Self-heat-preservation wall board and production method thereof

A technology of self-insulation and wall panels, applied in building components, buildings, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the accompanying drawings.

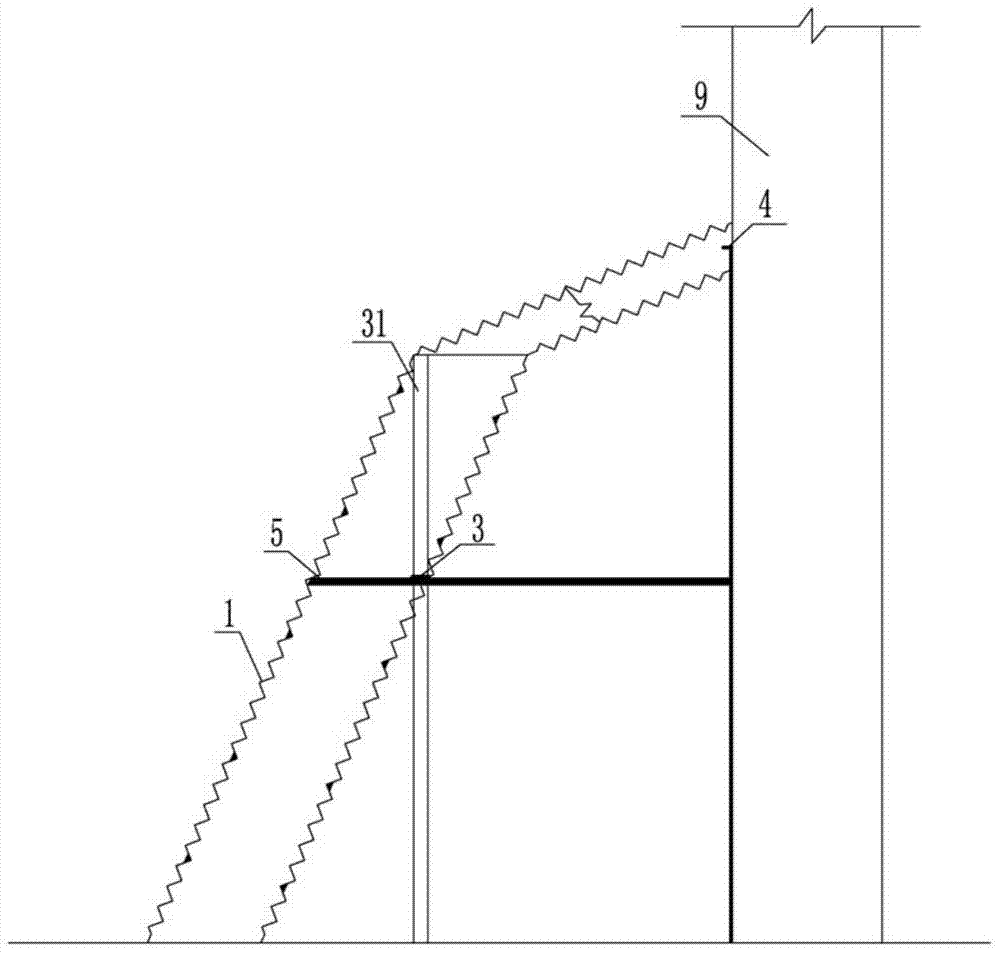

[0020] figure 1 It is the structural diagram of the steel skeleton body of the first embodiment of the present invention, such as figure 1 As shown, determine the position of the joint between the self-insulating wallboard and the building structure column 9, set the angle steel 4 for crack resistance and fixed position at the joint, and weld the angle steel or flat steel 5 between the vertical vertical steel pipe member 31 and the angle steel 4 to form an inner Structural member body of steel frame body 3.

