Design and debugging method of a special-shaped reference ring

A debugging method and reference ring technology, applied in the field of reference rings, can solve the problems of difficult adjustment of tuning circuits, cumbersome and complicated debugging steps, etc., and achieve the effect of simplifying the calibration steps and simplifying the debugging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

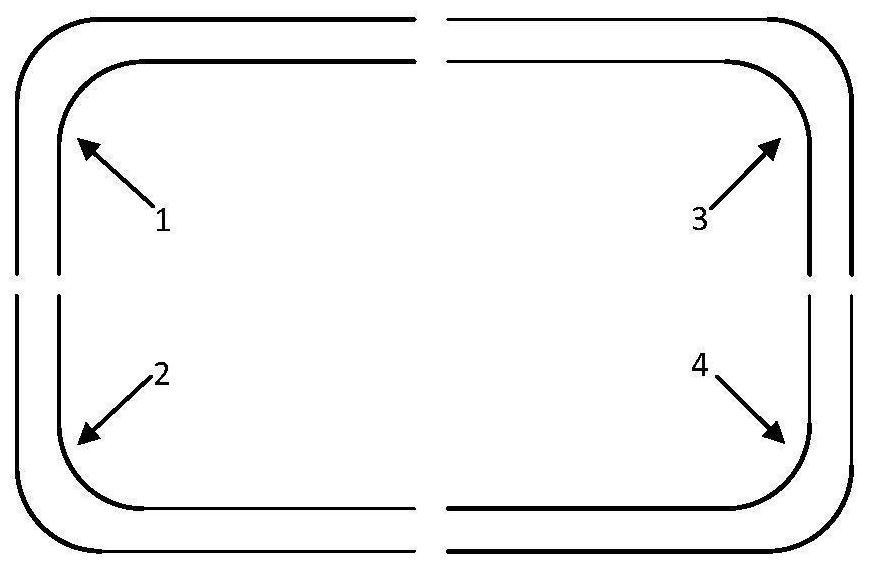

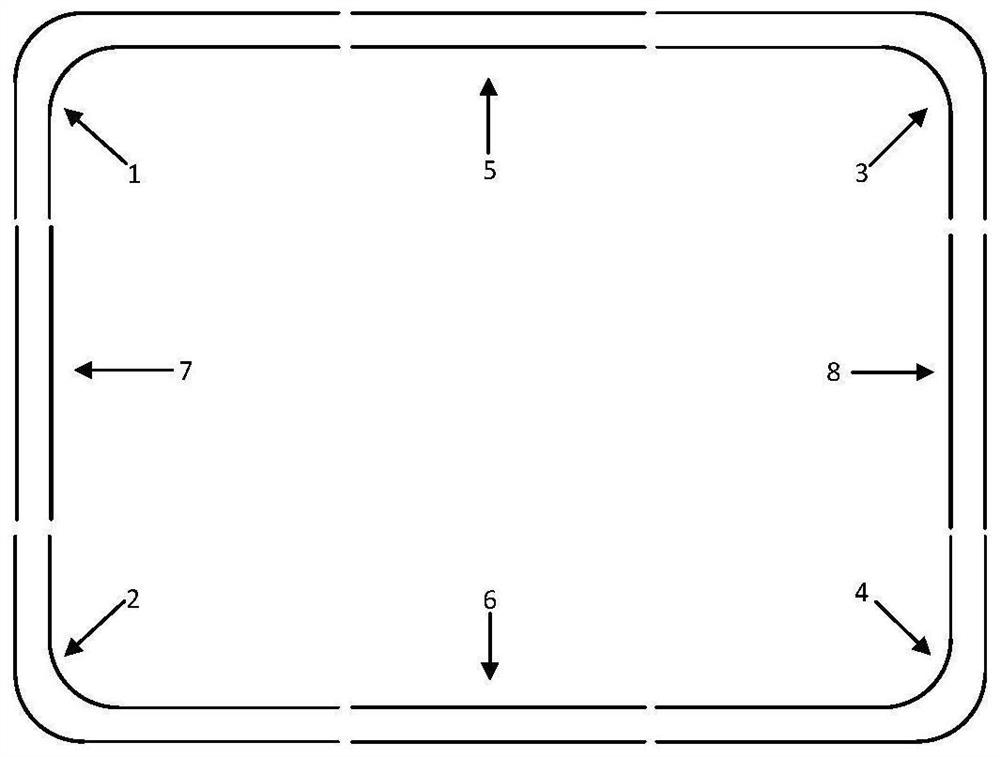

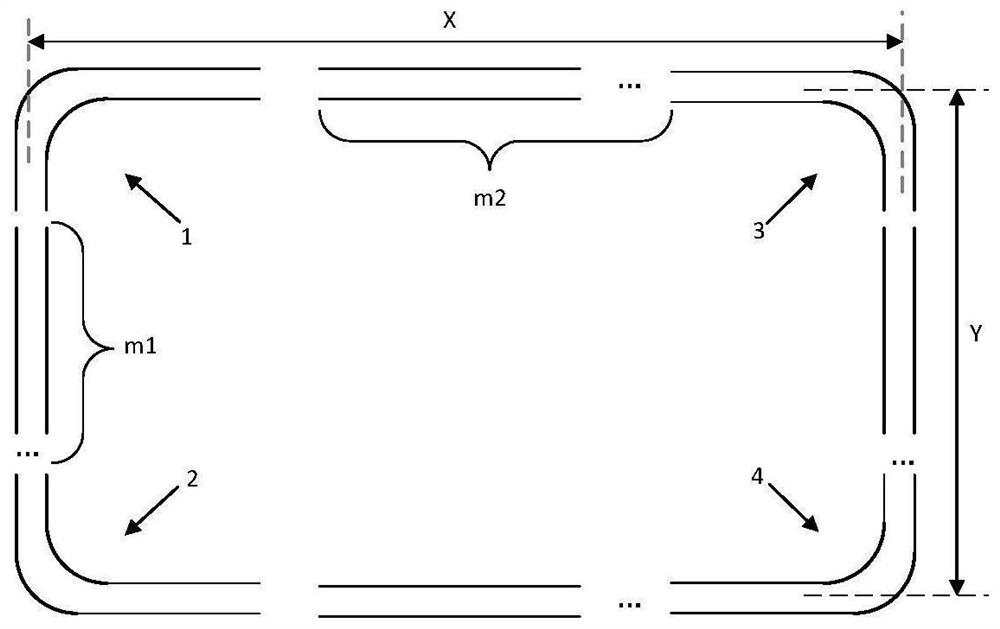

[0037] A four-sided reference ring structure Figure 2A Indicated. The X and Y represent the size of the reference ring length and wide, which consists of several joints, including 4 knots, symmetrical straight copper strips (ie Figure 2A In the arrow refers to it), and several linear copper strips (ie Figure 2A Mix M1 and M2). Among them, the reference ring wide side (ie Figure 2A The number of copper strips of the line Y is M1, long side (ie Figure 2A The number of linear copper strips is M2 in the middle x shown. The present invention defines the number M1 M1 of the linear copper strip, M2 is as follows:

[0038]

[0039] The 4-section is completely symmetrical. Figure 2B As shown, since the structure is completely symmetrical, the size is consistent, and the present invention is plotted only one of them. The long and wide dimensions of the right-angled copper strips are represented by A and B.

[0040] Some line copper strips such as Figure 2C As shown, since it is a structur...

Embodiment 2

[0048] A triangular reference ring structure Figure 6A Indicated. The present invention considers an equilateral triangular structure, X represents a triangular side length size, which is composed of a solid copper ring, including 3 sections, completely symmetrical rounded copper strips (ie Figure 6A In the arrow refers to it), and several linear copper strips (ie Figure 6A The m1 is shown). Among them, the number of copper strips of the reference loop line is M1, defined as follows:

