Value limiting stress concrete electric pole

A technology of concrete and electric poles, which is applied in the field of power transmission equipment, can solve the problems of loss of flexural strength and impact strength, complicated binding process of electric pole steel skeleton, and increase of production cost, so as to improve bearing capacity and toughness, reduce braiding Network equipment investment, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A limit stress concrete pole of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

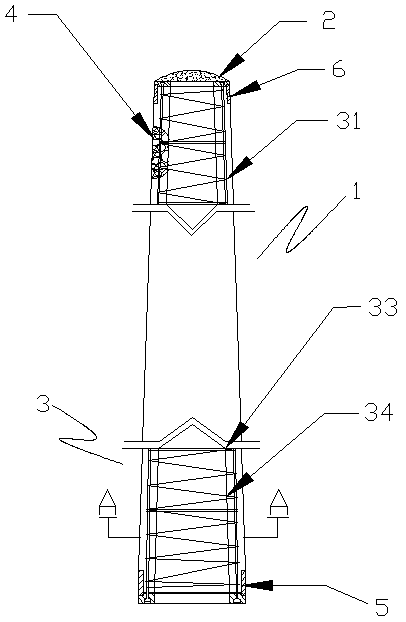

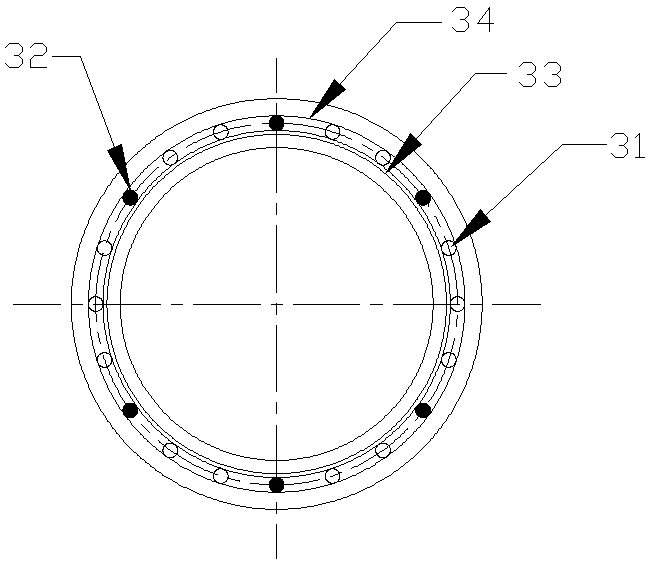

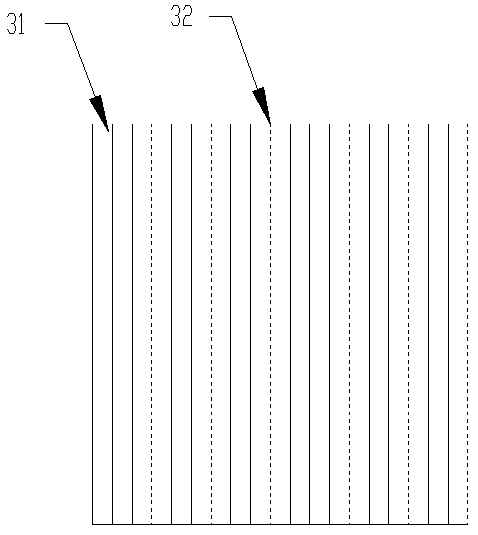

[0027] Such as figure 1 Shown, in a preferred embodiment, a kind of limit stress concrete electric pole of the present invention comprises the rod body 1 of the reinforced concrete of annular surface, and rod body 1 is pyramid shape, and taper is 1:75, and rod body 1 The top end is provided with a concrete roof 2, the rod body 1 includes a steel rod skeleton 3 and a concrete protection layer 4, the concrete protection layer 4 wraps the steel rod skeleton 3, and the steel rod skeleton 3 includes a main reinforcement 31 and an additional reinforcement 32 , erecting ribs 33 and spiral ribs 34, the main ribs 31 and additional ribs 32 are spaced apart from each other, and are PC steel rods with the same length, the stress of the main ribs 31 is controlled at 63%-68% of the design strength of the steel bar, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com