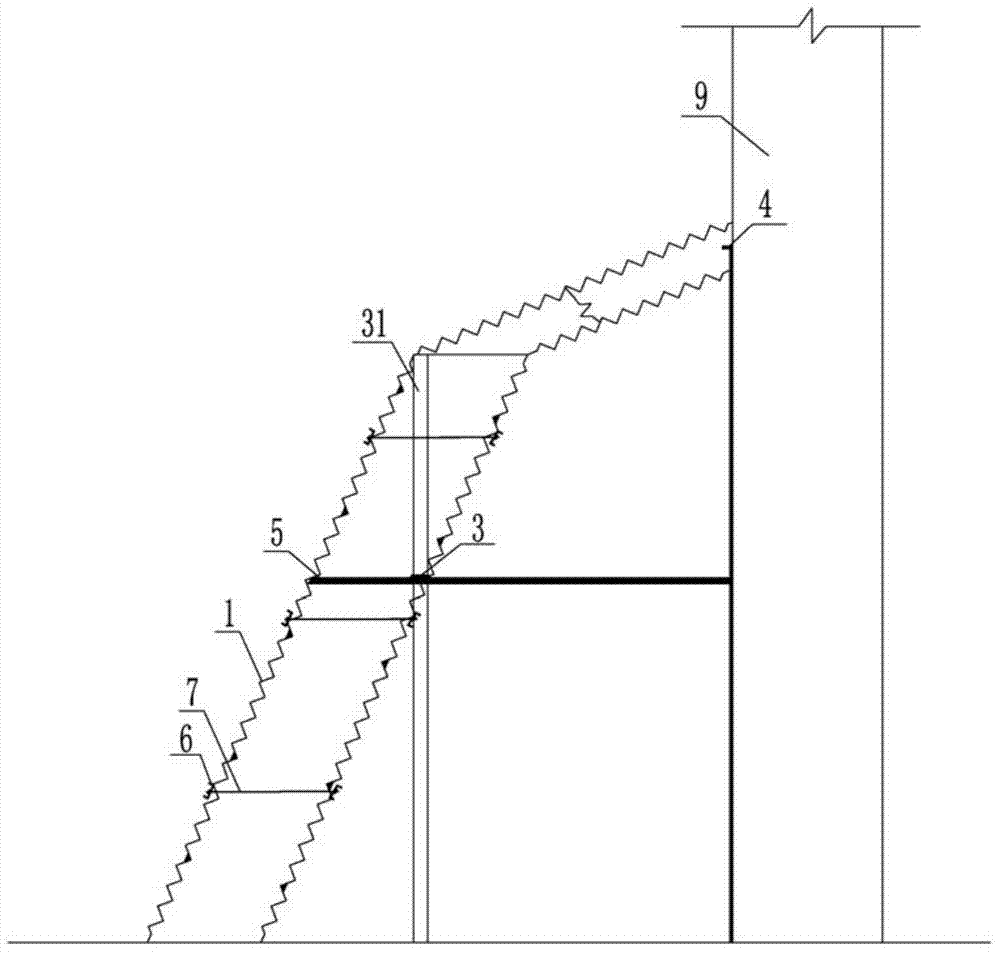

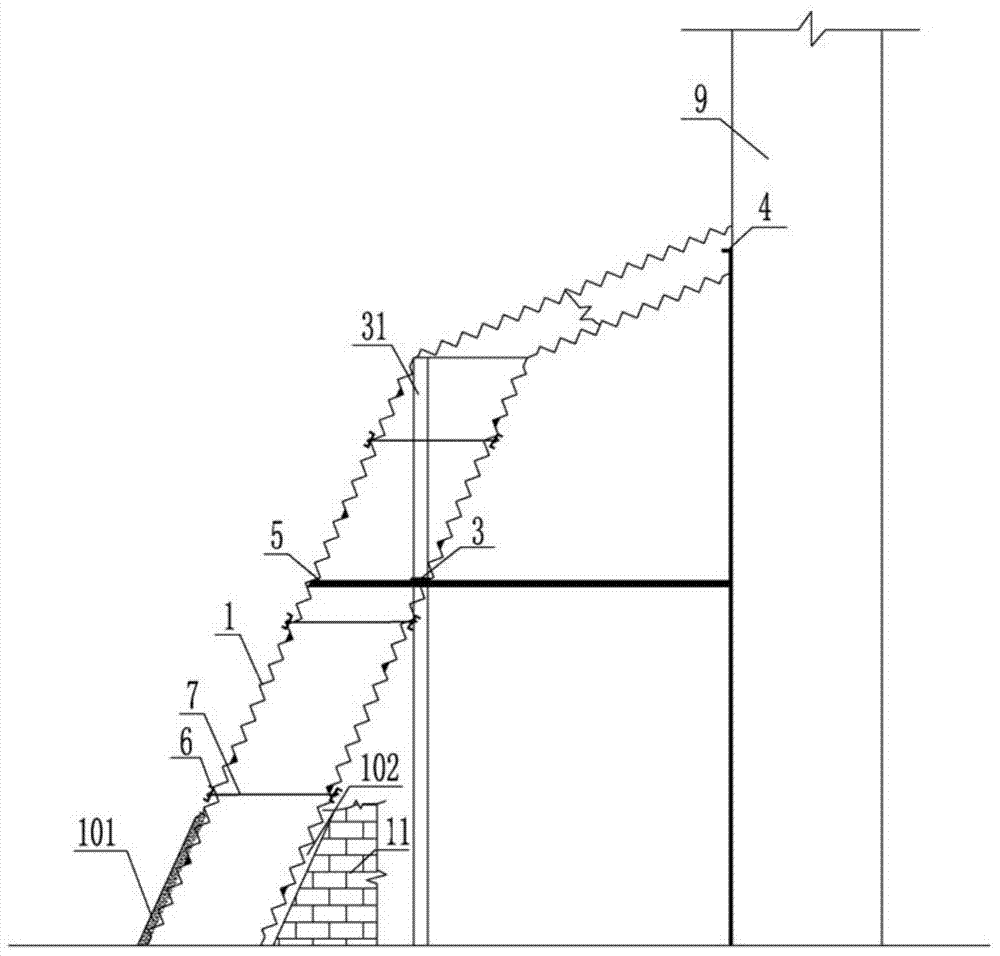

[0021] figure 2 It is a structural diagram of the self-insulating wall panel frame structure of the second embodiment of the present invention, such as figure 2 As shown, the galvanized steel plate machine is welded on the angle steel 4 of the building column to make a "["-shaped strip 6, which is used to strengthen the rigidity of the steel body and the restraint ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com