Patents

Literature

92 results about "Plastic bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

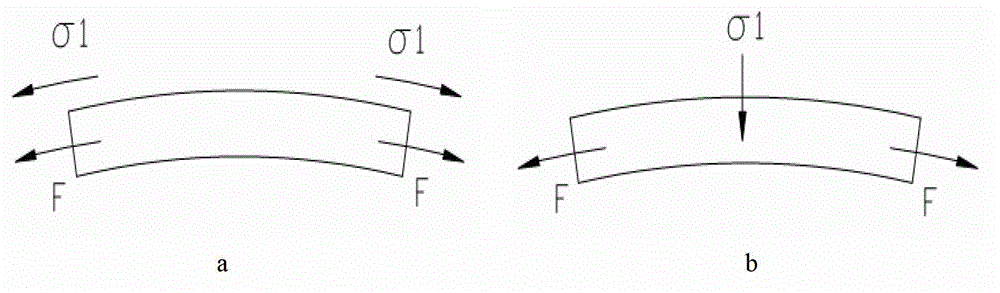

Plastic bending is a nonlinear behavior particular to members made of ductile materials that frequently achieve much greater ultimate bending strength than indicated by a linear elastic bending analysis. In both the plastic and elastic bending analyses of a straight beam, it is assumed that the strain distribution is linear about the neutral axis (plane sections remain plane). In an elastic analysis this assumption leads to a linear stress distribution but in a plastic analysis the resulting stress distribution is nonlinear and is dependent on the beam’s material.

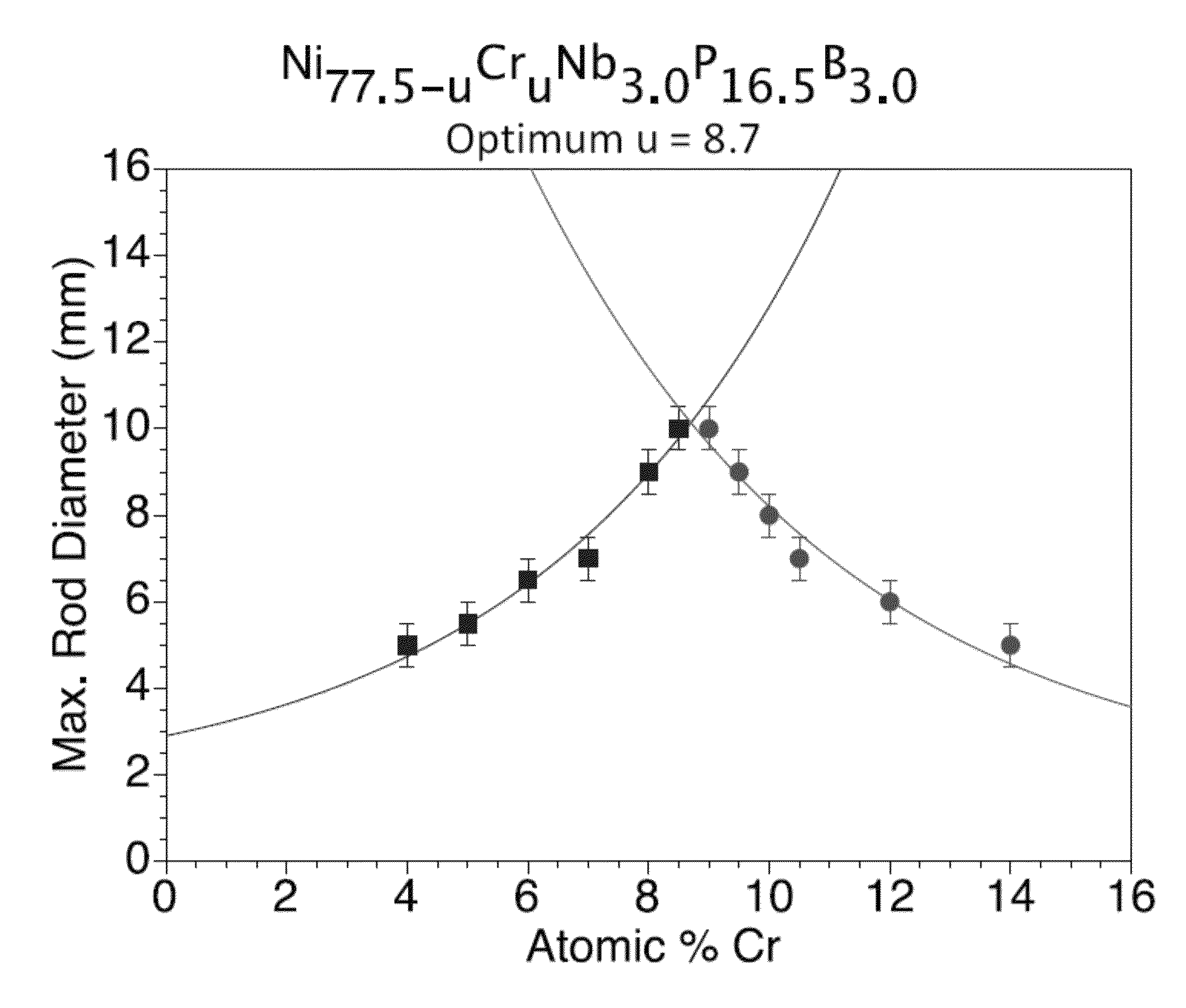

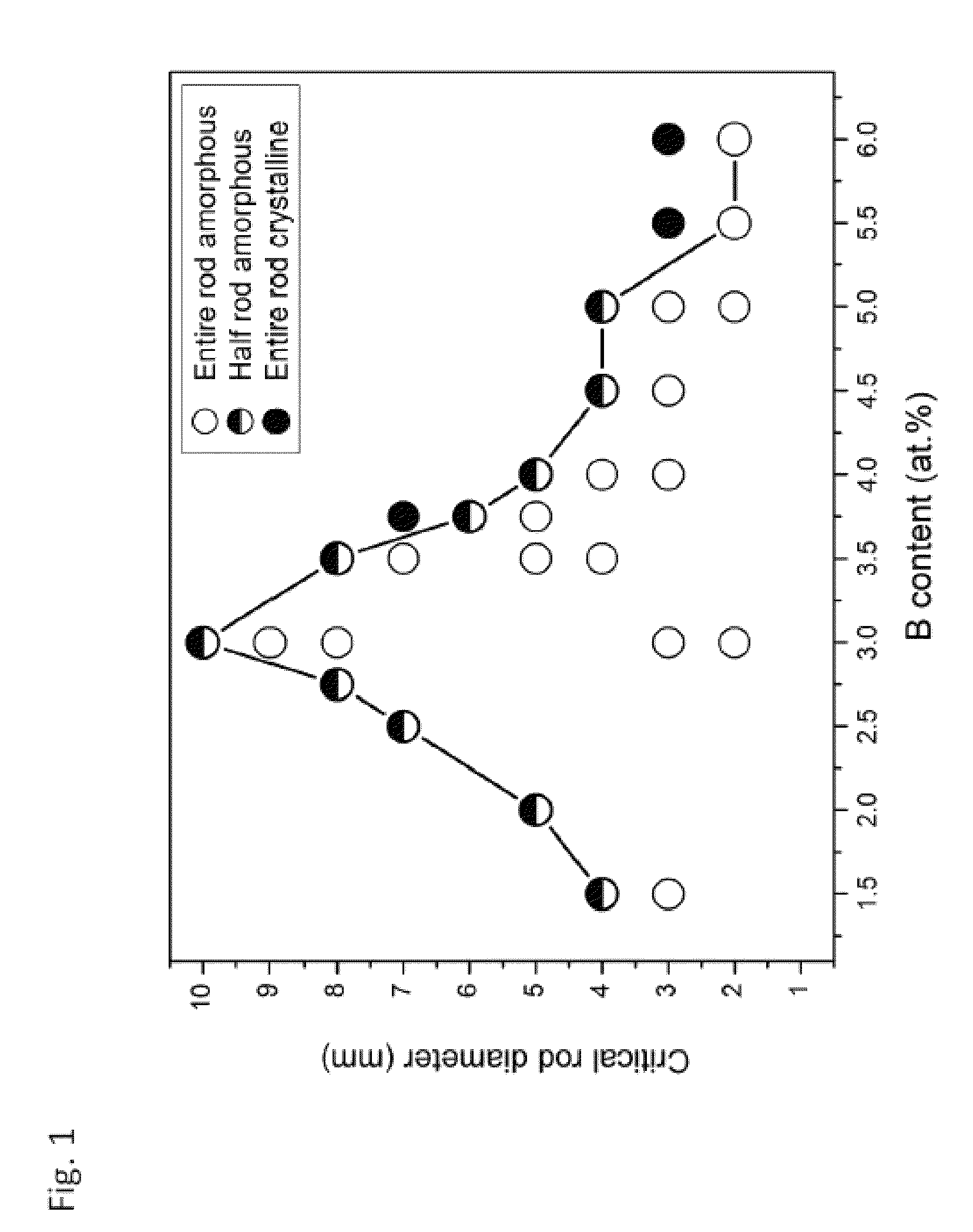

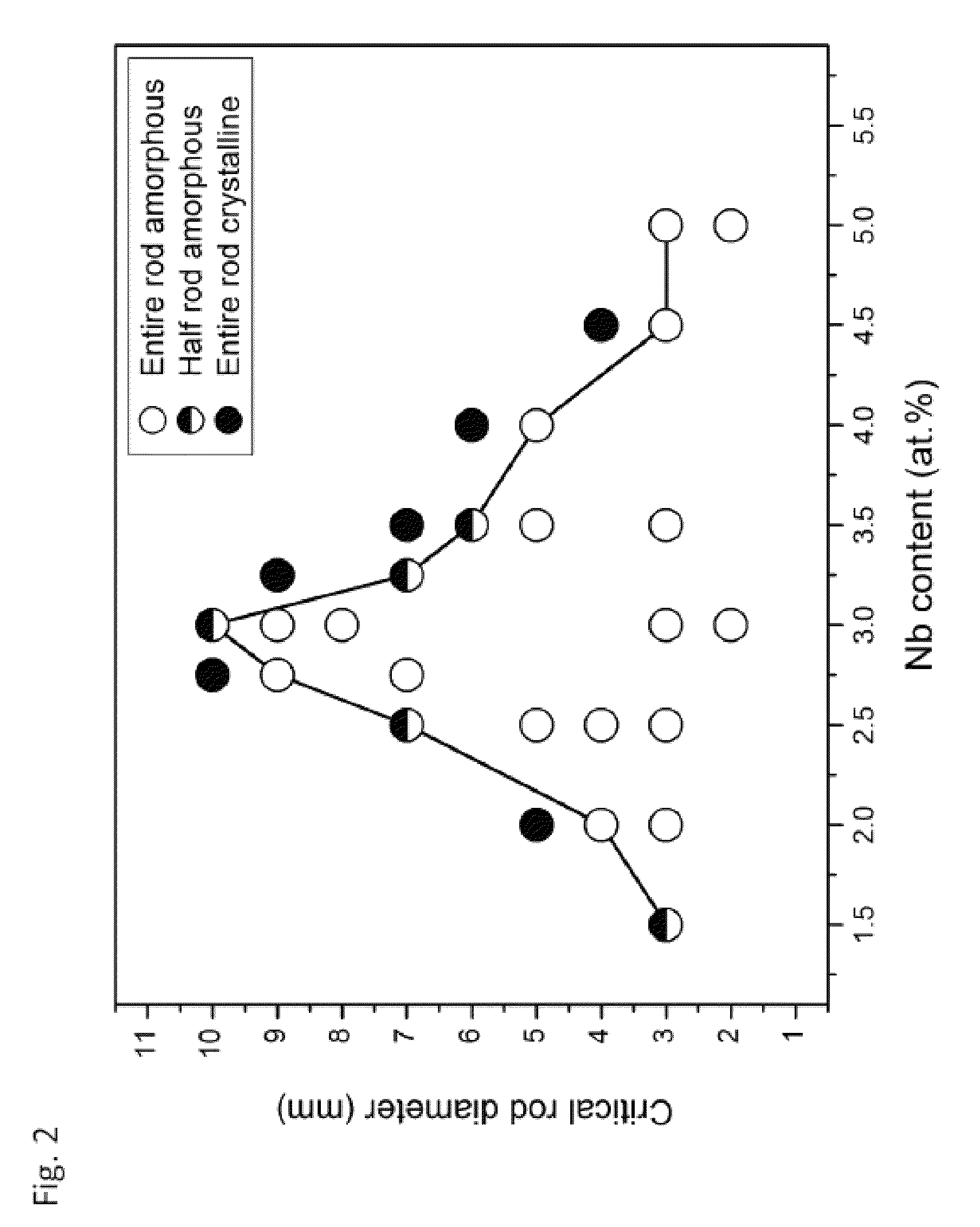

Bulk Nickel-Based Chromium and Phosphorous Bearing Metallic Glasses

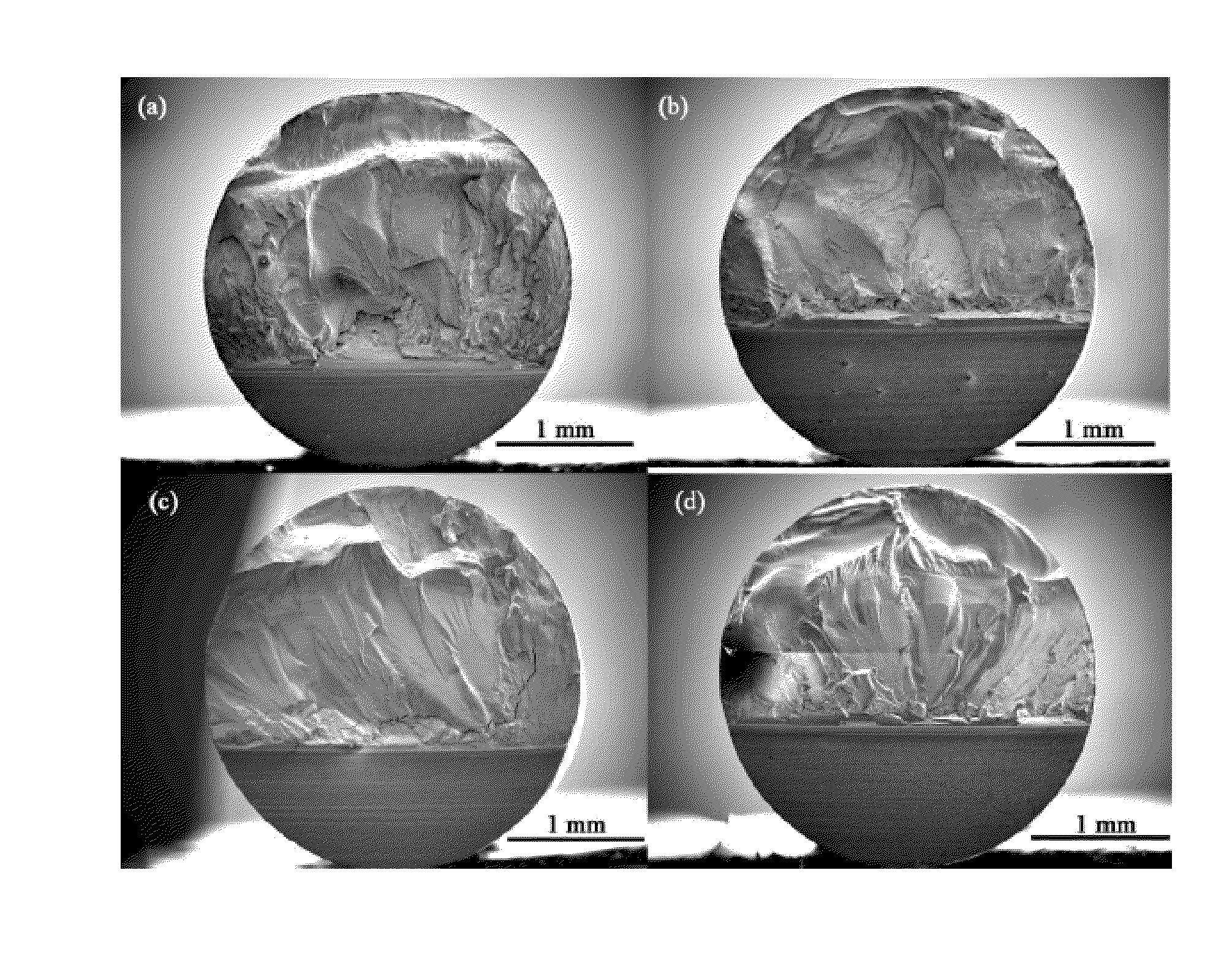

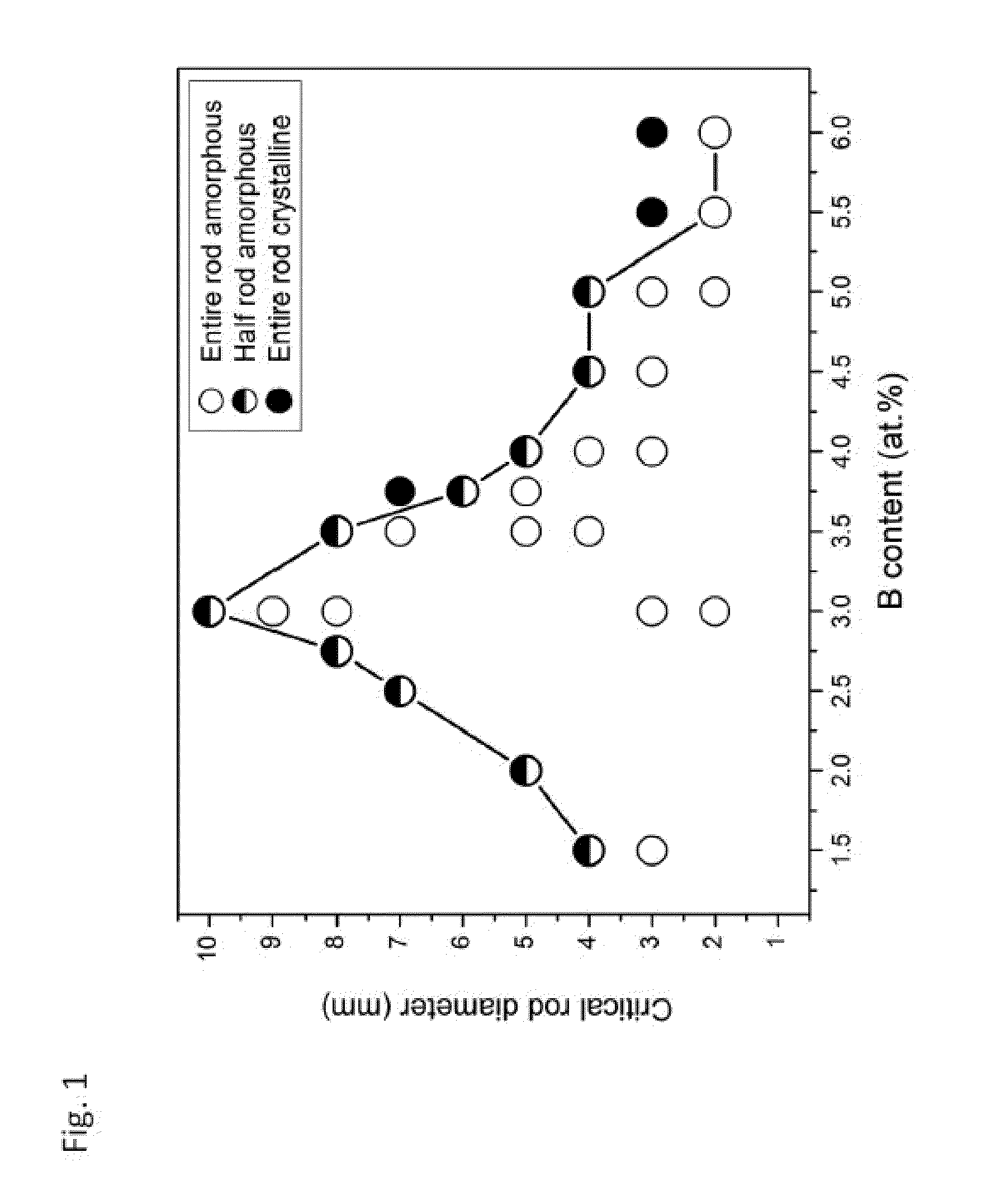

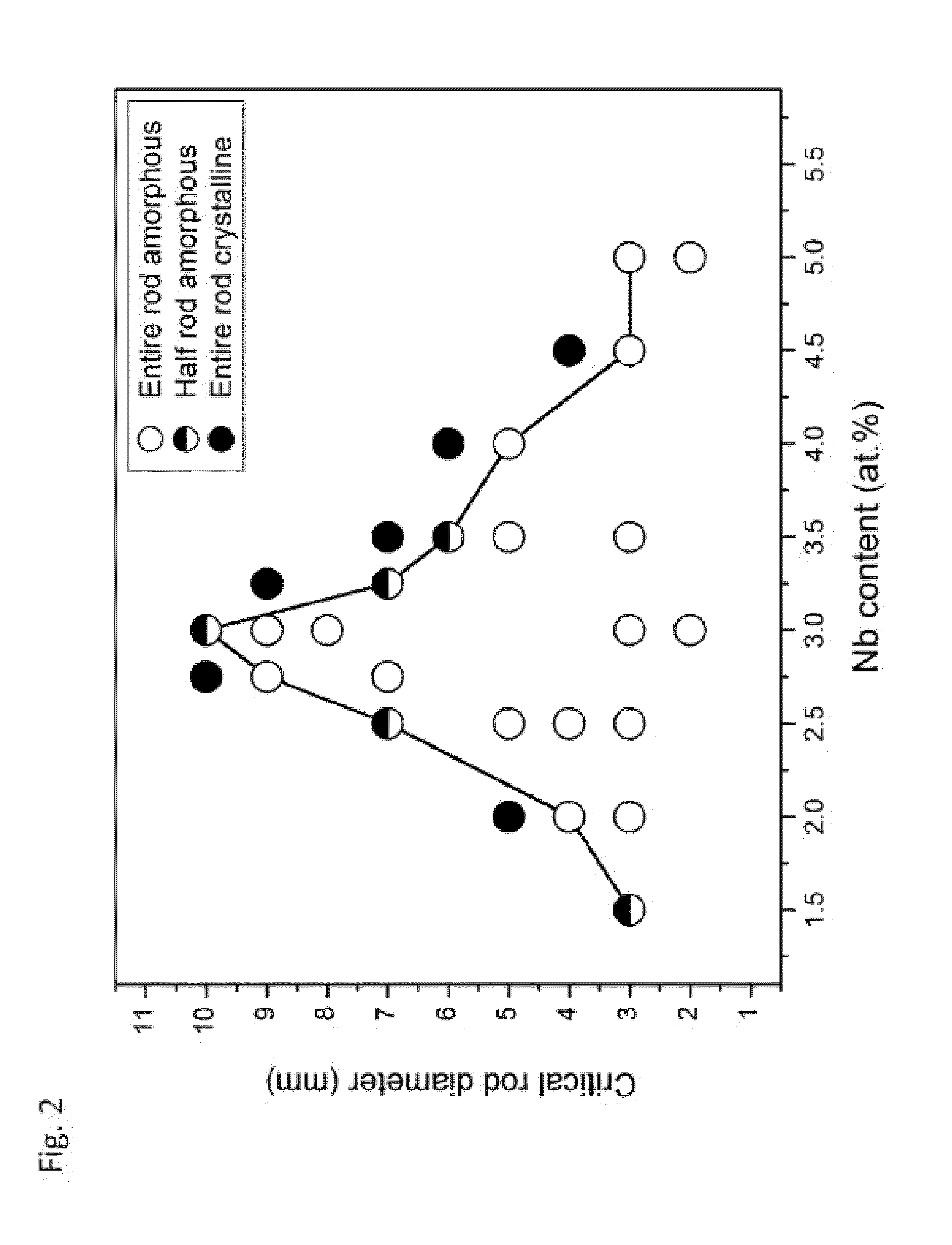

Ni-based Cr- and P-bearing alloys that can from centimeter-thick amorphous articles are provided. Within the family of alloys, millimeter-thick bulk-glassy articles can undergo macroscopic plastic bending under load without fracturing catastrophically.

