Patents

Literature

53results about How to "Meet structural design requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

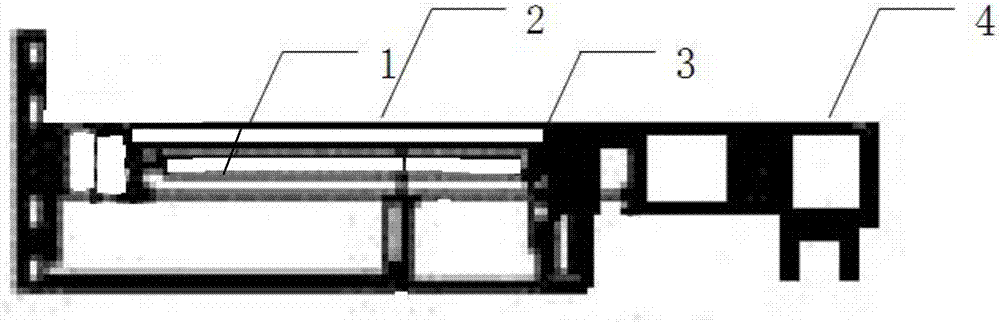

Display module

ActiveCN112289185AIncrease stickinessReduce the overall heightCasings with display/control unitsElectrical apparatus contructional detailsEngineeringMechanical engineering

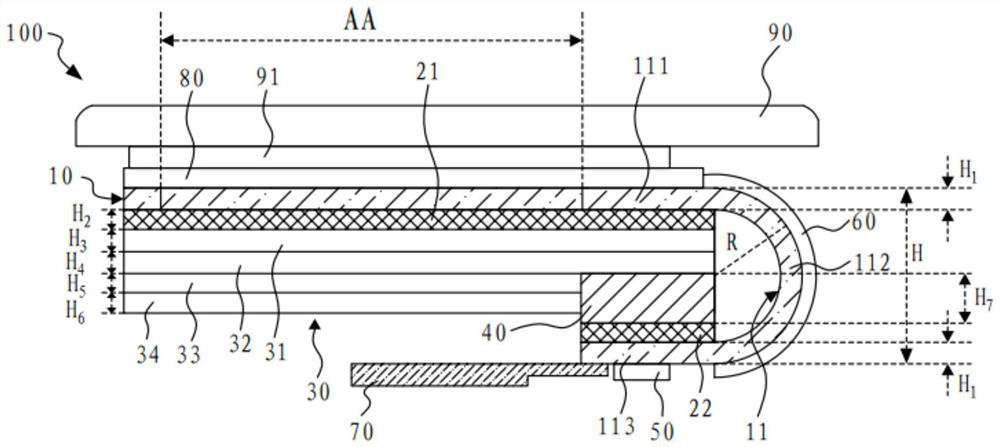

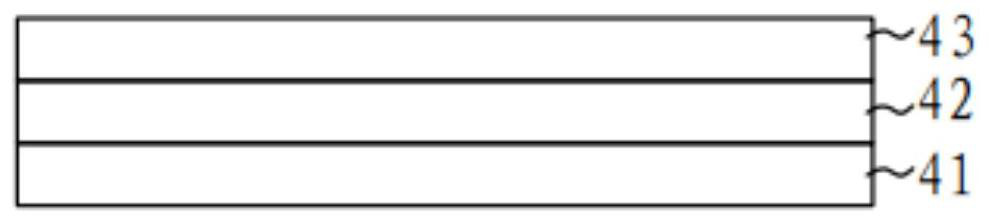

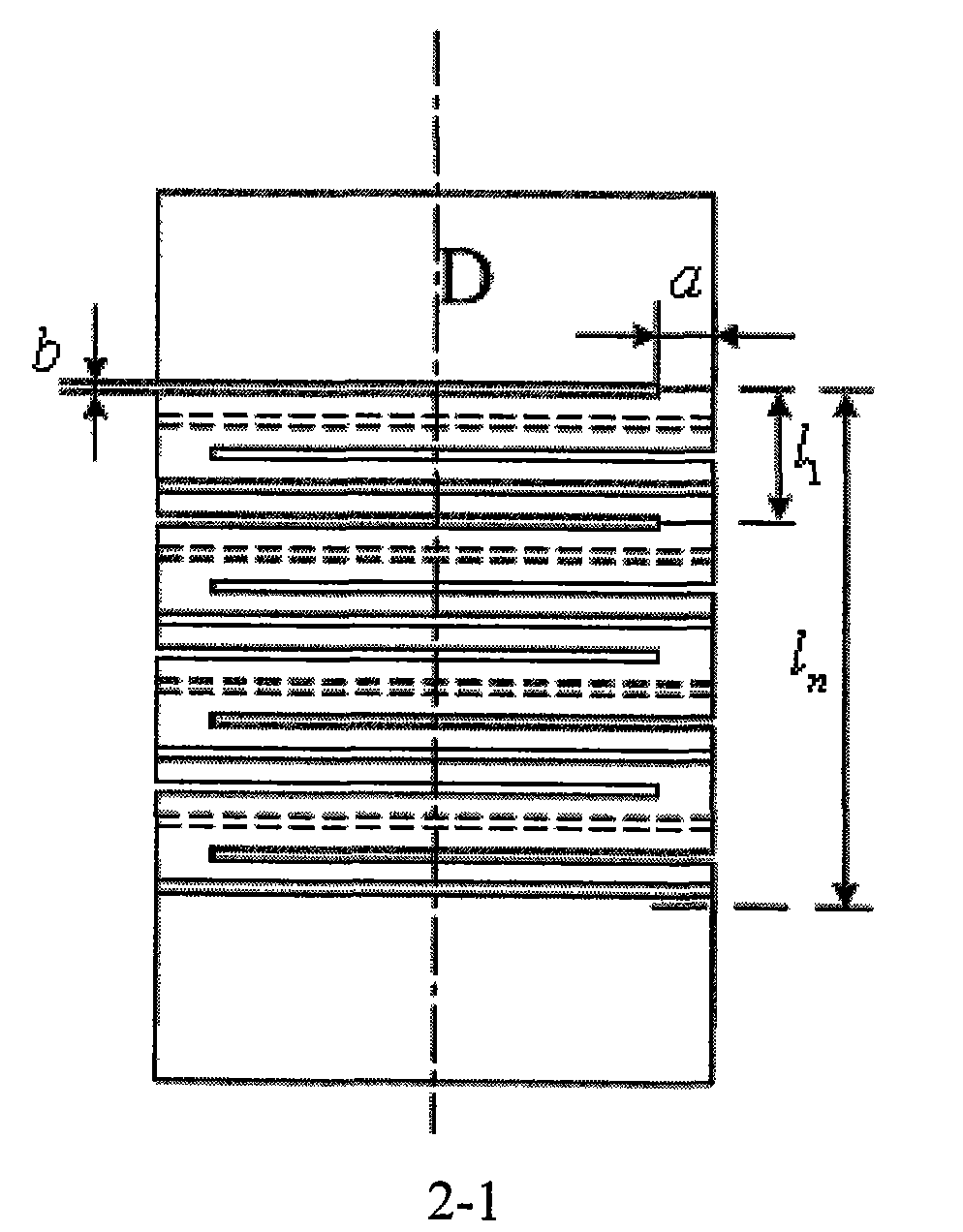

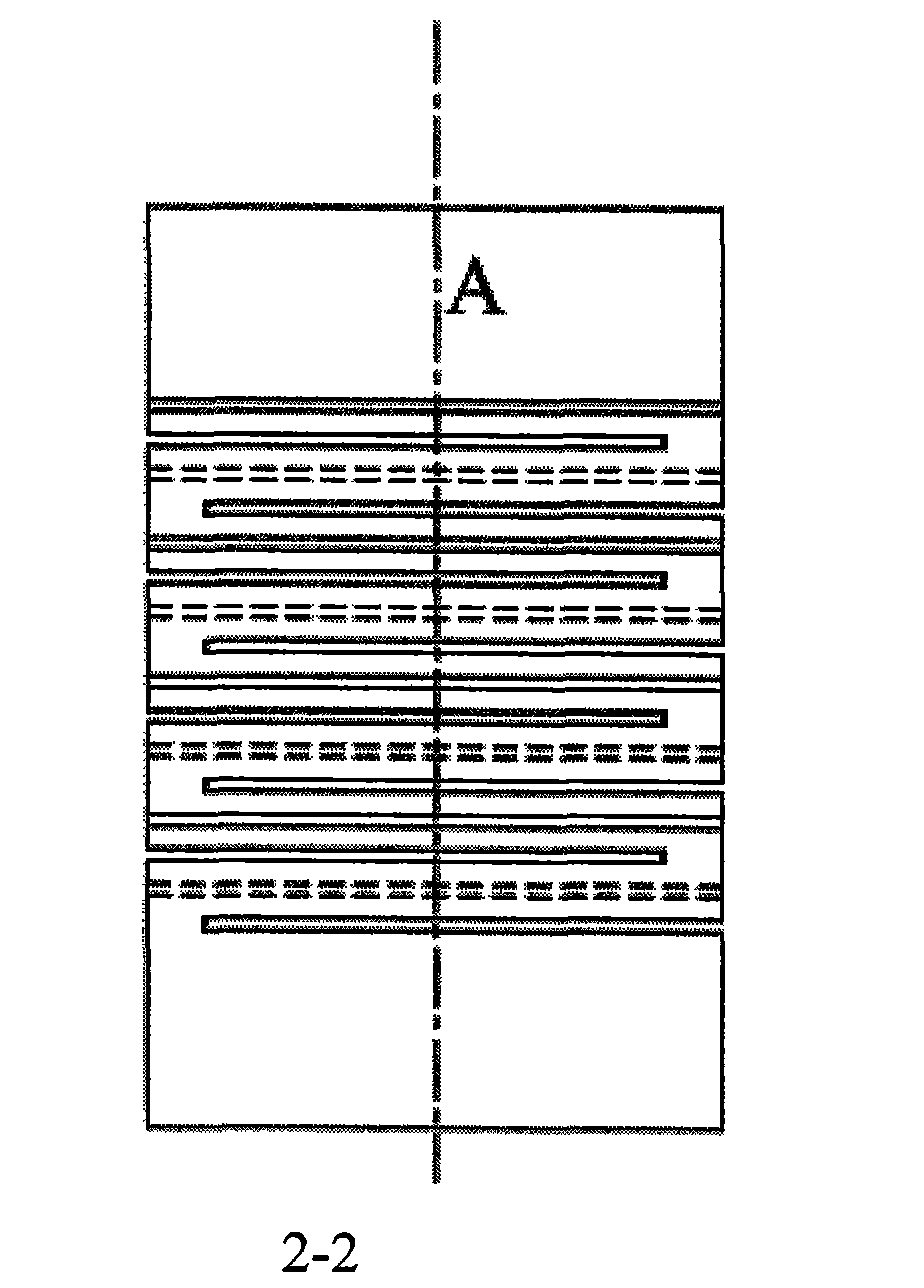

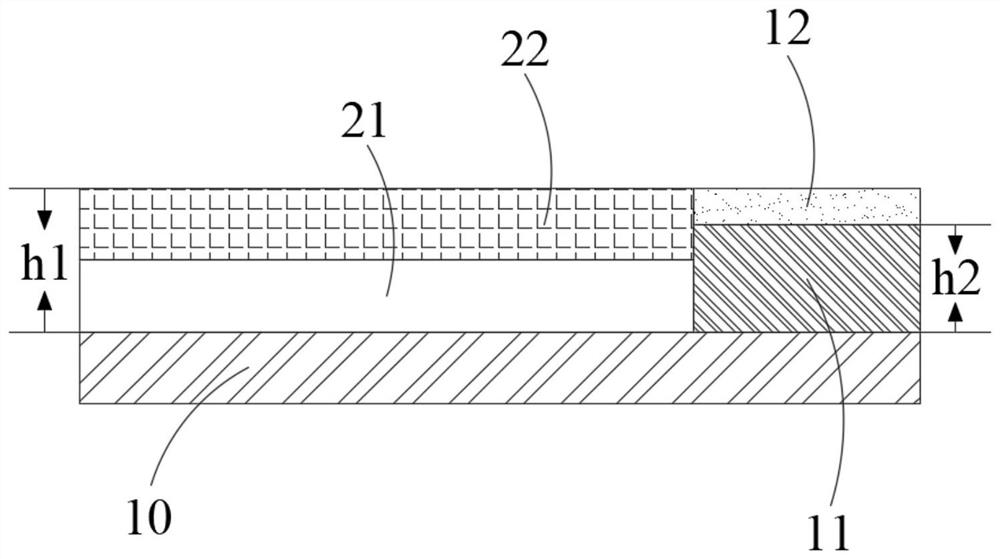

The invention discloses a display module, which comprises a display panel, a first backboard, an SCF assembly and a reinforcing plate, wherein the display panel comprises a display area and a bindingend located on one side of the display area, the end, which is away from the display area, of the binding end is connected with a driving chip, and the binding end is bent towards the side deviating from a light emitting surface of the display panel, so that the driving chip is located on the side, which deviates from the light emitting surface, of the display panel; the first backboard is arranged on the side, which deviates from the light emitting surface of the display panel, of the display panel; the SCF assembly and the reinforcing plate are both arranged on the side, which deviates fromthe display panel, of the first back plate; and an accommodating groove is formed in the side, which deviates from the display panel, of the SCF assembly, at least part of assemblies of the reinforcing plate are accommodated in the accommodating groove, and the driving chip is located on the side, which deviates from the display panel, of the reinforcing plate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

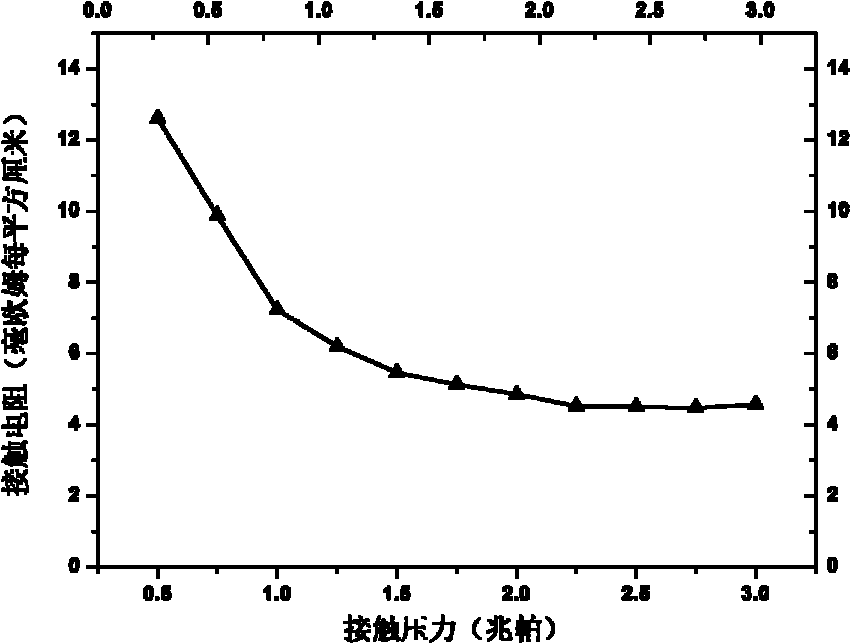

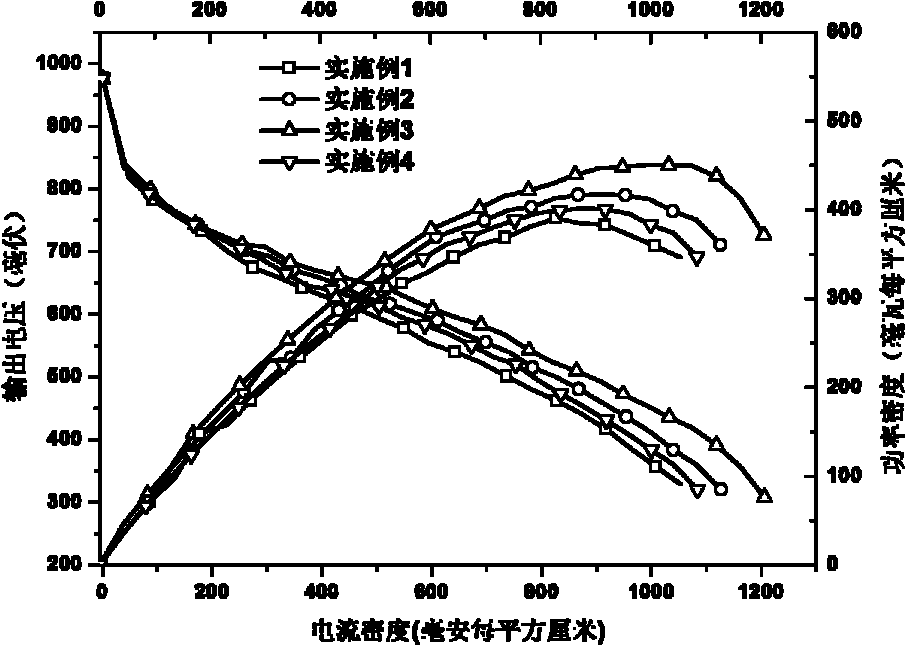

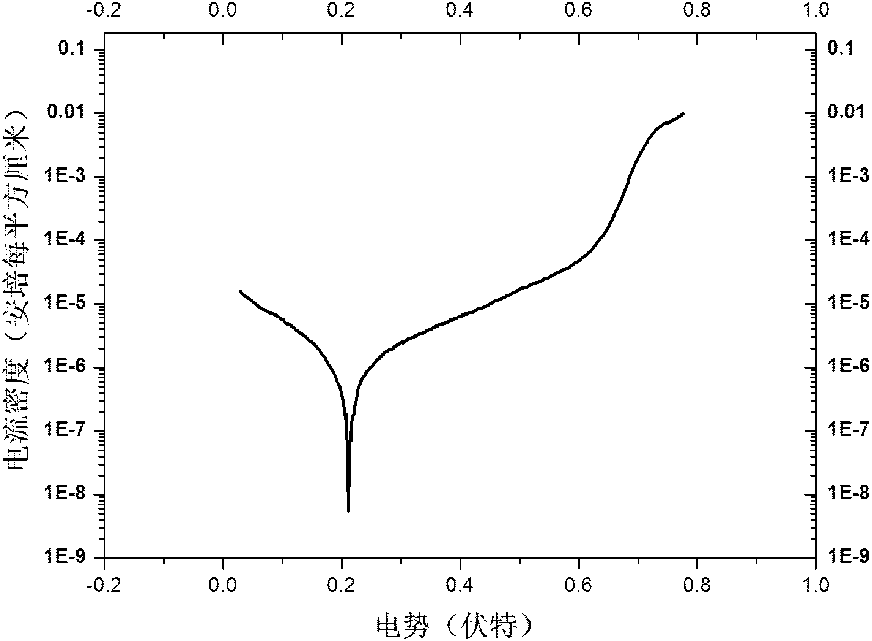

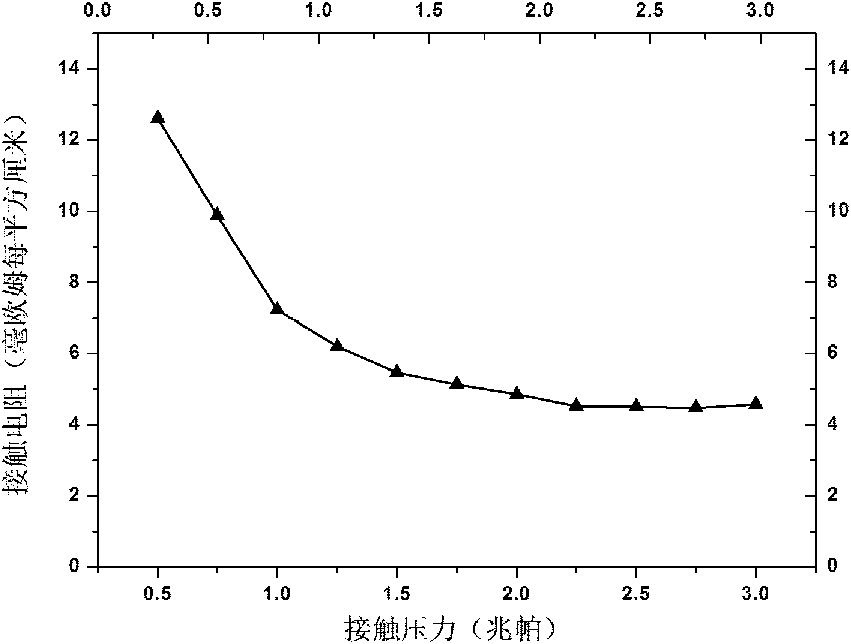

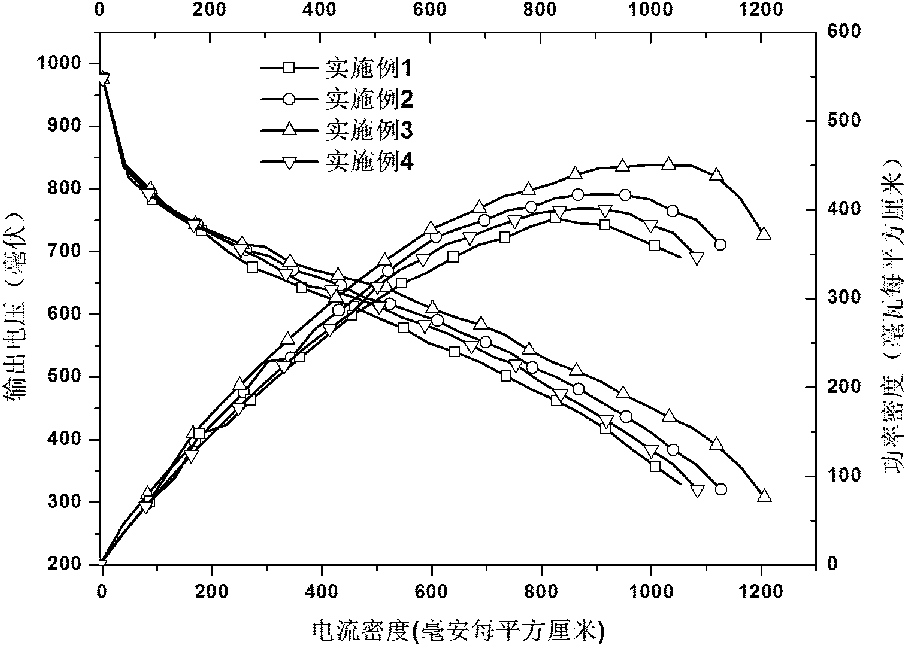

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277AImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

