Patents

Literature

32results about How to "Enough free space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

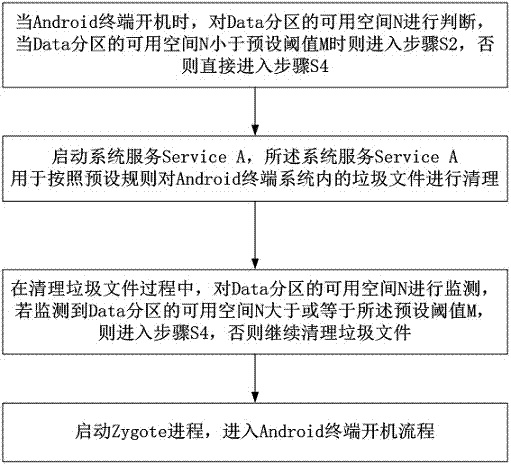

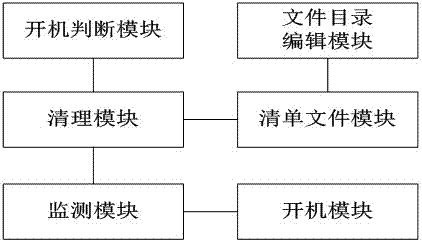

Method and apparatus for solving problem of no startup of Android terminal

ActiveCN105068844AEnough free spaceSolve the problem of not being able to bootProgram loading/initiatingComputer terminalComputer science

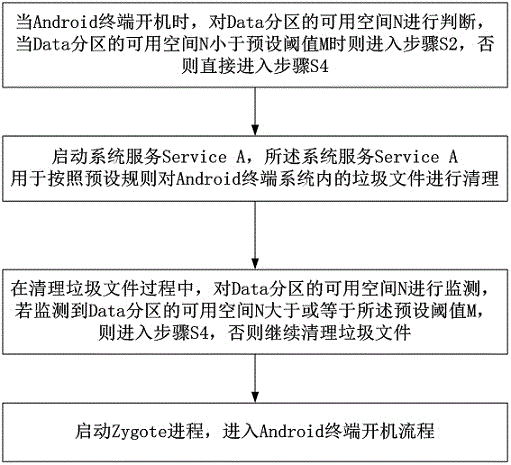

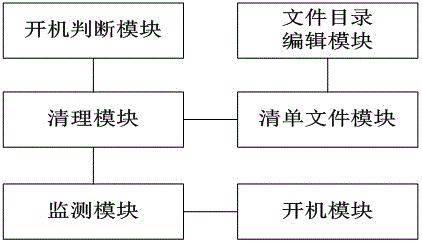

The invention discloses a method and an apparatus for solving the problem of no startup of an Android terminal. According to the method and the apparatus, available space N of a Data partition is judged when the Android terminal is started up; and when the available space N of the Data partition is smaller than a preset threshold value M, junk files in the Android terminal are cleaned for enabling the Data partition to have enough available space, so that the problem of no startup caused by repeated restart and Logo interface locking of a system due to sufficient available space of the Data partition (or insufficient available space of the Data partition) during startup of the Android terminal is well solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