Owner:CALIFORNIA INST OF TECH

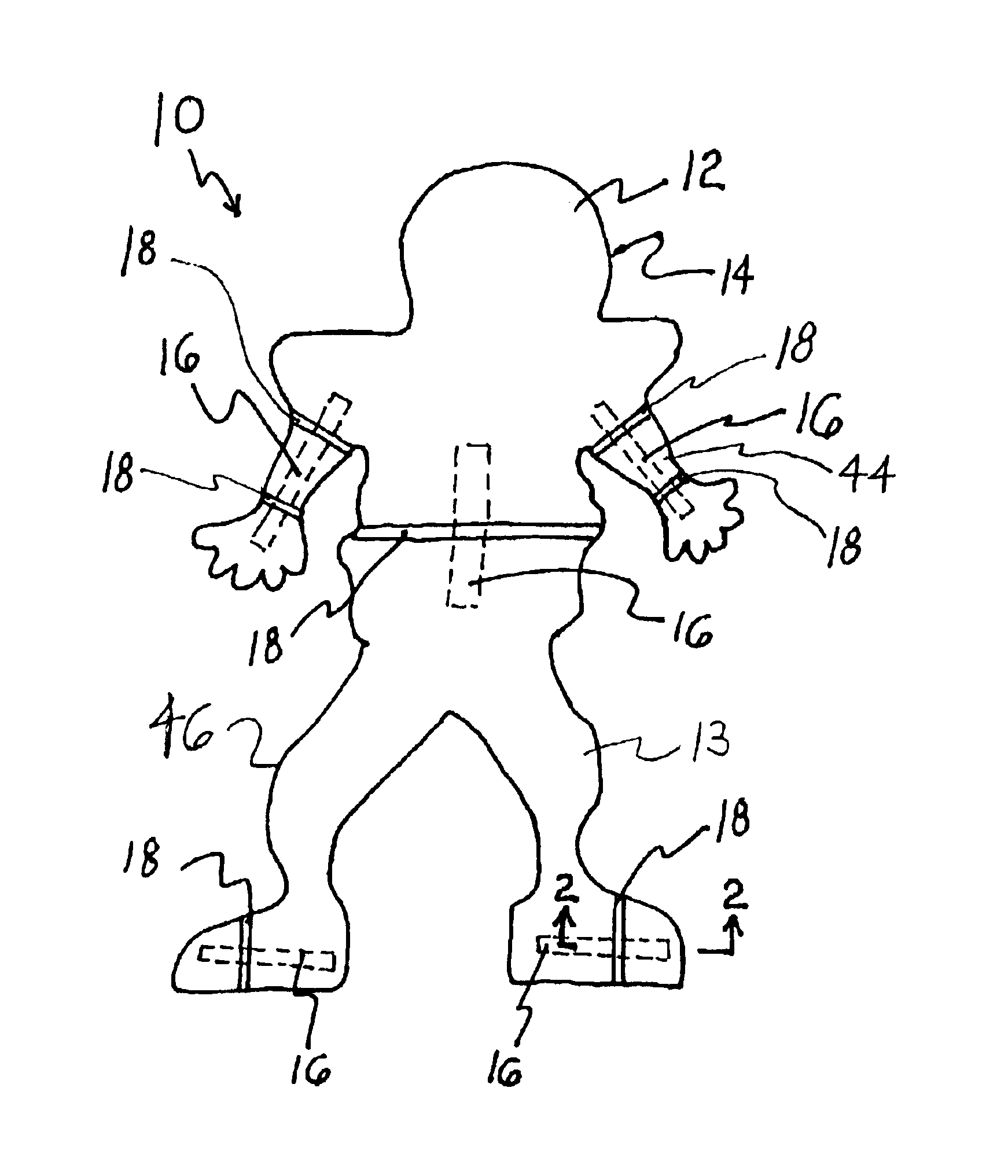

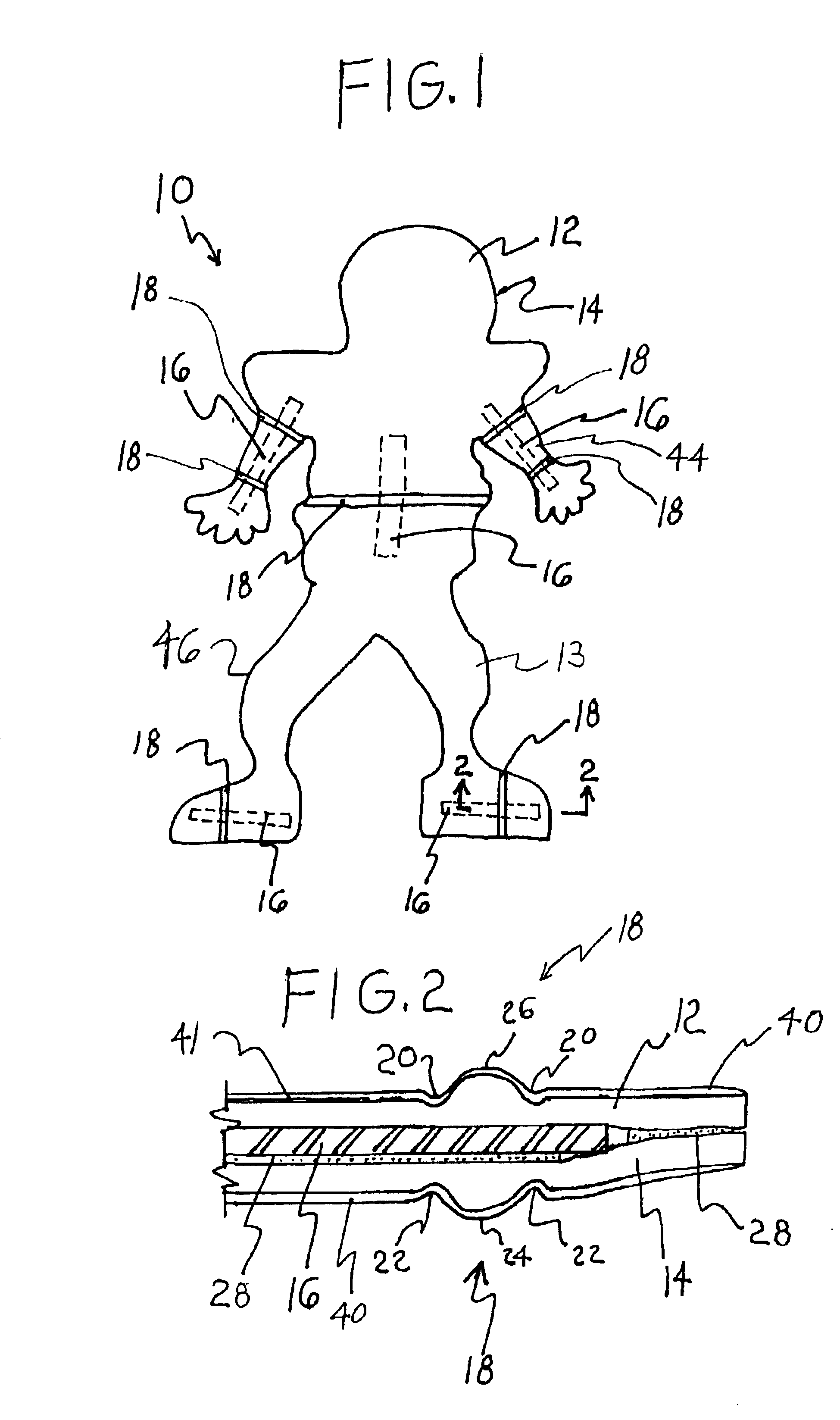

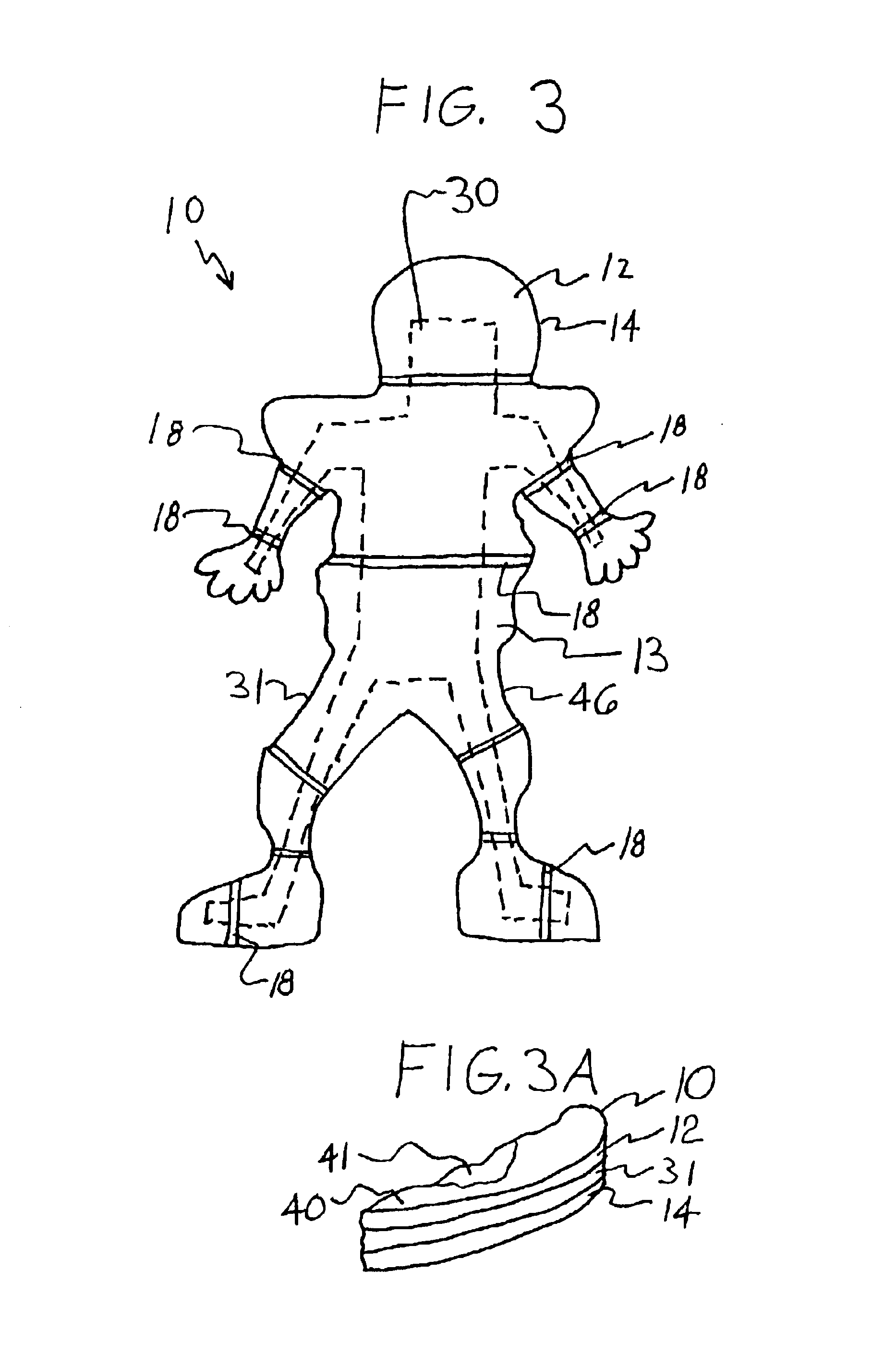

Articulated display

Owner:RAPID DISPLAY

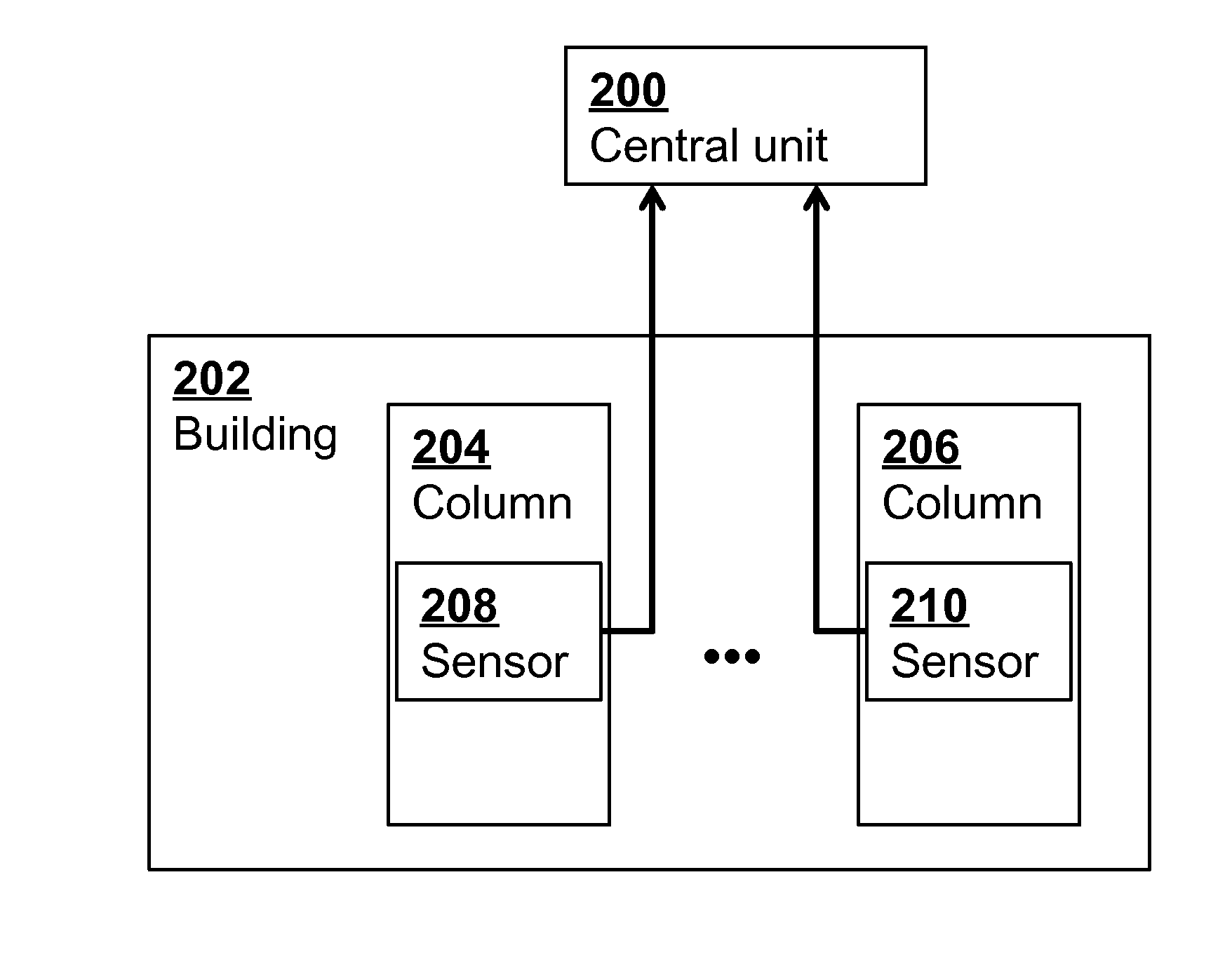

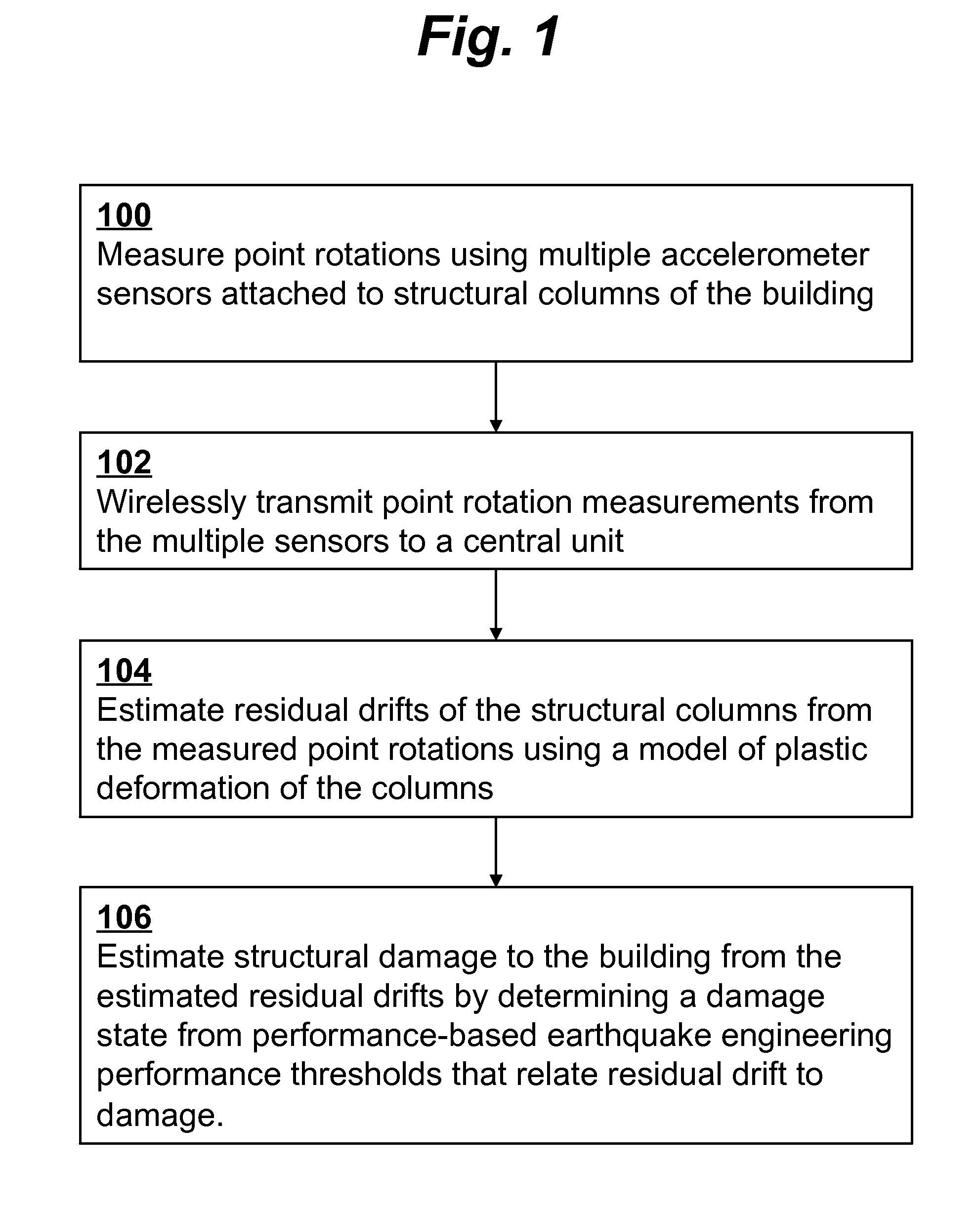

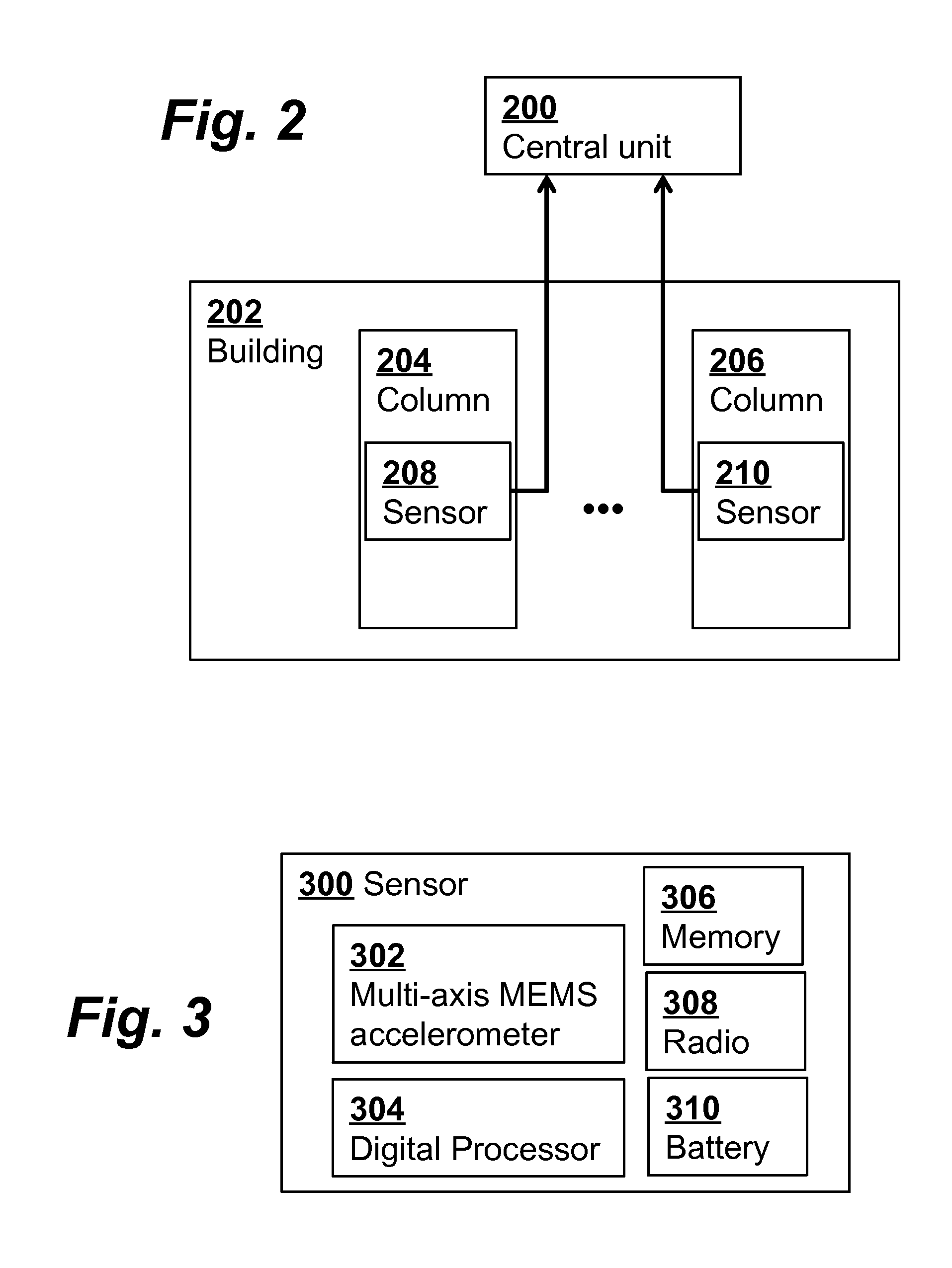

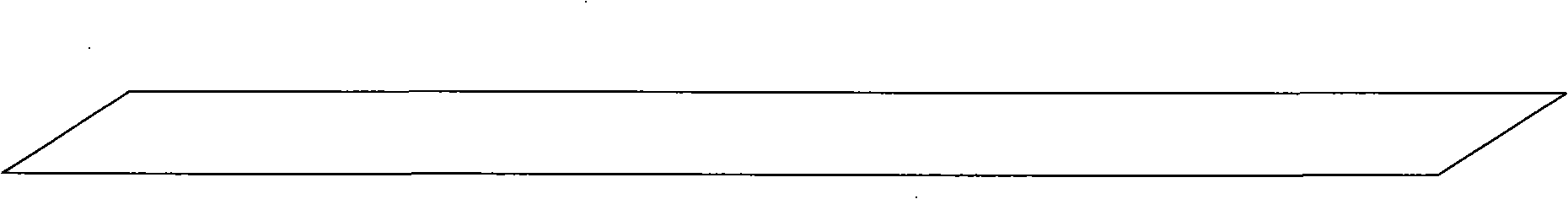

Structural damage estimation based on measurements of rotations

InactiveUS20140012517A1Plug gaugesSpecial data processing applicationsAccelerometerEarthquake engineering

Structural damage to a building is assessed based on measurement of point rotations using MEMS accelerometer sensors attached to structural columns of a building. The measured point rotations are wirelessly transmitted to a central unit which estimates residual drifts of the structural columns using a model of plastic deformation of the columns that incorporates empirically predetermined structural parameters of the columns such as a height of a column plastic bending point or a column curvature coefficient. The structural damage to the building is then estimated by determining a damage state from performance-based earthquake engineering performance thresholds that relate residual drift to damage. In some embodiments, multiple sensors are attached to each structural column of the building and measure corresponding point rotations at multiple points along the height of the column.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Magnesium alloy cellular board and manufacturing technique

InactiveCN101269553AImprove efficiencySolving the problem of overweight structuresVehicle componentsThin material handlingHigh intensityHoneycomb like

The invention relates to a magnesium alloy cellular plate and a production process thereof, the magnesium alloy cellular plate is formed by an upper panel, a lower panel, and a cellular core construction which are adhered and connected together, and is characterized in that magnesium alloy sheets are rolled to make the upper panel and the lower panel, the cellular core structure is a regular hexagon cellular-shaped structure which is made of magnesium alloy foil material through the processes of rolling, cutting, plastic bending precision molding, and positioning bonding. The magnesium alloy cellular plate has the advantages of high intensity and ultra-light weight, and can be widely used as the parts such as the wall plate, the floor plate, and the partition, etc. in the transportation equipment such as the spacecraft, the aircraft, the light high-speed train, and the urban rain train, etc., and the obvious weight-loss effect is achieved.

Owner:DALIAN JIAOTONG UNIVERSITY +1

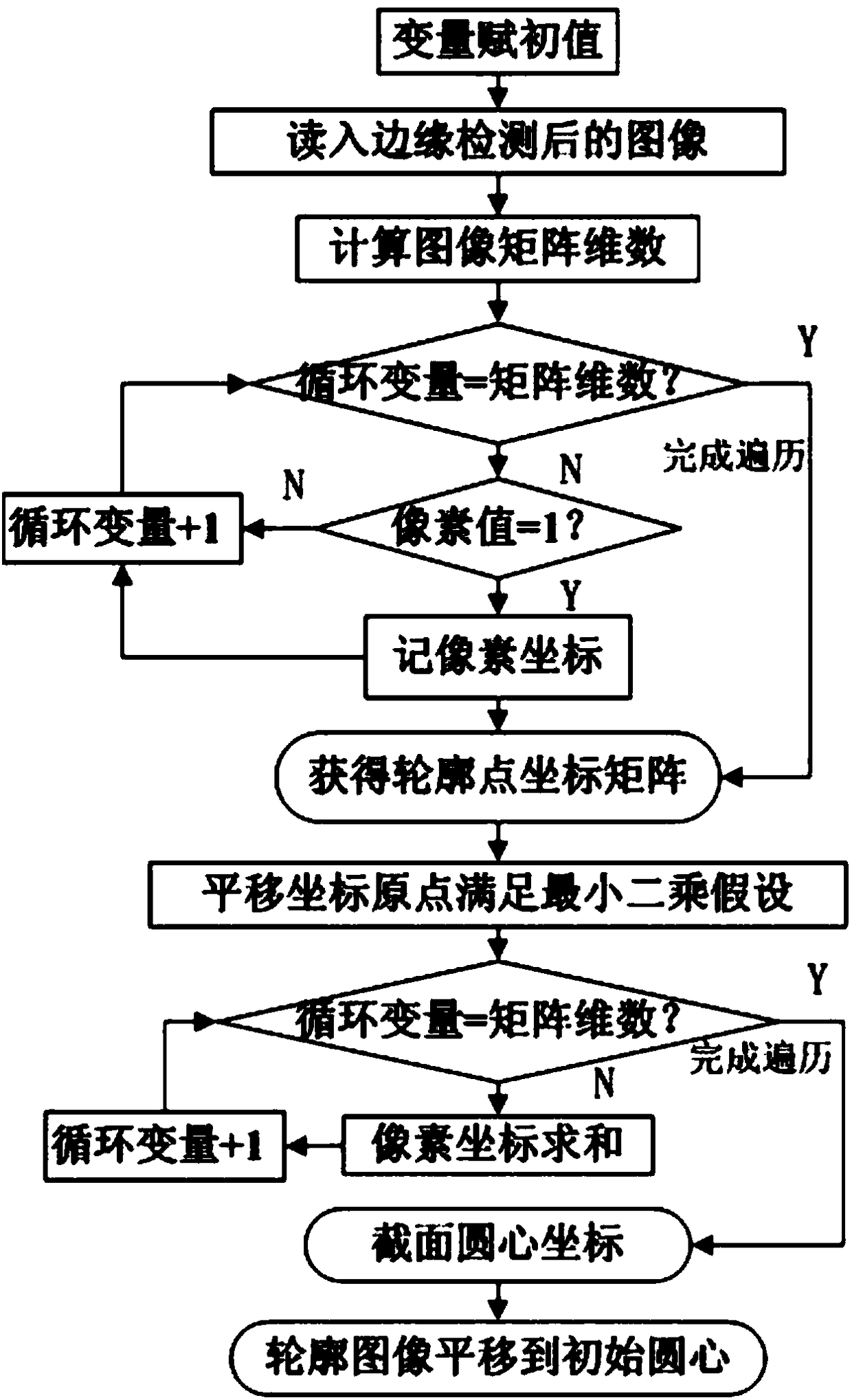

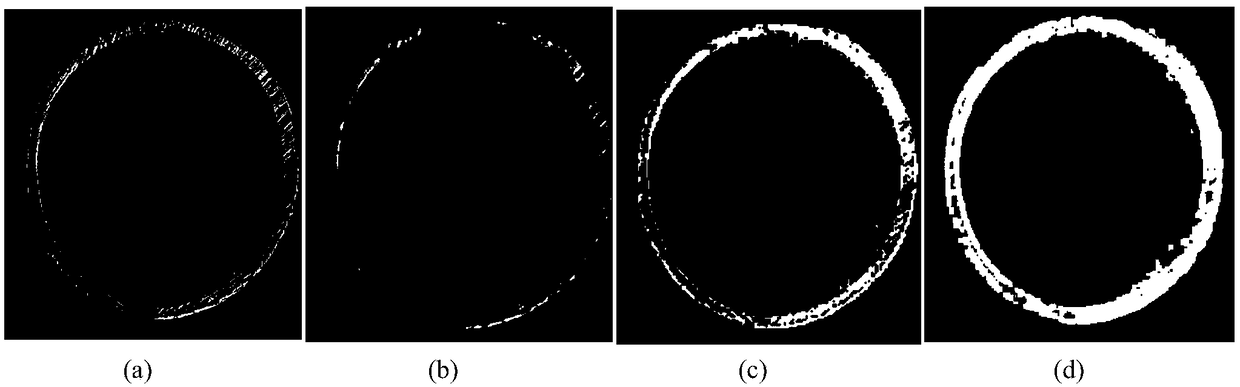

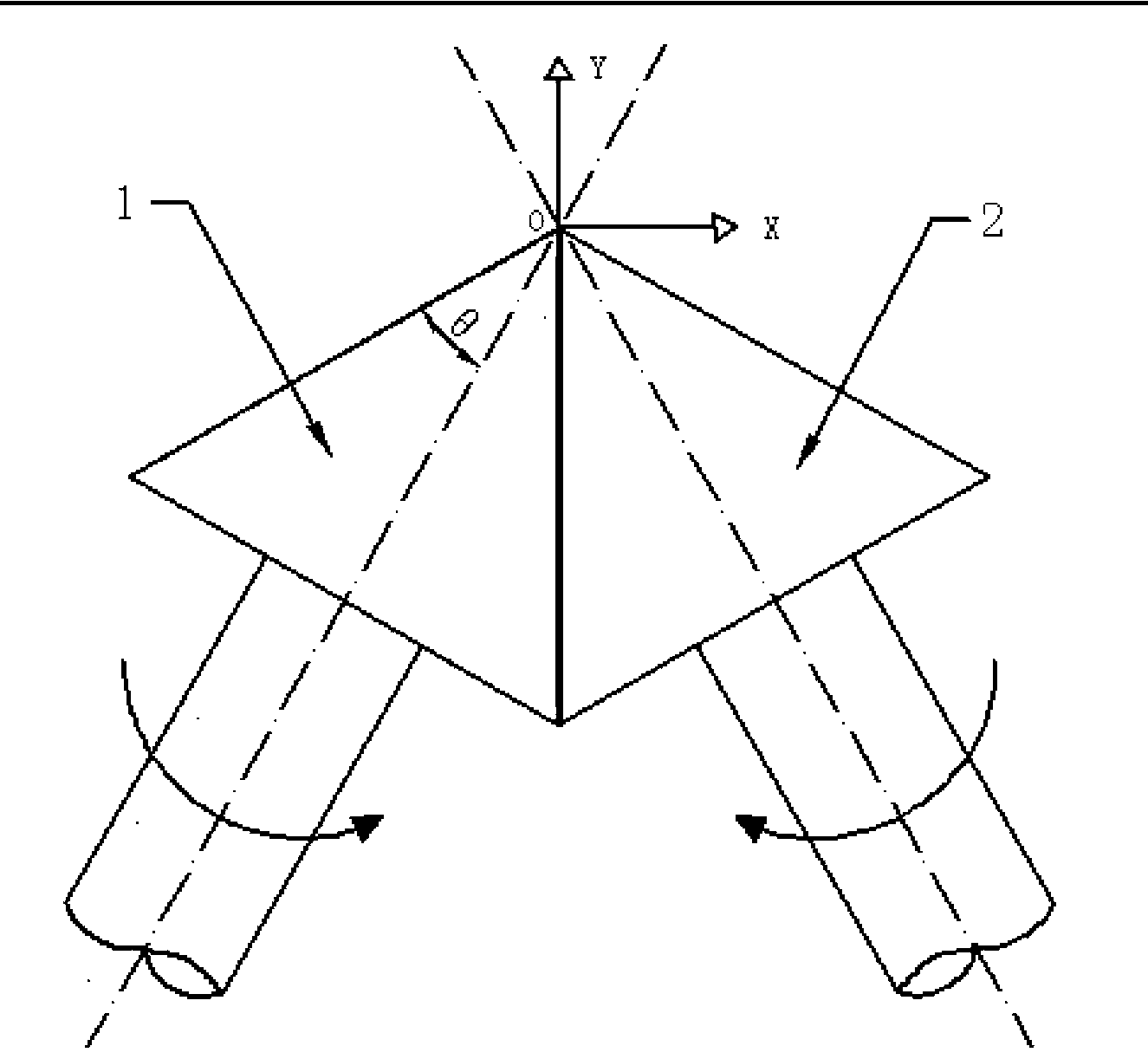

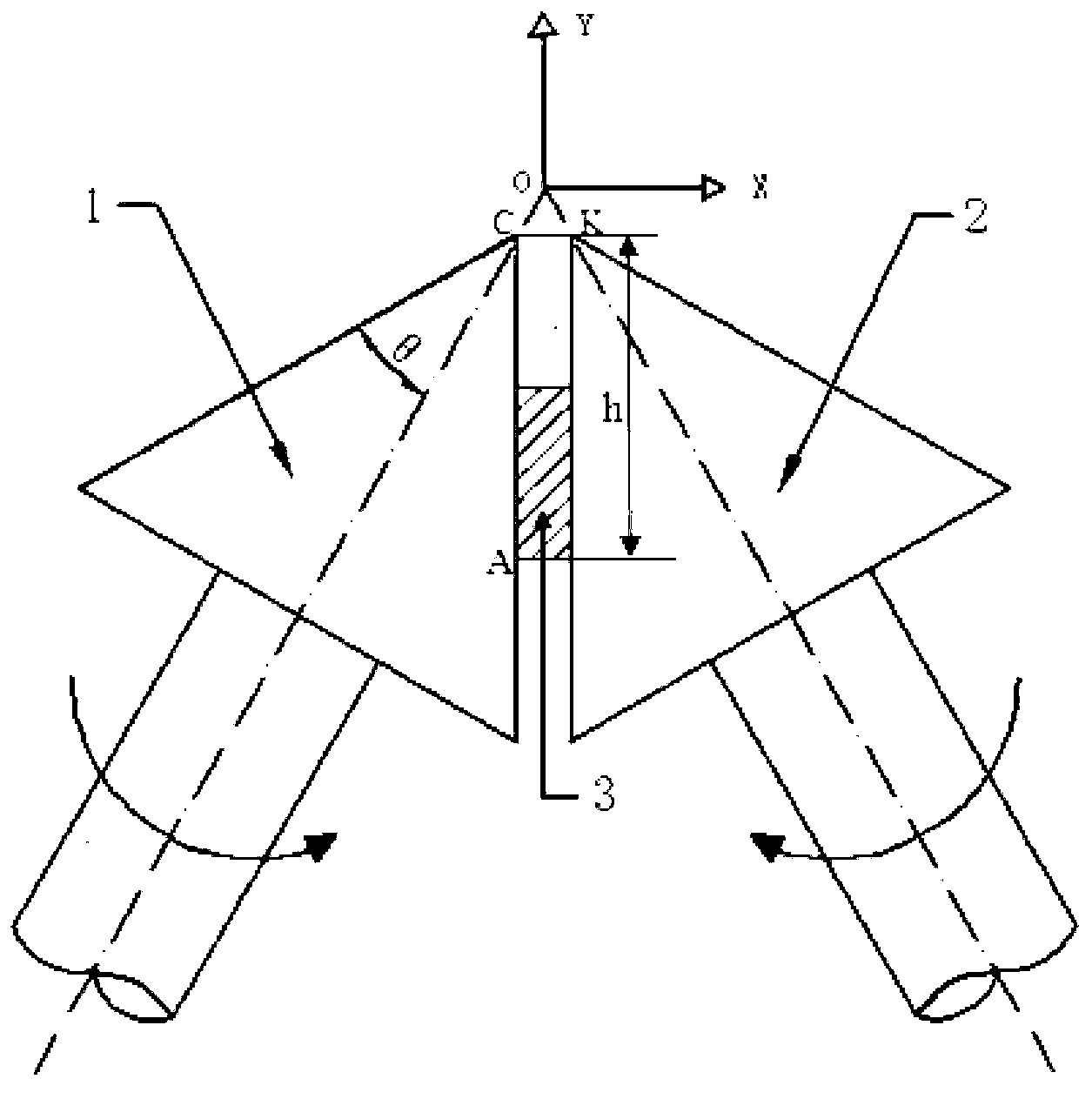

Method for determining large-plastic bending section profile curve of thin-walled pipe

The invention belongs to the technical field of metal pressure processing, and provides a method for determining a large-plastic bending section profile curve of a thin-walled pipe. The method mainlycomprises the following steps: 1, acquiring a contour image of the cross section of a curved and flattened thin-walled pipe by means of the image detection means; 2, detecting the outer edge of the flattened outline based on the image processing technology and acquiring the pixel coordinates of contour points; 3, determining the centroid of the pipe section of the thin-walled pipe before deformation through the least square circle method, and carrying out coordinate translation on the edge image; 4, through successively applying four form functions, carrying out curve fitting on the pixel coordinates of contour points, and finally determining the contour curve of the cross section of the pipe according to the fitting result. According to the method, the flattened deformation amount of thecross section of the thin-walled pipe after the large-plastic bending of the thin-walled pipe can be effectively controlled. Meanwhile, the quantitative evaluation on the quality and the precision ofthe cross section of the bent thin-walled pipe can be achieved.