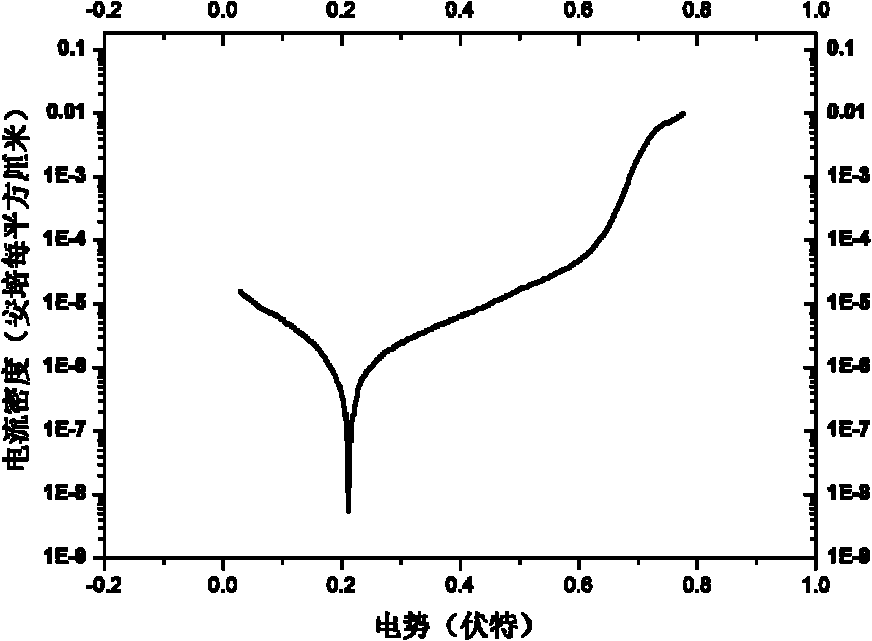

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:上海氢晨新能源科技有限公司

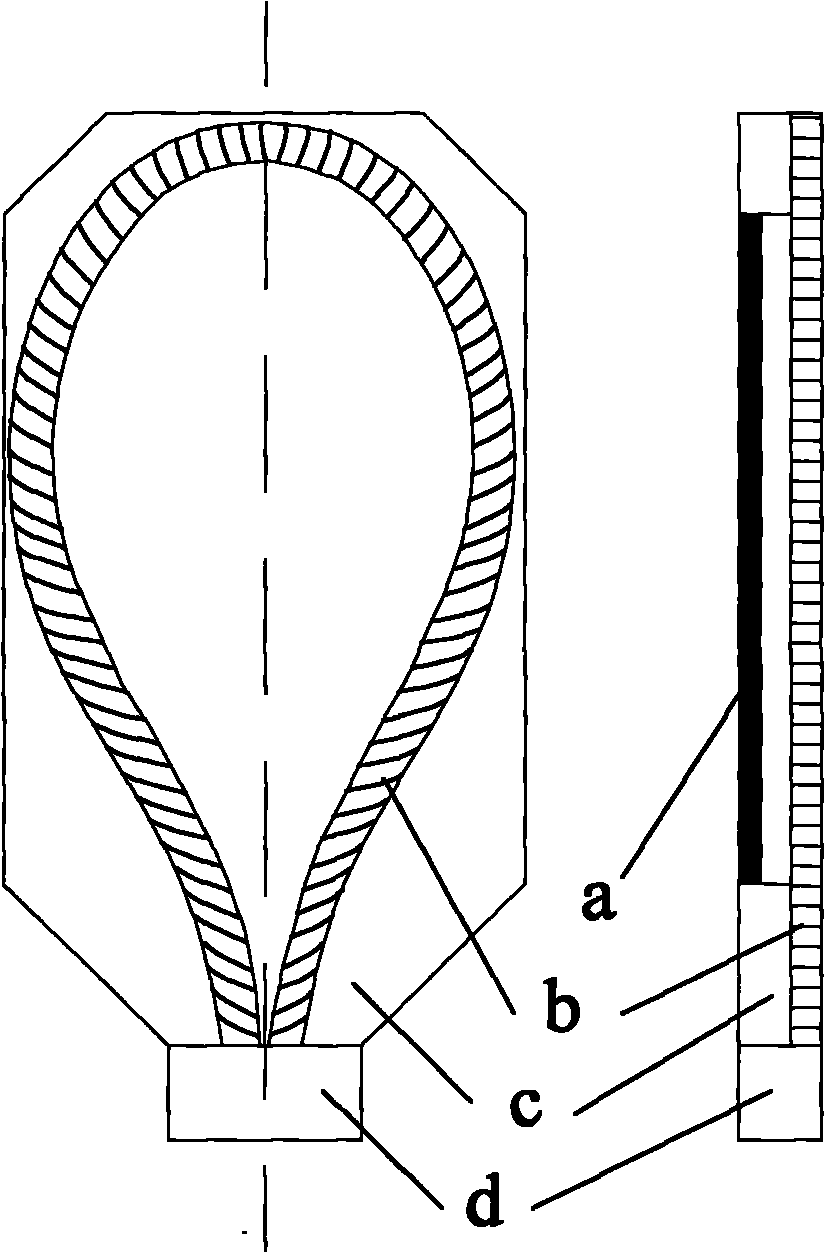

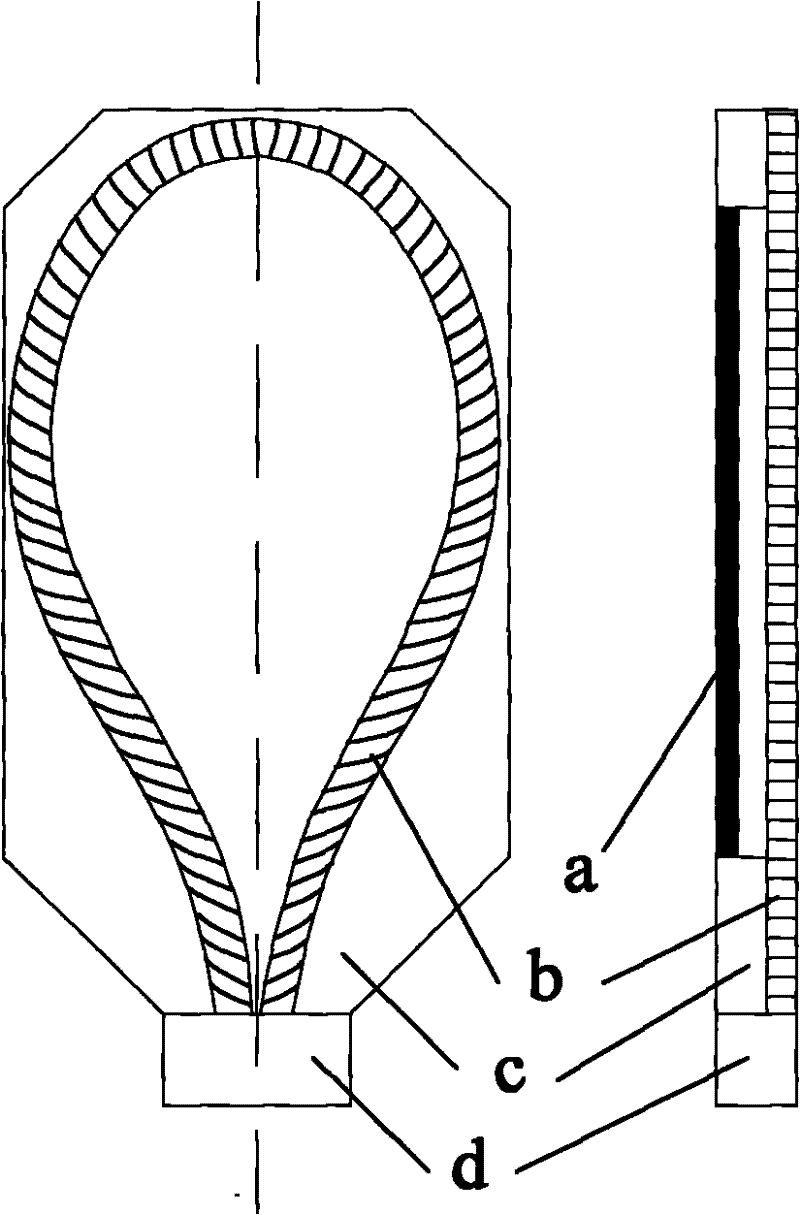

Adhesive toe for gecko robot and movement method thereof

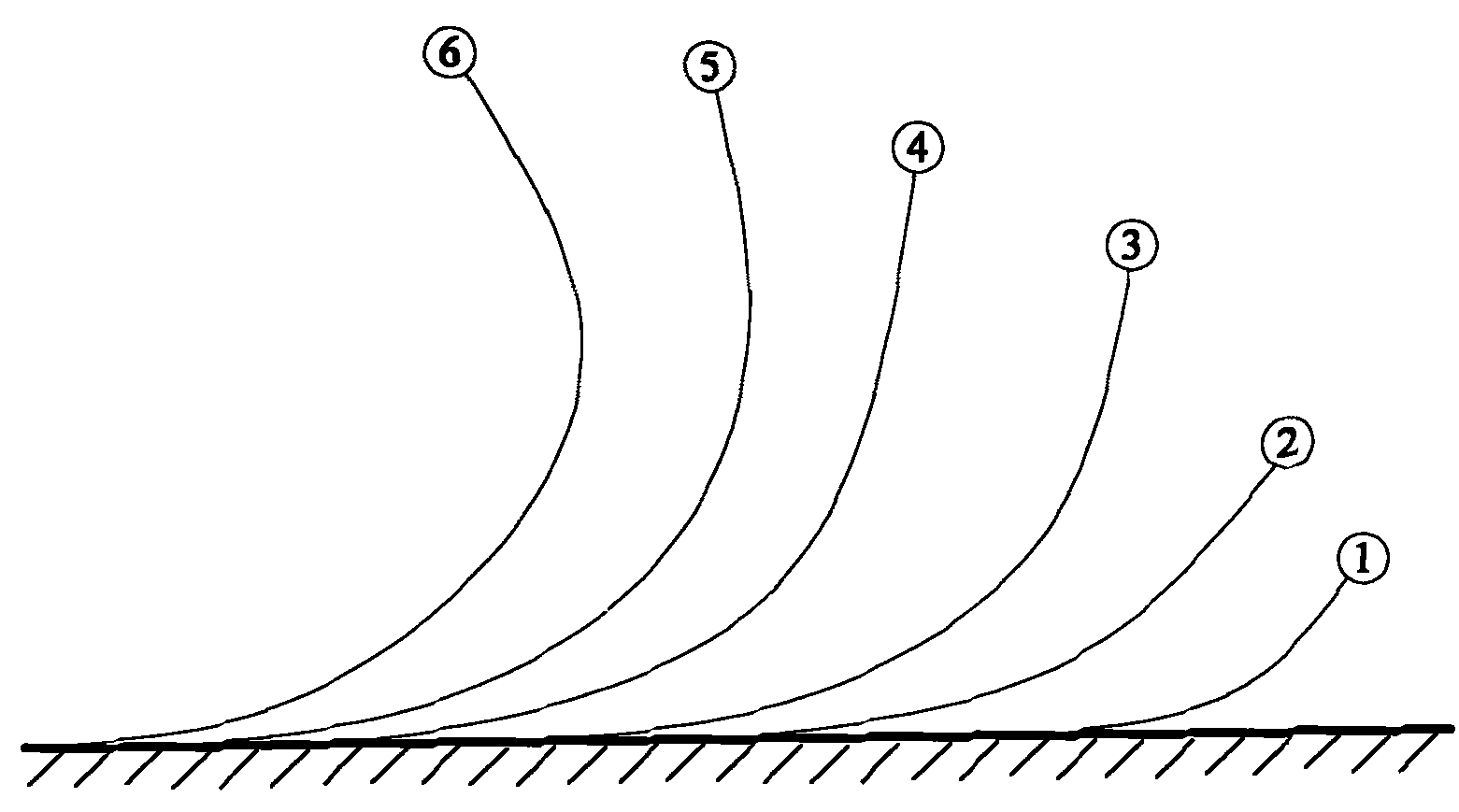

The invention relates to an adhesive toe for a gecko robot and a movement method thereof and belongs to the field of technical application of biomorphic robots. The toe comprises a flexible material toe base (c) and a sticky material layer (a) which is embedded into the flexible material toe base (c), wherein the height of the lower bottom surface of the sticky material layer (a) is equal to that of the flexible material toe base (c); and a spring layer (b) is also formed on the flexible material toe base (c). The toe has three specific structures, namely flat-shaped, semi-arc and arched stereo structures with bending of 180 degrees. According to the characteristic of a special cantilever type structure, the driven mode is adopted, so that the characteristics that the toe has the larger adhesion in one direction and the smaller desorption force in the negative direction are provided, and the mechanical anisotropy characteristics that a gecko has the larger adhesion in the one direction and the smaller desorption force in the negative direction can be simulated fully and are applied to the gecko robot.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

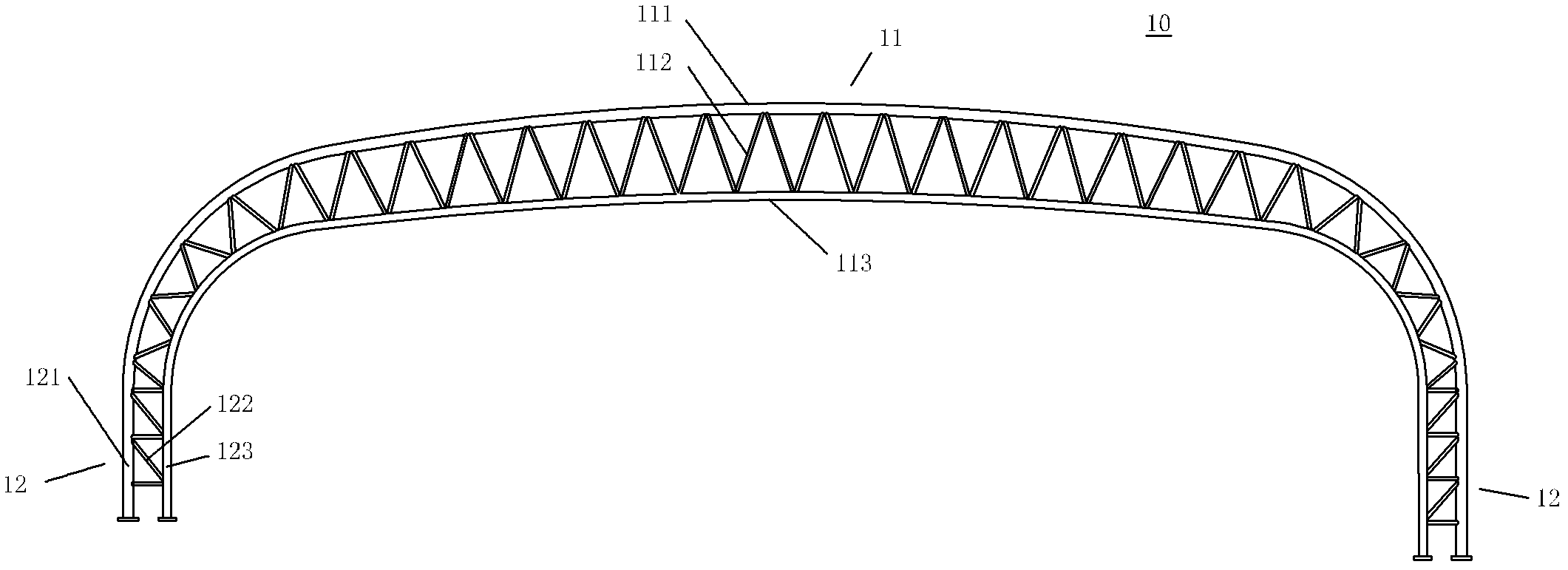

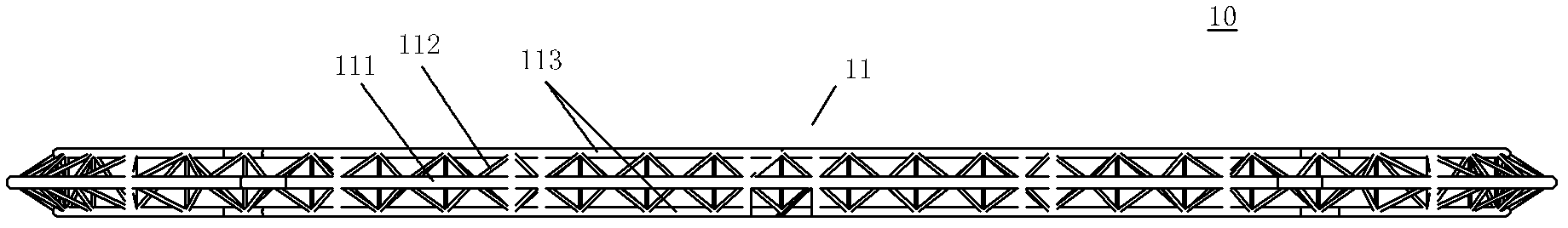

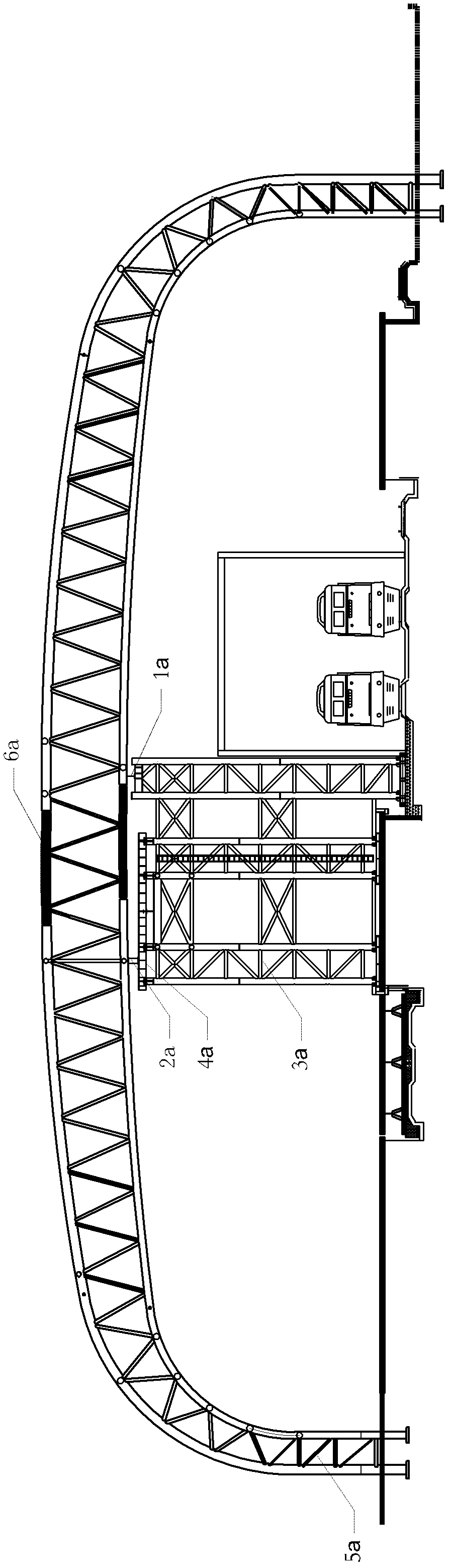

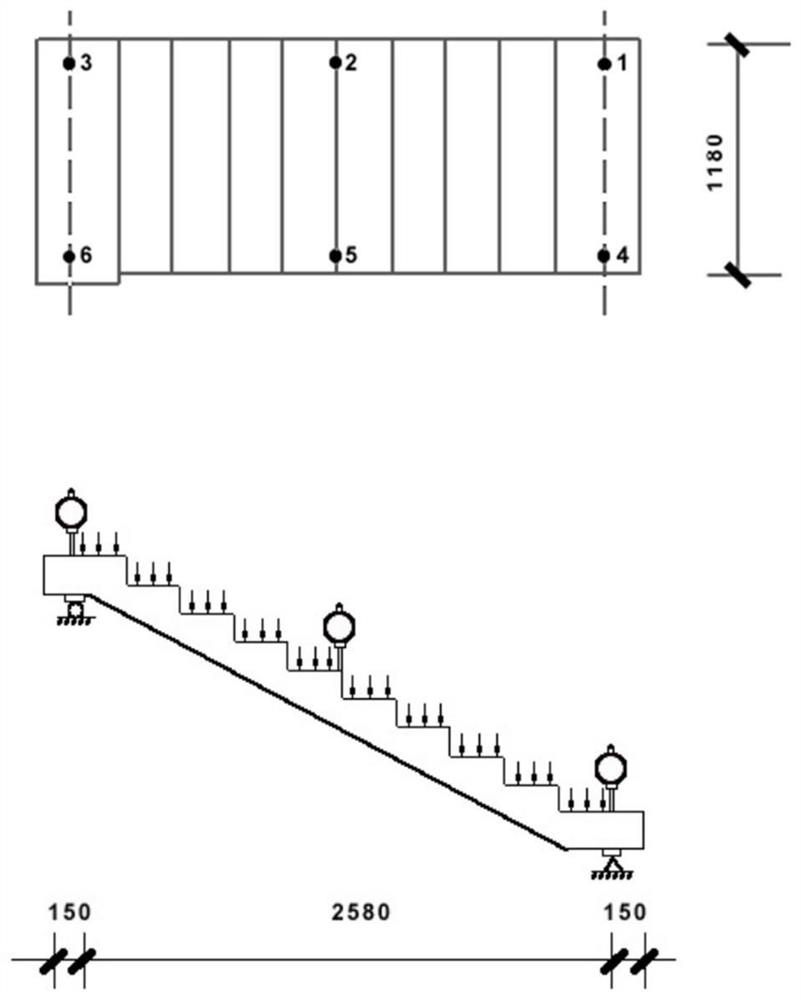

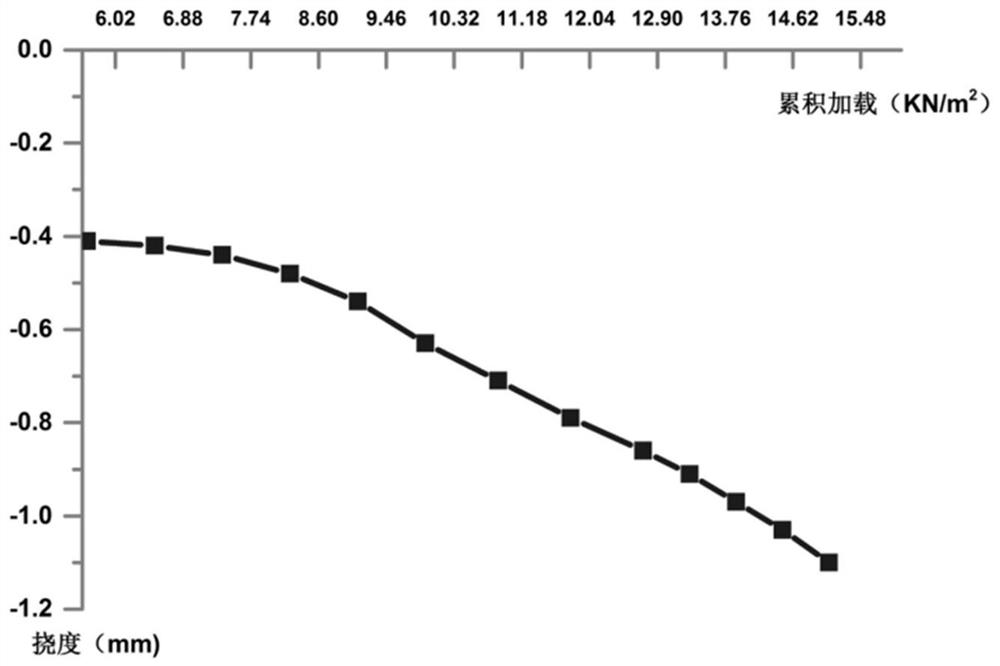

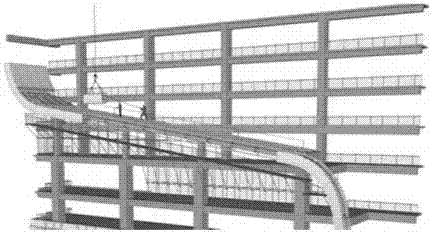

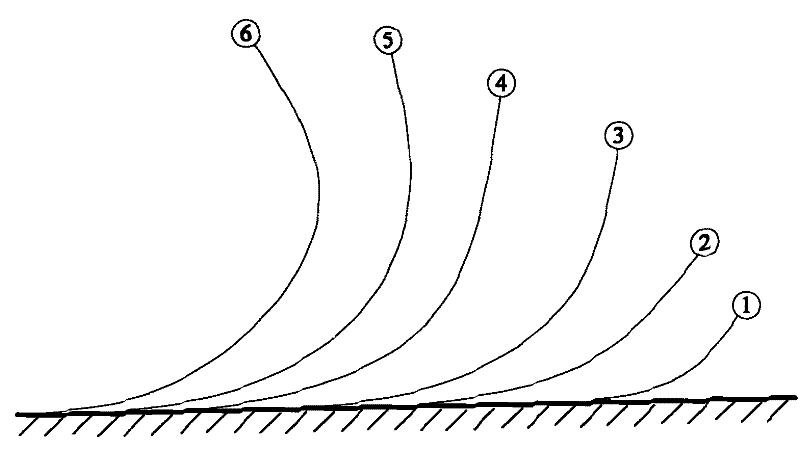

Carriage stepped unloading method after expanding large-span truss structure

ActiveCN102425313AReasonable order of uninstallationMeet structural design requirementsBuilding repairsShoresEngineeringSpandrel

The invention discloses a carriage stepped unloading method after expanding a large-span truss structure, which comprises the following steps that: a flexibility maximal value at a broken place on a truss structure and an allowable unloading maximal stress value are calculated; layer-by-layer unloading number of times N and layer-by-layer unloading height at each time are determined; for each truss structure, a jack is arranged on a supporting bracket below a main truss, cushion blocks with the quantity of M are superimposed onto the supporting bracket, M is equal to N, the height of each cushion block is respectively equal to each layer-by-layer unloading height, and the jack is disassembled; the supporting bracket stepped one-by-one unloading is executed for each truss structure which is sequentially and horizontally arranged until the supporting brackets below the truss structure are completely disassembled. The stepped unloading way is adopted for unloading the supporting bracket,so the unloading sequence is reasonable, the deformation of the truss structure can be effectively controlled, the security of the unloading process can be guaranteed, the quantity of the unloading devices can be reduced through the way for unloading the supporting brackets one by one, and the simultaneous execution of the unloading and the civil work can be realized.

