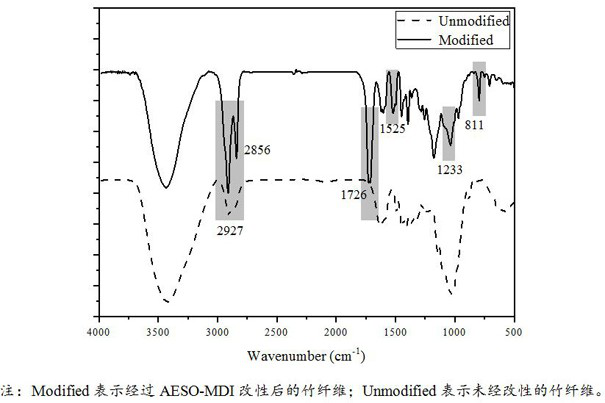

Modified bamboo fiber reinforced asphalt mixture and preparation method thereof

ActiveCN113185191AImproved interfacial adhesionEfficient couplingSolid waste managementPolymer chemistrySoybean oil

The invention belongs to the technical field of fiber reinforced asphalt mixtures, and particularly relates to a modified bamboo fiber reinforced asphalt mixture and a preparation method thereof, epoxidized soybean oil acrylate (AESO) and diphenylmethane diisocyanate (MDI) are adopted to modify bamboo fibers, and then the modified bamboo fibers are added in the preparation process of the asphalt mixture for reinforcement. The modified bamboo fiber reinforced asphalt mixture prepared by the invention is environment-friendly, and has good mechanical properties, high-temperature stability, low-temperature crack resistance and water stability.

Owner:FUJIAN AGRI & FORESTRY UNIV

Novel bamboo-plastic composite material

Owner:EAST CHINA UNIV OF SCI & TECH

Fully-degradable material for shopping bags, mulching films and greenhouse films and preparation method of fully-degradable material

The invention discloses a fully-degradable material for shopping bags, mulching films and greenhouse films and a preparation method of the fully-degradable material, and relates to the technical fieldof film production. The preparation method comprises the steps: adopting modified polyvinyl alcohol and modified vegetable gelatin or chitosan as main raw materials, adding a cross-linking agent, a waterproofing agent, a stabilizer, an anti-block agent, polyethylene wax, an antioxidant, a coupling agent and other agents, performing high-speed stirring, performing treatment by using a casting method or granulation through a twin-screw machine, and performing treatment by using a film blowing method so as to obtain the shopping bags, mulching films or greenhouse films. The fully-degradable material for the shopping bags, mulching films and greenhouse films and the preparation method of the fully-degradable material have the advantages that the prepared fully-degradable shopping bags, mulching films and greenhouse films have safety, no toxicity, harmlessness, toughness, softness and smoothness, good elasticity, high transparency, high tensile strength and low price, and traditional plastic products can be replaced completely; easy degradation is achieved, the material can be self-denatured through natural factors, and is decomposed and degraded into small molecular compounds, and thedecomposed products have the effect of soil improvement.

Owner:刘杰

Method for preparing vinyl-functionalized white carbon black for reinforcing methyl vinyl silicone rubber

ActiveCN103242683AReduce the number of hydroxyl groupsImprove hydrophobicityPigment treatment with non-polymer organic compoundsSal ammoniacPolymer science

The invention discloses a method for preparing vinyl-functionalized white carbon black for reinforcing methyl vinyl silicone rubber. The method is characterized by comprising the steps of: uniformly mixing tetraethoxysilane, ammonia water as a catalyst, absolute ethyl alcohol as a solvent and undecylenyl alcohol as a modifier according to the volume ratio of 6:3:1:1, reacting for 1-2 hours at 50-80 DEG C, then filtering to obtain solid matters, washing the solid matters for two to five times with the absolute ethyl alcohol as the solvent, and drying to obtain the vinyl-functionalized white carbon black. The vinyl-functionalized white carbon black prepared by using the method has a CH2=CH-functional group participating in a crosslinking reaction with methyl vinyl silicone rubber, and is added in the methyl vinyl silicone rubber as stuffing; vinyl on the surface of the white carbon black has a chemical bonding reaction with a molecule chain of the silicone rubber, so that a reinforcement effect of the white carbon black on the silicone rubber can be improved; and the method is applicable to the silicone rubber reinforcement industry.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Anti-cracking putty powder and preparation method thereof

ActiveCN106590132AImprove toughnessImprove thermal stabilityFireproof paintsAntifouling/underwater paintsCrack resistanceEvaporation

The invention discloses anti-cracking putty powder and a preparation method thereof. The anti-cracking putty powder is made of ash-calcium, coarse whiting, white cement, bentonite, gelatine powder and a slow release additive, and the slow release additive is made of sepiolite fabric powder, zeolite powder, modified nano silicon dioxide, polyoxyalkylene and water. The formula of the anti-cracking putty powder contains the special-component slow release additive, the sepiolite fabric powder and the zeolite powder that are contained in the slow release additive are materails in micropore structures, and in a preparation process, modified nano silicon dioxide can enter and fill a part of micropores, so that reinforced particles are formed; in the preparation process, ash-calcium and the slow release additive are mixed first, then the water is added, and evaporation to dryness is carried out, in an evaporation-to-dryness process, a part of ash-calcium can also fill the micropore structures, and the slow release additive is tightly combined with ash-calcium, so that the cracking resistance and the hardness of the putty powder are improved, and the waterproof performance of the putty powder is also improved to a certain extent.

Owner:平顶山锦亦翔墙釉科技有限公司

Manufacturing method of novel floor surface decorative material

InactiveCN109605516AVariety of colorsUniform and durable colorWood treatment detailsPressure impregnationVacuum pressureWood plank

The invention belongs to the technical field of decorative materials, in particular to a manufacturing method of a novel floor surface decorative material, comprising wood bark dyeing, impregnation treatment and curing treatment. The invention adopts bleaching and dyeing to carry out coloring, maintains the texture of the wood itself, and adopts the method of vacuum pressure impregnation to improve the impact resistance of the wood board.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Modification method of degradable plastic packaging material

The invention discloses a modification method of a degradable plastic packaging material, which comprises the following steps: (1) placing a citric acid-sodium citrate buffer solution in a water bathfor heating, adding pectinase and a coupling agent to treat bamboo fibers, carrying out bio-enzyme treatment, taking out the bamboo fibers, filtering the bamboo fibers with a screen mesh, washing thebamboo fibers with water to a neutral state, and carrying out vacuum drying to obtain bio-enzyme treated bamboo fibers; (2) adding 1-methylimidazole and esterified reed cellulose into ethanol, carrying out a stirring reaction in a water bath, carrying out washing with absolute ethyl alcohol, carrying out centrifuging, and carrying out vacuum drying to obtain ionic liquid modified esterified reed cellulose; and (3) preparing a degradable plastic packaging material, namely, drying polybutylene succinate in vacuum and putting the polybutylene succinate into an internal mixer, adding salinized polyester elastomer particles, the bio-enzyme treated bamboo fibers and the ionic liquid modified esterified reed cellulose, mixing the substances, discharging the blend, adding the blend into a double-screw extruder through a hopper, carrying out blending through the extruder, extruding the blend into a charging barrel of an injection molding machine through a discharge port, and carrying out injection molding.