Owner:NORTHEASTERN UNIV

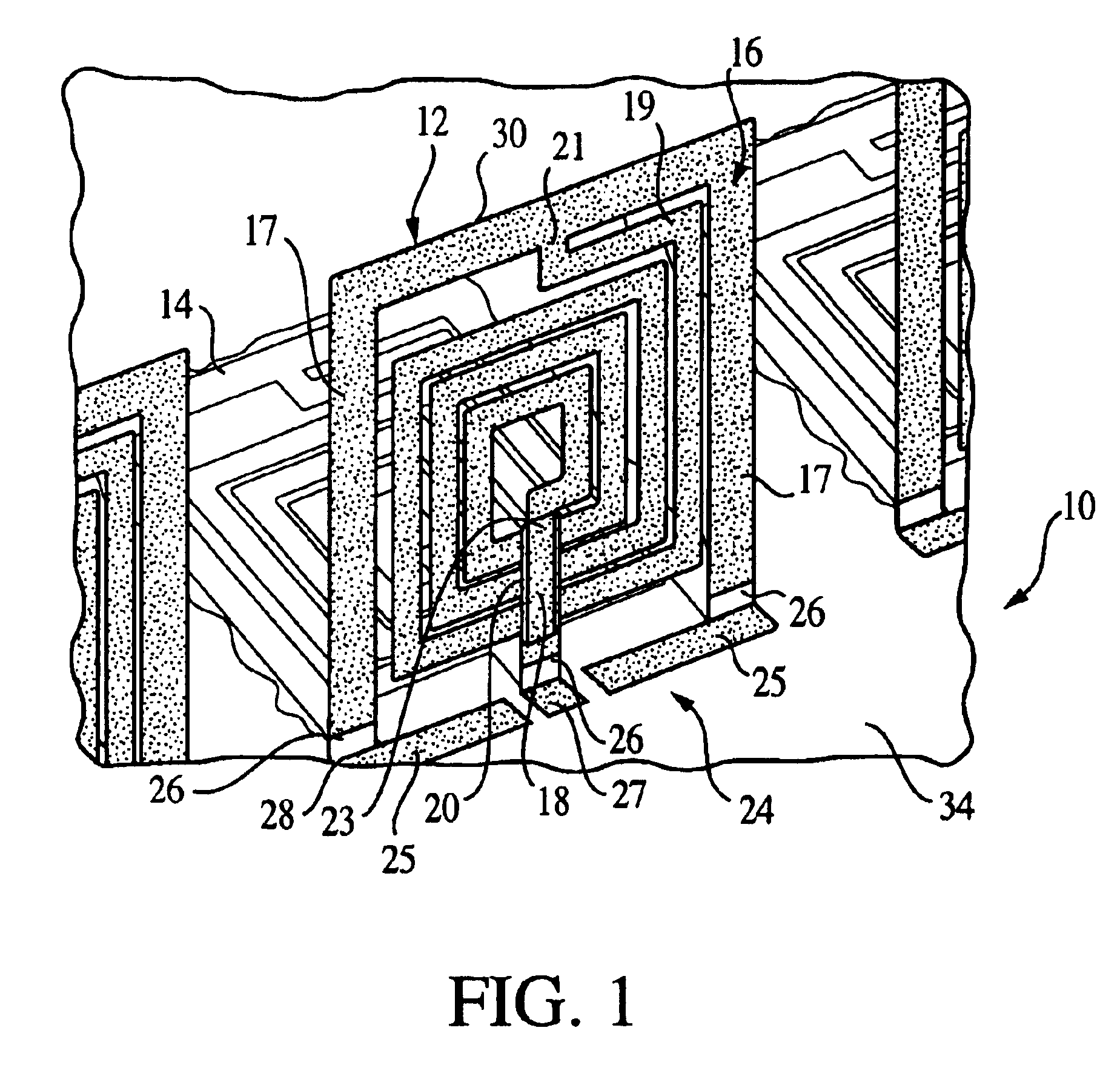

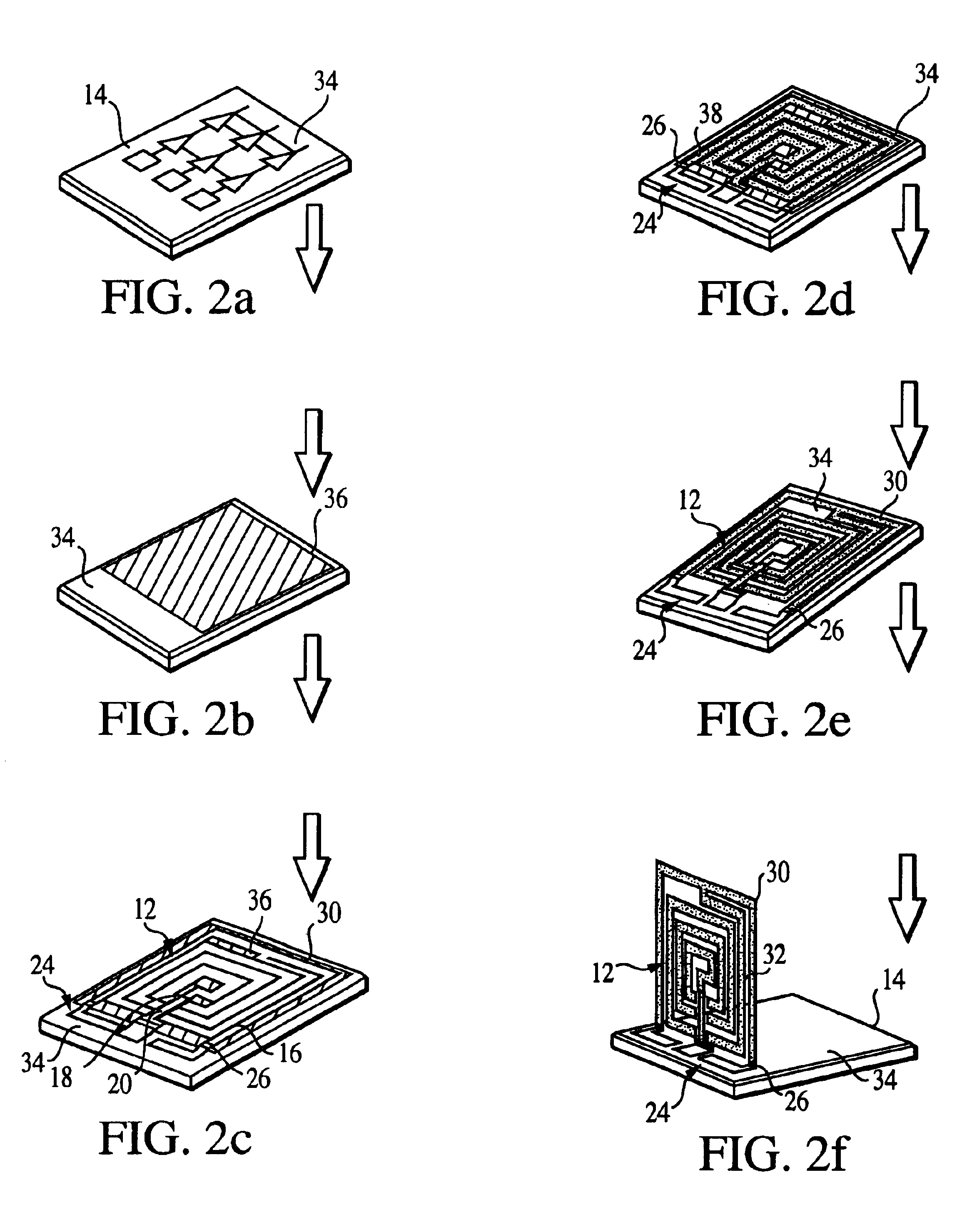

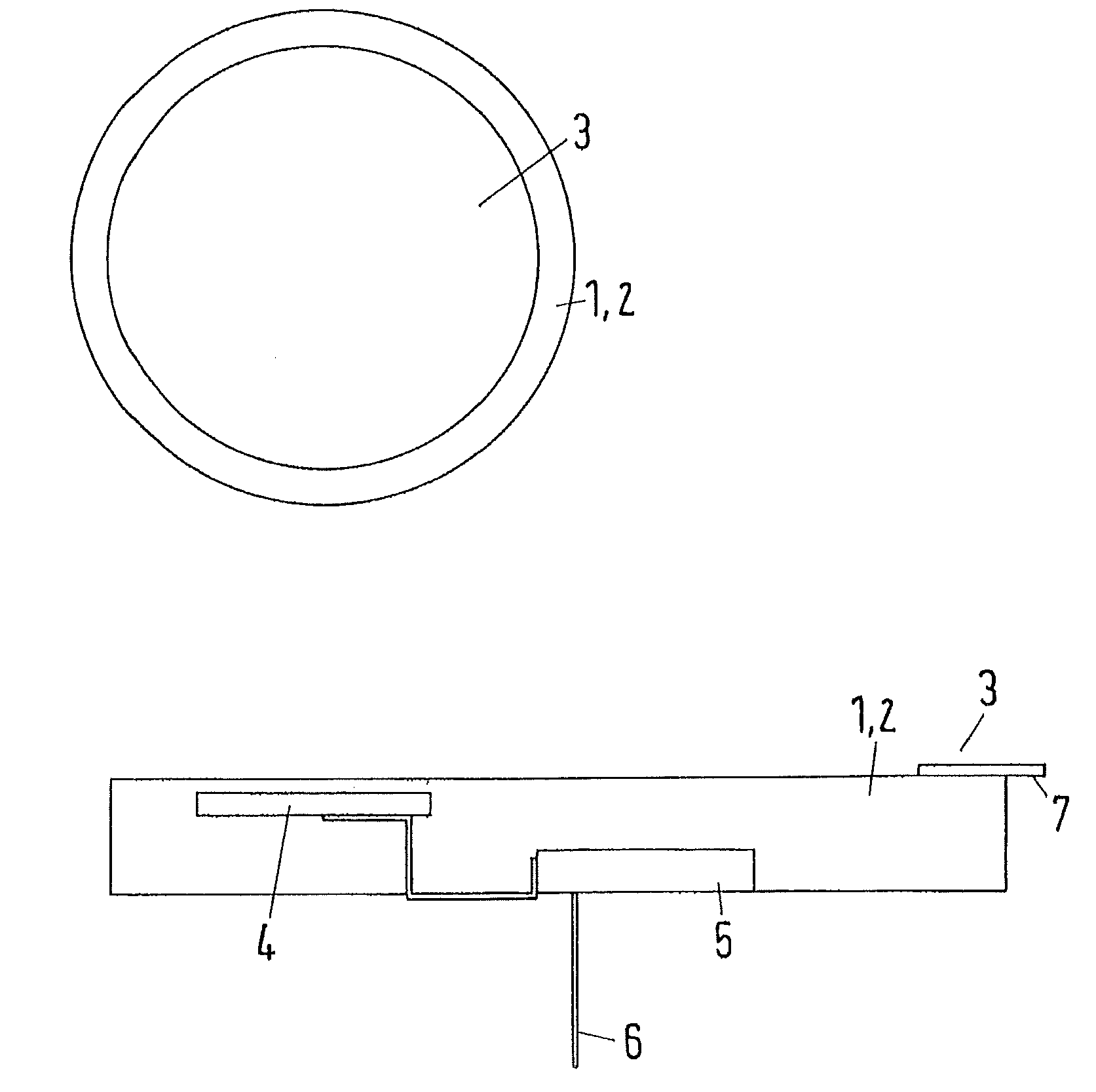

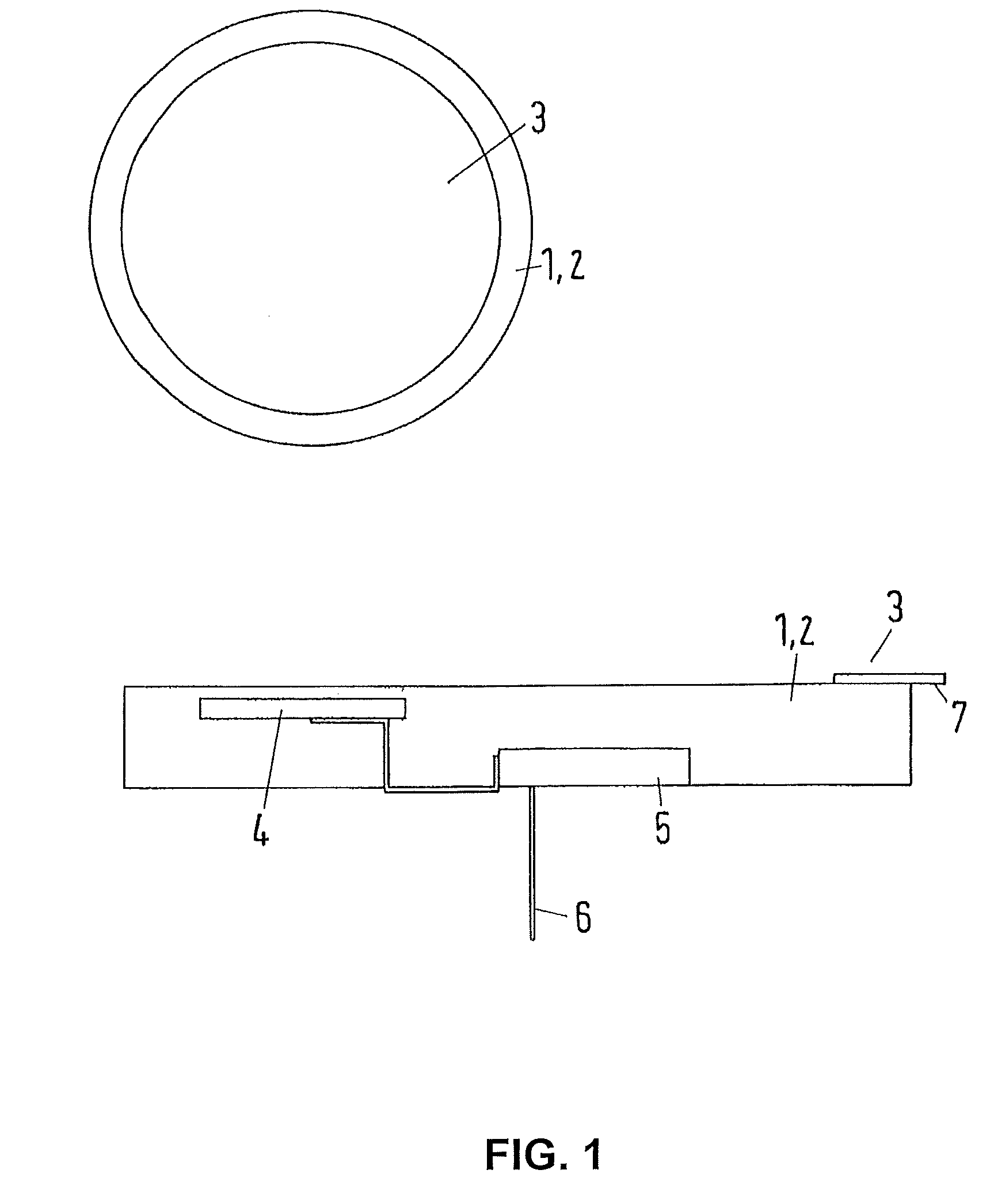

Raised on-chip inductor and method of manufacturing same

InactiveUS6922127B2Less susceptibleSmall footprintSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsPlanar inductorMagnetic layer

A raised on-chip planar inductor. An inductor is fabricated on a substrate. The inductor, except for an anchoring extremity, is lifted from the substrate, preferably by application of a magnetic field to a magnetic layer formed on the inductor. The lifting of the inductor deforms a plastic bending region. After the magnetic field is removed, the inductor remains raised with respect to the substrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Bulk nickel-based chromium and phosphorous bearing metallic glasses

Ni-based Cr- and P-bearing alloys that can from centimeter-thick amorphous articles are provided. Within the family of alloys, millimeter-thick bulk-glassy articles can undergo macroscopic plastic bending under load without fracturing catastrophically.

Owner:CALIFORNIA INST OF TECH

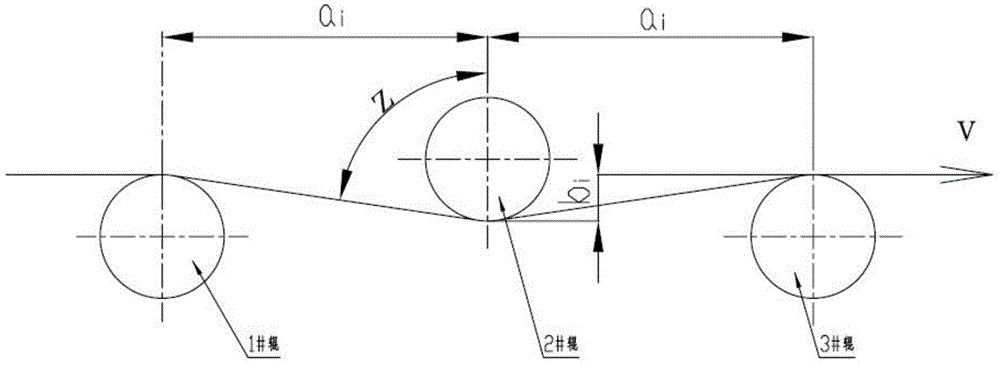

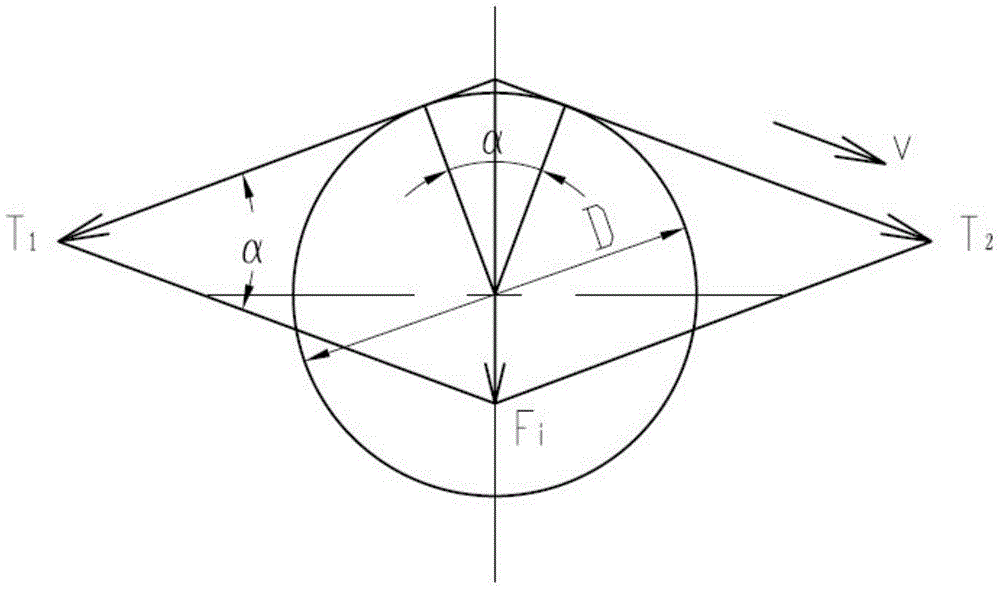

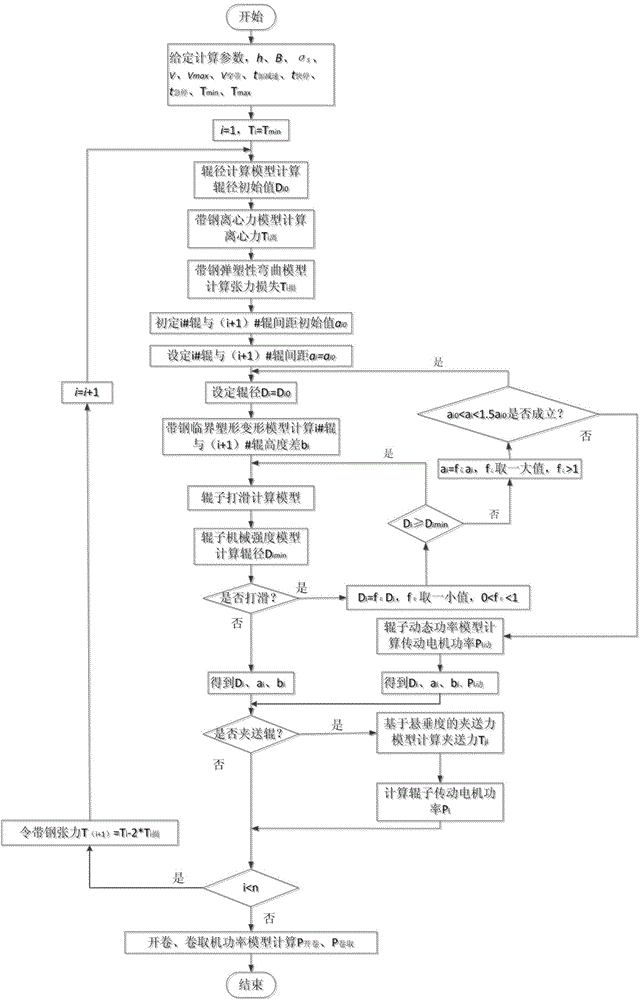

Ultra-thin strip steel finishing unit operation parameter design method

The invention discloses an ultra-thin strip steel finishing unit operation parameter design method. The ultra-thin strip steel finishing unit operation parameter design method comprises the steps that strip steel and finishing unit parameters, roller numbers and strip steel tension are set; a roller diameter initial value is set according to a roller diameter calculation model; strip steel centrifugal force is calculated according to a strip steel centrifugal force model; tension loss, caused by elastic plastic bending, of strip steel is calculated according to a strip steel elastic plastic bending model; the distance between a number i roller and an adjacent number (i+1) roller is set firstly; the height difference between the number i roller and the adjacent number (i+1) roller is calculated according to a strip steel critical plastic bending model; a roller slipping model is built; the minimum roller diameter of the number i roller is calculated according to a roller mechanical strength model; whether roller slipping conditions are met is judged; whether the number i roller needs a clamping roller is judged; the roller number i and the roller number n in the finishing unit are compared. The ultra-thin strip steel finishing unit operation parameter design method is perfect, and provides theoretical support and data support for judgment of reasonability of selected parameters.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

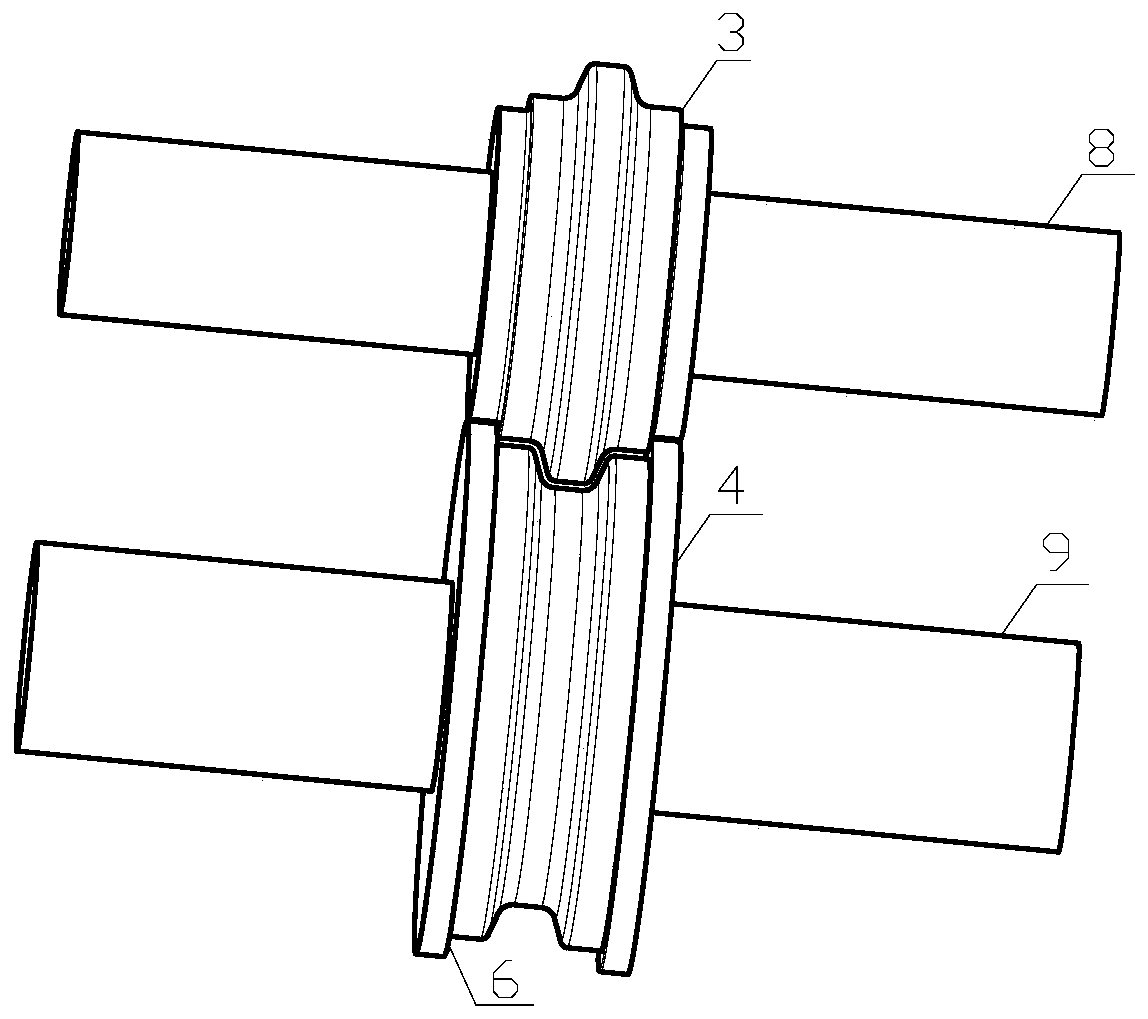

Method for reinforcing metal through roll bending and combined deformation

InactiveCN105132653AStructural refinementThe implementation process is simpleSurface layerGrain structure