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

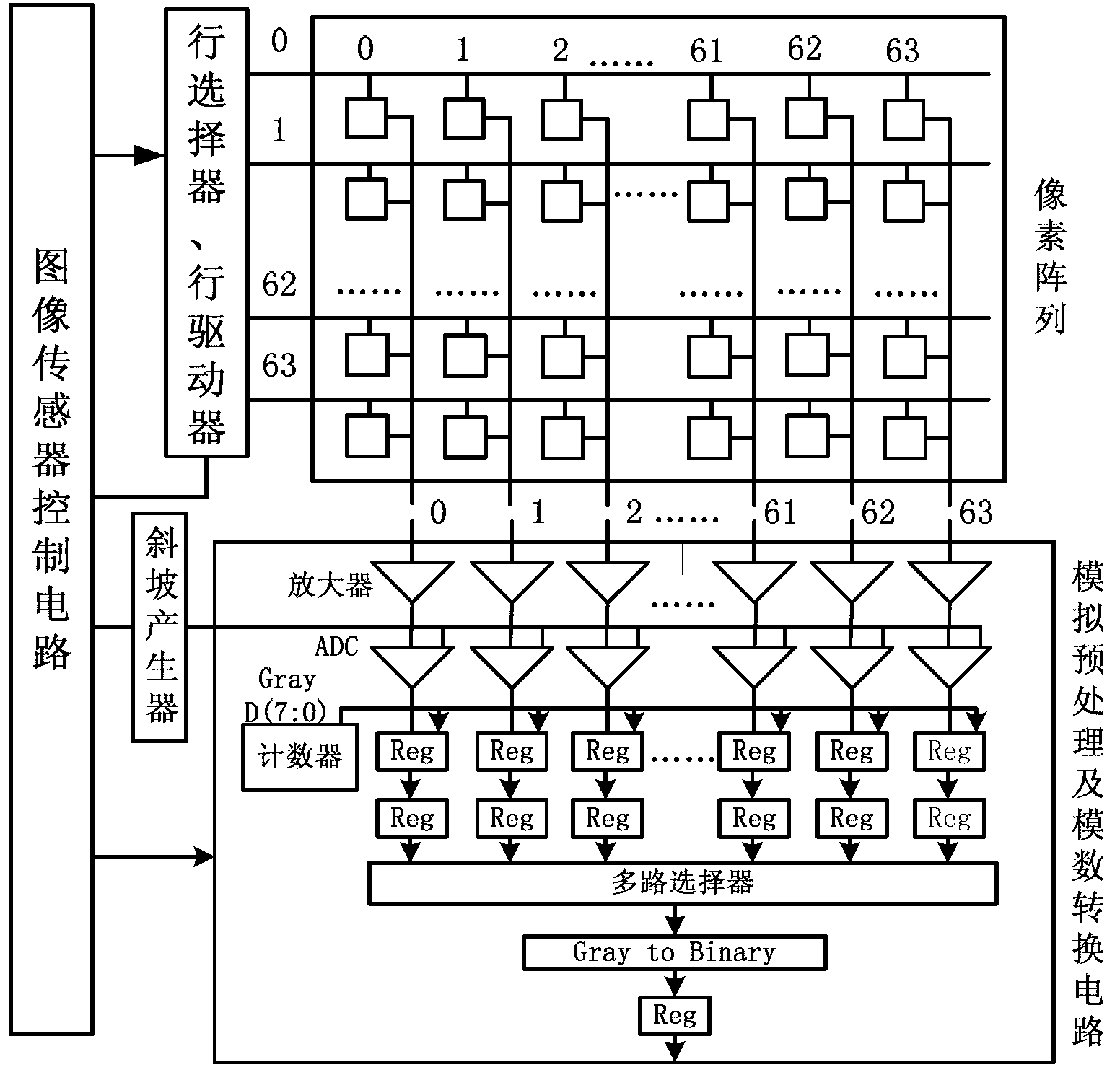

Common image surface imaging method based on CMOS (complementary metal oxide semiconductor) package

InactiveCN103024308AMeet real-time requirementsAvoid Poor Image EffectsTelevision system detailsColor television detailsCMOSLead bonding

The invention discloses a common image surface imaging method based on CMOS (complementary metal oxide semiconductor) package. Partition imaging layout is performed on imaging induction areas of a light induction chip, the light induction chip is divided into at least two imaging induction areas, the adjacent imaging induction areas are separated from each other by a spacer, each imaging induction area corresponds to an optical channel, different scene information or different spectral information of the same scene is simultaneously imaged on the light induction chip by respectively independent optical channels, the light induction chip is connected with an internal lead bonding area of a substrate dam through a gold wire, photoelectric conversion processes of pixels of the imaging induction areas are mutually independent, and photoelectric conversion signals of the imaging induction areas are uniformly processed by a peripheral support circuit. The method meets the integral structure design requirements of system microminiaturization on size and volume, the requirement of instantaneity of stereoscopic vision imaging is met, and poor imaging effects of imaging area junctions caused by image surface division completely depending on multiple optical paths are avoided.

Owner:TIANJIN UNIV

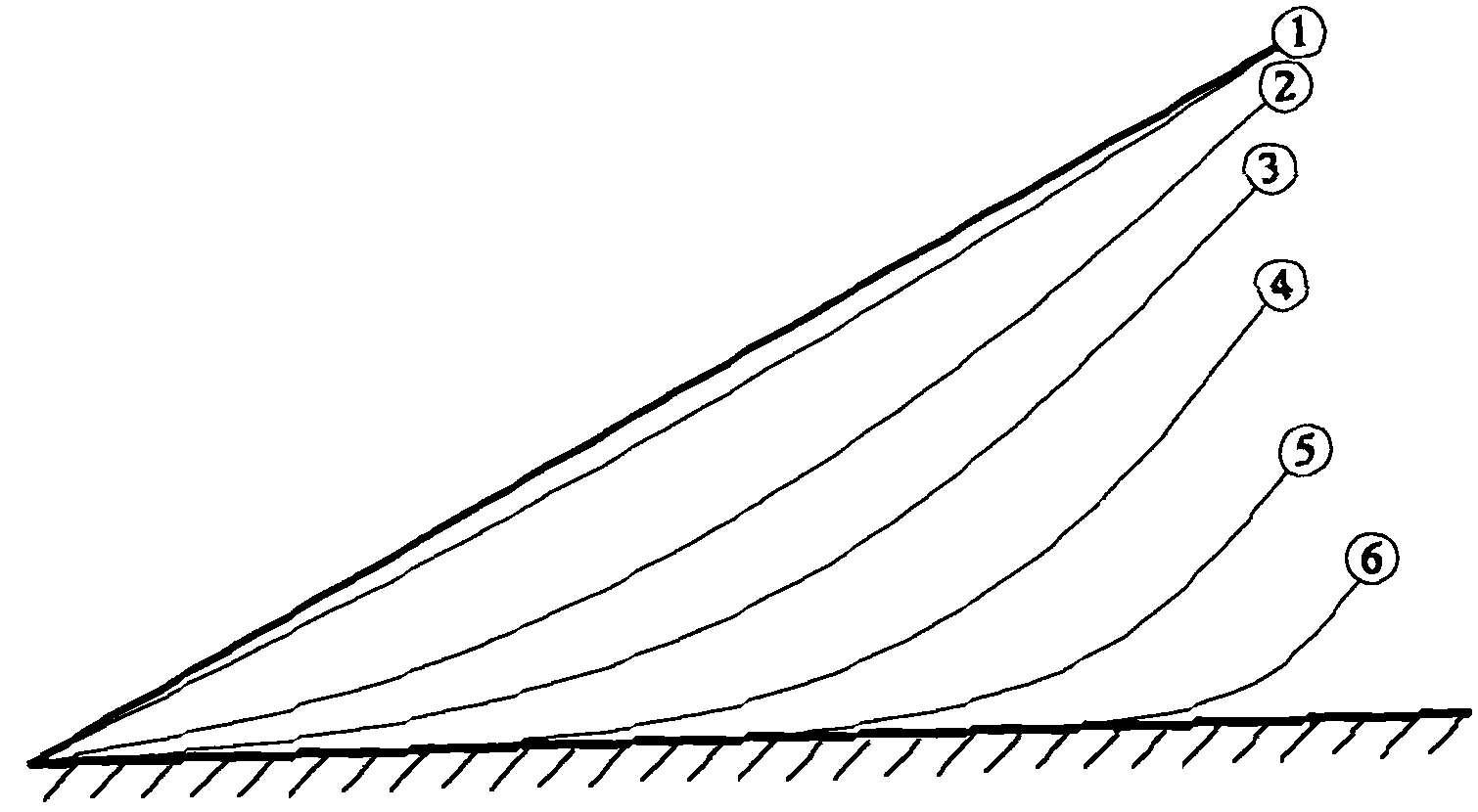

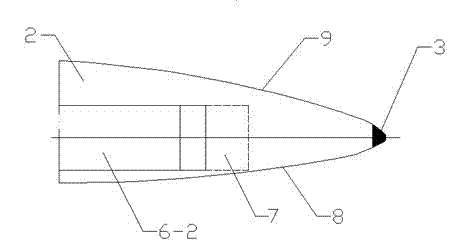

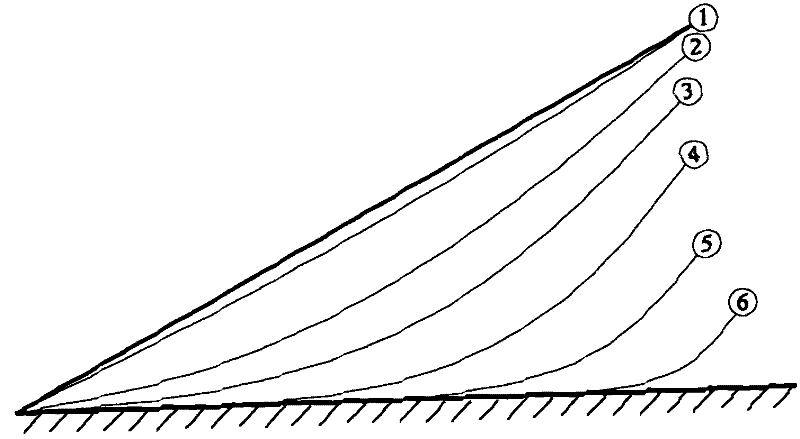

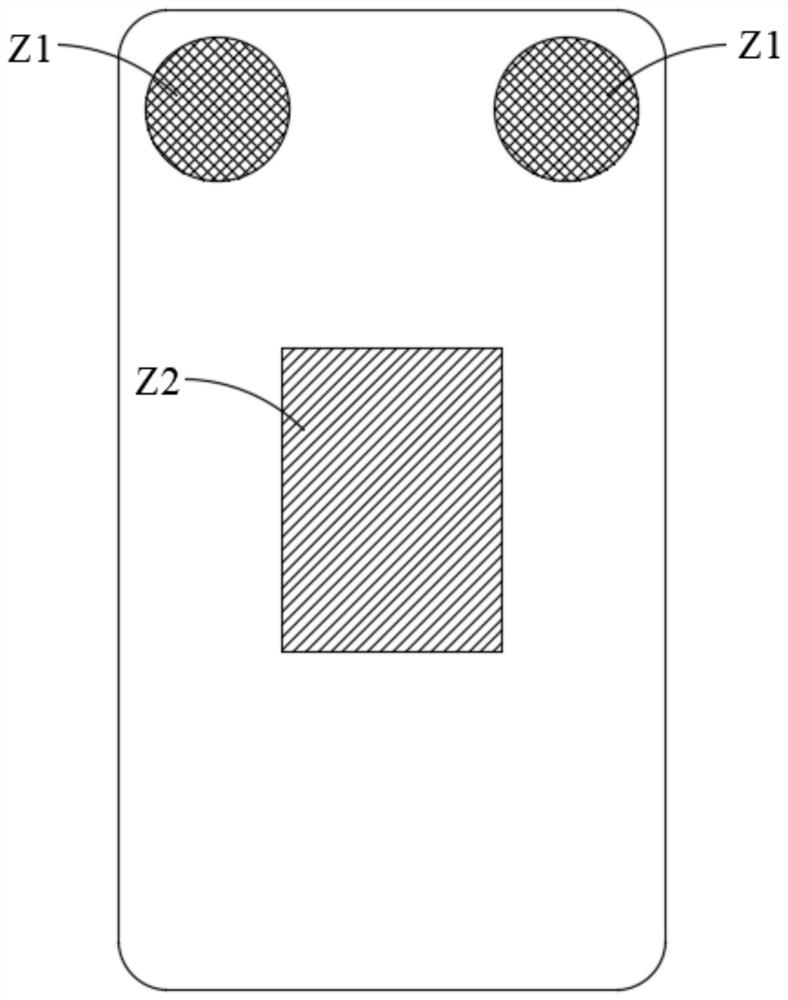

Method of beam cap connection for lengthening wind turbine generator blades

ActiveCN103573563ASafe and reliable structureImproved stiffness distributionFinal product manufactureWind energy generationClassical mechanicsStructural engineering

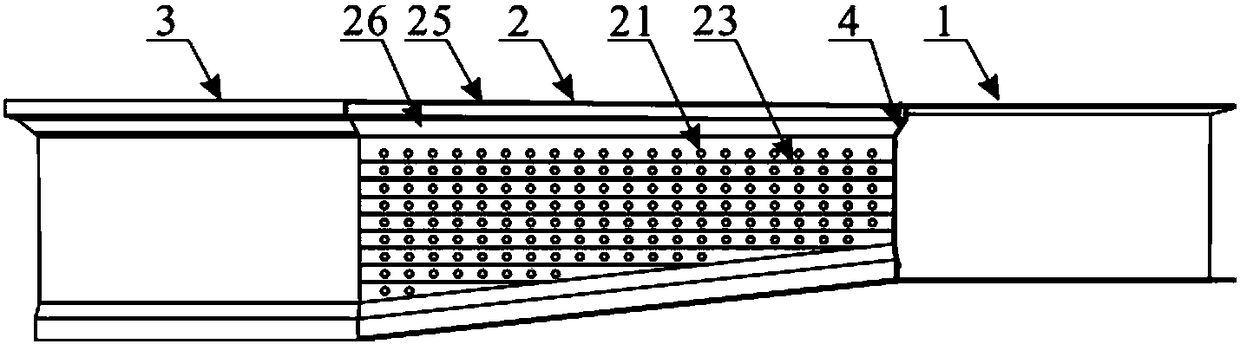

The invention relates to the method of beam cap connection for lengthening wind turbine generator blades. The method is particularly adopted for connecting beam caps of the blades in the lengthening and improving process of existing wind turbine generator blades. Each reinforced beam cap is manufactured in a beam cap reserved zone between one existing beam cap of one blade and the corresponding beam cap of one blade tip lengthening section, so that the problem of connection of every two existing beam caps is solved. The blades which are lengthened and improved through the method for connecting the beam caps of the wind turbine generator blades are safe and reliable in structure.

