A high thermal resistance self-insulation block and its material formula

A technology of self-insulating blocks and high thermal resistance, applied in building components, sustainable waste treatment, solid waste management, etc., can solve the problems of durability and safety of difficult external thermal insulation systems, high cost of external thermal insulation systems of external walls, etc., to achieve Excellent self-insulation performance, high compressive strength, and good self-insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

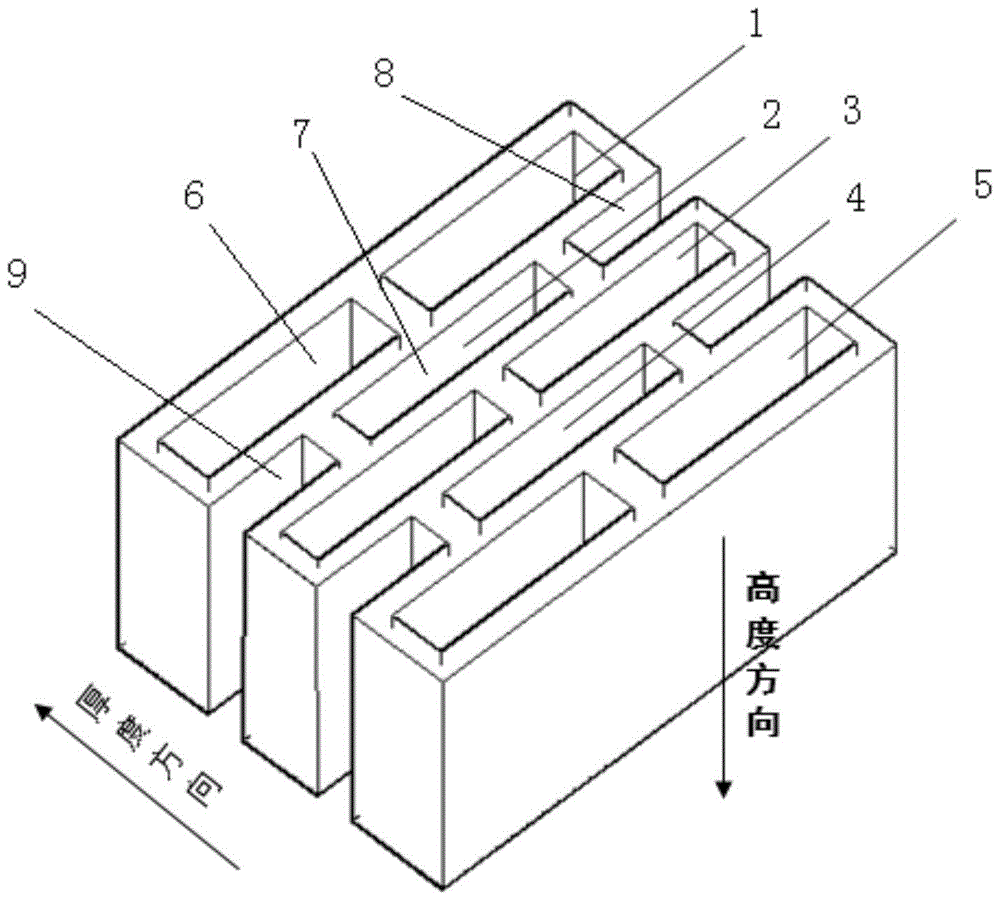

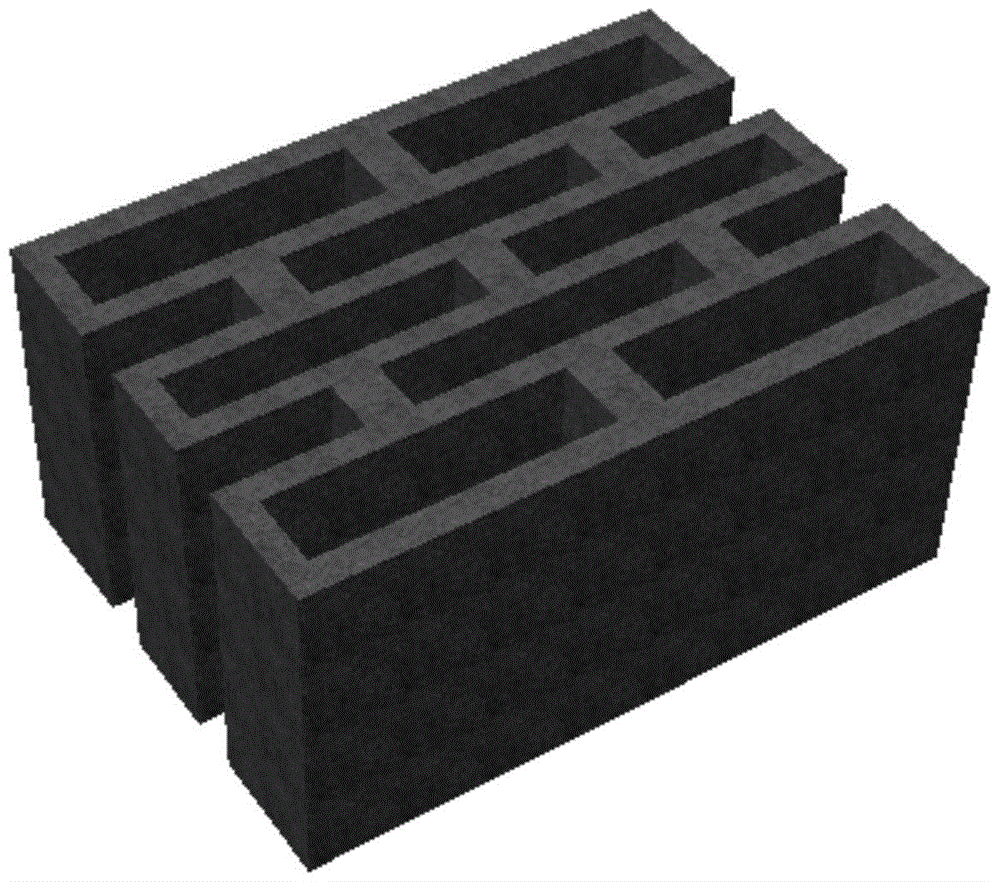

[0026] A high thermal resistance self-insulating block, such as figure 1 , 2 As shown, including the block body, the block body is provided with five rows of holes, respectively the first, second, third, fourth, and fifth rows of holes, wherein the first, third, and fifth rows of holes Both include two rows of closed first holes, and the two rows of first holes are symmetrically arranged, while the second and fourth rows of holes each include a row of closed second holes and two rows of third holes with openings at one end, two rows The third holes are respectively arranged on both sides of the second hole, and the openings of the third holes are far away from the second hole, and the length of the third hole is half of the length of the second hole; the block body is mixed with various ingredients Compression molding.