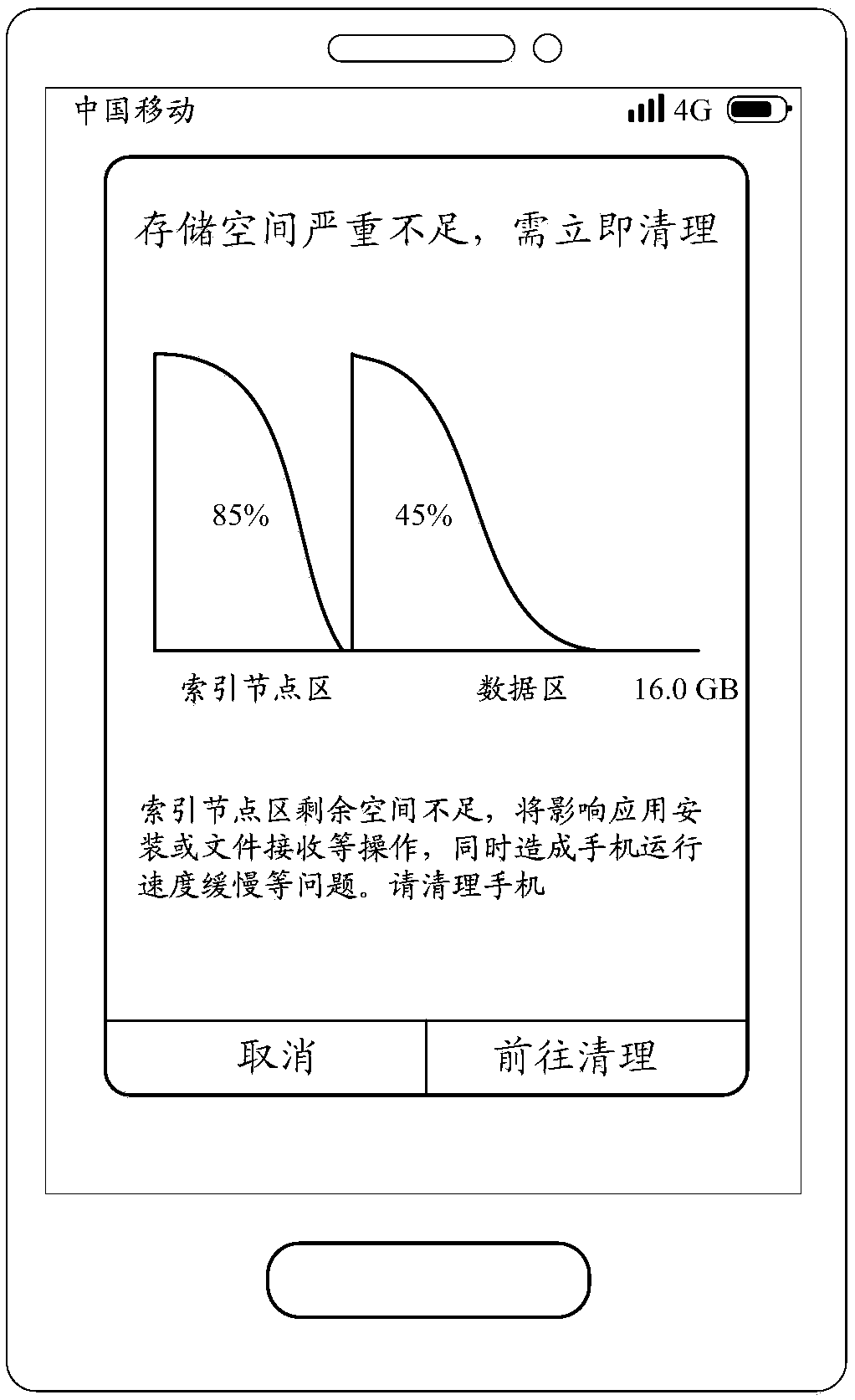

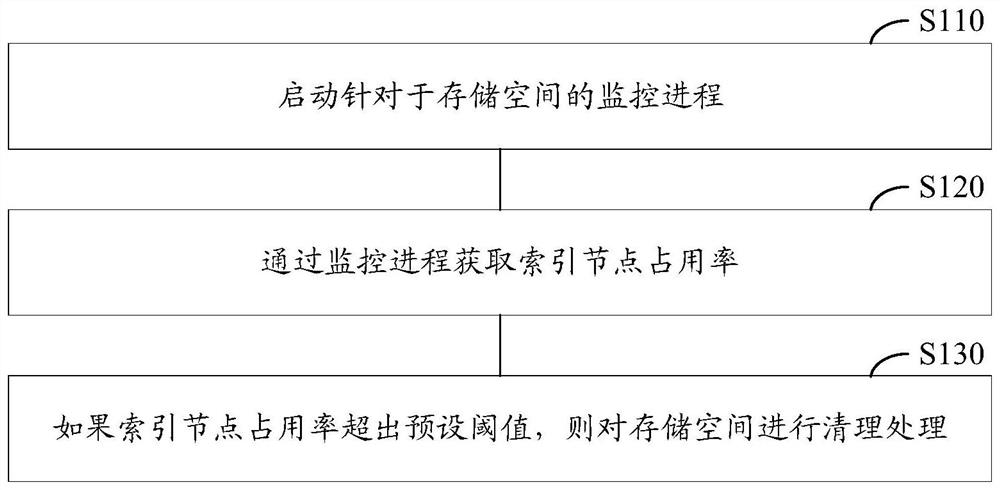

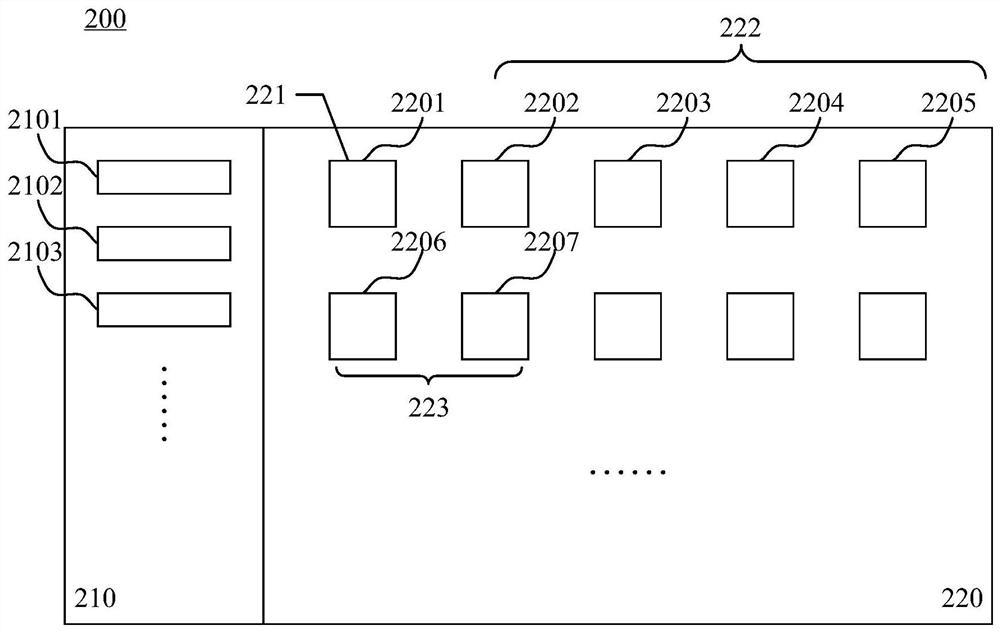

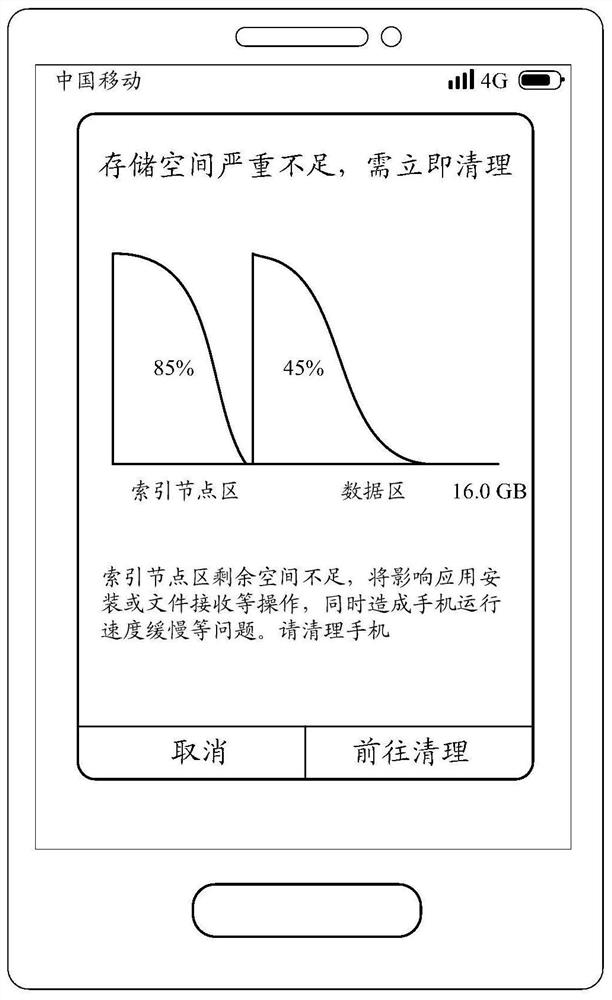

Storage space monitoring method and device, electronic terminal and storage medium

ActiveCN109656885AMonitor usageEnough free spaceFile access structuresFile/folder operationsOccupancy rateOperating system

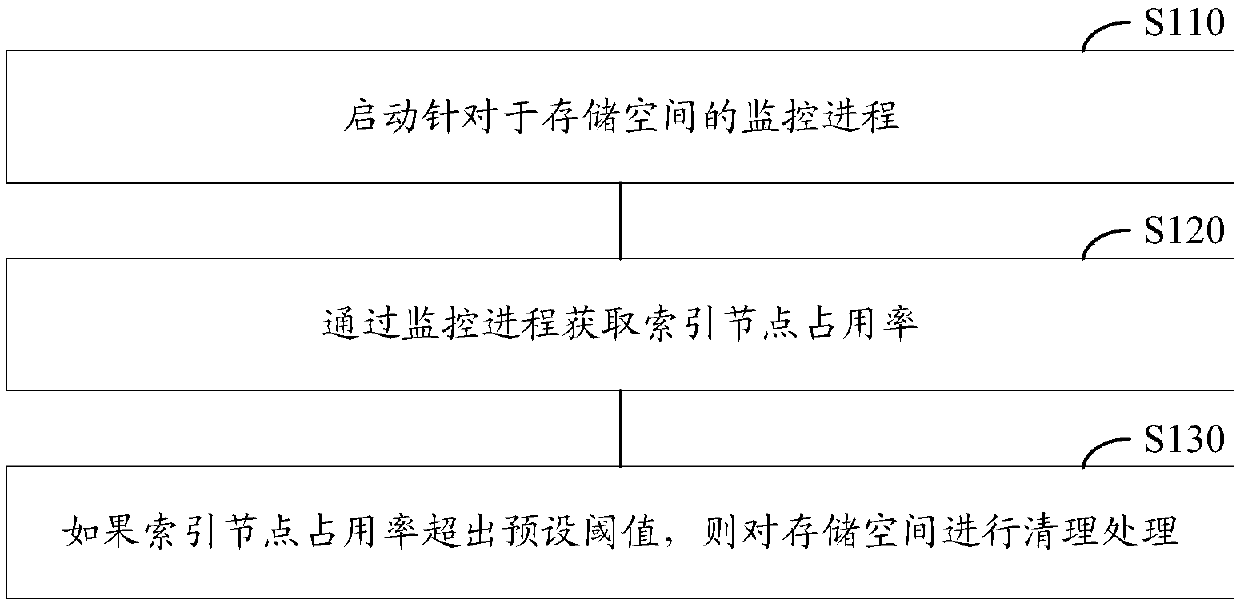

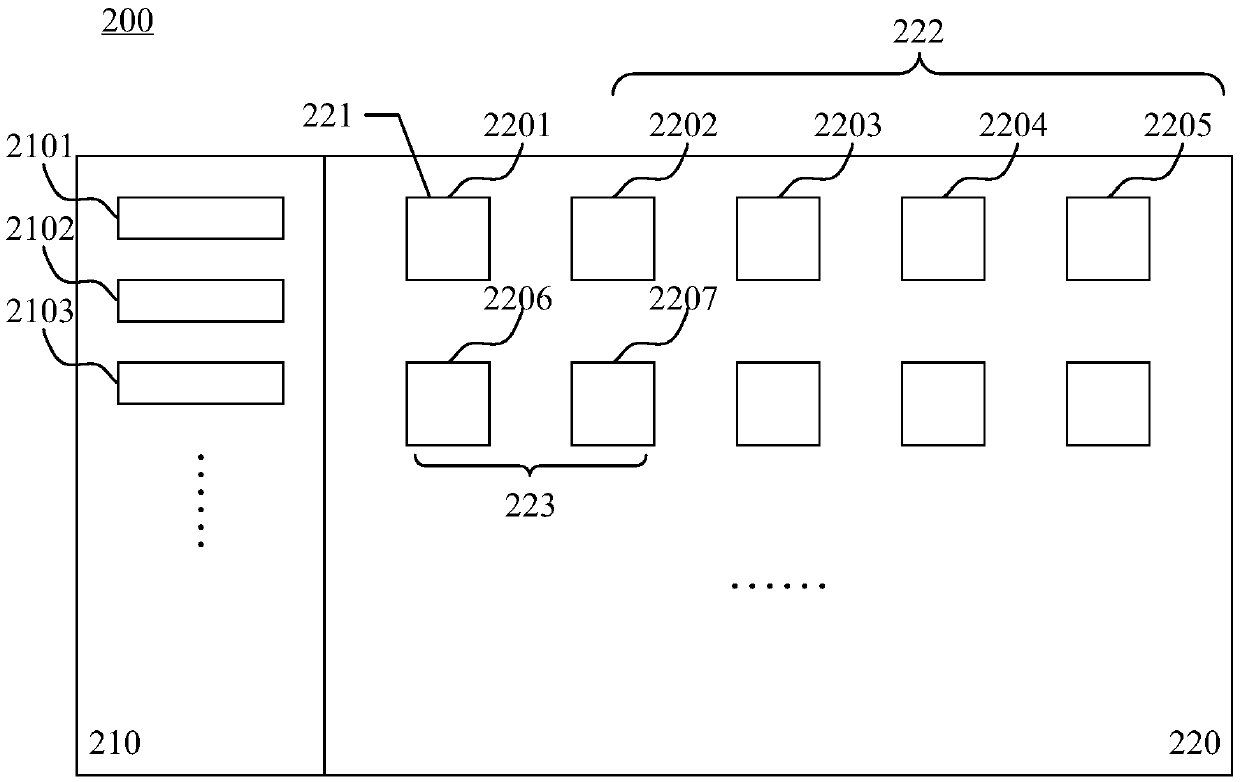

The invention provides a storage space monitoring method and device, an electronic terminal and a computer readable storage medium, and belongs to the technical field of computers. The method is applied to the electronic terminal and comprises the following steps of starting a monitoring process for a storage space, wherein the storage space comprises a data area and an index node area, the data area is used for storing files, and the index node area is used for storing index information of the files; Obtaining an index node occupancy rate through the monitoring process, wherein the index nodeoccupancy rate is the proportion of the occupied index nodes to all the index nodes in an index node area; And if the index node occupancy rate exceeds a preset threshold value, cleaning the storagespace. The index node area of the storage space can be monitored and managed, the abnormal occupation condition of the storage space can be effectively monitored, and the monitoring efficiency is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

One-time well completion method through VCR method

The invention discloses a one-time well completion method through a VCR method. The one-time well completion method comprises the following steps that a, a center hole is drilled in the center of a working face of a raise where a well is proposed to be completed, and then compensating holes and periphery holes surrounding the center hole are sequentially drilled by taking the center hole as a center; b, the center hole and the periphery holes are internally filled with explosives in a deck charge mode, and every two adjacent sections of explosives in the same hole are separated by a bulkhead;and c, the center hole is blasted firstly to expand a groove cavity, then a millisecond blasting method is utilized to conduct sectional blasting in the blasting sequence of the center hole first andthen the periphery holes, and tower blasting is formed till the whole raise is completely blasted. According to the one-time well completion method through the VCR method, one-time well completion canbe achieved by adopting the tower blasting mode, and the one-time well completion method has the advantages that the well completion effect is good and the well completion efficiency is high.