Owner:BEIJING KHANWIND TECH

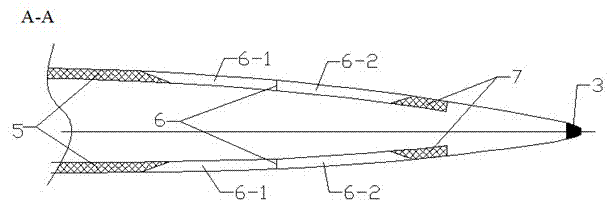

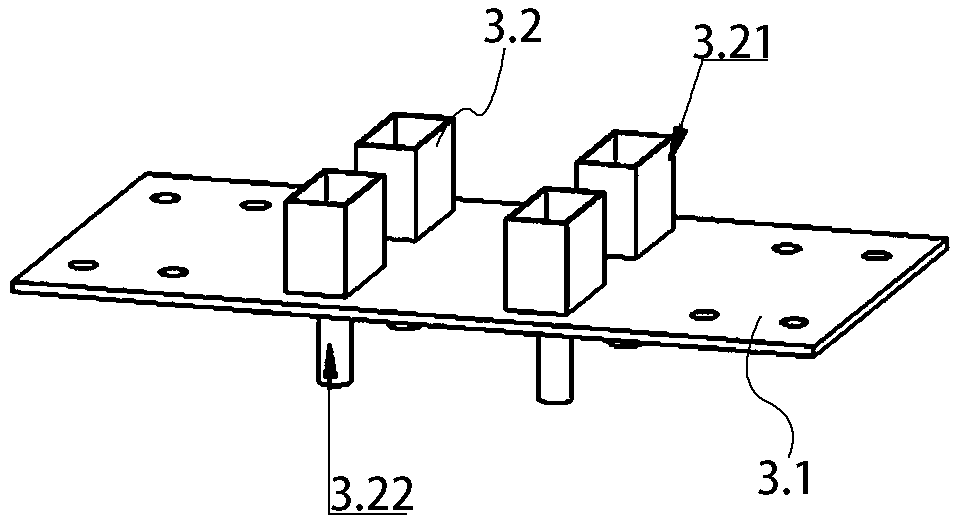

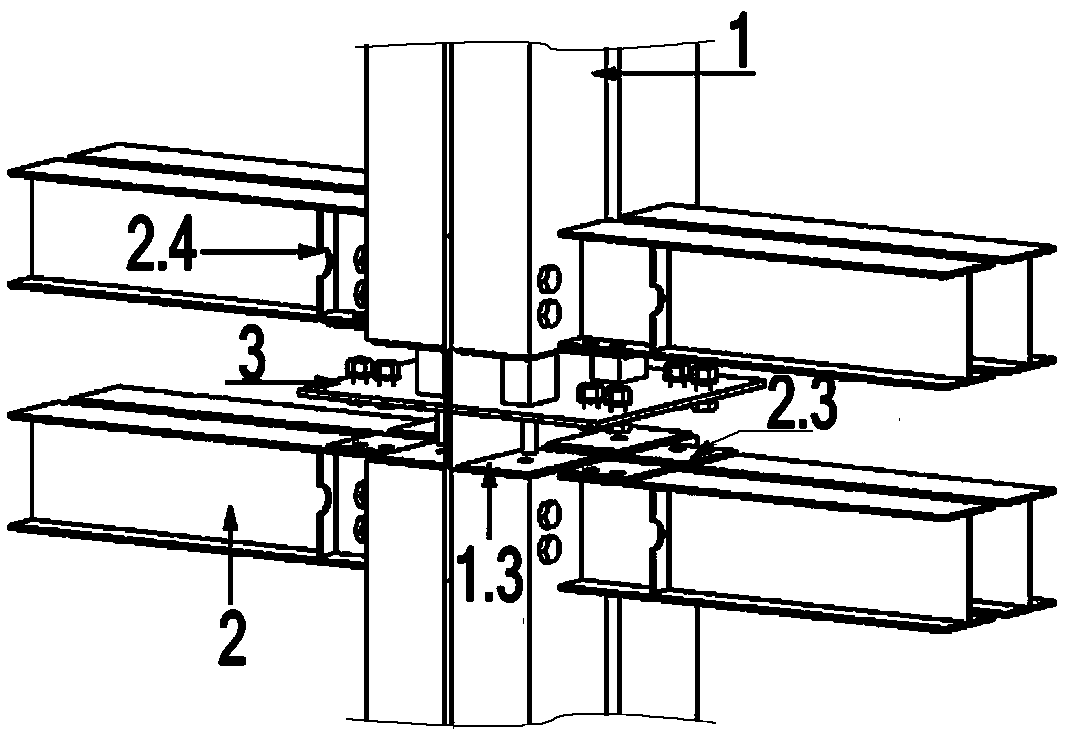

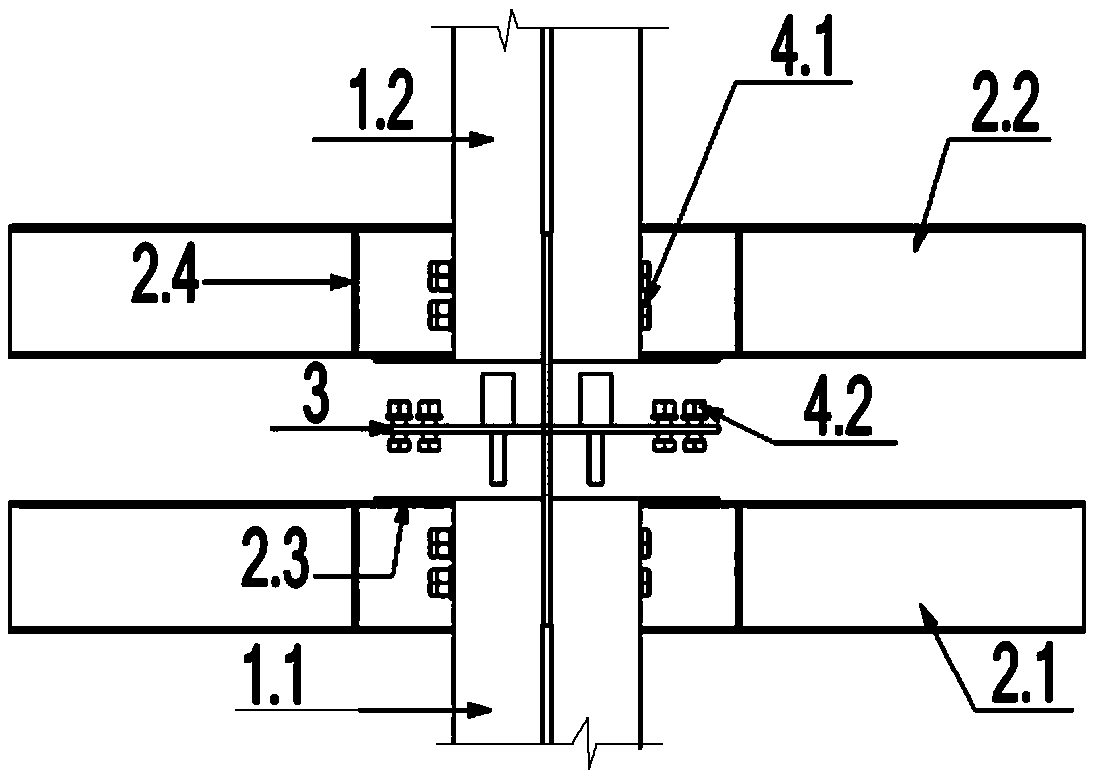

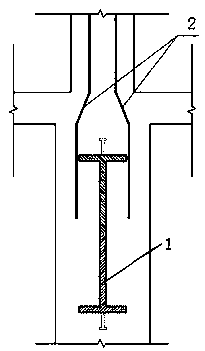

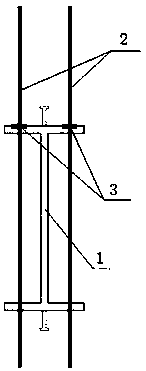

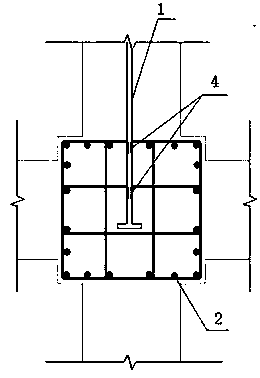

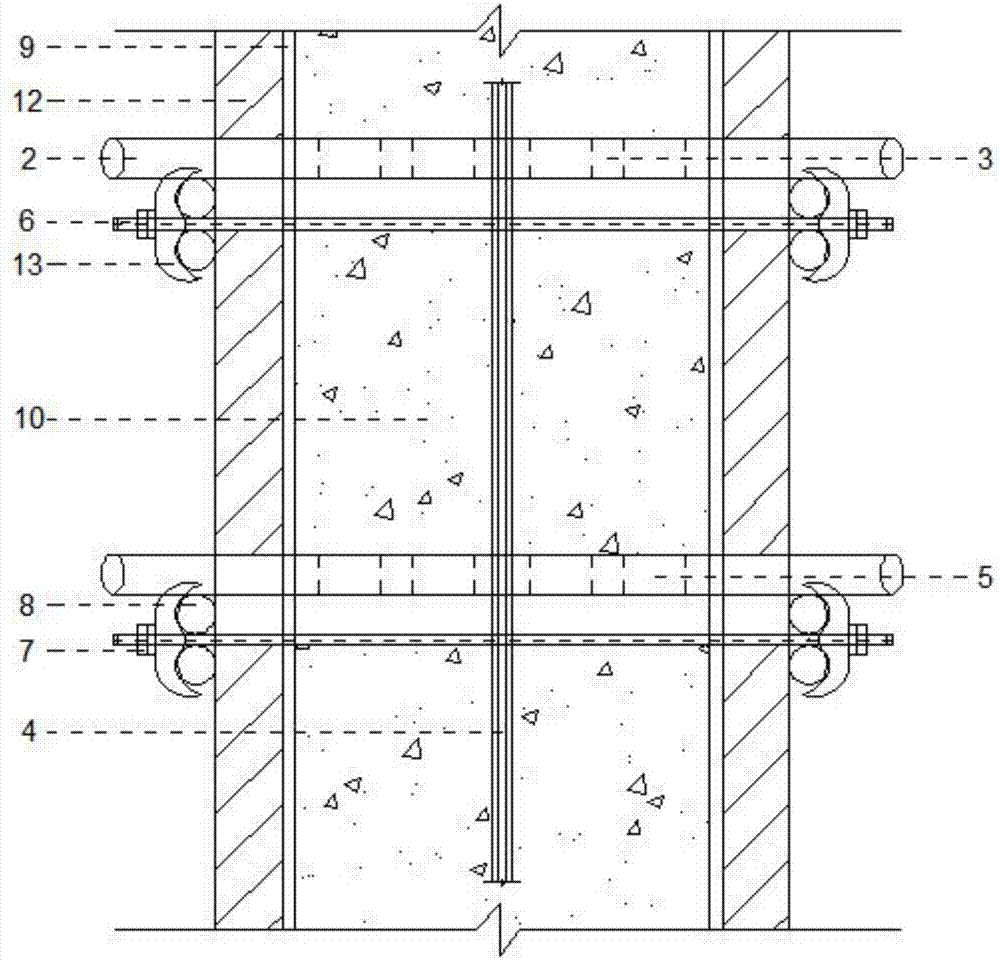

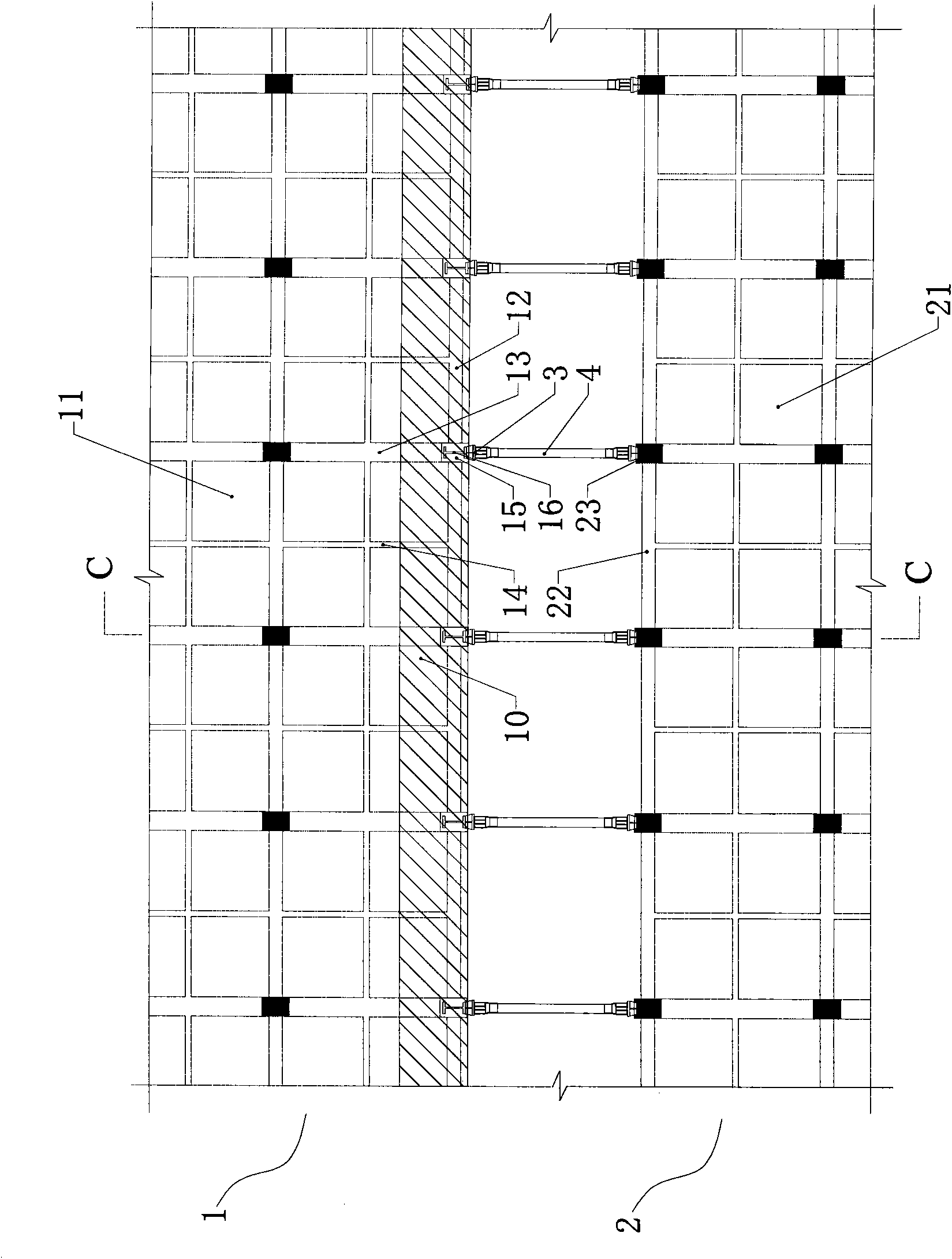

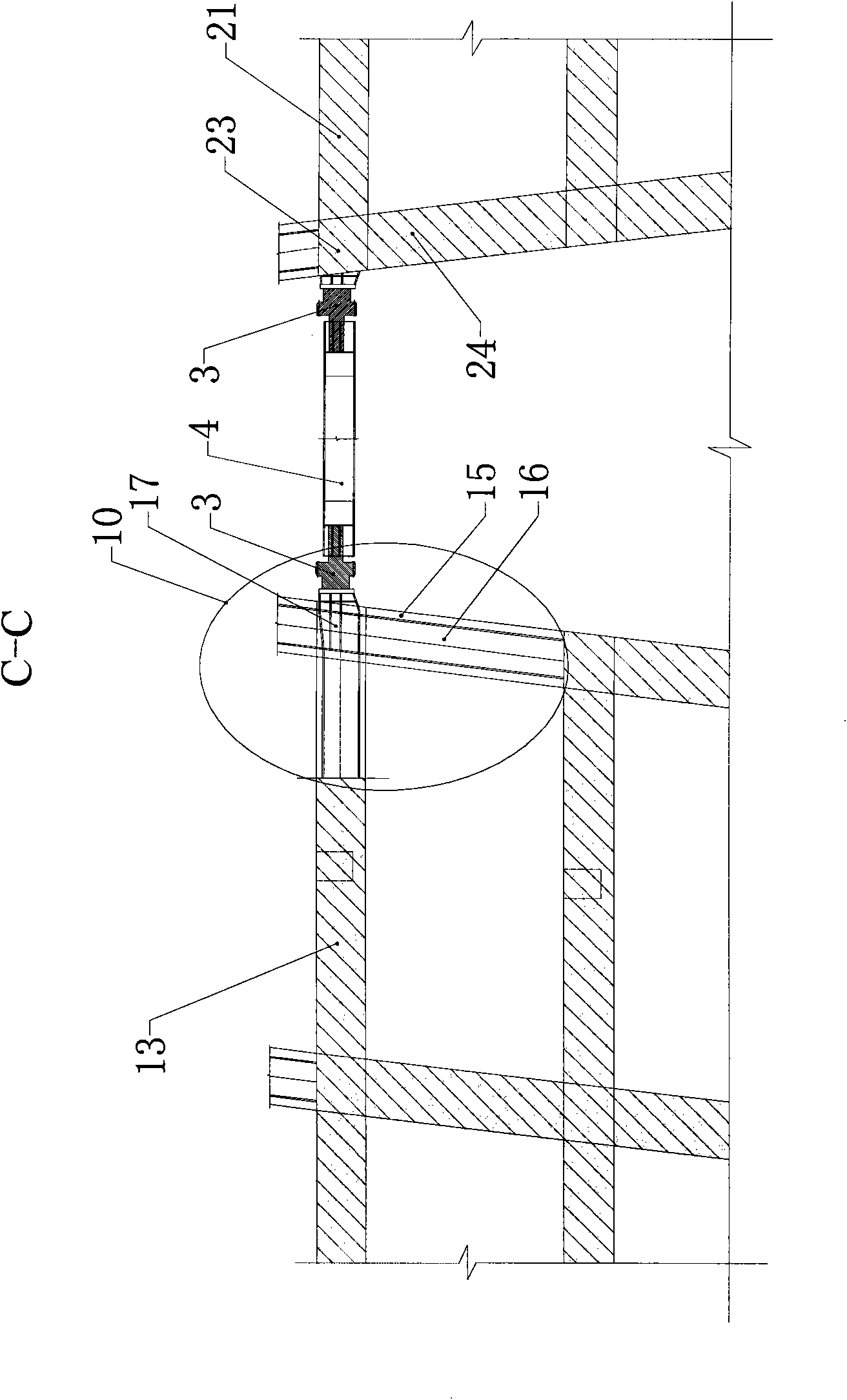

Box type integration building module reinforced connecting joint structure and installing method thereof

PendingCN110792170ASimple structureEasy to processBuilding constructionsSteel columnsMechanical engineering

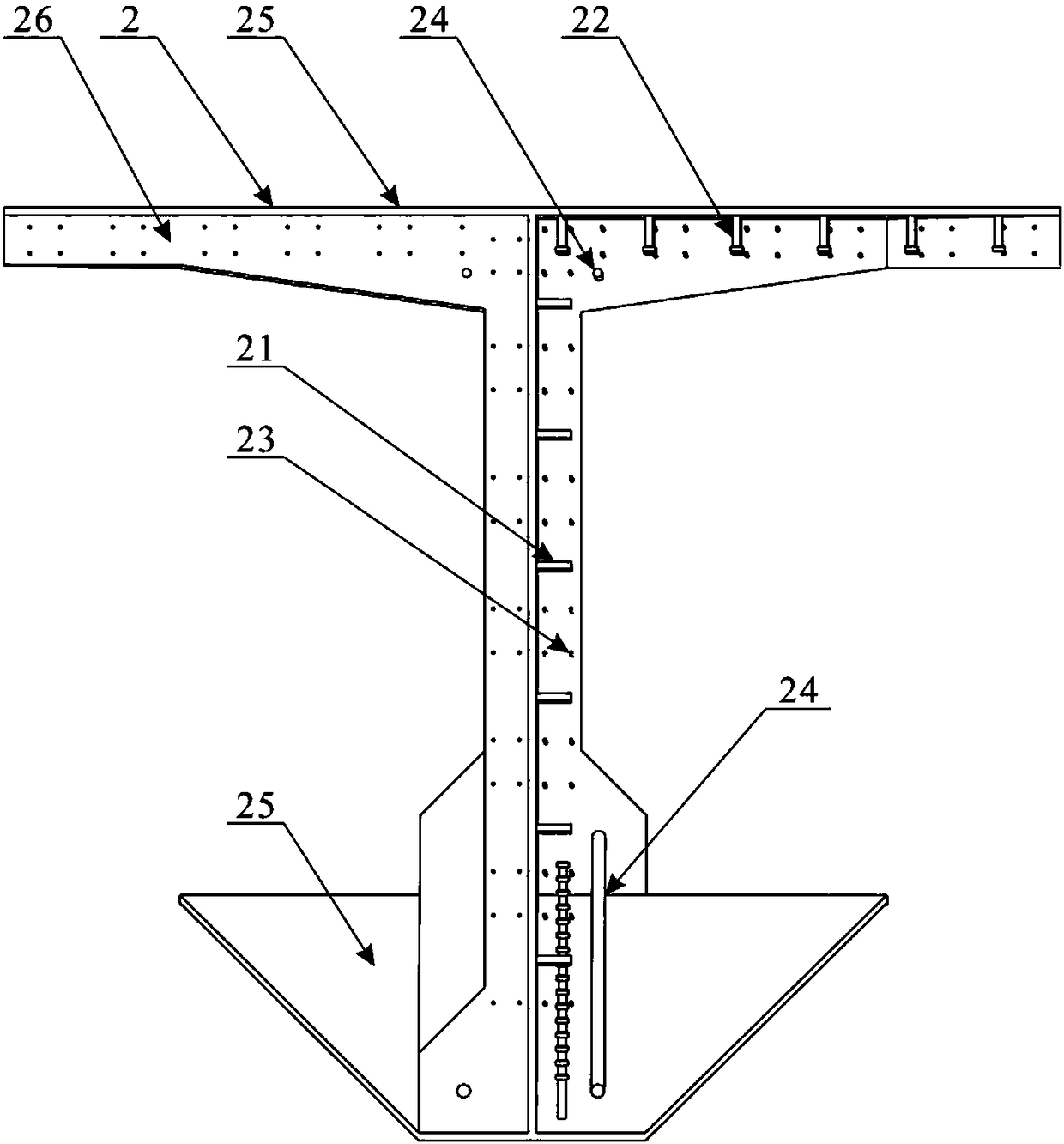

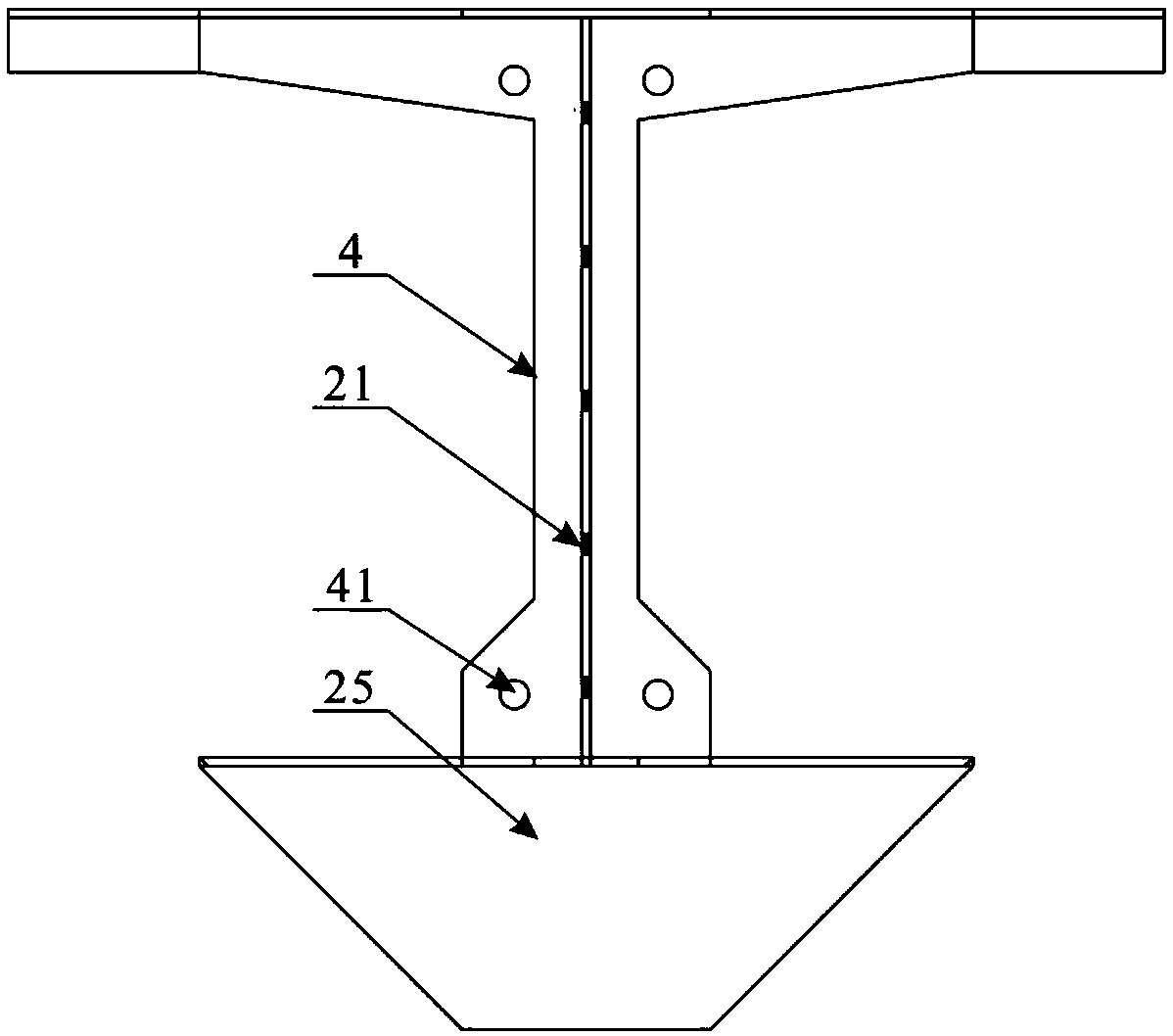

The invention discloses a box type integration building module reinforced connecting joint structure and an installing method thereof. The joint comprises a steel column, a steel girder, connecting positioning pieces, reinforcing connecting pieces and connecting bolts. The horizontal connecting bolt penetrates through the steel column so that the left reinforcing connecting piece and the right reinforcing connecting piece can be in cross-pulling connection, and the steel column and the steel girder can be horizontally connected. The vertical connecting bolt penetrates through a steel girder flange slab, a reinforced steel plate and a horizontal steel plate so that the upper reinforcing connecting piece and the lower reinforcing connecting piece can be in cross-pulling connection, and the steel column and the steel girder can be vertically connected. The connecting positioning pieces and the reinforcing connecting pieces are arranged at the module connection joint, horizontal connectionbetween modules at the same layer and vertical connection between layers can be achieved through bolt connection, the stress is reasonable, the girder and column joint integrity is better, the rigidity at the joint is larger, the design idea for 'strong-joint and weak-component' is realized, on-site assembling operation is facilitated, the requirement for structural design of permanent multi-layer or high-rise box type integration modularization buildings can be met, the joint design is simple and feasible, efficient production is facilitated, and efficient assembling can be achieved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

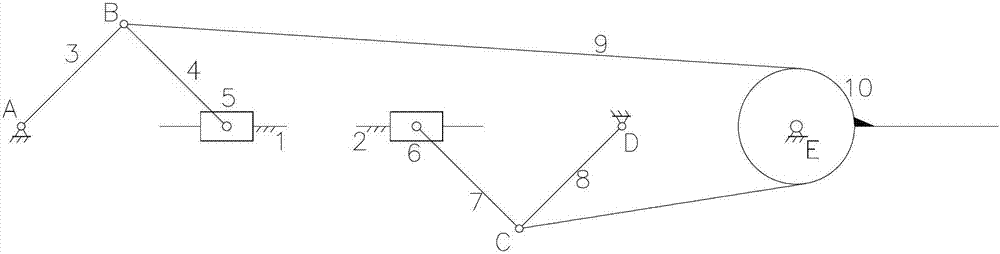

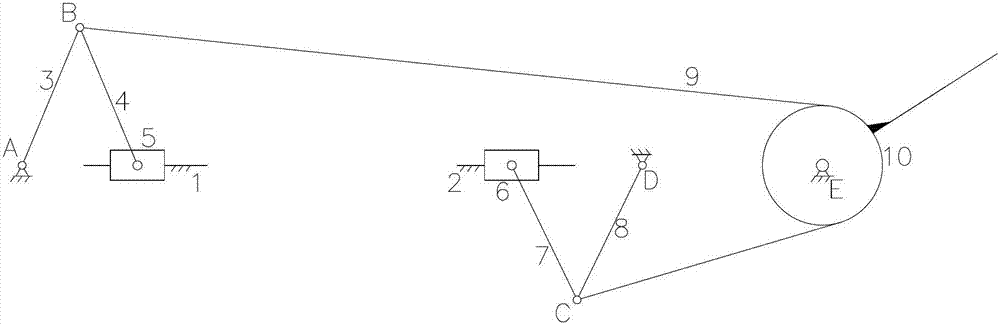

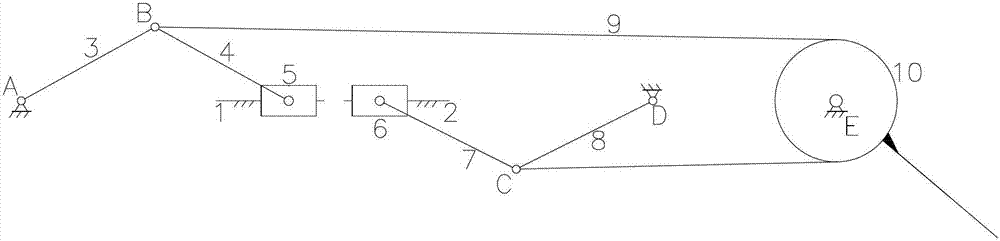

Muscle driving simulation robot joint

The invention discloses a muscle driving simulation robot joint, which belongs to the technical field of the biomimetic robot joint. The invention particularly relates to the muscle driving simulation robot joint which consists of a double-crank sliding block mechanism and is similar to the human muscle confrontation driving characteristic. The muscle driving simulation robot joint has the advantages of flexible action, big working space and simple structure and can be used for simulating the human muscle rigidity nonlinear driving. The muscle driving simulation robot joint comprises a rear crank sliding block mechanism, a front crank sliding block mechanism and a fixed pulley, wherein the rear crank sliding block mechanism and the front crank sliding block mechanism are respectively provided with a fixedly-connected linear guide rail for a rack; the fixedly-connected linear guide rail for the rack is provided with a sliding block; the sliding block is connected with one end of a connecting rod; the rotating center of the rack is provided with the first end of a fixed shaft rotating crank; the other end of the connecting rod is connected with the tail end of the fixed shaft rotating crank; the rotating center of the fixed pulley is provided with the fixed pulley; the fixed pulley is provided with a soft rope; and two ends of the soft rope are respectively connected with the junction of a rear fixed shaft rotating crank and a rear connecting rod as well as the junction of a front fixed shaft rotating crank and a front connecting rod.

Owner:NORTHEASTERN UNIV

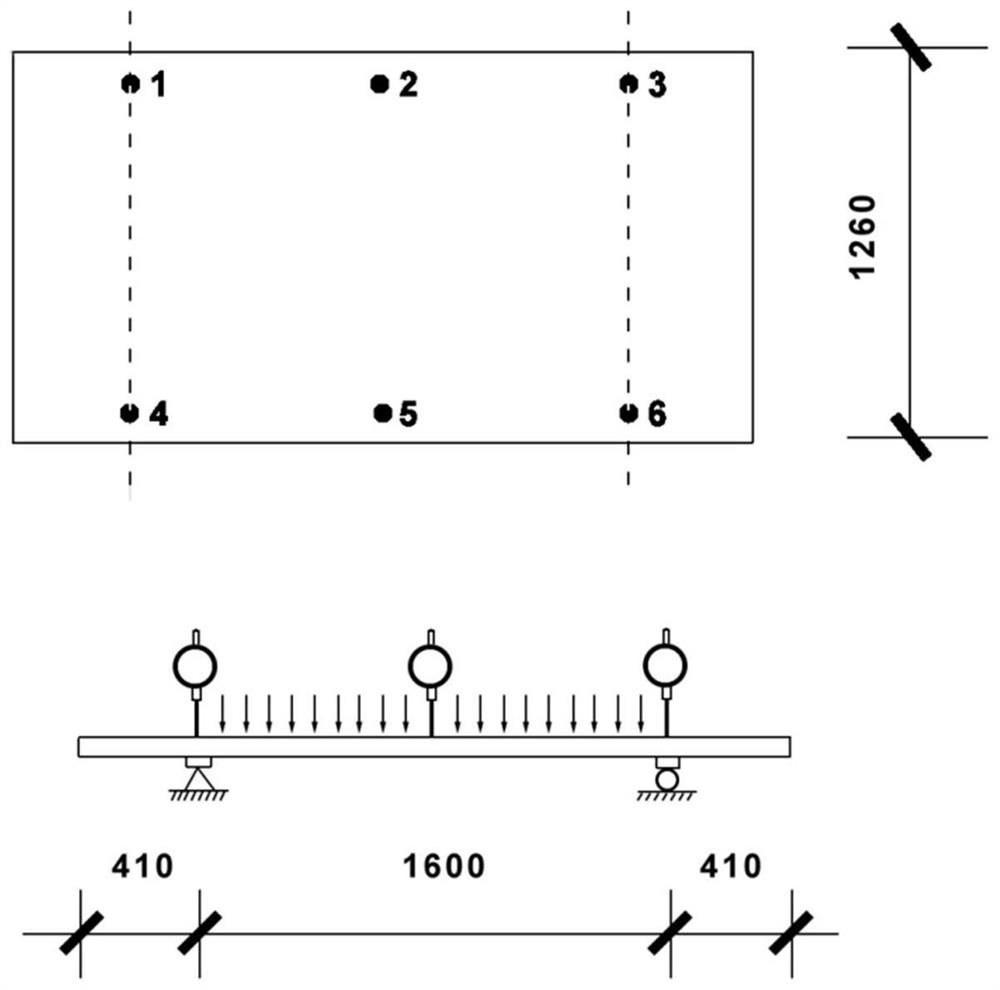

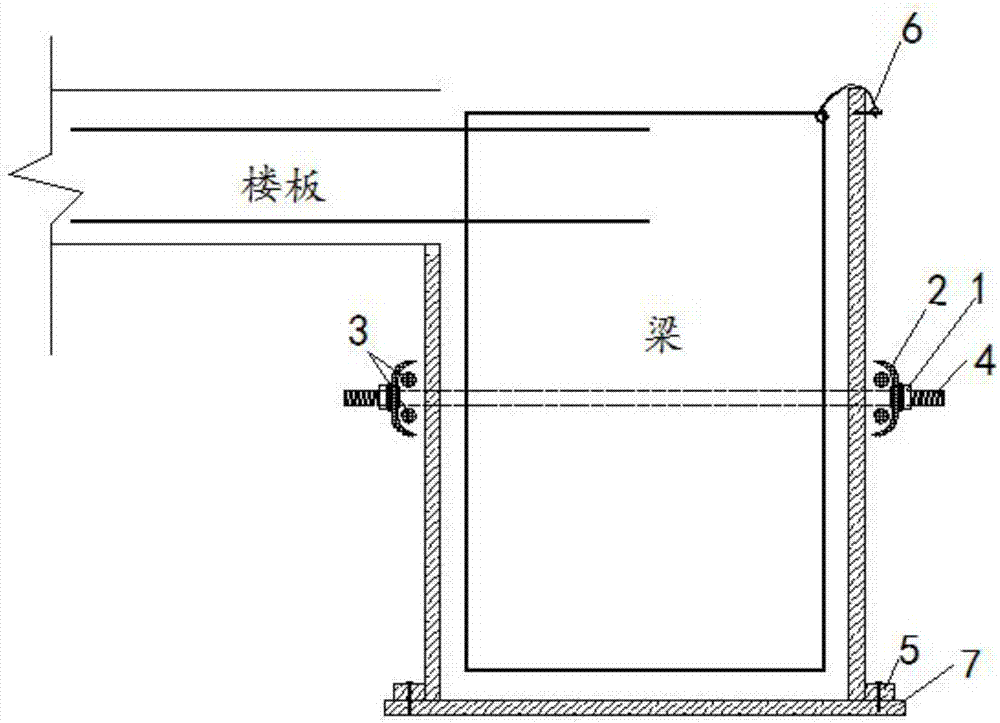

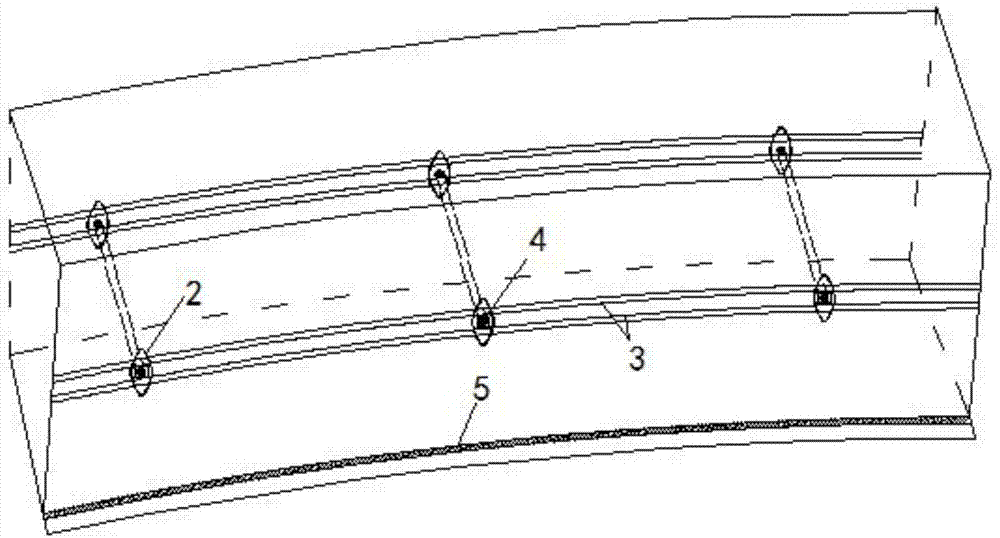

Upturned beam and cast-in-place slab overall pouring construction method

ActiveCN103883052AGood integrity and durability of the beam-slab structureMeet structural design requirementsFloorsForms/shuttering/falseworksSteel tubeRebar