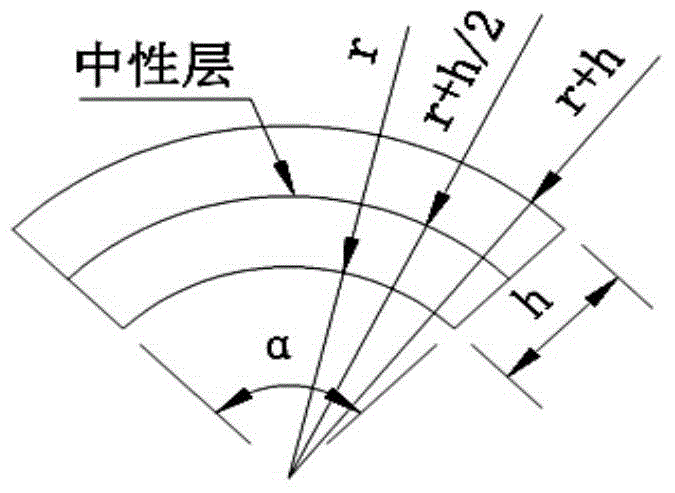

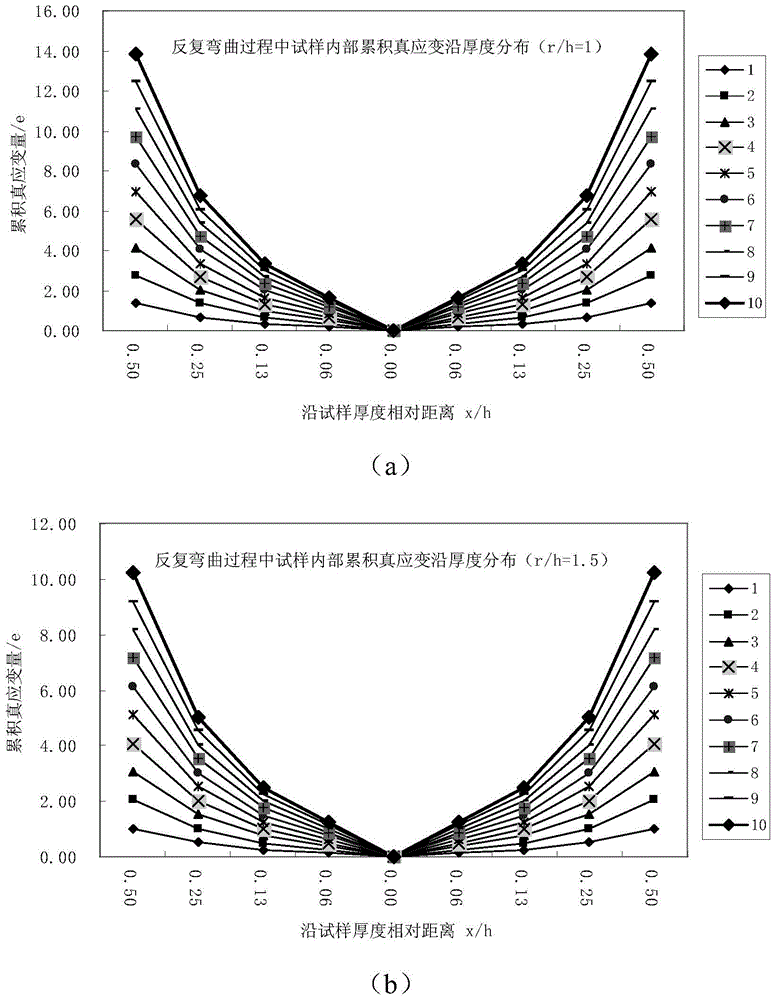

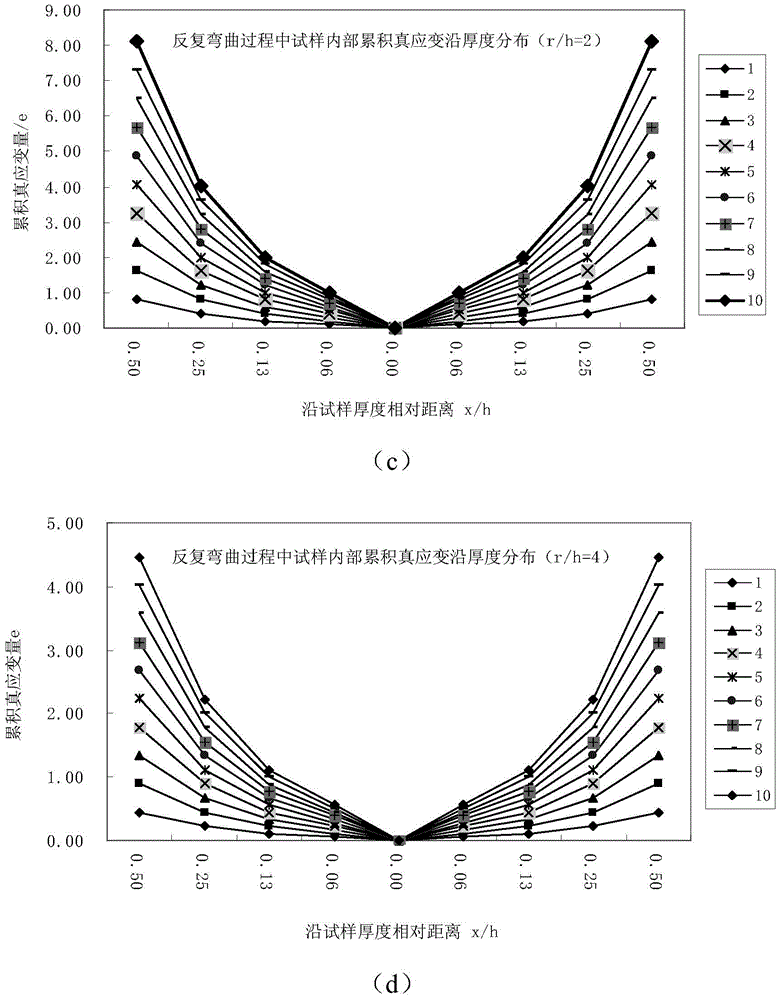

The invention relates to a method for reinforcing metal through roll bending and combined deformation. After a metal material is rolled to a certain size by using a rolling mill, the metal material is introduced to a bending roll system capable of realizing repeated plastic bending deformation through a pair of pinch rolls so as to be subjected to repeated plastic bending deformation. A metal structure of which accumulative strains from a neutral layer to a surface layer are progressively increased and grain structures are refined and progressively increased is formed inside the metal material through the repeated plastic bending deformation of the metal material in the bending roll system, so that a deformation method for increasing the strain capacity inside the metal and improving the toughness of the metal material and particularly the surface toughness of the metal material under the condition that the size of the metal material is basically invariable, namely the method for reinforcing metal through roll bending and combined deformation, is achieved