Owner:安徽华赛包装有限公司

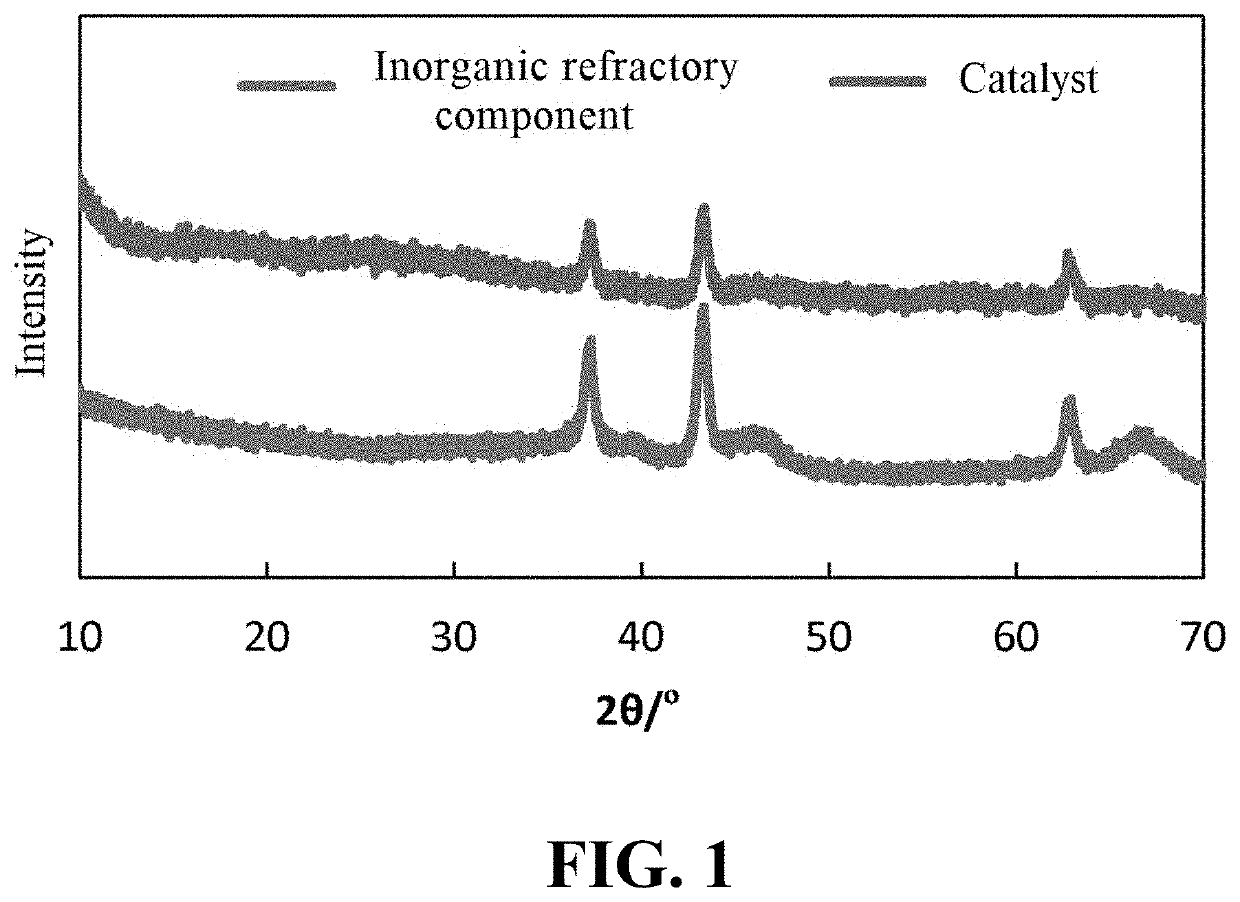

Hydrorefining catalyst, preparation method therefor and use thereof

ActiveUS20210094023A1Small sizeImprove catalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

Disclosed is a hydrofining catalyst comprising: an inorganic refractory component comprising a first hydrodesulfurization catalytically active component in a mixture with at least one oxide selected from the group consisting of alumina, silica, magnesia, calcium oxide, zirconia and titania; a second hydrodesulfurization catalytically active component; and an organic component comprising a carboxylic acid and optionally an alcohol. The hydrofining catalyst of the present application shows improved performance in the hydrofining of distillate oils. Also disclosed are a hydrofining catalyst system comprising the hydrofining catalyst, a method for preparing the catalyst and catalyst system, and a process for the hydrofining of distillate oils using the catalyst or catalyst system.

Owner:CHINA PETROCHEMICAL CORP +1

High-temperature-resistant high-airtightness composite material for repairing heat distribution pipeline, and preparation method and application of high-temperature-resistant high-airtightness composite material

The invention relates to a high-temperature-resistant high-airtightness composite material for repairing a heat distribution pipeline, and a preparation method and application of the high-temperature-resistant high-airtightness composite material. The composite material comprises 100 parts of ethylene propylene rubber, 5-10 parts of PIB, 3-5 parts of nanometer zinc oxide, 2-5 parts of polyethyleneglycol, 2-5 parts of a peroxide crosslinking agent, 1-2 parts of an assistant crosslinking agent, 0.2-3 parts of an anti-aging agent, 15-100 parts of carbon black N550, 15 parts of white carbon black, 5-15 parts of paraffin oil, 1-3.5 parts of resorcinol, 1-3 parts of a formaldehyde donor and 10-80 parts of flaky talcum powder. The composite material is prepared through mixing and open-milling; then the composite material is extruded to obtain a pipe; and the pipe is vulcanized at 150-180 DEG C to obtain a composite material pipe for repairing the heat distribution pipeline. The composite material disclosed by the invention is used for the pipe applied to heat distribution pipeline repairing, has good high temperature resistance, can be used for a long time at 150 DEG C, and is high in air tightness, good in mechanical property, heat resistance and aging resistance and the like.