Owner:SHANDONG GOLDENCITY CONSTR

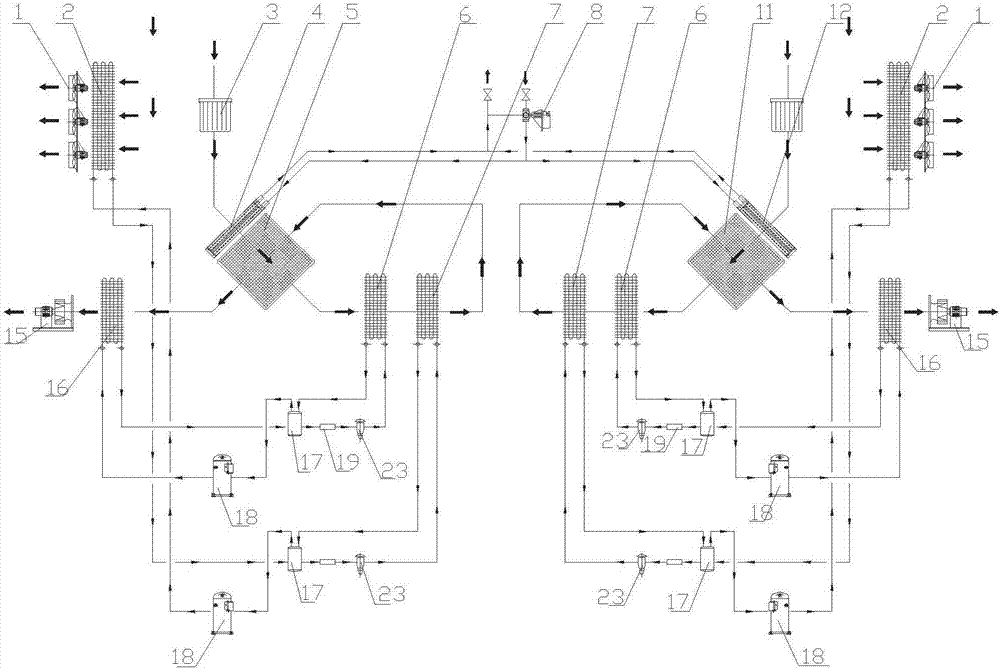

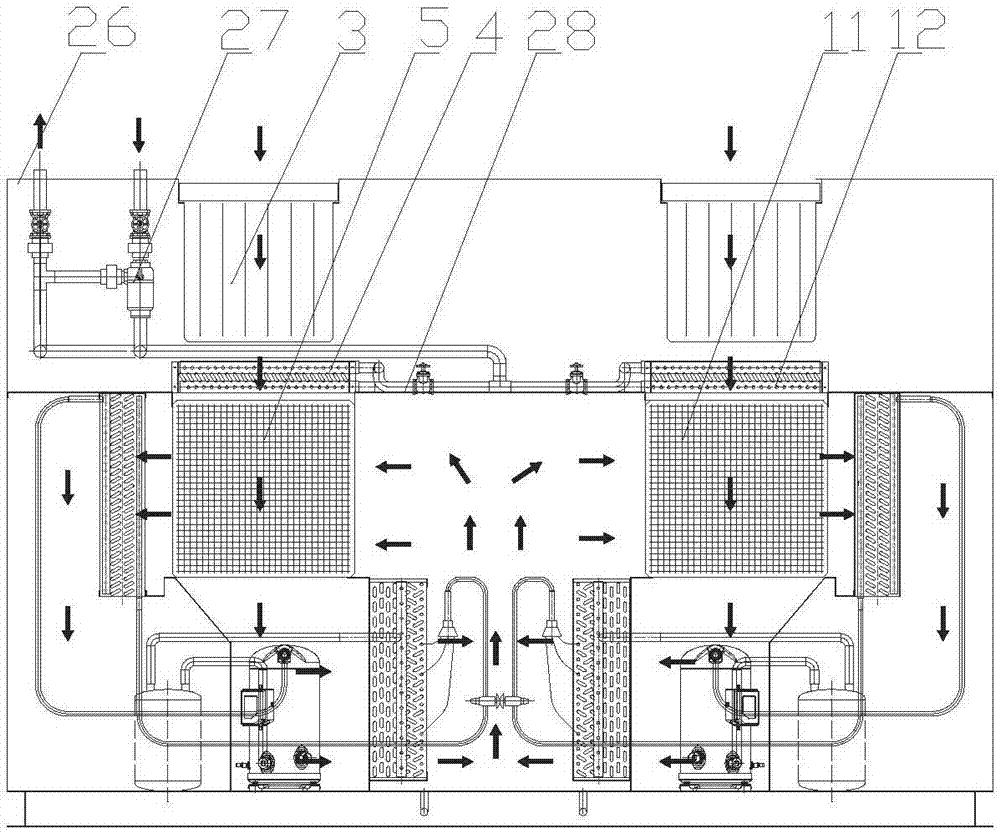

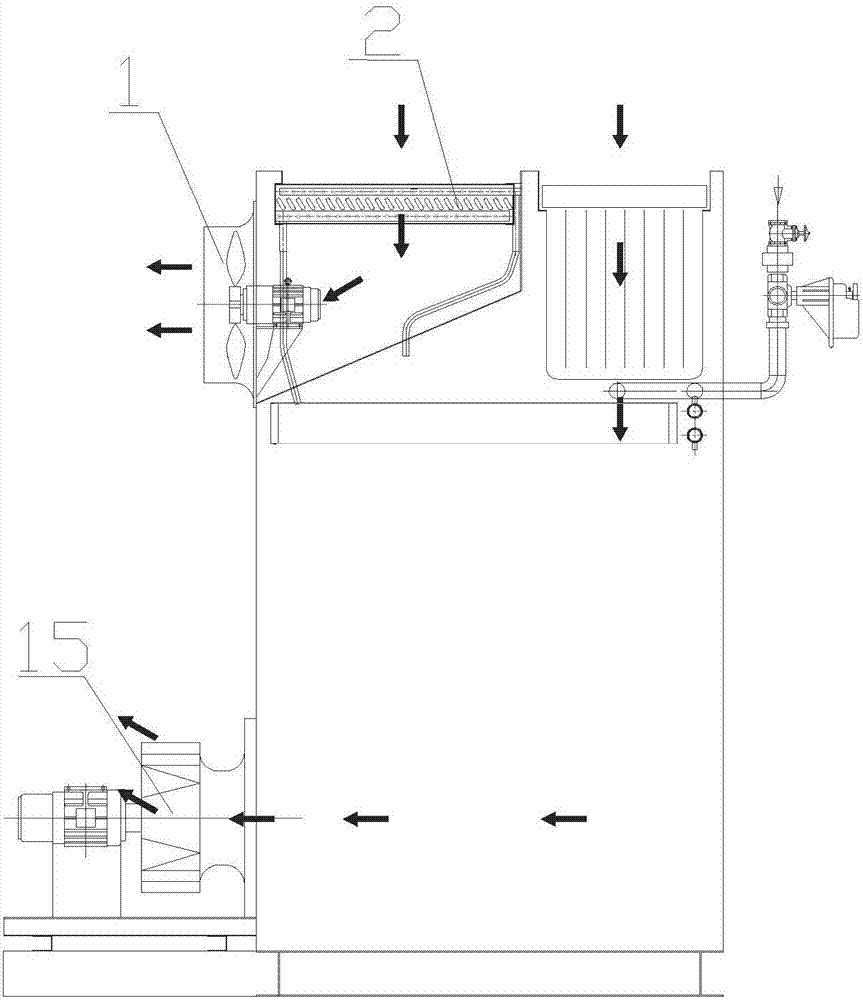

Temperature-adjustable four-effect drying system

ActiveCN107014198AShorten drying cycleAvoid it happening againSludge treatment by de-watering/drying/thickeningHeat recovery systemsSludgePulp and paper industry

The invention discloses a temperature-adjustable four-effect drying system. The temperature-adjustable four-effect drying system of an automatic temperature constant dehumidifying device comprises at least two dehumidifying heat pump assemblies and an auxiliary heat exchange assembly. Each dehumidifying heat pump assembly comprises at least one refrigerant module and an air module. The auxiliary heat exchange assembly is formed by connecting two heat exchangers in series through a circular pipeline. A refrigerant inlet and a refrigerant outlet are formed in the circular pipeline. The system has the following advantages that the dehumidifying amount can be increased by 10% or above, the closed drying process can be achieved, no peculiar smell is emitted in the sludge drying process, a deodorization device does not need to be mounted, the circular air amount and the dehumidifying air amount are designed separately, the sludge drying cycle can be shortened, dust caused by sludge drying is prevented, the structure design requirement of a sludge drying model can be met, meanwhile, the structure size of dehumidifying heat pump main bodies can be reduced, and the system is compact in structure and small in occupied area and maintaining space.

Owner:石曾矿

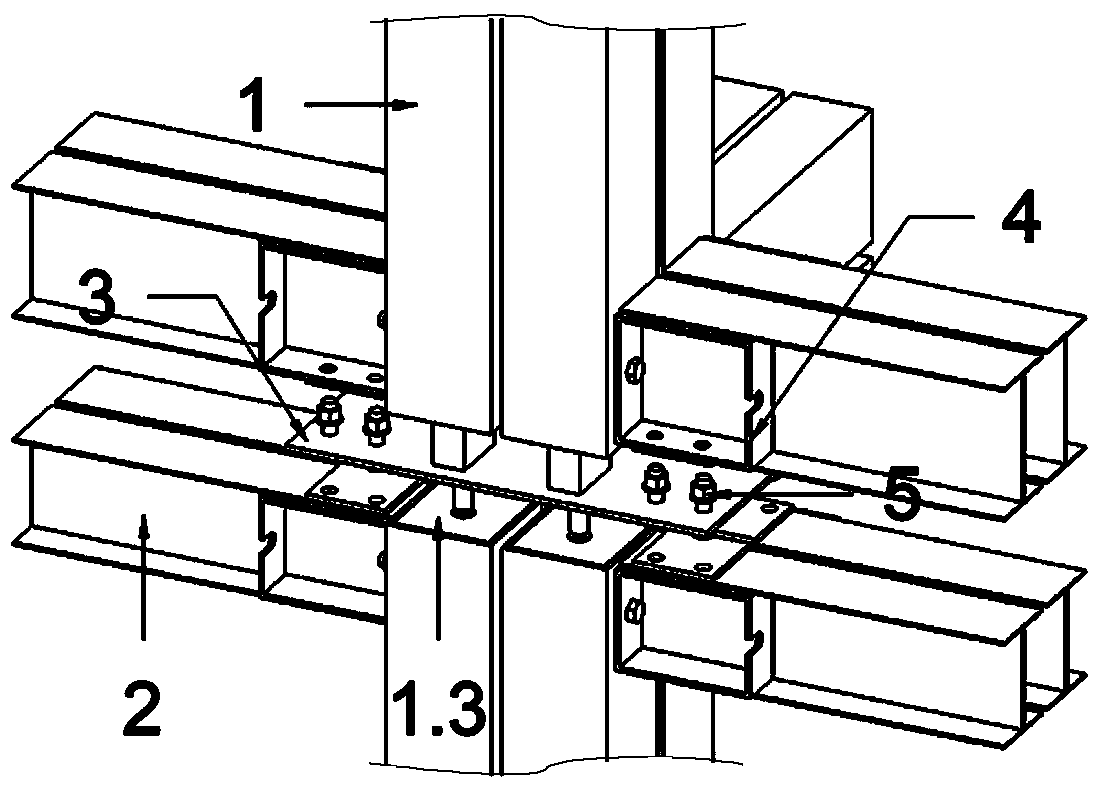

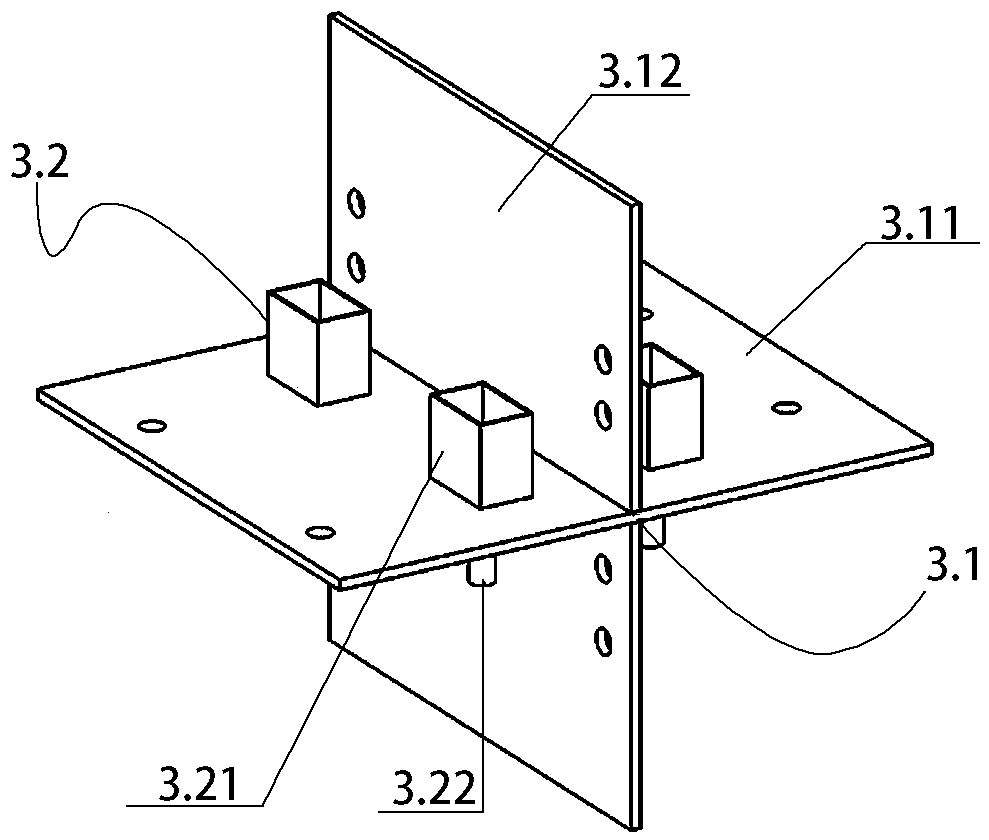

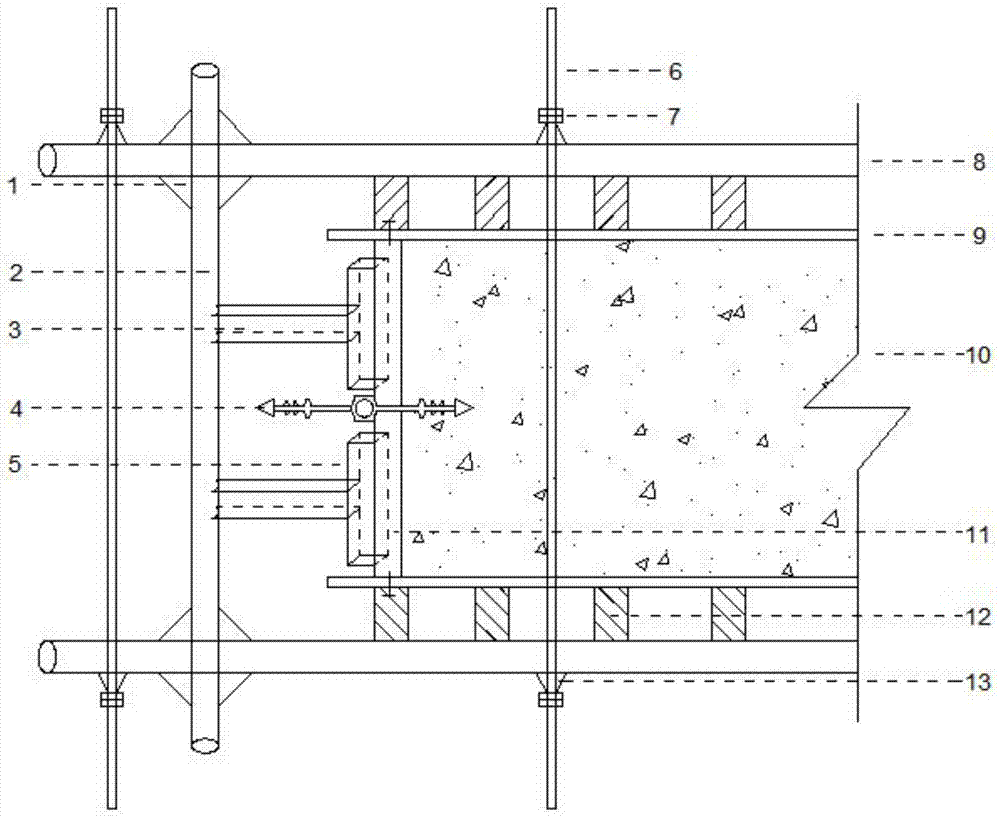

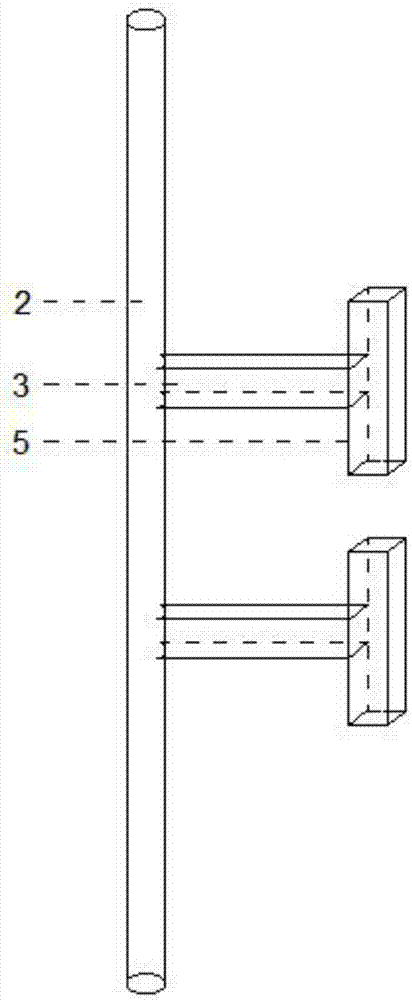

Box-type house permanent module beam-column joint with cross-shaped steel plate and installation method thereof

PendingCN110820936ASimple structureEasy to processBuilding constructionsStructural engineeringSteel columns

The invention provides a box-type house permanent module beam-column joint with a cross-shaped steel plate and an installation method of the box-type house permanent module beam-column joint with thecross-shaped steel plate. The box-type house permanent module beam-column joint with the cross-shaped steel plate comprises a steel column, a steel beam, a three-dimensional connection piece and connection bolts. The horizontal connection bolts enable the steel column and vertical plates of the three-dimensional connection piece to be fixedly connected, so that horizontal connection of the steel column is achieved. The vertical connection bolts penetrate through a steel beam flange plate, a stiffening steel plate and a horizontal plate of the cross-shaped steel plate, so that vertical connection of the steel column and the steel beam is achieved. According to the box-type house permanent module beam-column joint with the cross-shaped steel plate, the three-dimensional connection piece is arranged at the connection joint of modules, horizontal connection and layer-to-layer vertical connection between the modules on the same layer are achieved through bolts, stress is reasonable, the integrality of the beam-column joint is good, the rigidity at the joint is higher, the design concept of strong joints and weak components is achieved, on-site assembly operation is convenient, the structural design demand of a box-type house permanent module building can be met, design of the joint is easy and practicable, efficient production is convenient, and efficient assembly can be achieved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

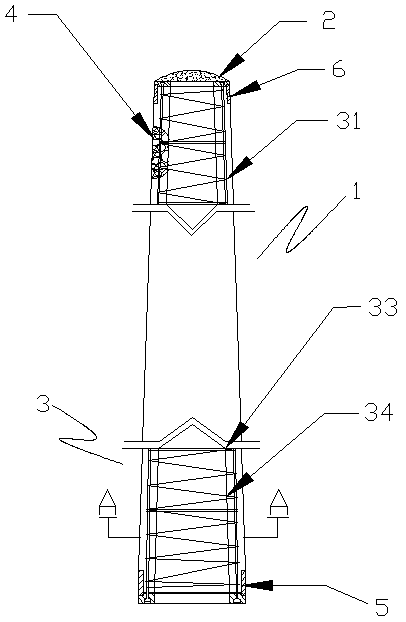

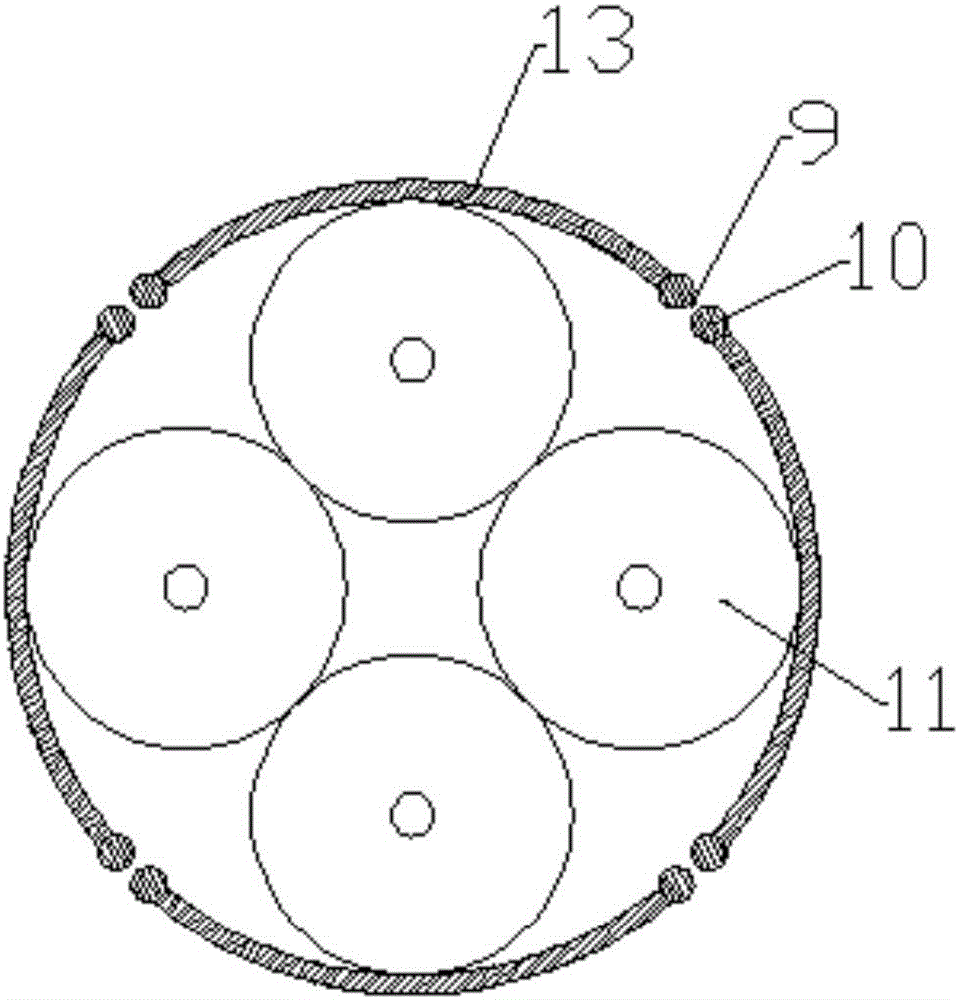

Value limiting stress concrete electric pole

InactiveCN107762239AScientific and reasonable designReinforcement is reasonableTowersRebarReinforced concrete

The invention belongs to the field of power conveying equipment, and particularly relates to a value limiting stress concrete electric pole. The value limiting stress concrete electric pole comprisesa reinforced concrete pole body, the cross section of the reinforced concrete pole body is an annular surface, the pole body is in a conical shape, the taper is 1 to 75, and the top end of the pole body is provided with a concrete top cover. The pole body comprises a steel bar skeleton and a concrete protective layer. The steel bar skeleton is wrapped with the concrete protective layer. The steelbar skeleton comprises main ribs, auxiliary ribs, an erection bar and a helical bar. According to the value limiting stress concrete electric pole, the main bars and the auxiliary bars adopt PC steelplates, by applying different stress, the comprehensive performance of the electric pole is improved, steel materials are saved, and the production efficiency is improved.

