Patents

Literature

52results about How to "Controllable length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

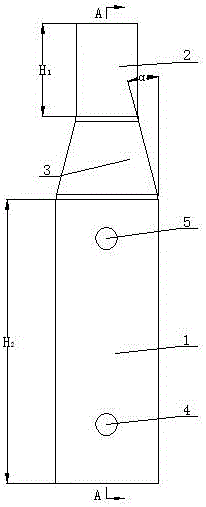

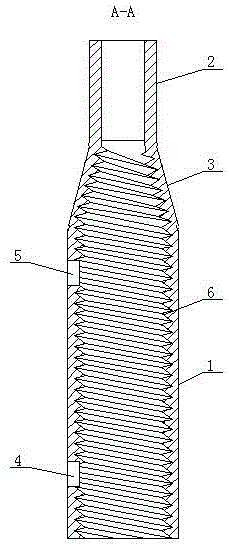

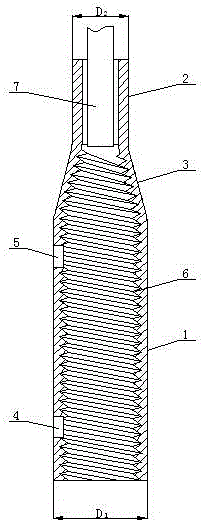

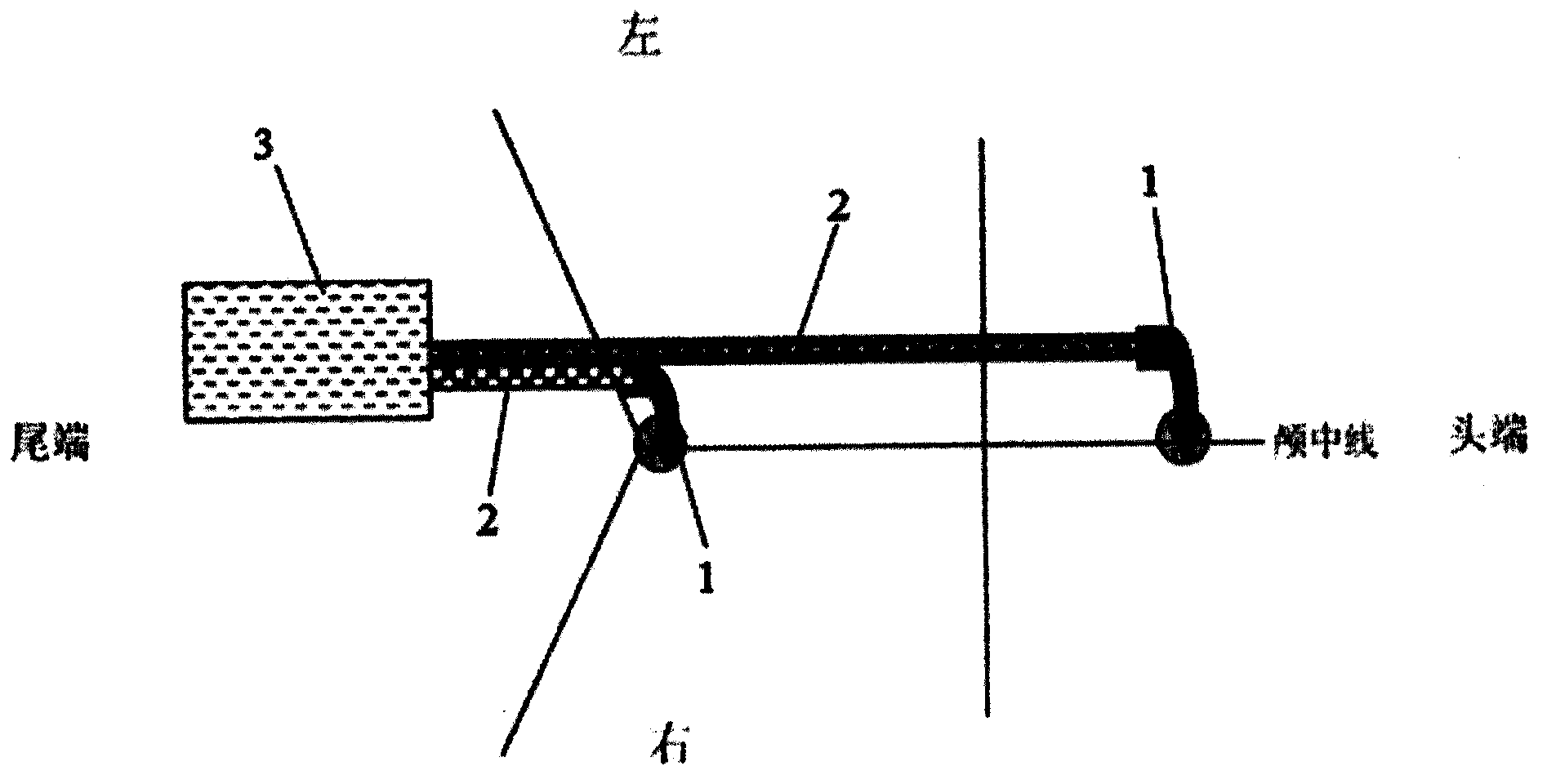

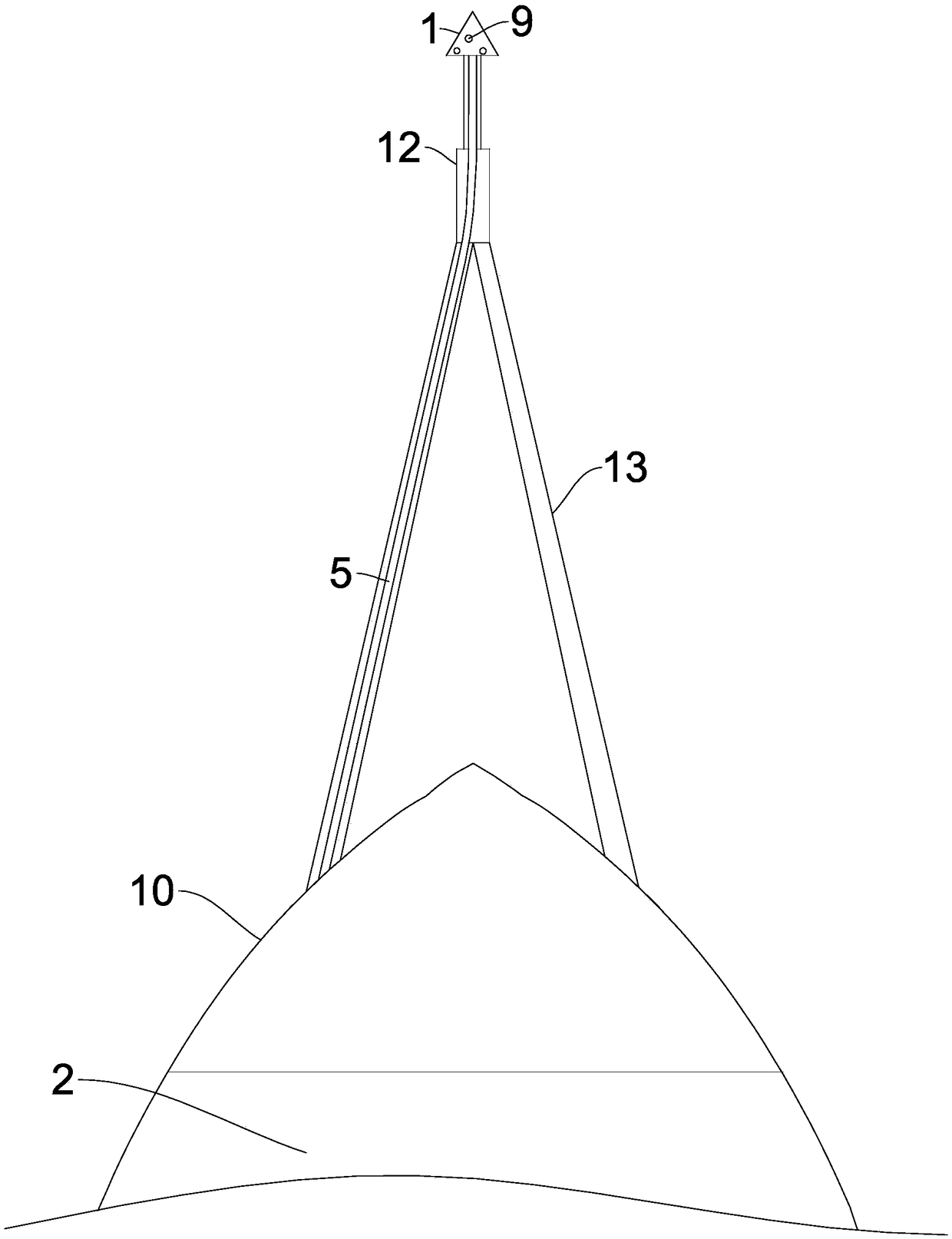

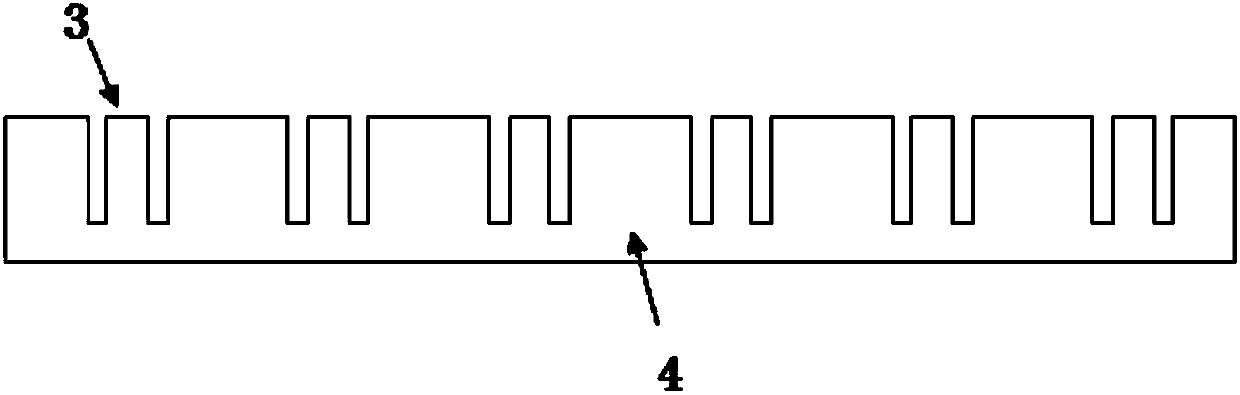

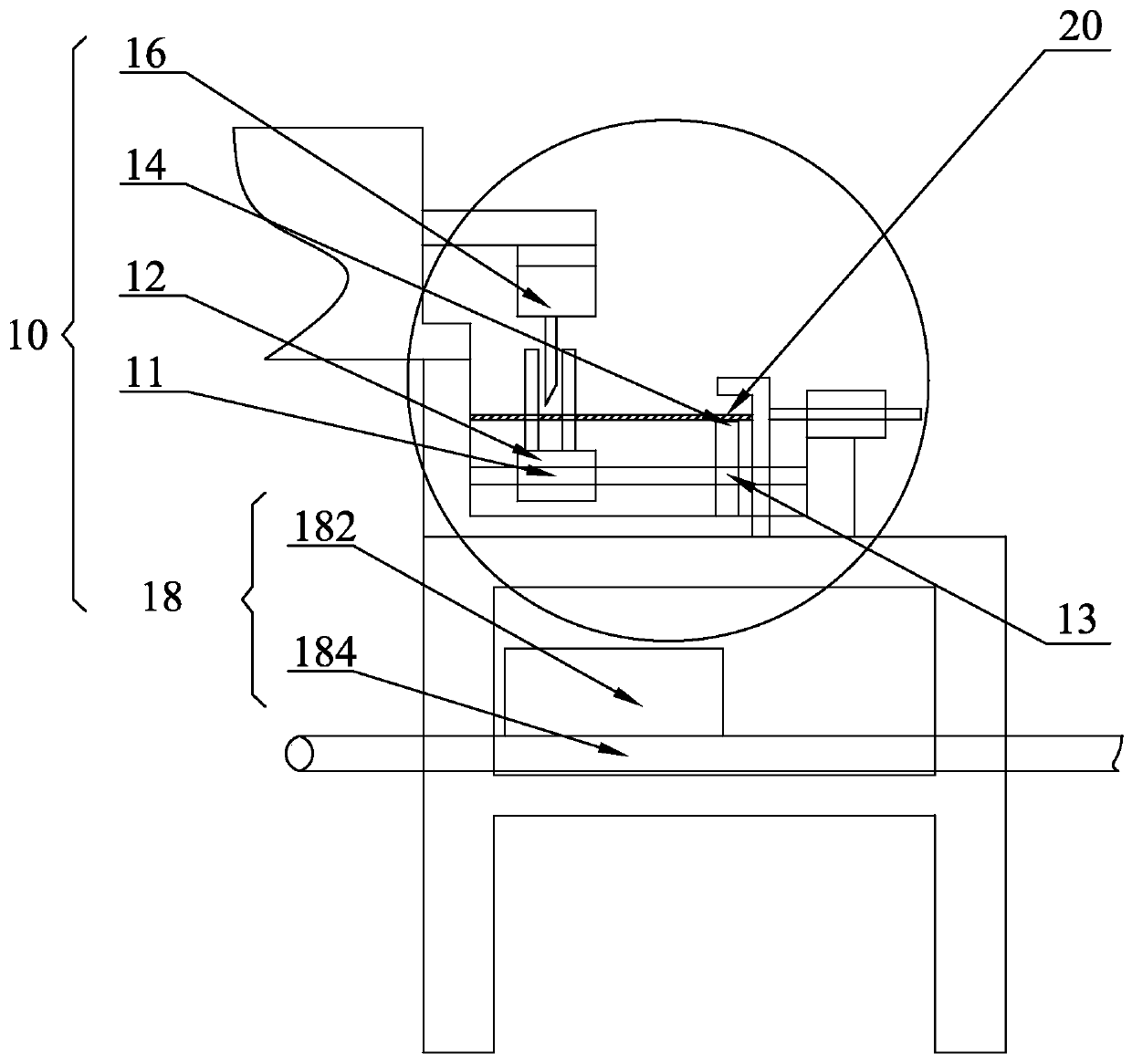

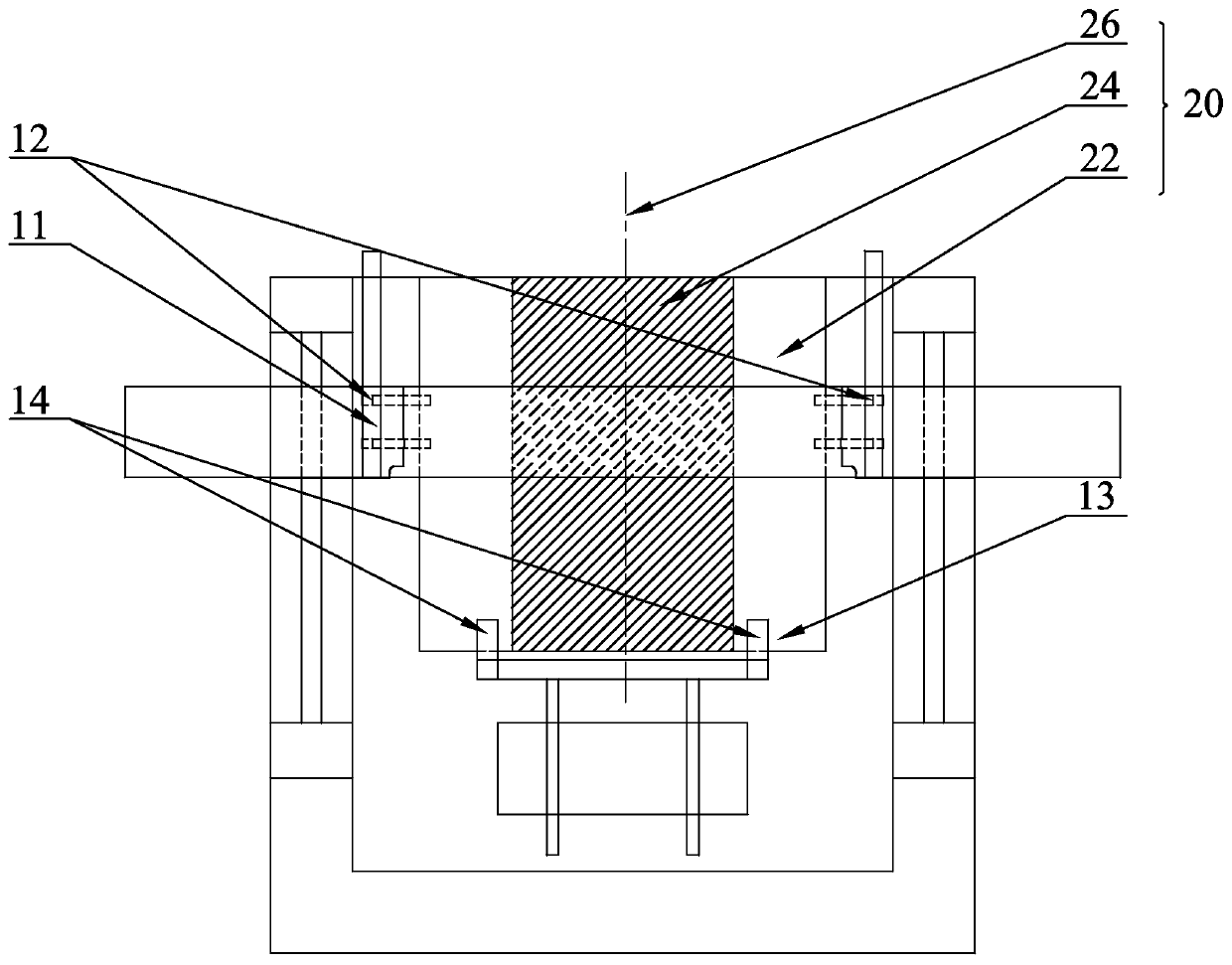

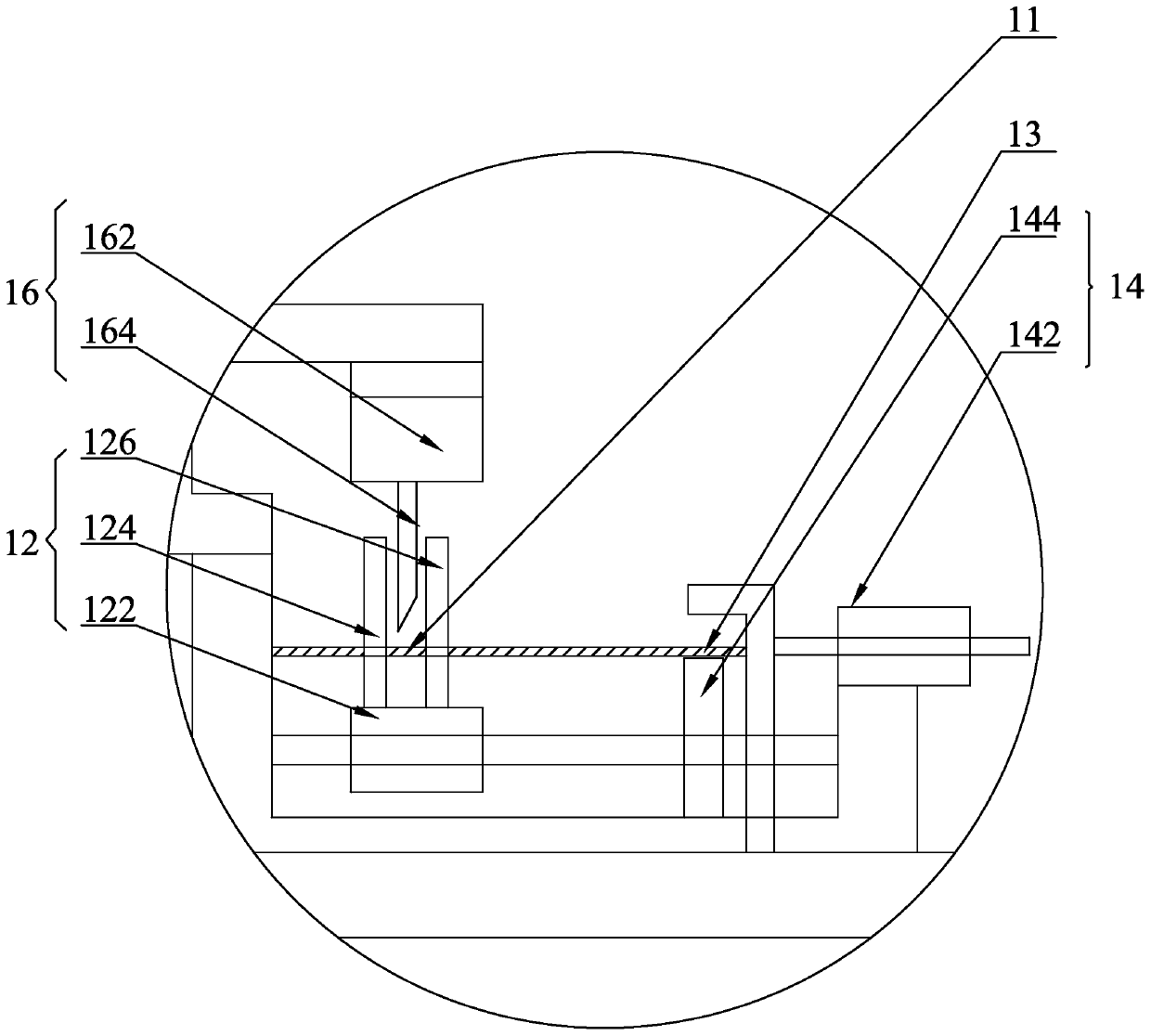

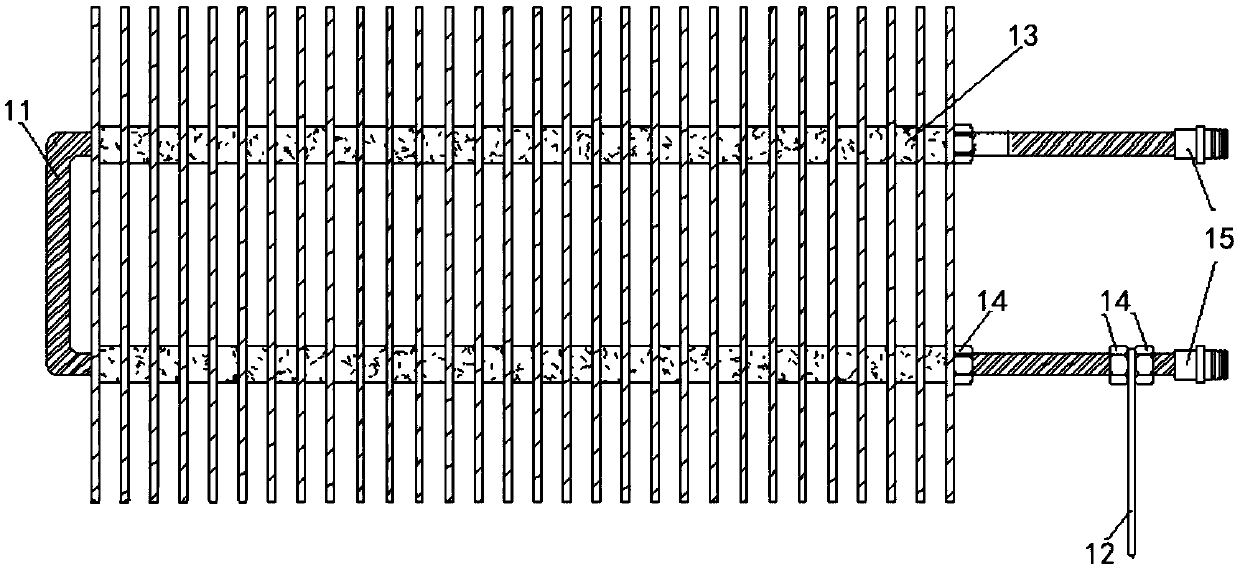

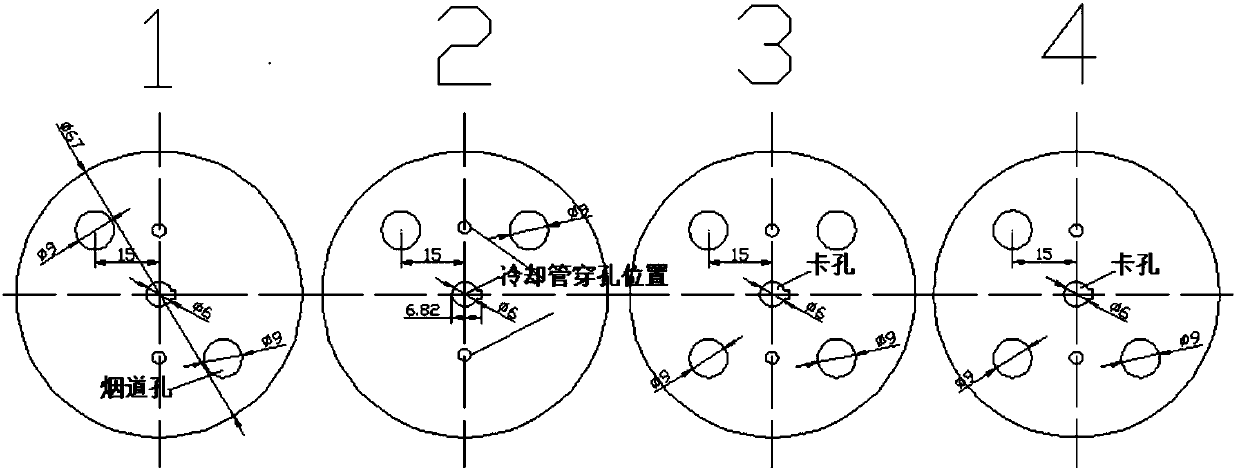

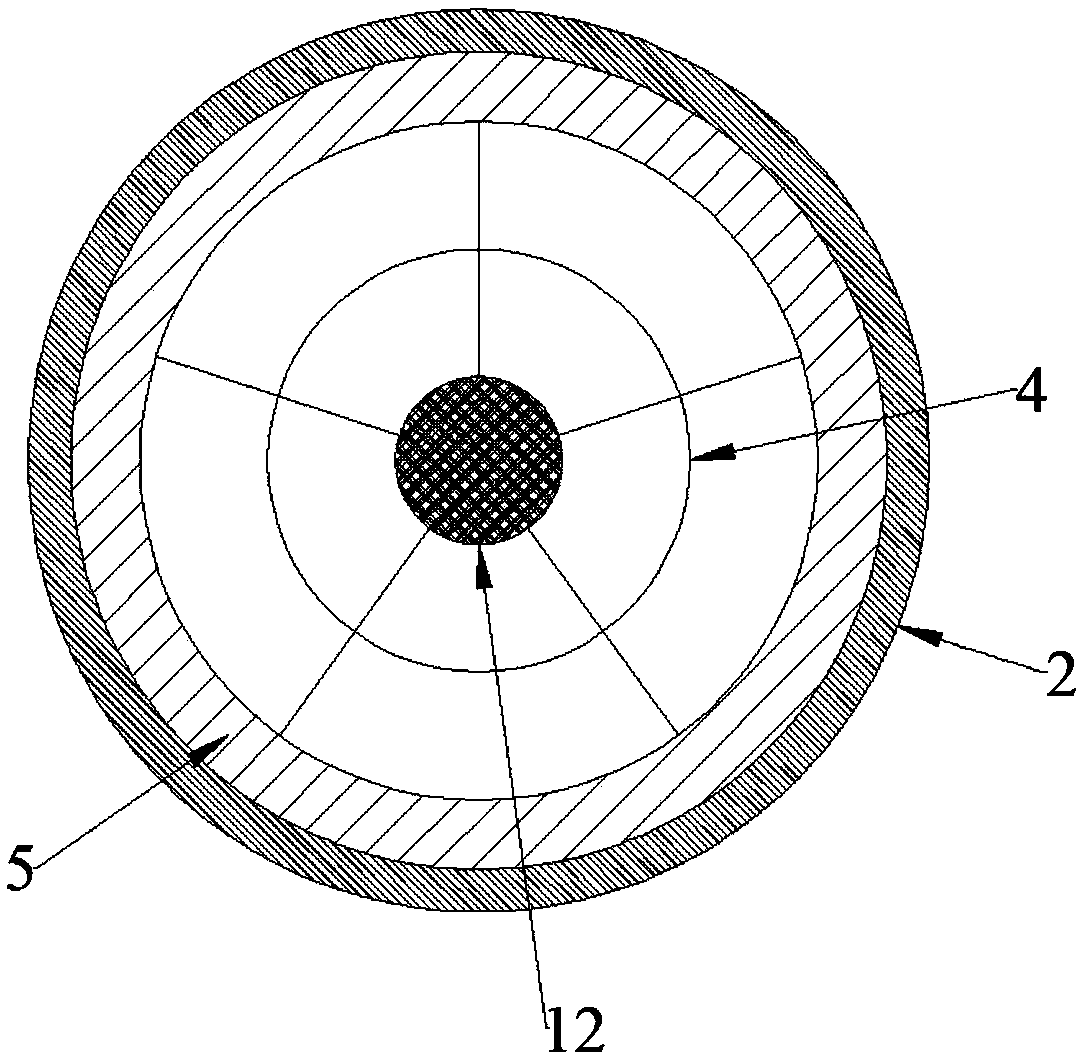

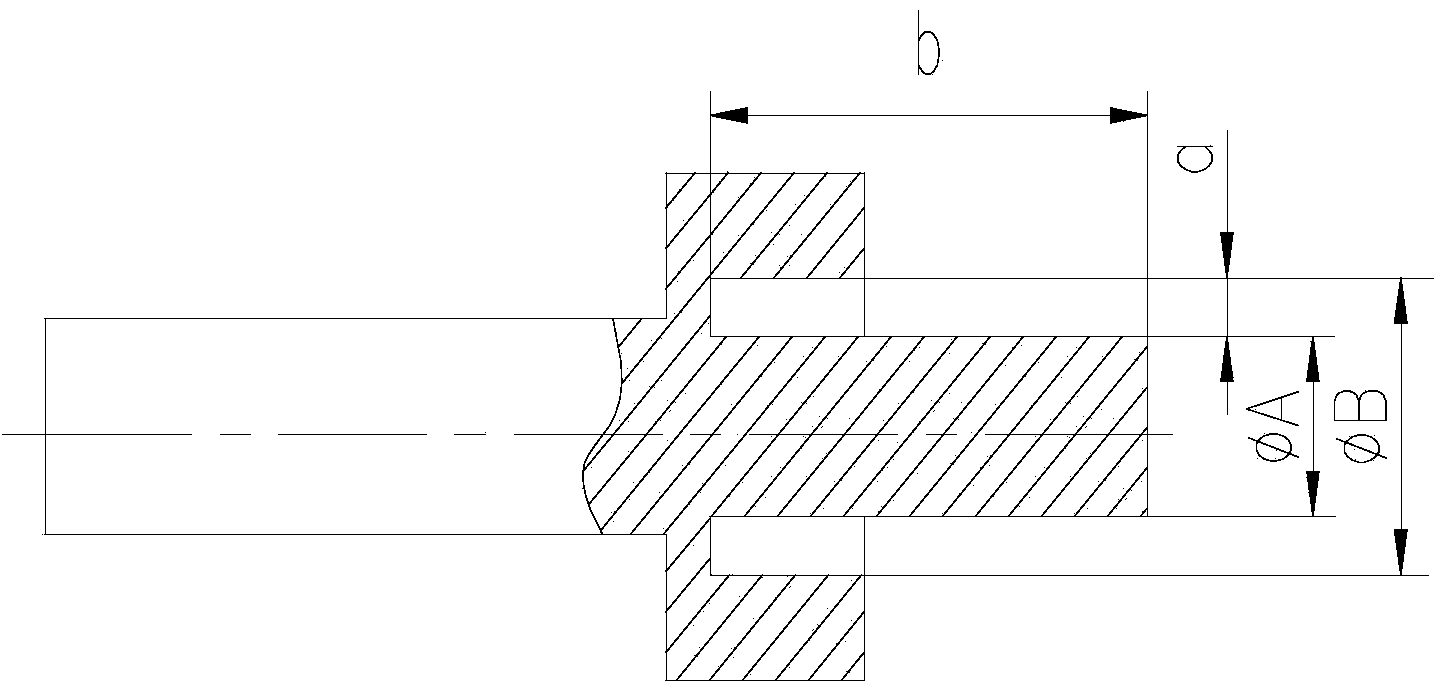

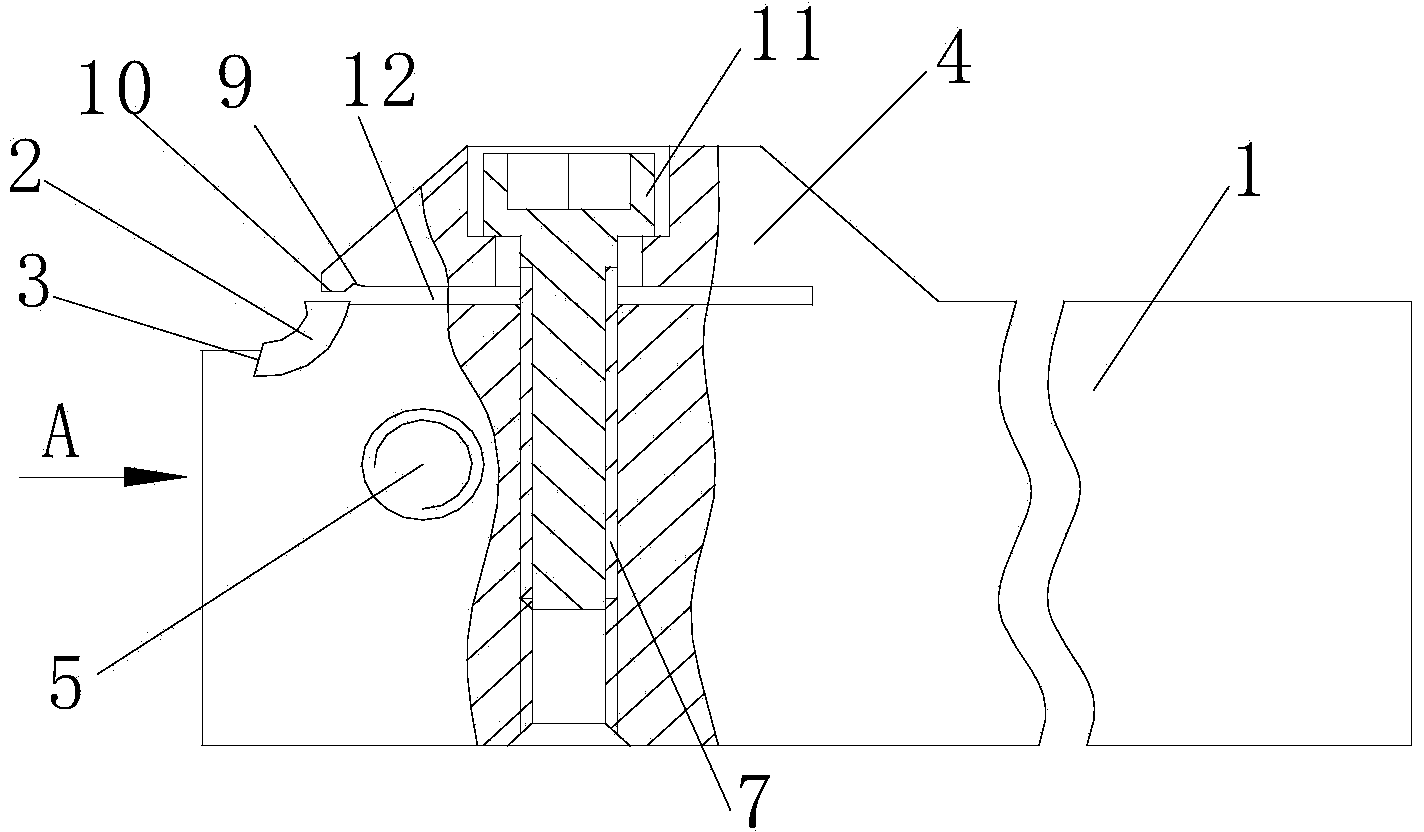

Variable-diameter half grouting sleeve and construction method thereof

InactiveCN105133795AControllable lengthShorten the lengthBuilding reinforcementsArchitectural engineeringRebar

The invention provides a variable-diameter half grouting sleeve and a construction method thereof. A seamless steel pipe is adopted as a body pipe, the inner wall of the body pipe is a concave-convex surface, the upper end of the body pipe is connected with the large-diameter end of a conical pipe, and the small-diameter end of the conical pipe is connected with one end of a cylindrical pipe. The construction method includes the steps that 1, the variable-diameter half grouting sleeve is manufactured; 2, a machining die is manufactured; 3, the upper portion of the short pipe in the step1 is heated; 4, the heated part of the short pipe is placed into a groove in a lower die, and an upper die is placed on the heated short pipe; 5, a grout injecting hole and a grout discharging hole are formed in the body pipe; 6, a connecting steel bar is inserted into the cylindrical pipe of the variable-diameter half grouting sleeve; 7, the variable-diameter half grouting sleeve, which is connected with the steel bar, in the step6 is placed into the die of a prefabricated component, and after concrete is poured for curing, and the steel bar connected with a building or the prefabricated component is placed into the body pipe to be connected after pouring. The variable-diameter half grouting sleeve makes tight contact with the connecting steel bar through extrusion to overcome the defects in the prior art.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

