Chain circulation intelligent lifting and descending system

An intelligent, chain technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high construction and use costs, accumulation of goods at transfer nodes, and occupying large space areas, achieving low maintenance costs and flexibility. High performance and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

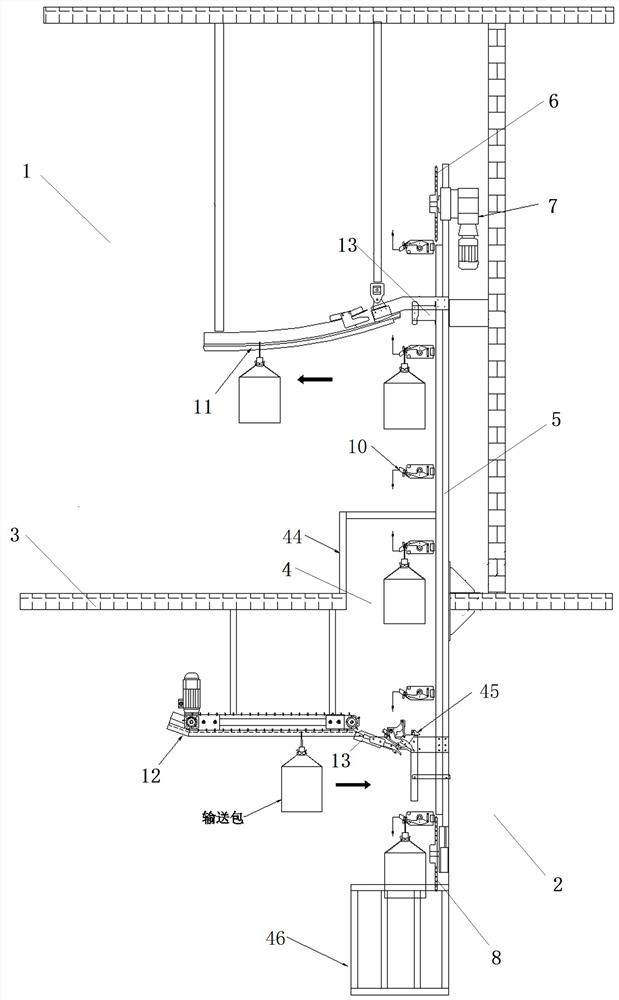

[0022] The present invention will be further described below with reference to the accompanying drawings.