Owner:TIBET HUATAILONG MINING DEV

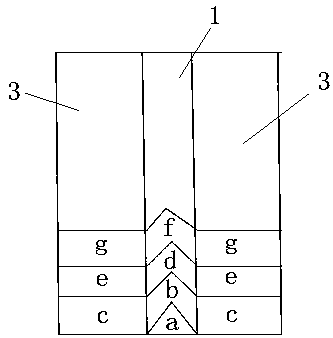

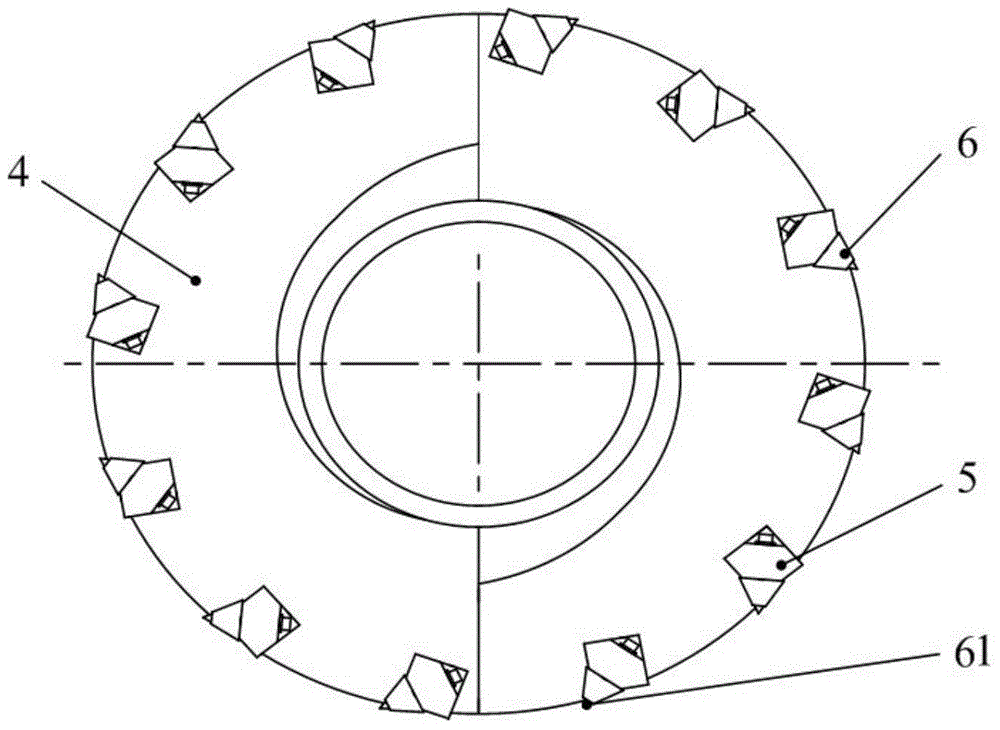

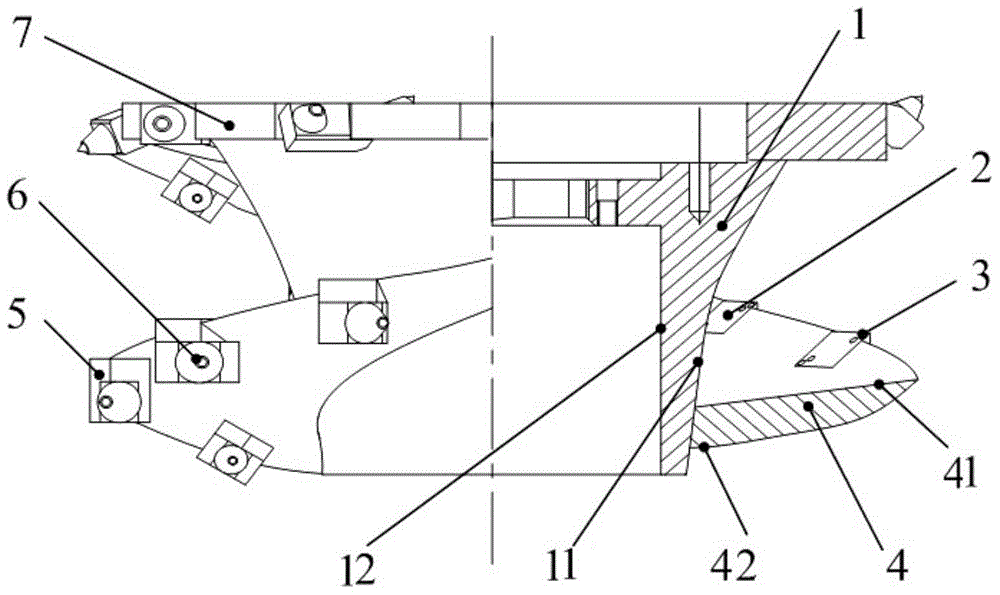

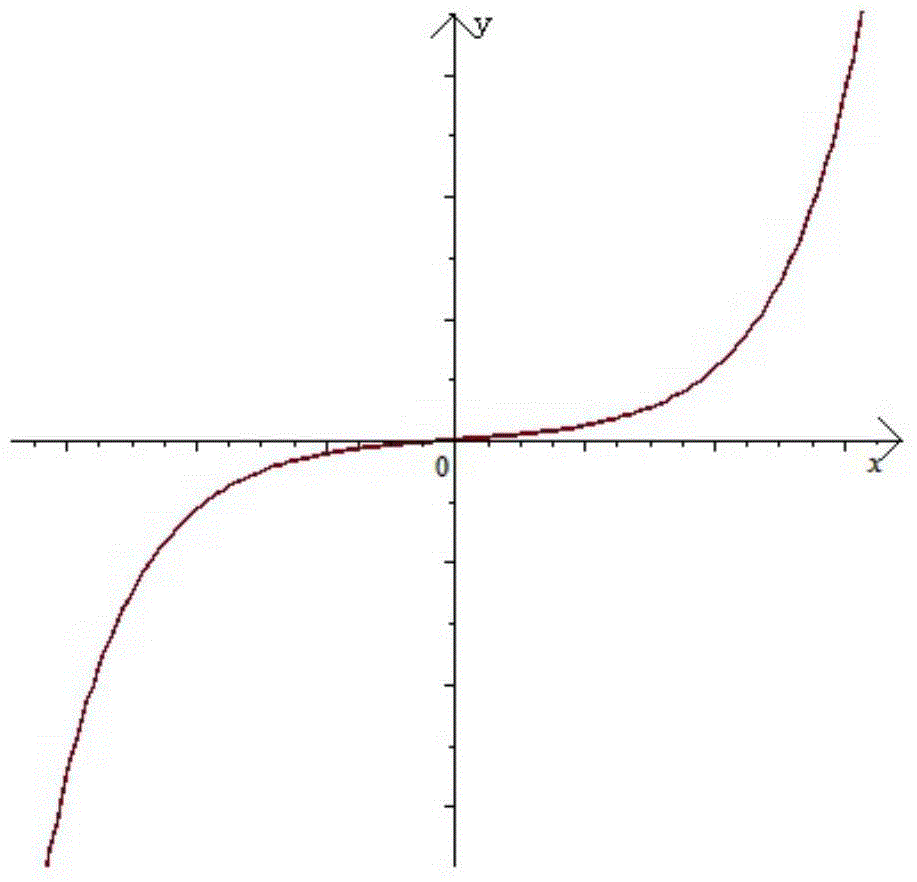

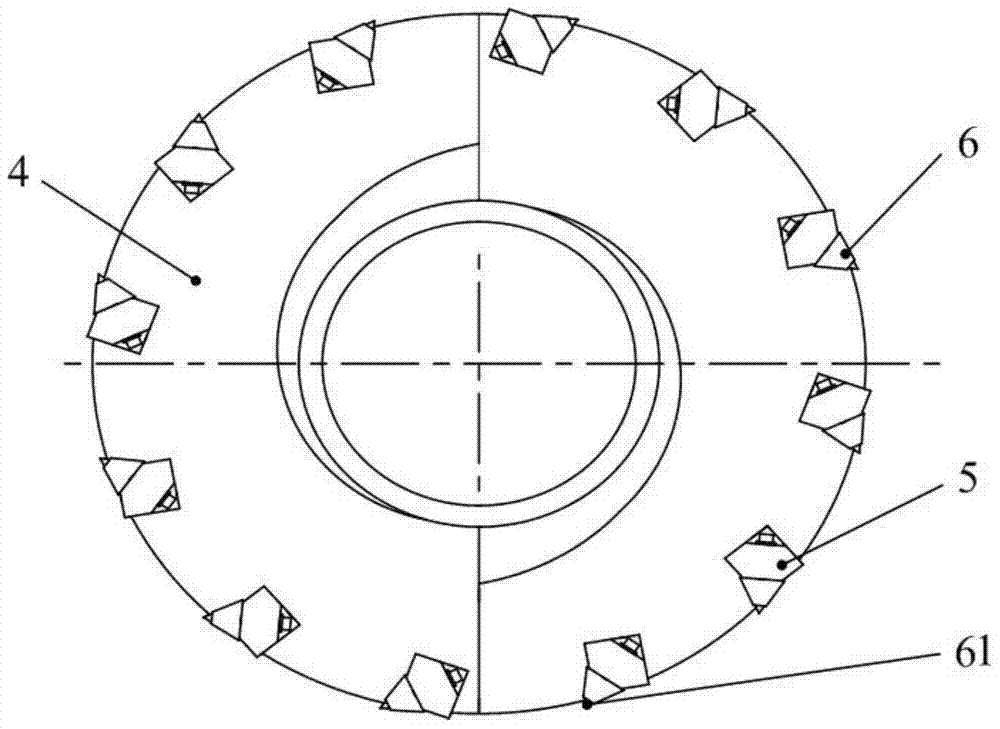

Thin coal seam coal mining machine drum

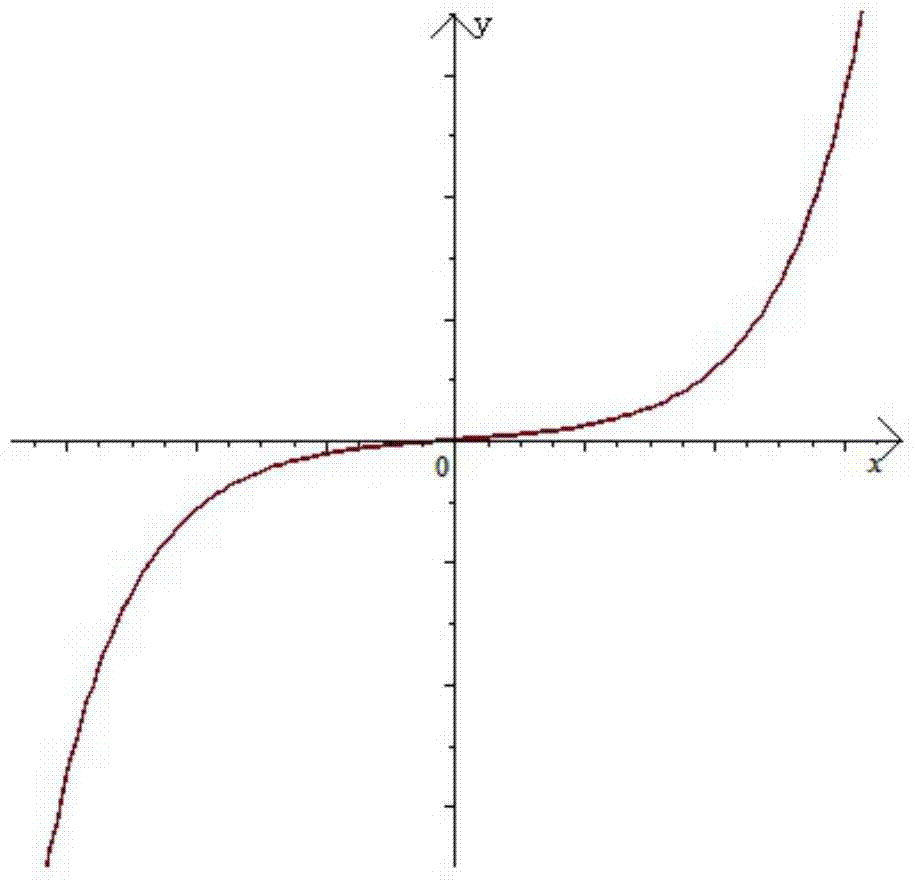

ActiveCN105134206AIncrease coal loading rateExtended service lifeCutting machinesCoal miningDistribution rule

The invention discloses a thin coal seam coal mining machine drum composed of an end plate, a spiral blade, a drum hub, cutting teeth, tooth holders and the like; the diameter of the drum hub is increased from the drum bottom to the end plate in a hyperbolic sine mode, an included angle of the section of the spiral blade with an inner cylindrical surface of the drum hub is not a right angle, a coal facing face of the spiral blade is cambered in shape, the tooth holder of each cutting tooth is mounted on the coal facing face of the spiral blade by a bolt fixing manner, and only an alloy head part of each cutting tooth exposes outside the spiral blade enveloping scope. According to the drum, according to motion and distribution rules of coal bodies in the loading and transportation process, main reasons of wear failure of the current drum are combined, and a special drum hub contour line, the cambered surface deflection spiral blade and the detachable cutting teeth and tooth holders are combined, so that the drum coal loading rate is increased by more than or equal to 20%, the drum life is increased by more than or equal to 6%, and the drum is suitable for mining of thin coal seams with the coal seam thickness of less than 1.3 m and the strike pitch of less than 20 DEG. The drum has the advantages of compact structure, convenient use, good coal loading effect and long service life.