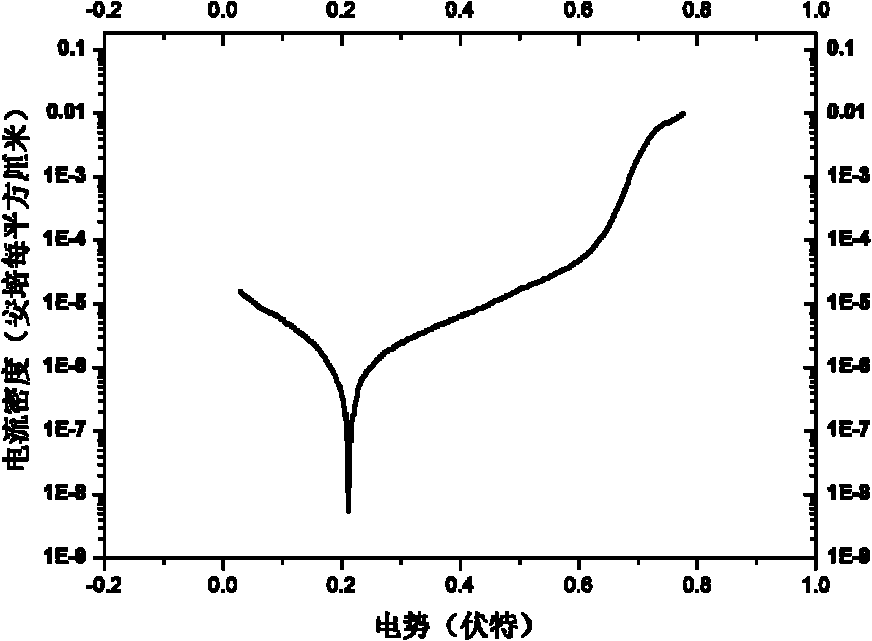

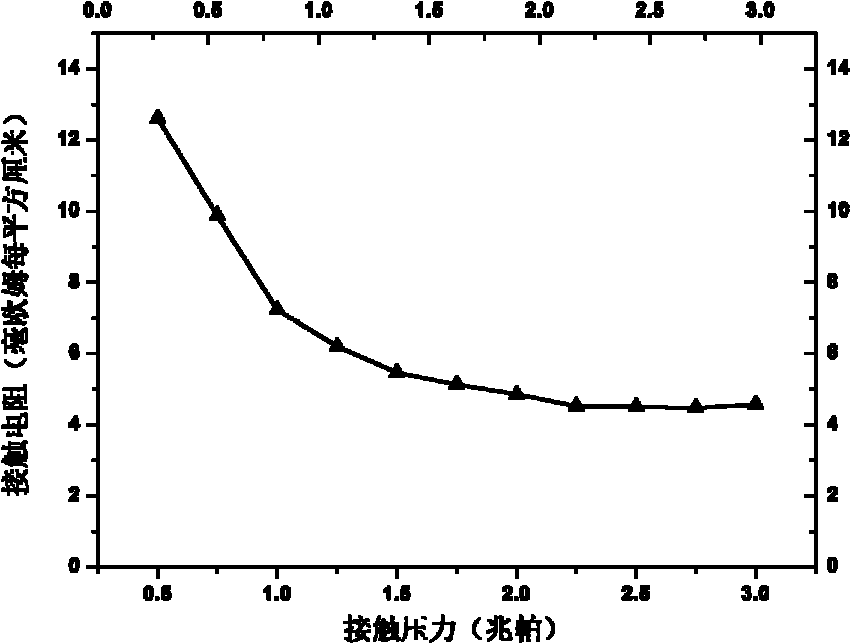

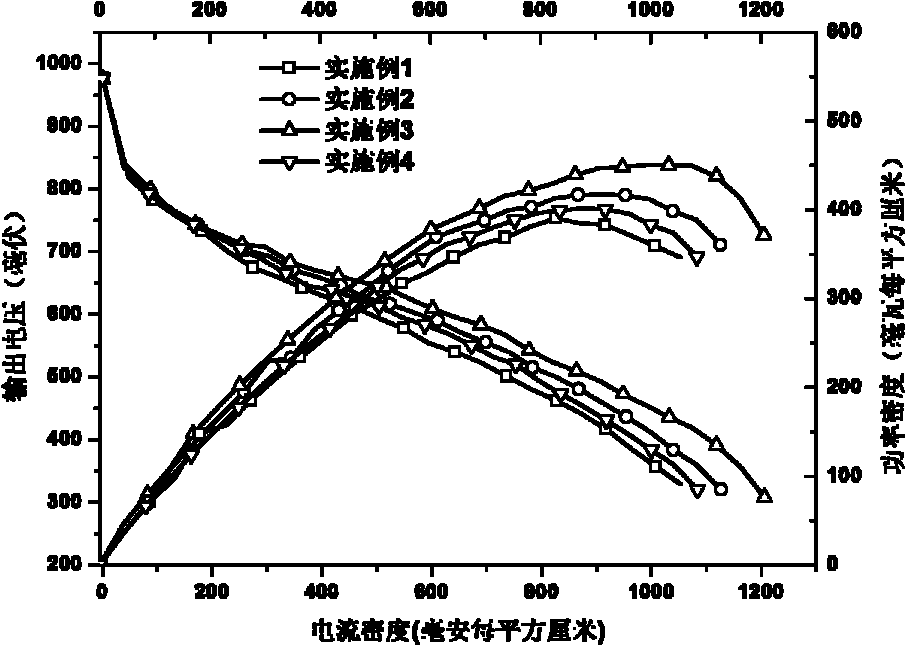

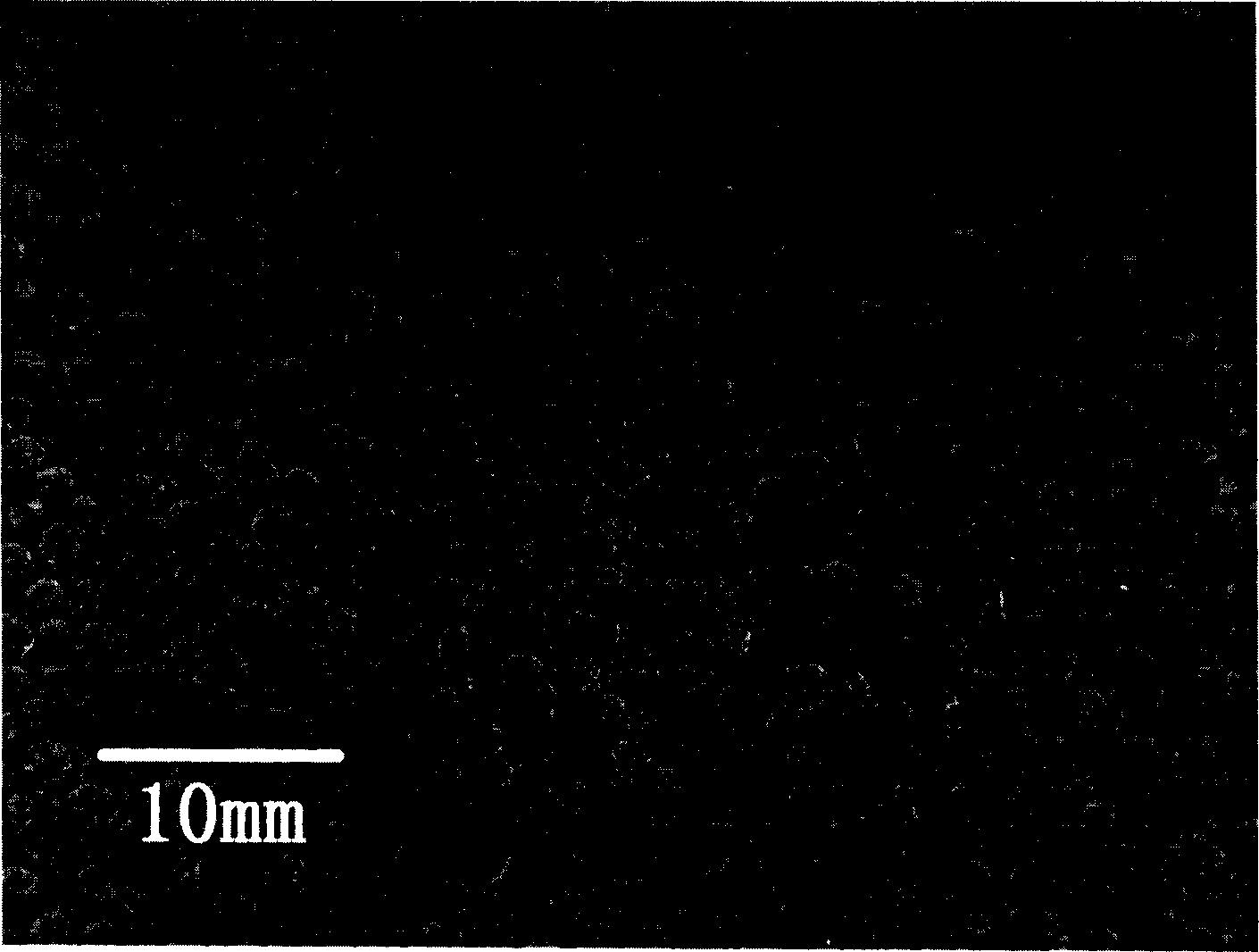

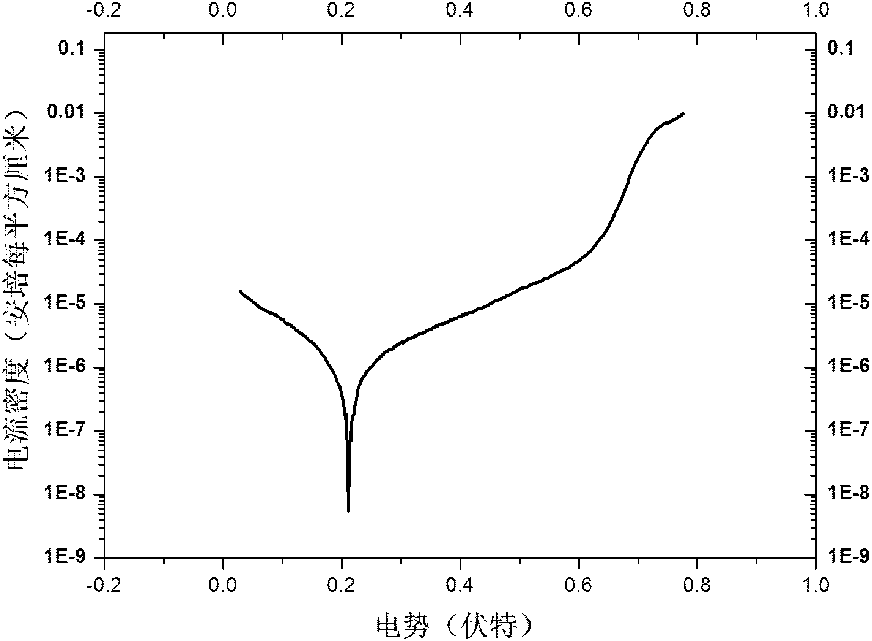

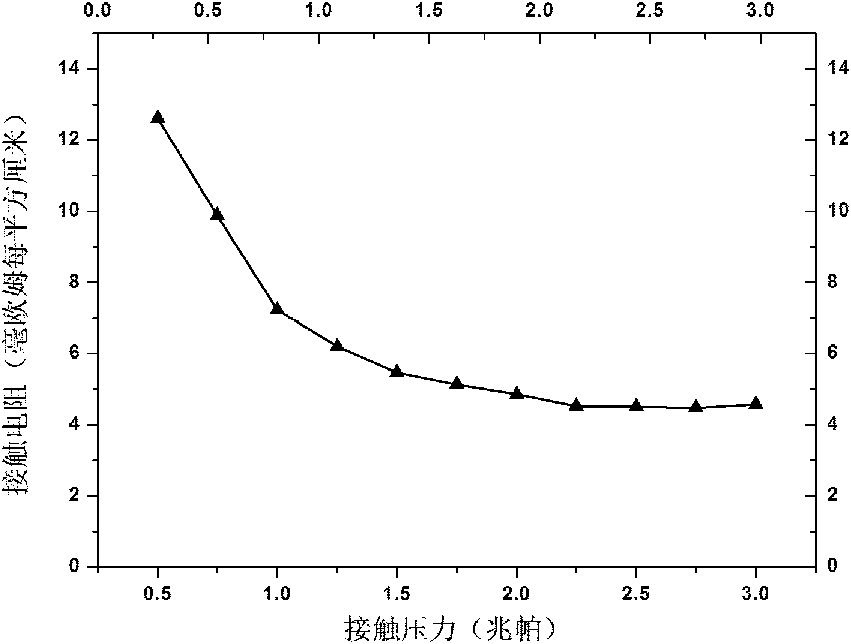

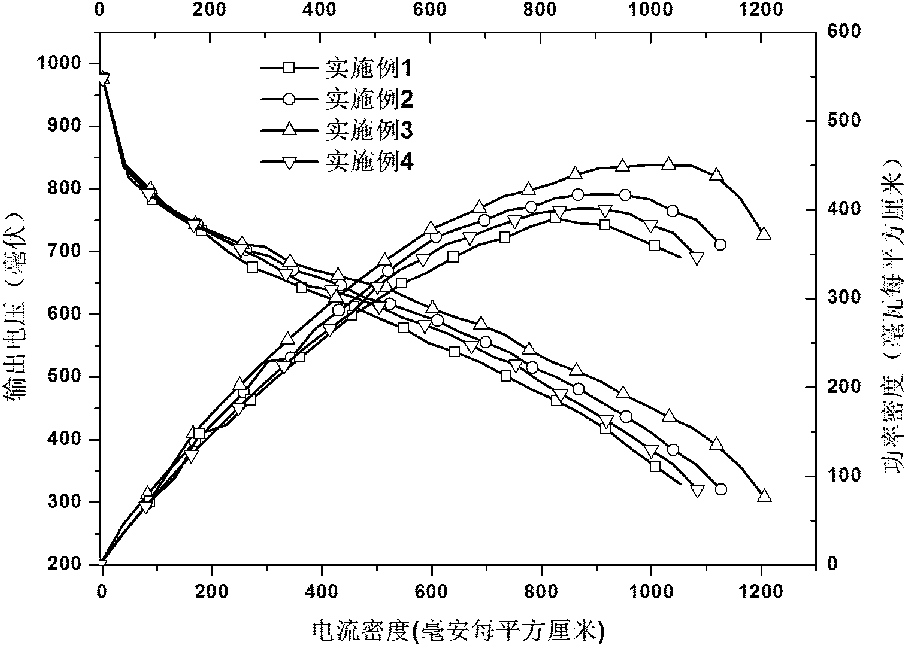

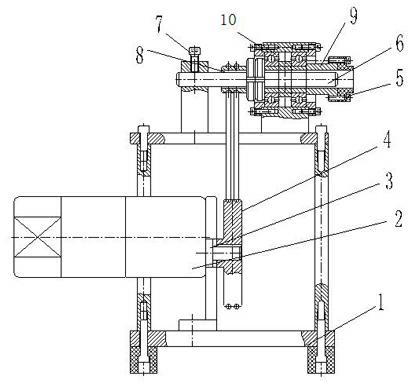

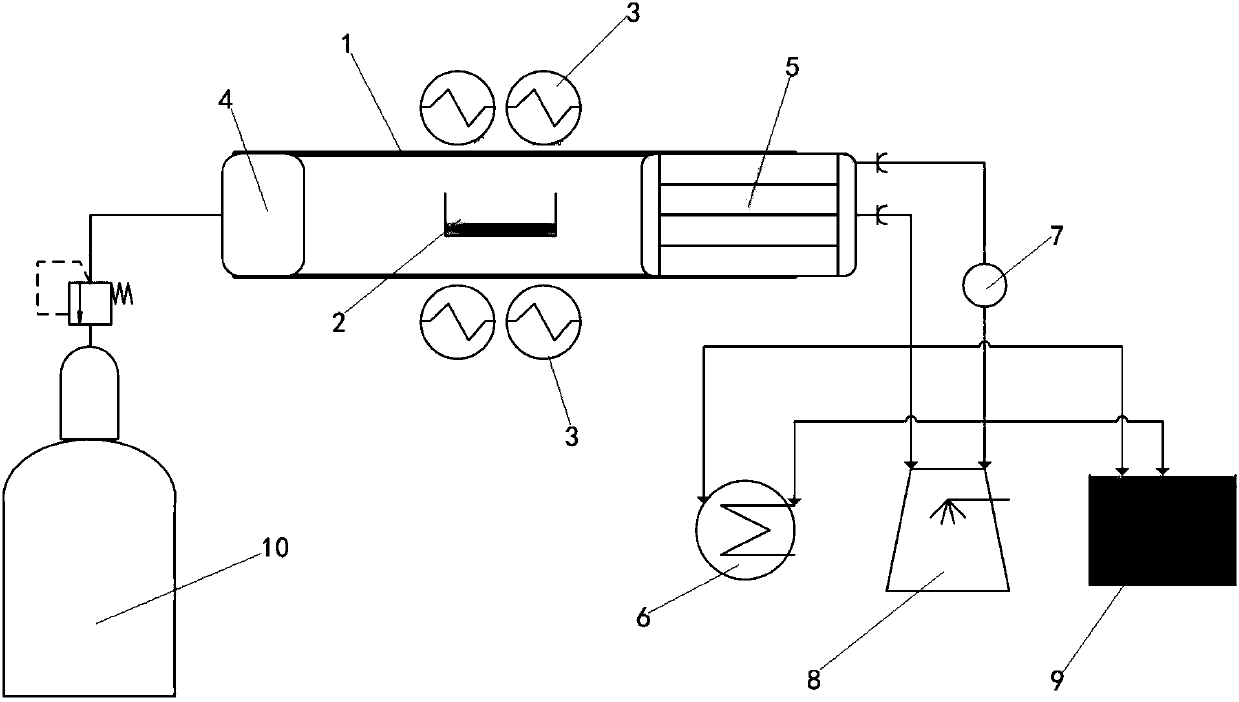

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277AImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:上海氢晨新能源科技有限公司

