Steel-concrete with ultrahigh performance joint section and manufacturing method thereof

A concrete combination, ultra-high performance technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of local component stress concentration, difficult construction of the joint section, sudden change in section size, etc., to achieve a smooth transition of stiffness and meet Structural design requirements, improving the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings:

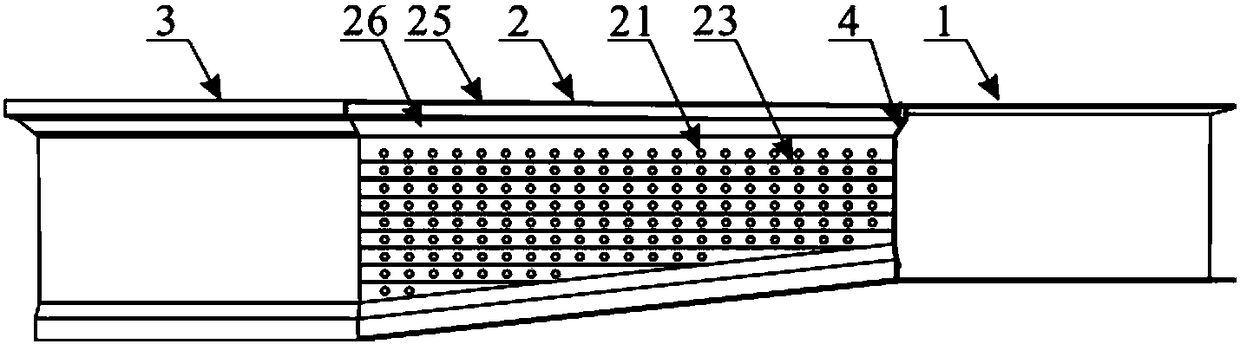

[0035] like figure 1 shown, which is a side view of the steel-UHC junction.