Owner:广东永基电力器材厂有限公司

Construction process of H-shaped steel concrete transfer beam-reinforced concrete column joint

InactiveCN110924537AGuaranteed carrying capacityMeet structural design requirementsBuilding constructionsReinforced concrete columnClassical mechanics

The invention relates to a construction process of an H-shaped steel concrete transfer beam-reinforced concrete column joint. The construction process comprises the following steps: (1) designing thejoint in a detailed manner; (2) processing, manufacturing and mounting steel ribs of a H-shaped steel concrete transfer beam; (3) welding and fixing beam side die reinforcing bolts and a steel beam web plate; (4) erecting a support frame body; (5) laying a beam bottom template; (6) installing beam bottom longitudinal steel bars ; (7) hoisting a steel beam; (8) mounting steel bars on the peripheryof the steel beam and welding draw hooks; (9) mounting concrete column reinforcing steel bars at the joints; (10) mounting and reinforcing a beam side form; (11) pouring concrete; (12) curing concrete. The construction process has the advantages that the problems of staggered arrangement and connection of column main reinforcements, stirrups and structural steel at the H-shaped steel concrete conversion beam-reinforced concrete column combined joint are effectively solved; the engineering quality and the joint bearing capacity are ensured; the structural design requirement is met; the construction process is simplified; and the construction efficiency is improved.

Owner:江林 +1

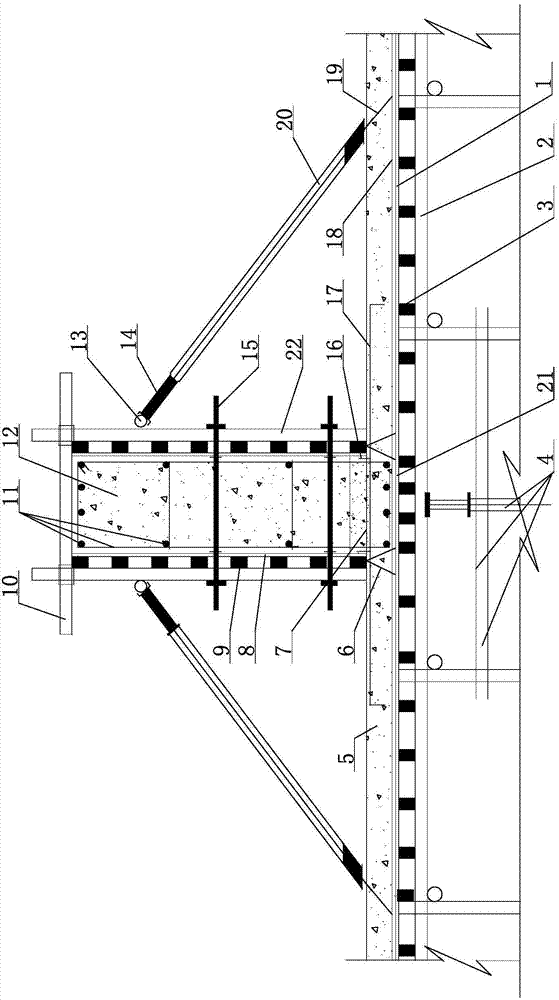

Method for reinforcing and constructing template of deformation joint of comprehensive pipe gallery structure

InactiveCN107975073AReduce misalignmentReduce mold expansionArtificial islandsUnderwater structuresKeelInstability

The invention discloses a method for reinforcing and constructing a template of a deformation joint of a comprehensive pipe gallery structure. The construction method comprises the following construction steps that firstly, template closing construction on the inner template and the outer template of the shear wall is performed, water stop screw rods are temporarily unfastened, and opposite-pulling water-stopping screw rod penetrates through the shear wall; then, middle-buried rubber water stop belt at the deformation joint of the shear wall is installed, the templates on the two sides of themiddle-buried type rubber water stop belt are plugged between the middle-buried water stop belt, the inner template and outer template, and the inner and outer opposite-pulling water-stopping screw rods are fastened; and finally, the lateral templates on the two sides of the middle-buried water stop belt are supported and reinforced by using a sizing steel supporting bracket, the sizing steel supporting bracket and a longitudinal steel pipe keel of the shear wall are connected into a whole, and the concrete lateral template reinforced at the deformation joint of the shear wall is completed. According to the method, a conventional wood square support is replaced by the sizing steel supporting bracket, the reinforcing supporting bracket at the deformation joint of the shear wall and the longitudinal steel pipe keel of the shear wall are ingeniously connected into a whole, the deformation, the deflection and the instability of the lateral support member are prevented, and concrete forming effect is good after being used for fixing the mounting process.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH +1

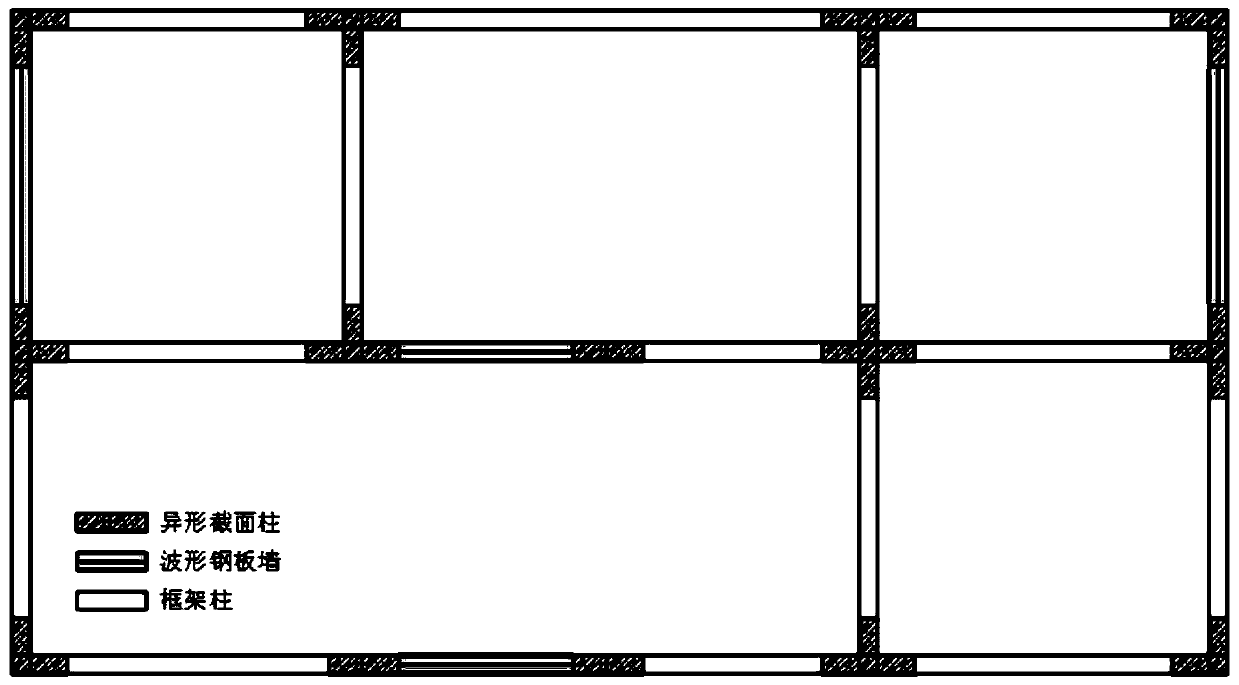

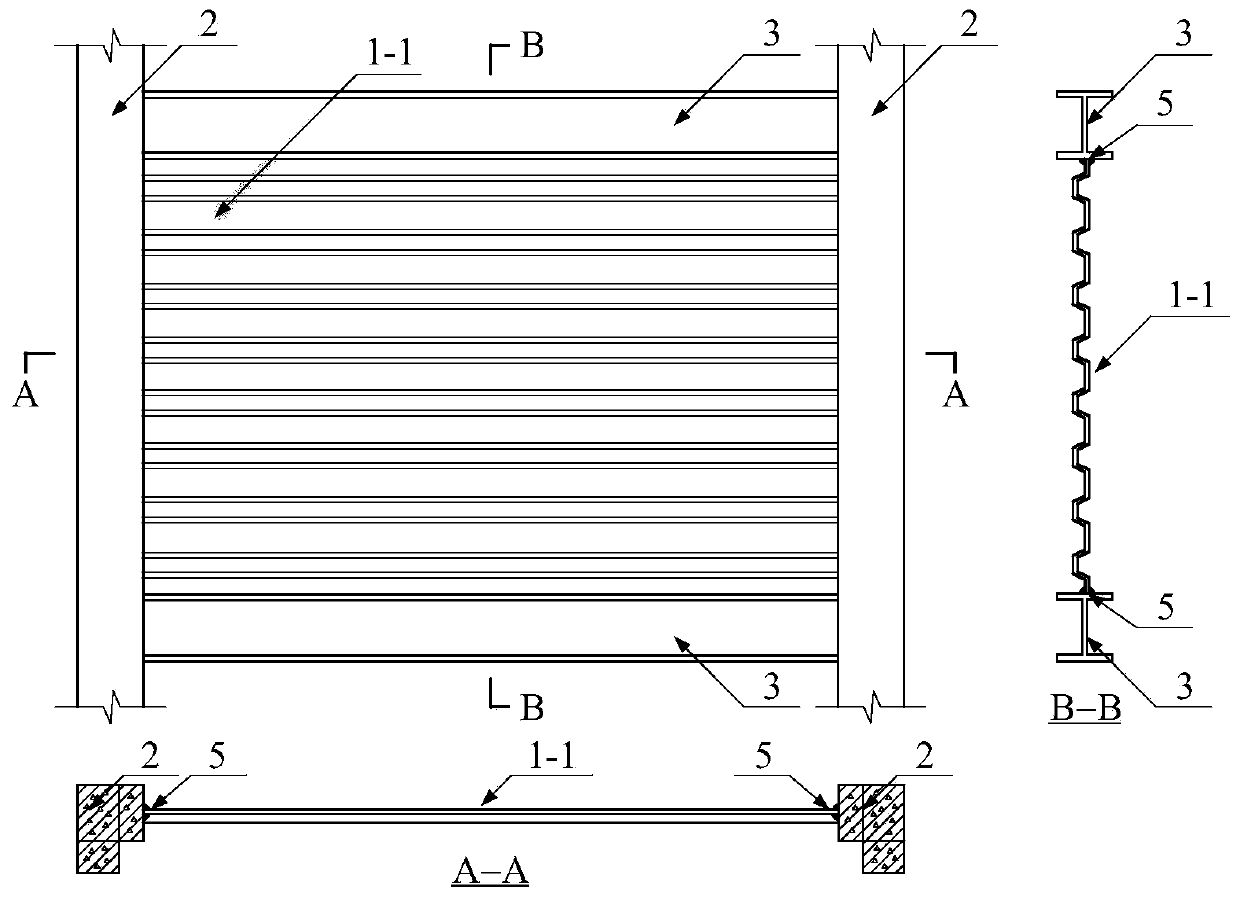

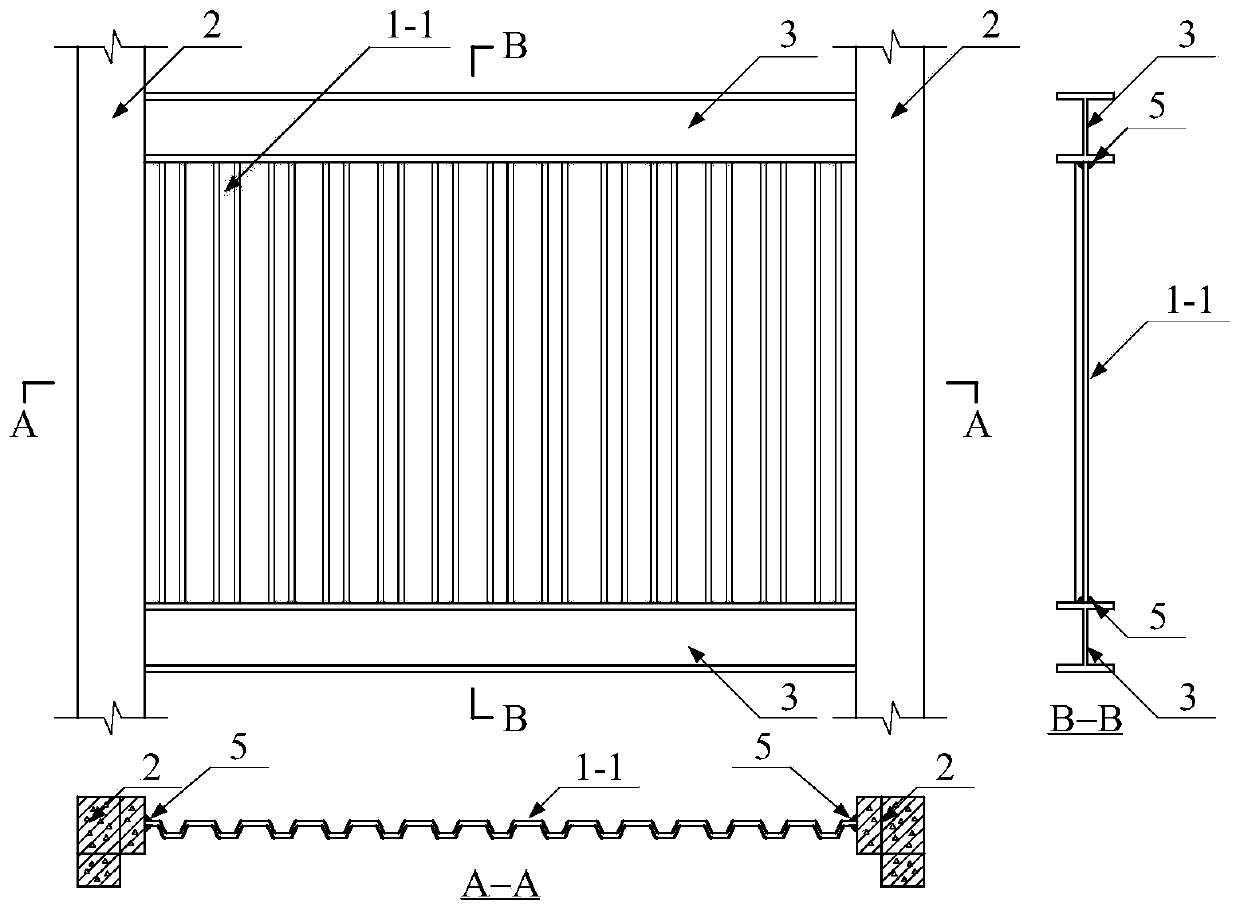

Structure system composed of special-shaped cross section column frame and corrugated sheet steel wall

PendingCN111188433AMeet the requirements of flexible layoutOvercome the problem of exposed beams and exposed pillarsConstruction materialWallsSheet steelSteel columns

The invention relates to a structure system composed of a special-shaped cross section column frame and a corrugated sheet steel wall, and belongs to the technical field of structure engineering. Thespecial-shaped cross section column frame-corrugated sheet steel wall structure system is composed of the special-shaped cross section column frame and the corrugated sheet steel wall embedded in theframe. The special-shaped cross section column frame adopts L-shaped, T-shaped and cross-shaped special-shaped cross section steel columns and special-shaped cross section steel pipe concrete columns.The corrugated sheet steel wall adopts a single corrugated sheet steel wall, a stiffening corrugated sheet steel wall, a double corrugated sheet steel wall in a parallel buckle connection mode, and adouble corrugated sheet steel wall in an orthogonal buckle connection mode. The stiffening corrugated sheet steel wall is formed by arranging stiffening ribs such as angle steel or U-steel on a corrugated sheet steel. The structure system provided by the invention has the characteristics of being flexible in plane arrangement, good in building impression, small in steel use amount, good in bearing performance, convenient to transport and install and capable of achieving corrugated sheet steel bolt connection, and has great economic benefits by being applied to residential structures.

Owner:TSINGHUA UNIV

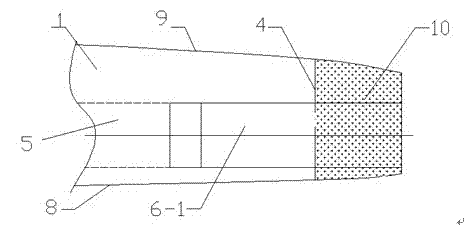

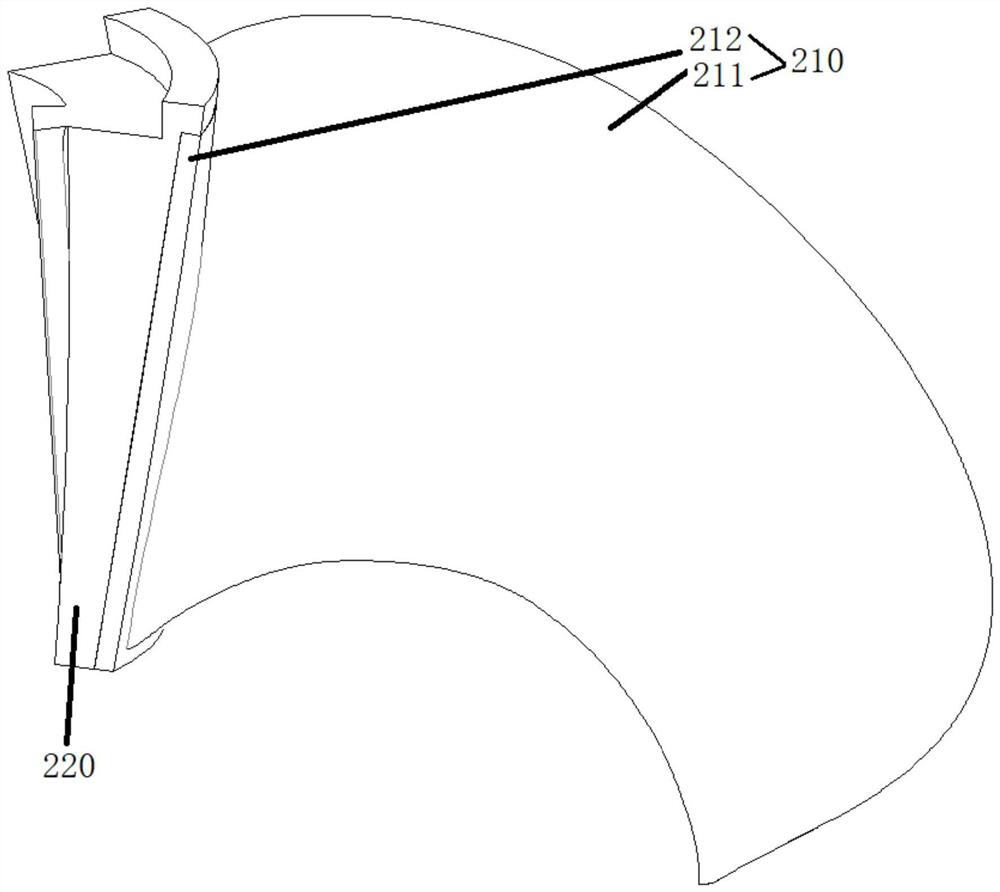

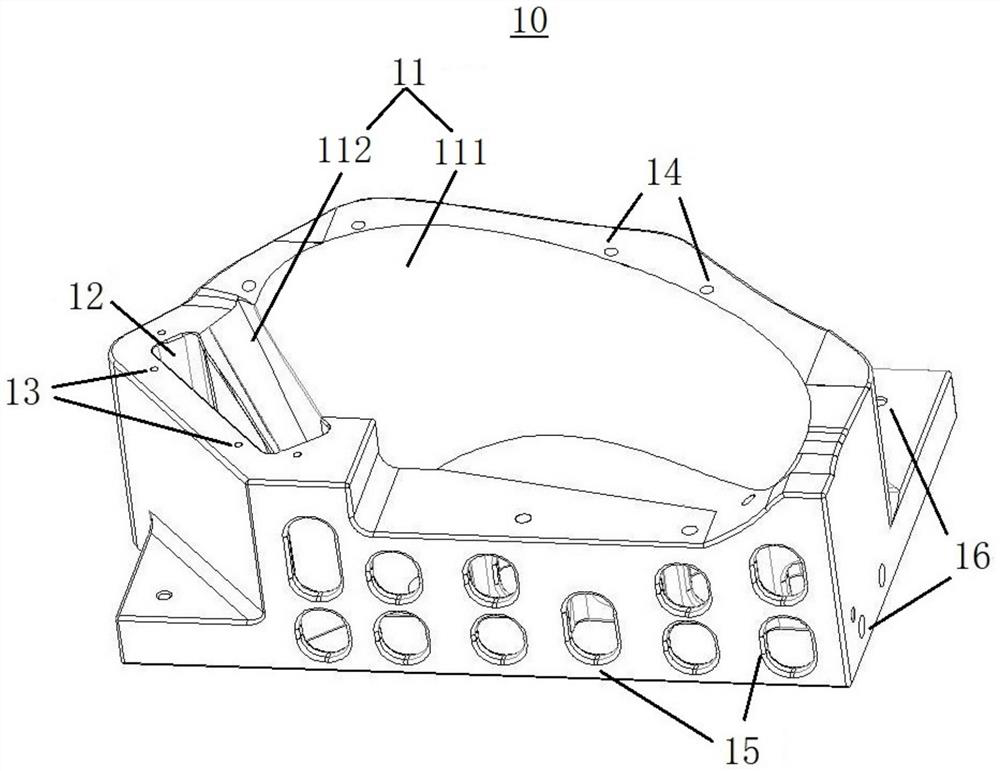

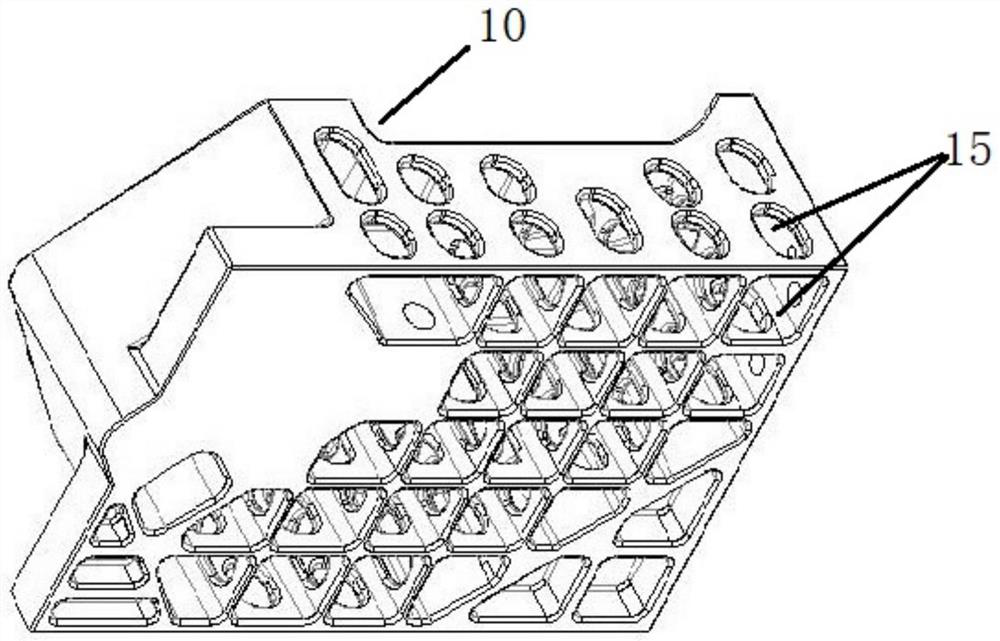

Hot-pressing tank forming mold and forming method for composite material blade of ship propeller

PendingCN114559680AGuaranteed tightnessGuaranteed accuracyDomestic articlesPropellerMaterials science

The invention relates to an autoclave forming die for a composite material blade of a ship propeller. The autoclave forming die comprises a main body die, a die loose piece and a die pressing plate, the main body mold is provided with a paddle cavity matched with a paddle profile value and a loose piece sliding groove matched with the mold loose piece, the paddle cavity comprises a blade cavity and a blade root cavity, the loose piece sliding groove is arranged close to the blade root cavity, and the mold loose piece is inserted into the loose piece sliding groove through an opening in the upper end of the loose piece sliding groove; the die loose piece is provided with a blade root mounting groove matched with the metal connecting piece, and an opening is formed in one side, facing the paddle cavity, of the die loose piece; the mold pressing plate covers an opening in the upper end of the movable block sliding groove, is fixedly connected with the main body mold and is used for applying pre-tightening pressure to enable a product to be closed in place; by additionally arranging the die base plate, the multi-time forming requirement of a large paddle can be met, and other paddles with similar structures can also be formed. The autoclave forming process of the large propeller composite material blade can be achieved, the high yield is guaranteed, meanwhile, the production efficiency can be improved, and the mold cost is reduced.