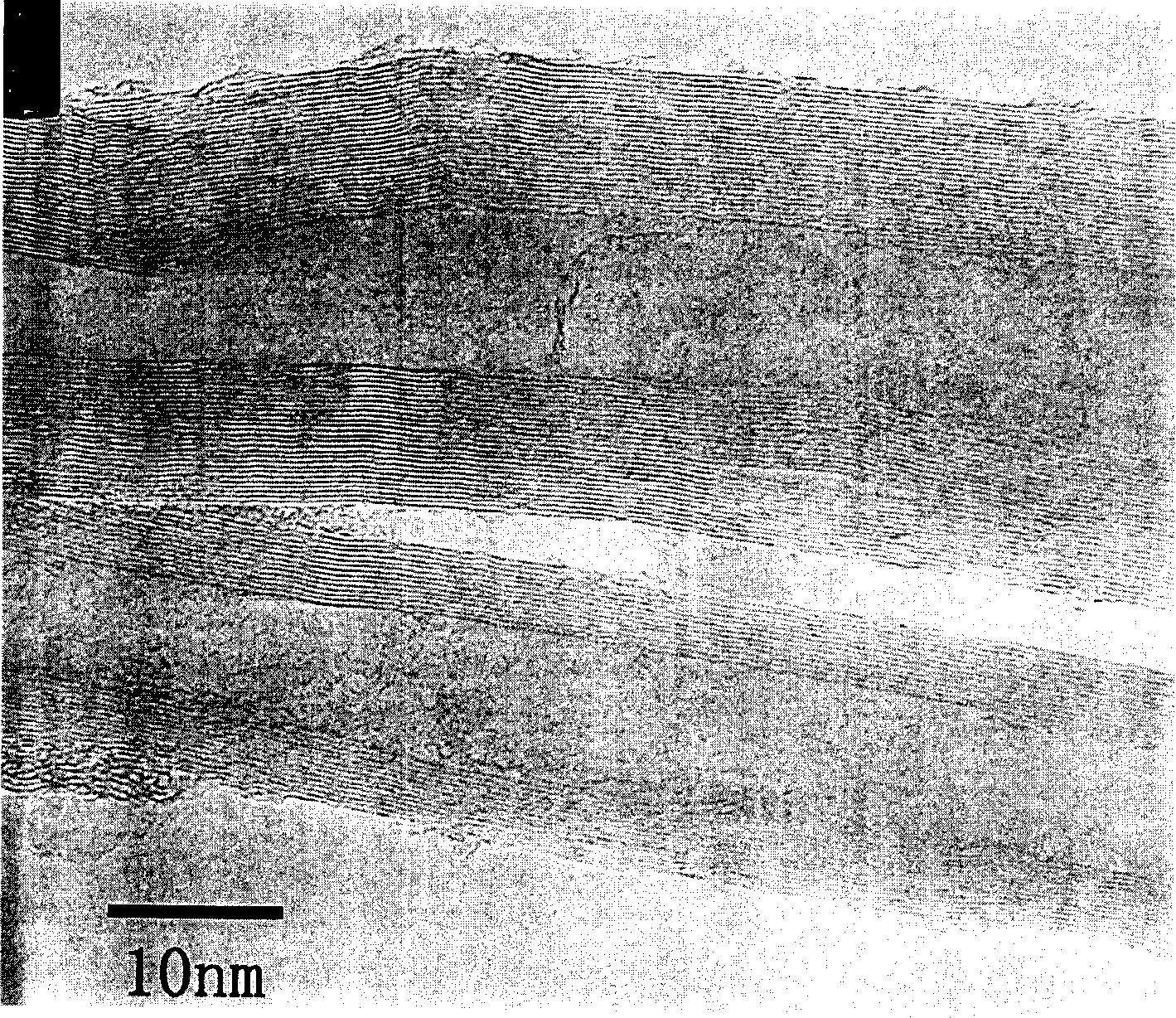

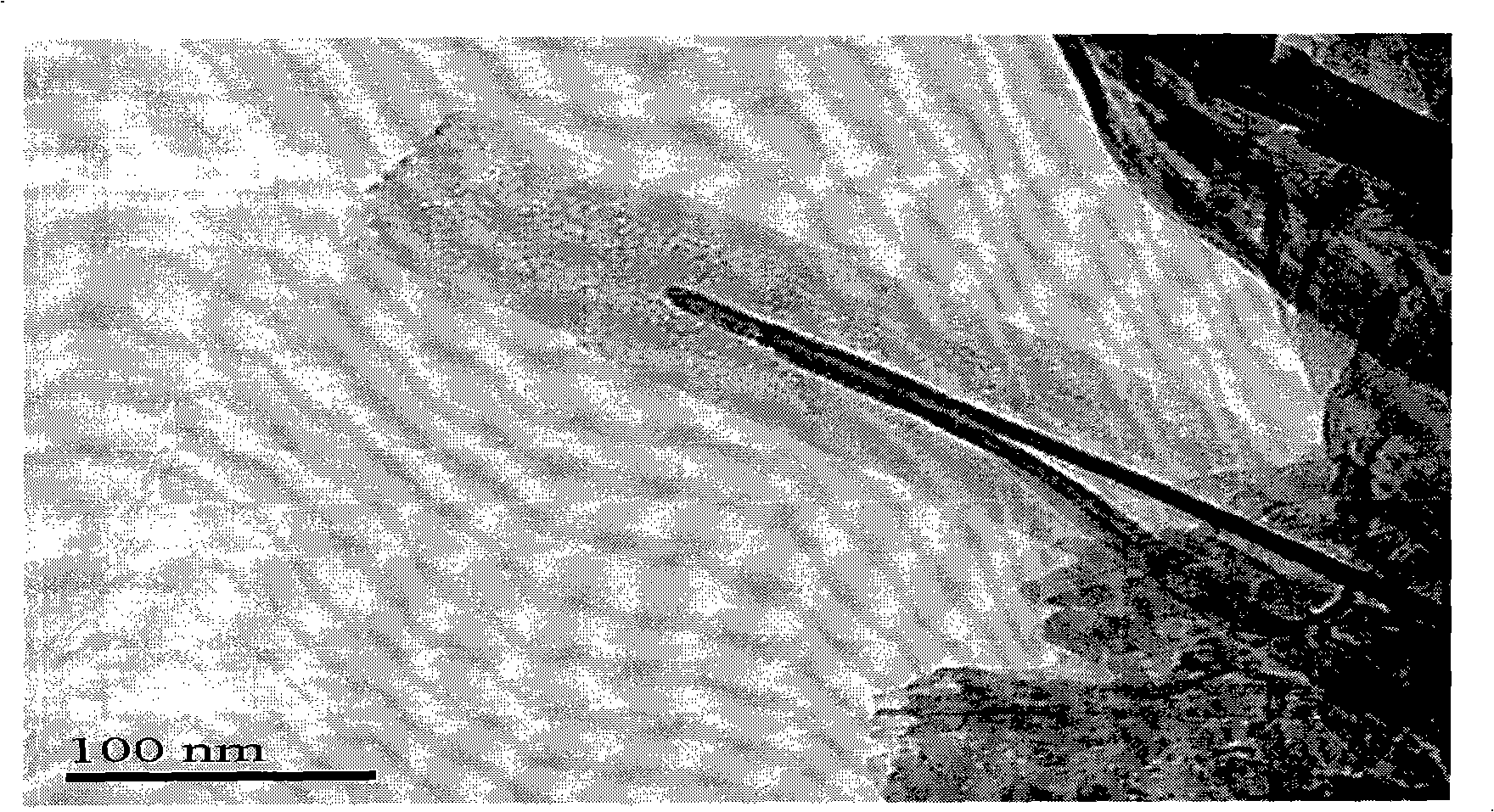

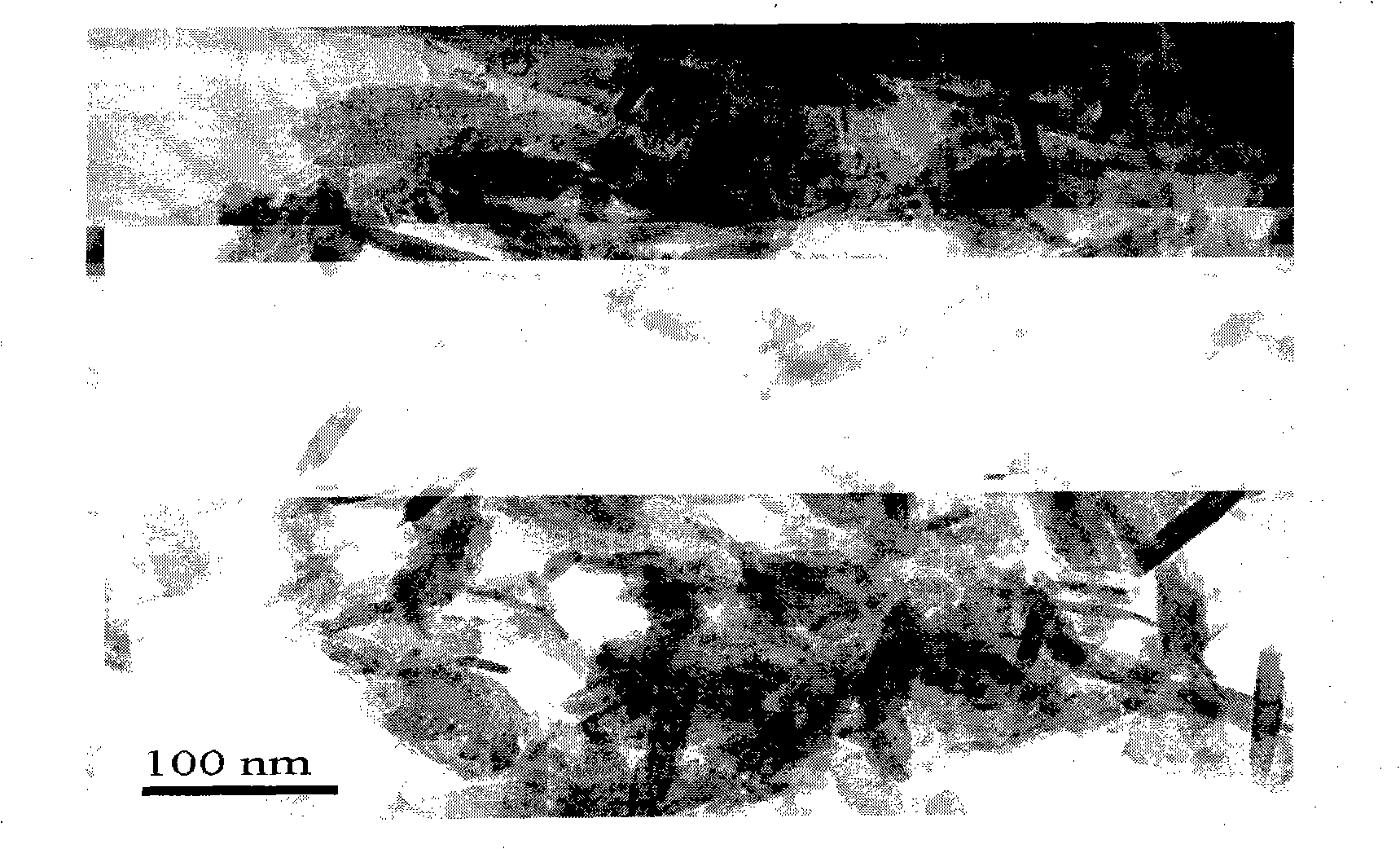

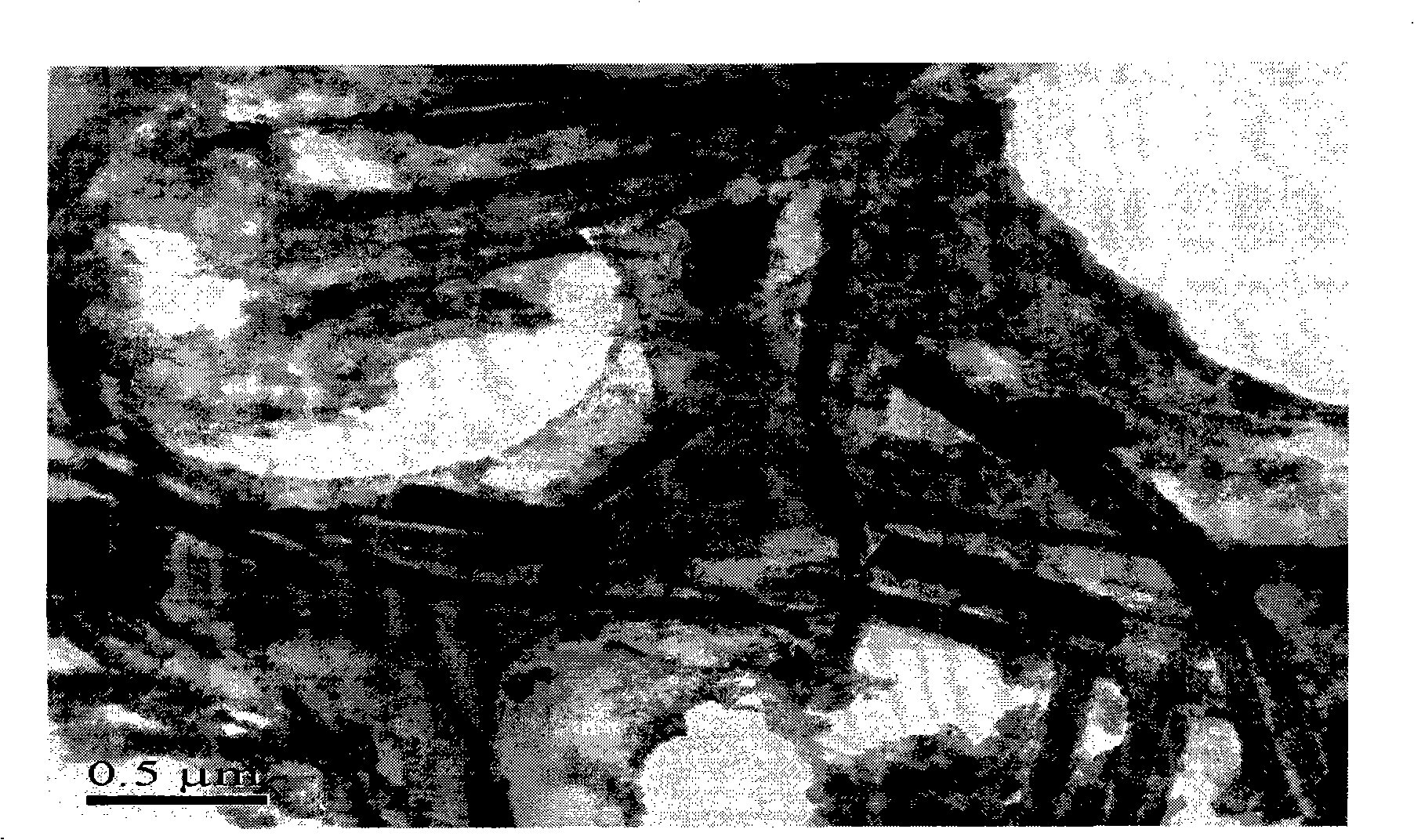

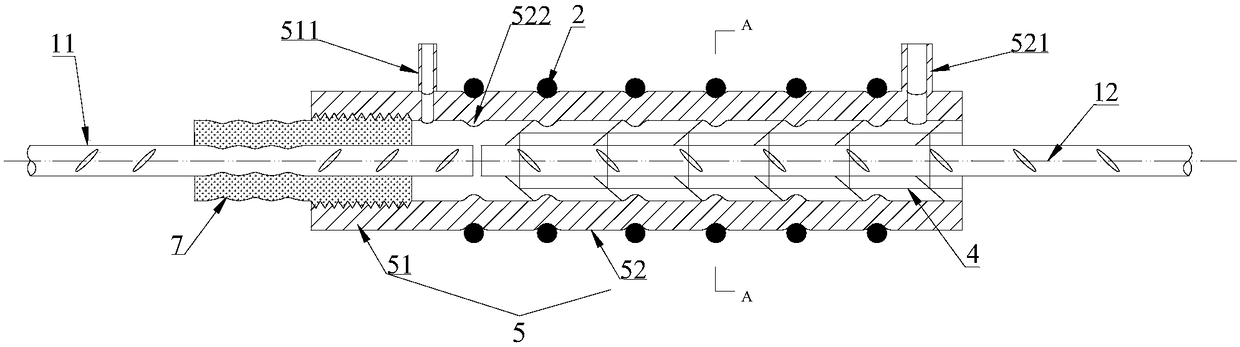

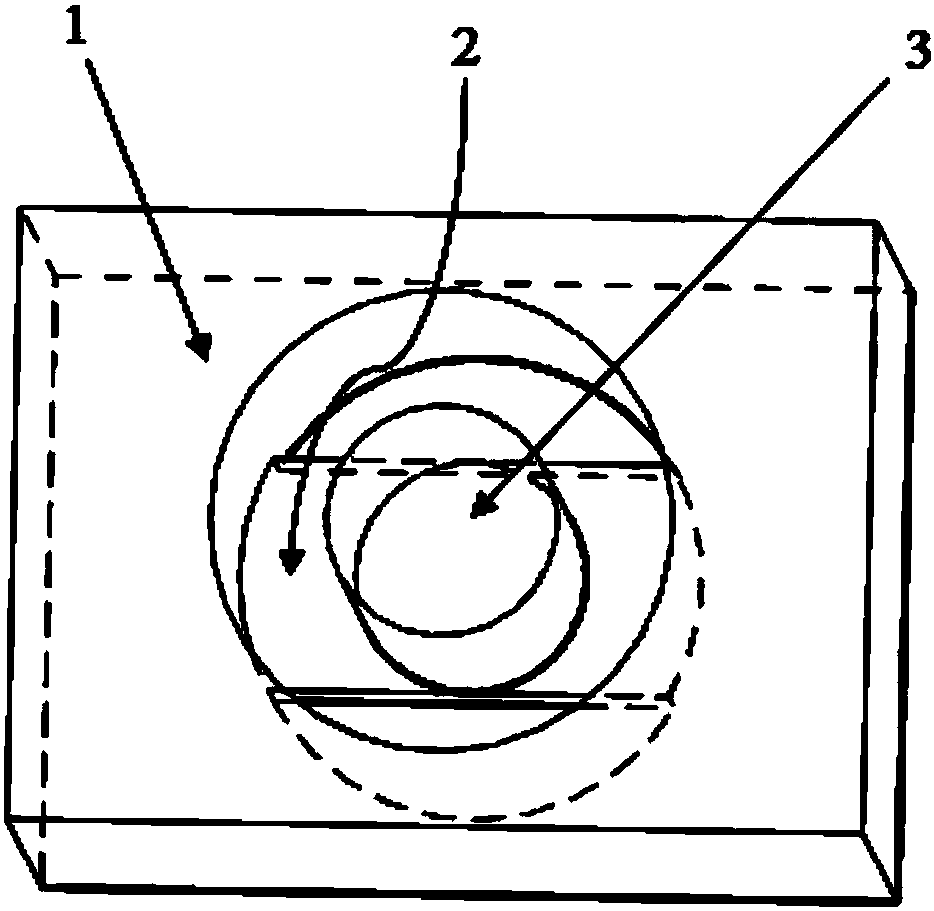

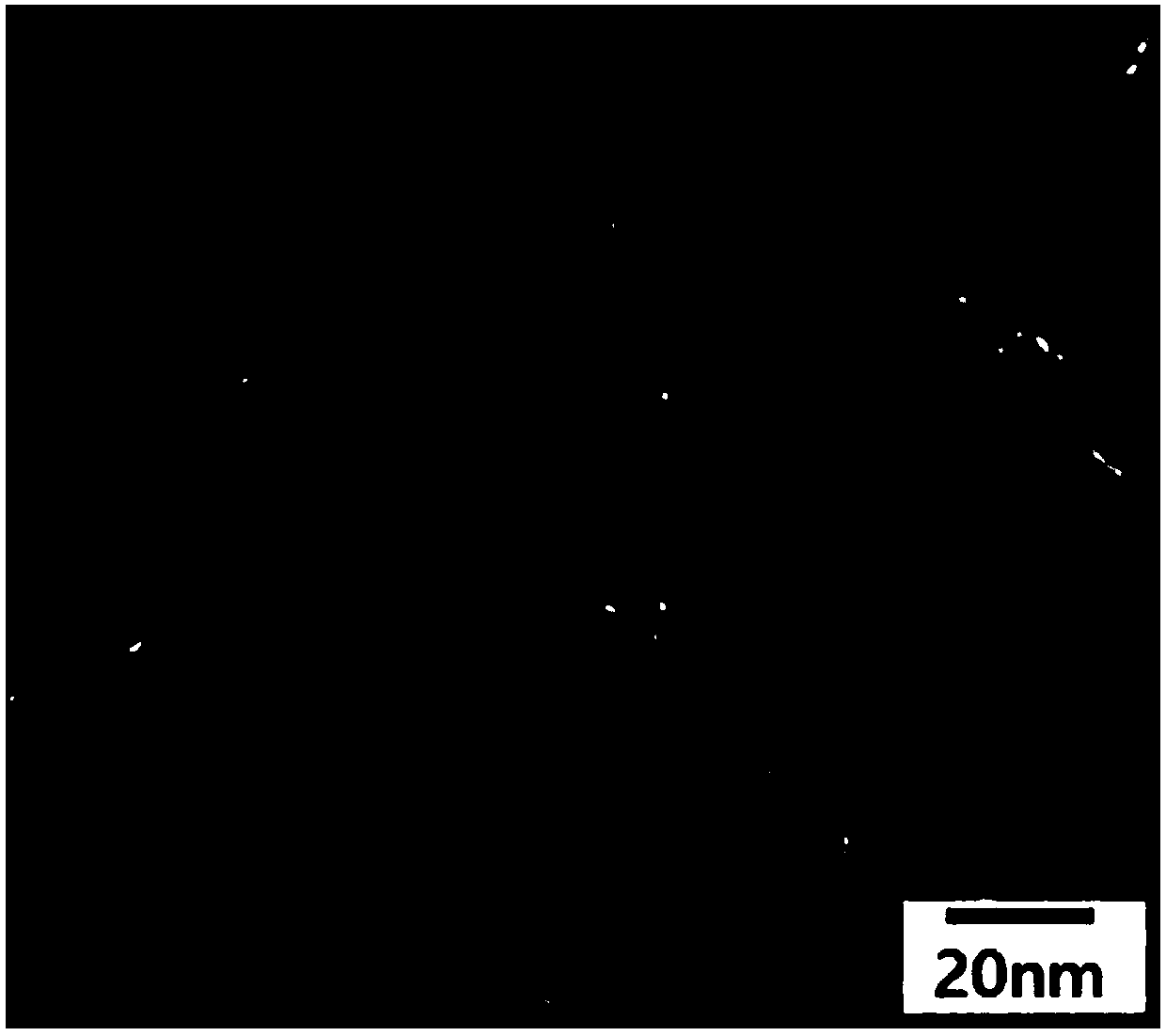

Method for large-batch preparing overlength carbon nano pipe array and its apparatus

ActiveCN1724343AIncrease productionGood orientationNanostructure manufactureChemical vapor deposition coatingFixed bedCarbon nanotube

A process and equipment for preparing ultra-long carbon nano-tube array in batch is disclosed. Said process includes such steps as providing monolithic reactor with artery structure, adding ZrO2, SiO2 or Al2O3 particles or their mixture, inserting structural member in fixed bed and chemical vapor deposition. Its advantages are high purity and output.

