Method for reinforcing and constructing template of deformation joint of comprehensive pipe gallery structure

A technology of structural deformation and formwork reinforcement, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve problems such as poor stability, easy mold expansion, and difficult reinforcement, and achieve good results and reduce deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

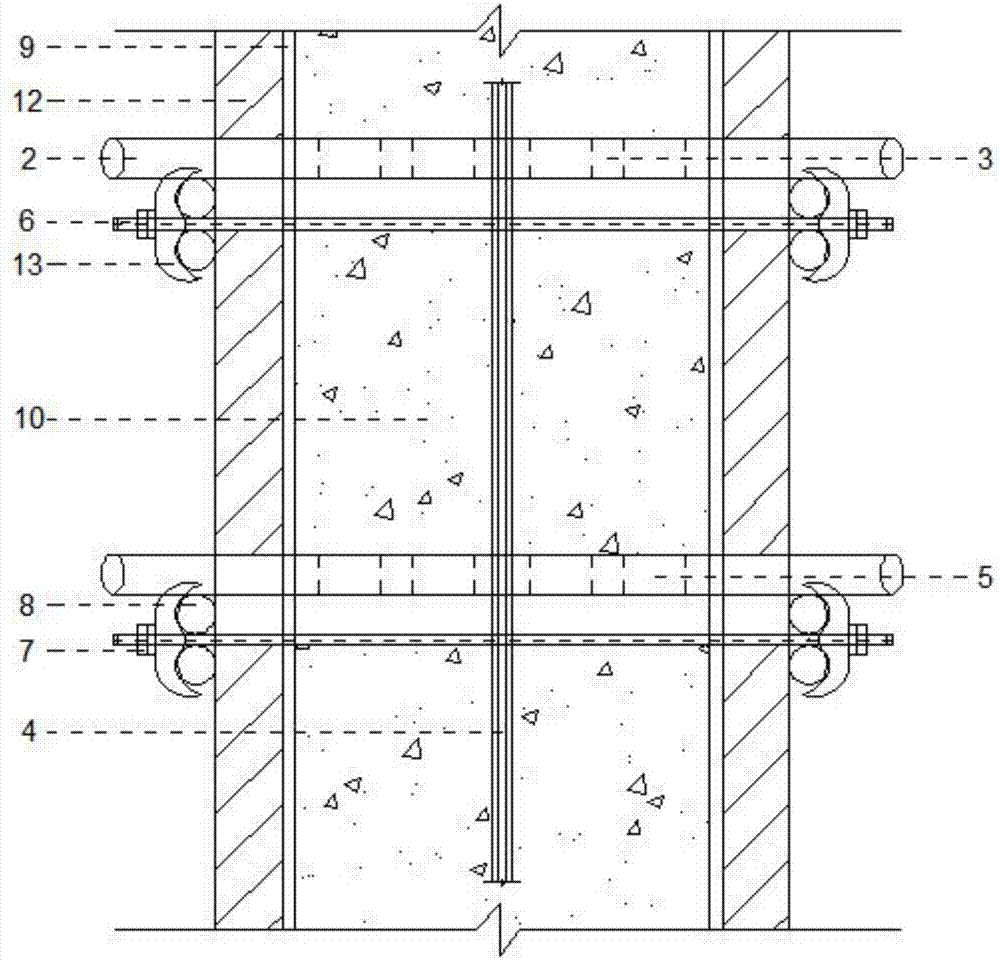

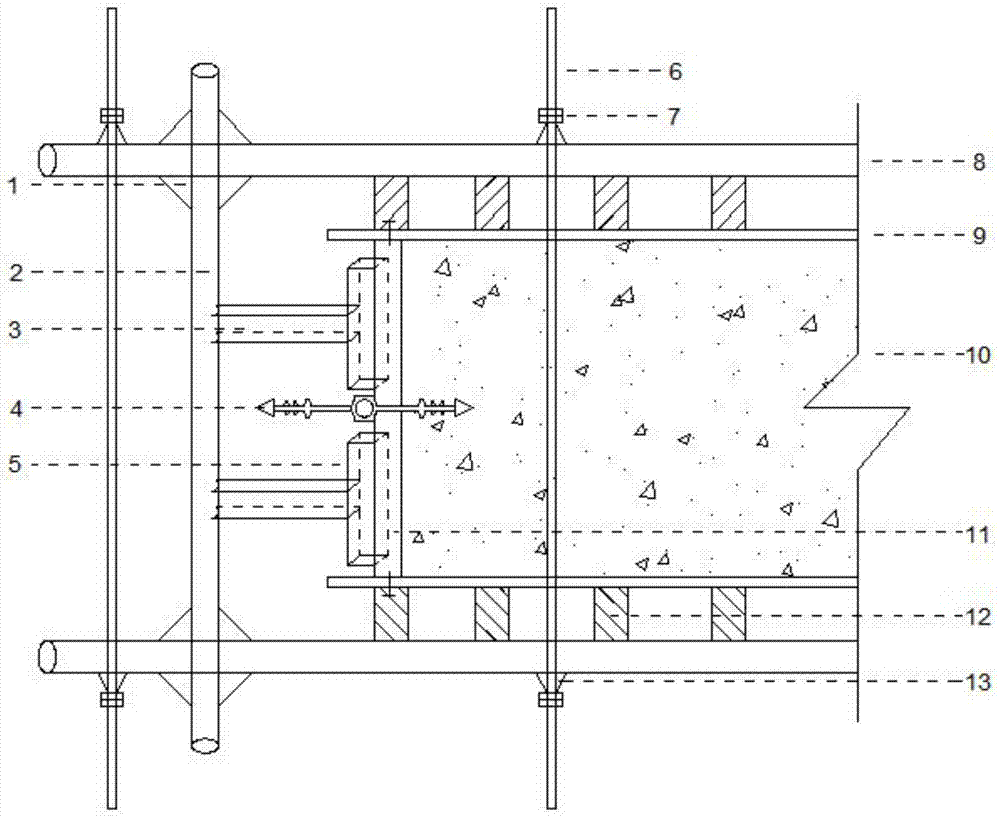

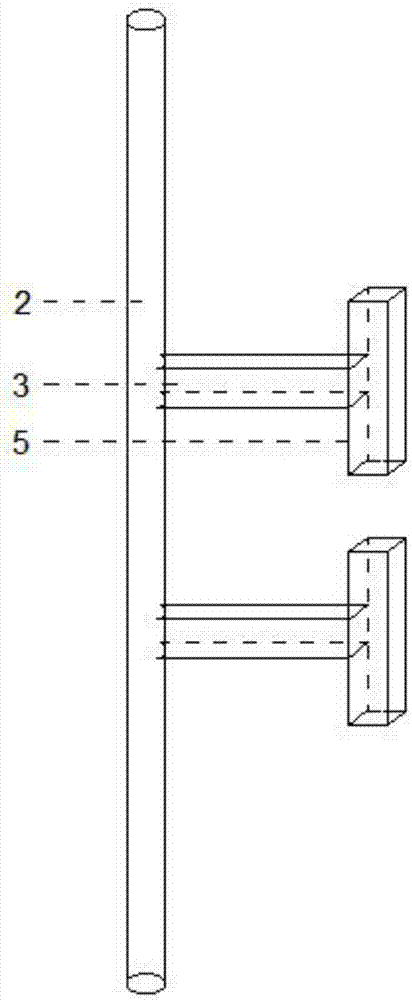

[0027] The construction method of the formwork reinforcement at the deformation joint of the shear wall of the urban comprehensive pipe corridor, see figure 1 , figure 2 , image 3 , the reinforcement method includes the following steps:

[0028] A. First, formwork 9 on the inner and outer sides of the shear wall 10 is molded using the opposite pull water-stop screw 6, mountain-shaped clip 13, nut 7, longitudinal steel pipe keel 8, and wooden square keel 12, but the water-stop screw is not used for the time being. 6. Tighten the nut 7 at the end; pull the water-stop screw 6 through the shear wall 10, the formwork 9 on both sides, the wooden square keel 12, and the longitudinal steel pipe keel 8, and then fit and install the mountain shape at both ends of the water-stop screw Card 13, nut 7;

[0029] B. Install the buried rubber waterstop 4 at the deformation joint of the shear wall: insert the lateral templates 11 on both sides of the buried rubber waterstop into the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com