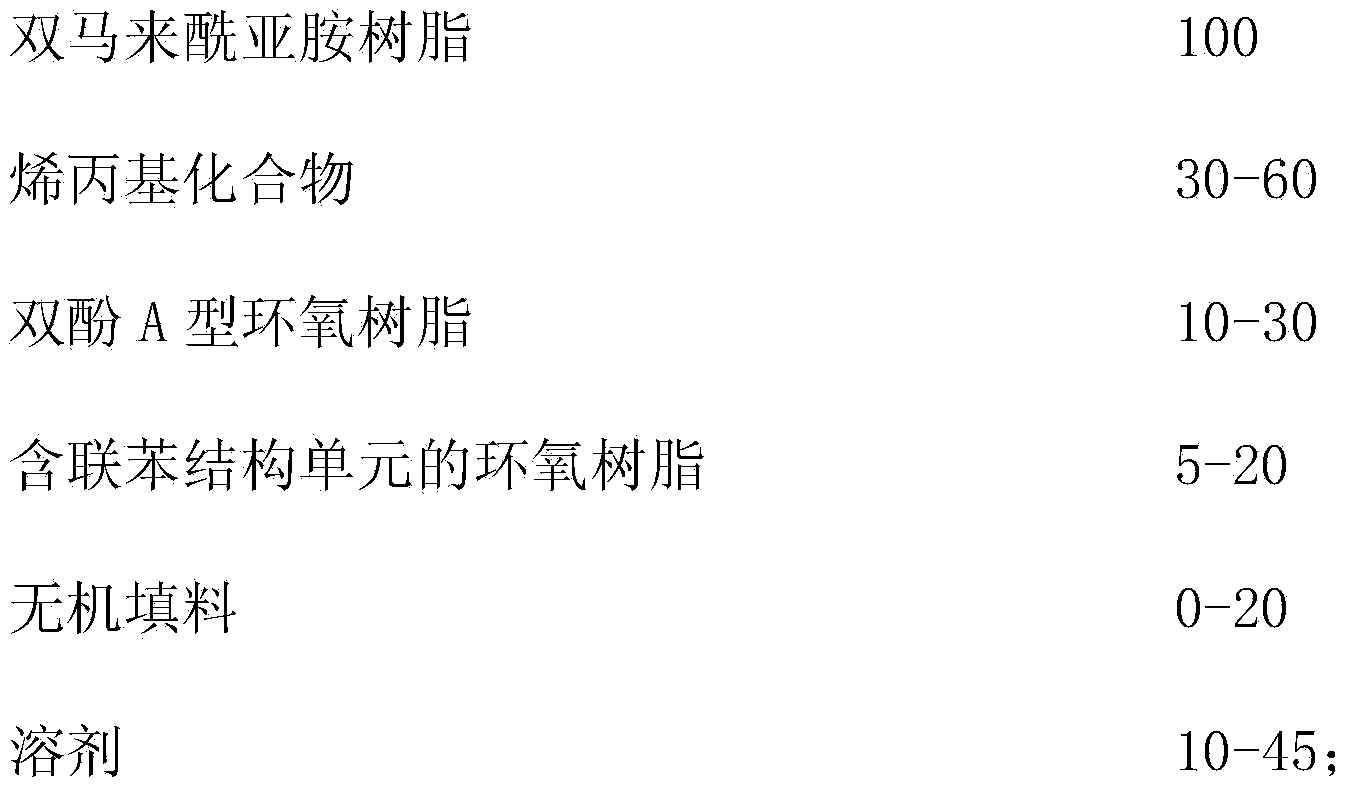

Low resin fluidity prepreg and preparation method thereof

A resin fluidity, prepreg technology, applied in the field of copper clad laminates, can solve problems such as difficult use requirements, poor adhesion of polyimide surfaces, and limited improvement in bonding, and achieve improved heat resistance, processing toughness, and high flexibility. performance and bond strength, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