Owner:ZHONG YU HOSES TECH CO LTD

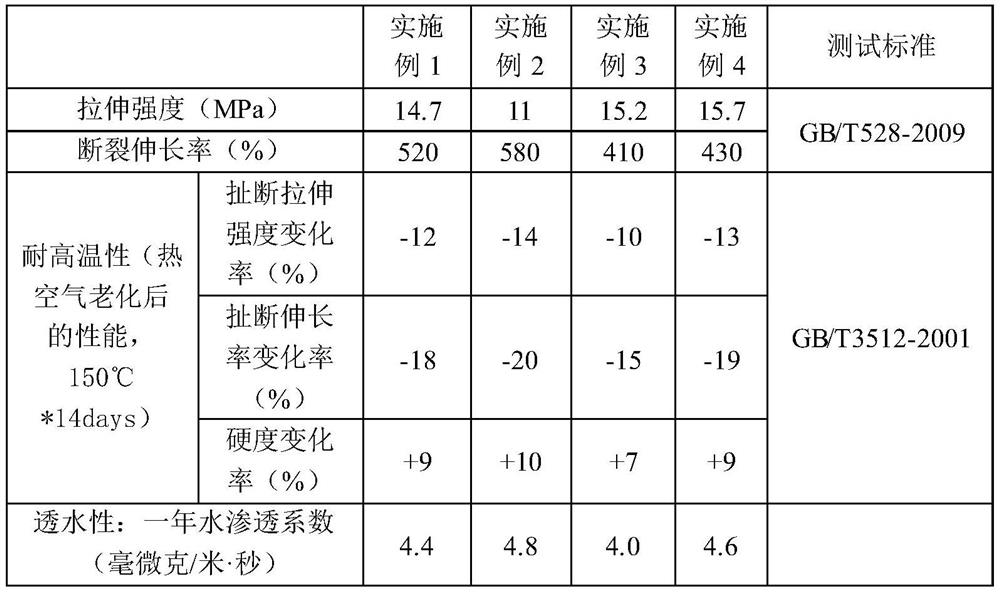

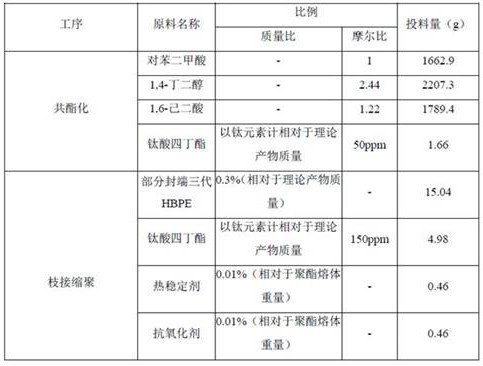

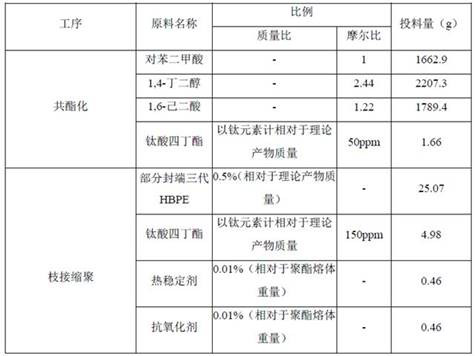

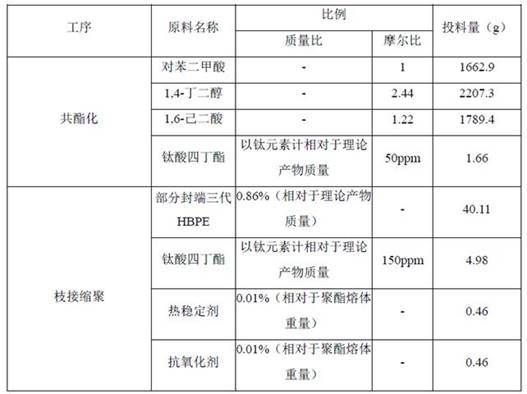

Hyperbranched PBAT polyester and preparation method thereof

ActiveCN114516950AIncrease profitAvoid Migration ProblemsBiodegradable productBiodegradable polyester

The invention belongs to the technical field of biodegradable materials, and particularly relates to hyperbranched PBAT polyester and a preparation method thereof.The hyperbranched PBAT polyester is obtained by synthesizing a series of hydroxyl-terminated hyperbranched polyesters (HBPE) with specific hydroxyl values through gradual reaction of a core unit and a monomer and then copolymerizing the hyperbranched polyesters with terephthalic acid, 1, 4-butanediol and adipic acid. The active terminal hydroxyl group of HBPE can participate in esterification and polycondensation reaction, and can be used as polyhydric alcohol to extend the linear structure of a molecular chain into a branched structure, so that the crosslinking density of PBAT is improved, and the strength of PBAT is improved; meanwhile, the polycondensation time is shortened, and the product acid value is lower; the HBPE molecules have a hyperbranched structure similar to a sphere, the molecules are not tangled, after the PBAT molecular chain is introduced, the biodegradable polyester has the characteristics of low viscosity and high flowability, and the polyester is particularly suitable for biodegradable products such as special-shaped injection molding parts and thin-wall injection molding parts with complex structures.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

Bamboo fiber reinforced thermoplastic resin composite material and preparation method thereof

InactiveCN110643102AImprove mechanical propertiesImproves dispersibility and solution flowModified carbonCompatibilization

The invention relates to the technical field of composite materials, and discloses a bamboo fiber reinforced thermoplastic resin composite material. The bamboo fiber reinforced thermoplastic resin composite material comprises the following components in parts by weight: 45-75 parts of thermoplastic resin, 10-30 parts of modified bamboo fiber, 4-8 parts of a modified filler, 6-12 parts of a flexibilizer, 2-5 parts of a compatilizer and 0.1-1 part of a flow modifier, wherein the modified filler is one or two selected from the group consisting of modified silicon dioxide and modified calcium carbonate. The invention further discloses a preparation method of the bamboo fiber reinforced thermoplastic resin composite material. Therefore, the compatibility among the main components of the composite material is improved, and the mechanical property of the composite material is improved.