Owner:SHANGHAI INST OF TECH

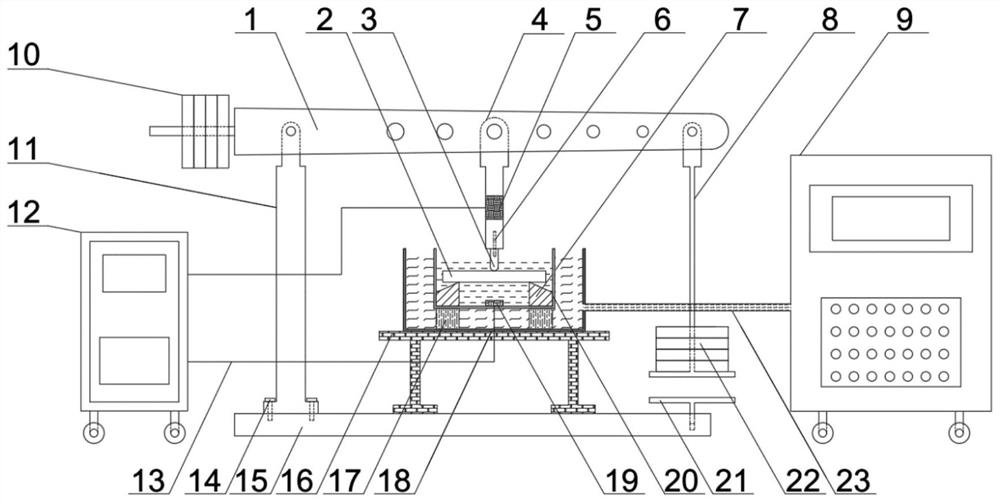

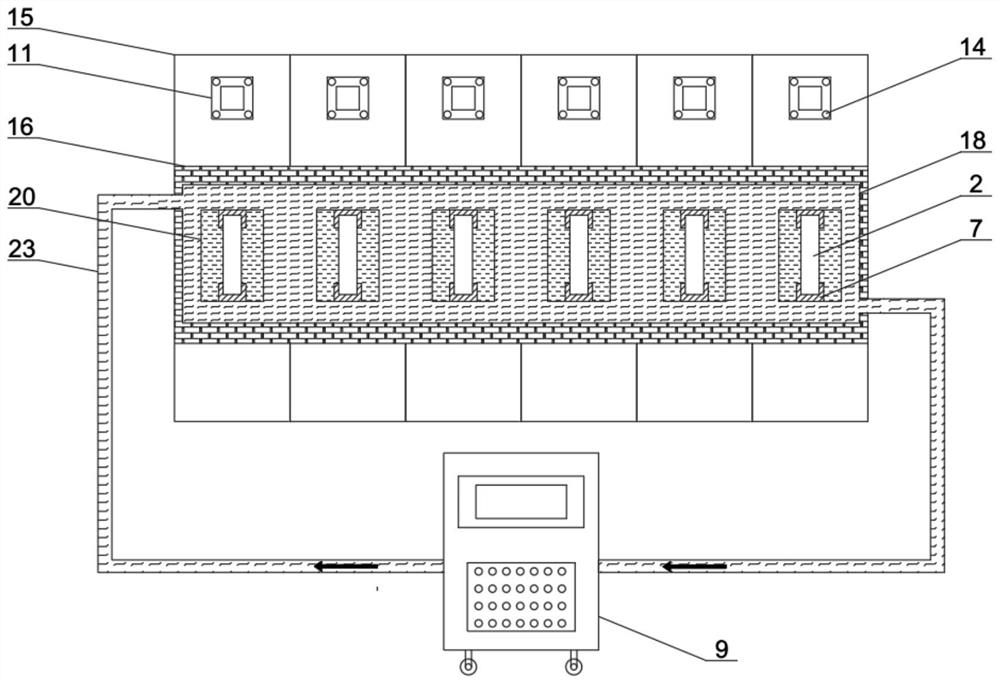

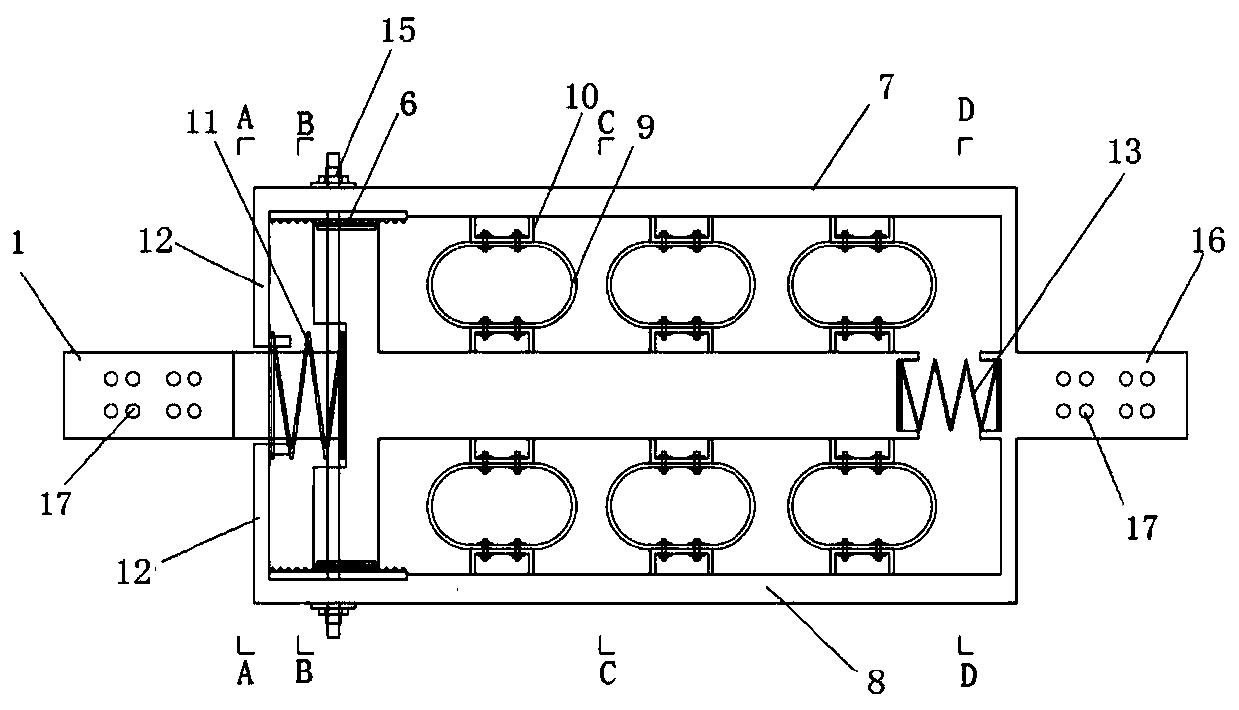

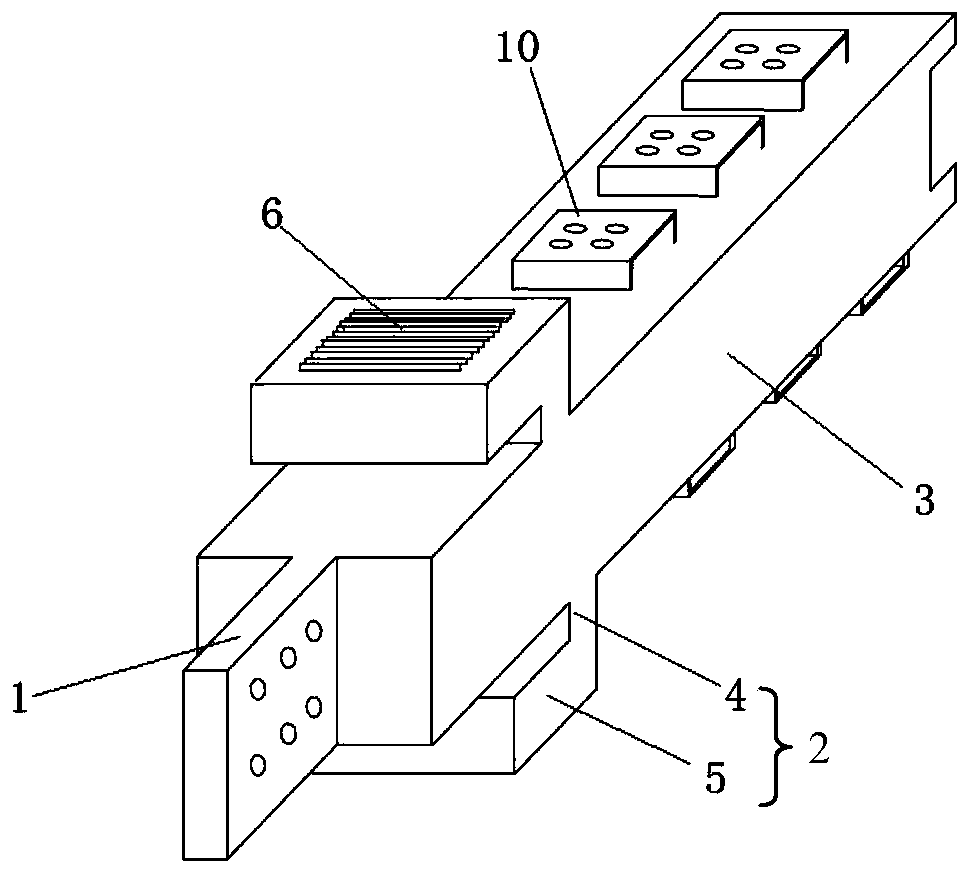

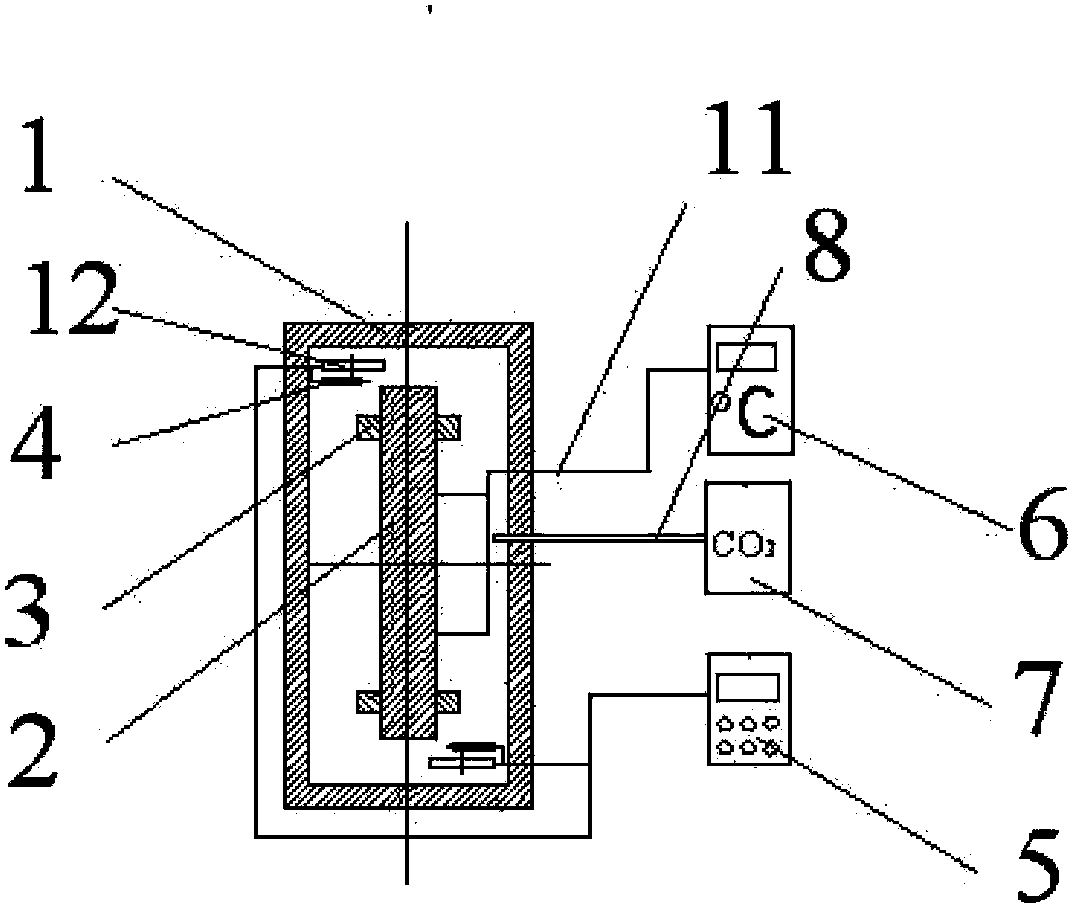

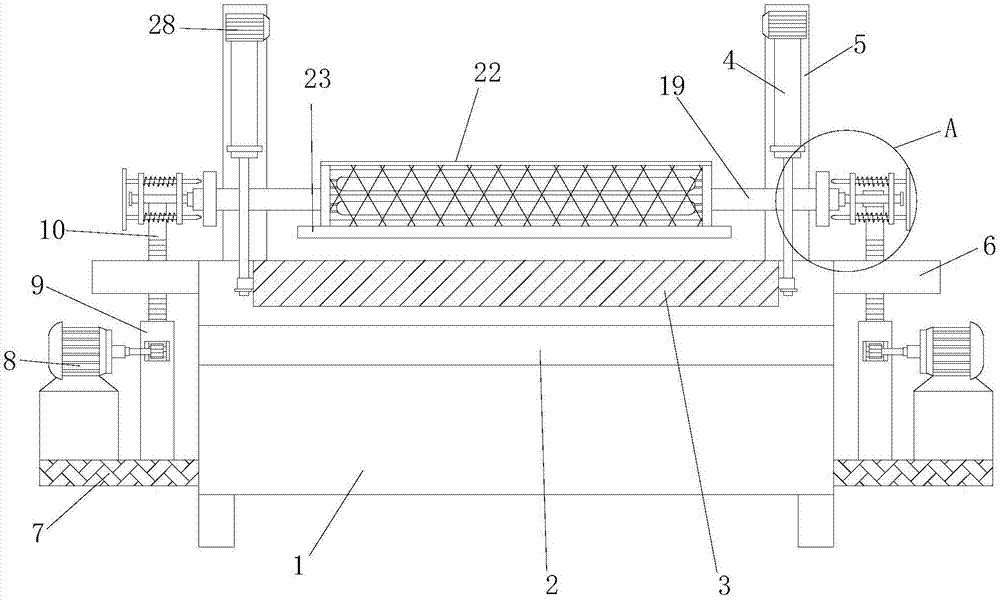

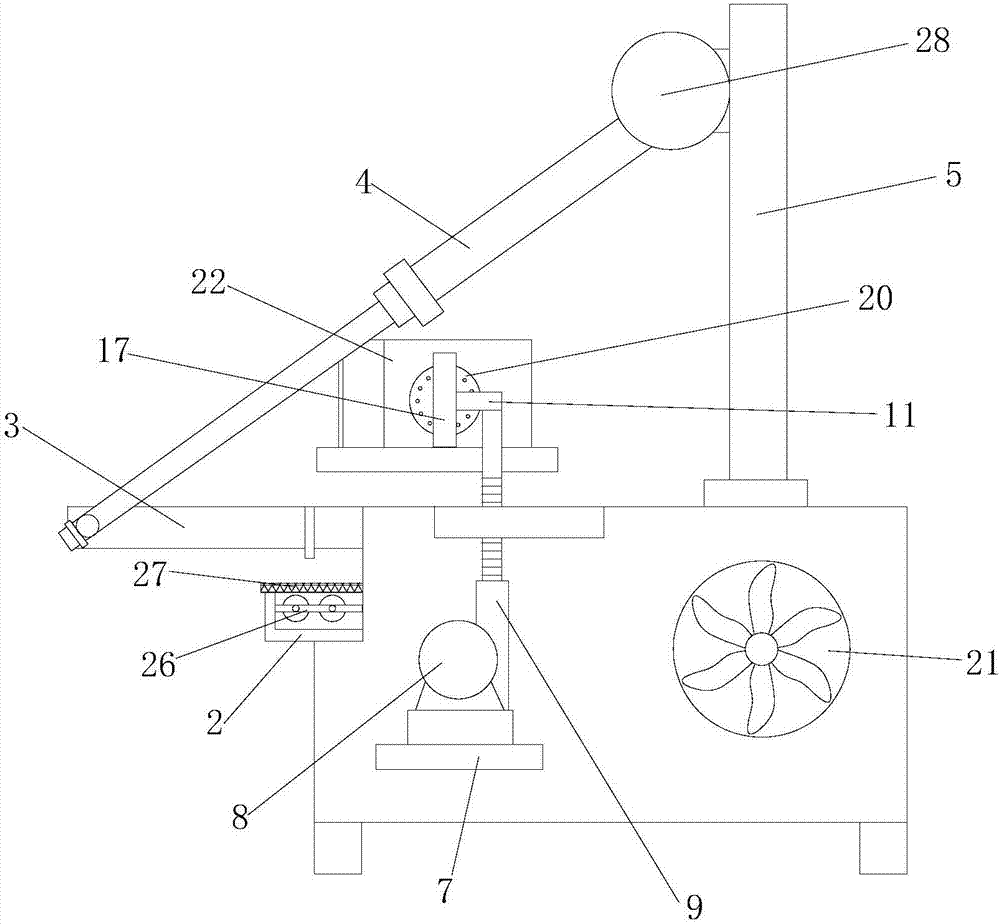

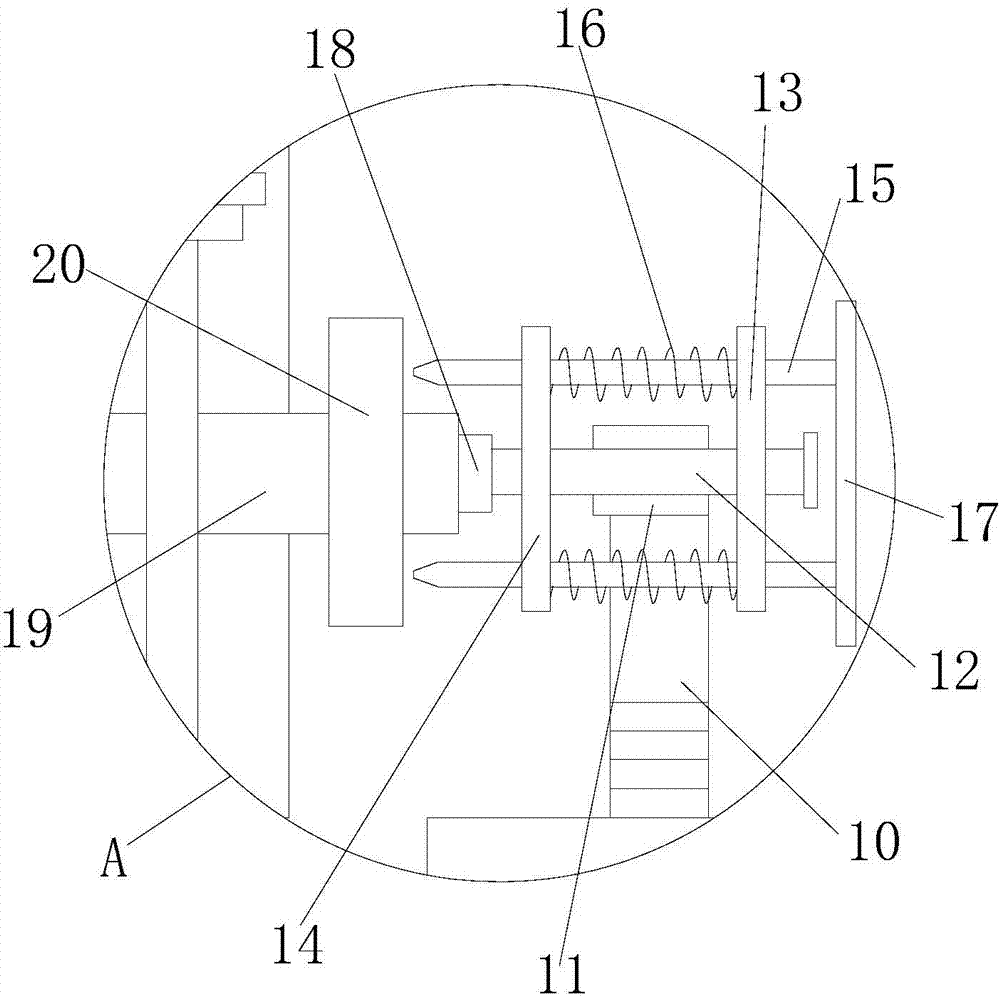

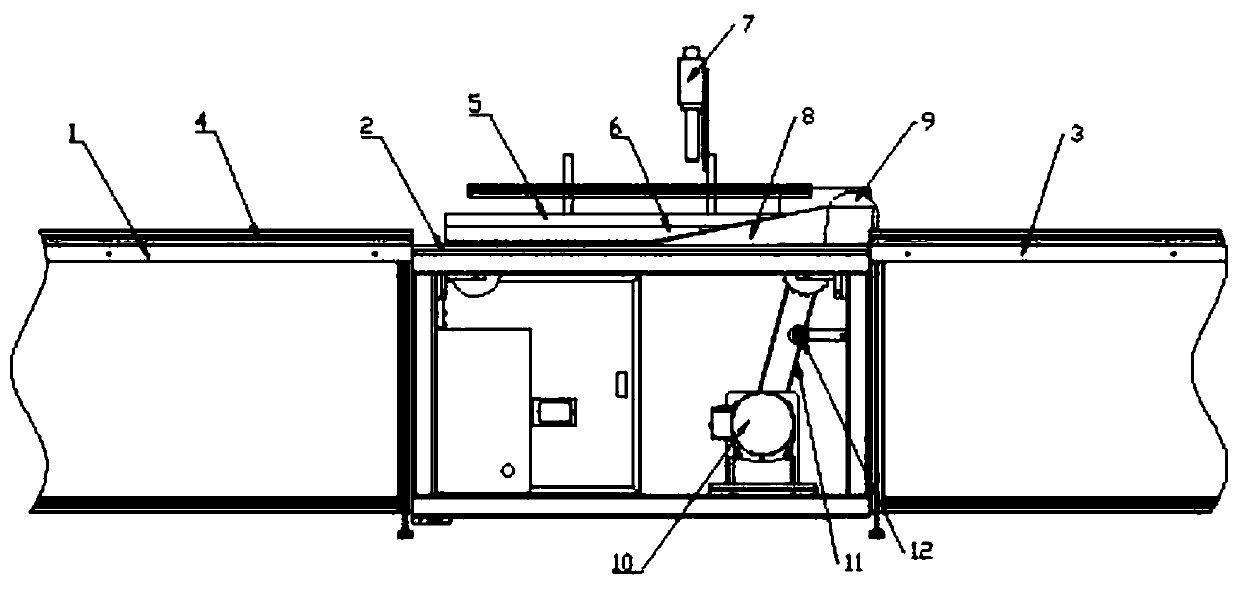

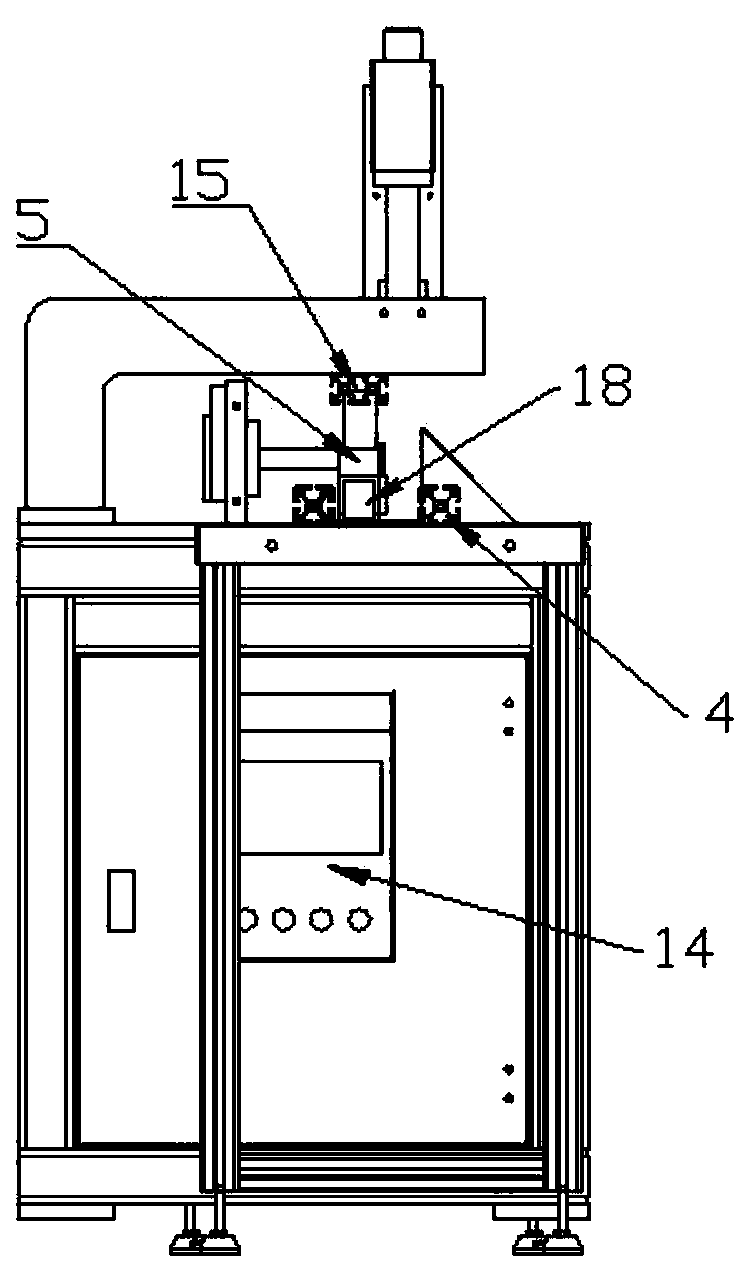

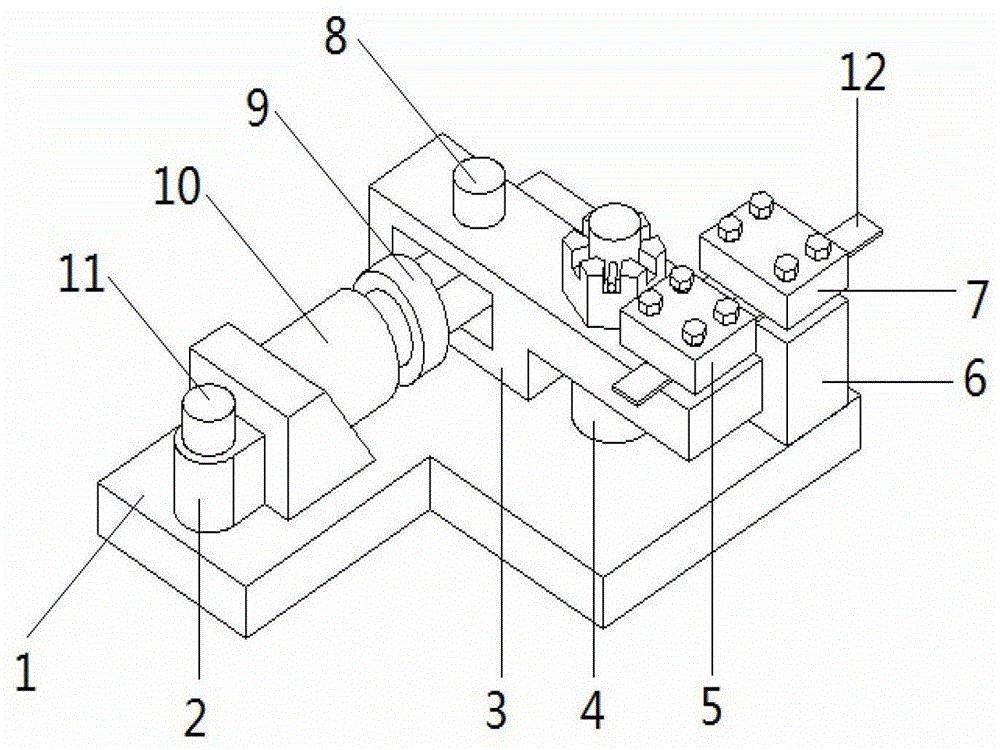

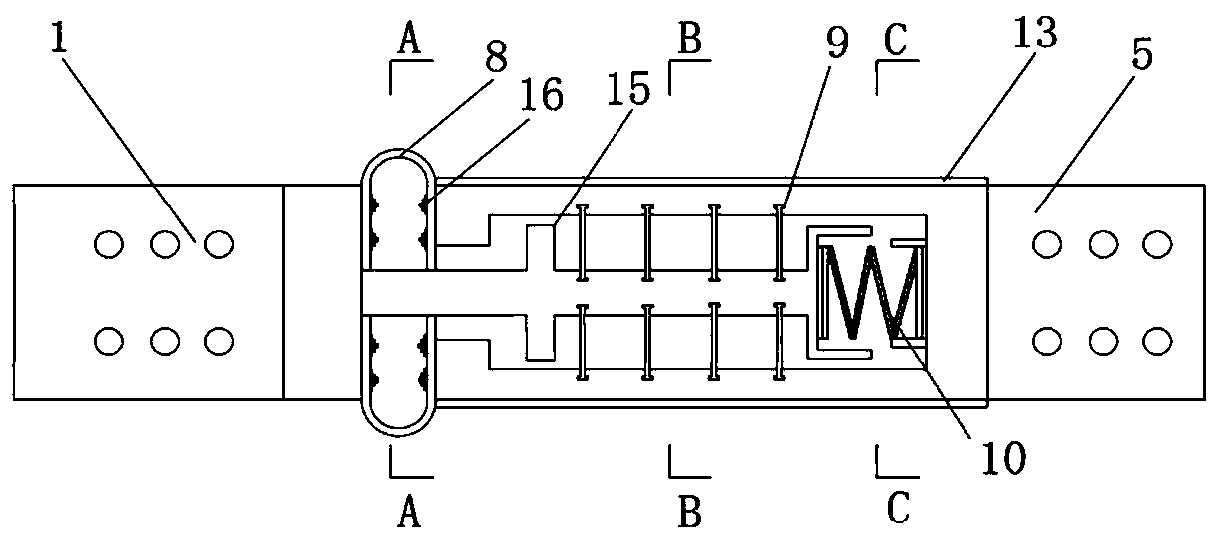

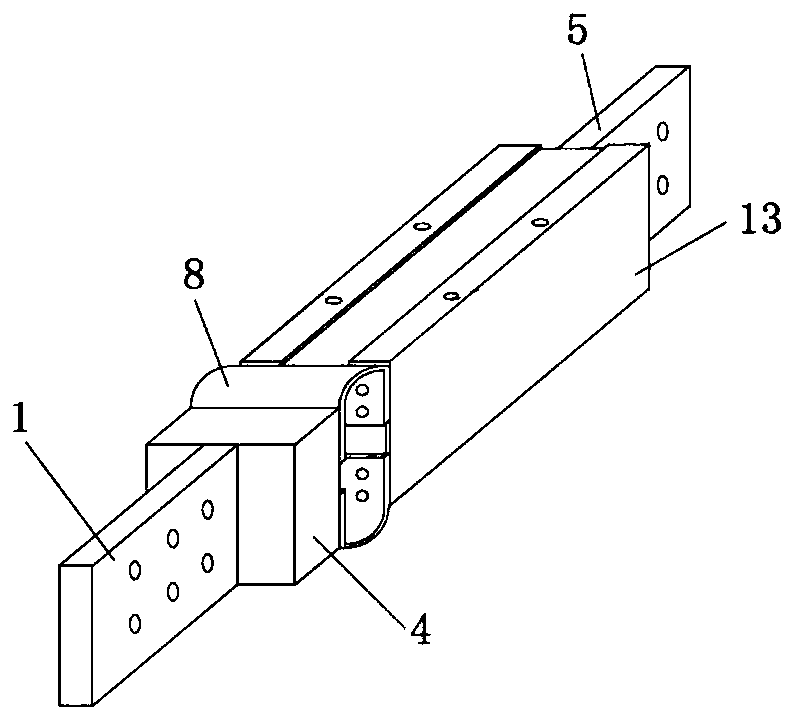

Multi-station integrated environment glass fiber reinforced plastic bending creep test apparatus and method

InactiveCN111735718AConvenient hierarchical loadingSimple structureMaterial strength using steady bending forcesGlass fiberTemperature control

The invention discloses a multi-station integrated environment glass fiber reinforced plastic bending creep test apparatus and method. The test apparatus comprises a lever loading device, a temperature control device and a data acquisition device; the lever loading device comprises a supporting column and a cross beam, the top of the supporting column is provided with the cross beam, the cross beam is provided with a vertical pressing rod, the bottom end of the pressing rod is provided with a pressing head for pressurizing a test piece, one end of the cross beam is provided with a balance weight, and the other end is provided with a loading weight; the temperature control device is used for adjusting the temperature of the sample; and the data acquisition device is used for acquiring creepparameters of the sample under a stress condition. The apparatus is simple in structure, the test load, temperature and medium environment are controllable., a specific service environment can be simulated to the greatest extent, large-batch tests can be carried out at the same time by adopting the multi-lever loading device, the time and economic costs can be effectively reduced, and an effective test way is provided for service performance attenuation research, service safety evaluation and service life prediction of resin-based composite materials such as glass fiber reinforced plastics.

Owner:XI AN JIAOTONG UNIV

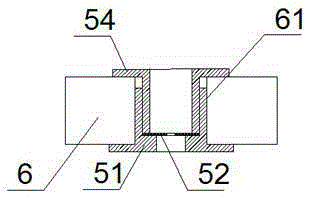

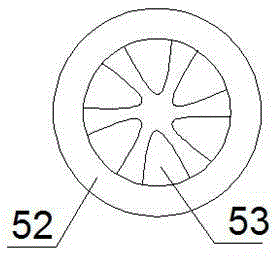

Flowmeter, in particular inductive flowmeter

InactiveUS20100077865A1Volume meteringVolume/mass flow by electromagnetic flowmetersPlastic materialsBiomedical engineering

Owner:ABB TECH AG

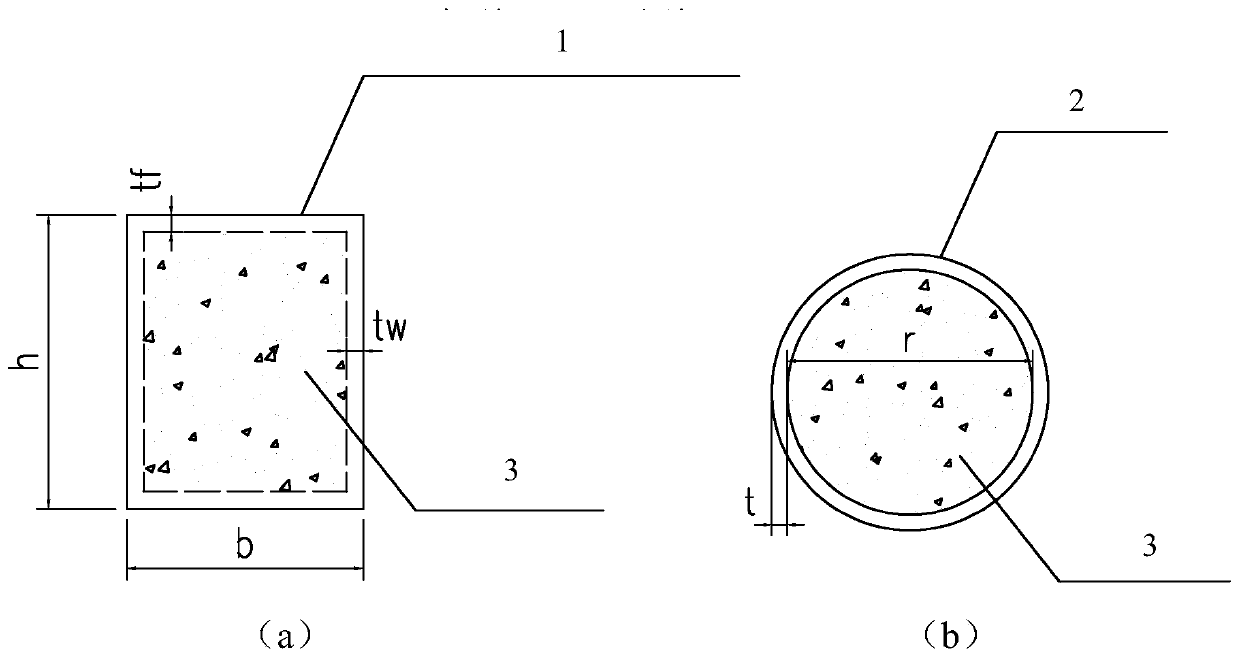

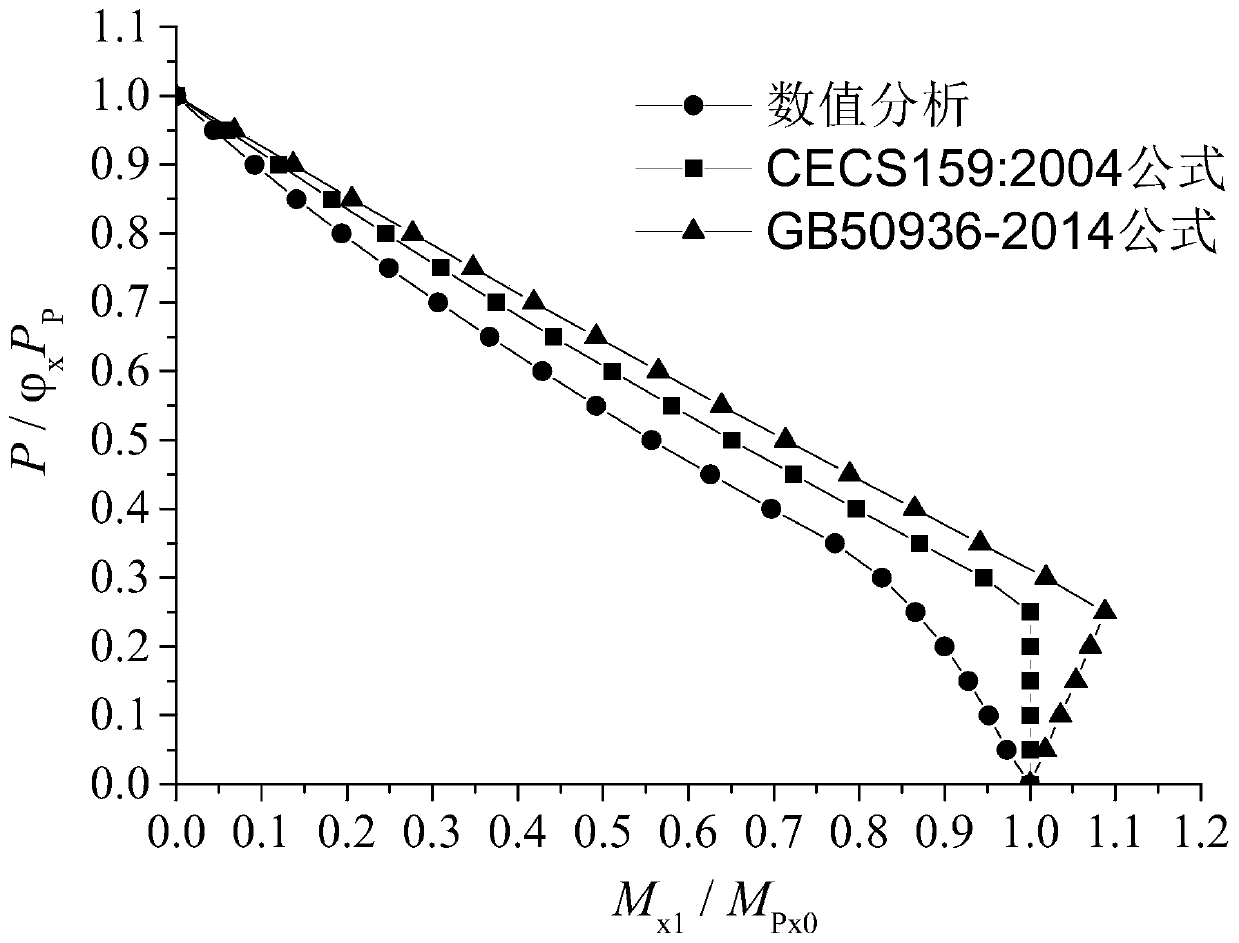

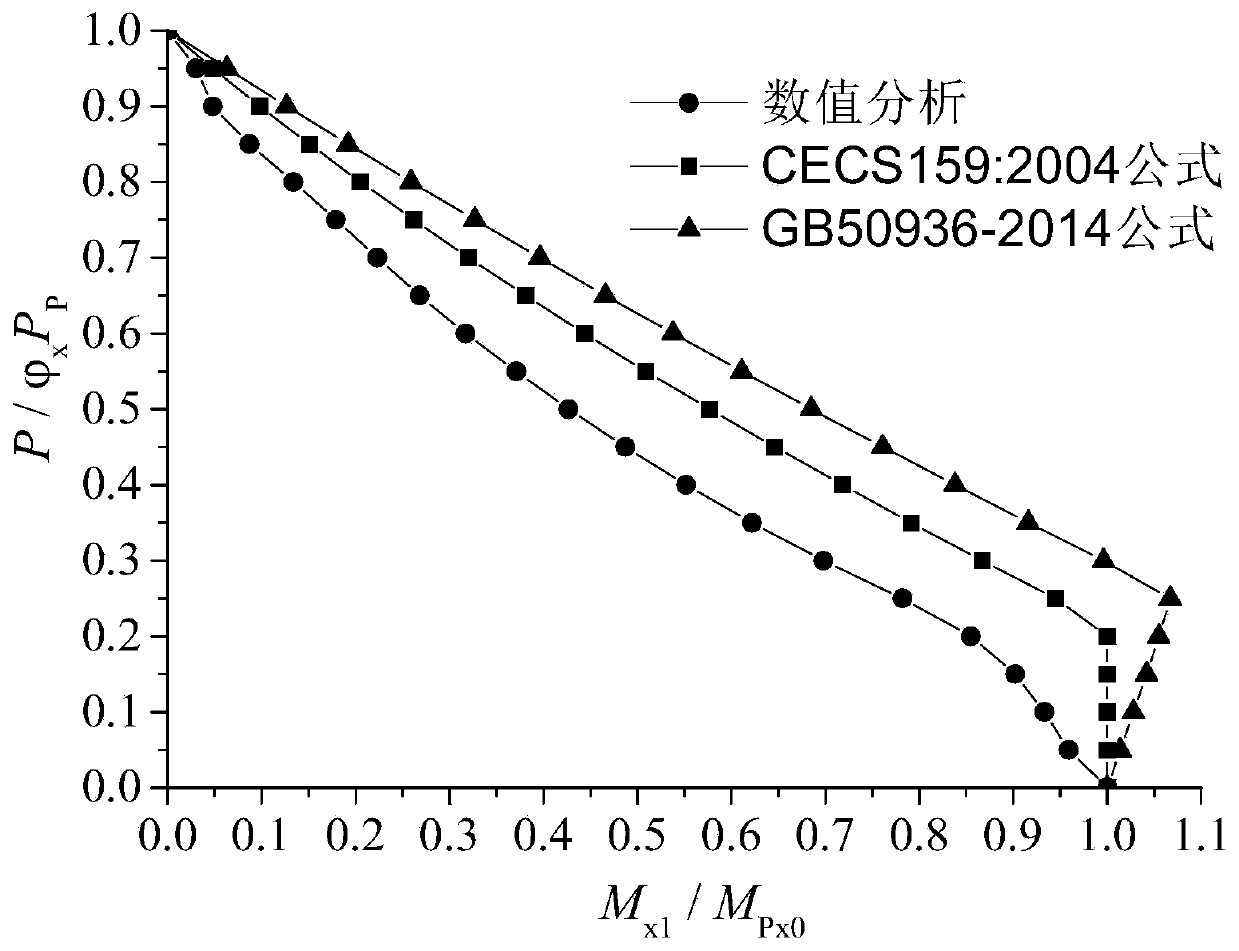

Method for judging stable bearing in steel pipe concrete column plane

ActiveCN109783940ASolve the problem of stable bearing judgmentImprove reliabilityStrutsSpecial data processing applicationsStructural engineeringBending moment

The invention discloses a method for judging stable bearing in a steel pipe concrete column plane. The concrete-filled steel tubular column is divided into a concrete-filled steel tubular column bodyfor bearing a one-way bending load and a concrete-filled steel tubular column body for bearing a two-way bending load. For bearing a one-way bending load, the equivalent bending moment coefficient ofthe concrete-filled steel tubular column is calculated firstly, then the bearing stability is judged, for bearing a two-way bending load, the equivalent bending moment coefficient of the concrete-filled steel tubular column is calculated firstly, then the ratio of the end bending moment around two bending shafts to the section plastic bending moment is calculated, and then the bearing stability isjudged. The method comprehensively solves the problem of stable bearing judgment in the plane of the concrete filled steel tubular column, has higher precision, greatly improves the reliability and safety of concrete filled steel tubular structure design, and is wide in application range.

Owner:HANGZHOU TONGMSK DESIGN CO LTD

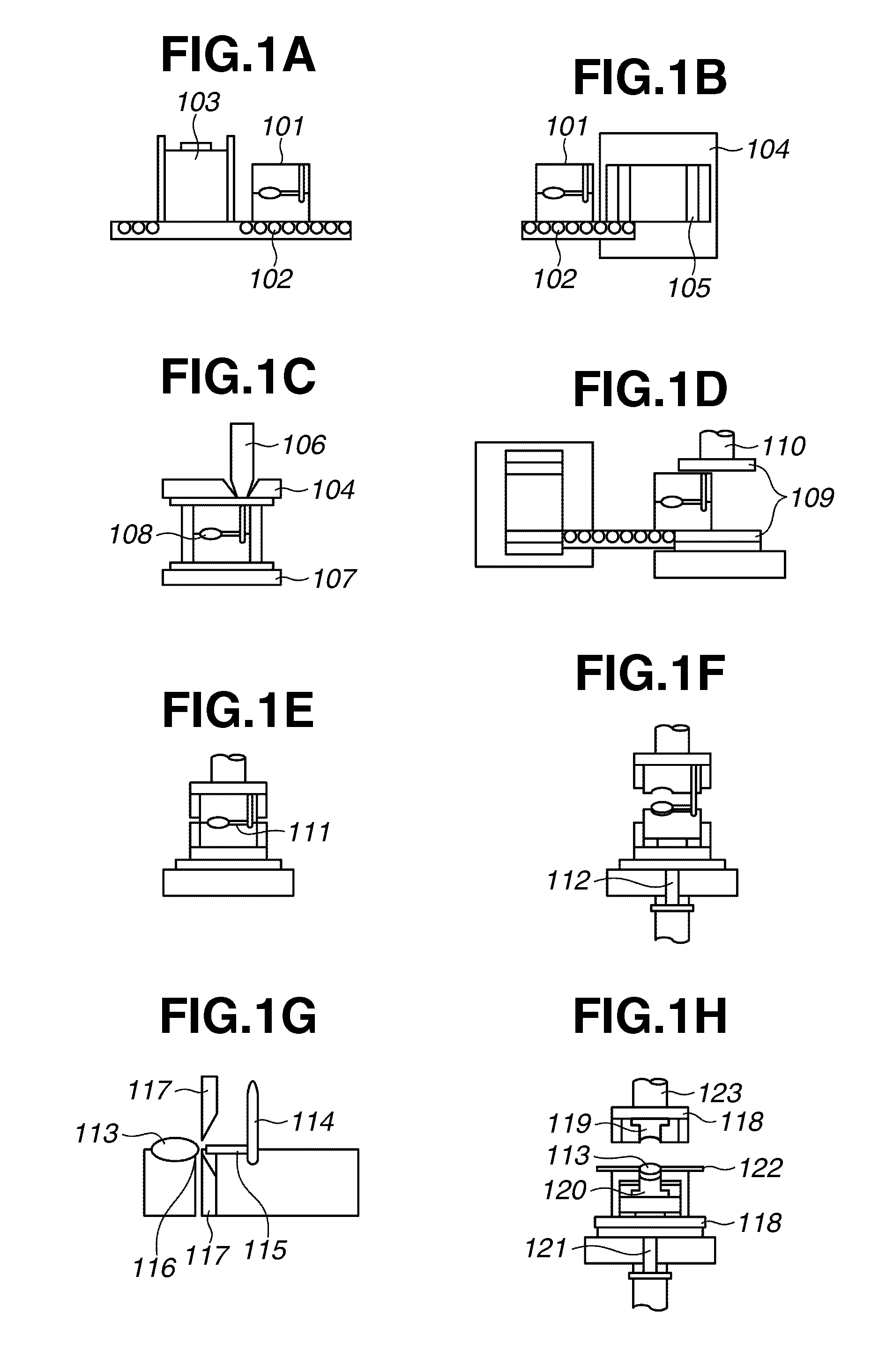

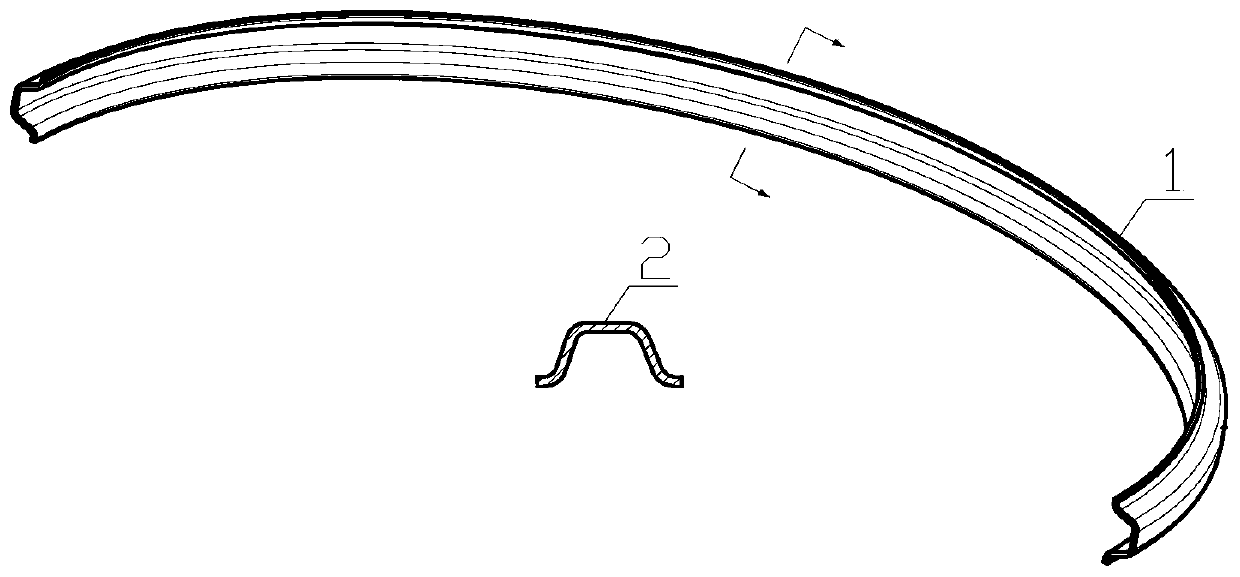

Equal-thickness in-plane continuous plate strip bending method

ActiveCN103302210AImprove mechanical propertiesAvoid wrinkling forming defectsMetal rollingWrinkle skinIn plane

An equal-thickness in-plane continuous plate strip bending method comprises the following steps: putting a plate strip into a roll gap determined between roll surfaces of two rolls; and positioning the lower surface of the plate strip at a point A, wherein the two rolls rotate synchronously face to face; the rotation speeds omega of the rolls are 2-10rad / s; at the beginning of forming, the plate strip has plastic deformation; since the linear velocities of the roll surfaces of the rolls have different distributions, the flow velocities of metal particles in the width direction of the plate strip in a deformed zone are in monotonous and uneven distribution; because of the distribution difference of the metal flow velocities, monotonous and uneven elongation deformation is generated in the length direction of the plate strip in the deformed zone; and due to coordinative development of the uneven elongation deformation, the plate strip develops in a direction forming a ring so as to be formed as an equal-thickness in-plane bent annular component. By the equal-thickness in-plane continuous plate strip bending method, during plastic bending, cracks in the outer zone of the bent component and wrinkles in the inner zone of the bent component caused by tension in the outer zone of the plate strip material and pressure in the inner zone of the plate strip material can be effectively avoided; and in the rolling process, the plate strip material is subject to work hardening, so that the mechanical properties of the plate strip material are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