Owner:SHANDONG UNIV OF SCI & TECH

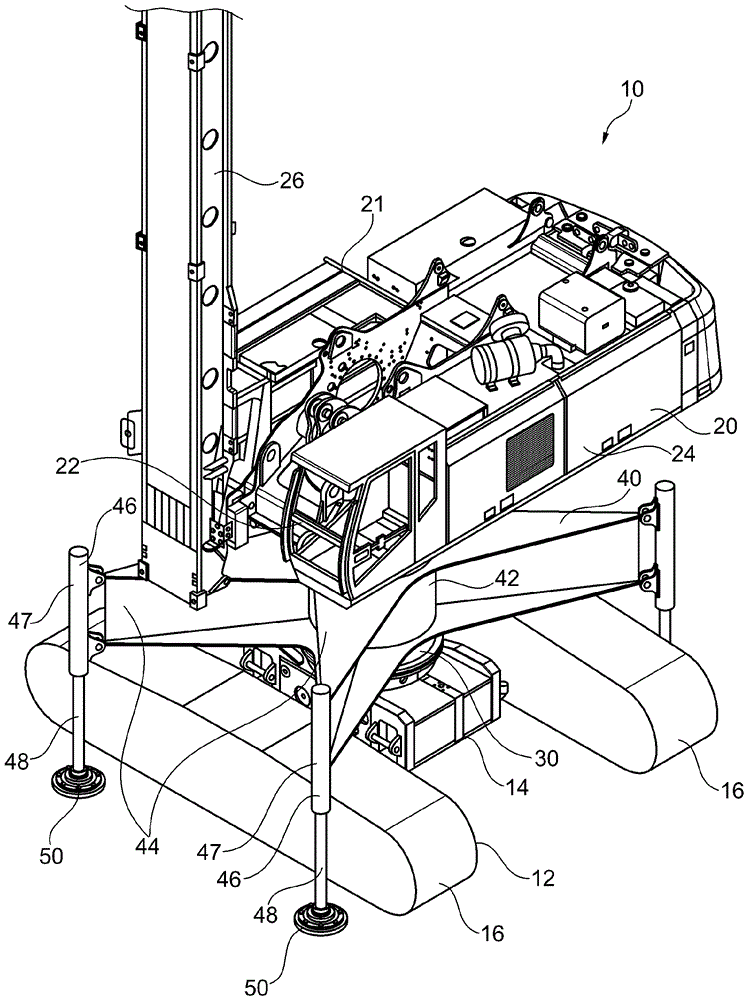

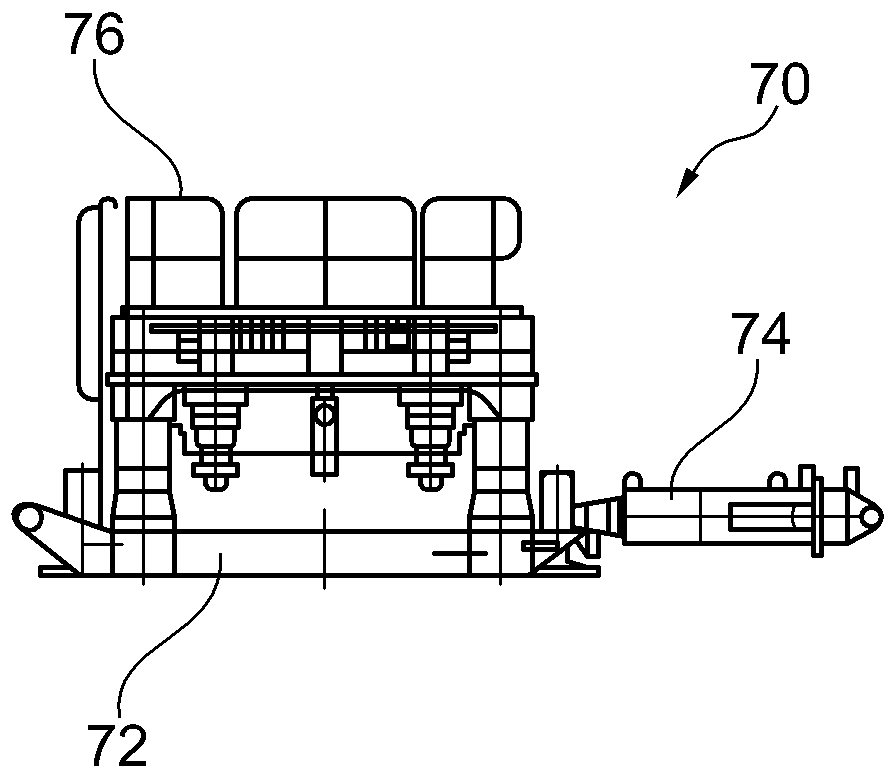

Earthworking tool and method for earthworking

InactiveCN105723032AReduce wearImprove working accuracyFluid removalSoil-shifting machines/dredgersEngineeringDrive motor

The invention relates to an earthworking tool, comprising an undercarriage, which is disposed as a chassis, and a superstructure, which is rotatably mounted on the undercarriage and which has a driver compartment and a drive motor for the undercarriage. A extension segment is arranged between the undercarriage and the superstructure, by means of which a vertical distance between the undercarriage and the superstructure can be extended. A support device to prevent tipping is provided on the extension segment between the undercarriage and the superstructure. The invention further relates to a method for earthworking by means of such an earthworking device.