Owner:TSINGHUA UNIV

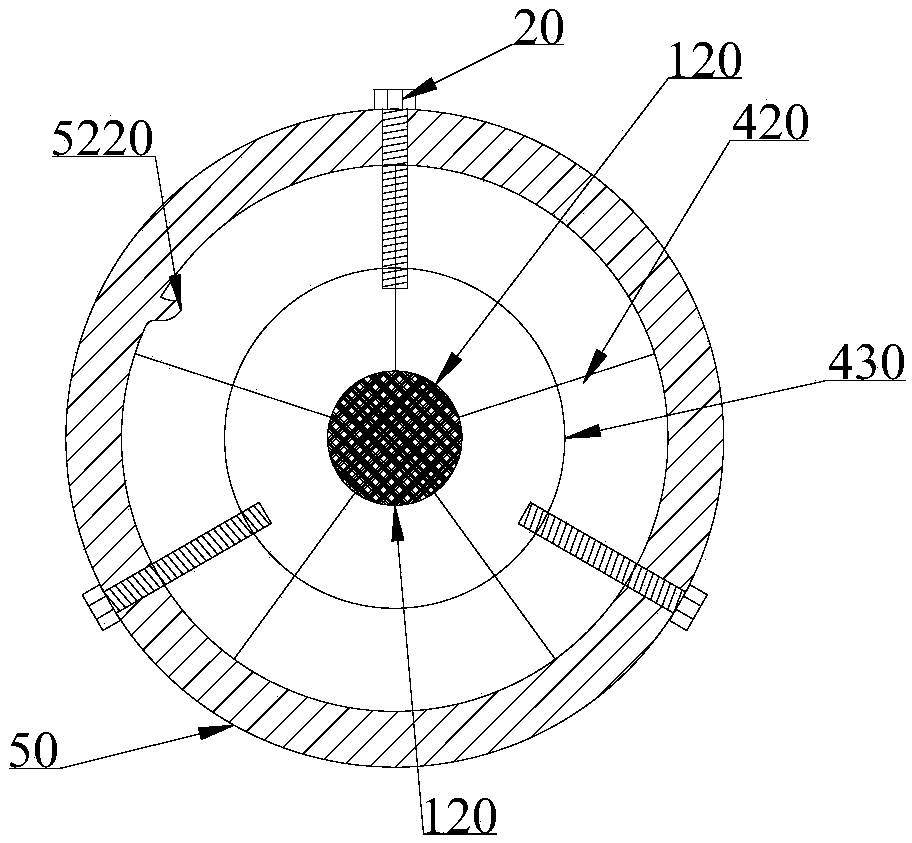

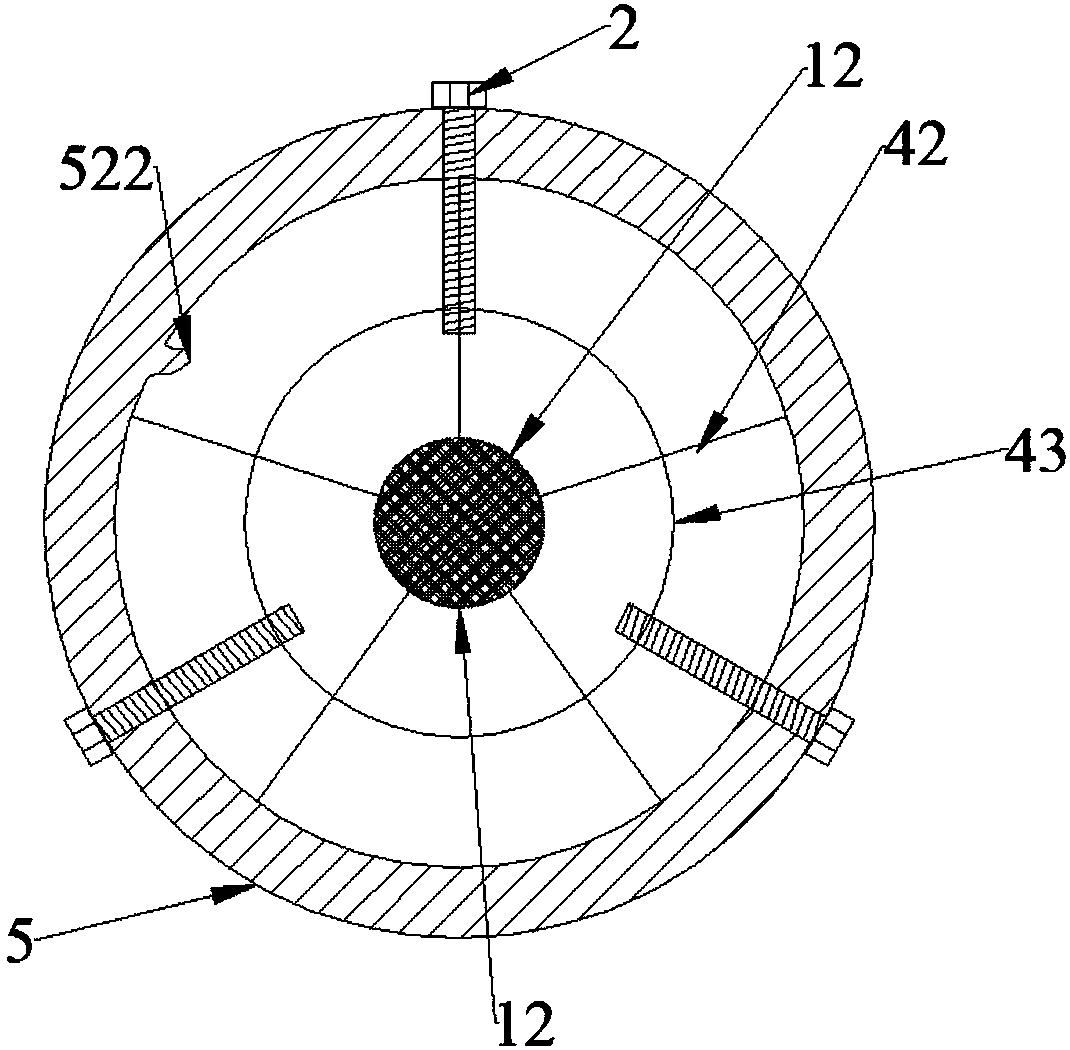

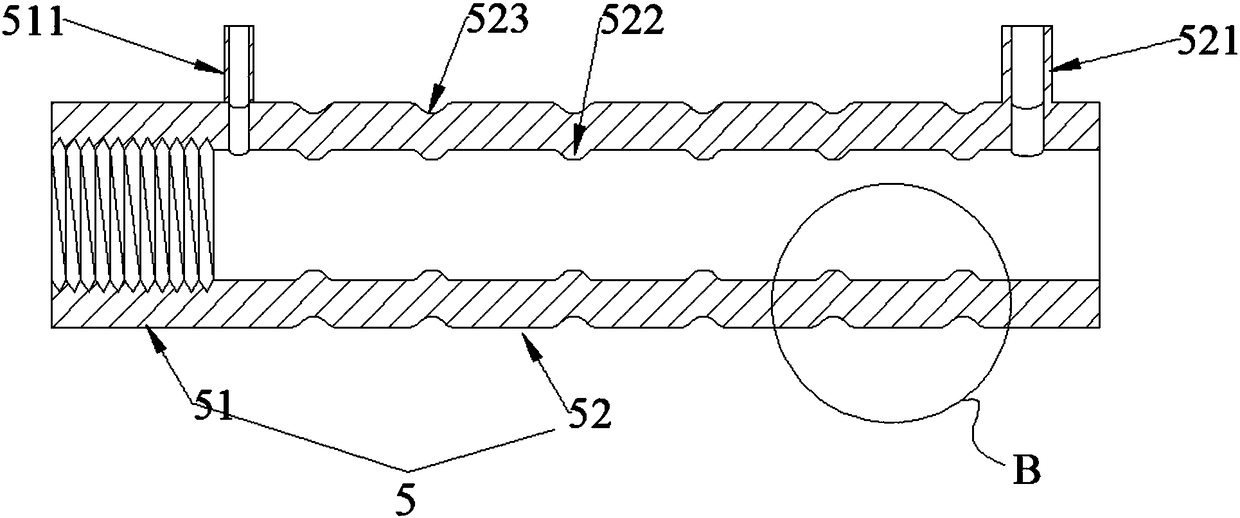

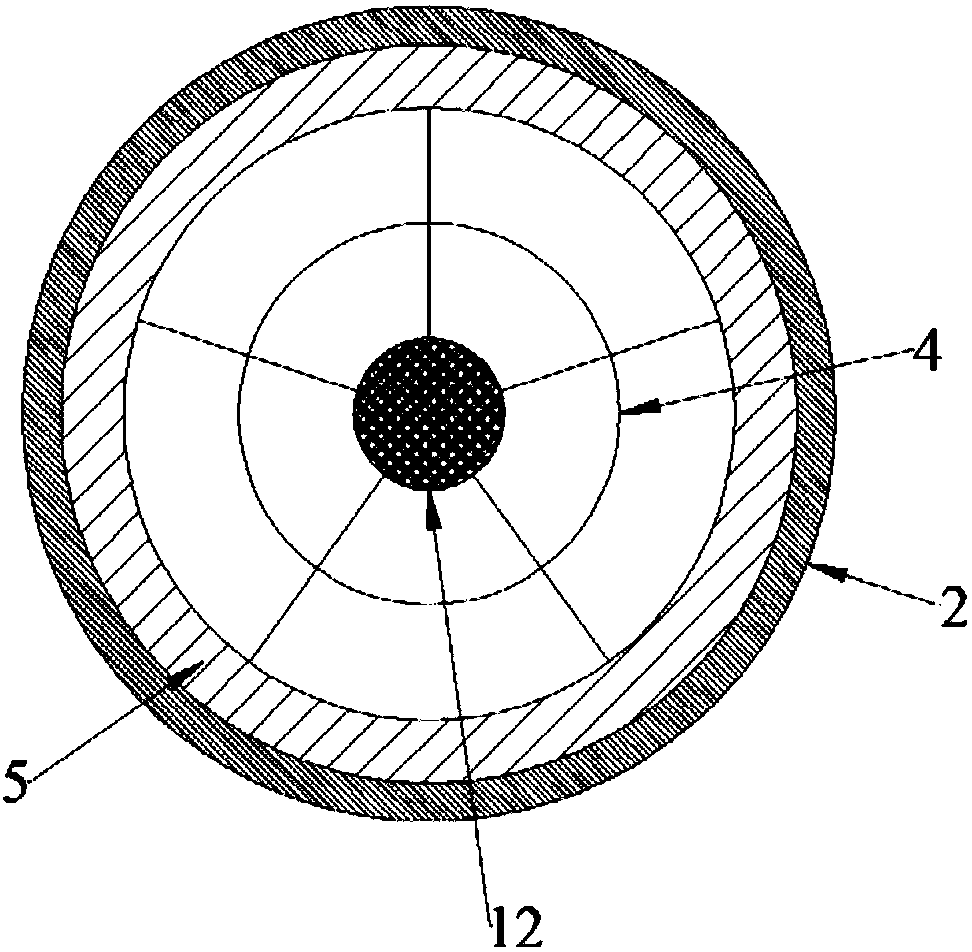

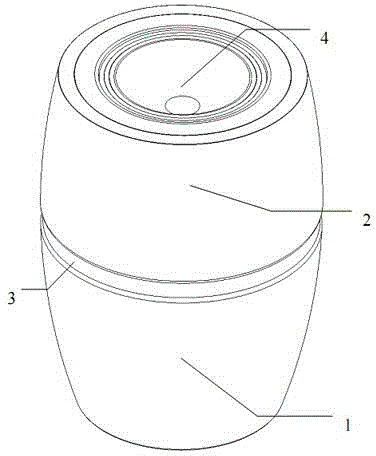

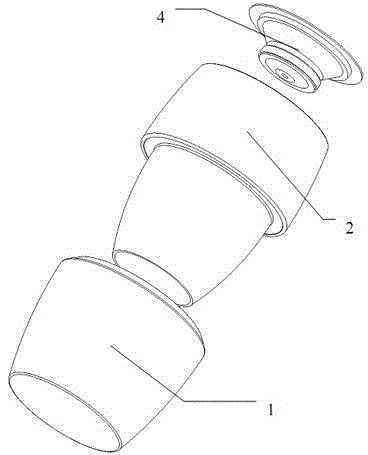

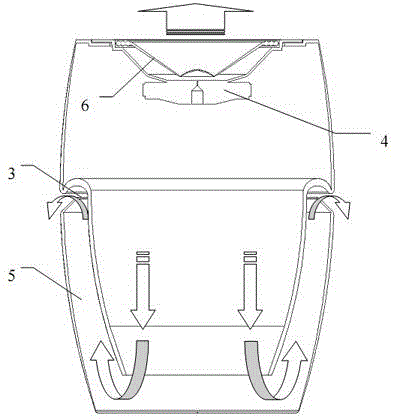

Assembly structure of assembly-type concrete member

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

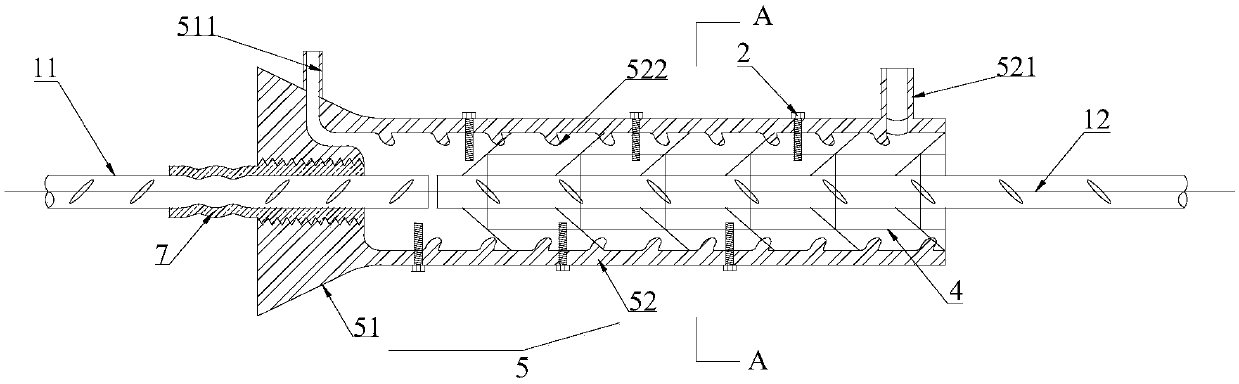

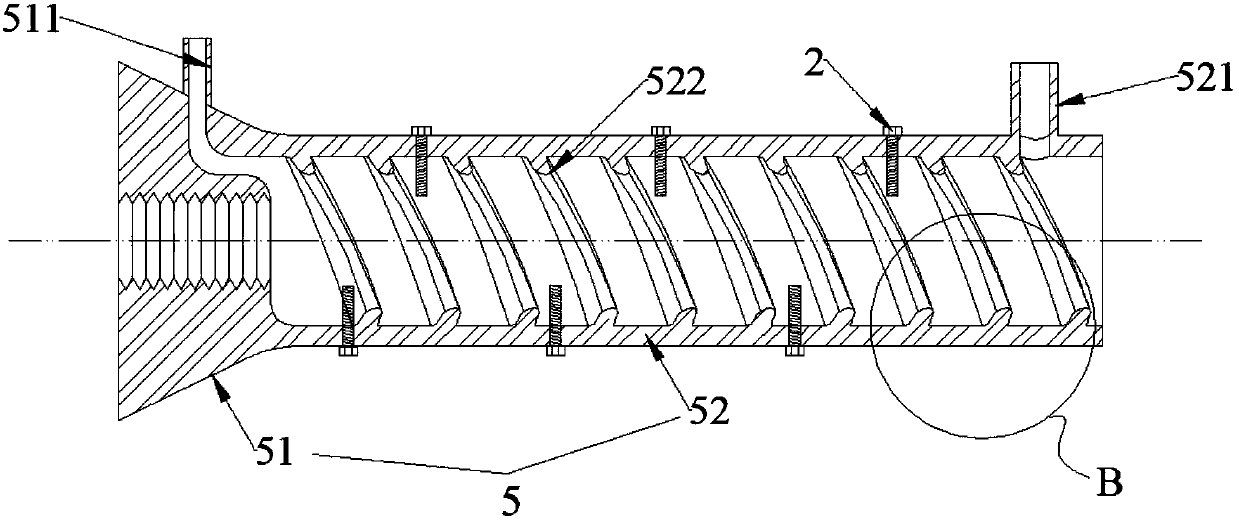

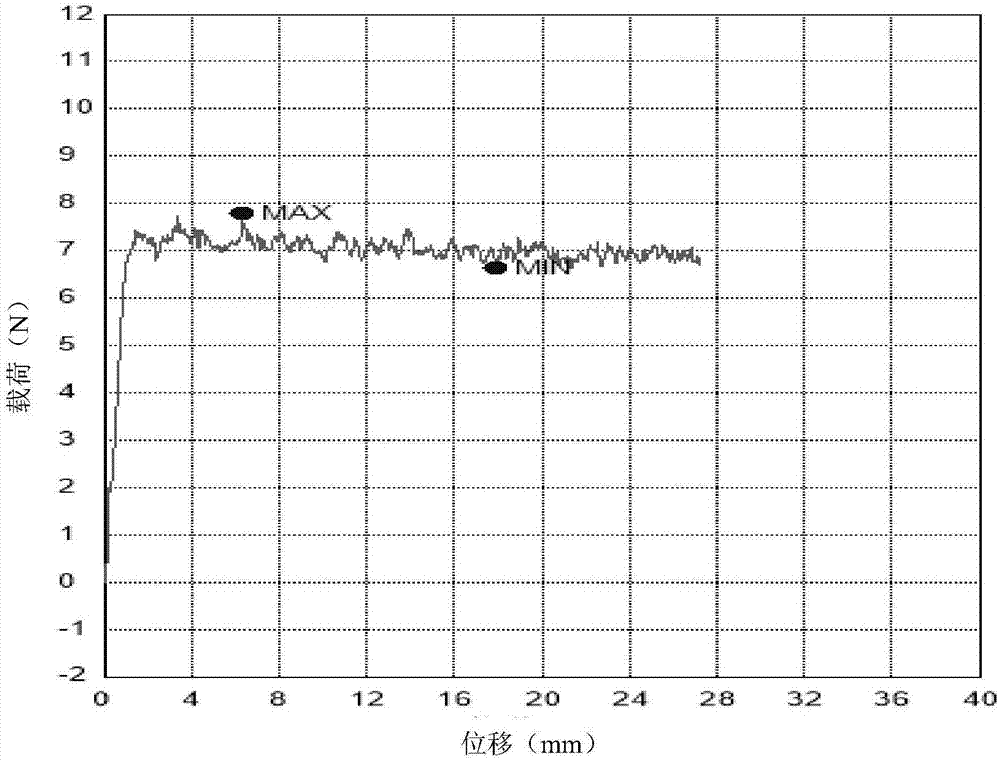

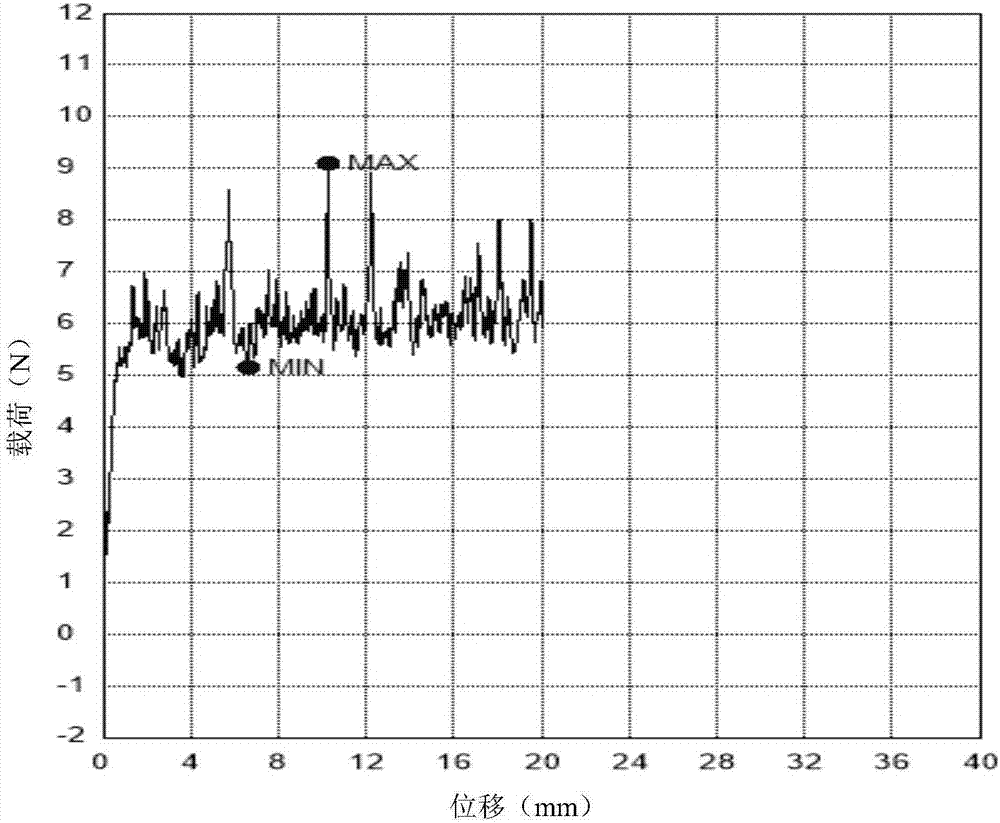

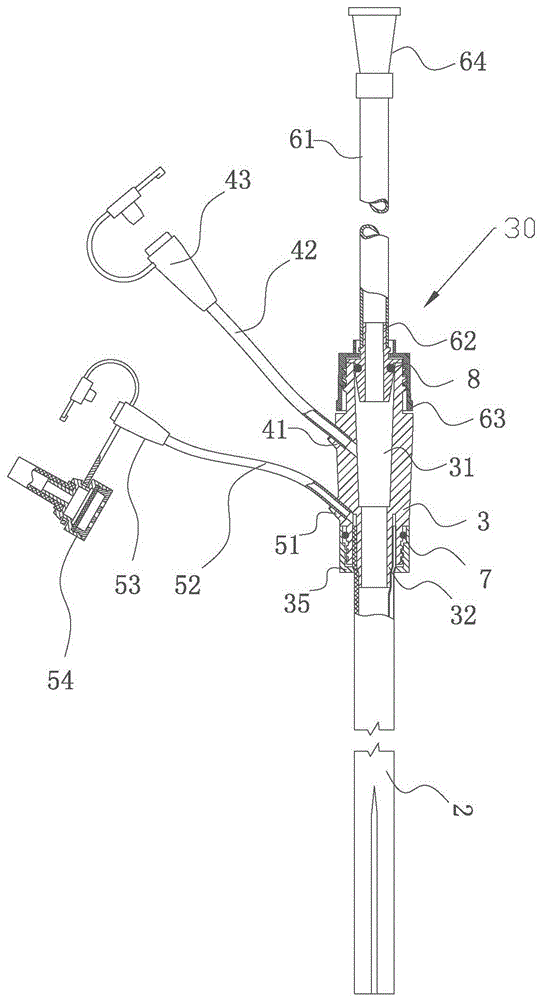

Anti-vibration assembly self-locking type semi-grouting sleeve

The invention provides an anti-vibration assembly self-locking type semi-grouting sleeve. The sleeve comprises a non-grouting connecting section and a grouting connecting section, wherein one tube body section of a steel tube transition section is fixedly arranged in the non-grouting connecting section; another tube body section extends to the outside of the non-grouting connecting section to forma rolling-pressing section which is in rolling-pressing connection with a first to-be-connected reinforcing steel bar; a steel framework comprises inner barbs and outer barbs; the inner barbs are enclosed to form a channel for allowing a second to-be-connected reinforcing steel bar to pass through, and the diameter of the channel is smaller than that of the second to-be-connected reinforcing steel bar; and the outline diameter enclosed by the outer bards is greater than the inner cavity diameter of the grouting connecting section. Each part of the grouting sleeve is separately processed and manufactured, re-assembled, and produced in batch, and easily controlled in quality; connection between the grouting sleeve and the steel tube transition section is operated in a plant through machinery, and threaded connecting quality is easily controlled; the first to-be-connected reinforcing steel bar and the steel tube transition section are directly connected in a rolling-pressing mode, so that processes are simple, and length, inserted into the sleeve, of reinforcing steel bars is easily controlled; and a self-locking type steel framework is adopted, so that the anti-pulling purpose is realized, and antiknock characteristic is improved.

Owner:HEFEI CONSTR ENG GRP

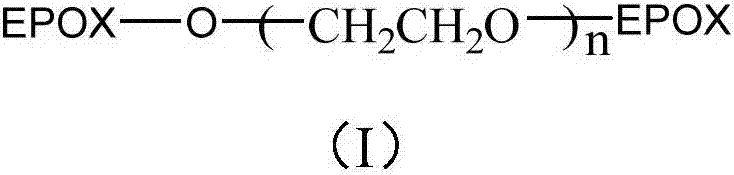

Multi-glycol epoxy derivative cross-linked sodium hyaluronate gel used for injection and preparation method thereof

ActiveCN107880282AGood flexibilityIncrease elasticityOrganic chemistryPharmaceutical delivery mechanismEpoxyCross-link

The invention discloses a multi-glycol epoxy derivative cross-linked sodium hyaluronate gel used for injection and a preparation method thereof. The multi-glycol epoxy derivative is preferably a compound with a single molecular weight, multiple ether bonds exist in the molecule, the compound is good in water solubility and can generate cross-linking reaction with polysaccharide more easily, and because the quantity of multi-glycol repeating units is easy to adjust and the length is relatively easy to control, the performance of sodium hyaluronate gel prepared as a cross-linking agent is relatively easy to regulate; and the cross-linked sodium hyaluronate gel is low in toxicity, less in residue, weak in extruding thrust, good in moulding property, good in enzyme resistance and long in retaining time in the body. The invention further discloses a mild cross-linking agent inactivation technology, unreacted epoxy group in the gel undergoes hydrolysis reaction in a carbonate buffer system with pH of 8-9, so as to effectively reduce the difficulty in impurity removal of cross-linked sodium hyaluronate gel and avoid the problem of toxicity of BDDE used in a cross-linking method of the prior art.

Owner:JENKEM TECH

Method for producing metal nano wire based on DNA template

InactiveCN101271748AAvoid distortionAvoid entanglementNanostructure manufactureLiquid/solution decomposition chemical coatingNano-deviceSilanol

The invention provides a method based on a DNA template for preparing metal nano-wire, comprising the processing steps as follows: 1) the substrate is arranged in an organic silanol to carry out amination disposal; 2) the DNA with suitable quantity is fixed on the substrate by a chemical bond; 3) the substrate is washed by a creepage pump and the DNA which is not well bonded is washed away; 4) the substrate is dipped in oxidant metal salt solution, so as to lead iron cation to be adsorbed; 5) the substrate is then dipped in a reducing agent, so as to gain the metal nano-wire which takes the DNA as framework. By adopting suitable process and content of DNA, the method for preparing the metal nano-wire realizes the uniformity and controllability of nano-wire, and leads the possibility that the DNA molecule is taken as nano-wire to fabricate nano-device to be realized.

Owner:CENT SOUTH UNIV