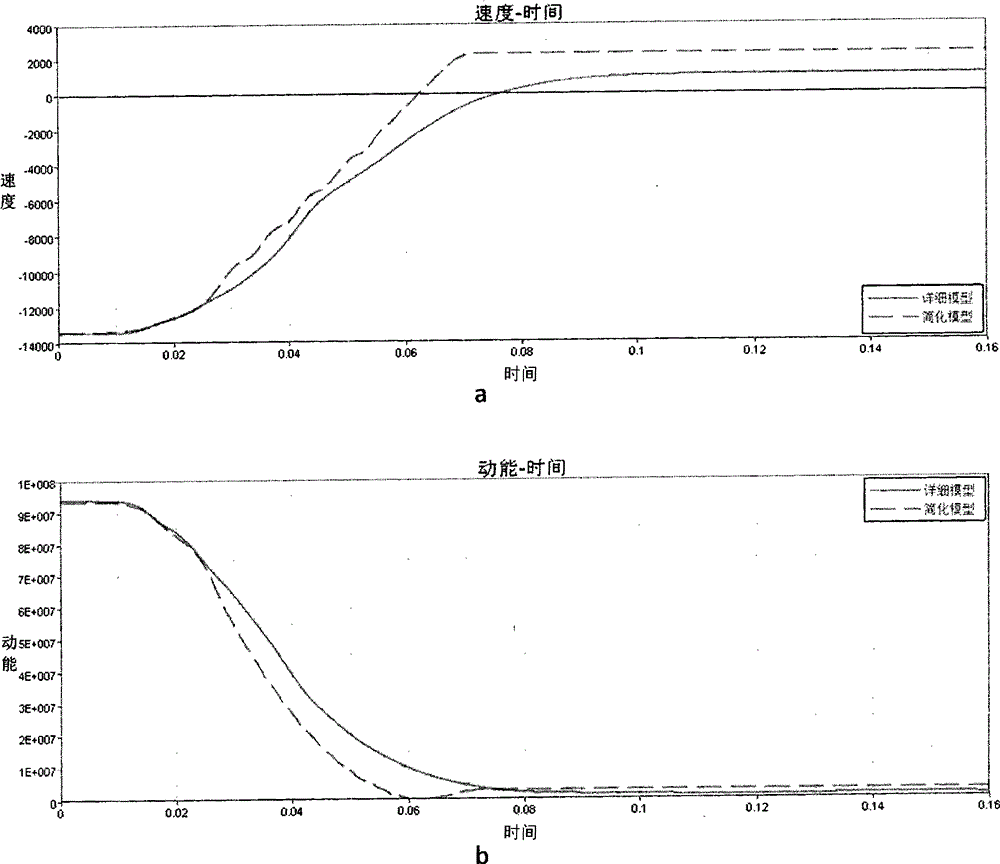

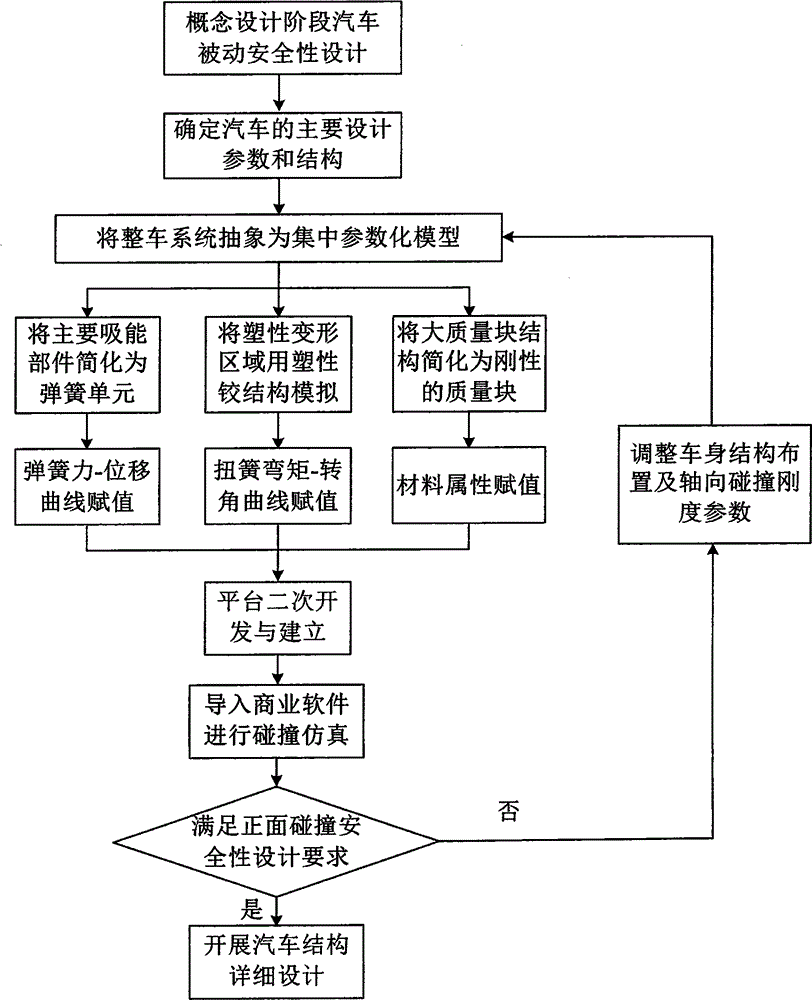

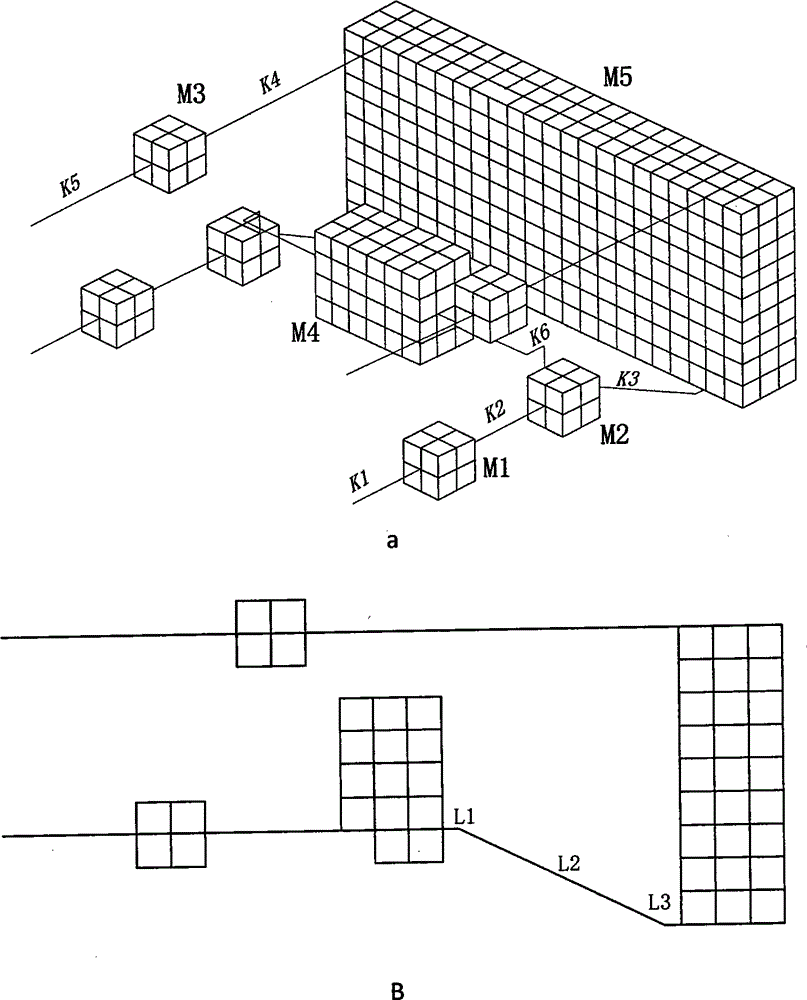

Front impact conceptual model design method for front structure of automobile

InactiveCN104573246AQuick buildRapid assessmentSpecial data processing applicationsEngineeringConceptual model

The invention discloses a front impact conceptual model design method for a front structure of an automobile. The front impact conceptual model design method for the front structure of the automobile includes that simplifying the front impact concept design for the automobile through building a lumped parameter model for the front of the automobile, and evaluating the impact resistance of the automobile at the concept design stage to regulate the axial impact resistance rigidity distribution of the automobile body and reinforce the impact resistance; building a multi-degree of freedom LPM consistent with the finished automobile structure at the concept design stage, and assigning a piecewise linear power-displacement relationship and a nonlinear moment-rotation curve to a corresponding spring unit in the LPM to define the axial impact rigidity and bending characteristics of the LPM. The front impact conceptual model design method for the front structure of the automobile simultaneously generates axial crushing and plastic bending deformation, realizes full automation, is capable of well meeting the demands on the impact resistance analysis for the automobile body in the automobile concept design stage, assists a designer in quickly building the LPM of the automobile, realizes to quickly evaluate and correct a primary design proposal, and enables the design period to be shortened.

Owner:JILIN UNIV

Method for improving bending performance of T5-state 6N01 aluminum alloy through local laser treatment

The invention discloses a method for improving the bending performance of T5-state 6N01 aluminum alloy through local laser treatment. The method comprises the following steps that the plastic bending deformation portion of the material is found, and the laser scanning portion is determined; then, the laser scanning portion is scanned with a high-energy laser, wherein the laser power is 200-500 W, the scanning speed is 10-20 mm / s, and the defocusing amount is 10-20 mm; plastic bending is conducted on the processed material; and finally, precipitation heat treatment is conducted, wherein the temperature is 170-190 DEG C, and the temperature is kept for 2-4 hours. After the T5-state 6N01 aluminum alloy is treated through the method, the overall heat treatment state of the T5-state 6N01 aluminum alloy is not changed, the bending performance of the T5-state 6N01 aluminum alloy is improved, and the overall strength of the material is not lowered. Besides, the method has the remarkable advantages of being high in production efficiency, short in machining time, low in manufacturing cost and the like.

Owner:NANJING UNIV OF SCI & TECH

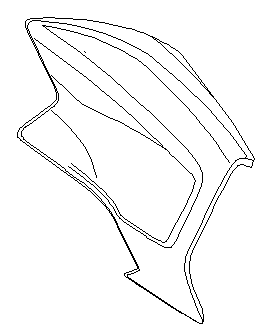

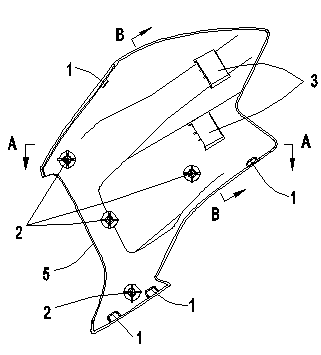

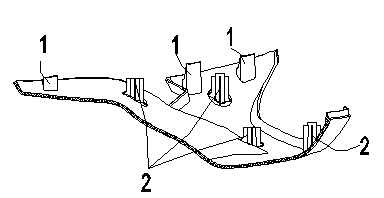

Outer plate for oil tank protection cover of motorcycle

The invention discloses an outer plate for an oil tank protection cover of a motorcycle, which is a plastic bending plate; first U-shaped hooks are arranged at the inner side of the bending plate along the upper edge and the lower edge of the bending plate; the two ends of the first U-shaped hooks are respectively connected with the inner wall of the bending plate; at least two studs and at leasttwo U-shaped hooks are arranged at the inner side of the bending plate; one end of each of the second U-shaped hooks is connected with the inner wall of the bending plate, and the other end of each of the second U-shaped hooks suspends in the air; a limiting bulge is arranged at the inner side of the second U-shaped hanger; the limiting bulge extends to the second U-shaped hook from the inner wall of the bending plate, and a gap L is reserved between the limiting bulge and the horizontal plate of the second U-shaped hook. The structure and the inner plate of the oil tank protection cover formthe oil tank protection cover of the motorcycle; the oil tank protection cover is designed into two parts to bake finish in different colors so as to simplify the process and the cost; the oil tank protection cover adopts a double-layer structure of the inner plate and the outer plate, so that the strength of the protection cover can be ensured; the connection is performed by using the hook and the studs, so that the influence on the appearance due to the fact that bolt are screwed outside the protection cover can be avoided.

Owner:力帆科技(集团)股份有限公司

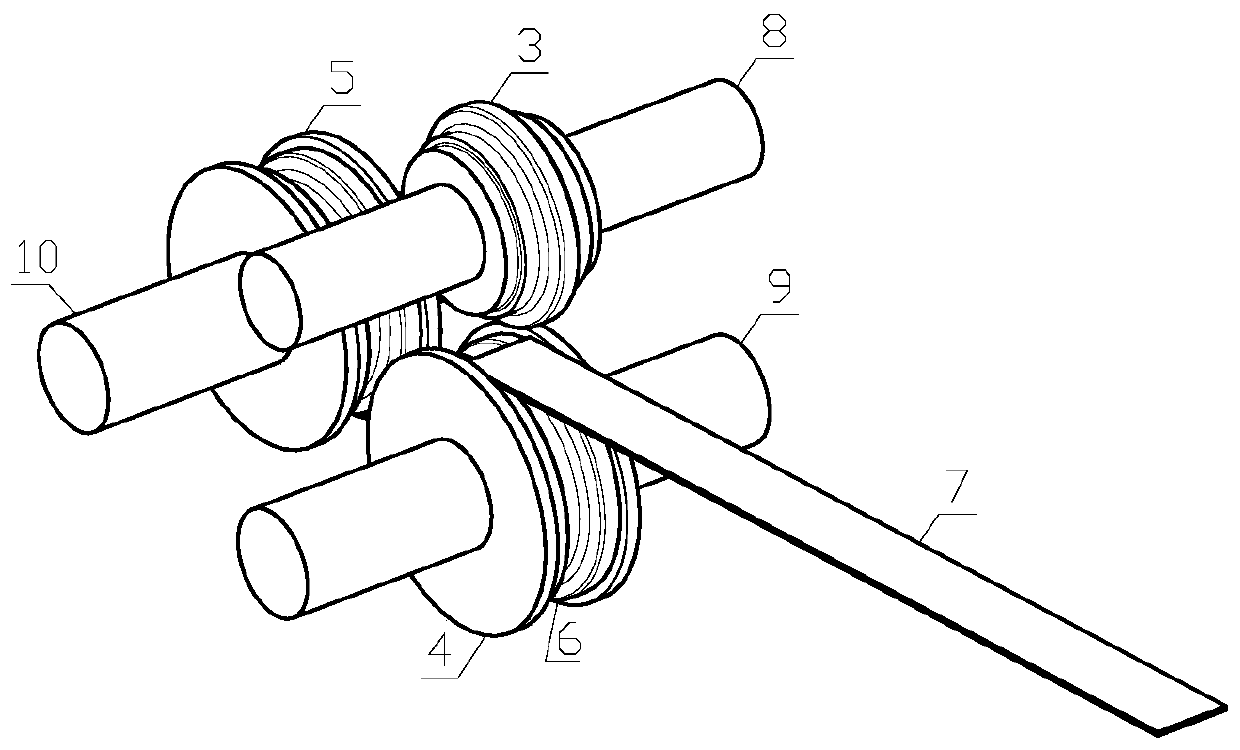

Repairable tooth-shaped and ring-shaped energy-consuming plate composite type metal damper

ActiveCN109763583AStrong energy dissipation and vibration reduction effectEasy to disassembleProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention discloses a repairable tooth-shaped and ring-shaped energy-consuming plate composite type metal damper. The repairable tooth-shaped and ring-shaped energy-consuming plate composite typemetal damper comprises a sliding guide rod and a protective shell, wherein the sliding guide rod is formed by combining a guide rod connecting part and an energy-consuming piece connecting part; the guide rod connecting part is connected with a building structure piece; a supporting block is arranged on the energy-consuming piece connecting part; the protective shell is arranged on the sliding guide rod in a sleeving way; a plurality of plastic bending deformation energy-consuming ring-shaped low-yield-point steel plates are arranged between the sliding guide rod and the protective shell and are connected and fixed through a groove-shaped connecting piece; the protective shell comprises an upper protective shell and a lower protective shell which are arranged in parallel; friction energy-consuming sawtoothed plates which are engaged with each other are arranged between the upper protective shell and the supporting block as well as between the lower protective shell and the supporting block; and a first spring and a second spring are arranged between the protective shell and the sliding guide rod correspondingly. The damper has strong energy-consuming and damping effects, is convenient to disassemble and can realize staged yield energy consumption.

Owner:JIANGSU UNIV OF SCI & TECH

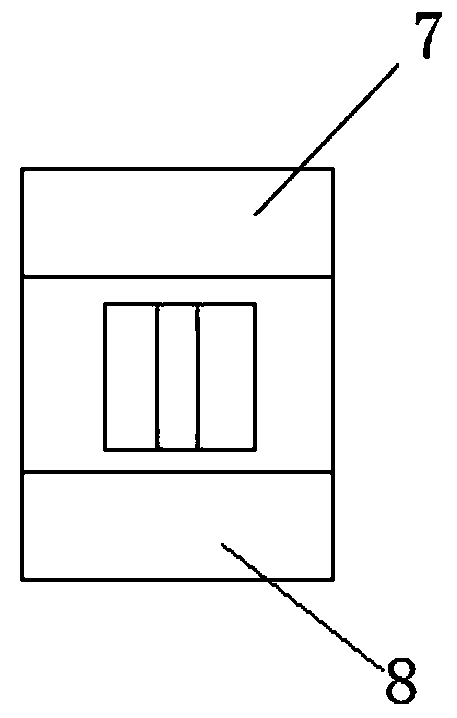

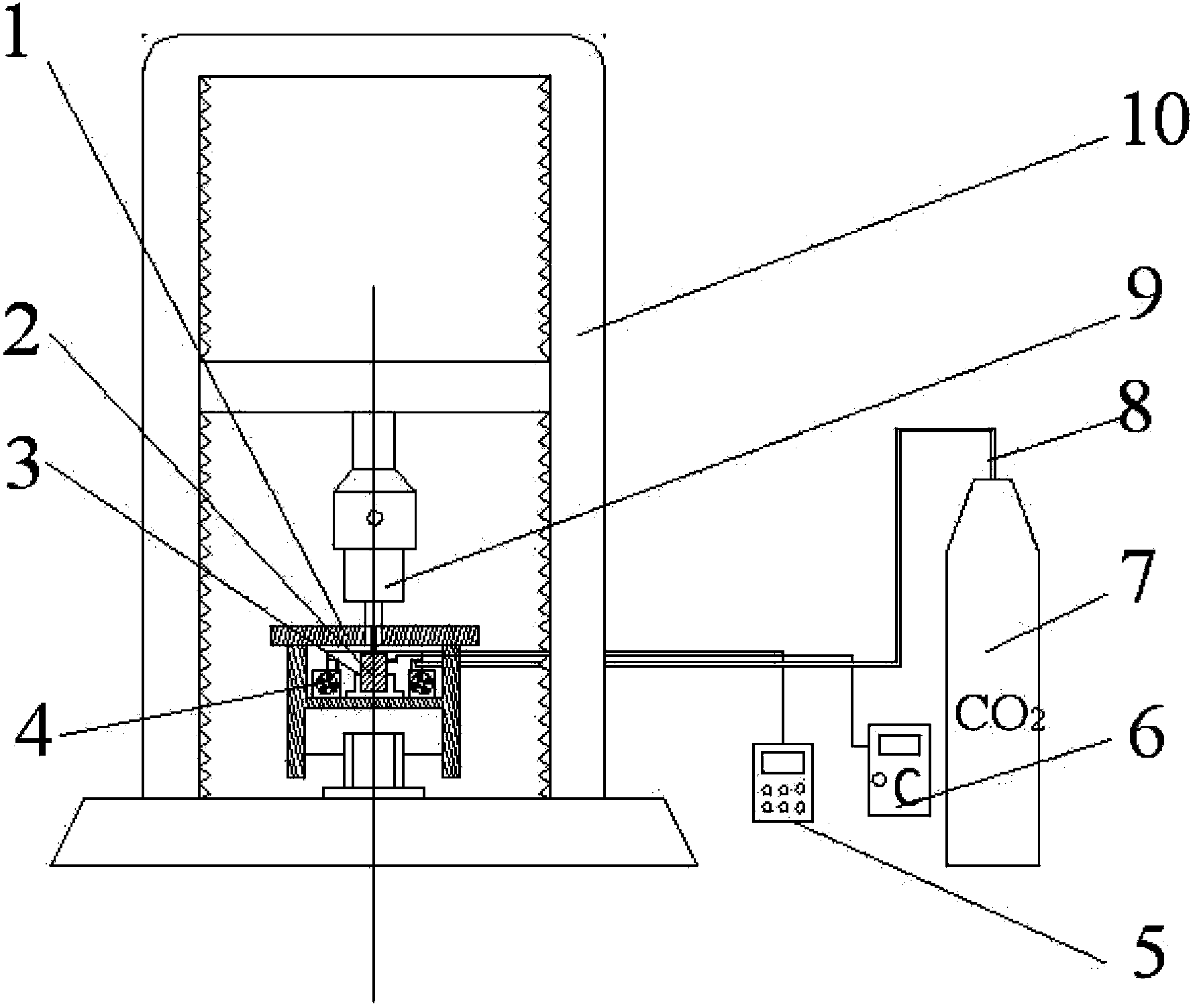

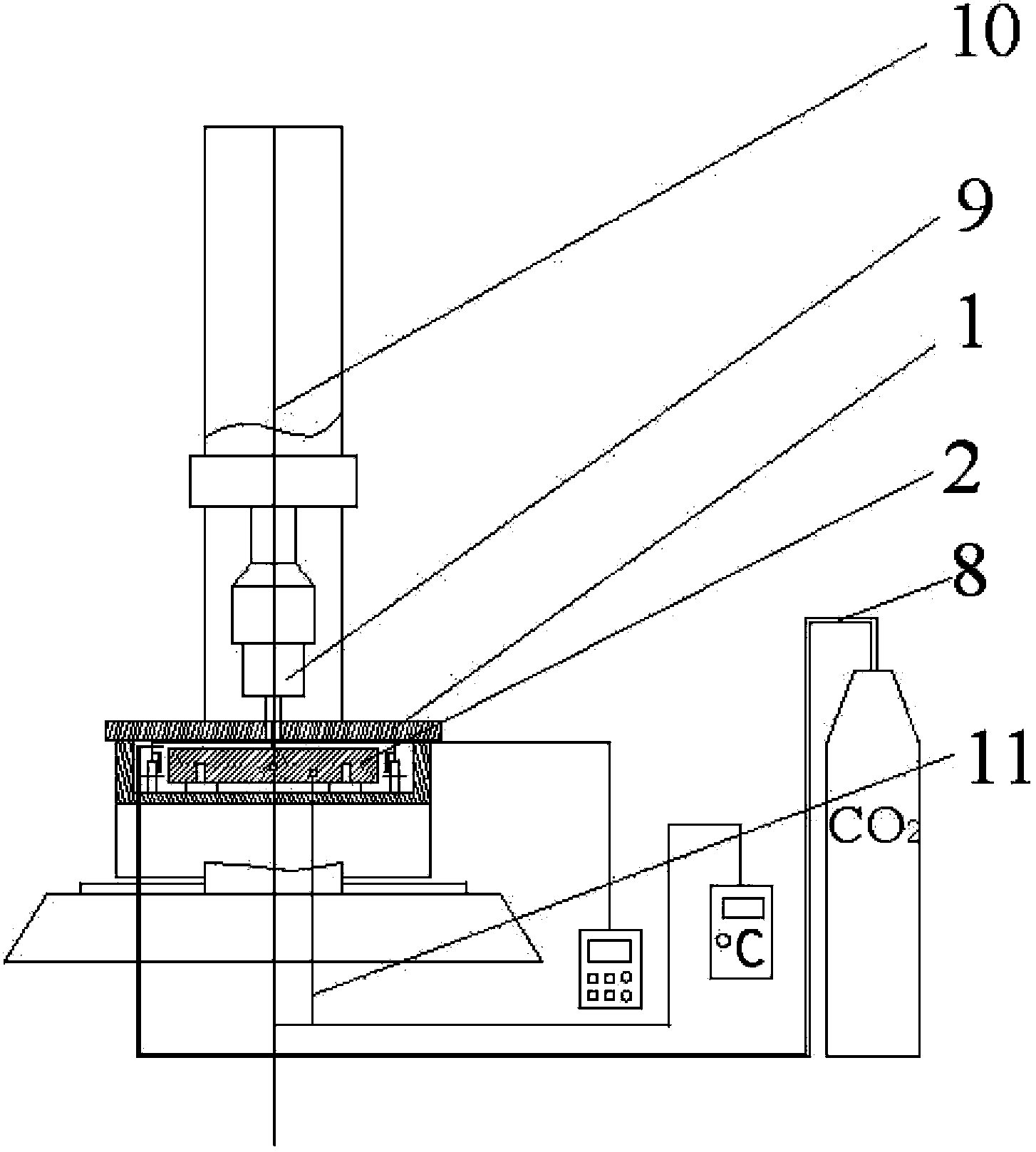

Temperature control device for measurement on modulus of elasticity in static bending of wood

InactiveCN103543767AAccurately control and stabilize sample test temperatureEasy to controlTemperatue controlMaterial strength using tensile/compressive forcesCopper wireThermal insulation

The invention discloses a temperature control device for measurement on modulus of elasticity in static bending of wood, and provides an automatic temperature setting, controlling and stabilizing device and an automatic temperature setting, controlling and stabilizing method for a process of measurement on modulus of elasticity in static bending of wood. The problem that the temperature of wood is changed over fast and is balanced difficultly in the traditional measurement on the modulus of elasticity in static bending of wood is solved. The temperature control device comprises a temperature control box, a temperature control unit, a temperature monitoring unit, a unit for measuring the modulus of the elasticity in static bending of the wood and a liquid carbon dioxide delivery unit, wherein the temperature control box is a closed temperature circulating device, and has a thermal insulation effect and a cold insulation effect; an small electric fan, an electric heating bar, a wood sample, a metal roller for supporting the wood sample and a copper wire tube for delivering carbon dioxide are distributed in the temperature control box; the wood sample is cooled down by delivery of the carbon dioxide and running of the fan; thermocouples distributed at two different positions of the wood sample are connected with the temperature monitoring unit, so that the change of the temperature of the wood can be monitored; and the small electric fan and the electric heating bar are connected with the temperature control unit, so that the environment temperature in the temperature control box can be adjusted.

Owner:NORTHEAST FORESTRY UNIVERSITY

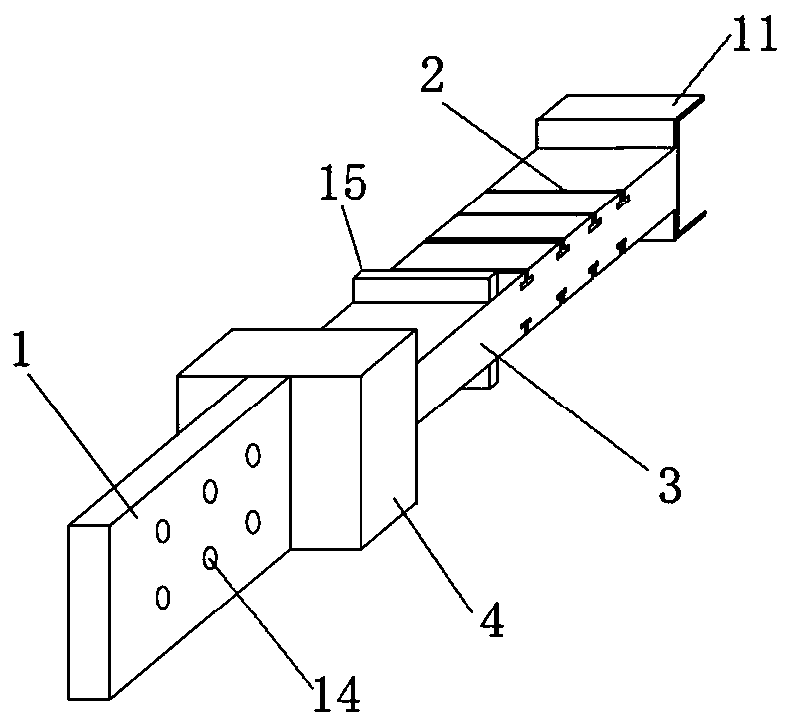

Plastic bending machine

The invention discloses a plastic bending machine, which comprises a frame. A bending baffle is installed on the front of the frame through hinges. Both sides of the bending baffle are fixedly equipped with electric telescopic rods. The rear is fixedly connected with the bottom of the support rod, and a push rod motor is fixedly installed above the front of the support rod. The plastic bending machine, through the setting of the pressing block, the pressing plate, the second heating lamp tube and the second isolation mesh, has the effect that the pressing block can not only press the plastic plate, but also heat the plastic plate, and then through the servo The setting of the motor, and the use of telescopic sleeves, movable telescopic rods, fixed blocks, fixed rods, movable plates, fixed plates, insertion rods, compression springs, pull plates, bearings, rotating rods and fixed plates, so that the plastic plate When bending, the bottom and top of the plastic board can be preheated at the same time to bend the plastic board immediately, and then the plastic board is not easy to break when it is bent.

Owner:黄石万鑫塑胶有限公司

Plastic plate continuous bending device

The invention relates to the technical field of plastic bending machines, in particular to a plastic plate continuous bending device. An existing bending device cannot perform continuous bending and is long in production cycle. The plastic plate continuous bending device comprises a bending device, a feeding platform and a shaping platform. The bending device is located between the feeding platform and the shaping platform. The bending device comprises a chain batten, a conveying pressing wheel, a heating device and a bending and guiding plate. The chain batten drives a tensioning wheel to rotate through a belt by means of a transmission motor so as to provide power. The bending and guiding plate is a rectangular thin plate. One end of the bending and guiding plate is attached to the surface of an operation platform, and the other end of the bending and guiding plate is perpendicular to the operation platform to form an arc-shaped plate with gradient. A limiting device is arranged on the feeding platform and the shaping platform. Continuous bending is realized, bending and shaping can be performed at the same time but different stages, the production cycle is shortened, and the plastic plate continuous bending device has broad development prospects in the technical field of plastic bending machines.

