Carriage stepped unloading method after expanding large-span truss structure

A technology of truss structure and rear support frame, which is applied in the direction of pillars, buildings, building maintenance, etc. It can solve the problems that the unloading synchronization of support frames cannot be guaranteed, the progress of civil construction on the ground is affected, and civil work cannot be carried out, etc., so that the sequence of unloading is reasonable , ensuring safety and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

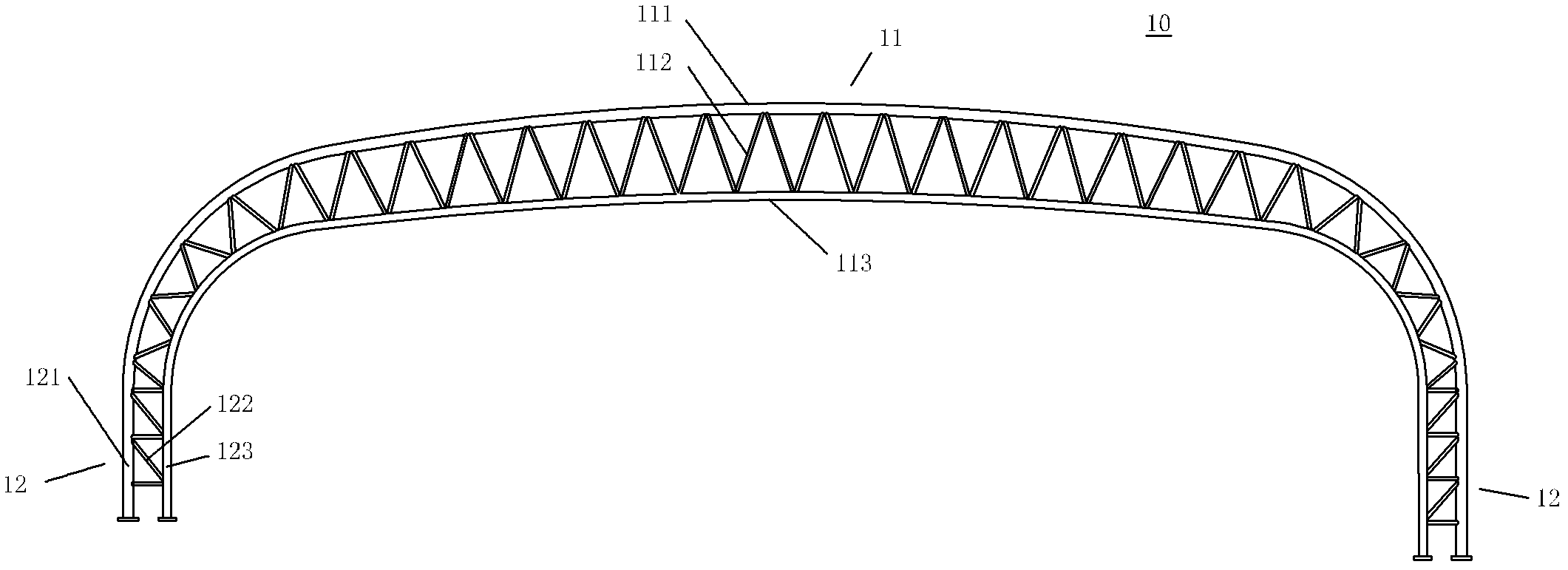

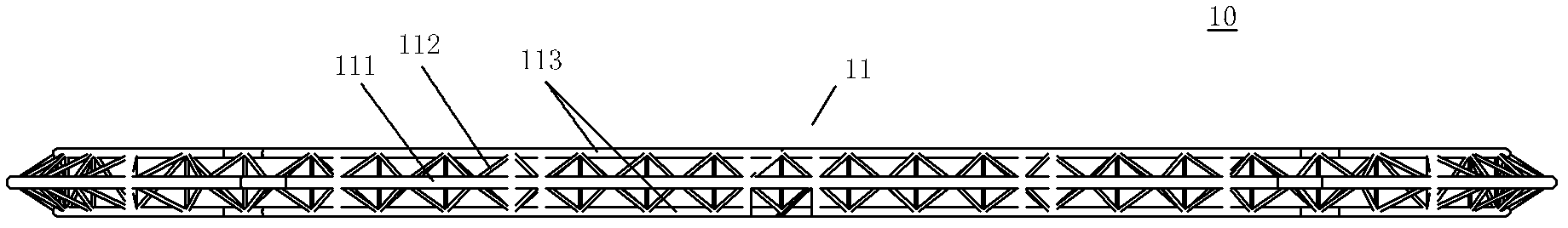

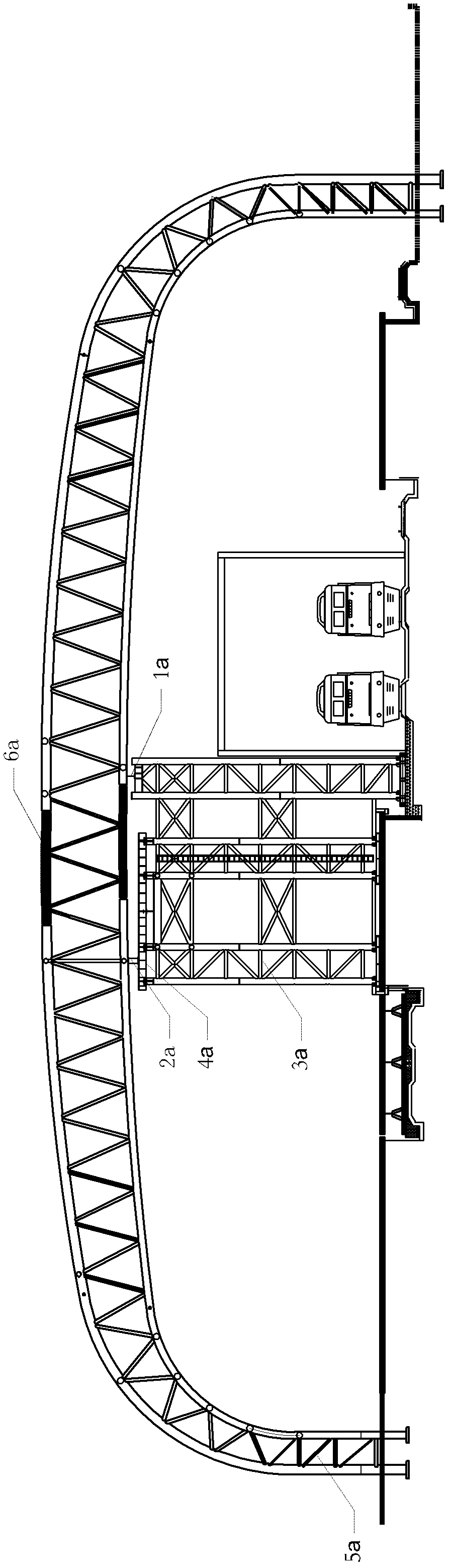

[0050] The first embodiment: for Figure 4 The shown long-span truss structure with 6 truss structures ( Figure 5 for Figure 4 Schematic diagram of the F direction), adopt the following step-like unloading method of the support frame:

[0051] Step 1: Calculate the maximum deflection of the disconnection on a truss structure 20 by the finite element calculation simulation analysis algorithm to be 40 mm, and calculate the deflection of the disconnection according to the material and structural characteristics of the long-span truss structure itself. The maximum allowable stress value of unloading is 310N / mm 2 .

[0052] Step 2: According to the calculated maximum deflection of 40mm and the maximum allowable stress value of unloading 310N / mm 2 , set the number of layer-by-layer unloading N as 2 times, and set the height of each layer-by-layer unloading as 20 mm. The added height of 20mm is equal to the maximum deflection of 40mm, and the unloading stress value is calculat...

no. 2 example

[0063] The second embodiment: for a large-span truss structure with 10 truss structures (one truss structure is the same as a truss structure in the first embodiment, both are Figure 5 The structure shown) adopts the following step-like unloading method of the support frame:

[0064] Step 1: Calculate the maximum deflection of the disconnection on a truss structure 20 by the finite element calculation simulation analysis algorithm to be 87 mm, and calculate the deflection of the disconnection according to the material and structural characteristics of the long-span truss structure itself. The maximum allowable stress value of unloading is 310N / mm 2 .

[0065] Step 2: According to the calculated maximum deflection of 87mm and the maximum allowable stress value of unloading 310N / mm 2 , set the number of layer-by-layer unloading N to 4 times (of course, it can also be set to 2 or 3 times, but the height of each layer-by-layer unloading should be changed accordingly), and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com