Owner:广东长虹智能制造技术有限公司

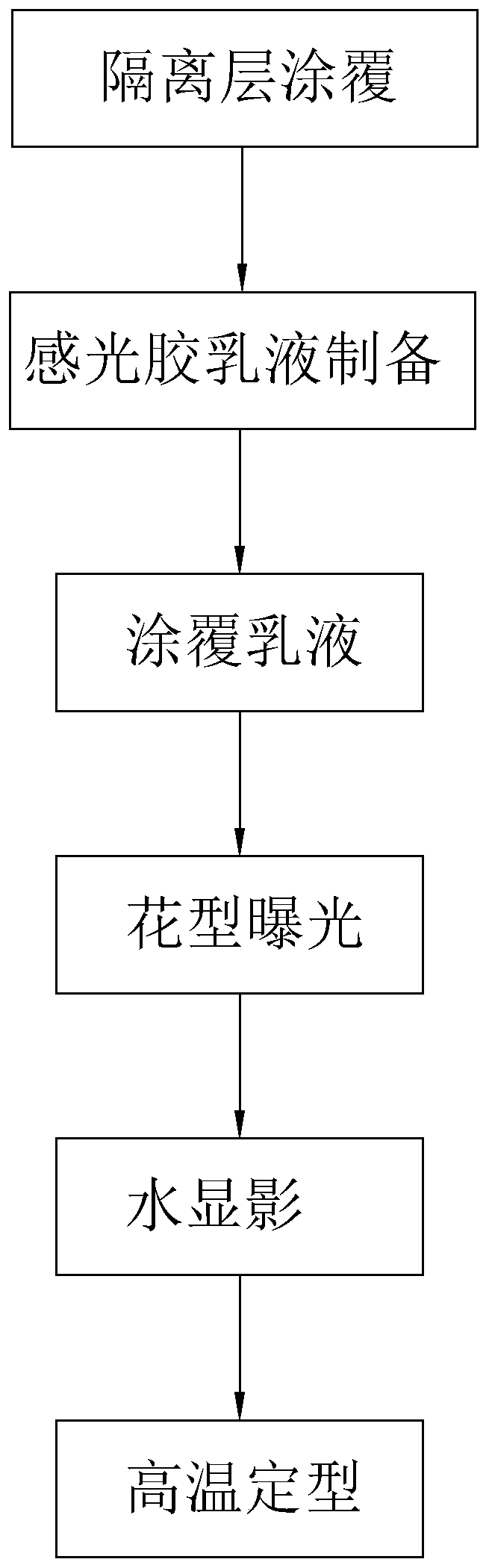

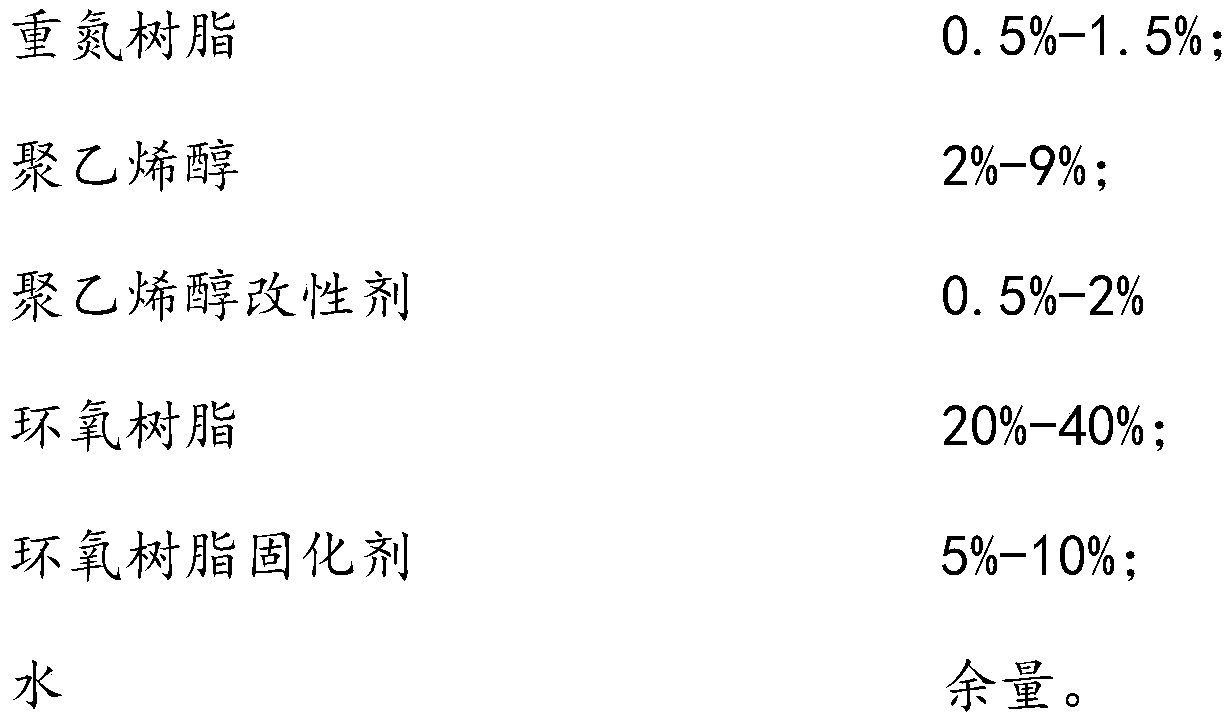

Preparation method of cylinder photosensitive resist

ActiveCN110058492AEasy to disengageReduce the number of hydroxyl groupsPhotomechanical coating apparatusPhotosensitive material processingResistIsolation layer

The invention discloses a preparation method of cylinder photosensitive resist, and relates to the technical field of photosensitive resist preparation. The preparation method comprises the followingsteps of S1, coating an isolation layer on the surface of a cylinder; S2, proportionally mixing and uniformly stirring raw materials of the photosensitive resist to obtain a photosensitive resist stock solution; S3, coating the photosensitive resist stock solution on the surface of the cylinder; S4, bonding a patterned film with a side wall of the cylinder after the photosensitive resist stock solution in Step S3 is dried; S5, performing pattern exposure on the cylinder bound with the film in Step S4; S6, removing the film on the exposed cylinder and then washing the cylinder with water; S7, performing high-temperature shaping on the cylinder after the water in Step S6 is dried; and S8, obtaining a required cylinder photosensitive resist forme after the cylinder shaping in Step S7 is completed. The preparation method has an effect of quickly and conveniently stripping a photosensitive resist layer.