Owner:BAUER SPEZIALTIEFBAU

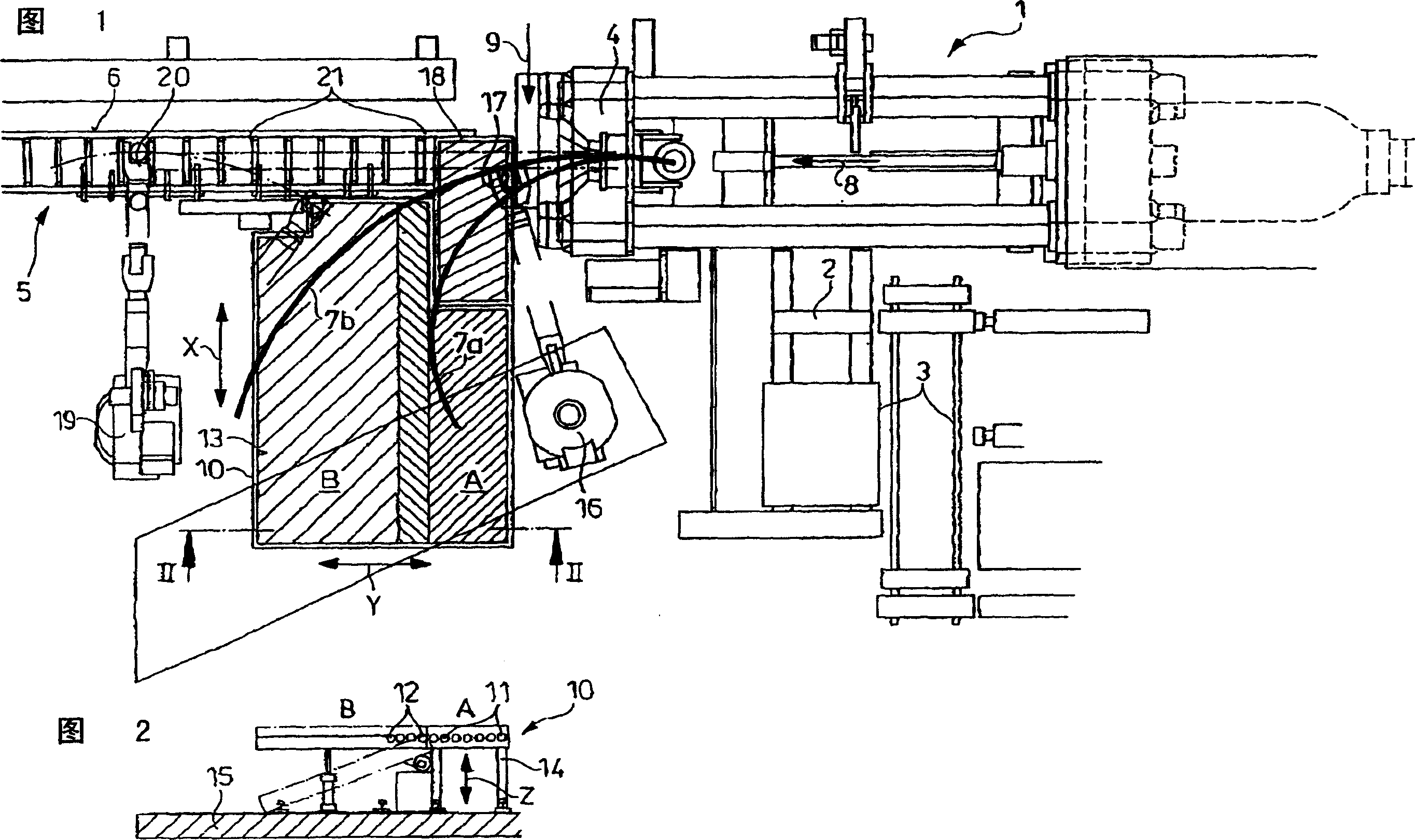

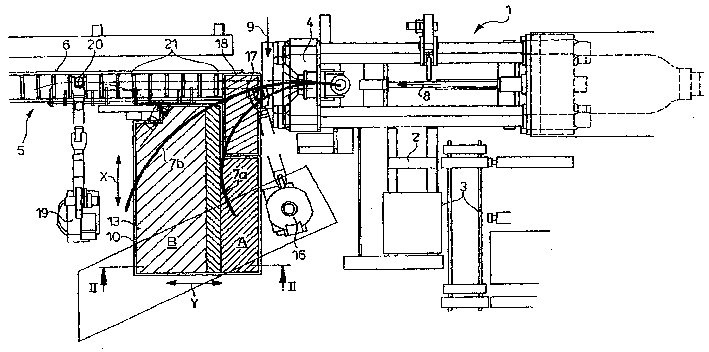

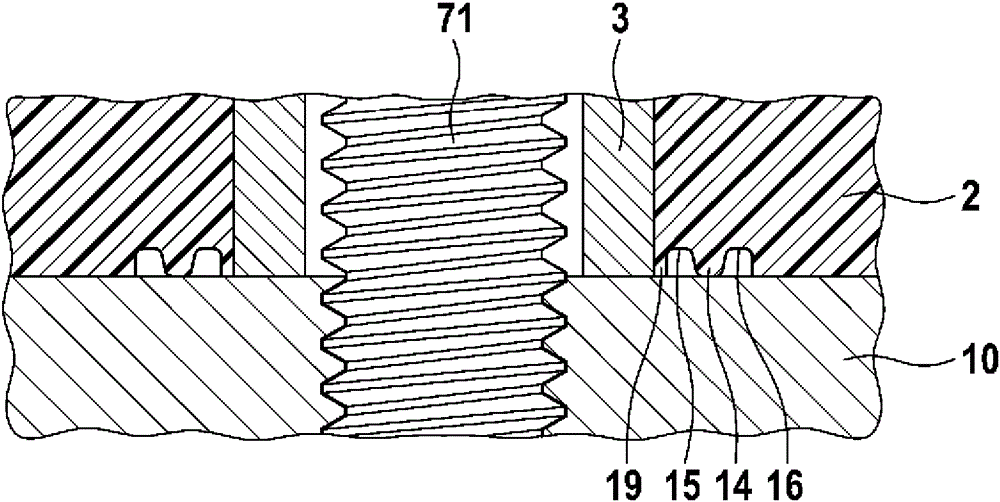

Method and device for extruding curved extrusion profiles

The invention relates to a method for extruding curved extrusion products (7a, 7b), whereby the extruded profile is formed in a die that is located upstream of a crosshead (4) of an extrusion installation (1) and is subsequently curved or bent by the action of external forces. The extruded strand (7a, 7b) is taken up at the press outlet by a bearing surface (10) that supports the underside of the strand. Once a partial length of strand has been separated, said length is moved (10) from the press flow and is transported away by the bearing surface, whereby the provision of a supporting surface for the subsequent strand is simultaneously maintained during said transportation by the bearing surface (10). To achieve this, a platform (10) that is located in the press outlet (5), that supports the extruded strand and that can be raised and lowered is divided into functional fields (A, B). The rear functional field (B), which adjoins the front functional field (A) closest to the machine, can be temporarily pivoted into an inclined position in relation to the base.