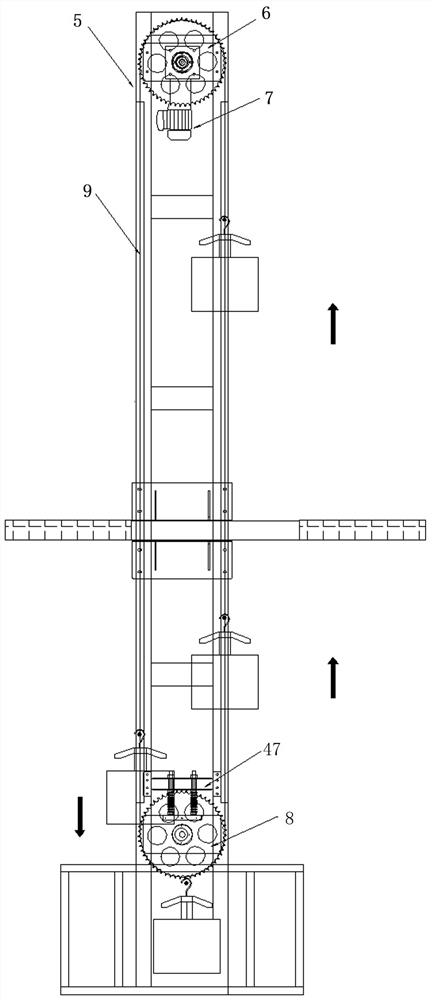

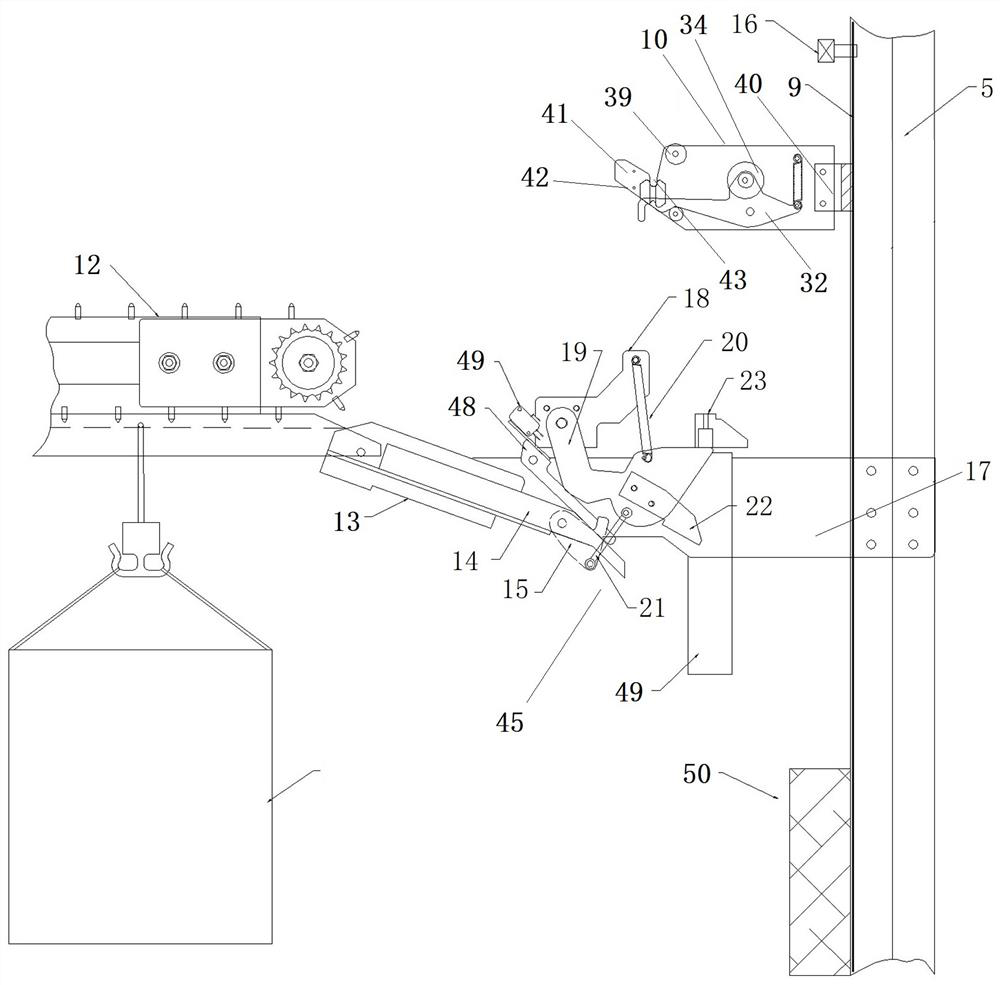

[0023] The first embodiment of the present invention discloses a chain circulation intelligent lifting and lowering system, such as figure 1 As shown, it differs from the prior art in that it includes an upper zone 1 and a lower zone 2, a floor layer 3 is provided between the upper zone 1 and the lower zone 2, and a lifting hole 4 is provided at the floor layer 3, and the upper zone 1 and the lower zone The main frame 5 is arranged between the areas 2, the main frame 5 is distributed through the above-mentioned lifting hole 4, the upper end of the main frame 5 is provided with a driving gear 6, and the driving gear 6 is driven by a driving motor 7, and the lower end of the main frame 5 is provided with a driven gear 8 , between the driving gear 6 and the driven gear 8, a transmission chain 9 is arranged, and several packing racks 10 are distributed at equal intervals at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com