Owner:绍兴市嘉诚感光材料有限公司

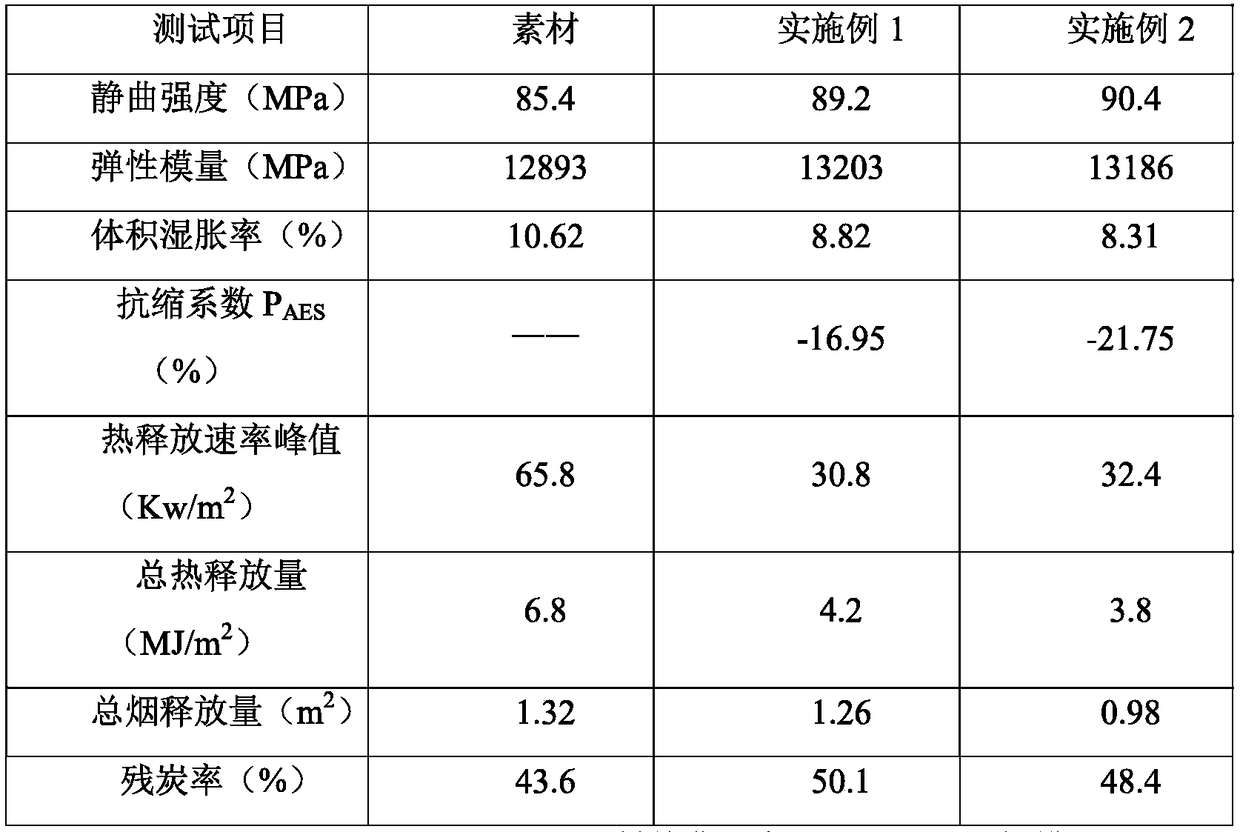

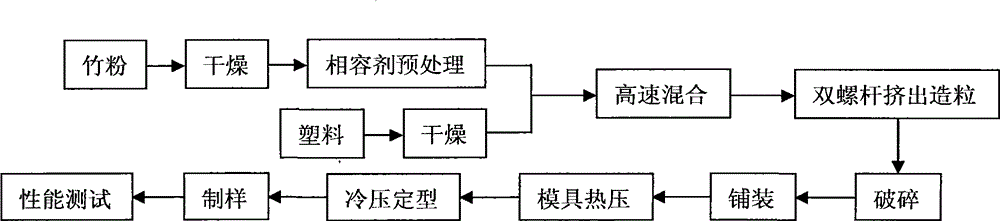

Manufacturing technology for preparing high-strength bamboo-plastic composite material through MAPE pretreatment

InactiveCN104552715AGuaranteed mechanical propertiesEfficient use ofFlat articlesManufacturing technologyAgglutination

The invention relates to a manufacturing technology of bamboo-plastic composite materials, in particular to a preparation method of an MAPE compatilizer for pretreating degree of reinforced agglutination. The manufacturing technology comprises the steps of raw material pretreatment, material mixing, pelleting, crushing, paving and hot-pressing. Through the control for the bamboo-plastic proportioning, the using amount of a coupling agent, the hot pressing temperature and the hot pressing time, the effect of the manufacturing technology with the optimum performance of the bamboo-plastic composite material with the thickness of 9mm is realized. In order to reinforce the performance of the bamboo-plastic board, the compatilizer is used for dispersing among organic fibers, inorganic filler, inorganic fibers and matrix resin, so that the effect of improving the compatibility is reached. Moreover, after the surface of bamboo fiber is pretreated, the interface bonding capacity between matrixes can also be promoted. The mechanical properties of a finished board product are measured through GB / T1449-2005 'Fiber Reinforced Plastic Bending Property Test Method', GB / T1451-2005 'Fiber Reinforced Plastic Simple-beam Impact Toughness Test Method' and GB / T17657-1999 'Artificial Board and Decorative Artificial Board Physical and Chemical Property Test Method', and all reach higher levels.