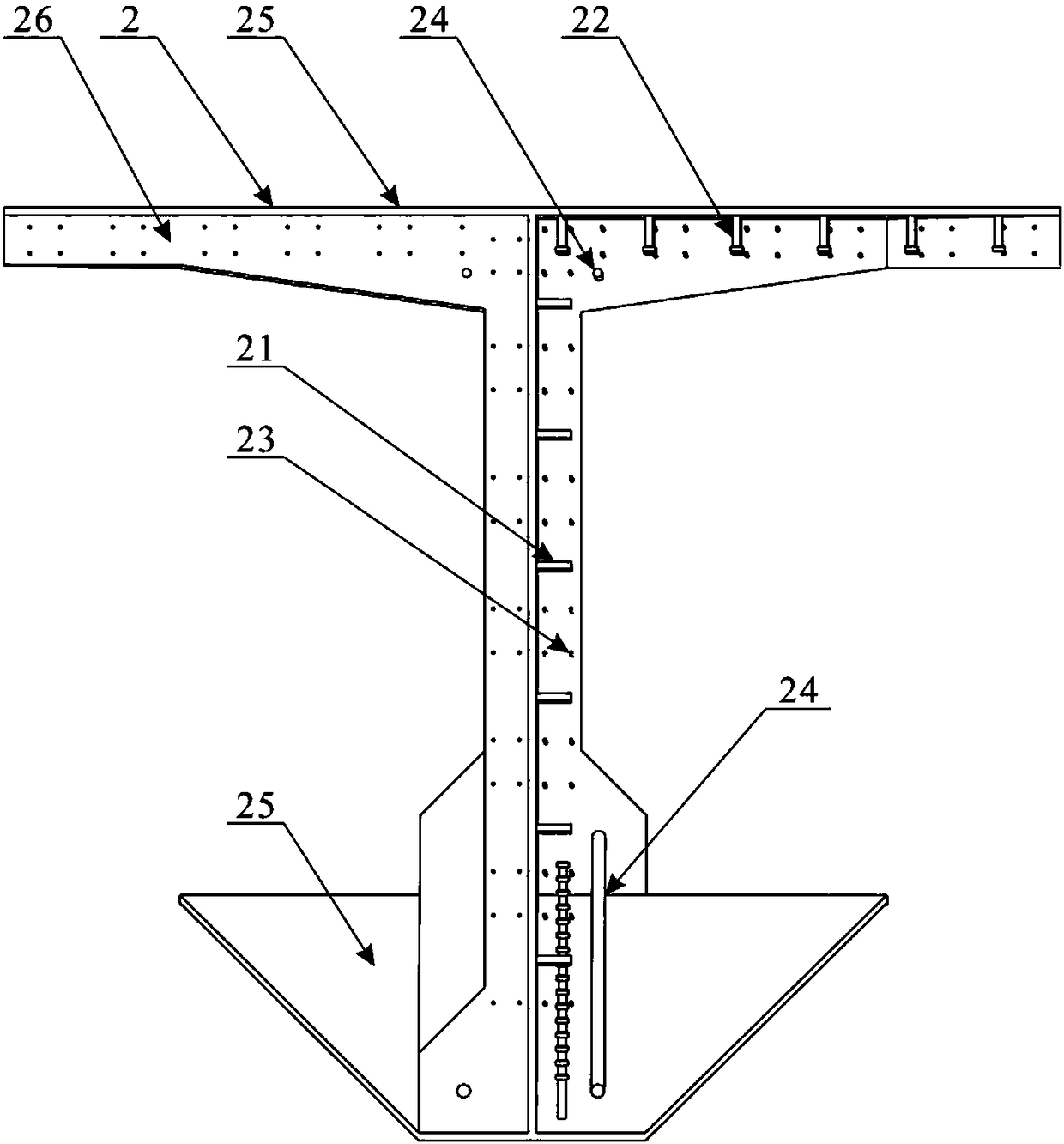

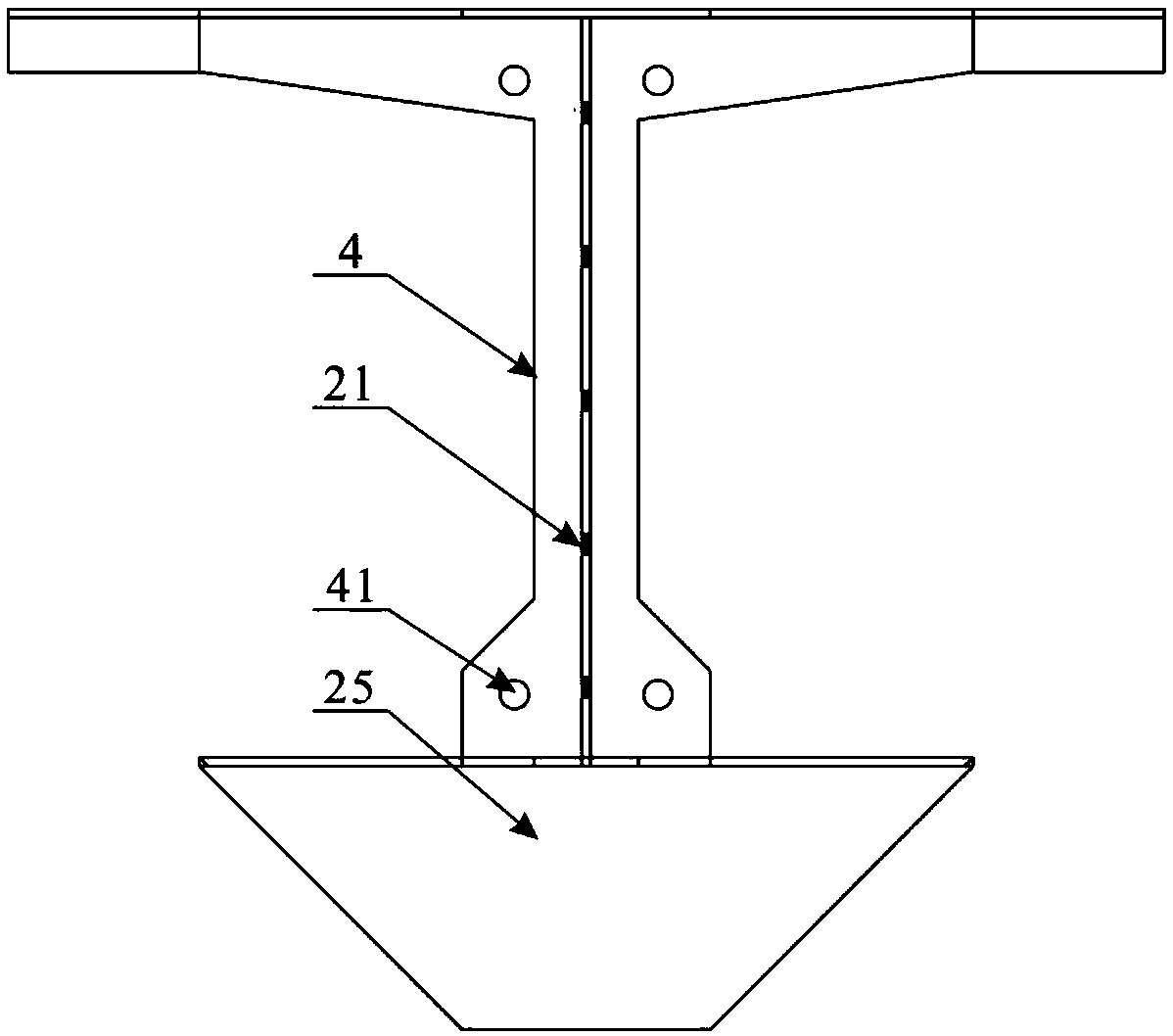

[0036] The present invention provides a steel-ultra high performance concrete joint section such as figure 1 As shown, it includes a combined beam 2, one end of the combined beam 2 is connected with the steel beam 1, the other end is connected with the concrete beam 3, and the connecting part of the combined beam 2 and the steel beam 1 is provided with a bearing plate 4; Shaped steel plate 25, both sides of the web of the I-shaped steel plate 25 and the inner side of the upper and lower wing plates are wrapped with an ultra-high performance concrete layer 26, and the cross-sectional shape of the combined beam 2 is different from the cross-sectional size of the concrete beam 3 and has the same structure, The height of the side where the I-shaped steel plate 25 is in contact with the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com