Method of increasing strength of cold worked part by ultrasonic shock treatment, and metal product with high fracture toughness and fatigue strength

A technology for impact treatment and metal products, which is applied in the field of metal products with high strength of cold-worked parts and high fracture toughness and fatigue strength by ultrasonic impact treatment, which can solve the problem of low site selectivity, difficult to handle large objects, and difficult to handle only Steel surface and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Hereinafter, the present invention will be specifically described through examples.

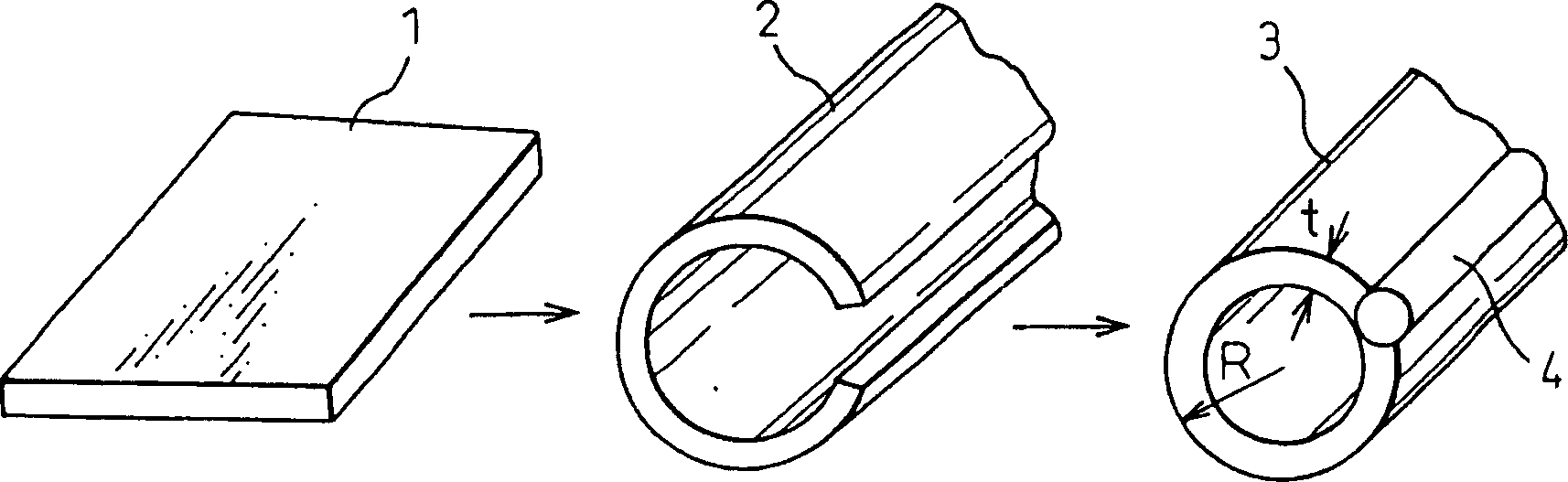

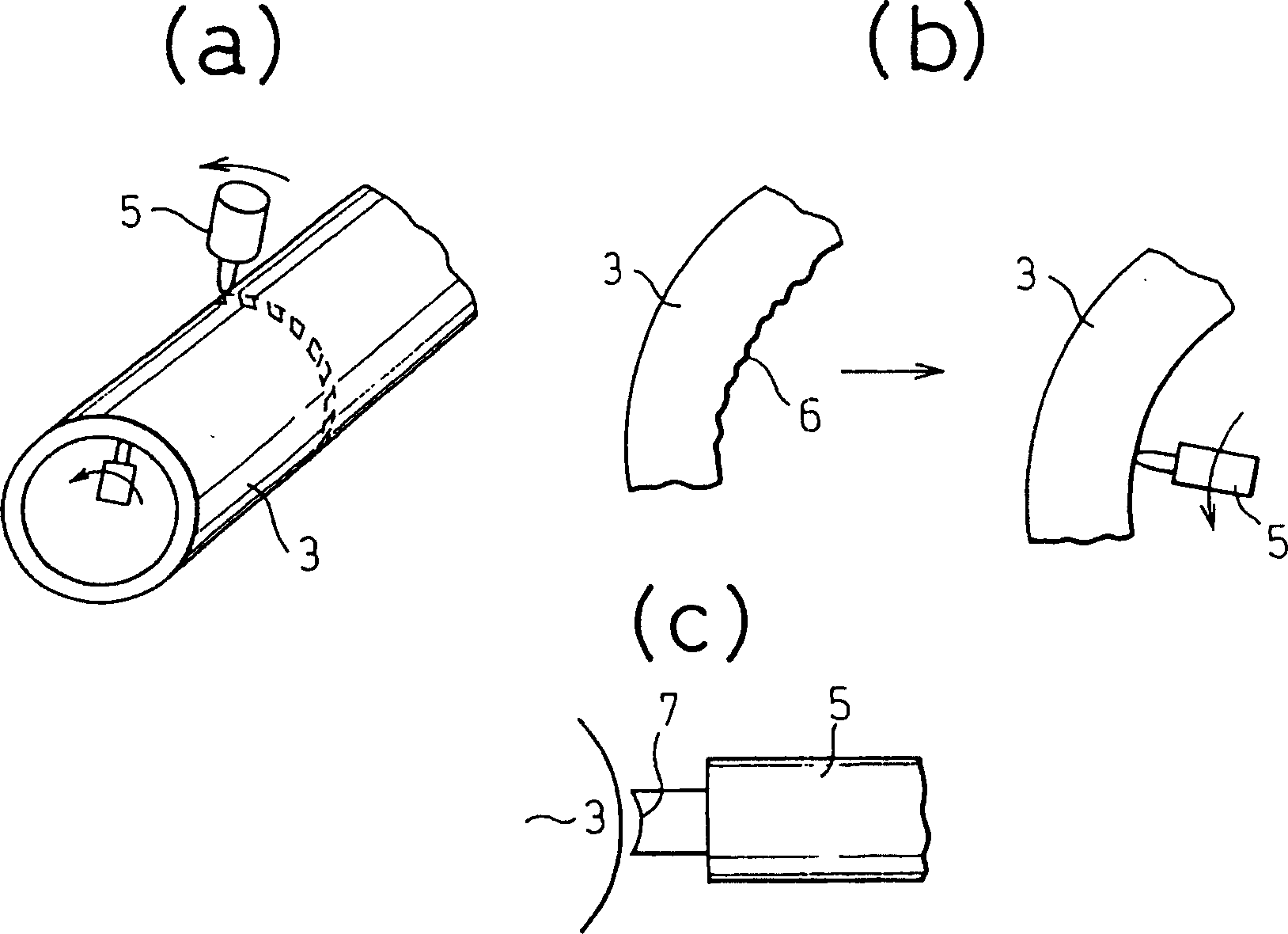

[0060] Steel materials are bent to produce BR pipes, which are then subjected to ultrasonic shock treatment. Then, after the ultrasonic treatment, a part of the steel pipe was cut out, and a fatigue test piece and a microscopic test piece were produced.