Owner:张双保 +6

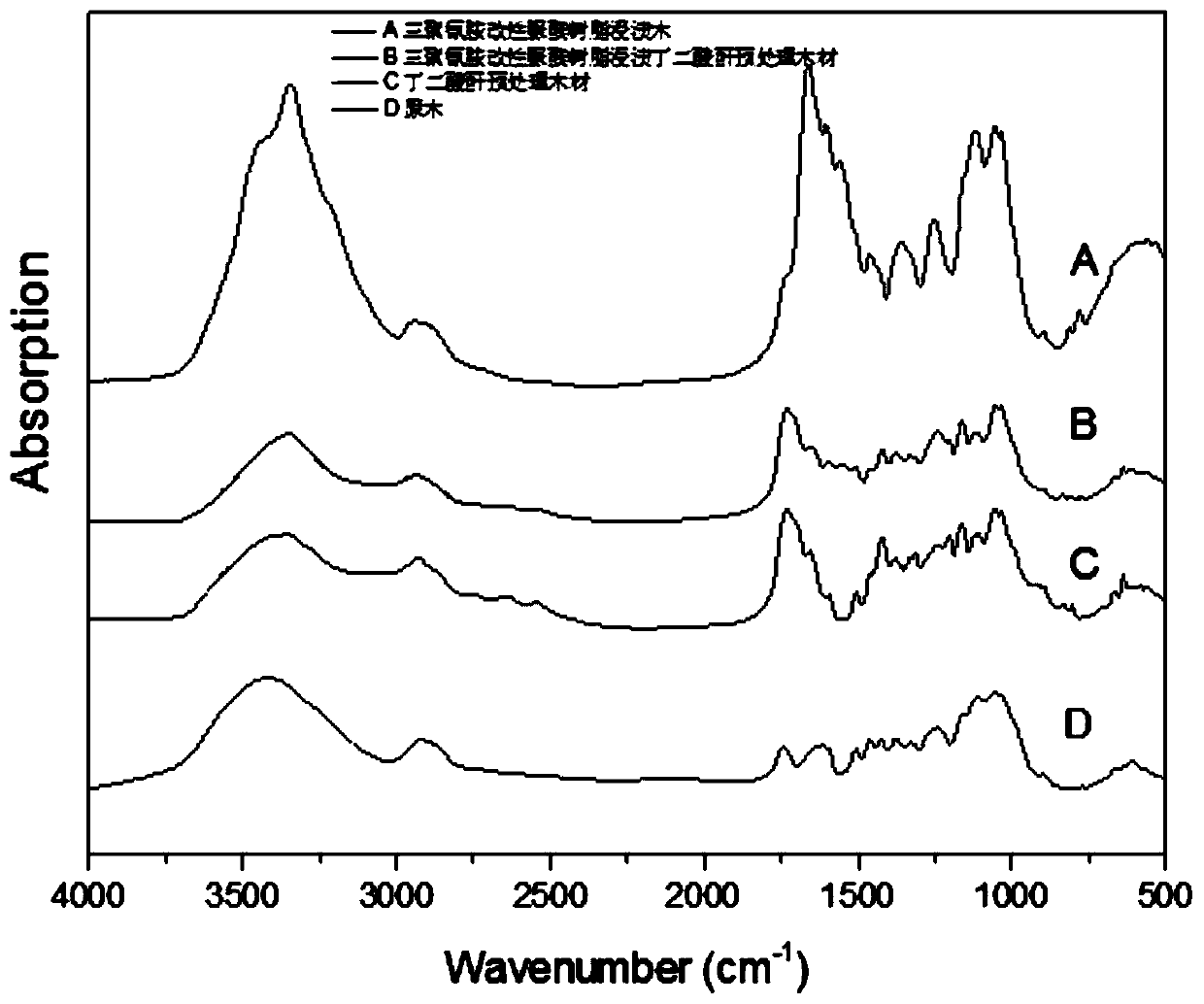

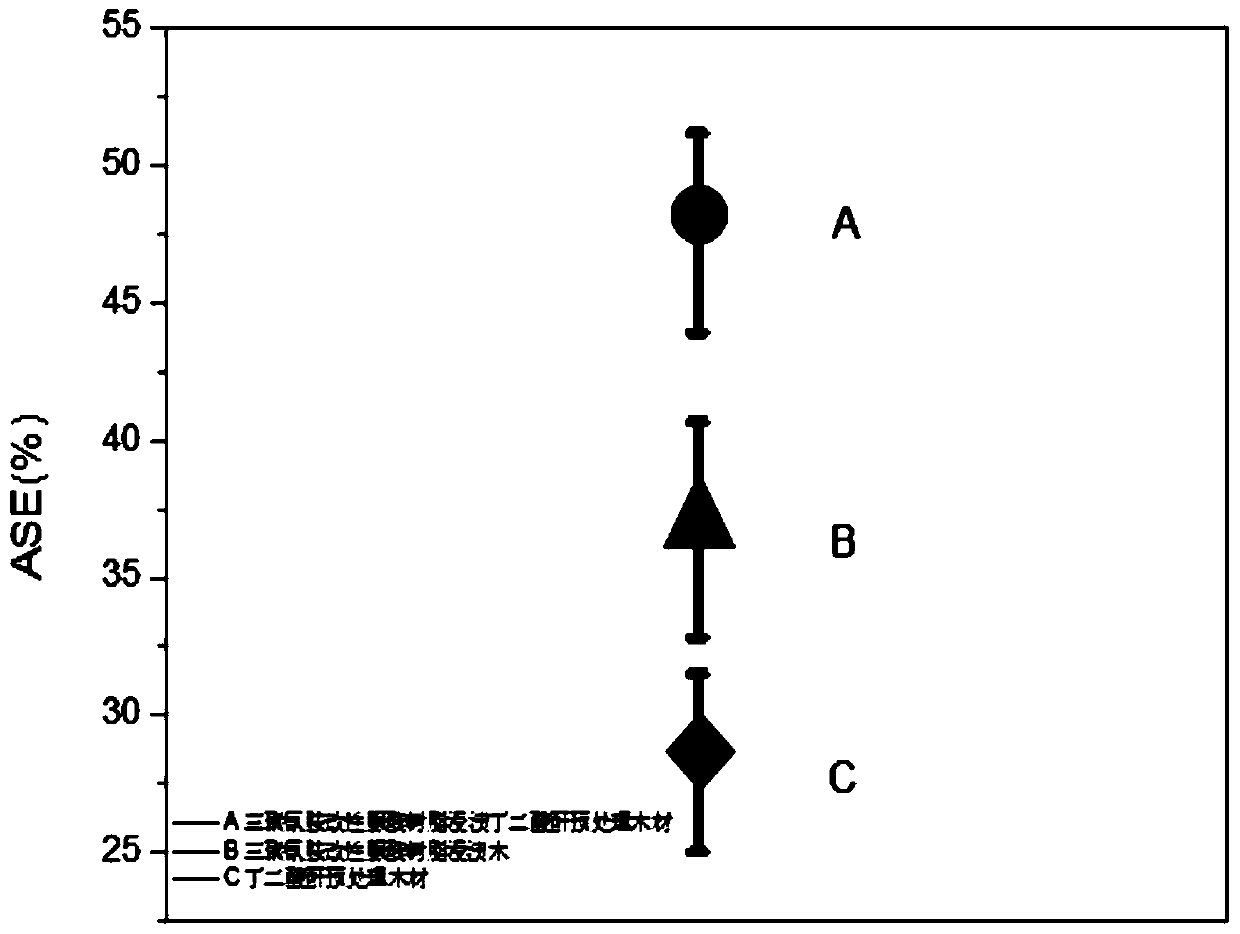

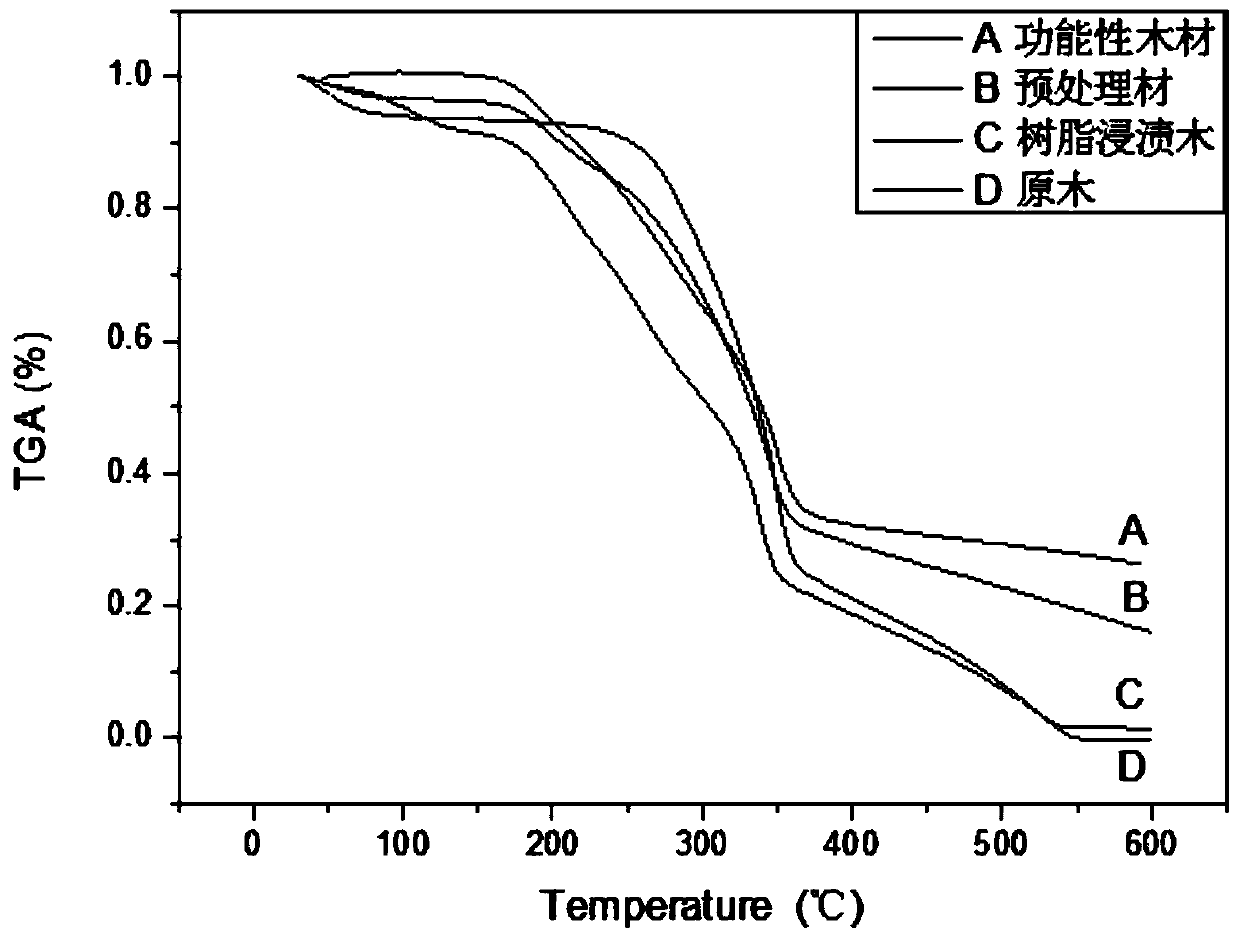

Method for preparing functional wood by resin impregnation pretreatment of wood

InactiveCN109693283AReduce the number of hydroxyl groupsImproved dimensional stabilityWood treatment detailsPretreatment apparatusWater contentChemistry

The invention discloses a method for preparing a functional wood by resin impregnation pretreatment of a wood, and belongs to the technical field of wood modification. The method concretely includes the following four steps: pretreatment of the wood by using succinic anhydride, drying treatment, impregnation of the succinic anhydride pretreated wood by using melamine modified urea-formaldehyde resin, and vacuum drying treatment. A wood sample with the water content of 20% or below is pretreated by using succinic anhydride, and the pretreated wood is dried to obtain the succinic anhydride modified wood; and the water-soluble low molecular weight melamine-modified urea-formaldehyde resin is impregnated into the succinic anhydride-modified wood by a vacuum pressure impregnation technique, andthen the impregnated wood is subjected to the vacuum drying treatment to finally obtain the functional wood. Compared with methods using single