Owner:武汉海威船舶与海洋工程科技有限公司 +3

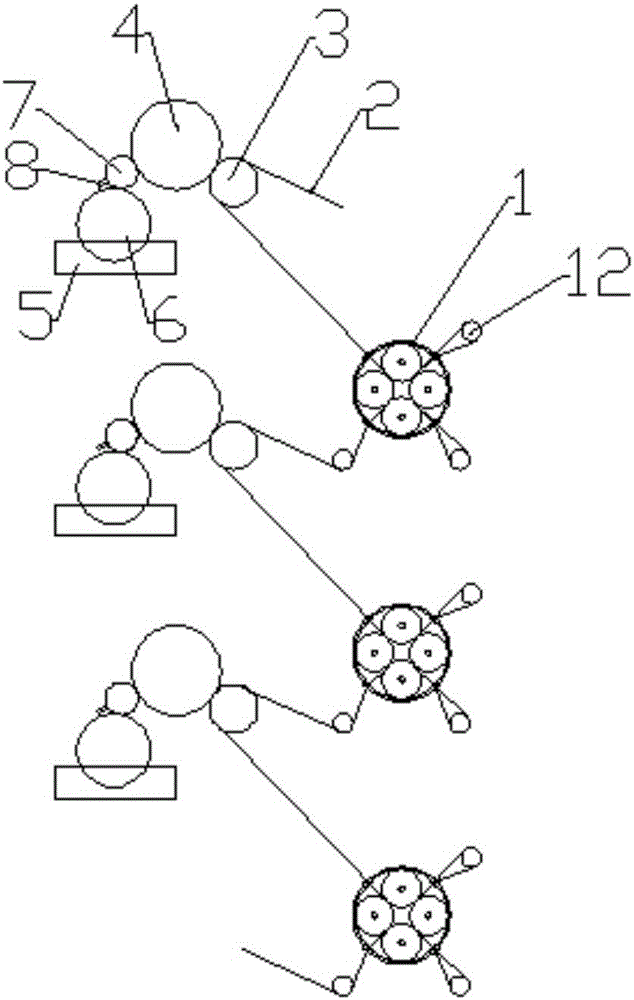

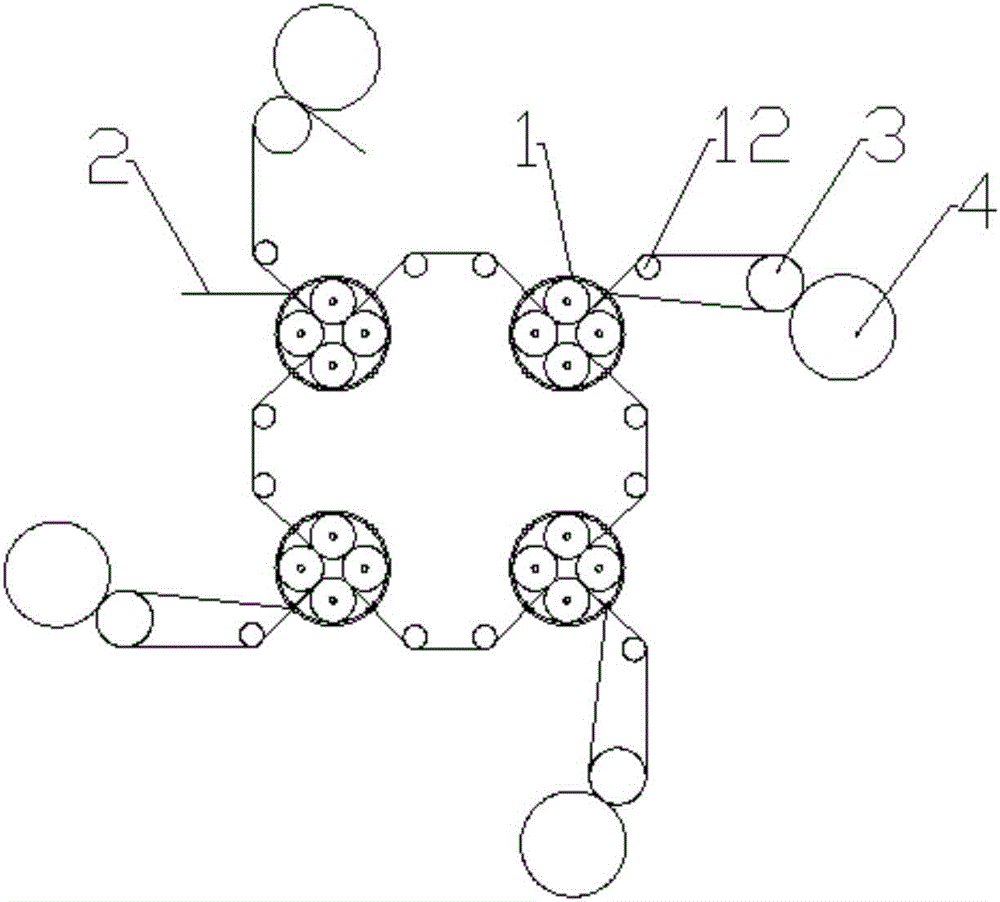

High-accuracy paper printing equipment

InactiveCN106476419AGuaranteed reasonablenessAvoid interactionPrinting press partsPulp and paper industryHumidity

The invention discloses high-accuracy paper printing equipment. The high-accuracy paper printing equipment comprises a plurality of constant-temperature moisturizing boxes, printing components and printing paper, wherein each constant-temperature moisturizing box is of a cylindrical structure, and mainly comprises a housing and a plurality of rolling shafts which are uniformly distributed in the housing; a plurality of through grooves are arranged in the sidewall of the housing along a central axis direction, and a cylindrical bar is arranged on the sidewalls of the two ends of each through groove along the central axis direction of the housing respectively; each printing component comprises an impression roller, a printing plate roller, an ink container, an ink foundation roll, an anilox roll and a scraping plate which are arranged outside the corresponding constant-temperature moisturizing box; and the printing paper is provided with an input end, and the middle part is sequentially wound on the rolling shafts, guide rods and the impression rollers. According to the high-accuracy paper printing equipment disclosed by the invention, constant-temperature moisturizing devices are additionally arranged in traditional printing equipment and used for adjusting the temperature and humidity of the surface of the paper in a short time, thus achieving an accuracy requirement of printing.

Owner:马飞

Industrial solid waste concrete for prefabricated member, preparation method and application thereof

The invention relates to industrial solid waste concrete for a prefabricated member, a preparation method and application thereof. The industrial solid waste concrete for the prefabricated member comprises the following raw materials in parts by weight: 220-280 parts of cement, 90-200 parts of a composite admixture, 740-790 parts of fine aggregate, 1070-1130 parts of coarse aggregate, 7.5-8 partsof an additive and 140-160 parts of water, wherein the composite admixture comprises fly ash, steel slag, regenerated powder and desulfurized gypsum in a weight ratio of (16-35):(5-10):(2-4):(0.5-1).According to the industrial solid waste concrete for the prefabricated member, on the premise that the using performance requirement of the concrete for the prefabricated member is met, large-mixing-amount multi-element multi-scale industrial solid waste is adopted, and the solid waste concrete for the prefabricated member, which is prepared in an economical, environment-friendly and industrial production mode, is developed.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277BImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:SHANGHAI H-RISE NEW ENERGY TECH CO LTD

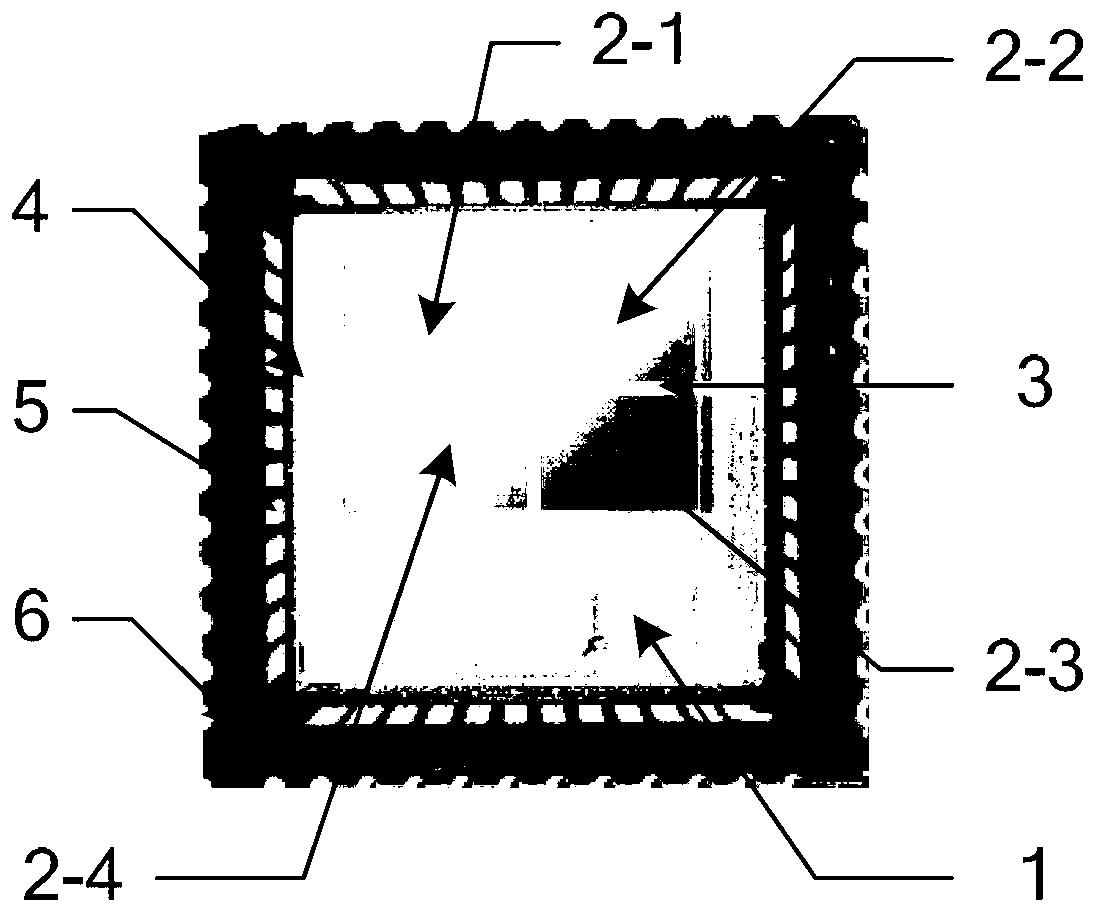

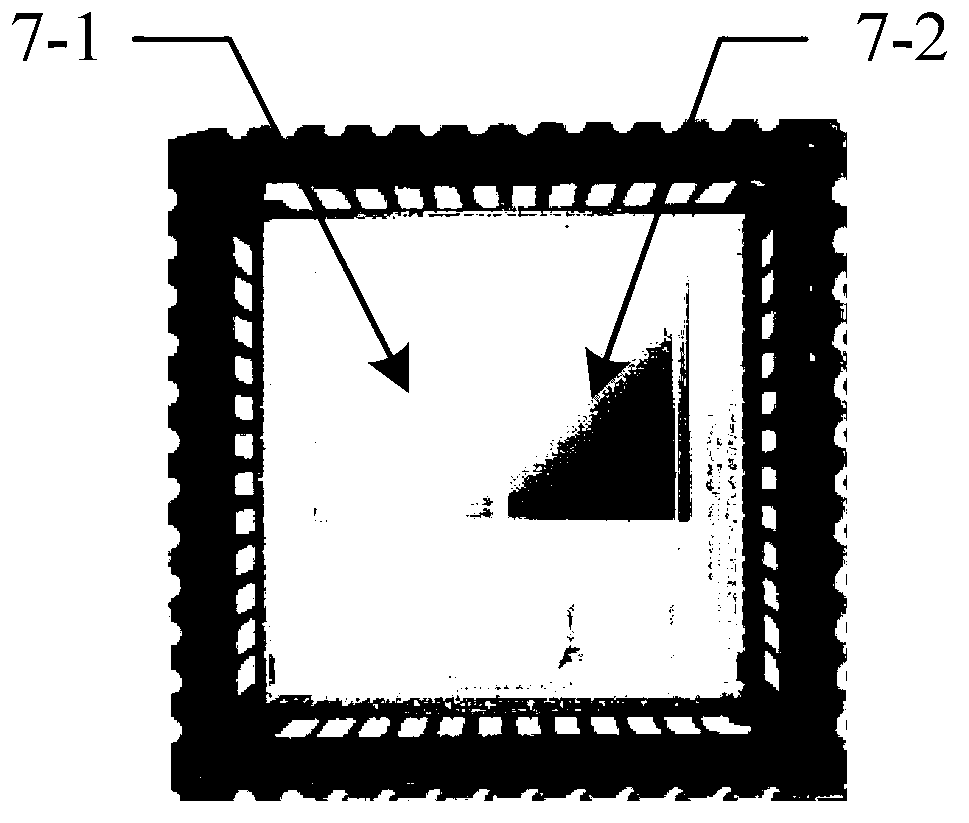

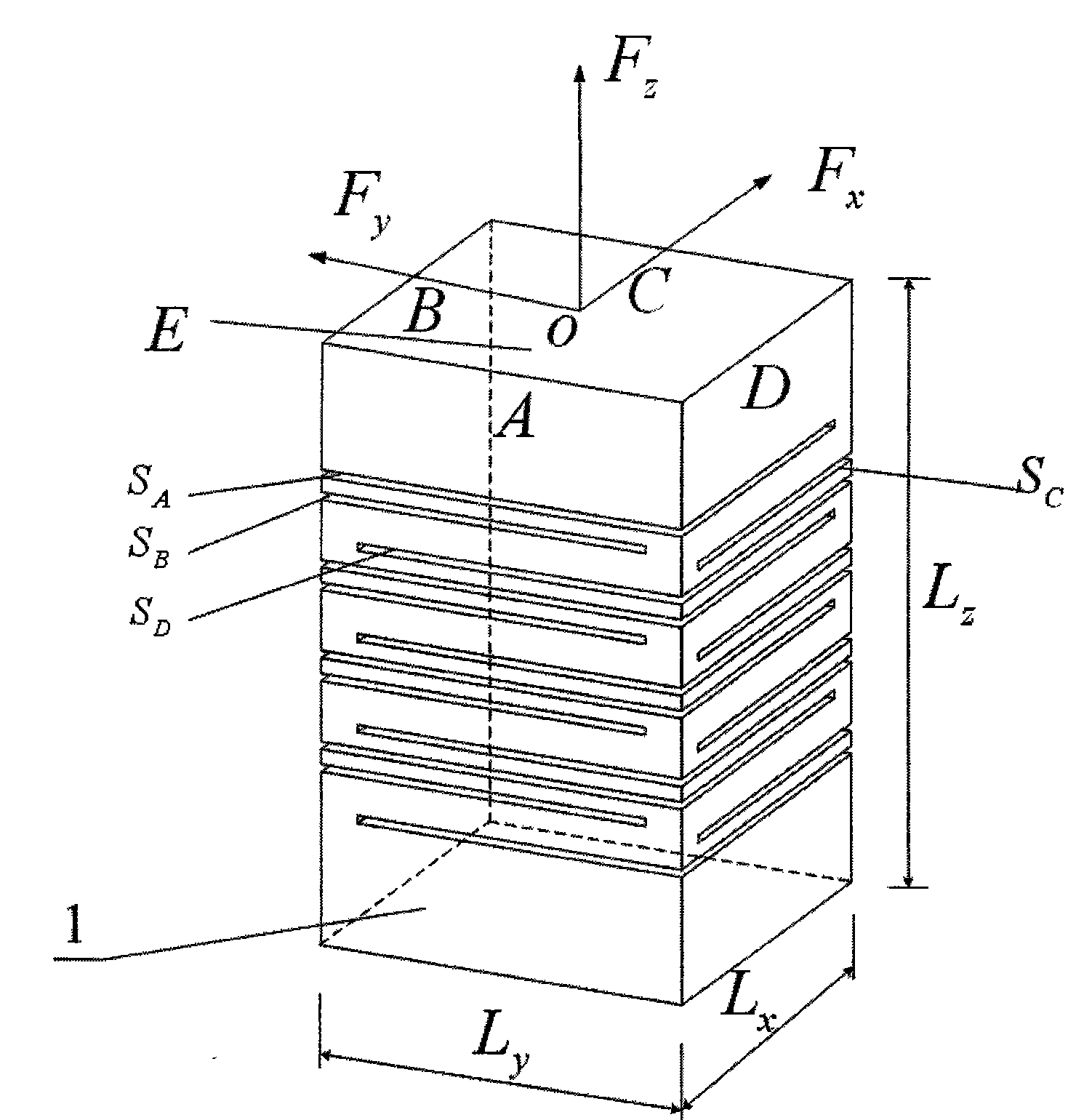

Three-dimensional force sensor

InactiveCN101571433BEnables 3D force testingSimple structureForce measurementElectrical resistance and conductanceLeg type

The invention relates to a three-dimensional force sensor, which belongs to the technical field of sensors. The main body of the sensor has a rectangular structure, a quadrangular frustum pyramid structure or a parallelepiped structure; 4n horizontal cutting grooves are arranged on the main body of the sensor at equal intervals in turn along the vertical direction;, the lateral surfaces of the sensor corresponding to the notch cut surfaces of the horizontal cutting grooves from the first one to the 4nth one are arranged circularly in a clockwise mode or an anticlockwise mode; four continuous horizontal cutting grooves form a cutting unit; and n cutting units are formed; and strain foils are four same strain foils which are adhered to the four lateral surfaces of the rectangular structure,and each strain foil and a corresponding resistor form an independent Wheatstone bridge circuit. The three-dimensional force sensor has the characteristics of light weight, small volume, strong decoupling property, simple structure and the like. The three-dimensional force sensor can be applied to three-dimensional contact force detection of a human leg part of a microminiature leg-type robot, andcan be used as a component of a human leg structure of the microminiature leg-type robot.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

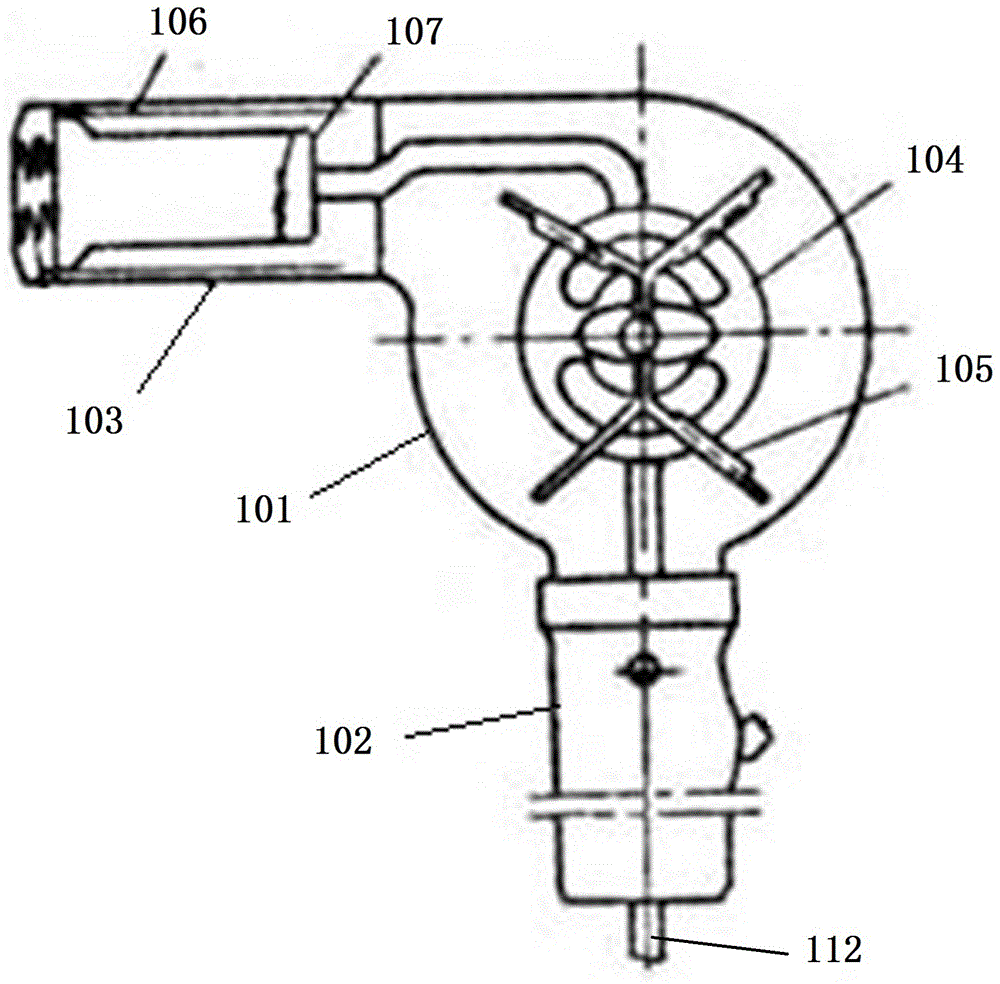

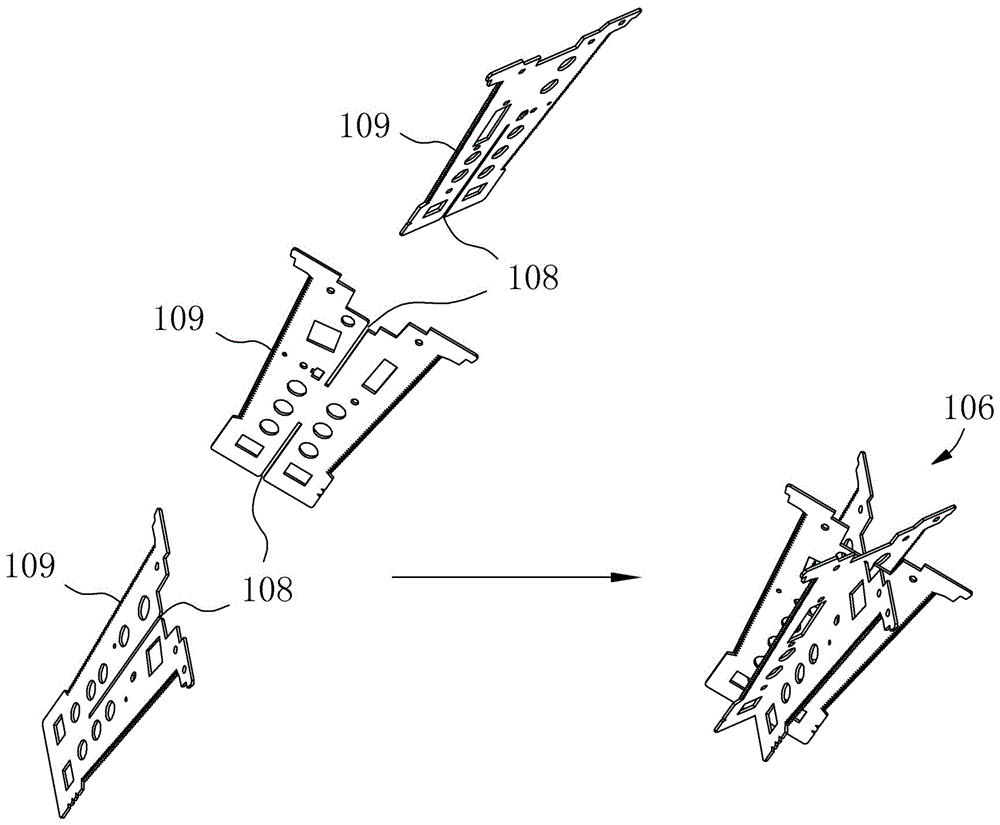

Storage type electric hair drier

The invention relates to a storage type electric hair drier. Main parts such as a motor and a heating wire are arranged in a main shell, an air duct is detachably installed on an air outlet of the main shell or the top of a handle, wherein the air duct is in a work state when installed on the air outlet of the main shell, a wire can be wound around a handle when the electric hair drier is stored, the air duct is detached from the air outlet and arranged outside the handle in a sleeving mode, the traditional air guiding function can be kept, the wire can be stored, the size of the hair drier is reduced fundamentally, and the space occupancy rate is reduced more thoroughly and effectively. Besides, multiple air ducts in different shapes can be arranged and can be selected according to use requirements to obtain different use effects, and diversity and applicability of the electric hair drier are improved.