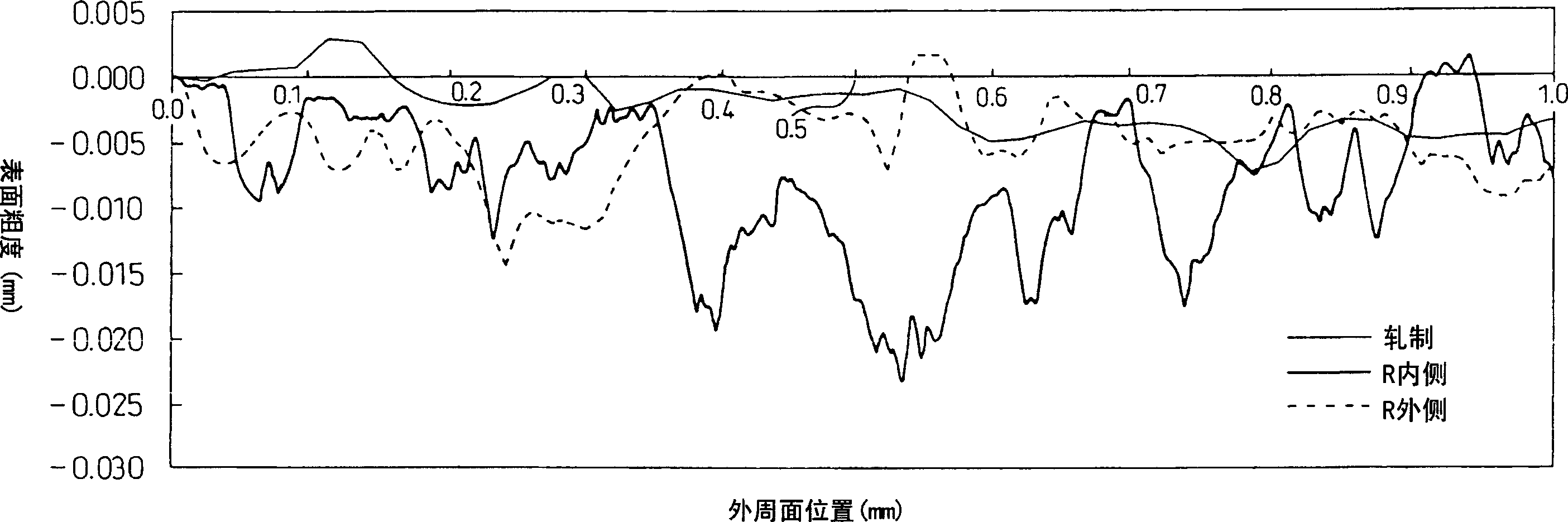

[0061] Since it is difficult to directly measure the fracture toughness, the particle size is measured by a microscopic test, and the particle size is used as a parameter of toughness (for example, in Iron and Steel Research No. 327 "Improvement of Toughness of HSLA Steel HAZ by Finely Dispersed Ti Oxide" In Fig. 7, toughness (migration temperature) and particle size, with y=-1059(x 0.5 )+40 [y is the migration temperature, z is the relationship between the particle size]). The hardness was also measured by a microscopic test.

[0062] Table 1 shows the steel materials used, and Table 2 shows the specifications of the bending proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com