Owner:SMS欧姆科股份有限公司

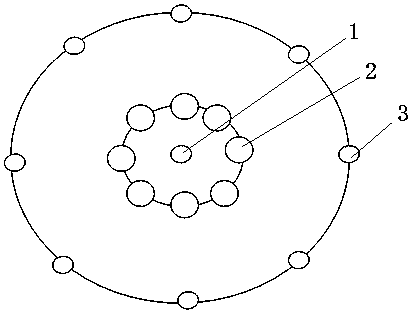

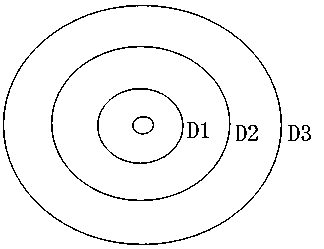

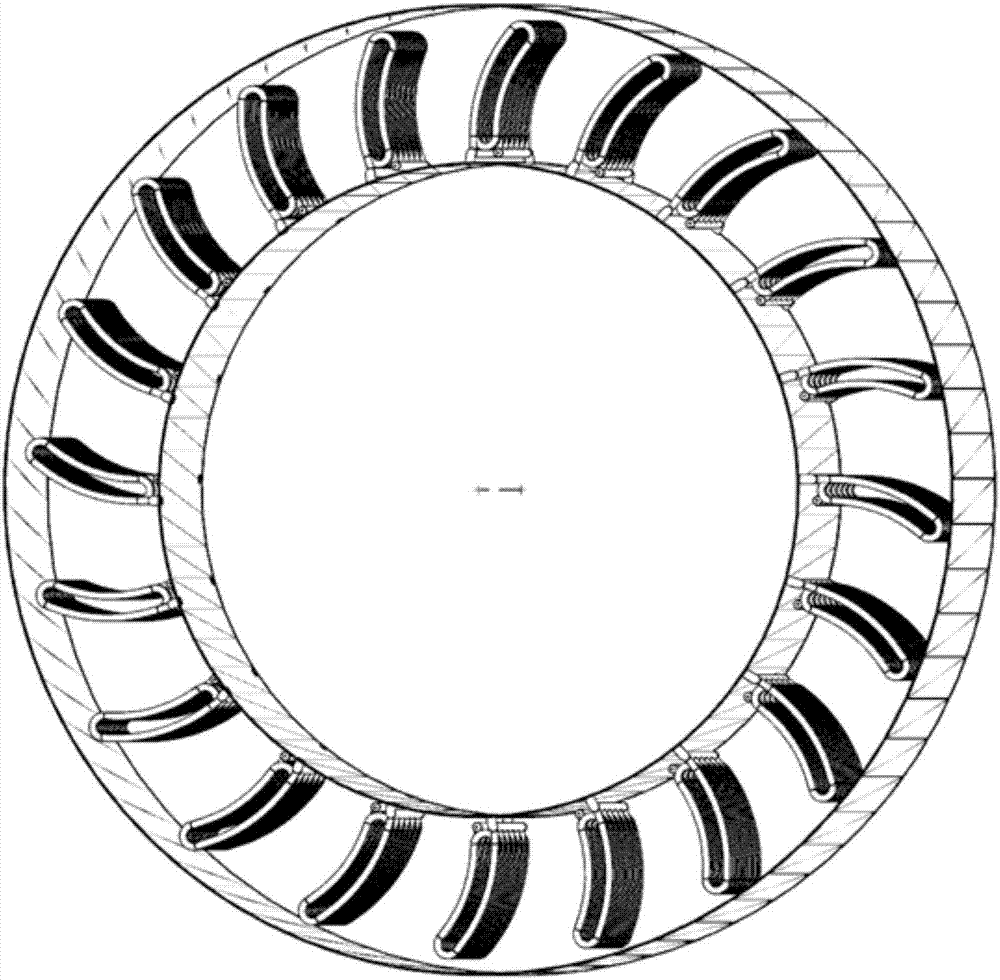

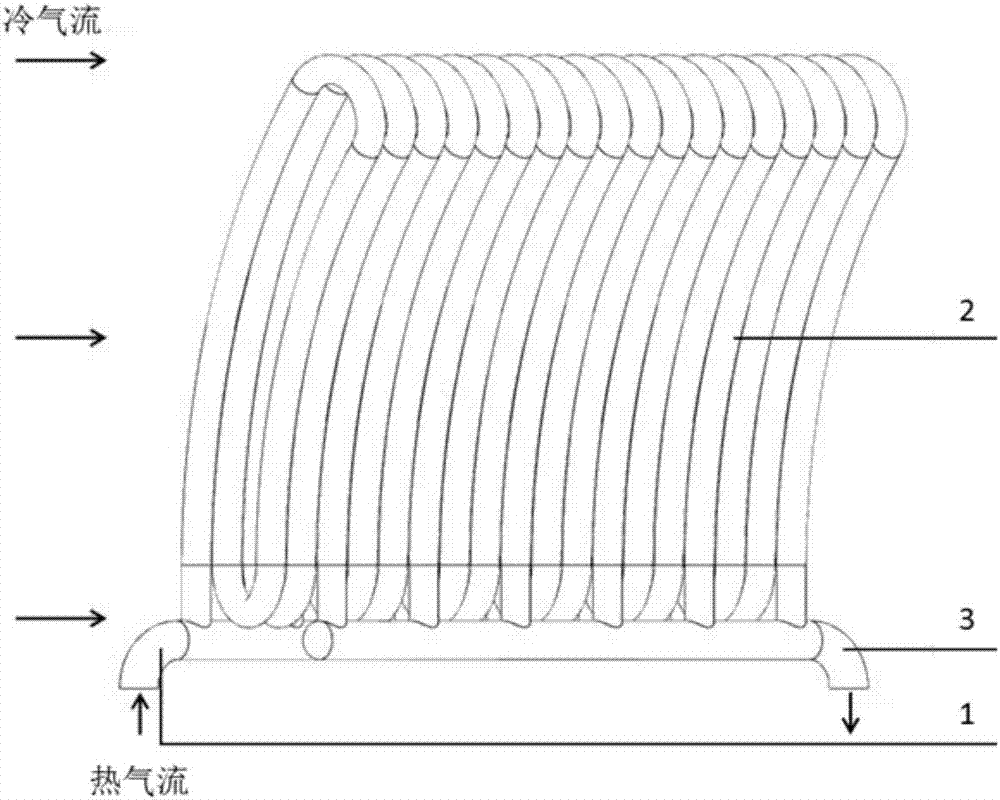

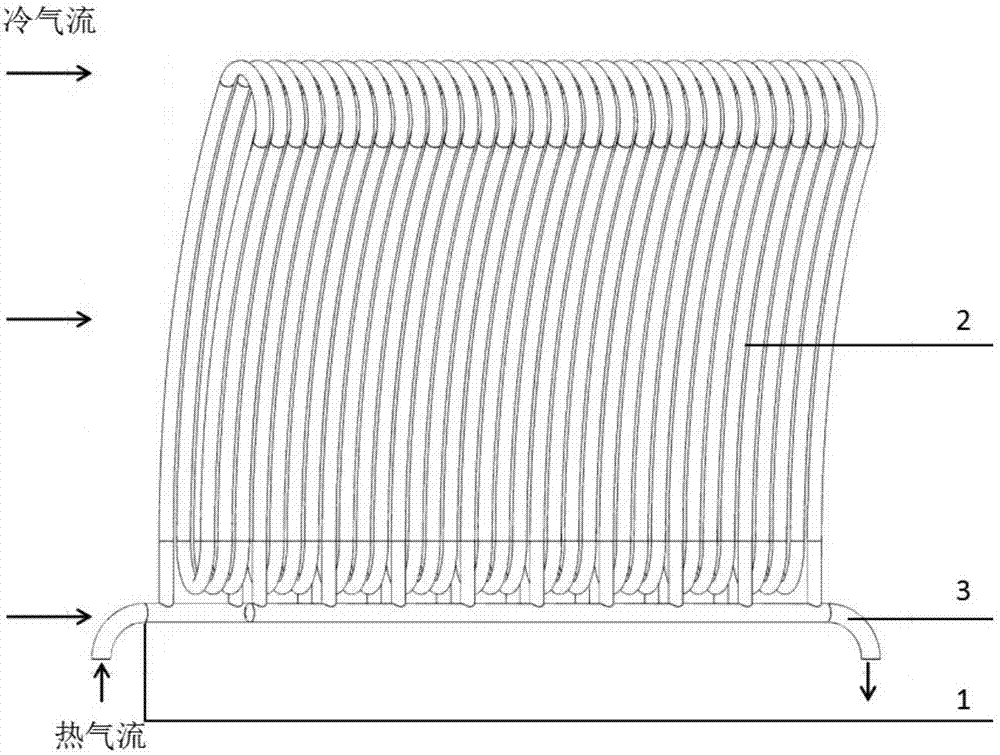

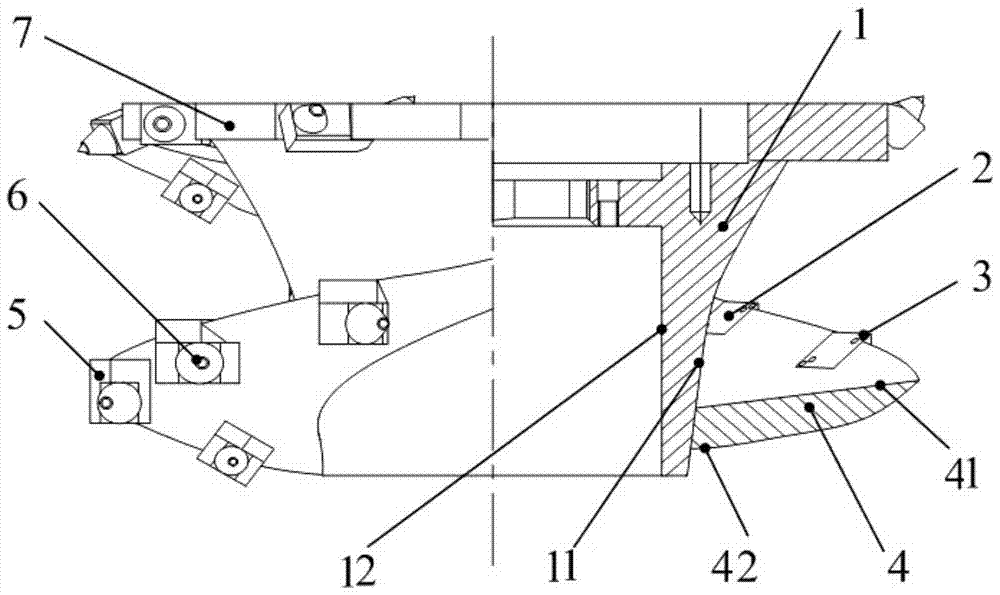

Spiral tube type air-air heat exchanger in circular passage

InactiveCN107192279AImprove compactnessGood thermal expansion adaptabilityStationary tubular conduit assembliesCold airPlate heat exchanger

The invention discloses a spiral tube type air-air heat exchanger in a circular passage, and relates to the field of air-air heat exchangers. The spiral tube type air-air heat exchanger in the circular passage comprises a plurality of heat exchanging units which are evenly arranged in the circular passage in the circumferential direction of the circular passage. Cold air flow in the circular passage moves in the axial direction. Each heat exchanging unit comprises a hot air flow inlet air collecting pipe and a hot air flow outlet air collecting pipe which are arranged in the flowing direction of the cold air flow and a plurality of spiral heat exchanging pipes, wherein the two ends of each spiral heat exchanging pipe communicate with the hot air flow outlet air collecting pipe and the hot air flow inlet air collecting pipe correspondingly. The spiral heat exchanging pipes are distributed in sequence in the flowing direction of the cold air flow to form a heat exchanging pipe bundle. An outlet of each hot air flow outlet air collecting pipe and an inlet of each hot air flow inlet air collecting pipe are located at the same end of the corresponding heat exchanging unit and penetrate through the inner wall or the outer wall of the circular passage. The other end of each heat exchanging unit is a free end.

