Front impact conceptual model design method for front structure of automobile

A technology of frontal collision and front structure, applied in computing, special data processing applications, instruments, etc., can solve problems such as mass block rebound, error, and new car model guidance, and achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

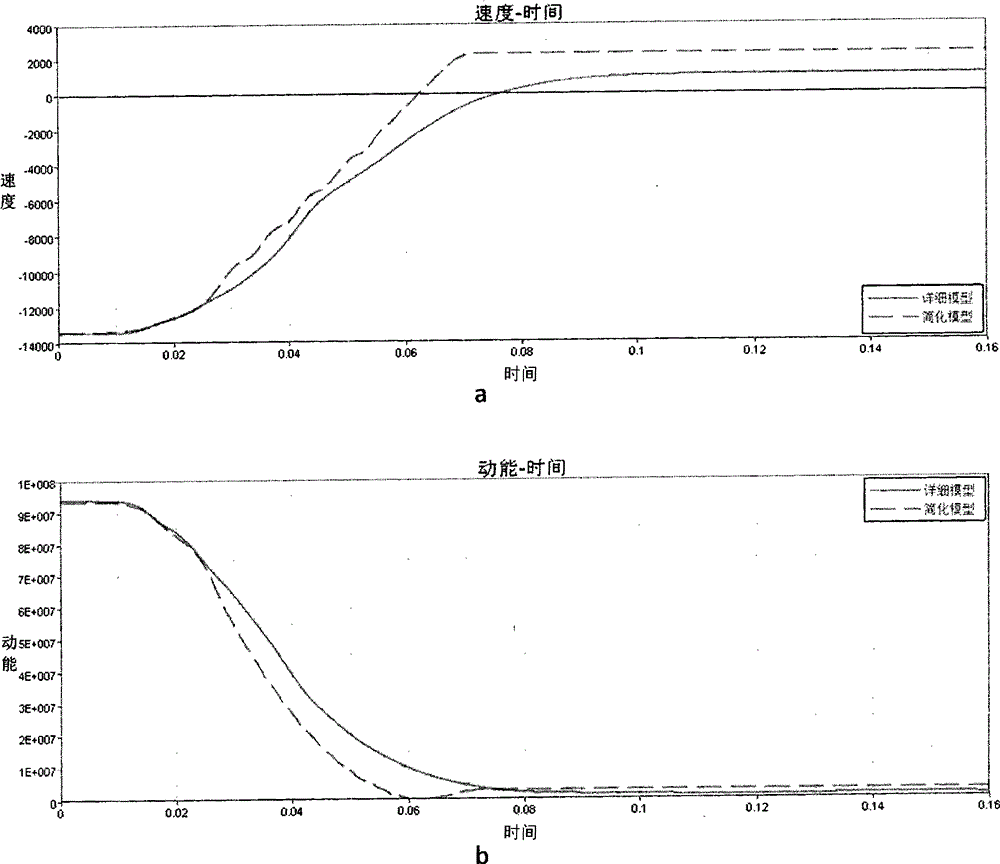

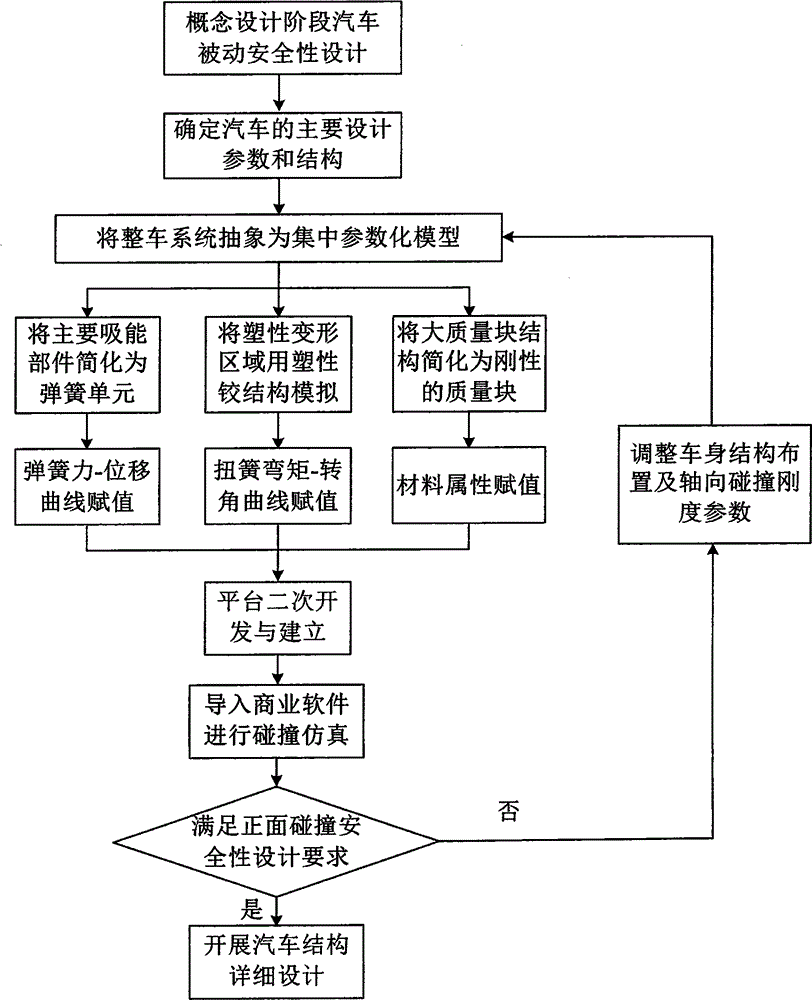

[0025] figure 1 It is a flow chart of the vehicle frontal collision concept design method based on the centralized parameterized model of the present invention, which includes the following specific steps:

[0026] Step 1: The designer conducts an overall design of the vehicle structure in the conceptual design stage, and determines the main parameters and structure of the vehicle, such as body length, width, height and vehicle quality.

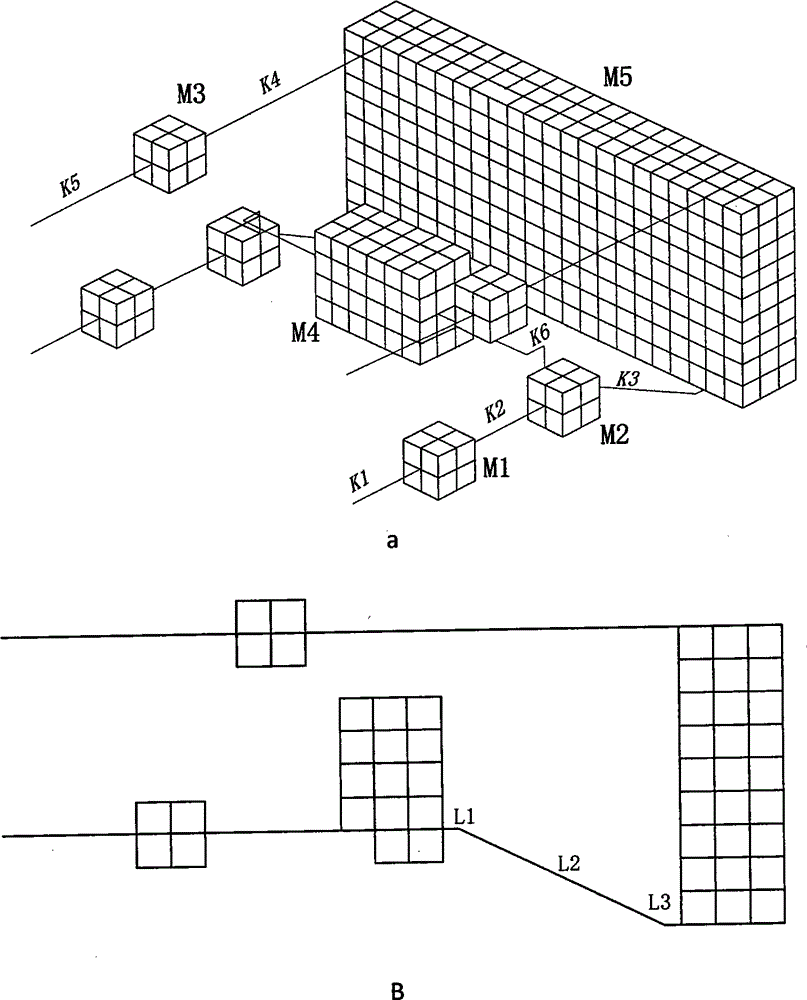

[0027] Step 2: The designer determines the scale and shape of the LPM according to the needs of the actual design problem of the frontal crash safety of the vehicle, that is, the number of degrees of freedom of the model, the spatial layout structure, that is, the actual size and position of each subsystem of the energy-absorbing structure of the front of the vehicle body, etc. ;Due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com