resin impregnation treatment, the method adopted in theinvention enhances the dimension stability, mechanical properties and durability of the prepared wood and makes the wood have excellent thermal stability and flame retardation performance due to thegeneration of new strong chemical bonds between the resin impregnation modifier and the succinic anhydride pretreated wood.

Owner:BEIJING FORESTRY UNIVERSITY

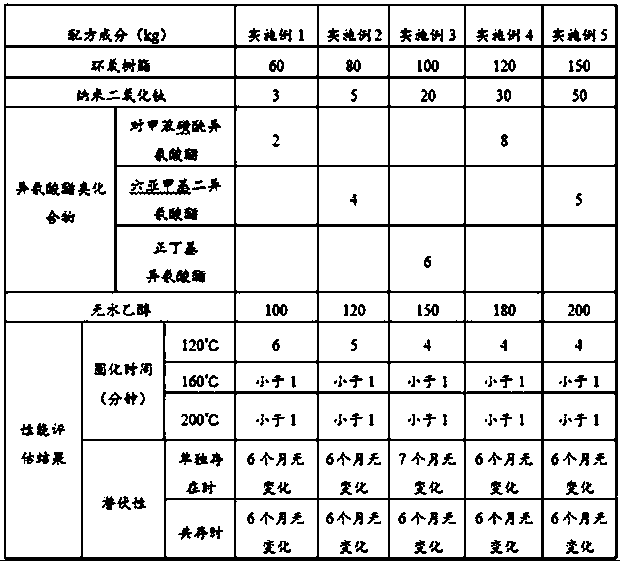

Curing agent with latency for quick thermal curing of acrylic resin

The invention discloses a curing agent with latency for quick thermal curing of acrylic resin. The curing agent is prepared from the following materials in parts by weight: 60 to 150 parts of epoxy resin, 3 to 50 parts of nanometer titanium dioxide, 2 to 10 parts of isocyanate compound, and 100 to 200 parts of anhydrous ethyl alcohol. The curing agent has the advantages that when the acrylic resinis thermally cured, the complete curing can be realized after treating for 6min at the temperature of 120 DEG C, and the thermal curing efficiency of the acrylic resin is greatly improved; the curingagent and the acrylic resin can be stored together under the sealing and high-temperature conditions, the chemical and physical properties are not changed within 6 months, and the latency is good.