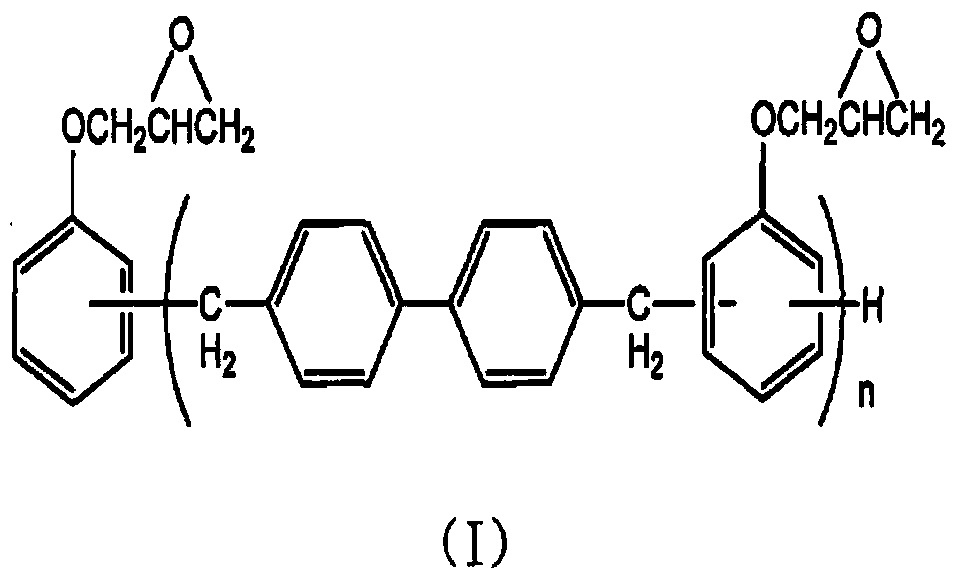

Method used

Image

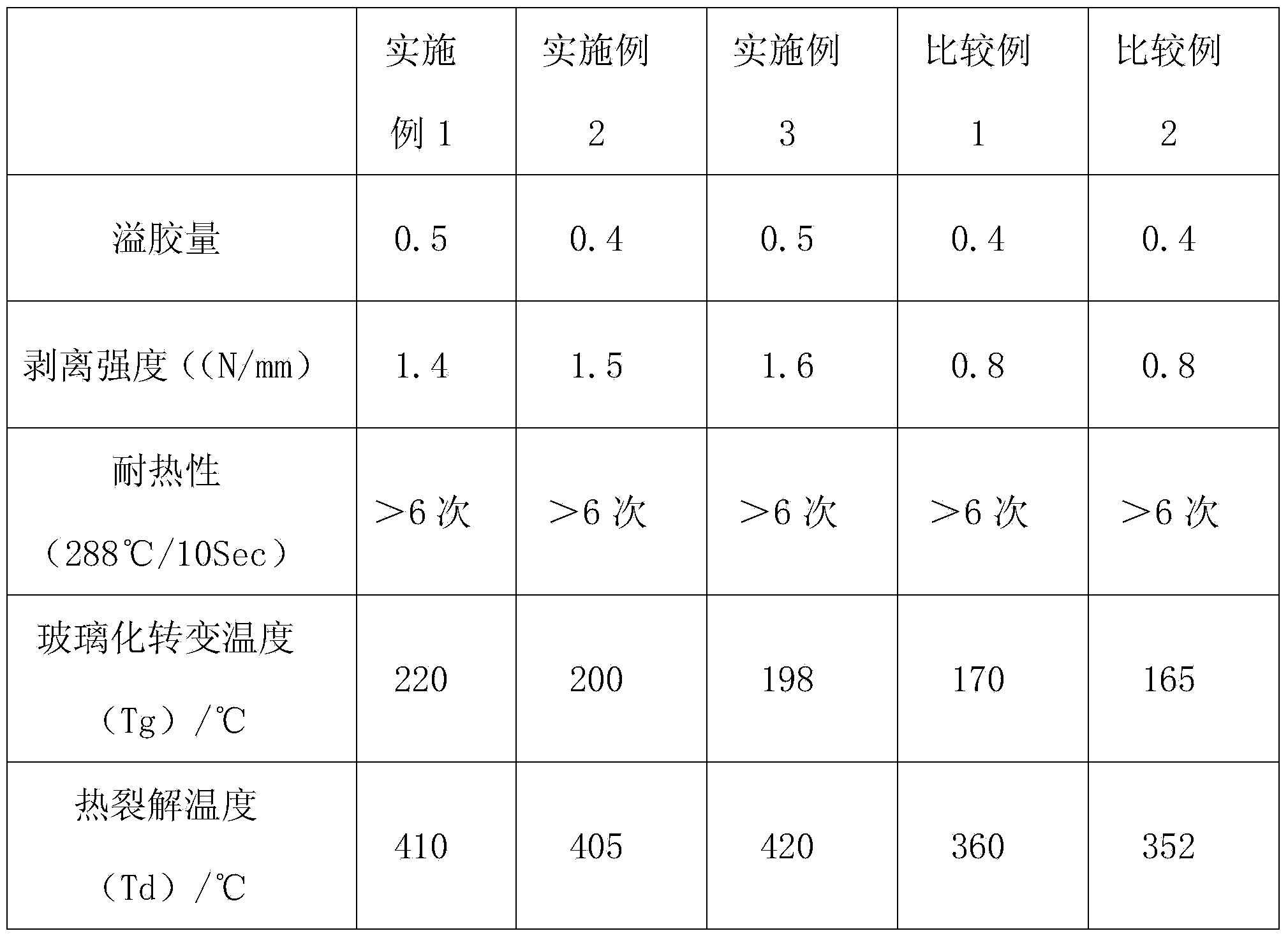

Examples

Embodiment 1

[0030] 1. Weigh 100kg of B920, 50kg of 912A and 15kg of P59 into a 500ml container and mix thoroughly, react at 130°C for about 60min, and add 15kg of MEK to dissolve the solid after the reaction is completed;

[0031] 2. After the above solids are completely dissolved, add 10kg of 705 and the remaining MEK, stir for more than 2 hours, and mix well to form a glue with a resin content of 60%;

[0032] 3. Immerse the above glue on 1080 electronic grade glass fiber cloth, put it into an oven at 150-170°C and bake for 6-8 minutes, so that the glue is semi-cured to B-stage, and the low resin fluidity is obtained. prepreg.

Embodiment 2

[0034] 1. Weigh 100kg of B920, 50kg of 912A and 15kg of P59 into a 500ml container, react at 130°C for about 60 minutes, and add 15kg of MEK to dissolve the solid after the reaction is completed;

[0035] 2. After the above solids are completely dissolved, add 15kg of 705 and the remaining MEK, stir for more than 2 hours, and mix well to form a glue with a resin content of 60%;

[0036] 3. Immerse the above glue on 1080 electronic grade glass fiber cloth, put it into an oven at 150-170°C and bake for 6-8 minutes, so that the glue is semi-cured to B-stage, and the low resin fluidity is obtained. prepreg.

Embodiment 3

[0038] 1. Weigh 100kg of B920, 50kg of 912A and 15kg of P59 into a 500ml container, react at 130°C for about 60min, and add 15kg of MEK to dissolve the solid after the reaction is completed;

[0039] 2. After the above solids are completely dissolved, add 20kg of 705, 15kg of spherical silica and the remaining MEK, stir for more than 2 hours, and mix well to form a glue with a resin content of 60%;

[0040] 3. Immerse the above glue on 1080 electronic grade glass fiber cloth, put it into an oven at 150-170°C and bake for 6-8 minutes, so that the glue is semi-cured to B-stage, and the low resin fluidity is obtained. prepreg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com