[0049]

[0050] The 3-section is completely symmetric rounded copper strip such as Figure 6B As shown, since it is a 3-section complete symmetrical structure, the size is consistent, this diagram only draws one of them. Rounded copper strip edge length with A represents.

[0051] Some linear copper strips (such as Figure 6C As shown), since the size is fully consistent, this figure exists only one of the following. Linear copper strips length with B represent.

[0052] The value of the M1 of the p...

Embodiment 3

[0057] The different type reference ring of the present embodiment, the same copper ring as the same structure, respectively, in 27 MHz and 4 MHz. Cut copper strips in each copper ring are connected by printed circuit boards (eg Figure 4 The PCB board is shown). The resonant circuit of each board is LC resonant circuit (eg Figure 5b Disted), equivalent resonance formula is

[0058] Among them inductance L (eg Figure 5b The inductance L shown) is the inductive value of the single-segment copper ring, and the inductance value of the entire copper ring before the cutting segment is measured, and the single-segment electrical value is calculated according to the number of cutting segments, and the like is erected inductance L.

[0059] Among them, the capacitance value c (eg Figure 5b The medium capacitance C is shown in accordance with the desired resonance point to debug different inductance values. Adjusting at 27M ring and 4M ring, respectively.

[0060] The reference ring tuning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com