Owner:简兵 +1

Shiitake mushroom stick non-cut water-holding film with fungicidal preservative effects and preparation method thereof

The invention discloses shiitake mushroom stick non-cut water-holding film with fungicidal preservative effects, produced from, by weight, 62-81 parts of polylactic acid, 32-41 parts of starch, suitable distilled water, 15-20 parts of Na-montmorillonite, 4-10 parts of sodium tripolyphosphate, 2-6 parts of urea, suitable glycine-hydrochloric acid buffer solution, suitable dichloromethane, 1-3 parts of glycerol, 1-2 parts of propanetriol, 1-4 parts of chitosan, suitable acetic acid, 0.05-0.2 part of ethyl vanillin, and 0.05-0.1 part of potassium sorbate. Polylactic acid is used as a basic film-forming agent combined with starch and montmorillonite to obtain the non-cut water-holding film, shiitake mushroom may grow out by the aid of its growing force, deformed mushroom is avoided, the shape and quality of shiitake mushroom are improved greatly, the non-cut water-holding film has good water-holding property, can effectively inhibit the evaporation of water in the mushroom sticks and can effectively maintain water inside and breathability.

Owner:淮南市润吉生态农业有限公司

Preparation method for taxifolin

InactiveCN102746263AReduce the number of hydroxyl groupsLow priceOrganic chemistryNon toxicityDistillation

The invention relates to a preparation method for taxifolin, which comprises the following g steps: adding crushed larix gmelini and water in a reaction vessel for reacting, physically separating the solid and the liquid to obtain an activated larix gmelini solid, adding the activated larix gmelini solid and water in the reaction vessel for reacting and physically separating the solid and the liquid to obtain a solution, passing the solution through a chromatography column, injecting glycerol in a chromatography column for washing to obtain an eluate, and distilling and crystallizing the eluate to obtain taxifolin. One time distillation is required in the preparation technology, the energy consumption due to excessive distillation frequency can be reduced, the energy can be saved, the cost of glycerol used for washing is low, the washing capability is strong and the amount is less, the generation cost is reduced, and the glycerol enables non toxicity, no damage is generated on the human body and environment during the production process, the taxifolin without toxicity can be obtained, the solid-liquid separation employs the physical separation, and the separating operation is simple, the chemical separating with other impurities introduction can be avoided, and the purity after crystallization is greater than 99%.

Owner:陈秀海

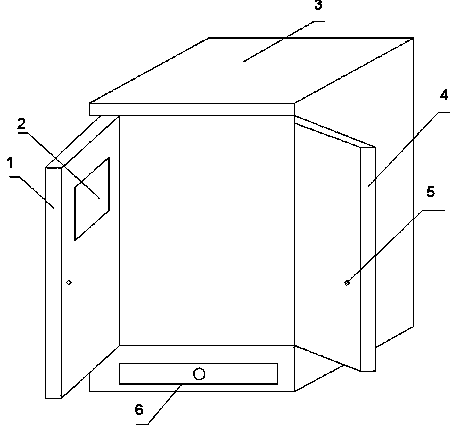

Water-proof and rust-proof distribution box

ActiveCN109802315AExtended service lifeReduce security risksSubstation/switching arrangement casingsAnti-corrosive paintsEngineeringErosion

The invention provides a water-proof and rust-proof distribution box, which belongs to the technical field of distribution boxes. The water-proof and rust-proof distribution box comprises a box body and a box door which are matched, wherein the box door comprises an outer box door and an inner box door; the box body is formed by an upper box surface, a lower box surface, a first side box surface,a second side box surface and a rear box surface in a surrounding mode; the inner box door is hinged with one side of the first side box surface; the outer box door is hinged with the second side boxsurface; a plane is formed between the outer box door and the upper box surface, the lower box surface, the first side box surface and the second side box surface; and the surfaces of the box body andthe inner box door are coated with an insulated paint. Rainwater can be effectively prevented from entering the inner part of the distribution box along the gap between the box door and the box body,the insulated paint coating the surface of the distribution box is water-proof and anti-corrosion, good comprehensive performance is presented through long-time sunshine and rainwater erosion, and the protective effects are good.

Owner:国网河南省电力公司镇平县供电公司

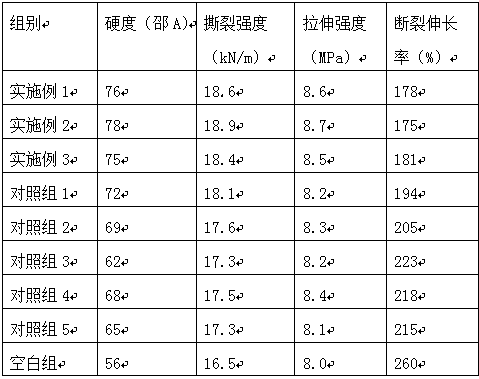

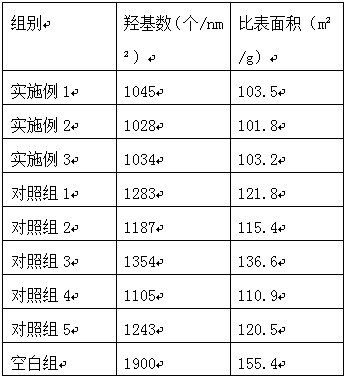

Modification method of lowering amount of hydroxyl groups on surface of white carbon black for silicone rubber

InactiveCN109054389AImprove the uniformity of modificationHigh tear strengthPolymer scienceVulcanization

The invention belongs to the technical field of white carbon black modification and particularly relates to a modification method of lowering the amount of hydroxyl groups on the surface of white carbon black for silicone rubber. The modification method comprises the following steps of preparing a dried material, mixing the dried material with onion essential oil, absolute ethyl alcohol, glacial acetic acid and nitrogen-contained organic alkali, performing sealing in a ball milling tank, and performing ball milling for 3-5h to obtain a ball milling material; and putting the ball milling material in a muffle furnace, rising the temperature to 500-600 DEG C, and performing thermal insulation for 30-40min to obtain modified white carbon black for the silicone rubber. Compared with the prior art, the modification method has the advantages that the preparation steps of the modified white carbon black are strictly controlled, the modification uniformity of the white carbon black can be improved, and the amount of the hydroxyl groups on the surface of the white carbon black and the specific surface area are lowered; through synergistic modification of the raw materials including the onionessential oil, the white carbon black can be effectively combined with the silicone rubber, and the vulcanization rate is increased; the white carbon black generates cross-linking reaction with the silicone rubber, so that the mutual action of the white carbon black with the silicone rubber is strengthened, and the tearing strength and hardness of the silicone rubber can be effectively improved.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com