Owner:新乡市仲达塑胶电子有限公司

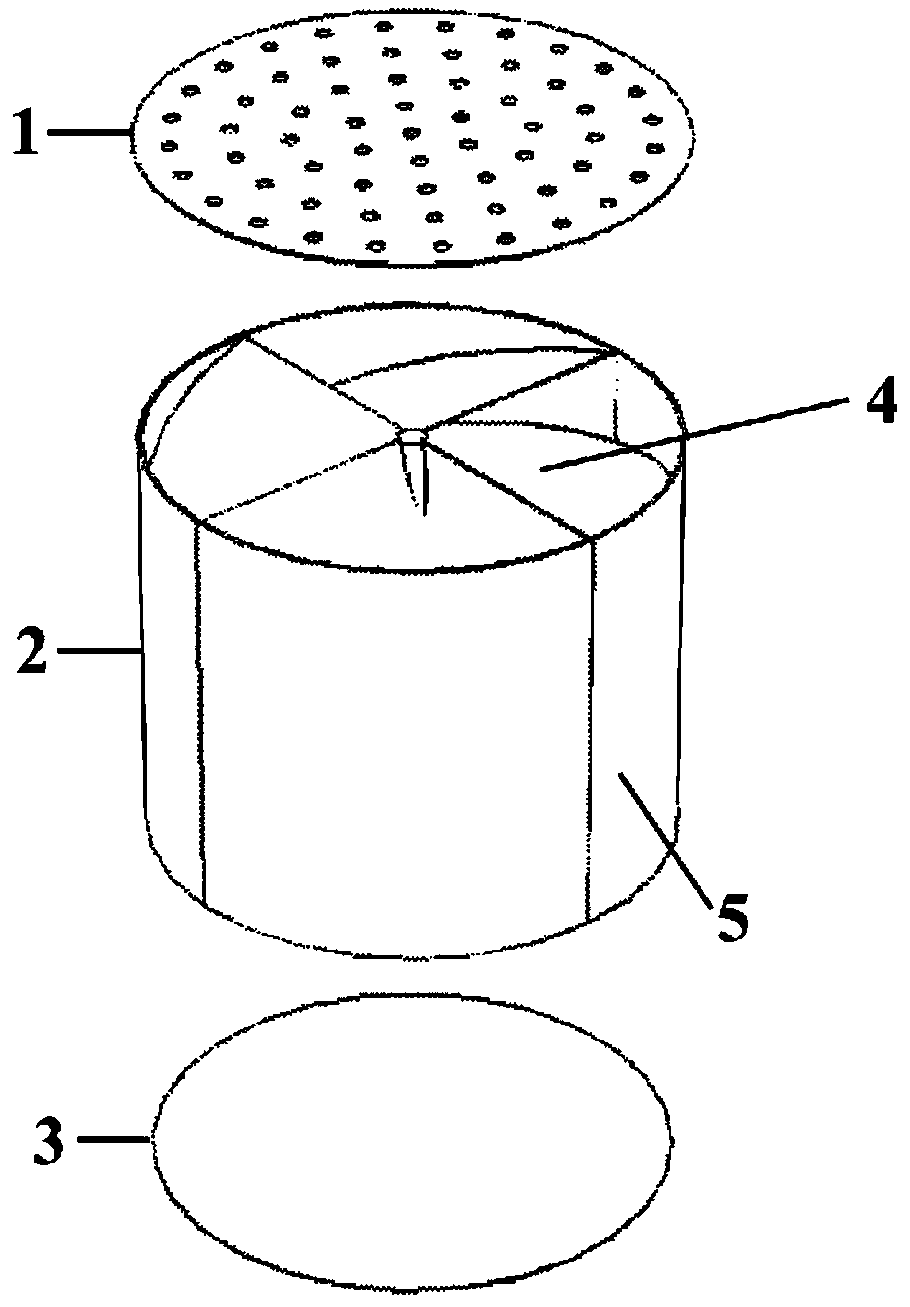

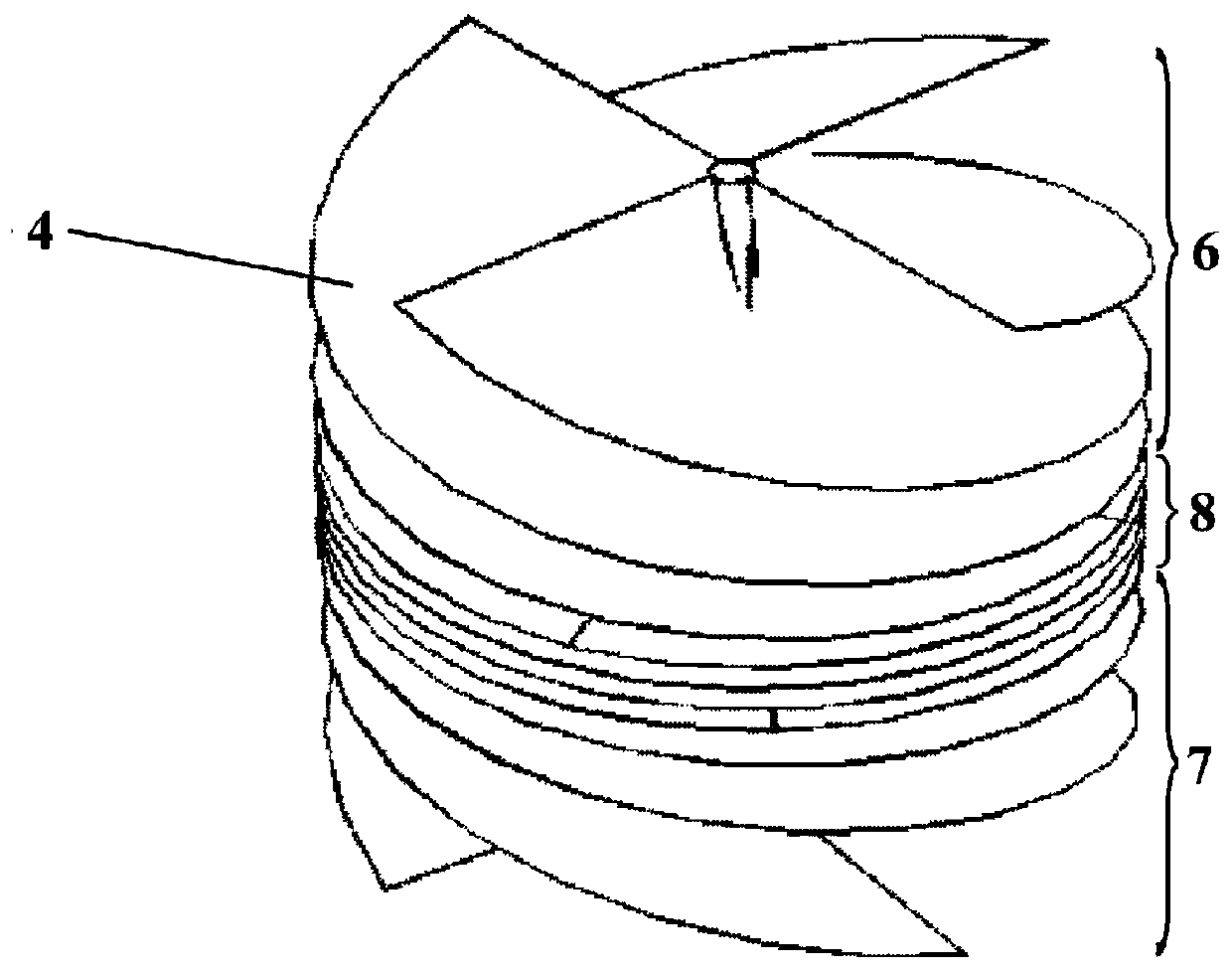

Spatial bending and sound absorption superstructure with impedance matching layers

ActiveCN110473511AImprove Impedance MismatchSimple control functionSound producing devicesAcoustic absorptionImpedance matching

The invention discloses a spatial bending and sound absorption superstructure with impedance matching layers. The space bending and sound absorption superstructure comprises a perforated panel, a spatial bending back cavity with parameter gradient change, and a rigid backing, wherein the perforated panel and the rigid backing are located at the two ends of the spatial bending back cavity with theparameter gradient change; a plurality of sound absorption holes are formed in the perforated panel; the opening directions of the sound absorption holes are all perpendicular to the perforated panel;the hole diameters of the sound absorption holes are submillimeter-sized; the spatial bending back cavity with the parameter gradient change is composed of an internal spiral structure and an outer cylinder; and the internal spiral structure is composed of the upper impedance matching layer, the lower impedance matching layer and a narrow and long spiral structure. The bending back cavity is composed of the narrow and long bending structure in the middle and the impedance matching layers at the two ends, and the shapes of the narrow and long bending structure and the impedance matching layersare controlled by a simple parameter equation set and are easy to adjust; the sound absorption superstructure is simple and practical; the sound absorption wave peak in the impedance matching frequency band is remarkably widened, so that the impedance mismatching problem of the spatial bending structure is greatly improved; and the superstructure has good and wide application prospects.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

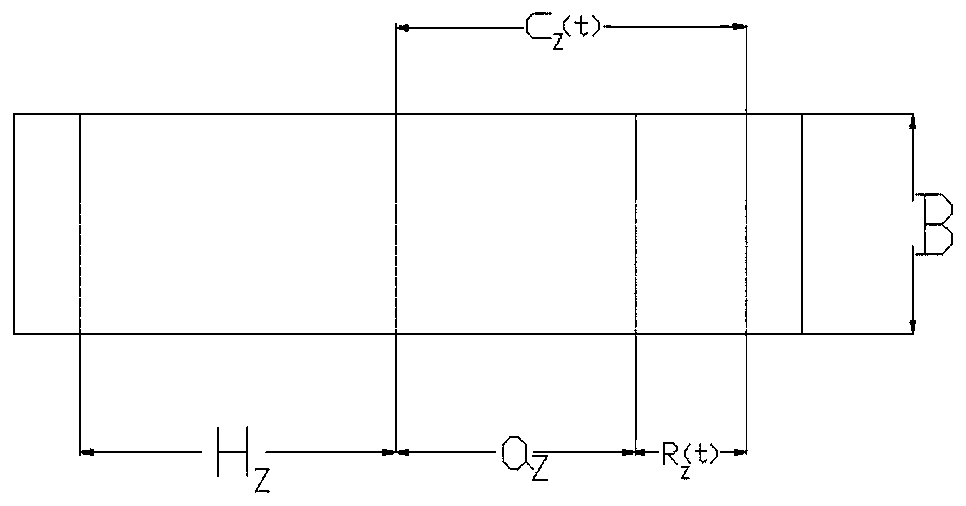

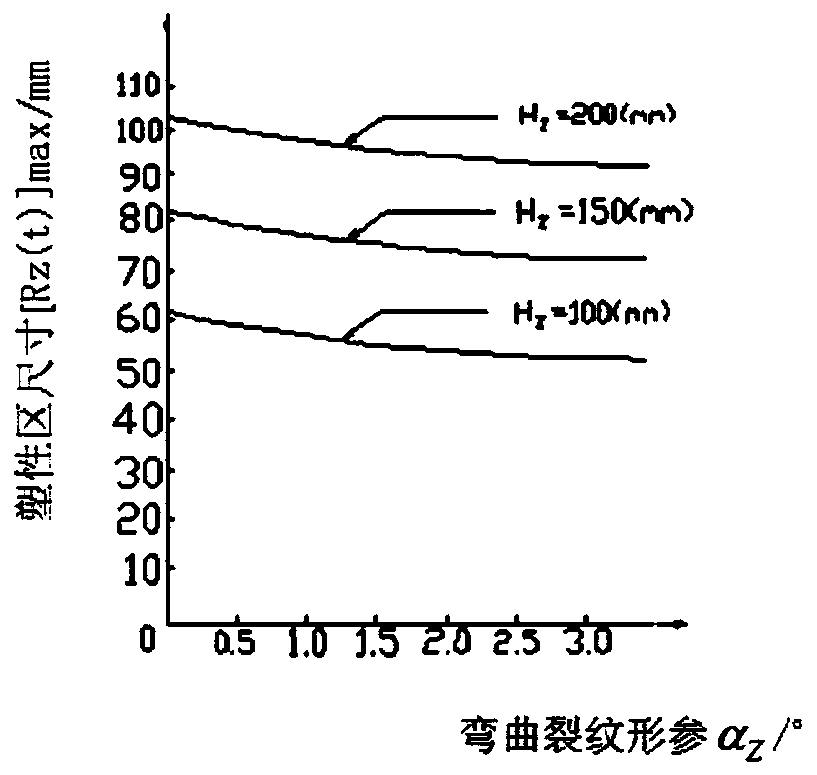

JZ integral of three-dimensional elastic-plastic bending crack tip under function of quasi-static loads

InactiveCN108801788AAccurate serviceMaterial strength using tensile/compressive forcesDesign optimisation/simulationCrazingEngineering

The invention discloses a JZ integral of a three-dimensional elastic-plastic bending crack tip under function of quasi-static loads. A relation of the JZ integral of the three-dimensional elastic-plastic bending crack tip is shown in the description; under the function of same external load, the JZ integral of the three-dimensional bending crack tip corresponding to the same length of the straightline part of the three-dimensional crack and the same shape parameters of the three-dimensional bending crack is reduced along with the continuous increase of the thickness of a three-dimensional crack body; when the thickness of the three-dimensional crack body is the same, the JZ integral of the three-dimensional bending crack tip is increased along with the continuous increase of the externalload; the larger the thickness of the three-dimensional crack body is, the slower the increasing speed of the JZ integral of the three-dimensional bending crack tip along with the continuous increaseof the external load is under the conditions of the same length of the straight line part of the crack and the same bending degree. The JZ integral has the advantage that the size of the JZ integral of the three-dimensional bending crack tip under the function of quasi-static loads is calculated by a second-order perturbation method, so as to more precisely apply to the engineering practices.

Owner:ZHENGZHOU TECHN COLLEGE

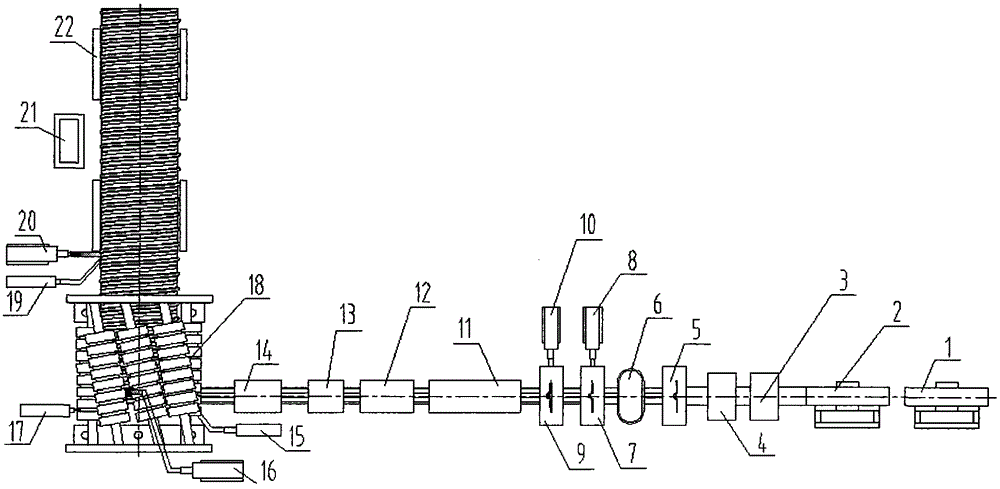

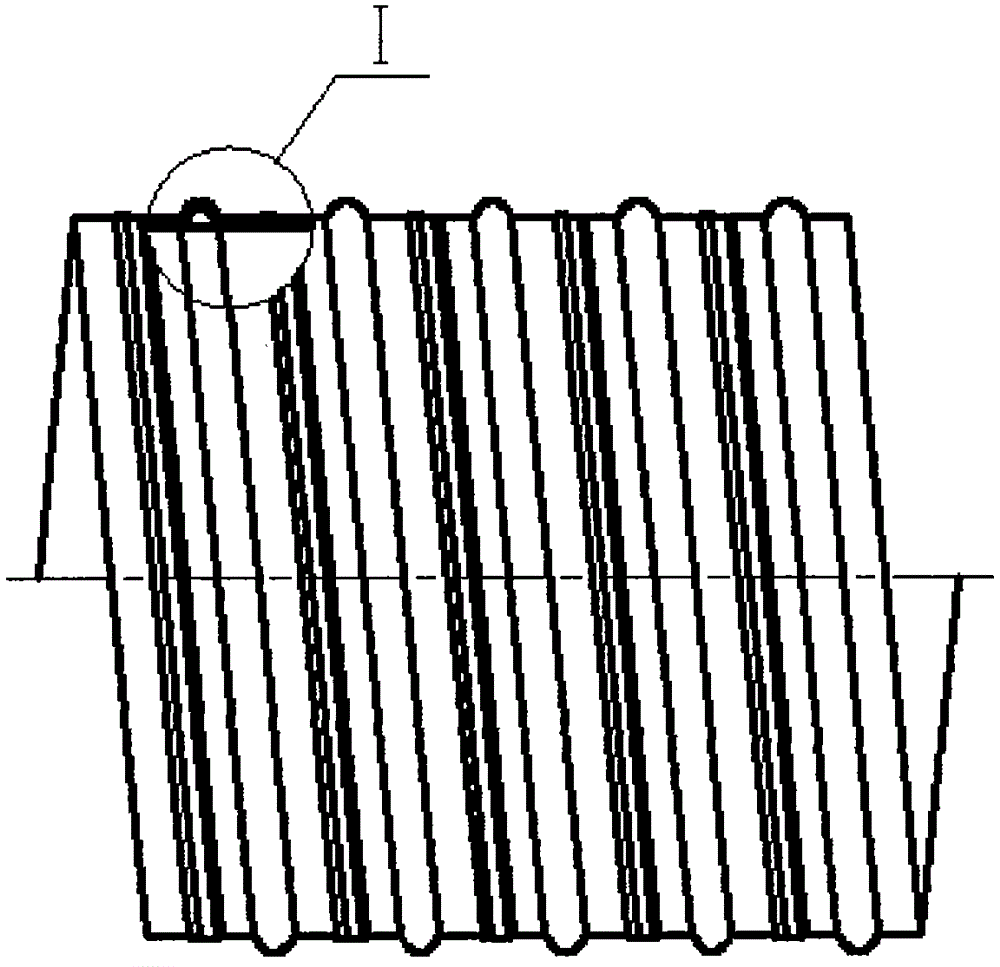

Device and process for producing steel-plastic winding and welding corrugated pipes

The invention discloses a device and a process for producing steel-plastic winding and welding corrugated pipes. The device comprises a steel strip winding and unwinding device, a steel strip butting device, a steel strip derusting device, a strip forming device, a steel strip drying and heating device, a gluing die, a glue layer extruder, an inner-outer layer coating die, an inner-outer coating extruder, a coated strip forming device, a coated strip dragging device, a coated strip cutting device, a coated strip conveying device, an inner layer heating device, an inner layer welding strip extruder, a welding device, a bending and forming device, an outer layer heating device, an outer layer welding strip extruder, a pipe cutting device and a pipe support bracket. The device and the process for producing the steel-plastic winding and welding corrugated pipes have the effects that the steel-plastic winding and welding corrugated pipes are continuously produced; since the steel-plastic winding and welding corrugated pipes are continuously welded, the steel-plastic winding and welding corrugated pipes have the characteristics of common steel strip corrugated pipes and common plastic-steel winding riffled pipes and also have the independent advantages of being capable of bearing strong axial tension.

Owner:于德胜

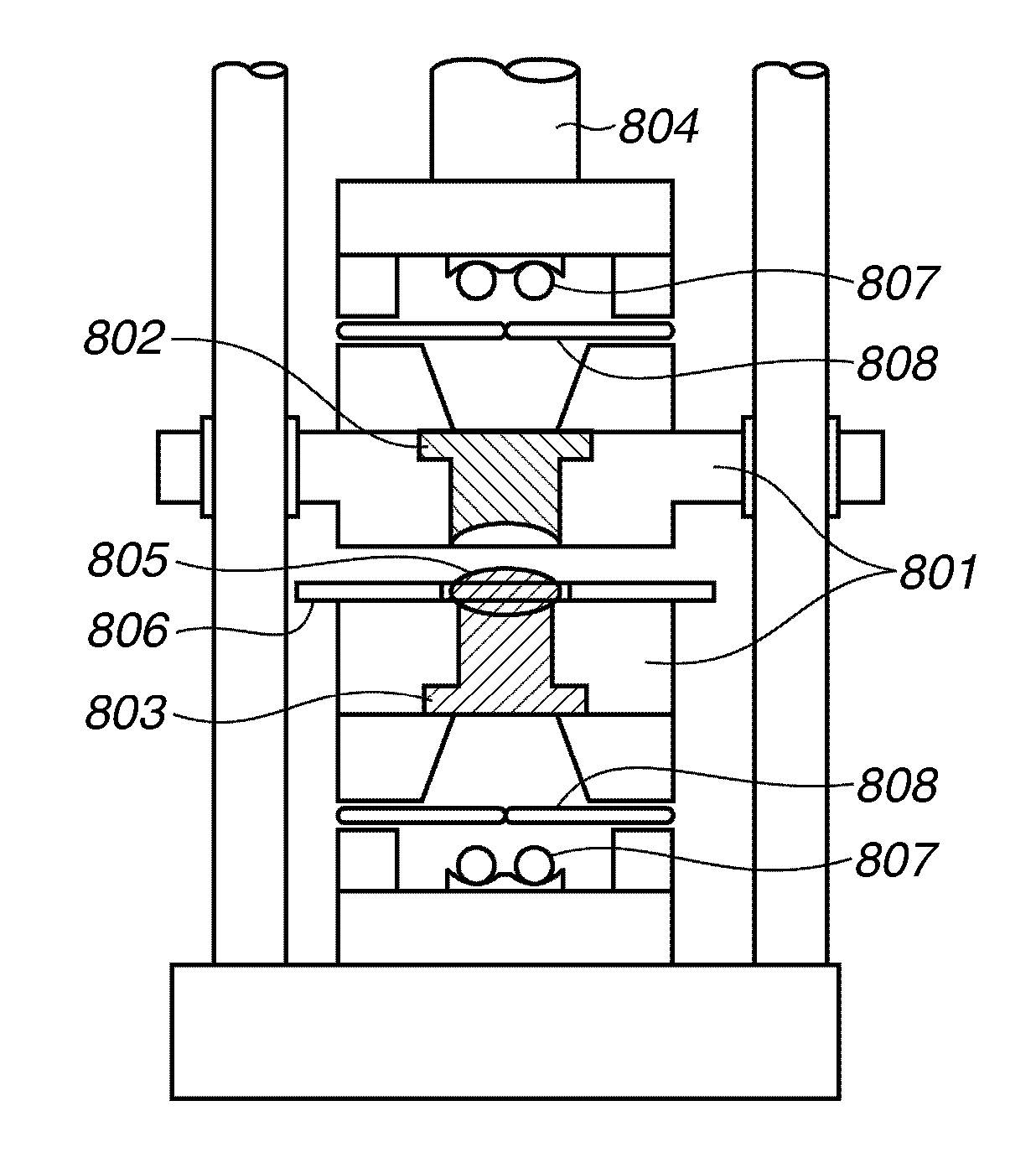

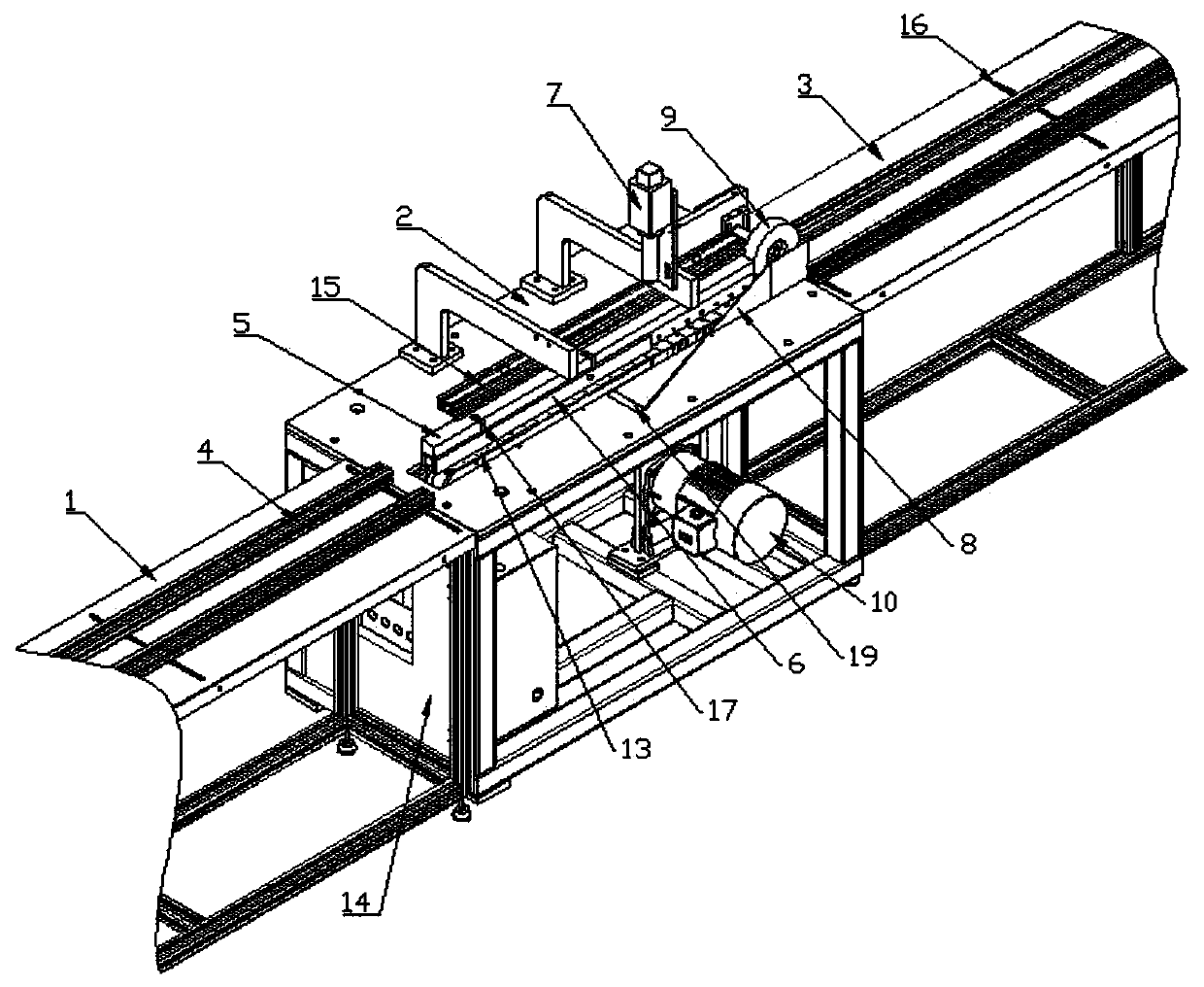

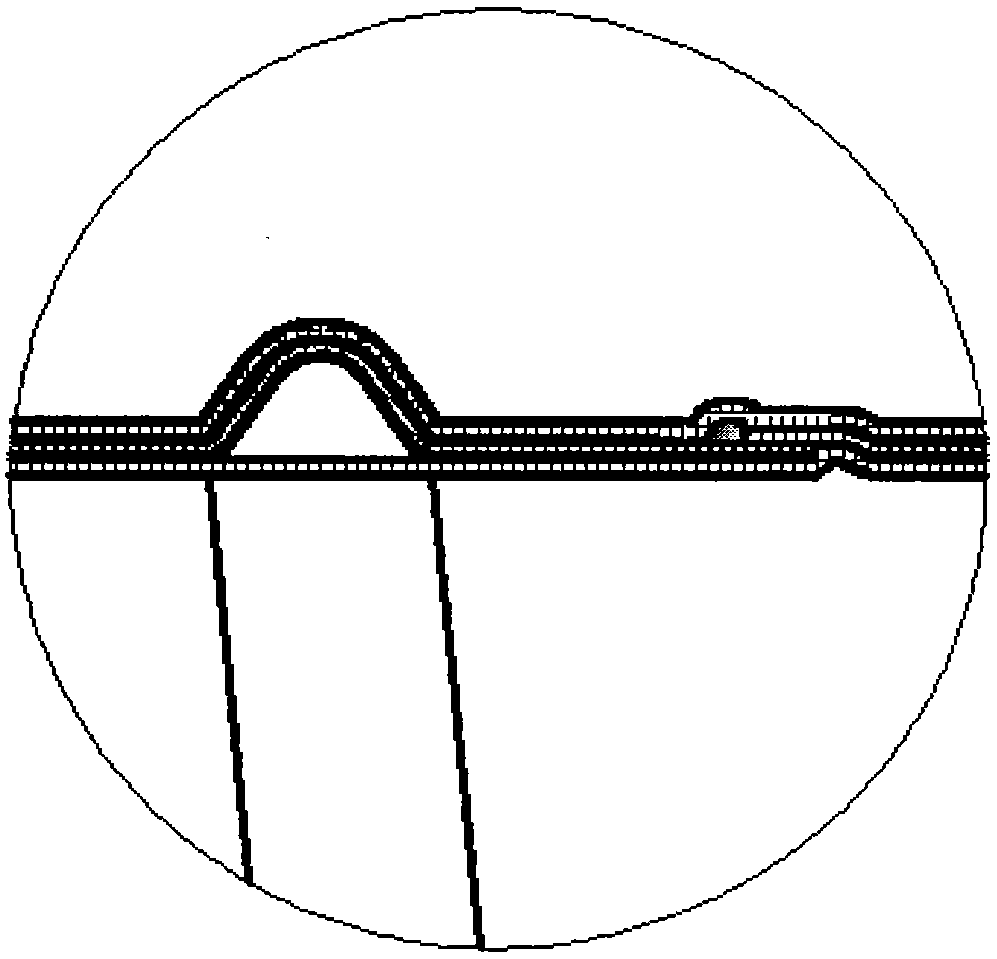

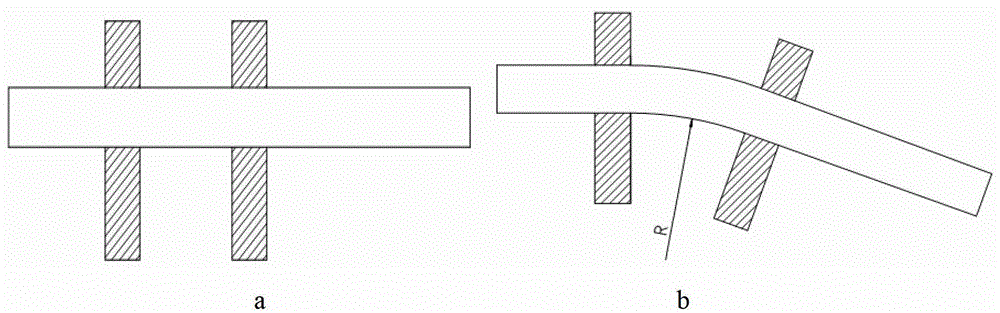

Forming device and method through uneven stretching and in-plane bending of aluminum alloy plate

InactiveCN103357797BAvoid the problem that the formability is not fully exertedFlow helpsMetal rollingIn planeAlloy

The invention discloses a forming device and method through uneven stretching and in-plane bending of an aluminum alloy plate. The forming method comprises the following steps: fixing the aluminum alloy plate through a clamping part; realizing the partial uneven stretching of the aluminum alloy plate in the length direction through the rotation of a mechanical device; accumulating and coordinating partial deformation to enable the aluminum alloy plate to deform in an in-plane bending manner so as to form a circular ring. The device and the method have the advantages that the rotation radius of the upper edge of the aluminum alloy plate is larger than that of the lower edge of the aluminum alloy plate through the rotation of the mechanical device; during the process of rotation, the increment of the arc length of the upper edge is larger than that of the arc length of the lower edge of the aluminum alloy plate, so that the upper edge and the lower edge of the aluminum alloy plate are lengthened unevenly; according to the principle of incremental forming, the partial deformation is accumulated and coordinated so as to enable the aluminum alloy plate to deform in an in-plane plastic bending manner; then the aluminum alloy plate develops in the direction of forming the circular ring; meanwhile, due to an intermittent loading procedure, parts with different radians and complex shapes can also be formed.