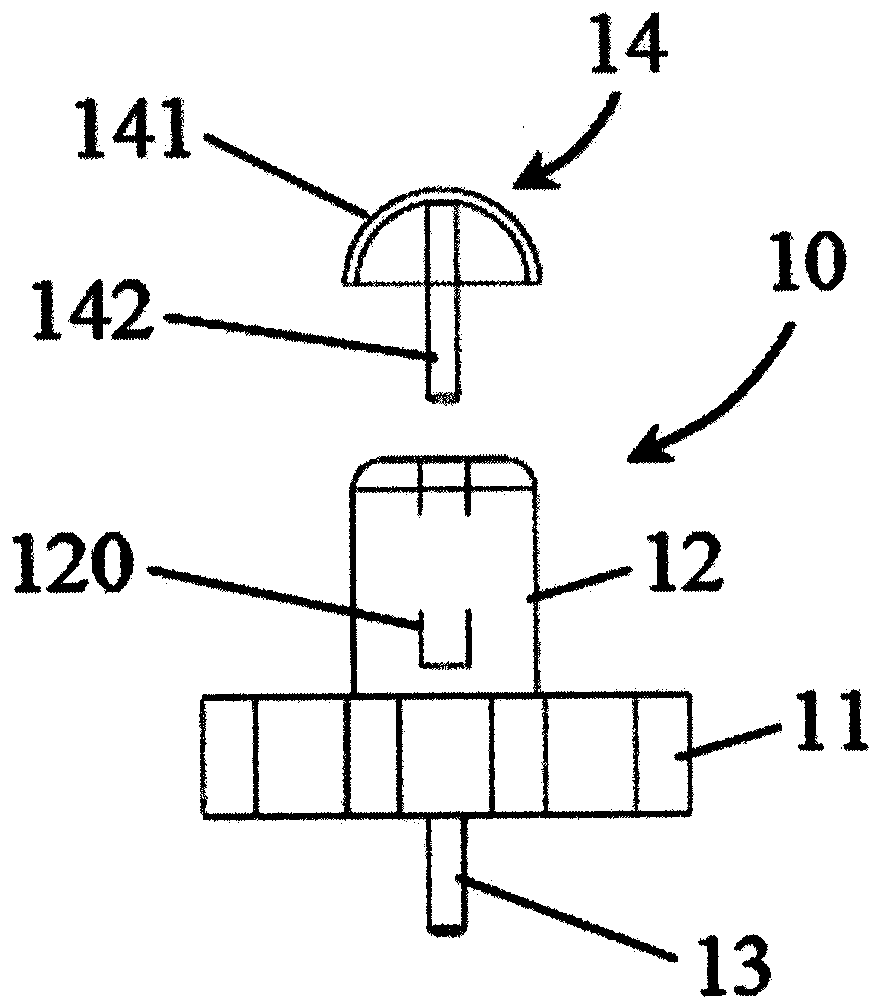

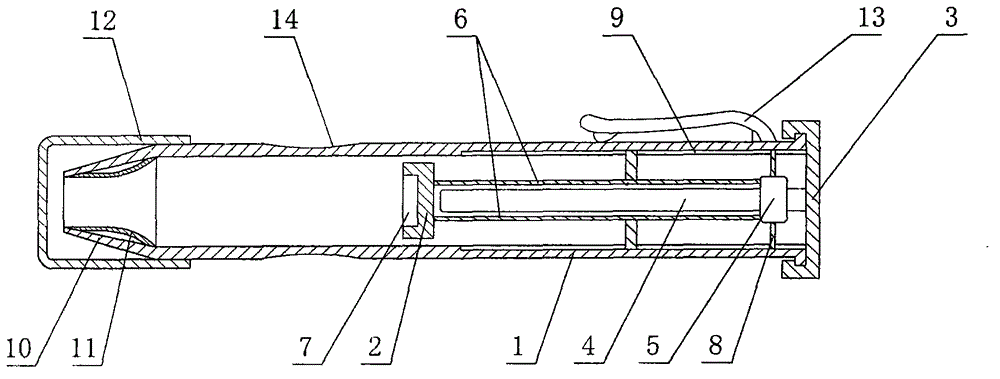

Rat cerebral electrical stimulation device and electrode fixing bases thereof

PendingCN104324446AEnsure safetyGuaranteed reliabilityInternal electrodesExternal electrodesElectricityDura mater

The invention provides a rat cerebral electrical stimulation device and electrode fixing bases thereof. The electrical stimulation device comprises an electric simulator, two electrode fixing bases, and an electrode wire capable of electrically connecting the electric simulator and the electrode fixing bases, wherein each electrode fixing base comprises an insulated fixing section, an electrode inserting section, a conductive contact section and a bolt; two or more bolt limiting holes are formed in the insulated fixing section in a center symmetry manner; the electrode inserting section is fixedly arranged at the center position of the upper end surface of the fixing section; a conductive electrode inserting hole is formed in the center of the inserting section; the conductive contact section is arranged at the center position on the lower end surface of the fixing section; the upper end of the contact section penetrates through the fixing section and is connected with the electrode inserting hole; the lower end of the contact section is arranged to contact a cerebral dura mater of a rat after passing through the rat brain; and the bolt is matched with the bolt limiting hole and is used for fastening the fixing section on a rat skull. According to the rat cerebral electrical stimulation device, a simulation electrode can be stably arranged on the rat skull in a plug and play manner, and the technical problems that an electrode in the prior art easily falls off and the electrode inserting depth is difficult to control are solved.

Owner:王麟鹏 +4

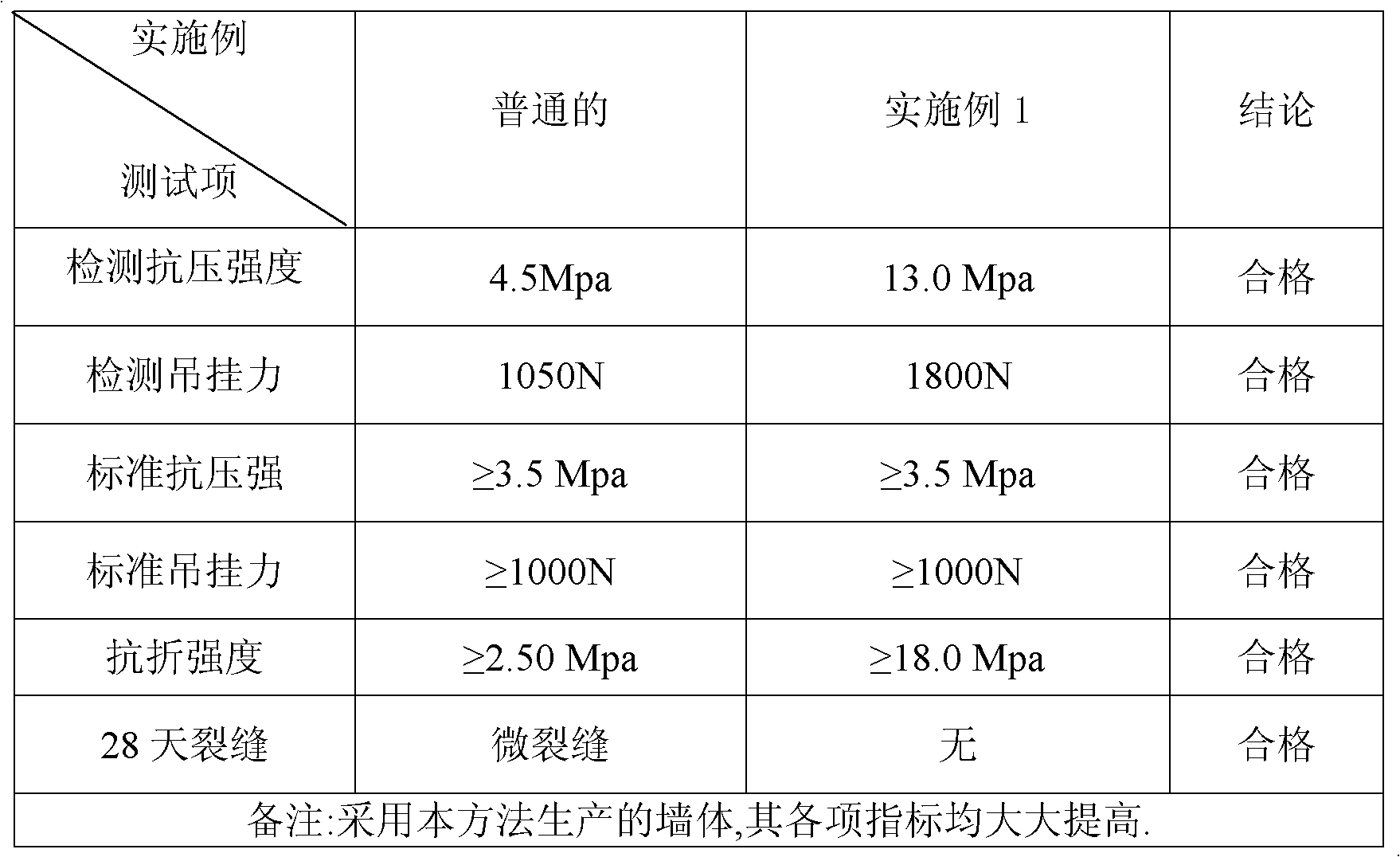

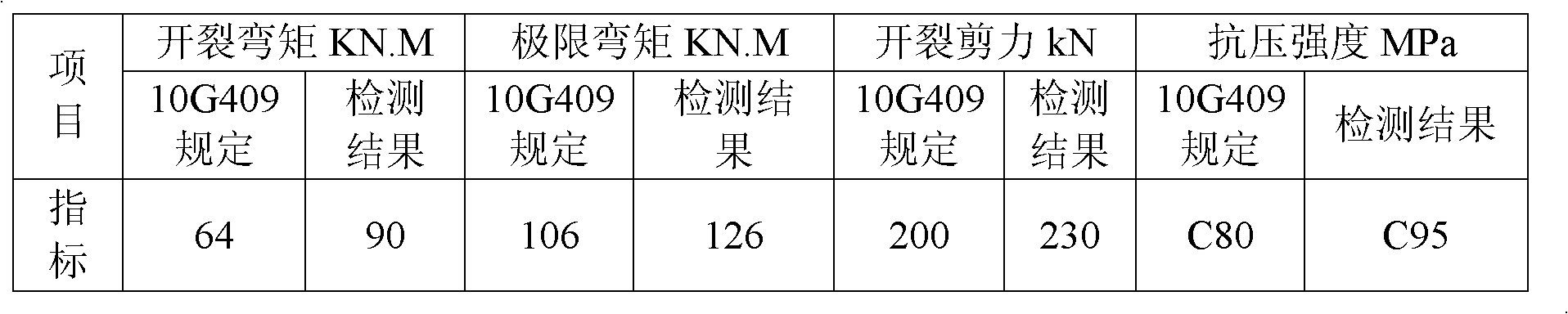

Method for preparing high-performance concrete and application

The invention discloses a method for preparing high-performance concrete and application. The method comprises the following steps of: designing a concrete mixing proportion; sequentially adding fine aggregate, engineering fibers and gel material into a stirrer, and stirring till the engineering fibers are uniformly distributed; and adding water to prepare mortar, adding coarse aggregate, stirring uniformly, and adding an admixture to obtain the high-performance concrete required by design. The prepared high-performance concrete can be used for preparing high-performance concrete products. The method is simple and convenient for processing; the length of the utilized engineering fibers is easily controlled, so that the concrete has good workability, the forming velocity and the production efficiency are improved, the concrete has the advantages of tensile resistance, shearing resistance, cracking resistance, fatigue resistance, high toughness and the like, and concrete cracks caused by temperature stress can be reduced; the microstructure of the cement slurry is improved, and the compactness of the concrete is increased, so that the strength and the durability of the concrete are improved, and the service life of the concrete is prolonged; and the concrete has good safety and economic and social benefits.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

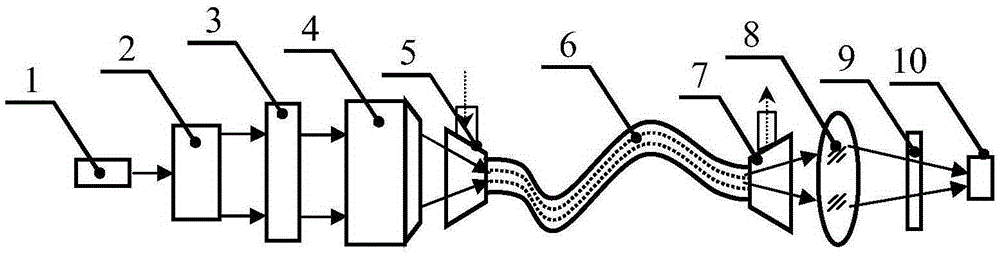

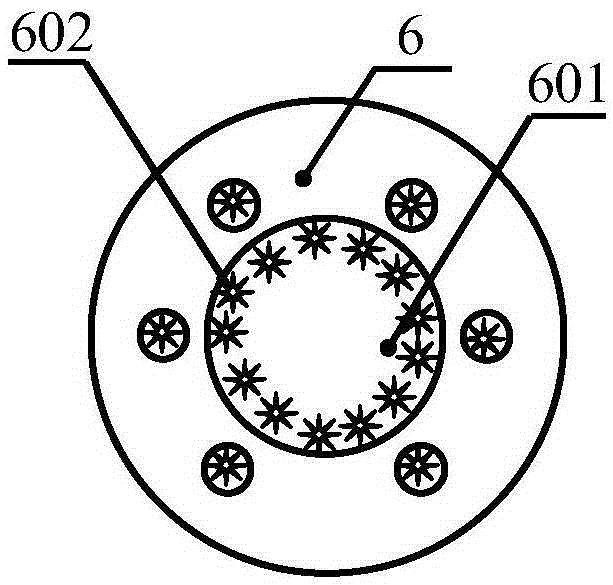

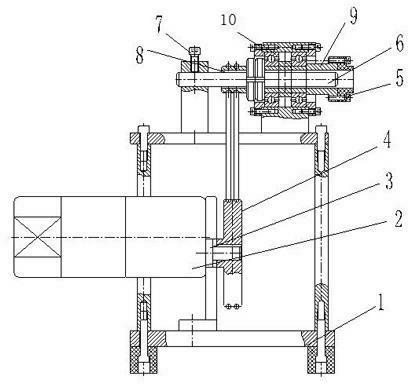

Raman gas analyzing device of column vector field excited hollow core photonic crystal fiber

InactiveCN105241865AEasy to control the lengthReduce dosageRaman scatteringSignal-to-noise ratio (imaging)Physics

The invention relates to a Raman gas analyzing device of column vector field excited hollow core photonic crystal fiber. The prior art has defects of complex structure, low sensitivity and high structural requirement. According to the invention, the surface-enhanced Raman effect and the hollow core photonic crystal fiber technology are combined, and the device is based on the gas Raman analysis principle. A detected gas flows through hollow cavity of hollow core photonic crystal fiber, and a surface-enhanced Raman structural layer is arranged at the inner side of the hollow cavity of the hollow core photonic crystal fiber; by a column vector filed, one end of the fiber is coupled into the hollow core photonic crystal to realize Raman excitation, a photoelectric detection part detects a Raman scattering signal, and analysis is carried out to obtain matter character information of the detected gas. The device provided by the invention has characteristics of low dosage of the detected gas, high sensitivity, high signal to noise ratio, strong resistance to interference, low positioning requirement, easily constructed system, easy miniaturization, strong analysis and discrimination capability, wide application range, easily expanded function and the like.