[0027] The first, second, third, fourth and fifth rows of holes gradually narrow in width along the height direction.

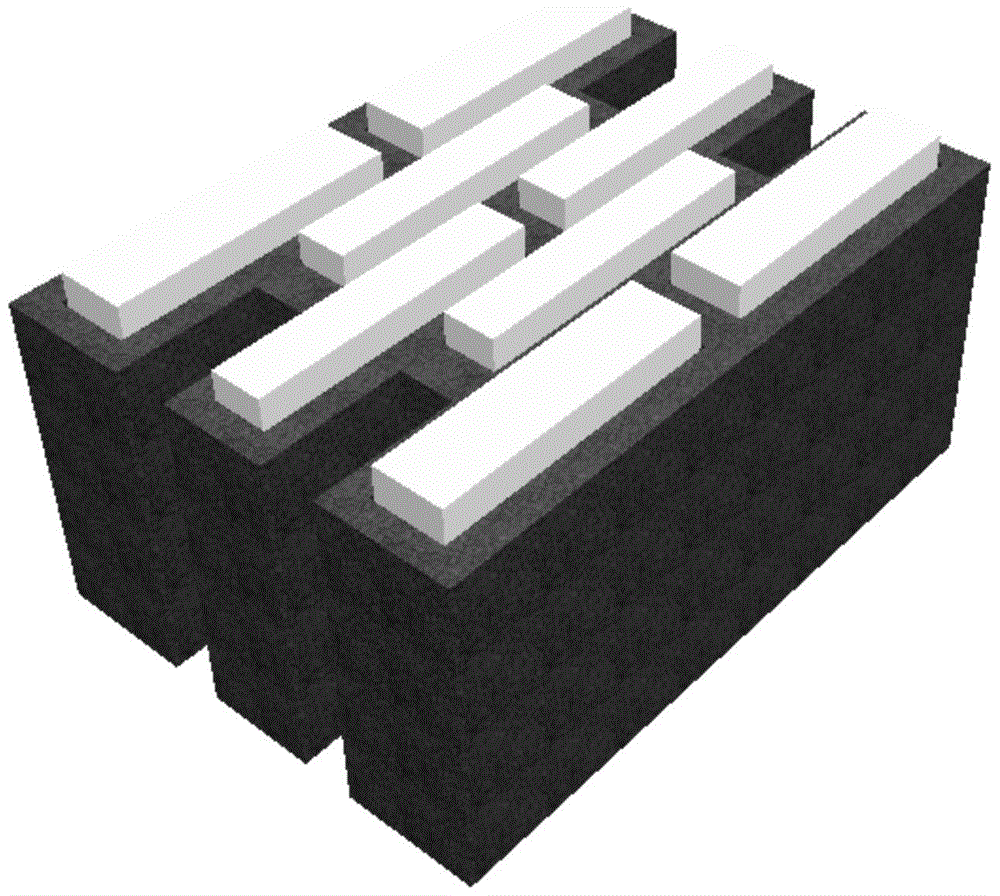

[0028] When building, such as ima...

Embodiment 2

[0039] The difference between this embodiment and Example 1 is that its proportioning materials account for different percentages of the total mass: the proportioning materials of this embodiment account for the percentage of total mass as follows:

[0040]

[0041] In order to better illustrate the technical scheme of the present invention, an example is given for illustration:

[0042] In the embodiment of the present invention, such as figure 2 As shown, the size of the block is 390mm×280mm×190mm, the five rows of holes are all rectangular, and the long side is perpendicular to the thickness direction; the five rows of holes are arranged symmetrically along the thickness direction, and the first and fifth rows are closed holes of 40mm×160mm. 3 rows are closed holes of 30mm×160mm; there is a row of holes in the middle of rows 2 and 4, the size is 30mm×170mm, and there are two open holes on both sides, the size is 30mm×80mm. The size of the closed hole after the opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com