Owner:通达科技(东莞)有限公司

Groove connected repairable low-yield point steel damper

ActiveCN109763582AImprove shock absorptionThe effect of energy dissipation and shock absorption is achievedProtective buildings/sheltersShock proofingEngineeringShock absorber

The invention discloses a groove connected repairable low-yield point steel damper which comprises a guide rod connecting part, an energy dissipation component connecting part, a sliding guide rod anda protection shell, wherein the guide rod connecting part is connected with a building structure part; a T-shaped groove is formed in the energy dissipation component connecting part; the sliding guide rod is composed of connecting blocks for connecting the guide rod connecting part with the energy dissipation component connecting part; the protection shell is arranged on the sliding guide rod ina sleeving manner and has a T-shaped groove; a U-shaped energy dissipation low-yield point steel plate is arranged between the protection shell and the guide rod connecting part; an energy dissipation low-yield point steel piece with wing edges is arranged between the T-shaped groove of the energy dissipation component connecting part of the sliding guide rod and the T-shaped groove of the protection shell. The damper disclosed by the invention is not only good in energy dissipation and damping effect, but also convenient to disassemble, due to adoption of energy dissipation parts of two different structures, namely the U-shaped energy dissipation low-yield point steel plate and the energy dissipation low-yield point steel piece with the wing edges, the sliding guide rod is moved leftwards and rightwards under the action of earthquake or wind loads to result plastic bending deformation, and thus effects of energy dissipation and seismic mitigation can be achieved.

Owner:JIANGSU UNIV OF SCI & TECH

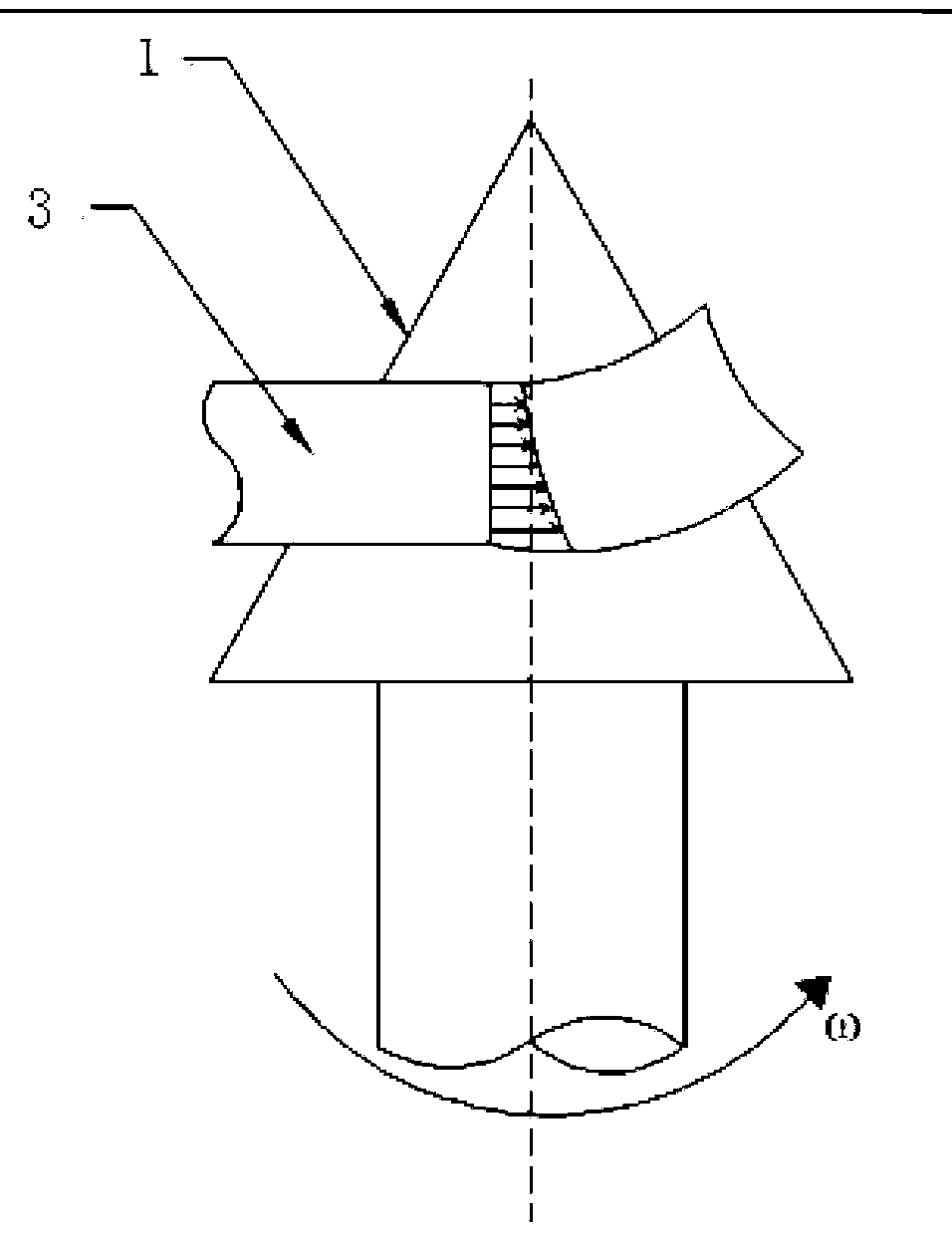

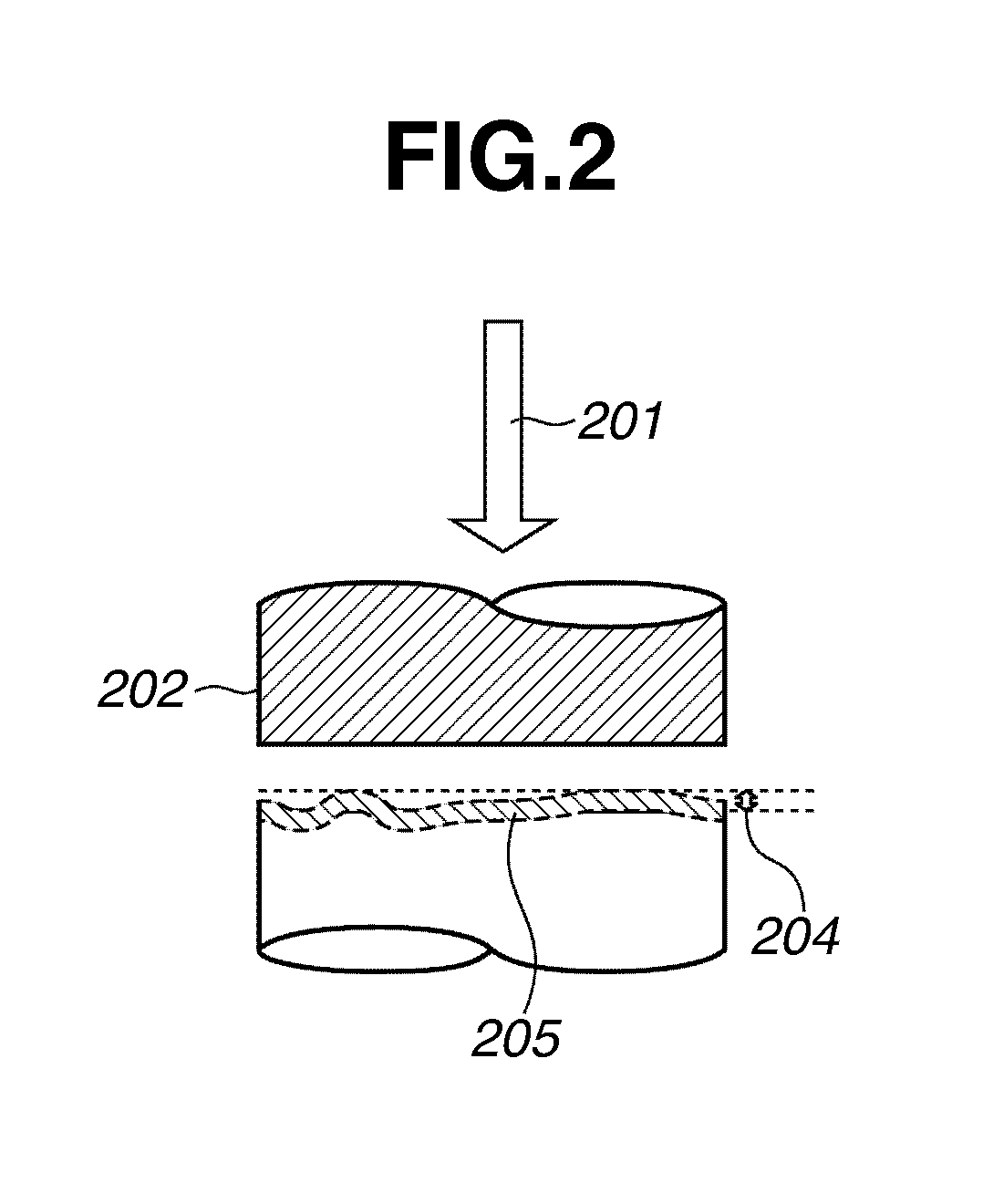

Roll bending forming die and forming method of large-curvature semi-arc-shaped pipe orifice reinforcing part

InactiveCN110639988ASimple structureSimple and convenient installation methodEngineeringStructural engineering

The invention discloses a roll bending forming die and a forming method of a large-curvature semi-arc-shaped pipe orifice reinforcing part. The forming die comprises a forming cam, a forming concave wheel and a driven concave wheel; the forming cam, the forming concave wheel and the driven concave wheel are respectively mounted on three different rollers of an asymmetric three-axis roller bendingmachine; during forming, blank positioning is carried out firstly, then the relative position relation between the forming cam, the forming concave wheel and the driven concave wheel is set, then thethree-axis roll bending device is used for forming, and finally, the pipe orifice reinforcing part passes between the three synchronous rotating rollers and continuously generates axial and longitudinal plastic bending deformation, so that the required cross-sectional shape and the radian shape are obtained.

Owner:XIAN AIRCRAFT IND GROUP

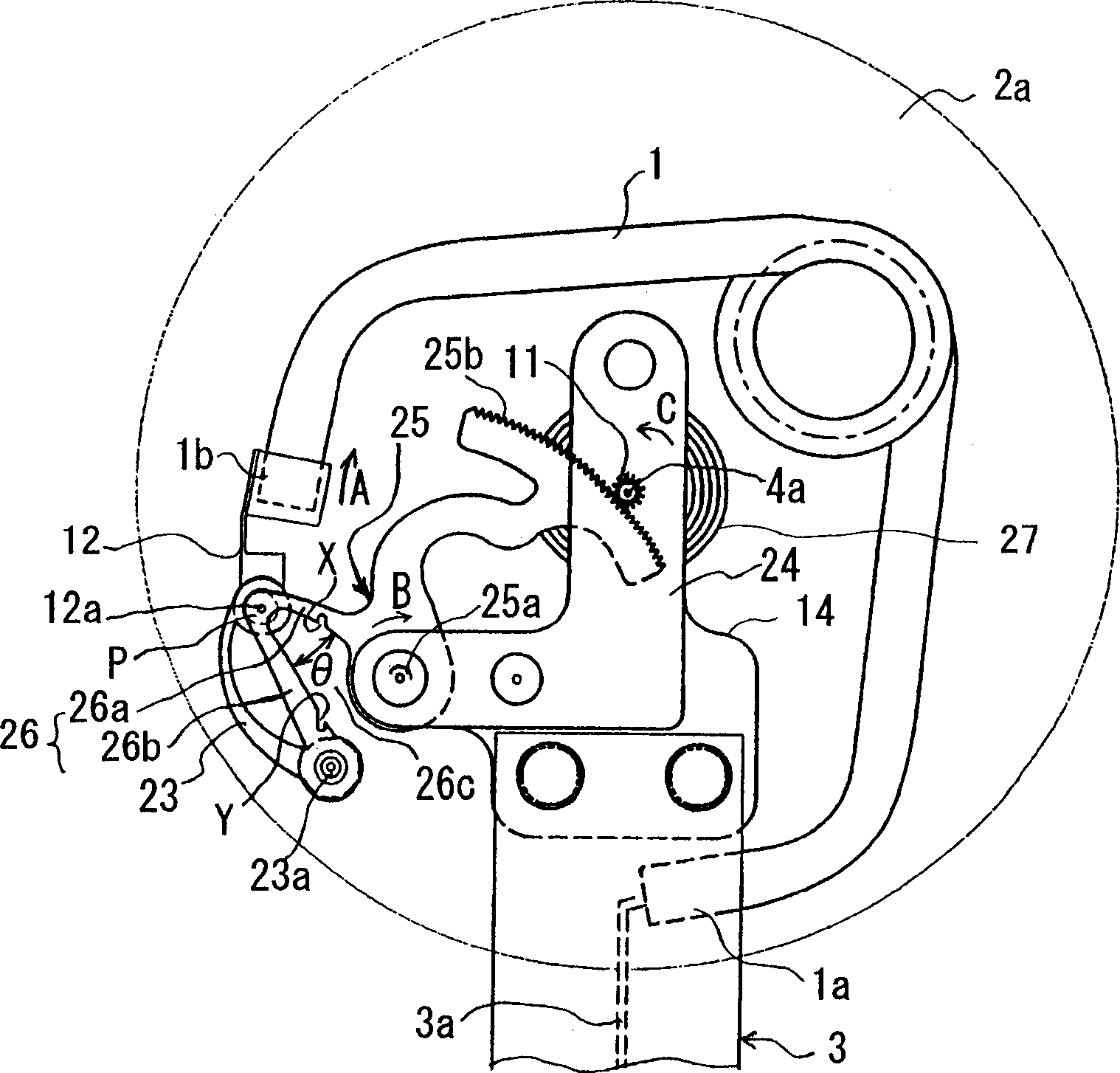

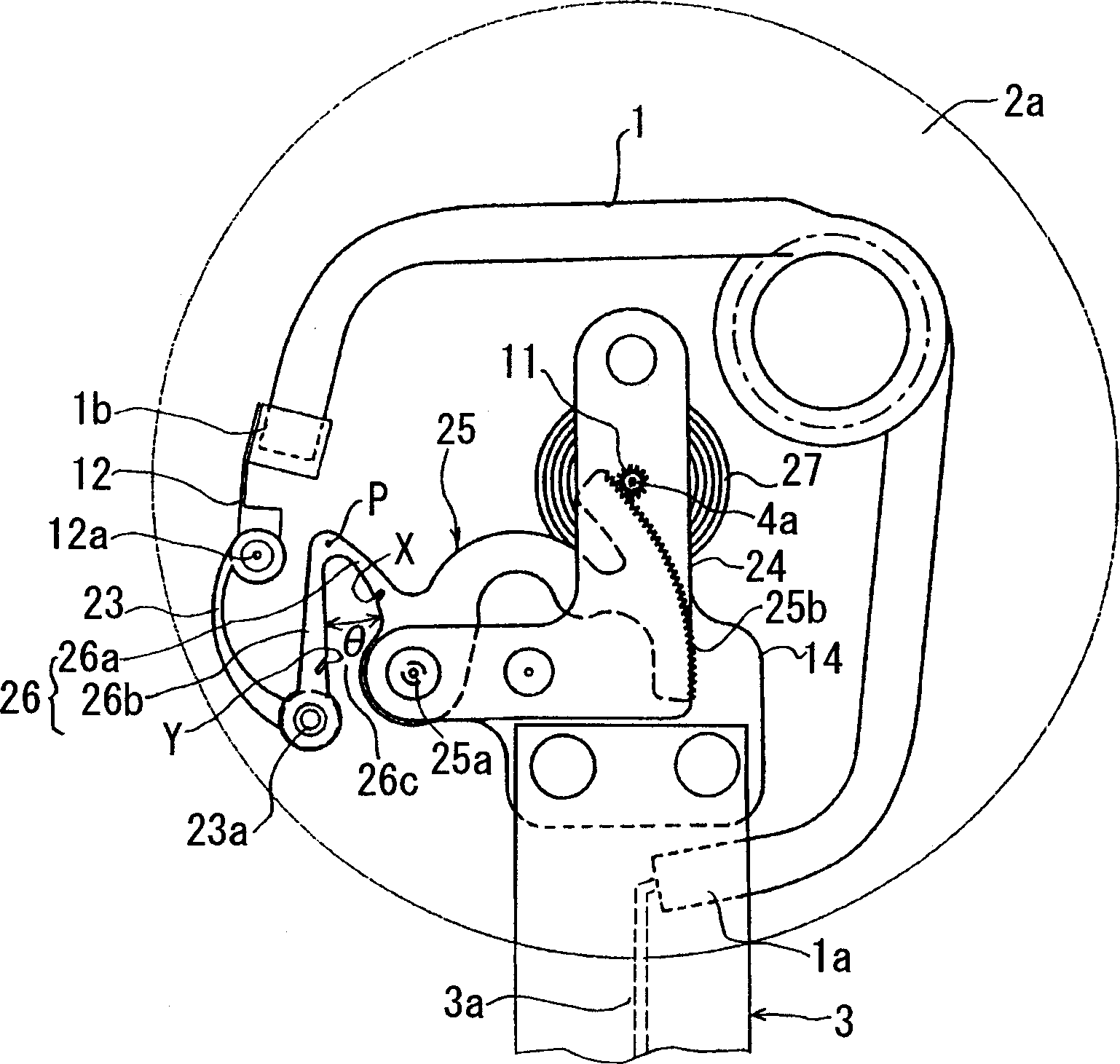

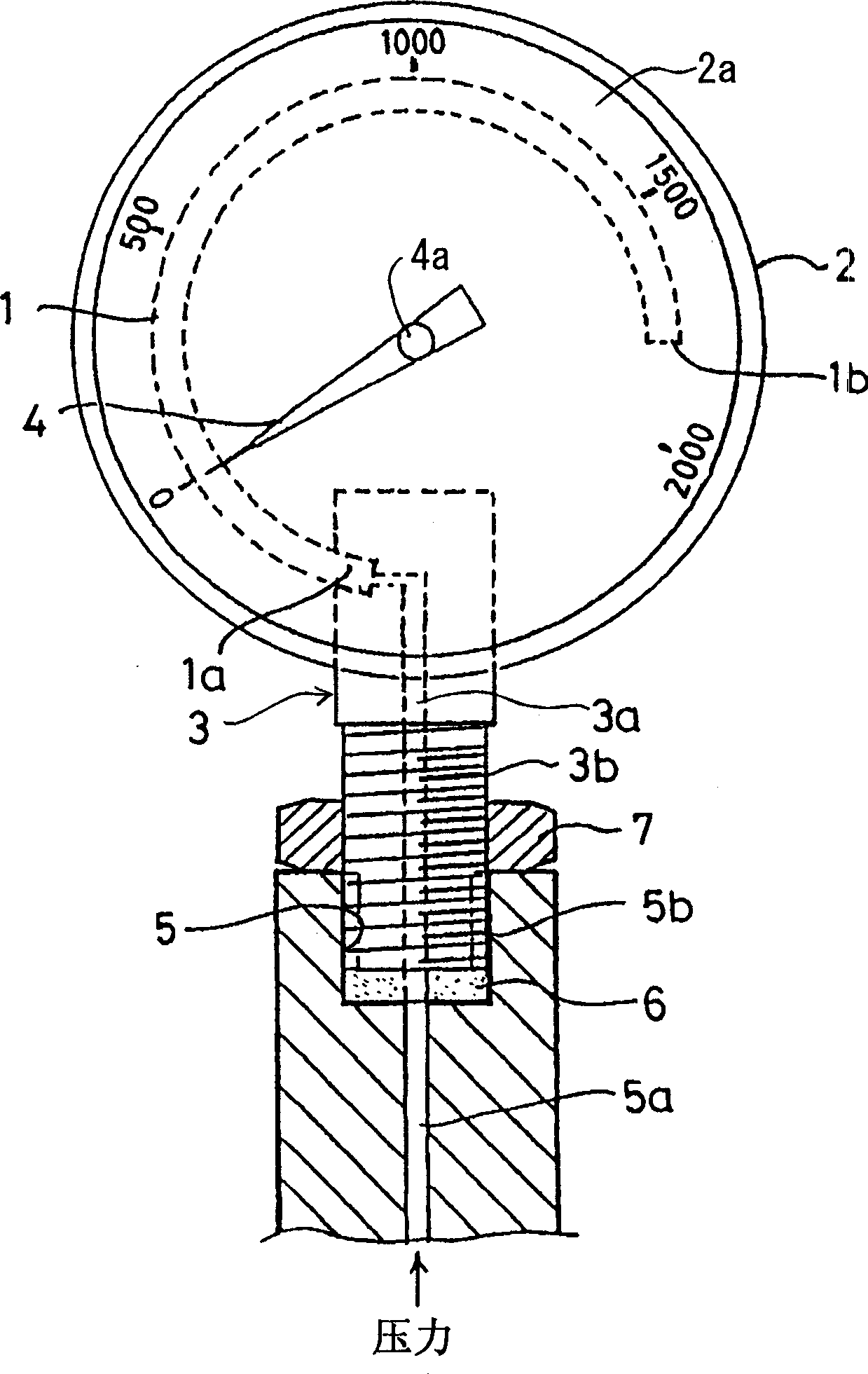

Bourdon tubular gauge

InactiveCN1409095ANot easy to come acrossEasy adjustment of plastic deformationFluid pressure measurement using elastically-deformable gaugesKinematic pairMaximum pressure

To provide a Bourdon tube pressure gage capable of preventing a pointer from becoming out of order greatly from zero graduation even if it is returned into a non-pressure condition after attaching the pointer to a pointer shaft in the non-pressure condition while the pointer agrees with the zero graduation and making the pointer agree with the maximum graduation by plastically deforming a plastically bent arm part of a displacement enlargement mechanism in the maximum pressure applied condition to greatly improve the efficiency of the work for setting to graduation and calibration. In this Bourdon tube pressure gage, the displacement enlargement link mechanism is composed of a protruding piece (12) attached to a tube tip (1b), a bow-shaped articulated link (23), and a rotary plate (25). A V-shaped arm piece (26) as an adjusting piece in the maximum pressure applied condition in the rotary plate (25) is used, and a bendable nodal point P is provided as a position where it is overlapped on a first turn kinematic pair part (12a) of the protruding piece (12) and the bow-shaped articulated link (23) in the non- pressure condition.

Owner:FUJI BOURDON TUBULAR GAUGE

Power distribution cabinet provided with buffer strip

InactiveCN106532459AImprove cooling effectAvoid damageSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMagnet

The invention discloses a power distribution cabinet provided with a buffer strip. The power distribution cabinet comprises a cabinet body and a cabinet door. The two sides of the cabinet body are respectively provided with a heat dissipation opening. The front end of the cabinet body is provided with a panel, which is provided with an opening. The left side of the panel is connected with the cabinet door in a hinged manner, and the right side of the panel is provided with the buffer strip. The buffer strip is arranged vertically, and the middle part of the buffer strip is provided with a buffer groove, and a magnet is disposed in the buffer strip. The cabinet door is provided with a protruding strip cooperated with the buffer groove, and the magnet is disposed in the protruding strip, and the magnetism of the magnet disposed in the protruding strip is the same as that of the magnet disposed in the buffer strip, and the direction of the magnet disposed in the protruding strip is opposite to the direction of the magnet disposed in the buffer strip. The bottom plate of the cabinet body is provided with a plurality of plastic rings, which comprise upper plastic rings and lower plastic rings. The upper plastic rings are in a threaded connection with the lower plastic rings in the installation holes in the bottom plate. The power distribution cabinet is advantageous in that the structural design is reasonable, use is convenient, and heat dissipation performance is good; function of buffering collision between the cabinet door and the panel is provided, and electric components in the cabinet body are protected; an external cable is clamped tightly without damaging the external layer of the cable, and the service lifetime of the cable is prolonged.

Owner:国网山东济南市长清区供电公司 +1

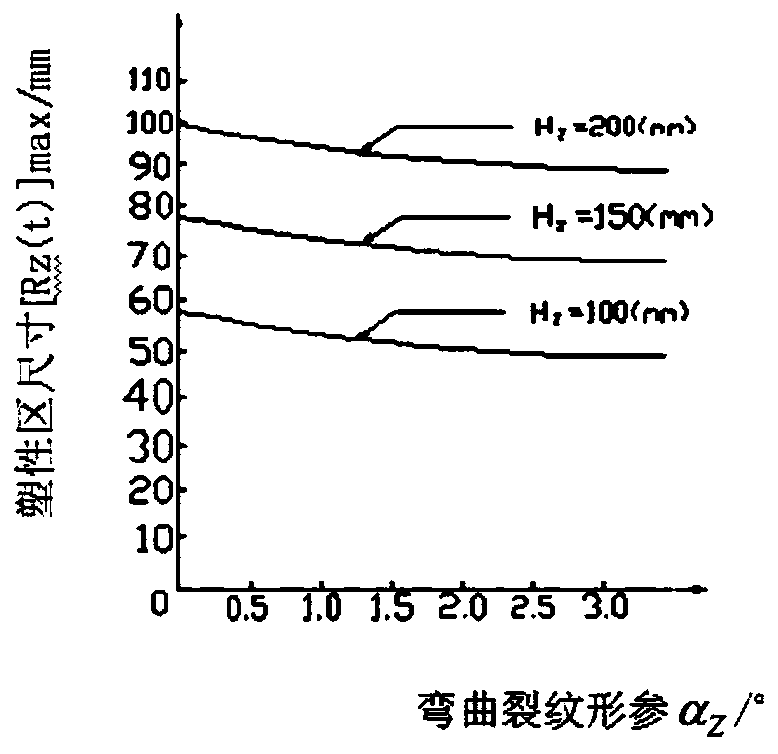

Analysis method of three-dimensional impact load elastic-plastic bending crack tip plastic region

PendingCN110489900AAccurate serviceSpecial data processing applications3D modellingShear stressEngineering

The invention discloses an analysis method of a three-dimensional impact load elastic-plastic bending crack tip plastic region. The impact action stress is comprehensively considered; impact normal stress and impact shear stress are applied to the boundary of the three-dimensional plastic area; a dynamic plastic region of the tip of the three-dimensional elastic-plastic bending crack is calculatedby using a numerical solution; under the action of the same external load, the dynamic plastic region at the tip of the three-dimensional elastic-plastic bending crack is reduced along with the increase of the thickness of the three-dimensional crack body; along with the uniform increase of the thickness of the three-dimensional crack body, the maximum size of the plastic region at the tip of thethree-dimensional elastic-plastic bending crack is continuously decreased, the decreasing amplitude is smaller and smaller, and finally the maximum size of the plastic region at the tip of the elastic-plastic bending crack tends to the maximum size in a plane strain state. When the three-dimensional crack body has a geometric dimension phase, the maximum size value of the plastic region at the tip of the three-dimensional bent crack is gradually increased along with the continuous increase of the impact load. A brand-new theoretical model for calculating the dynamic plastic region of the three-dimensional elastic-plastic bending crack is established, and engineering practice can be more accurately served.

Owner:ZHENGZHOU TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com