Owner:HANGZHOU DIANZI UNIV

Method for large-batch preparing overlength carbon nano pipe array and its apparatus

ActiveCN1312033CIncrease productionGood orientationNanostructure manufactureChemical vapor deposition coatingFixed bedCarbon nanotube

A process and equipment for preparing ultra-long carbon nano-tube array in batch is disclosed. Said process includes such steps as providing monolithic reactor with artery structure, adding ZrO2, SiO2 or Al2O3 particles or their mixture, inserting structural member in fixed bed and chemical vapor deposition. Its advantages are high purity and output.

Owner:TSINGHUA UNIV

Hydrothermal preparation method of shape-controllable titanium dioxide nano tube

InactiveCN103395831AControllable lengthUniform diameterMaterial nanotechnologyTitanium dioxideSurface-active agentsUltrasonic oscillation

The invention provides a hydrothermal preparation method of a shape-controllable titanium dioxide nano tube. The hydrothermal preparation method comprises the following steps of: adding 10-50mL of NaOH solution with the concentration being 8-15mol / L into a reaction kettle; then adding 0.1-10g of cetyl trimethyl ammonium bromide and 01-3g of titanium dioxide nano powder into the reaction kettle, and carrying out ultrasonic oscillation to mix the materials uniformly; carrying out hydrothermal reaction in the reaction kettle at the temperature of 100-200 DEG C for 15-30 hours; pouring out supernatant, and washing the obtained solid powder with water to be neutral; adding 0.1-1mol / L of nitric acid or hydrochloric acid into the obtained powder, carrying out ultrasonic oscillation for 1-3 hours at the temperature of 50-100 DEG C; washing a product (which is obtained after acid treatment) with water to be neutral nearly, filtering and drying; and calcining the dried powder for 1-5 hours at the temperature of 400-800 DEG C. The obtained titanium dioxide nano tube is influenced by the adding amount of a surface active agent, the length is controllable, the tube diameter is more uniform, the two ends are open, the tube forming efficiency is high, and therefore the titanium dioxide nano tube can be favorably applied to nanoscience, biomedicine and the like.

Owner:HARBIN ENG UNIV

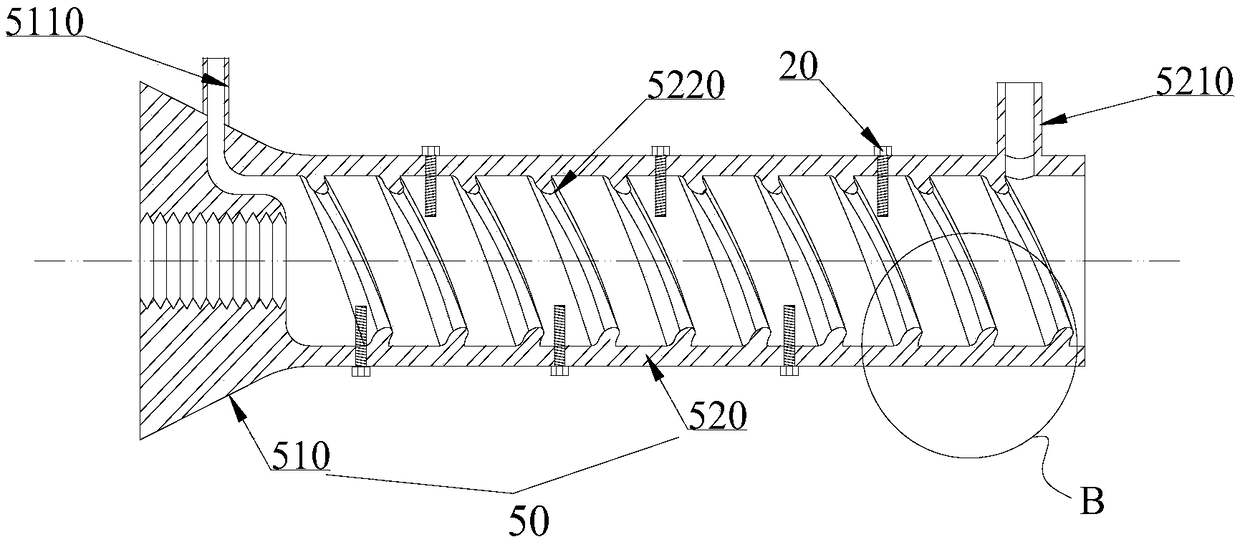

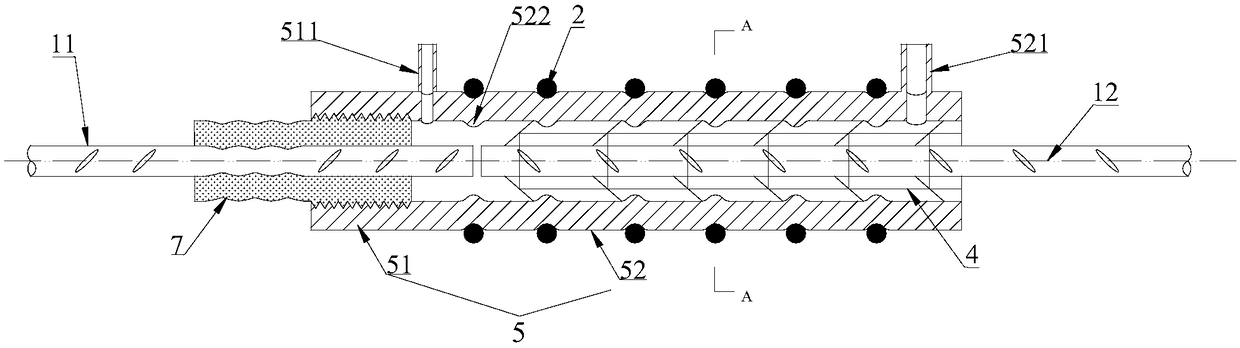

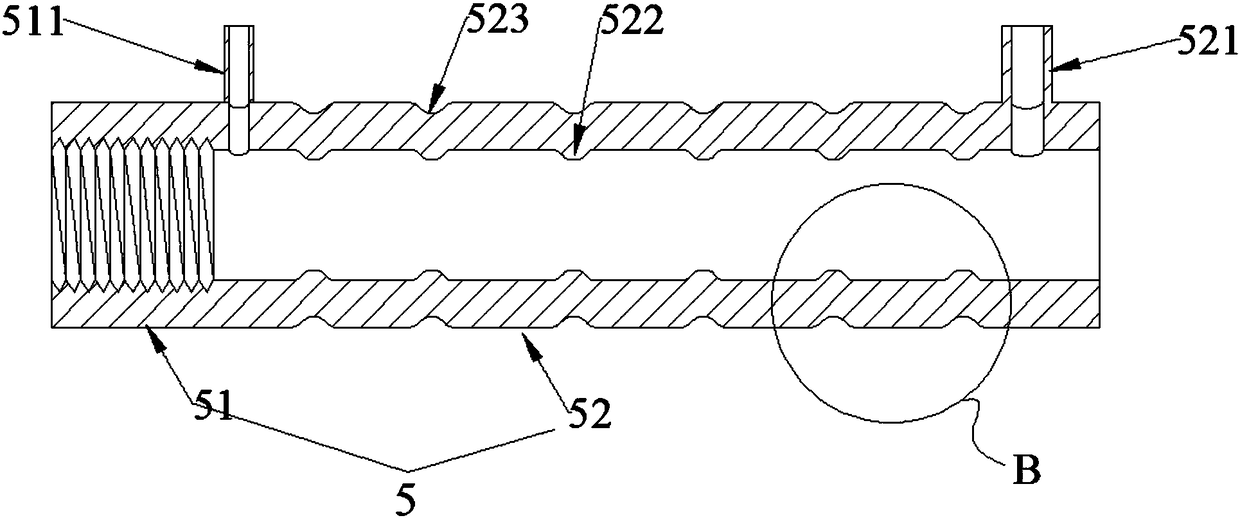

Processing method of anti-seismic self-locking-type rolling semi-grouting sleeve and processing method of concrete component

The invention provides a processing method of an anti-seismic self-locking-type rolling semi-grouting sleeve and a processing method of a concrete component. The processing method of the anti-seismicself-locking-type rolling semi-grouting sleeve comprises the following steps that 1) a seamless steel pipe with proper wall thickness is selected, an appropriate length of the seamless steel pipe is cut to prepare the sleeve, and the sleeve comprises a non-grouting connecting section and a grouting connecting section; and internal threads are formed in the inner wall of the non-grouting connectingsection, a plurality of grooves are formed in the grouting connecting section, and a plurality of convex ribs are rolled on the inner surface of the grouting connecting section; 2) annular reinforcing ribs are installed in the grooves of the side walls of the sleeve; 3) a seamless steel pipe with proper wall thickness is selected, a proper length of the seamless steel pipe is cut to prepare a steel pipe transition section, wherein external threads are formed on one section of the pipe body of the steel pipe transition section, and the other section of the pipe body of the steel pipe transition section is a rolling depression section; and 4) a plurality of longitudinal guiding rebars, a plurality of annular fixing steel rings and inclined steel branches are welded into a self-locking steelskeleton. Each part of the grouting sleeve is processed and manufactured separately, and the quality of each part is easy to control. The connection between the grouting sleeve and the steel pipe transition section is operated by machineries, the quality of threaded connection is easy to control, and the self-locking steel skeleton is adopted to realize pulling-resistance and improve anti- seismic performance.

Owner:HEFEI CONSTR ENG GRP

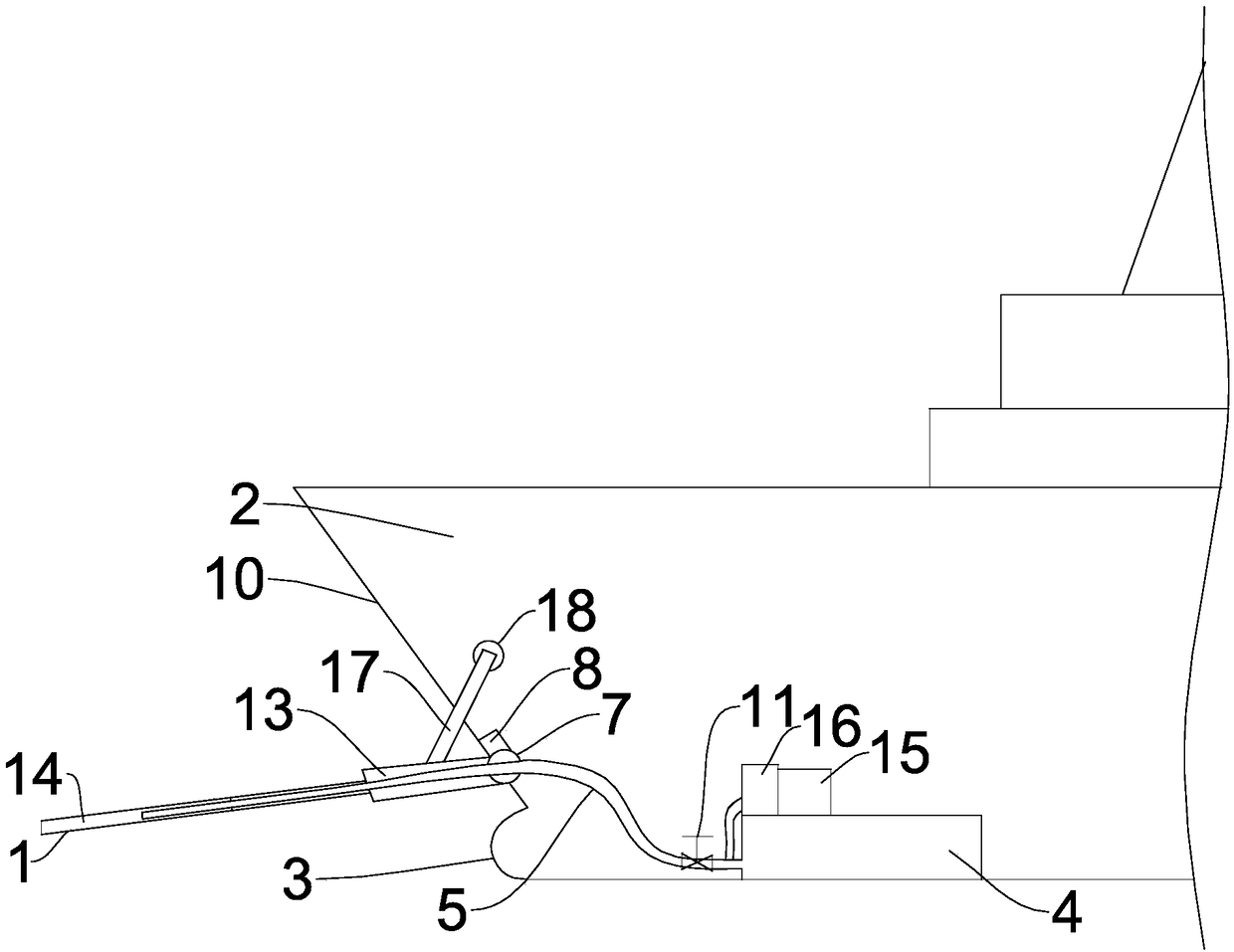

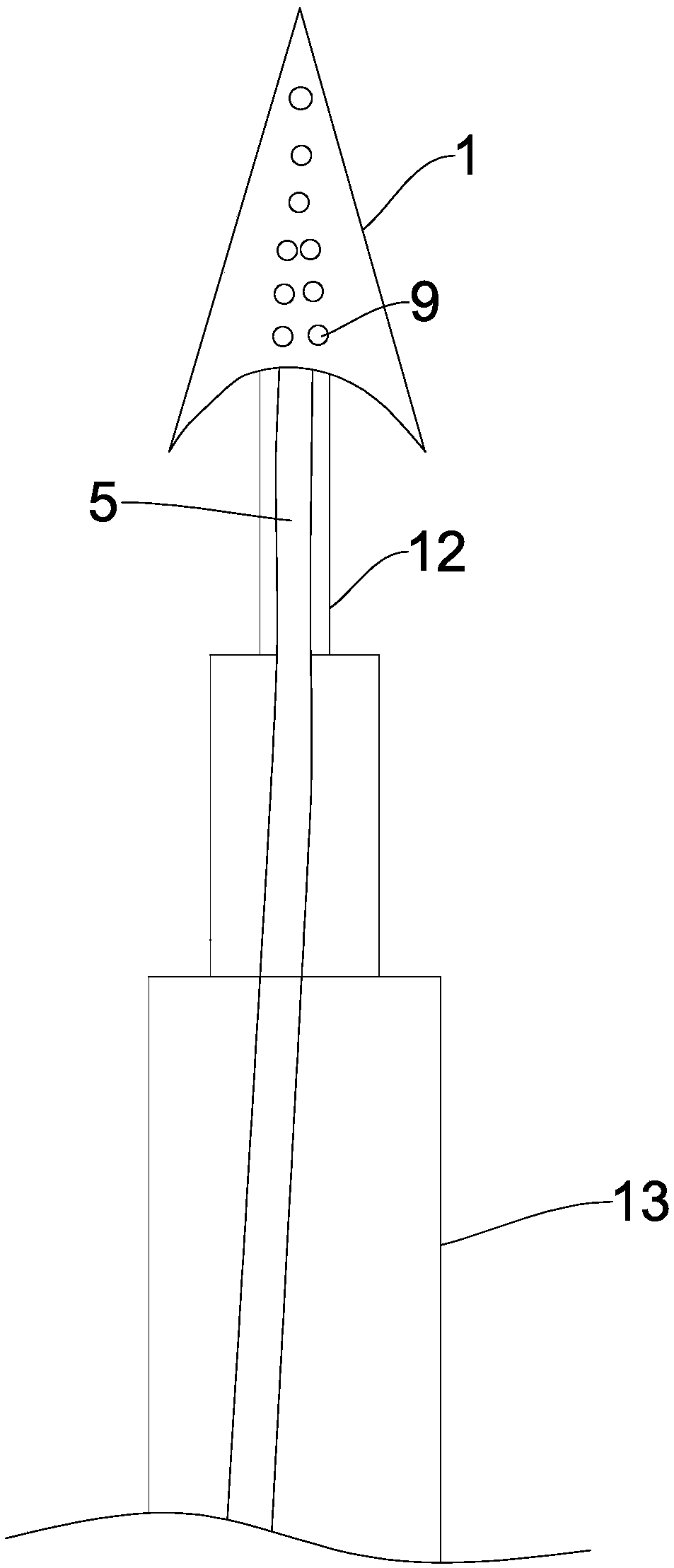

Device and method for reducing wave-making resistance of warship

InactiveCN109229272AReduce wave resistanceReduce frictionWatercraft hull designHydrodynamic/hydrostatic featuresMarine engineeringWave-making resistance

The invention relates to a device and a method for reducing the wave-making resistance of a warship, which includes a hull, the lower part of the bow of the ship hull is provided with a forward projecting mechanism extending out of the ship hull, and an inner cavity is arranged inside the protruding mechanism, the inner cavity is communicated with an air source arranged in the hull through a gas pipe, A gas flow regulating device is arranged on the trachea, the protruding mechanism is provided with a nozzle communicated with the inner cavity, The invention is used for ejecting bubbles to change the height, phase and frequency of the first wave of the warship, and the aspect ratio of the warship to achieve the purpose of reducing the wave resistance, and the ejected bubbles can reduce the frictional resistance of the surface warship, increase the speed of the surface warship, save the energy consumption and carbon emission in the shipping process, and the gas source is provided with anozone generator. When needed, ozone is injected through the nozzle along with the bubbles to reduce the breeding of aquatic organisms, reduce the daily maintenance workload, reduce fuel consumption ofships, increase ship speed and reduce emissions.

Owner:重庆中电大宇卫星应用技术研究所有限公司

Chalk sleeve

InactiveCN102975523ARoll out length is easy to controlControllable lengthWriting connectorsNon-propelling pencilsEngineeringMechanical engineering

Owner:曲政宇

Double-sided isomer micro-nozzle and manufacturing method thereof

ActiveCN107627605AControllable lengthSimple preparation processHollow filament manufactureFilament/thread formingSpray nozzleEngineering

The invention provides a manufacturing method of a double-sided isomer micro-nozzle. The manufacturing method of the double-sided isomer micro-nozzle adopts the double-sided alignment technology and the silicone deep etching technology. A needed figure is etched on the first side of a silicon wafer, and after perfect alignment is achieved through the double-sided alignment technology, a figure isetched on the second side of the silicon wafer and communicates with the figure on the first side; different figures are etched on the two sides of the silicon wafer, so that a conjoined morphology structure in different shapes is manufactured in the same vertical organism, and then a functional structure body in the nozzle is formed; and besides, the two figure structures are integrated at the converging position, and therefore the double-sided isomer micro-nozzle having super-high mechanical strength is obtained.

Owner:SHANGHAI HUIPU ELECTROMECHANICAL SCI & TECH CO LTD

Aluminum tape wrapping device and its operation method

The invention discloses an aluminum tape wrapping device and its operation method. The device comprises a fixed jaw and a moveable jaw. Both of the jaws are symmetrically arranged on the device body. The inner side of the fixed jaw is provided with an arc surface which cooperates with the shape of the wire outer surface. The upper end of the fixed jaw is provided with a flexible notch. One end of the flexible notch is fixedly arranged on the fixed jaw while the other end of the flexible notch is provided with an aluminum tape clamping notch. Through the arrangement of the arc surface with the shape of the wire outer surface and at the inner side of the fixed jaw and the arrangement of the flexible notch, the nut can be rotated and adjusted so that the flexible notch can rotate within zero to fifteen degrees. During the process of aluminum tape wrapping, the fixed jaw presses the aluminum tape tightly onto the outer surface of the wire. In this way, the loosened wrapping of aluminum tape can be avoided. According to the operation method of the aluminum tape wrapping device, it is possible to calculate the length L required by the aluminum tape according to the clamp width so that the cut length of the aluminum tape can be controlled, therefore, avoiding waste of aluminum tape caused for its excessive cut length. The method is simple to operate and adopts a uniform technology.

Owner:国网四川省电力公司超高压分公司 +1

Metal gas diffusion layer used for fuel cell and preparation method thereof

ActiveCN102082277BImprove performanceMeet the challenge of weak acid working environmentCell electrodesCarbon coatingUltrasonic oscillation

The invention relates to a metal gas diffusion layer used for a fuel cell and a preparation method thereof. The preparation method comprises the following steps: preparing a stainless steel short fiber sintering felt by adopting a vacuum high temperature sintering method, then sequentially preparing a chromium layer and a graphite layer on the pretreated stainless steel short fiber sintering feltby adopting a closed field unbalanced magnetron sputtering ion plating technology, and then carrying out hydrophobic processing on the entire of the coated stainless steel short fiber sintering felt by utilizing polytetrafluoroethylene; and finally coating powdered carbon on the surface by adopting an ultrasonic oscillation method to obtain the metal gas diffusion layer used for the fuel cell. Inthe invention, stainless steel fiber with low price is taken as raw material, the high temperature vacuum sintering method is adopted to prepare the sintering felt, and the magnetron sputtering ion plating technology is utilized to prepare a carbon coating so as to improve the contact performance and anti-corrosion performance of the metal gas diffusion layer, thus the high-performance gas diffusion layer used for the fuel cell is prepared with low cost.

Owner:SHANGHAI H-RISE NEW ENERGY TECH CO LTD

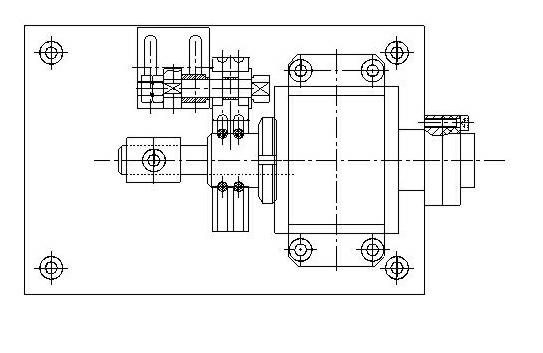

Nut screwing machine of connecting rod

InactiveCN102513817AImprove interchangeabilityTo achieve the purpose of one machine with multiple functionsMetal working apparatusAgricultural engineeringProduction control

The invention discloses a nut screwing machine of a connecting rod, comprising a base and a motor arranged on the base. The nut screwing machine of the connecting rod also comprises a main shaft, wherein an output shaft of the motor is connected with one end of the main shaft through a multi-wedge belt wheel transmission mechanism; the other end of the main shaft is fixedly connected with a nut clamp and the main shaft is supported on the base through a bearing; the main shaft is hollow and the main shaft is sleeved at the periphery of a limiting rod; one end of the limiting rod is fixedly mounted on the base and the other end of the limiting rod is placed in an inner cavity of the main shaft; and the limiting rod and the main shaft are coaxial. The nut screwing machine provided by the invention has strong interchangeability; a changeable nut clamp is only replaced to be capable of mounting nuts on screw rods with different specifications ,therefore, the purpose that one machine has multiple functions is achieved and the installation efficiency is multiple times that of the operation that the nut is manually screwed; and the screwed length is easy to control by a limit rod. The nut screwing machine provided by the invention has the advantages of low manufacturing cost, convenience for adjustment and installation, and convenience for production and management.

