Reinforced points warehouse structure disassembly-free energy-saving composite thermal-insulation formwork

A composite thermal insulation and compartmentalization technology, which is applied in the direction of formwork/formwork components, building components, building structures, etc., can solve the problems of high cost, large consumption, time-consuming, labor-intensive and labor-intensive installation and removal of the mold system, etc. problems, to achieve the effect of shortening the construction period, reducing construction and installation costs, and ensuring quality and construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

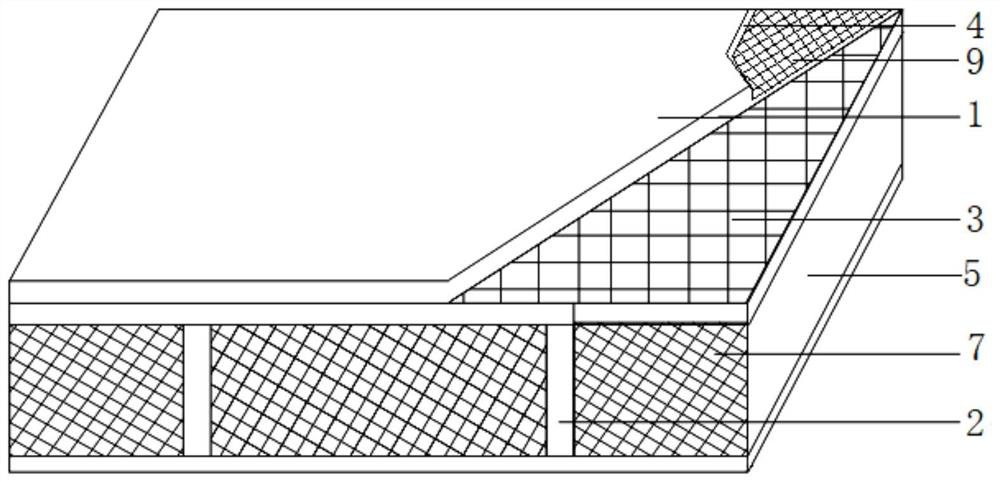

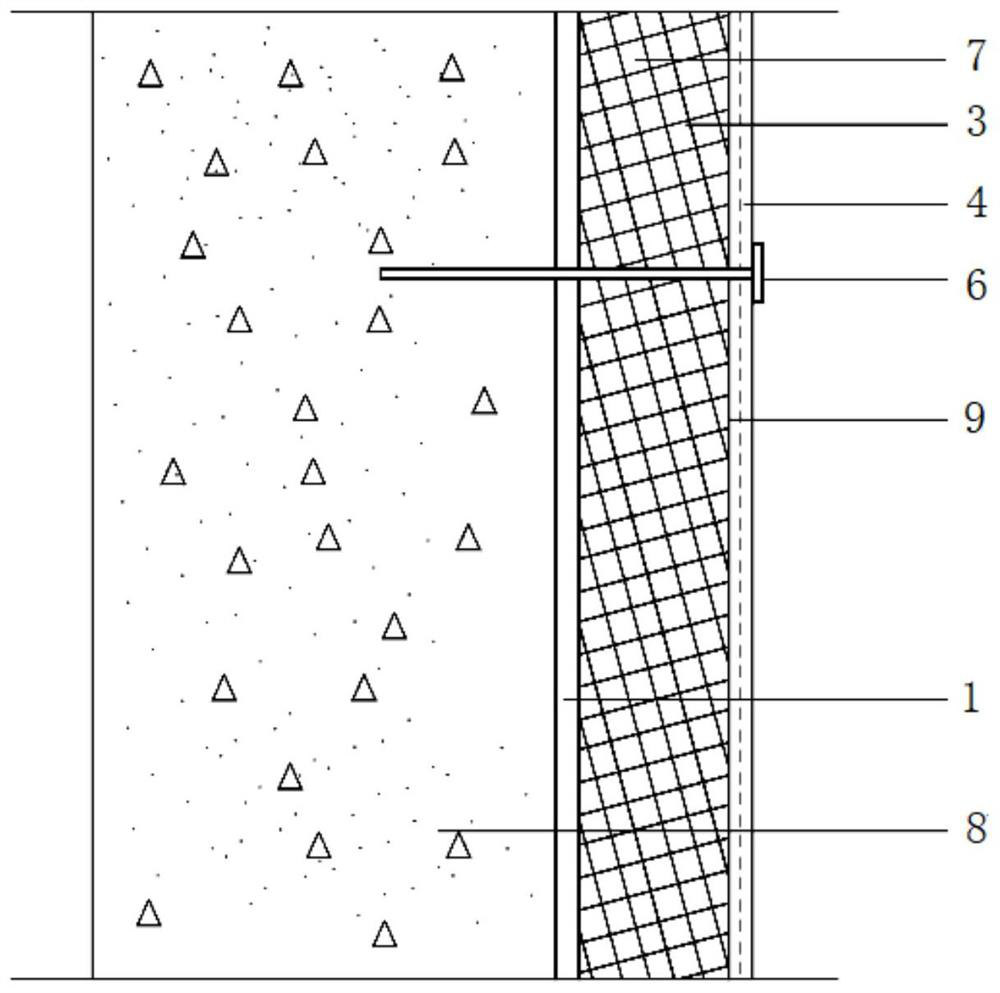

[0024] Embodiment 1: as attached figure 1 As shown, the thermal insulation filling layer 7, that is, the A-grade thermal insulation material, is evenly divided into bins at intervals of the compartment ribs 2, and the bonding mortar 5 is filled in the gaps, so that the A-grade thermal insulation materials of the thermal insulation filling layer 7 are connected to each other. Form a whole, then, glue the mortar 5 on one side of the thermal insulation filling layer 7, and at the same time, place the steel mesh sheet 3 to enhance the structural strength, and compound the inorganic mortar 4, which is a special cement-based composite mortar, to form the outer surface of the board body A pockmarked adhesive layer 1 with pitted surface; the other side is compounded with adhesive mortar 5, so that the inside and outside surface of the board body has a pockmarked surface adhesive layer 1 to form a board body.

[0025] In the foregoing, the inorganic mortar 4 is used for the adhesive la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com