Owner:PHOENIX ELECTRICAL APPLIANCE

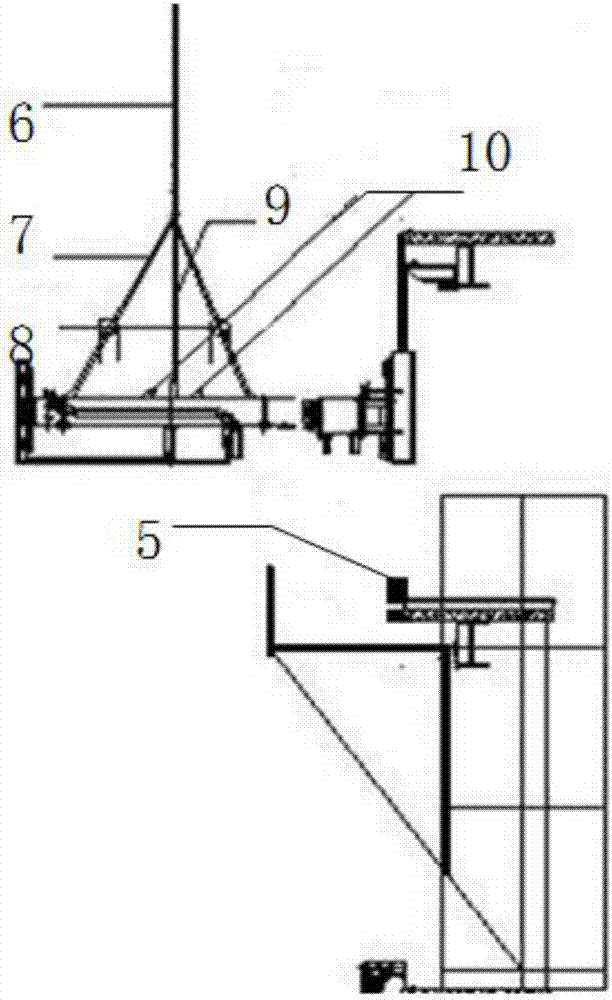

Construction method of high flying-wing segmental structure of curtain wall structure

ActiveCN106968371AMeet structural design requirementsImprove construction progressWallsSocial benefitsAluminium alloy

The invention discloses a construction method of a high flying-wing segmental structure of a curtain wall structure. The high flying-wing segmental structure of the curtain wall structure comprises flying-wing glass and a connecting body, the connecting body is of a steel structure, one end is used for being connected with an aluminum alloy glass groove of the flying-wing glass, and cushion blocks are arranged on the two sides of the flying-wing glass. A part of the structure extends outside by about 1 m only through erection, the large flying-wing and large suspension deep design of the curtain wall structure is combined closely with site construction conditions so that curtain wall structure design requirements can be met, meanwhile, the construction progress is speeded up, and significant economic and social benefits are achieved.

Owner:广州珠江监理咨询集团有限公司

Adhesive toe for gecko robot and movement method thereof

InactiveCN101890988BImprove adhesionSmall desorption forceVehiclesMechanical engineeringFuture of robotics

The invention relates to an adhesive toe for a gecko robot and a movement method thereof and belongs to the field of technical application of biomorphic robots. The toe comprises a flexible material toe base (c) and a sticky material layer (a) which is embedded into the flexible material toe base (c), wherein the height of the lower bottom surface of the sticky material layer (a) is equal to thatof the flexible material toe base (c); and a spring layer (b) is also formed on the flexible material toe base (c). The toe has three specific structures, namely flat-shaped, semi-arc and arched stereo structures with bending of 180 degrees. According to the characteristic of a special cantilever type structure, the driven mode is adopted, so that the characteristics that the toe has the larger adhesion in one direction and the smaller desorption force in the negative direction are provided, and the mechanical anisotropy characteristics that a gecko has the larger adhesion in the one direction and the smaller desorption force in the negative direction can be simulated fully and are applied to the gecko robot.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Construction method for releasing strong restraint stress of steel connecting rods of oblique and stiffened concrete structures

ActiveCN101881082ASpeed up the construction progressGood economic and social benefitsBuilding material handlingMaterials scienceSocial benefits

The invention relates to a building construction method, and discloses a construction method for releasing strong welded connection restraint stress of steel connecting rods on upper parts of two stiffened concrete structures which are oblique relatively. The construction method comprises the following steps: A, carrying out concrete pouring on floors and beams of the nth storey in one building; correspondingly setting after-cast section areas on which concrete pouring does not be carried out temporarily, at a place, which is required to be connected with a steel connecting rod, on nth storey in the other building, and constructing concrete pouring on the remaining floors and beams thereof; B, carrying out installation of steel connecting rods between nth floors of two oblique and stiffened concrete structures; and C, carrying out concrete pouring in the after-cast areas on the nth storey of the oblique and stiffened concrete structure of the other building after finishing installation of the steel connecting rods, completely cooling and fully releasing strong restrain stress. By adopting the construction technology of reasonably presetting the after-cast section areas, the invention enables the strong restrain stress generated by the steel connecting rods to be released successfully, enables the construction to meet structure design requirements, simultaneously, accelerates construction speed and achieves obvious economic benefits and social benefits.

Owner:广州珠江建设发展有限公司

Display panel and display equipment

InactiveCN113112927AMeet electrostatic discharge requirementsMeet structural design requirementsElectrostatic discharge protectionIdentification meansMechanical engineeringElectrostatic discharge

The embodiment of the invention provides a display panel and display equipment. The display panel comprises an electrostatic discharge layer, an electrostatic discharge connecting part and a composite functional film layer which are located on the same side of the electrostatic discharge layer, and a display substrate located on the side, away from the electrostatic discharge layer, of the composite functional film layer. A first accommodating space formed in the side, close to the display substrate, of the electrostatic discharge layer can accommodate at least part of the electrostatic discharge connecting part, and the display substrate is conducted with the electrostatic discharge layer through the electrostatic discharge connecting part, so that the conductive contact area between the display substrate and the electrostatic discharge layer can be increased; therefore, electrostatic charges gathered at the display substrate quickly and timely flow into the electrostatic discharge layer through the electrostatic discharge connecting part, so that the electrostatic discharge requirement of the display panel is met. An orthographic projection, on the electrostatic discharge layer, of the electrostatic discharge connecting part contained in the first accommodating space is located in the electrostatic discharge layer, so that the structure of the display panel does not need to be greatly adjusted, and the structural design requirement of the display panel can be met.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Steel-concrete with ultrahigh performance joint section and manufacturing method thereof

PendingCN108374318AImprove toughness and strengthHigh compressive strengthBridge erection/assemblyConcrete beamsBuilding construction

Owner:SOUTHWEST JIAOTONG UNIV

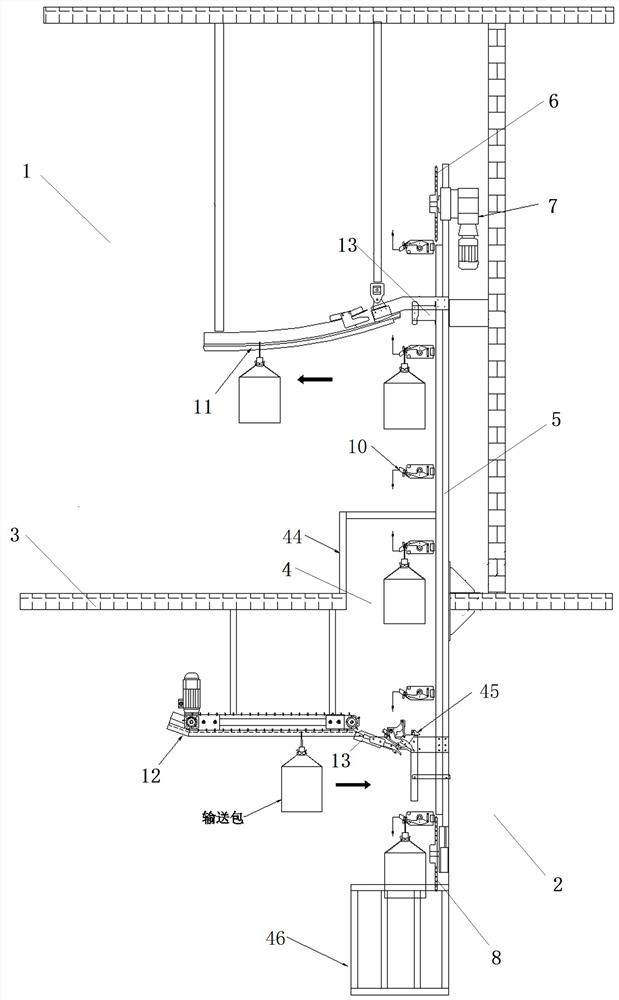

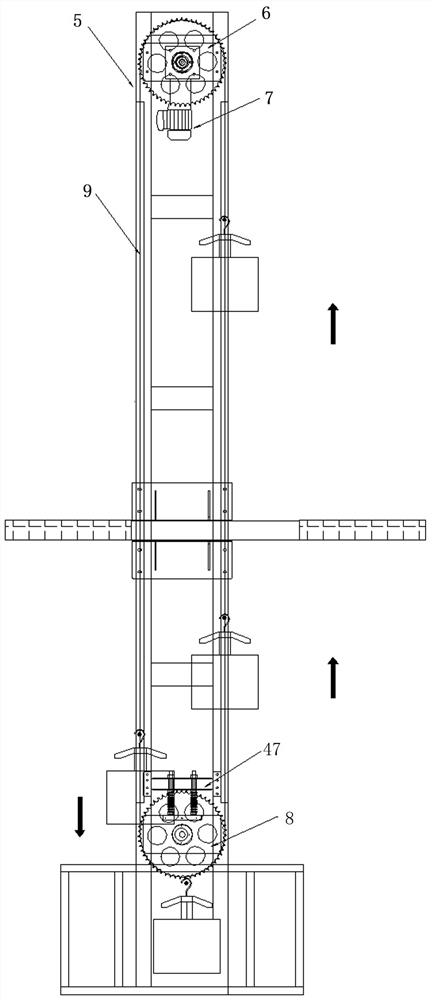

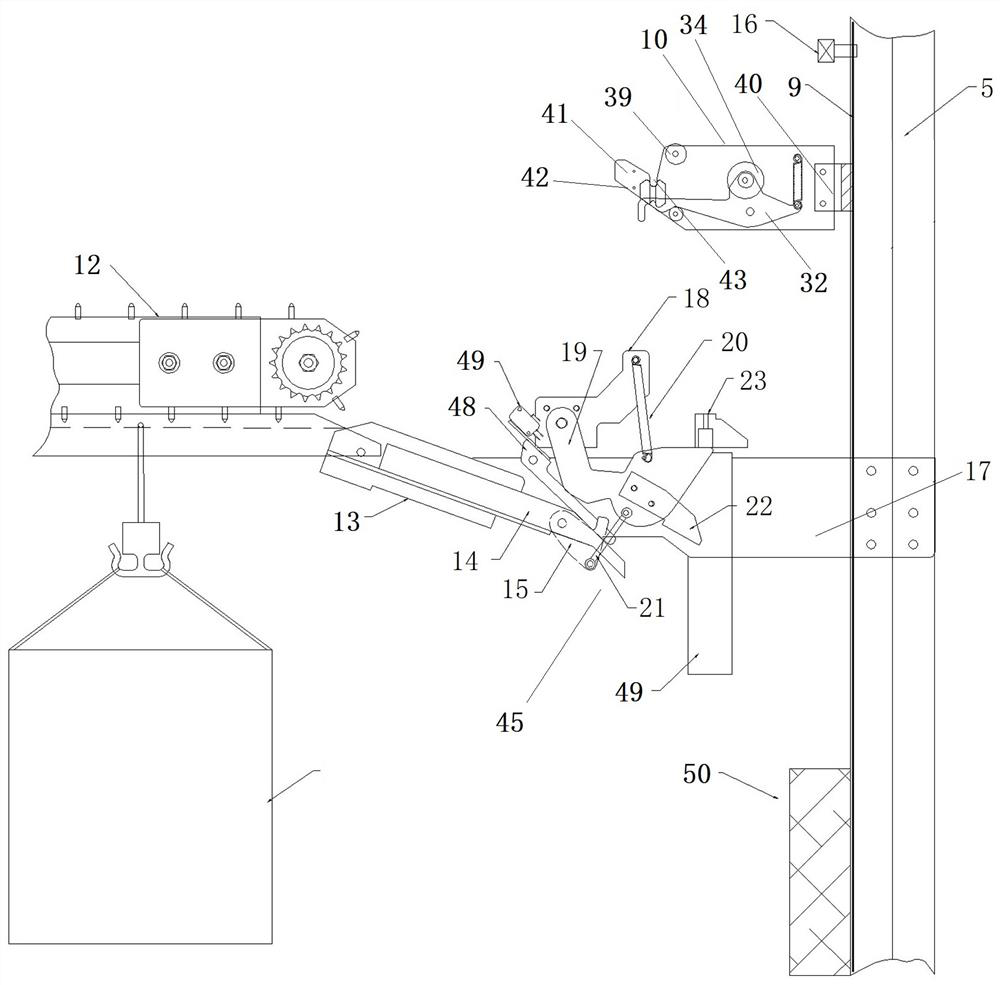

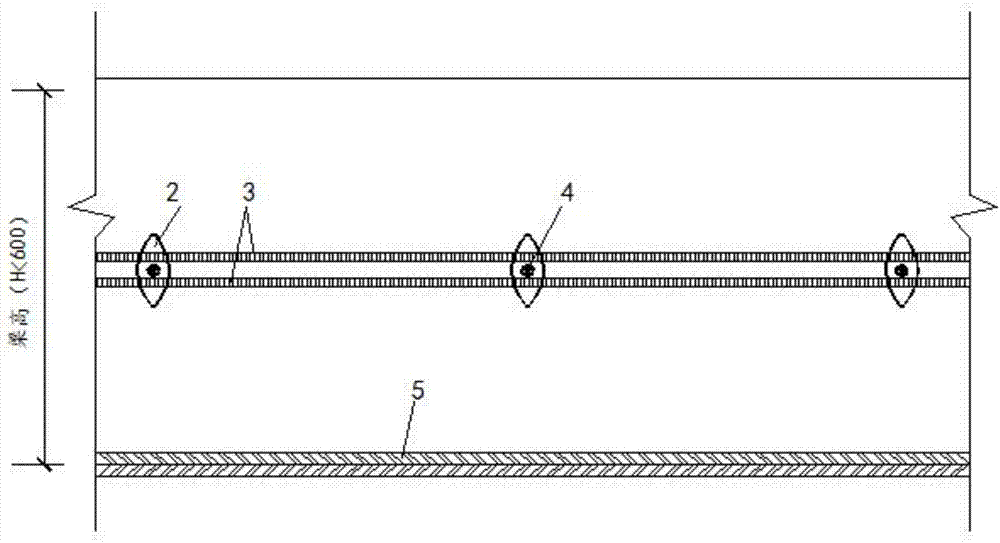

Chain circulation intelligent lifting and descending system

PendingCN114013925ARealize input and outputAvoid accumulationConveyorsConveyor partsGear wheelControl engineering

The invention discloses a chain circulation intelligent lifting and descending system which is characterized in that a driving gear is arranged at the upper end of a main machine support and driven by a driving motor, a driven gear is arranged at the lower end of the main machine support, a transmission chain is arranged between the driving gear and the driven gear, and a plurality of bagging frames are distributed at the transmission chain at equal intervals; output lines matched with the bagging frames are arranged in the upper-layer area, input lines matched with the bagging frames are arranged in the lower-layer area, a bag unloading device matched with the bagging frames is arranged on the upper-layer area section of the main machine support, and an automatic bagging mechanism matched with the input lines is arranged on the lower-layer area section of the main machine support. The system is suitable for a spring-layer vertical circulating conveying chain system; precise package loading and unloading are achieved through a mechanical linkage structure; input and output of goods are achieved through a simple mechanical linkage structure; and the system is good in practicability, small in occupied space, high in flexibility, low in maintenance cost, good in working stability and capable of effectively preventing package hanging frames from being stacked at transfer nodes.

Owner:SHANGHAI SANHE GARMENT LOGISTICS EQUIP MFG

Reinforcement method for arc-shaped formwork

The invention discloses a reinforcement method for an arc-shaped formwork. The reinforcement method for the arc-shaped formwork includes the following steps that firstly, the lower portion of the beam formwork is reinforced through formwork bars in an edge pressing mode; secondly, the middle portion of the beam formwork is reinforced preliminarily through tension screws, rebar fixing butterfly-shaped clamps and rebar outer keels; thirdly, the upper portion of the formwork is reinforced in the mode that iron wires are tied to beam rebars and fixedly tied to iron nails on the formwork; and finally, reinforcement of the arc-shaped formwork is completed by fixedly tightening nuts on the tension screws on the middle portion. The number of inner keel ordinary battens is reduced, and the structure design requirement can be met after reinforcement through the flexibility and anti-bending performance of the rebars, so that the rebar outer keels are better fixed. The specially made rebar fixing butterfly-shaped clamps are used to prevent movement during and after reinforcement. The concrete forming effect is good after the fixing and installing technology is used.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

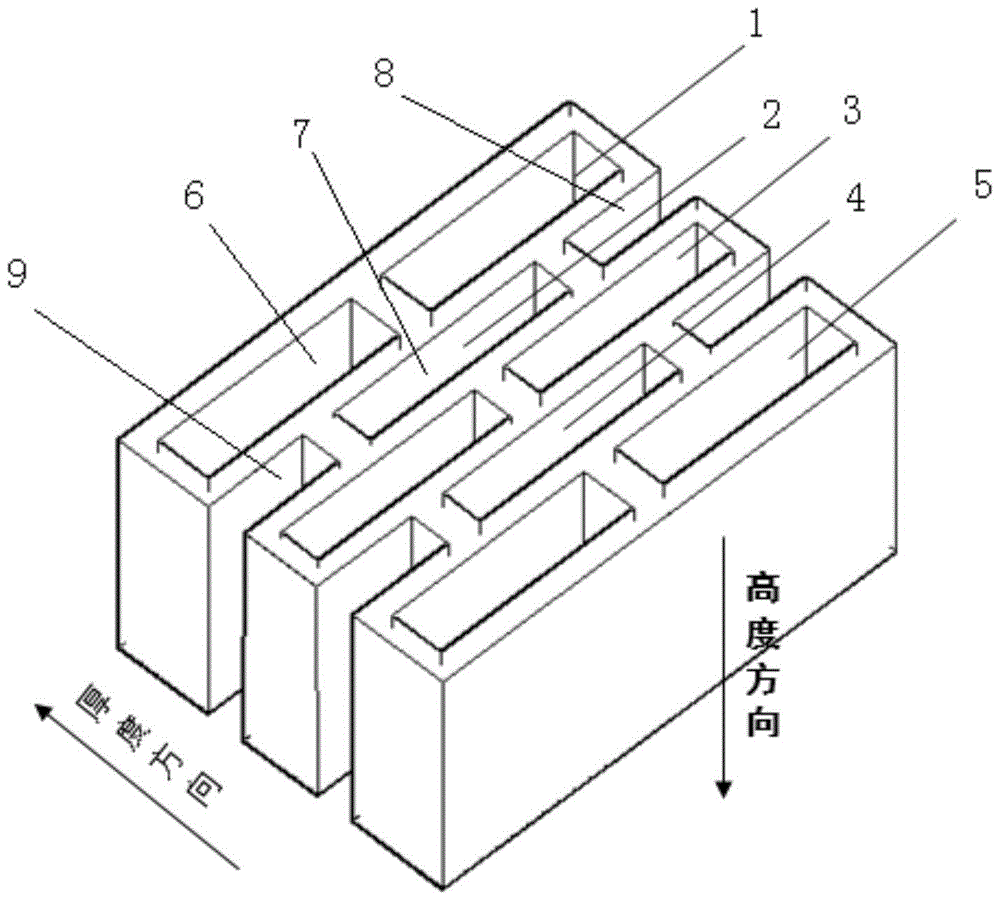

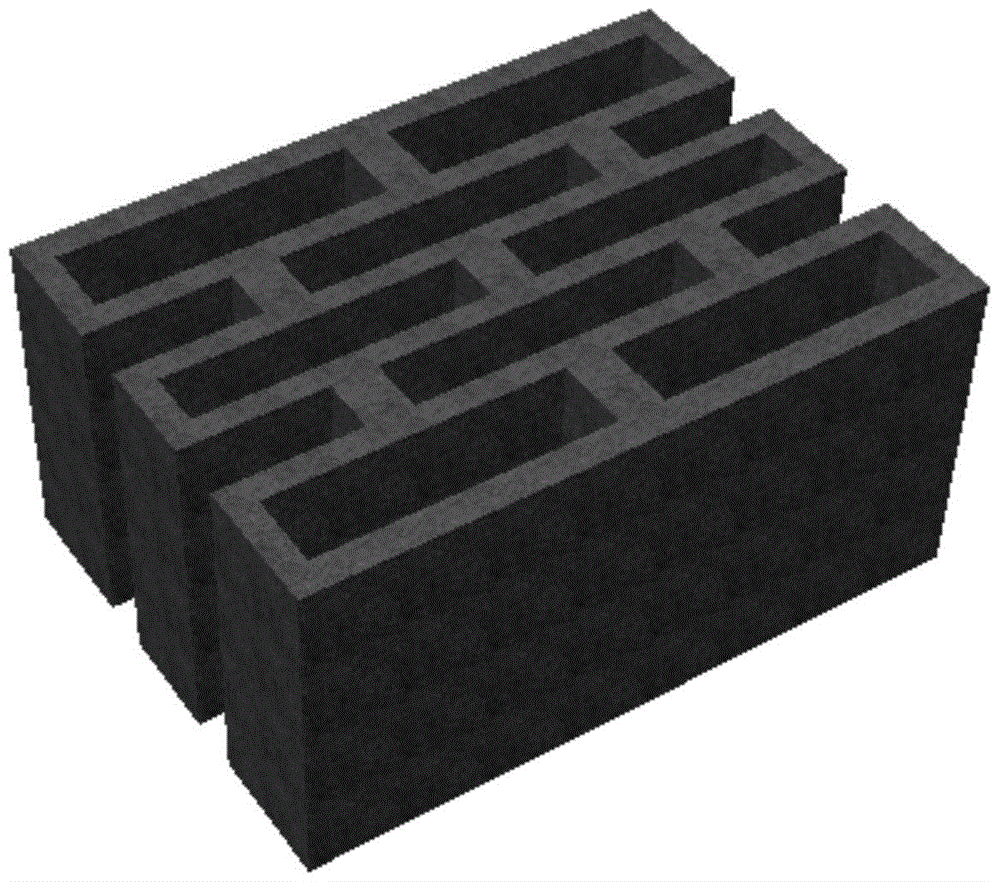

A high thermal resistance self-insulation block and its material formula

ActiveCN104594541BMeet building energy-saving requirementsGood self-insulation effectSolid waste managementBuilding componentsThermal insulationSlag

Owner:NANJING SHIHAO BUILDING ENERGY SAVING TECH

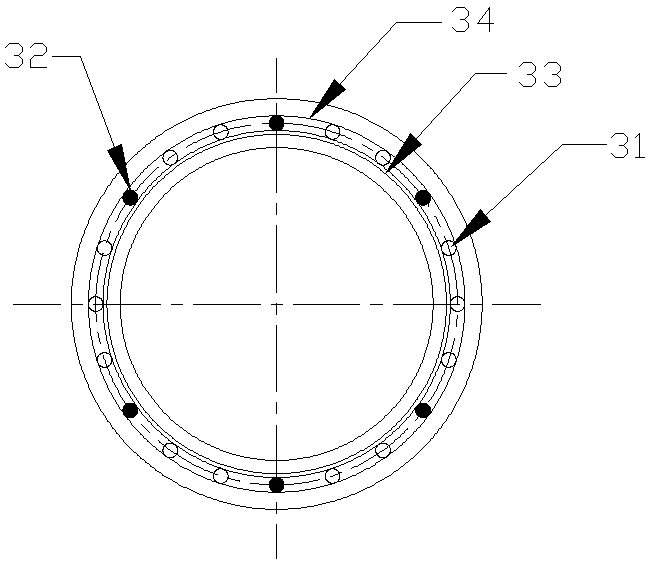

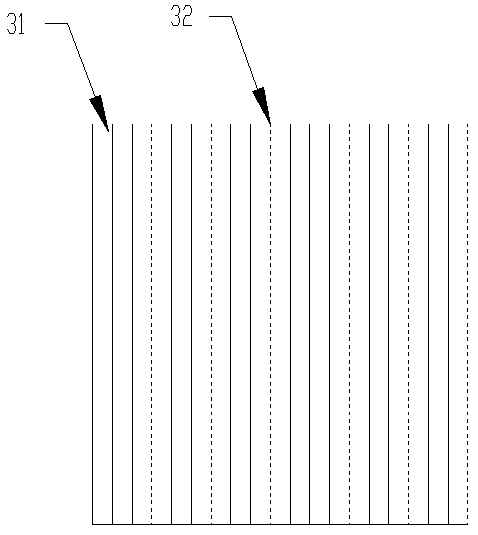

Design and debugging method of a special-shaped reference ring

ActiveCN111193559BSimplified commissioning stepsSimplify the calibration stepsTransmitters monitoringReceivers monitoringCapacitanceResonance

Owner:BEIJING JIAODA SIGNAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com