Owner:希西维轴承(镇江)有限公司

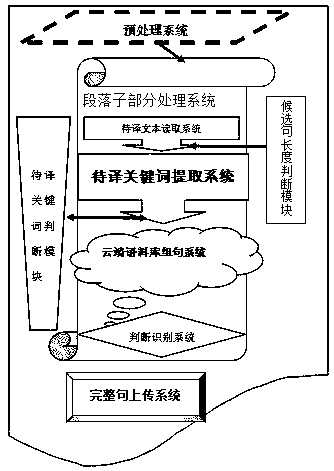

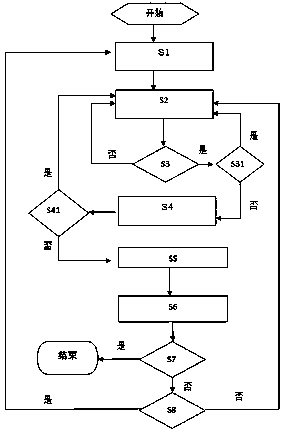

Complete sentence recognition method and system for machine translation

PendingCN109325237AControllable lengthFull meaningNatural language translationSemantic analysisMachine translationParagraph

The present application proposes a complete sentence recognition system for machine translation. The system comprises: (1) a preprocessing system which preprocesses a text to be translated including paragraph recognition, end recognition, etc., and obtains a subset of paragraphs in units of paragraphs, for example, identifying the beginning and end of a paragraph, and also identifying the full-text end of the text to be translated; (2) a paragraph subpart processing system which processes the set of paragraph subparts in units of paragraphs to output complete sentences; (3) a complete sentenceuploading system which uploads the complete sentence output from the paragraph subpart processing system to the machine translation engine.

Owner:TRANSN IOL TECH CO LTD

Sleeve type inverter tube

InactiveCN105635889AUniform radiationLarge effective cross-sectional areaFrequency/directions obtaining arrangementsEngineeringWoofer

A sleeve type inverter tube comprises a cylindrical hollow housing and a hollow housing. The hollow housing sleeves the cylindrical hollow housing, thereby forming a slit type inverter tube outlet and an inverter tube chamber. The hollow housing is provided with a bass loudspeaker unit. The sleeve type inverter tube is advantageous in that simple sound field reconstruction in a complicated sound construction condition; no specific requirement for placement exists; low bass extension, enough sound strength and attractive tone are realized; and furthermore surrounding feeling of the sound can be improved.

Owner:杨菊梅

A silver-magnesium doped alumina nano-material covered with nitrogenized graphite doped nanometer silica, a preparing method thereof and applications of the material

InactiveCN107694591AUniform particle size distributionParticle size controllableMaterial nanotechnologyCell electrodesChemical synthesisOrganic synthesis

The invention belongs to the technical field of material synthesis, and particularly relates to a Ag-Mg doped Al2O3 nano-material covered with nitrogenized graphite doped nanometer SiO2, a preparing method thereof and applications of the material. The method includes 1) preparing Ag-Mg doped aluminum hydroxide sol through a liquid phase synthesis process, subjecting the sol to gelatinization to obtain Al-Mg doped aluminum hydroxide gel, and drying and roasting the gel to obtain Ag-Mg doped Al2O3 nanometer powder; and 2) preparing the Ag-Mg doped Al2O3 nanometer powder covered with silicic acidsol in which an organic matter is dissolved through a liquid phase synthesis process, subjecting the sol to gelatinization to obtain Ag-Mg doped Al2O3 nanometer powder covered with silicic acid gel in which the organic matter is dissolved, and drying and roasting the powder to obtain the Ag-Mg doped Al2O3 nano-material covered with nitrogenized graphite doped nanometer SiO2. The nano-material canbe used as various chemical synthesis catalysts, electrochemical synthesis catalysts, organic synthesis catalysts, lithium ion battery anode materials, chemical product additives, and the like.

Owner:HUBEI ENG UNIV

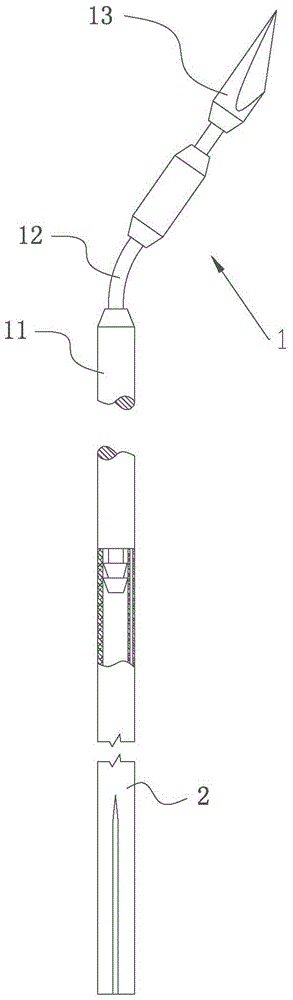

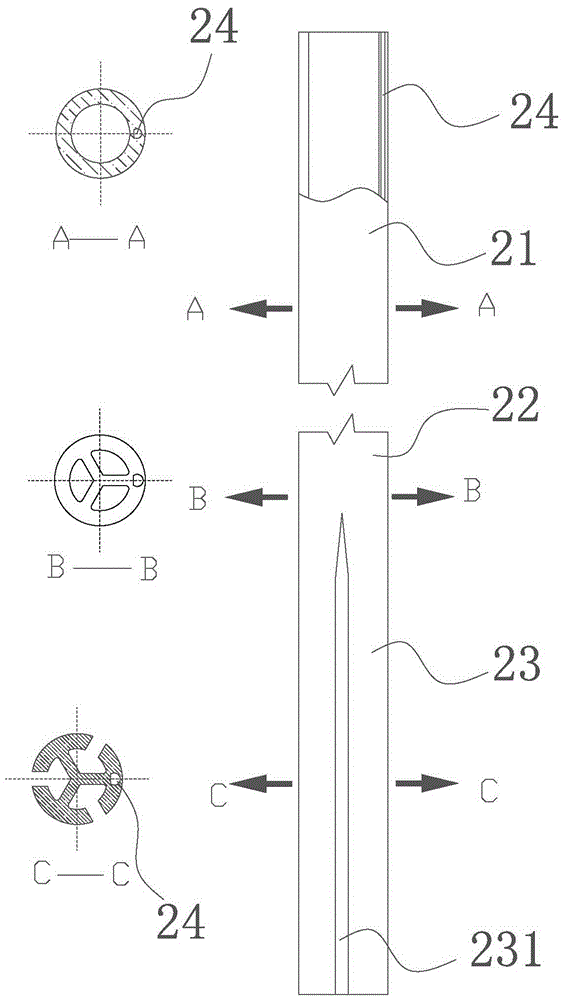

Drainage tube with puncture needle and utilization method of drainage tube

The invention discloses a drainage tube with a puncture needle and a utilization method of the drainage tube. The drainage tube comprises a drainage cannula, the puncture needle and a drainage component. The drainage cannula comprises a single-cavity sealed section, a multi-cavity sealed section and a multi-cavity open section in sequential communication. At least one passage is formed in the single-cavity sealed section which is sealed, the multi-cavity sealed section is sealed and internally partitioned into a plurality of passages, the multi-cavity open section is provided with a notch along the length direction of the wall and internally partitioned into a plurality of passages, and one end, away from the multi-cavity open section, of the single-cavity sealed section is connected with the puncture needle. Before suture of a surgical wound, the puncture needle enters the cavity from the wound and punctures outside from a nearby part of the wound, then pulling is performed until length of the drainage cannula indwelled in the cavity is equal to a preset length, cutting is performed at the single-cavity sealed section to withdraw the puncture needle, and the single-cavity sealed section connected with the multi-cavity sealed section is connected with the drainage component at the cut position. Risks of infection and wound stabbing caused by the puncture needle can be effectively avoided, safety, convenience and quickness are realized, and better drainage effects are achieved.

Owner:广东先来医疗器械有限公司

Optical cable branch line protection structure

ActiveCN105301717BEfficient use ofEnough free spaceFibre mechanical structuresEngineeringSingle-core

The present invention discloses an optical cable branching protection structure. The optical cable branching protection structure comprises: a main optical cable, a plurality of sub-optical cables formed by branching the main optical cable, and a deconcentrator sleeved at the outside of the branching of the main optical cable and a plurality of sub-optical cables. A junk ring bush compressing a coating layer sleeves the outside of the main optical cable section, and the sub-optical cable sections have no a junk ring bush. Aramid fibers are located between the coating layer and the steel pipe, and the movement of the aramid fibers may be effectively utilized to make optical fibers in the main optical cable have enough free activity space, so that the optical fibers have enough length to satisfy various usage environment and the optical performance and signal transmission effect of the optical fibers are ensured. According to the invention, single core fibers and aramid fibers are located in the steel pipe, the steel pipe and the coating layer are integrated into one body to fix with a thermoplastic pipe, and the length of the outer coating layer may be determined; and when a branching is made, length of each single core sub-optical fiber is controllable, and the length consistency of the branch sub-optical fiber may be effectively ensured.

Owner:SHENZHEN ACE ARMORED CABLE CO

Cutting machine for cutting lithium battery pole pieces and cutting method for cutting lithium battery pole pieces

ActiveCN106827010BSimple structureEasy to operateMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of cutting, in particular to a sheet cutting machine and a sheet cutting method capable of achieving high soft sheet cutting quality. The sheet cutting machine comprises a cutter mechanism, a clamping mechanism and a tensioning mechanism, wherein the clamping mechanism and the tensioning mechanism are arranged in the sheet conveying direction and can both move in the sheet conveying direction. During sheet cutting, the clamping mechanism clamps a sheet and drives the sheet to move from a first position to a second position in the sheet conveying direction; the tensioning mechanism clamps the sheet in the second position; the clamping mechanism loosens the sheet, returns to the first position and clamps the sheet again, and the clamping mechanism clamps two portions of the sheet; and the cutter mechanism cuts off the sheet from the position between the two portions clamped by the clamping mechanism. The sheet cutting machine and the sheet cutting method have the advantage of high soft sheet cutting precision.

Owner:山西能际智能科技有限责任公司

Device and method for collecting lead and zinc nonferrous metallurgic slag volatile matters at high temperature

ActiveCN109513229AInto a smooth and stableGuaranteed purityMultiple-effect/fractional condensationCooling towerCrucible

The invention discloses a device and method for collecting lead and zinc nonferrous metallurgic slag volatile matters at high temperature. The device comprises a tube furnace / vacuum atmosphere furnace, a protective gas, a water suction pump and a cooling tower, wherein a seal element is arranged at one end of the tube furnace / vacuum atmosphere furnace; a protective gas introduced pipeline is connected with the tube furnace / vacuum atmosphere furnace through the seal element; the other end of the tube furnace / vacuum atmosphere furnace forms a cooling loop with the cooling tower through the watersuction pipe; the constant temperature section of the tube furnace / vacuum atmosphere furnace is provided with a crucible for sample placement; and a collector is arranged at the joint of one end of the tube furnace / vacuum atmosphere furnace and the cooling loop. The device can be used for collecting lead and zinc slag volatile matters at high temperature efficiently and relatively completely without changing substance properties; and the high temperature property of lead and zinc slag can be accurately studied and has better reference value by adopting the volatile substances collected by thedevice.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

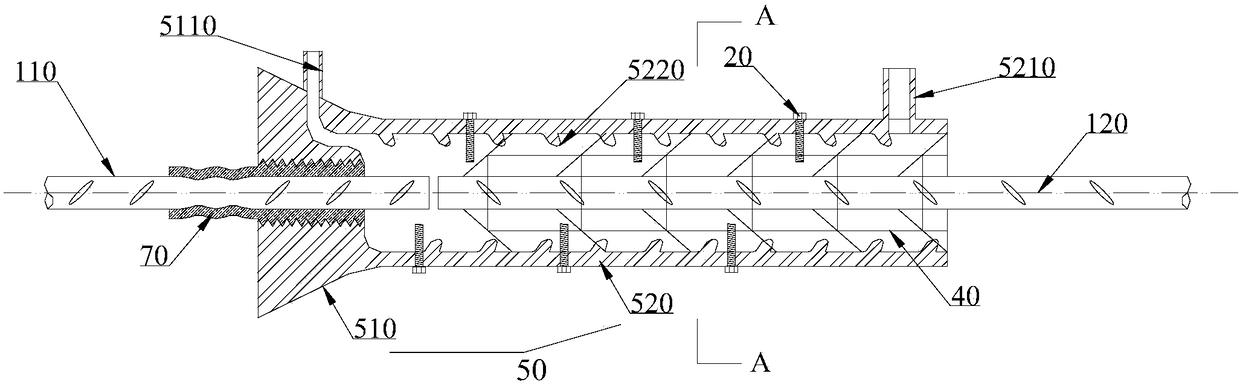

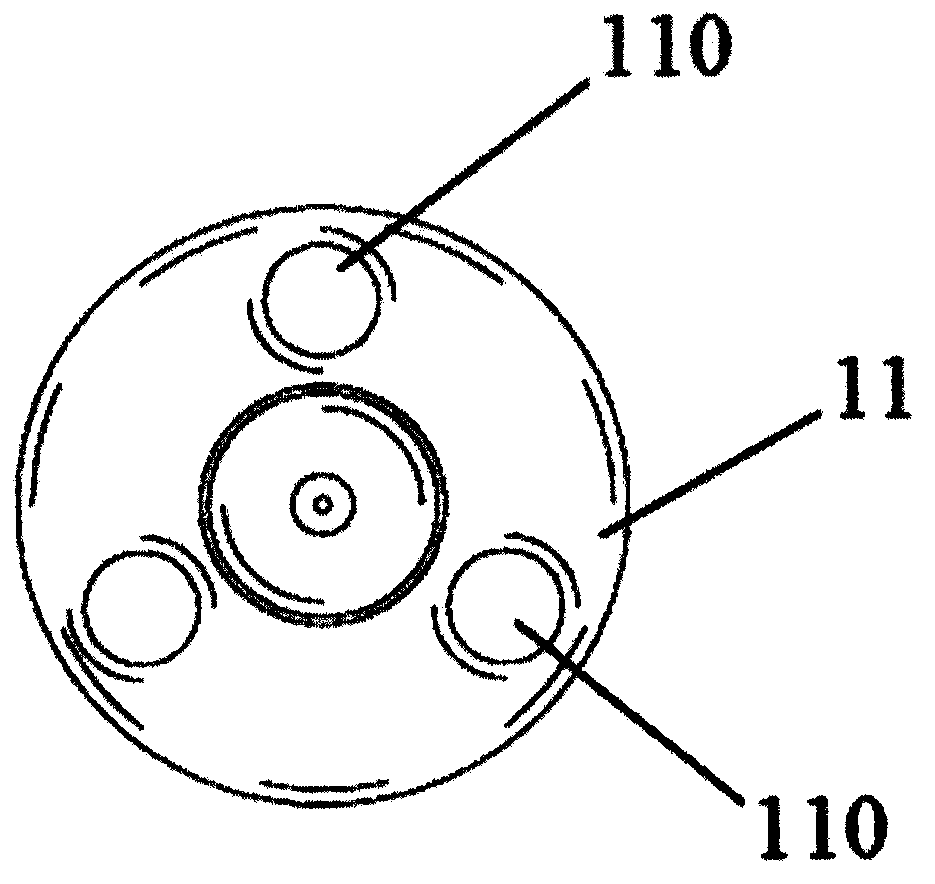

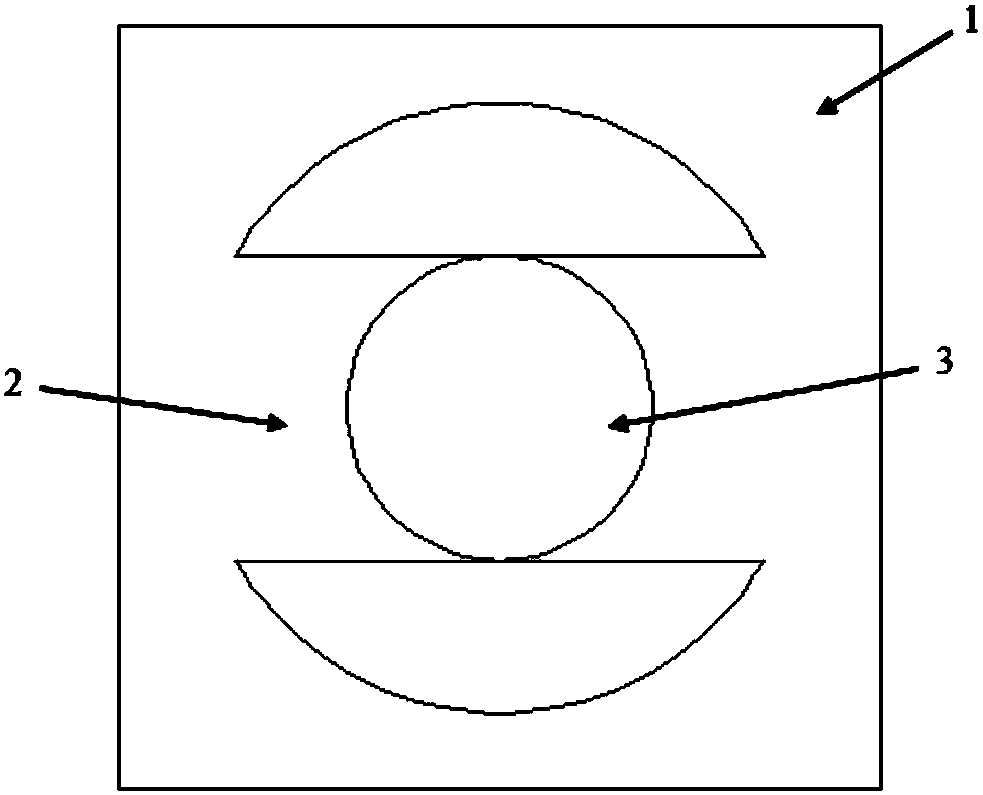

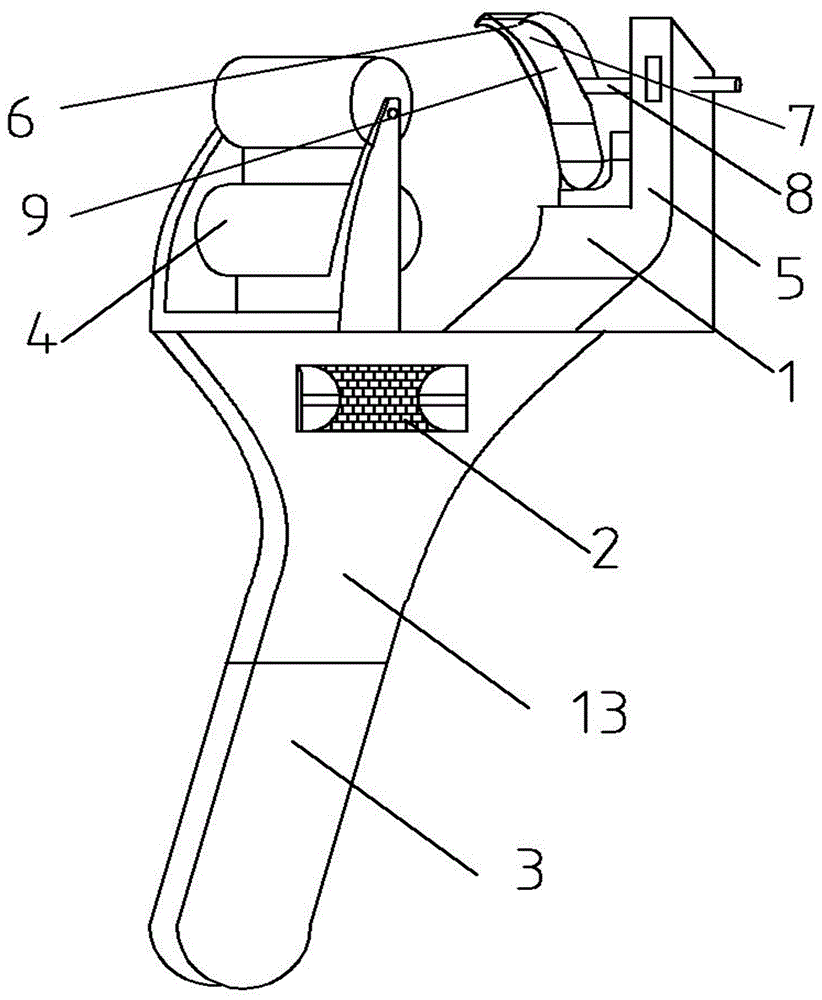

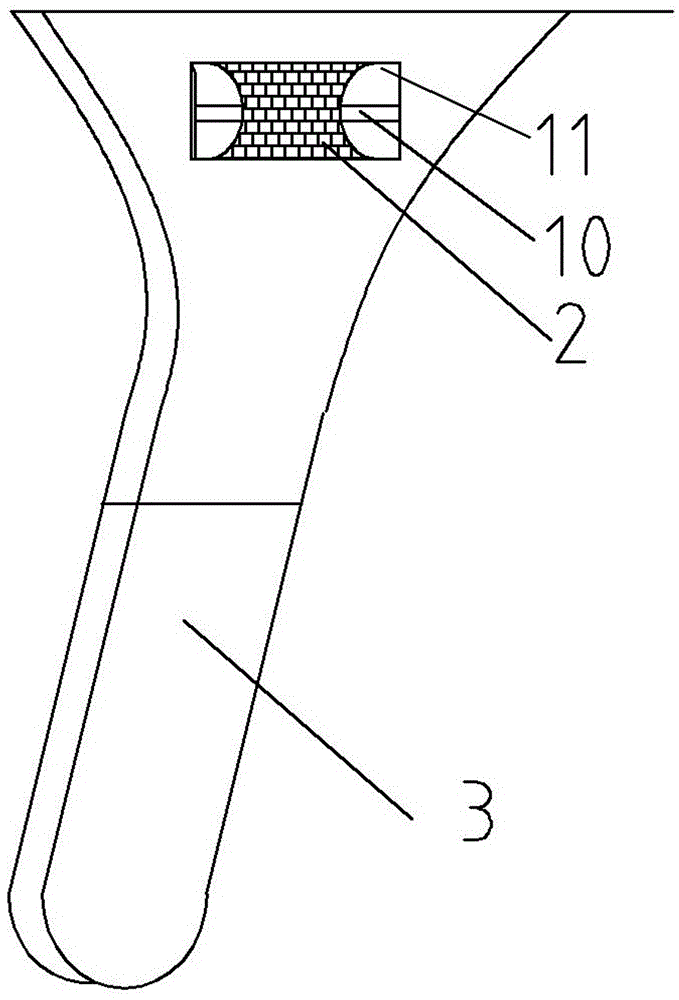

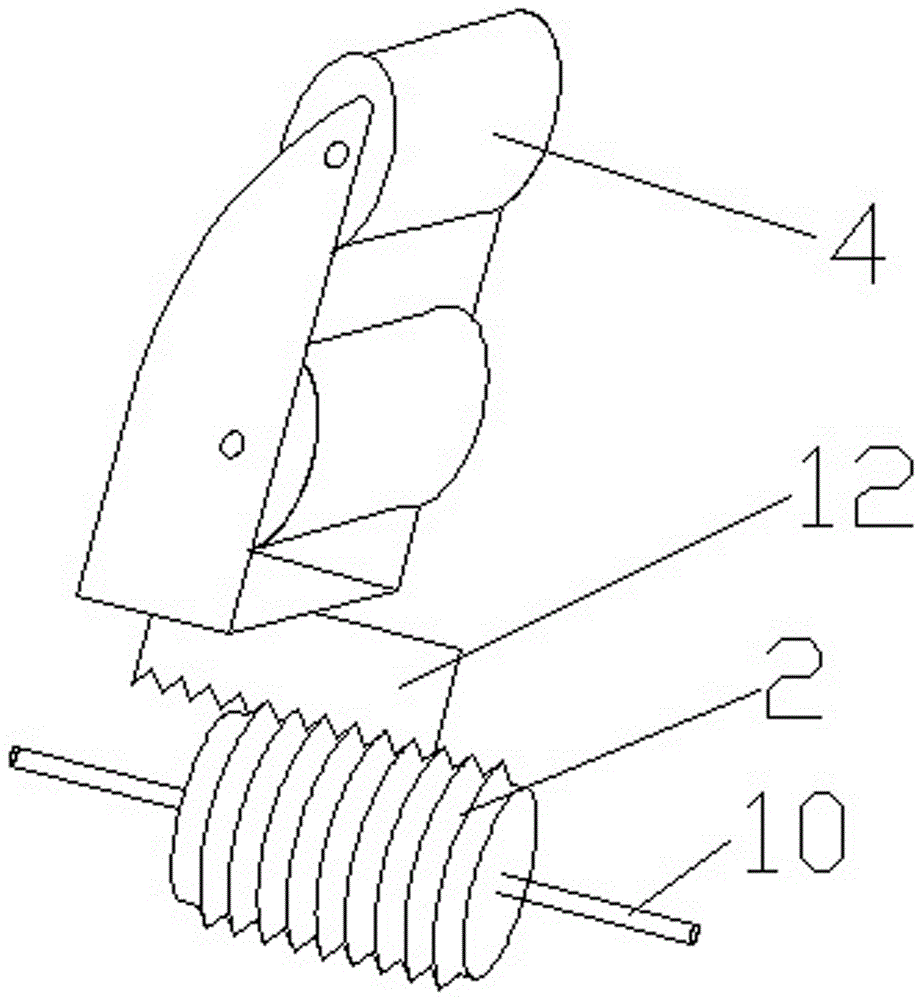

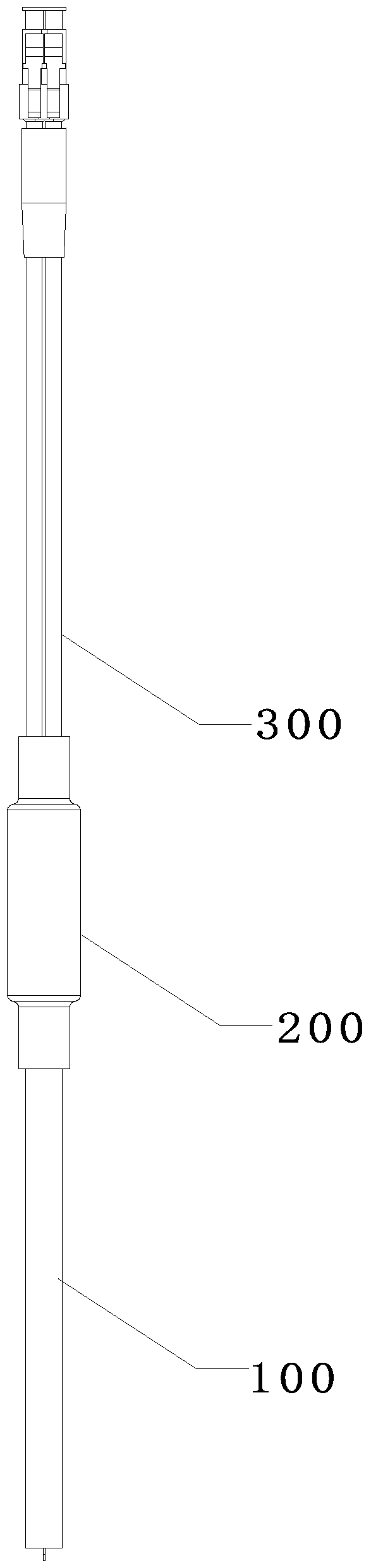

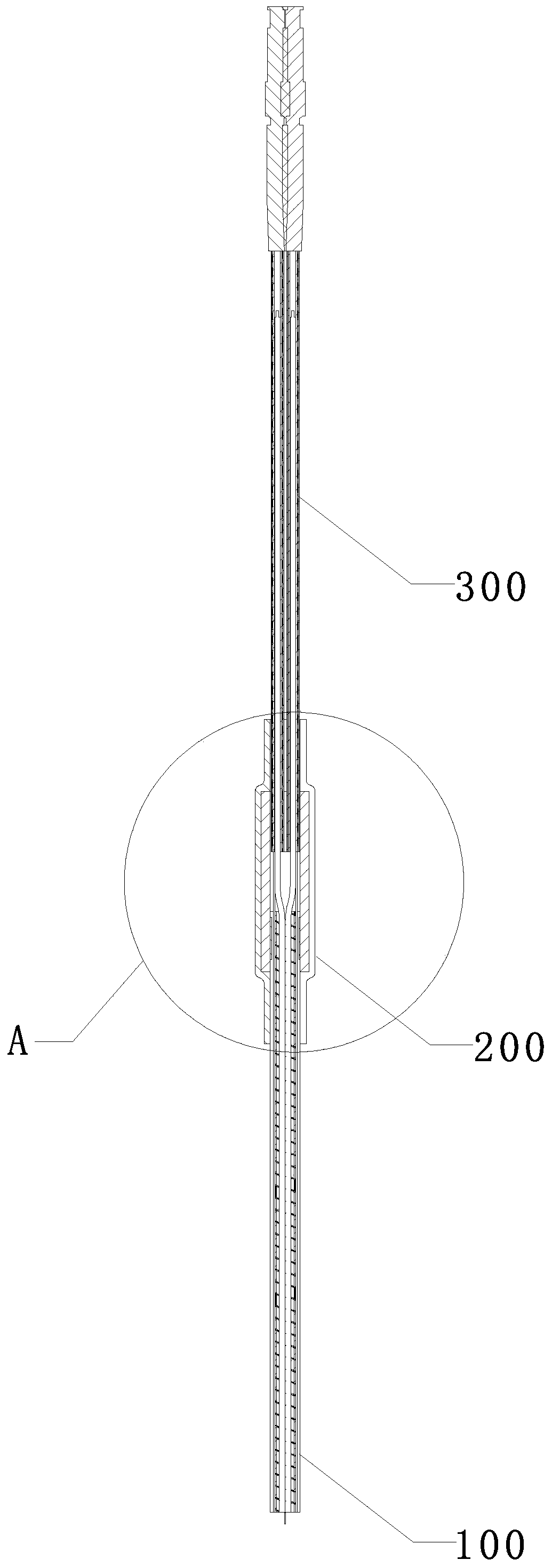

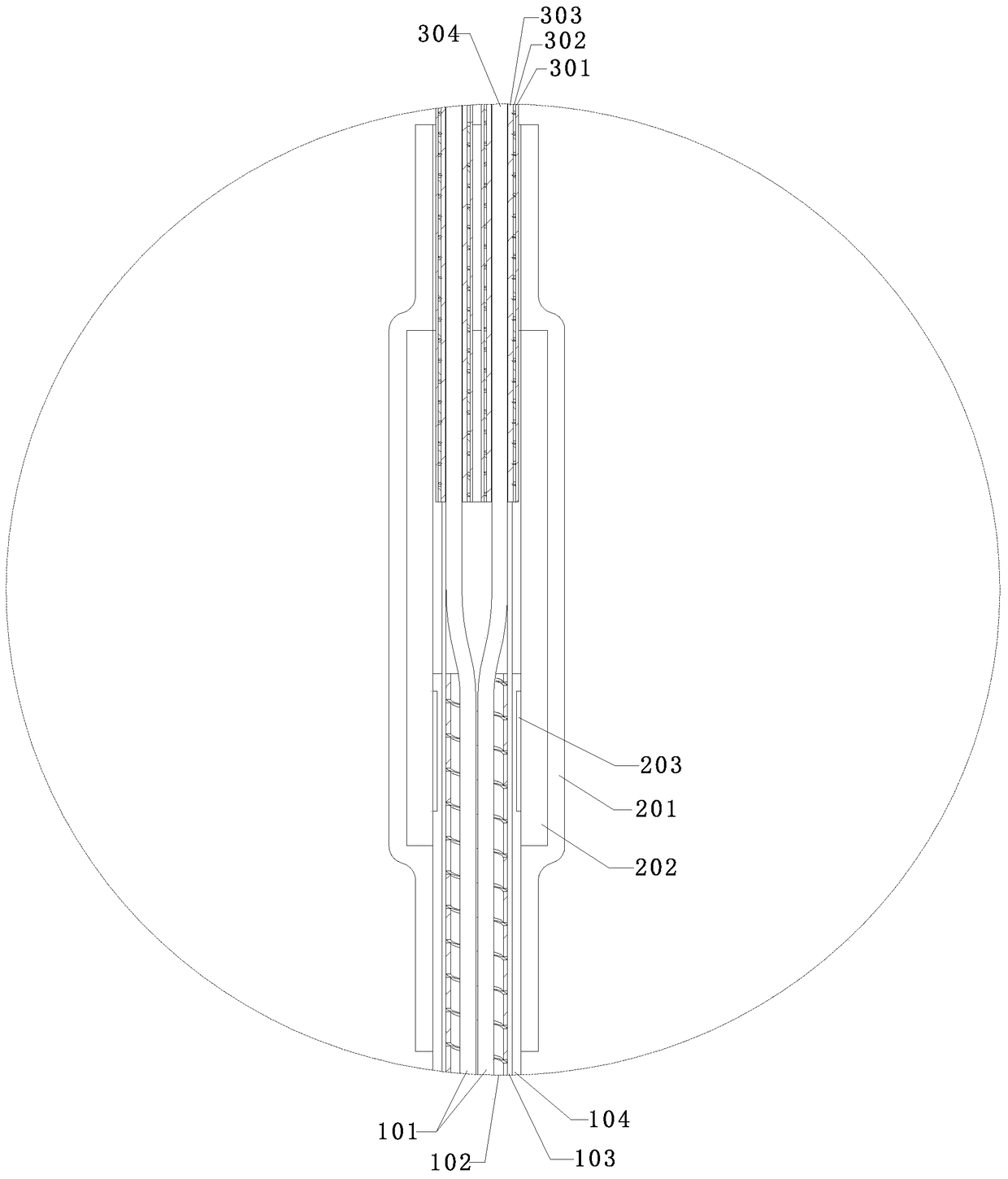

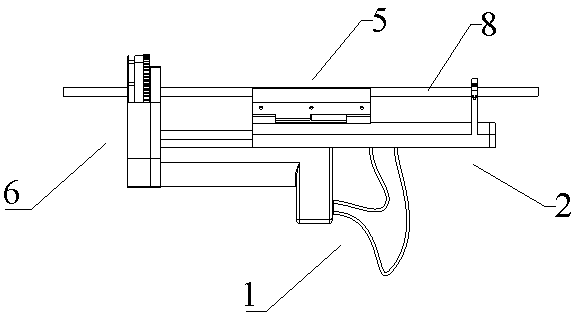

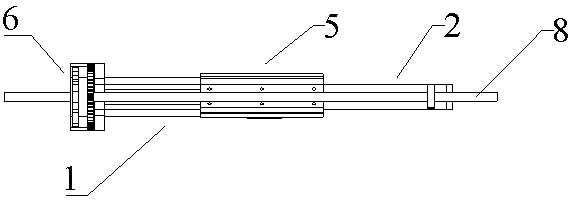

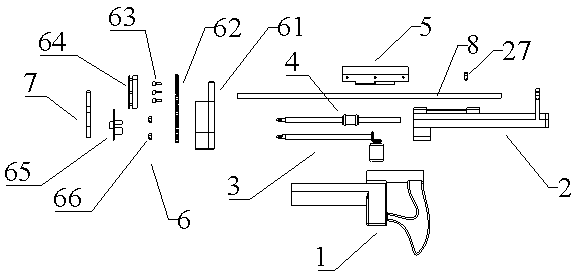

Shock-resistant assembly self-locking type rolling half grouting sleeve

InactiveCN108301571AQuality controllableControllable lengthBuilding reinforcementsShock resistanceEngineering

The invention provides a shock-resistant assembly self-locking type rolling half grouting sleeve which comprises a non-grouting connection section and a grouting connection section. A plurality of grooves are circumferentially formed in the outer wall of the grouting connection section, circumferential stiffened ribs are fixed into the grooves, and a plurality of convex ribs are circumferentiallyarranged on the inner wall of the grouting connection section. One section of pipe body of a steel pipe transition section is fixed into the non-grouting connection section, and the other section of pipe body of the steel pipe transition section extends out of the non-grouting connection section to form a rolling section which is in rolling connection with a first to-be-connected steel bar. A steel skeleton comprises inner barbs and outer barbs; a passage allowing a second to-be-connected steel bar to pass through is defined by the multiple inner barbs, and the diameter of the passage is smaller than that of the second to-be-connected steel bar; and the outline diameter defined by the outer barbs is larger than the diameter of an inner cavity of the grouting connection section. All parts of the grouting sleeve are machined and manufactured correspondingly, and the quality of all the parts is easy to control; and connection of the grouting sleeve and the steel pipe transition section isoperated by machines, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance isimproved.

Owner:HEFEI CONSTR ENG GRP

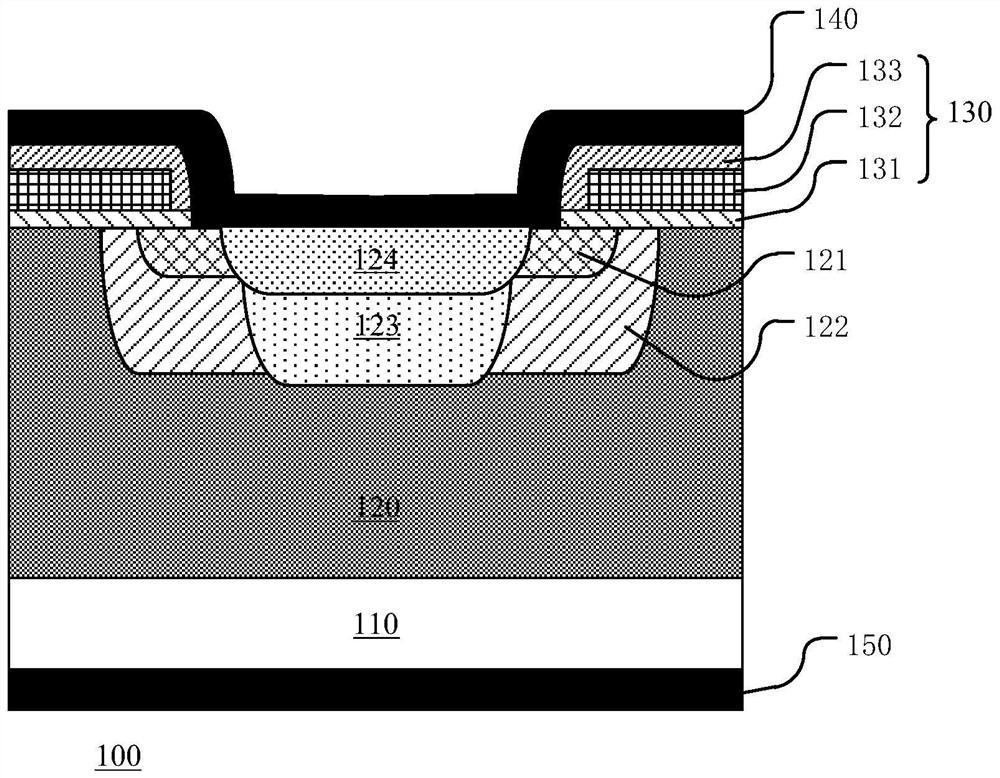

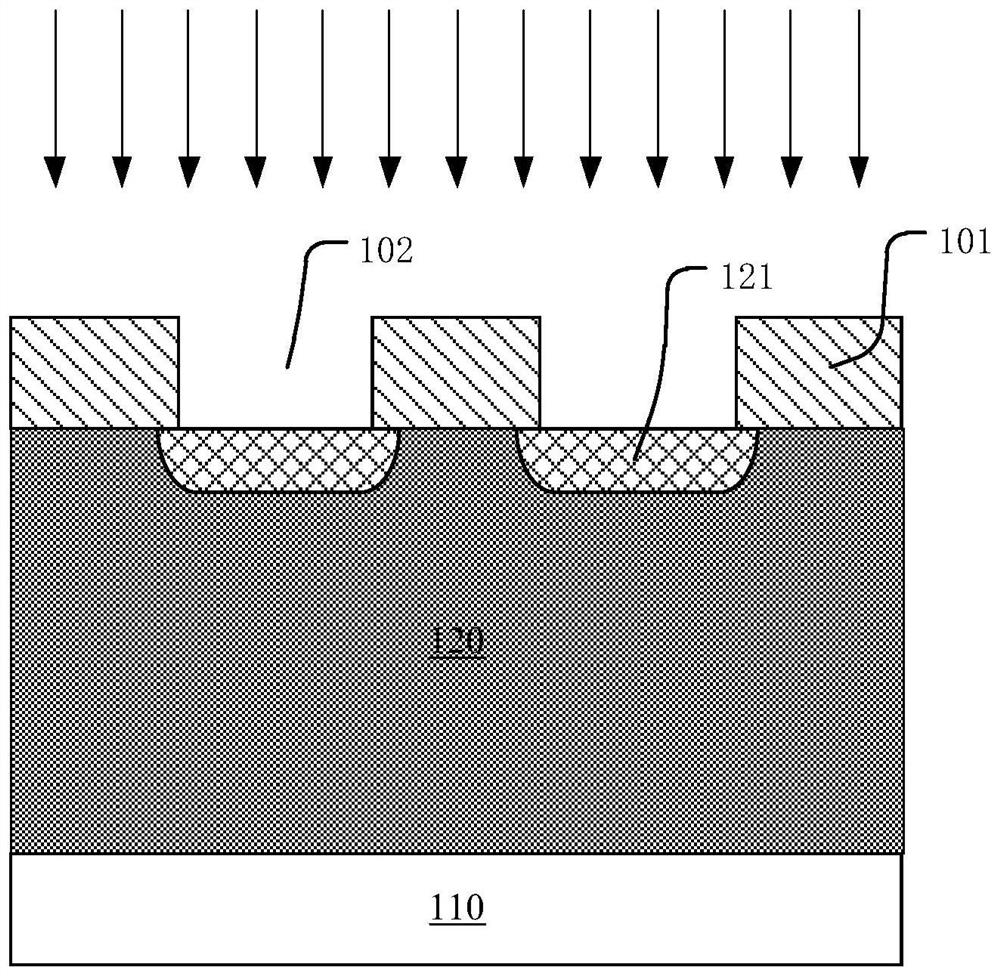

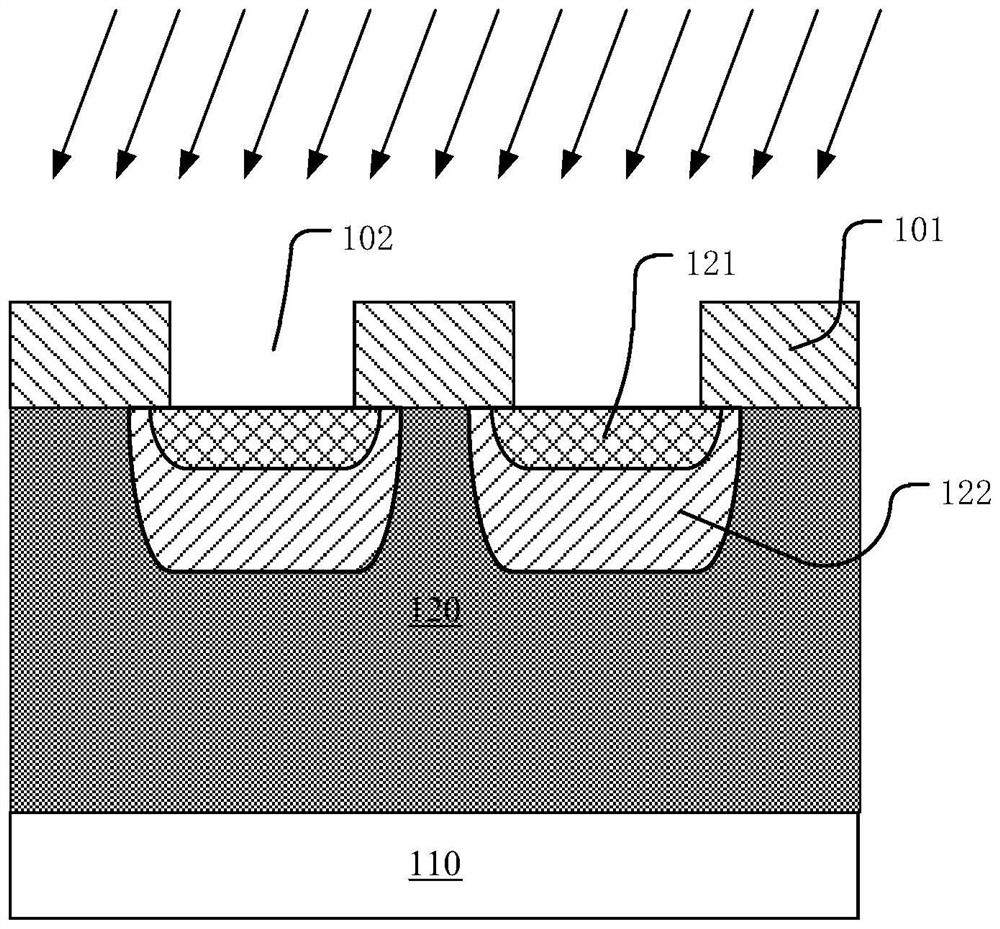

Silicon carbide MOSFET device and manufacturing method thereof

ActiveCN113628973APrecise length controlControl lengthEfficient power electronics conversionSemiconductor/solid-state device manufacturingMOSFETCarbide silicon

The invention discloses a silicon carbide MOSFET device and a manufacturing method thereof. The method comprises the following steps: forming an epitaxial layer on a first surface of a substrate; forming a source region in the epitaxial layer; forming a body region in the epitaxial layer; forming a gate structure on the first surface of the epitaxial layer, wherein the gate structure comprises a gate dielectric layer, a gate conductor and an interlayer dielectric layer; forming an opening in the interlayer dielectric layer to expose the surface of the source region; and forming the source contact on the surface of the interlayer dielectric layer and connected with the source region through the opening, wherein the transverse extension range of the body region is larger than that of the source region by means of dip angle control of ion implantation, so that a transversely-extending channel is formed in the portion, located on the periphery of the source region, of the body region, and at least a portion of the gate conductor is over the channel. According to the manufacturing method of the silicon carbide MOSFET device, the length of the channel is accurately controlled by adjusting the incident angle and the incident energy of the whole region during ion implantation, so that the short channel is realized, and the on-resistance is reduced.

Owner:HANGZHOU SILICON-MAGIC SEMICON TECH CO LTD

Aluminum tape automatic winder for overhead lines

InactiveCN106505462BAchieve windingEasy to wrapApparatus for overhead lines/cablesEngineeringConductor Coil

The invention discloses an aluminum armor tape automatic winder for an overhead line. The aluminum armor tape automatic winder includes a handle, a fixed device body, a power unit, a slave unit, a fixed lock plate and a winding device, wherein the power unit is arranged in the handle and a power output end of the power unit extends to the outside of the handle, the handle and the fixed device body are correspondingly arranged, the power output end of the power unit and a power receiving end of the slave unit are correspondingly arranged, the power unit can drive the slave unit to move, and the fixed lock plate is fixedly arranged on the fixed device body. The aluminum armor tape automatic winder for the overhead line can realize automatic winding, the winding efficiency is high, the overall structure is compact, the automatic winder can be hung on an electric wire, the workload is reduced, and safe and reliable operation is ensured; operation of workers is facilitated, a reference line can be determined in advance through positioning with the fixed lock plate, a winding position is relatively accurate, the length is easy to control, and the automatic winder is applicable to different situations, thereby realizing operation requirements of aluminum armor tapes; and the stability of the fixed device body is increased.

Owner:杨建伟

Turning tool device for turning narrow and deep end face groove with shaft

The invention provides a turning tool device for turning a narrow and deep end face groove with a shaft. The turning tool device is provided with a cutter rod and a cutter blade, wherein the cutter rod is rectangular on the whole, the rear end of the cutter rod and a cutter frame are assembled to form a whole in a clamped mode, the front end of the cutter rod is provided with a groove, the cutter blade is of a concave annular shape on the whole, the cutter blade is held in the groove, the two ends of the cutter blade both extend out of the groove, the upper end face of the cutter rod is provided with a pressing plate, the pressing plate presses the cutter blade into the groove through a sunk screw, the side face of the cutter rod is further provided with a threaded hole I, a screw rod is screwed into the threaded hole I and is locked through a nut, and the end face of the nut abuts against the rear end portion of the cutter blade. The turning tool device is a combination piece on the whole, each single piece is a machined piece, the cutter rod and the cutter blade do need to be welded, when the cutter blade is severely abraded or broken, what is needed is to grind a front corner and a rear corner from the broken portion of the cutter blade, and then the cutter blade can be used; the strength and the rigidity of the cutter rod are good; the abrasion resistance of the cutter blade is good; the extending length of the cutter rod is easy to control; the repeated clamping error is small; the pressing plate and the cutter rod are of an integrated structure, and clamping is easy to achieve; the service life is greatly prolonged, manufacturing is easy to achieve and cost is low.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com