Owner:XI AN JIAOTONG UNIV

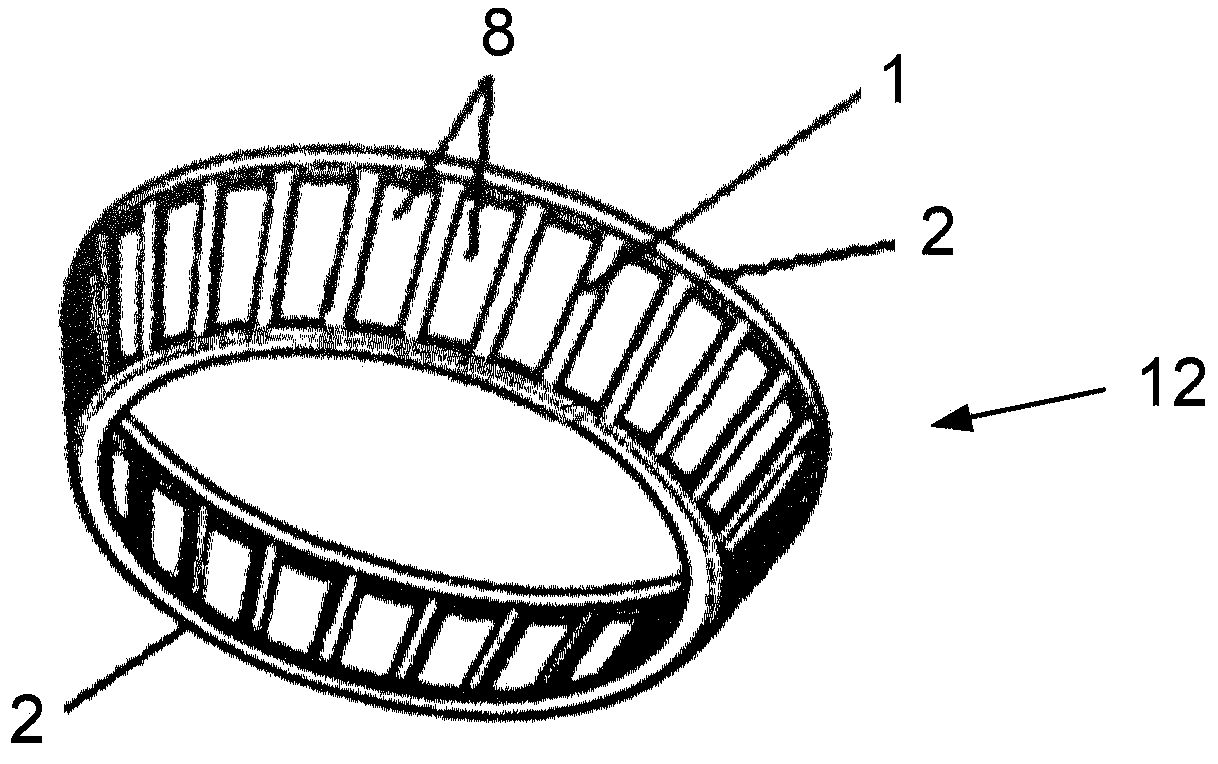

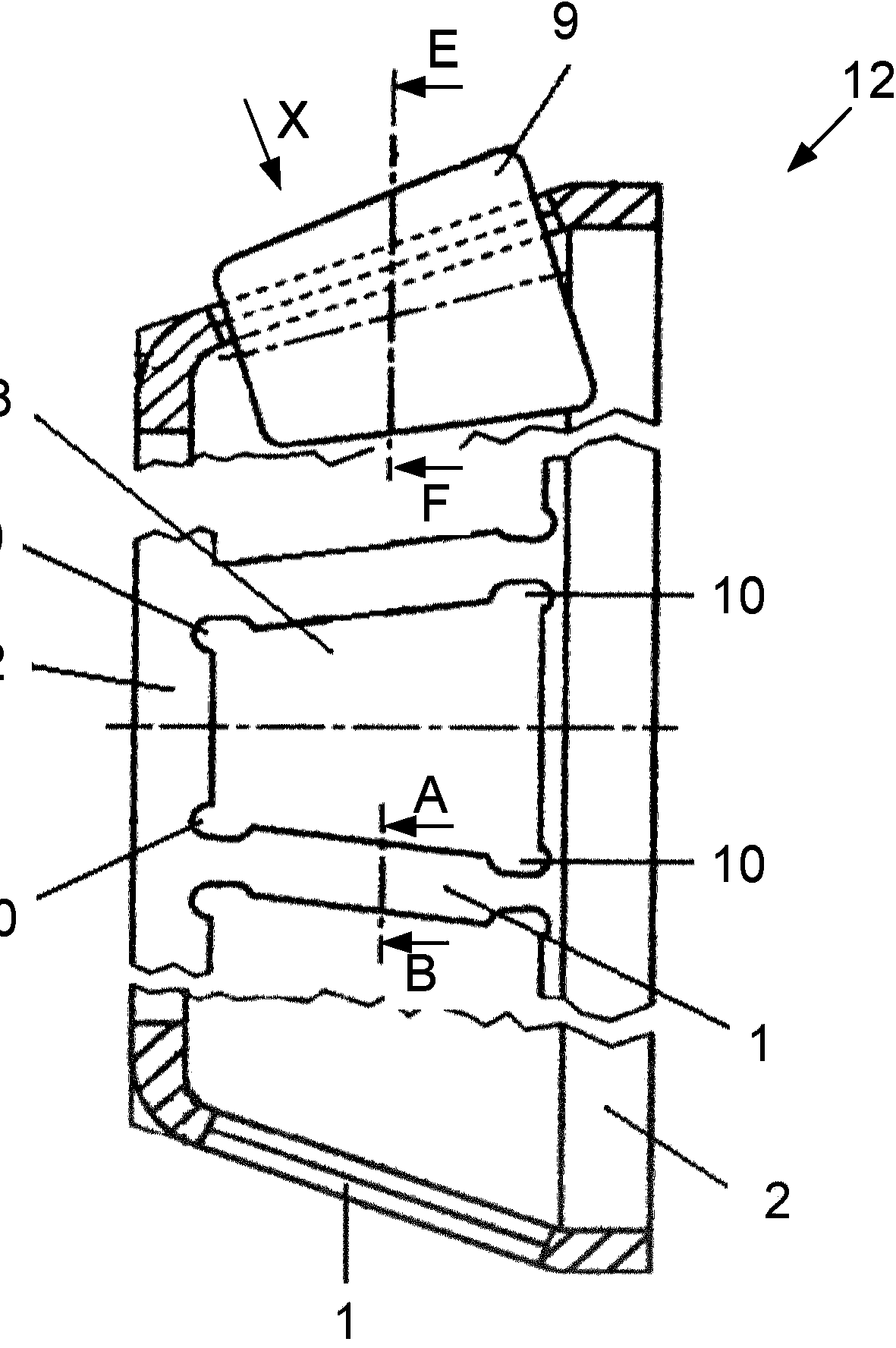

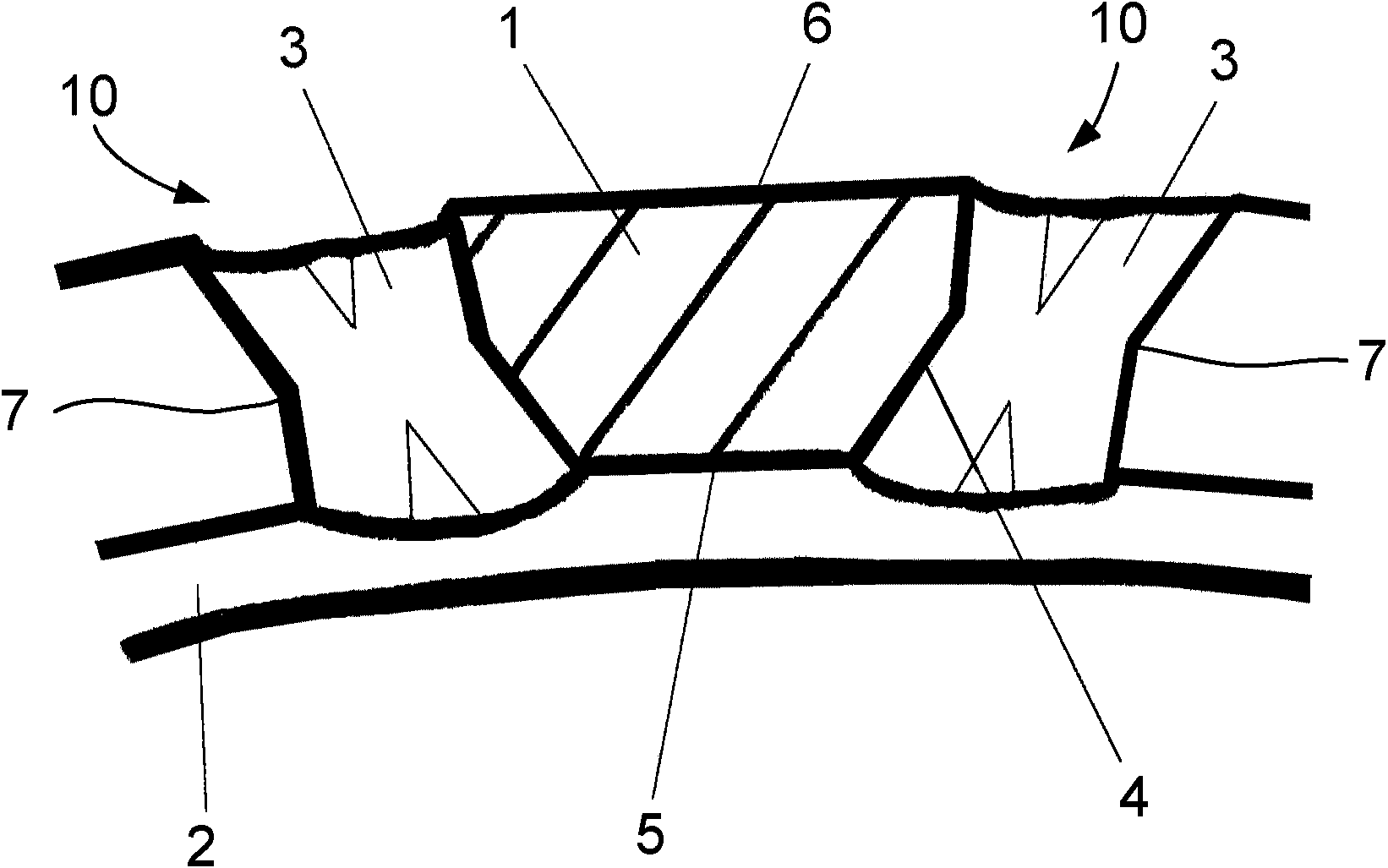

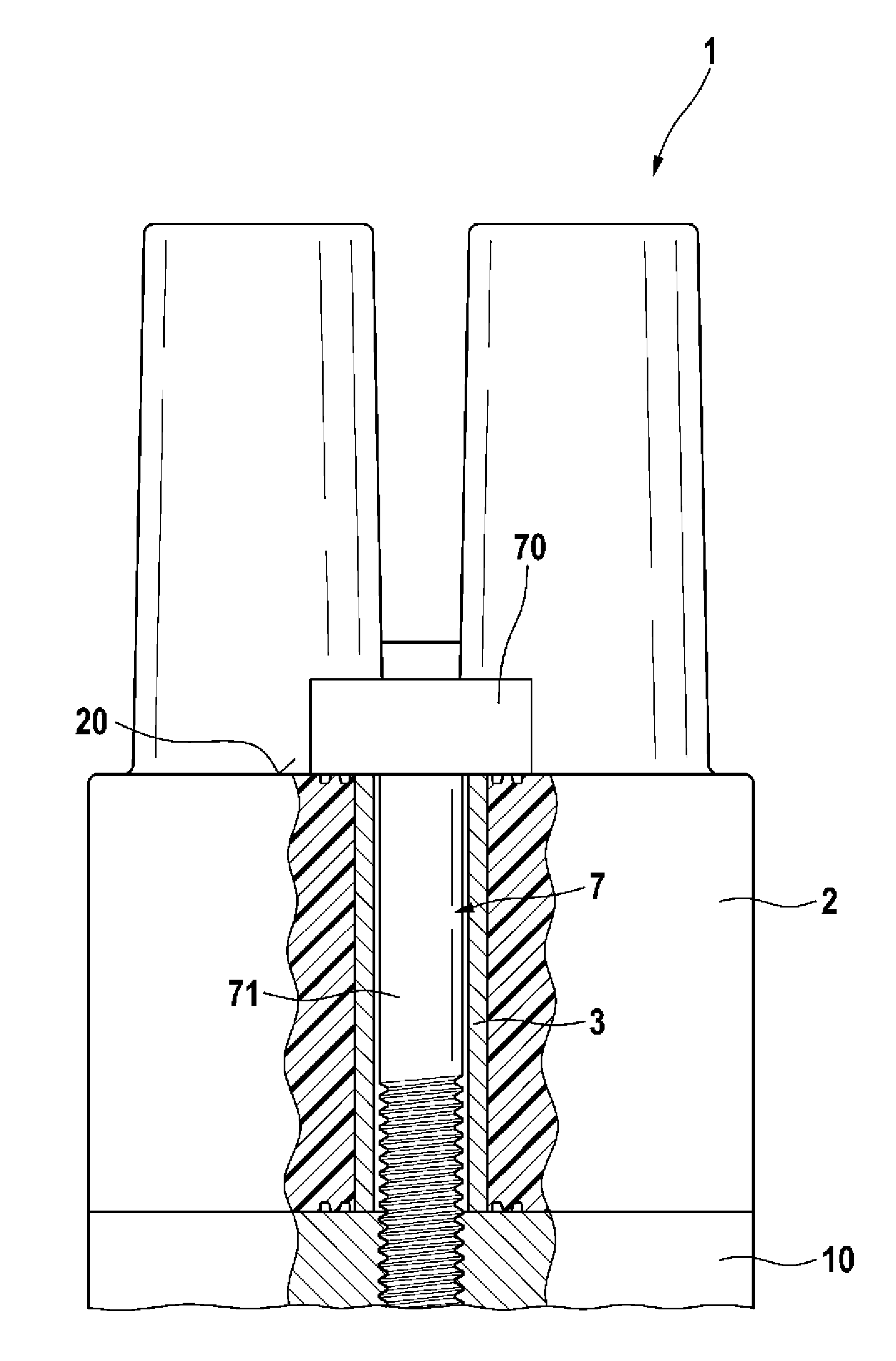

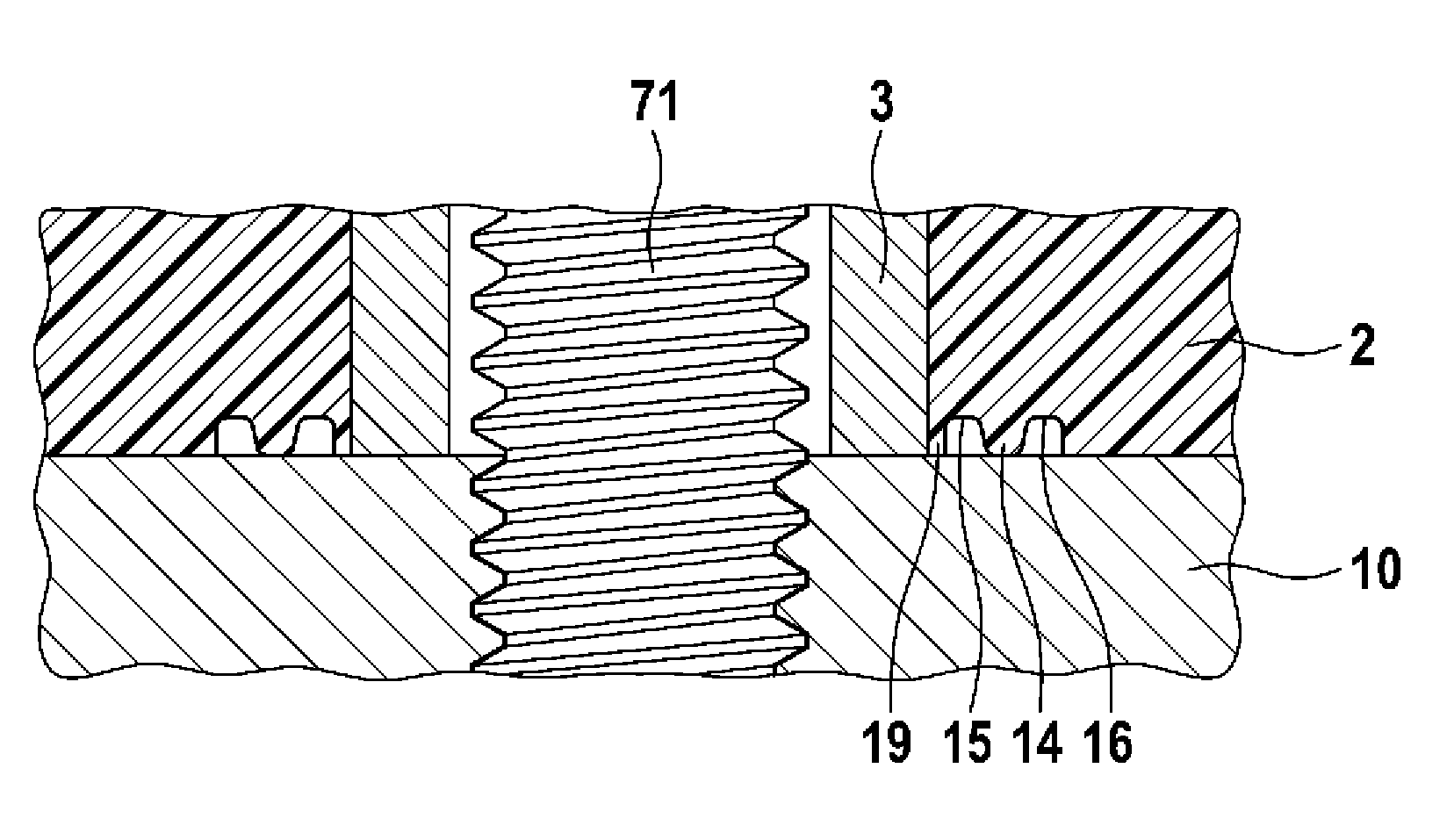

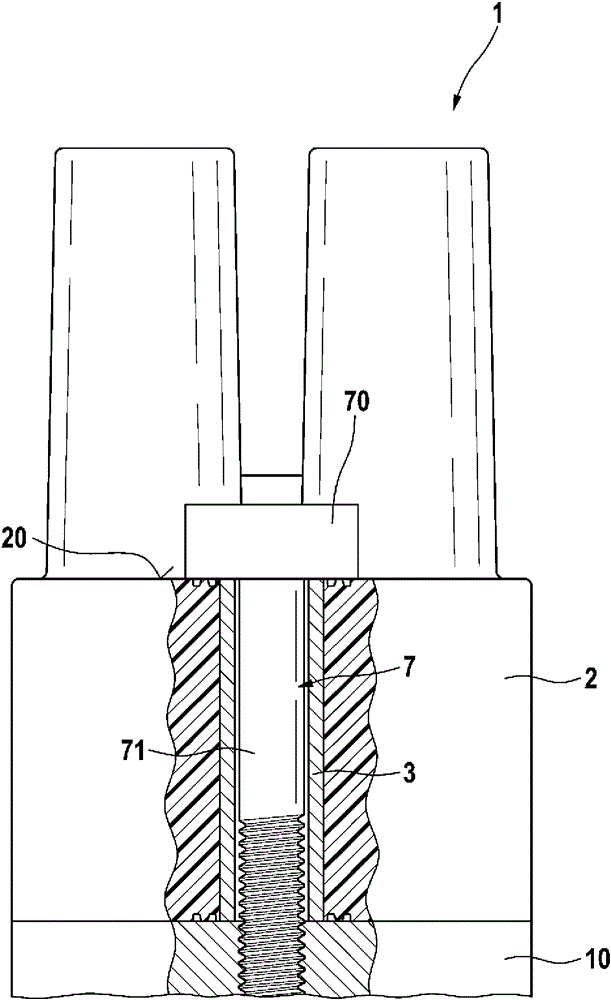

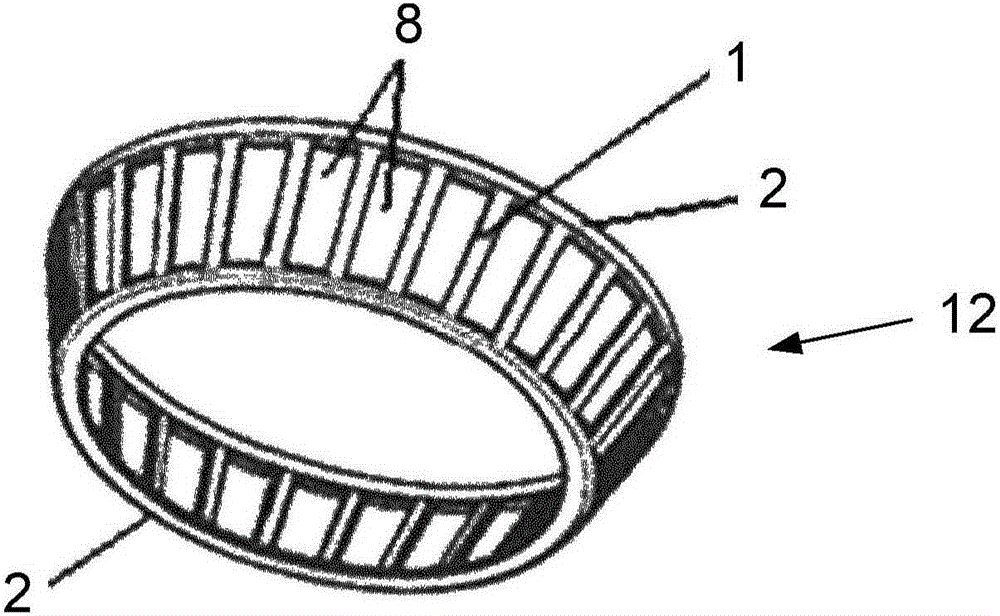

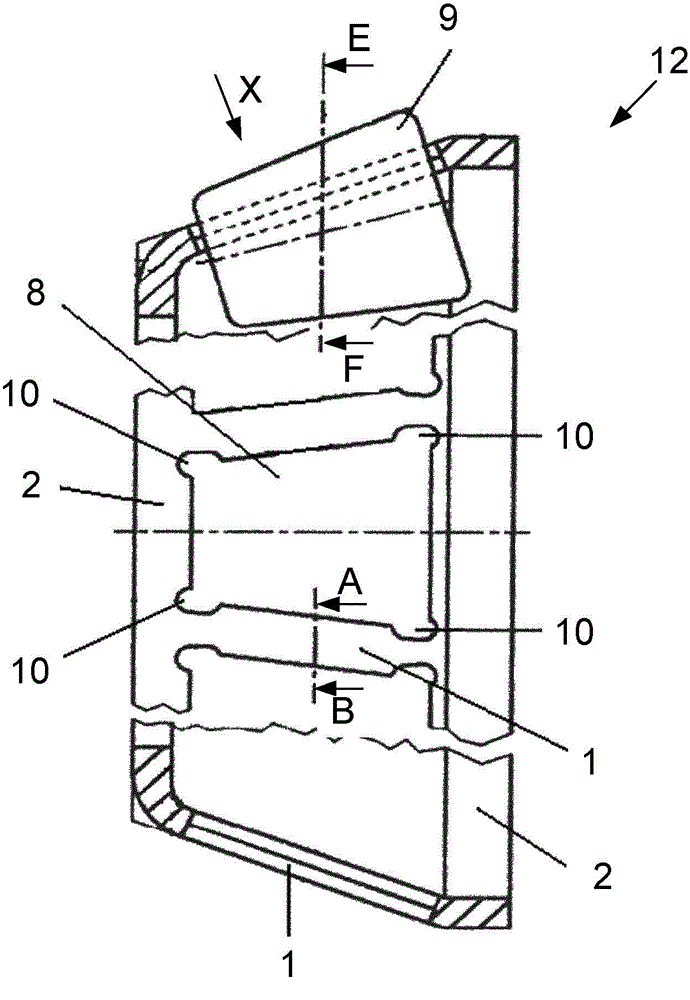

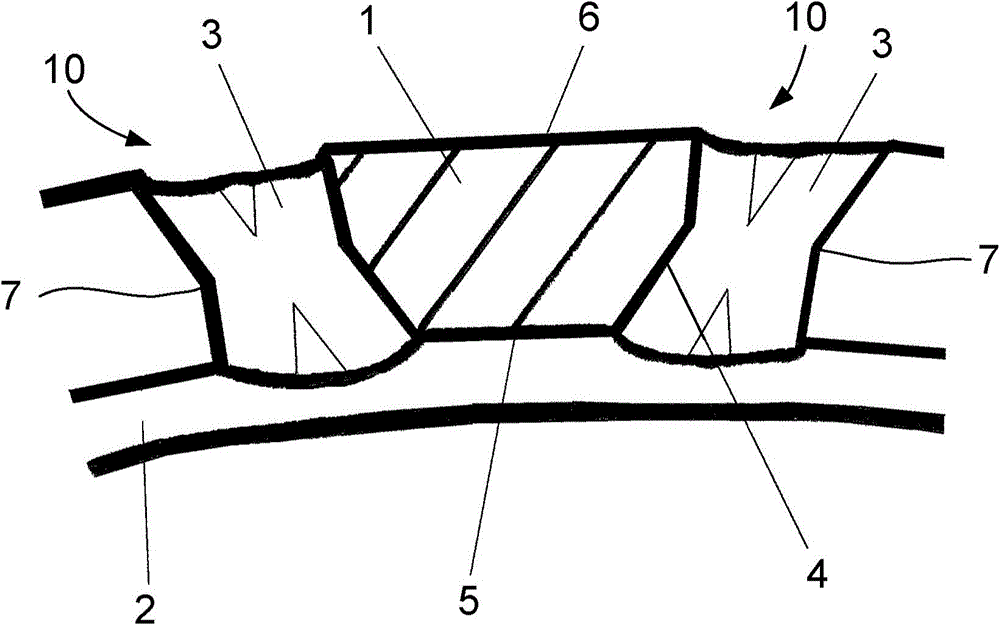

Rolling-element bearing cage and method for producing a rolling-element bearing cage

ActiveCN103443485AImprove carrying capacityAvoid stopRolling contact bearingsShaftsRolling-element bearingEngineering

The invention relates to a rolling-element bearing cage (12) comprising two lateral rings (2) and a plurality of cage webs (1), wherein the laterals rings (2) and the cage webs (1) form a plurality of cage pockets (8). In order for said rolling-element bearing cage (12) to have an especially light and stable design, according to the invention a respective recess (3) is formed in each of the corners (10) of the cage pockets (8). Said recess is tapered or reduced toward the radial center (7) of the recess without forming a running surface for the associated rolling element (9). The invention further relates to a method for producing the rolling-element bearing cage (12) according to the invention, wherein a plurality of cage pockets (8) are milled into a solid cage blank, wherein the corners (10) of the cage pockets (8) are milled in such a way that a respective recess (3) is formed in each of the corners of the cage pockets, which recess is tapered or reduced toward the radial center (7) of the recess without forming a running surface for the associated rolling element (9).

Owner:SCHAEFFLER TECH AG & CO KG

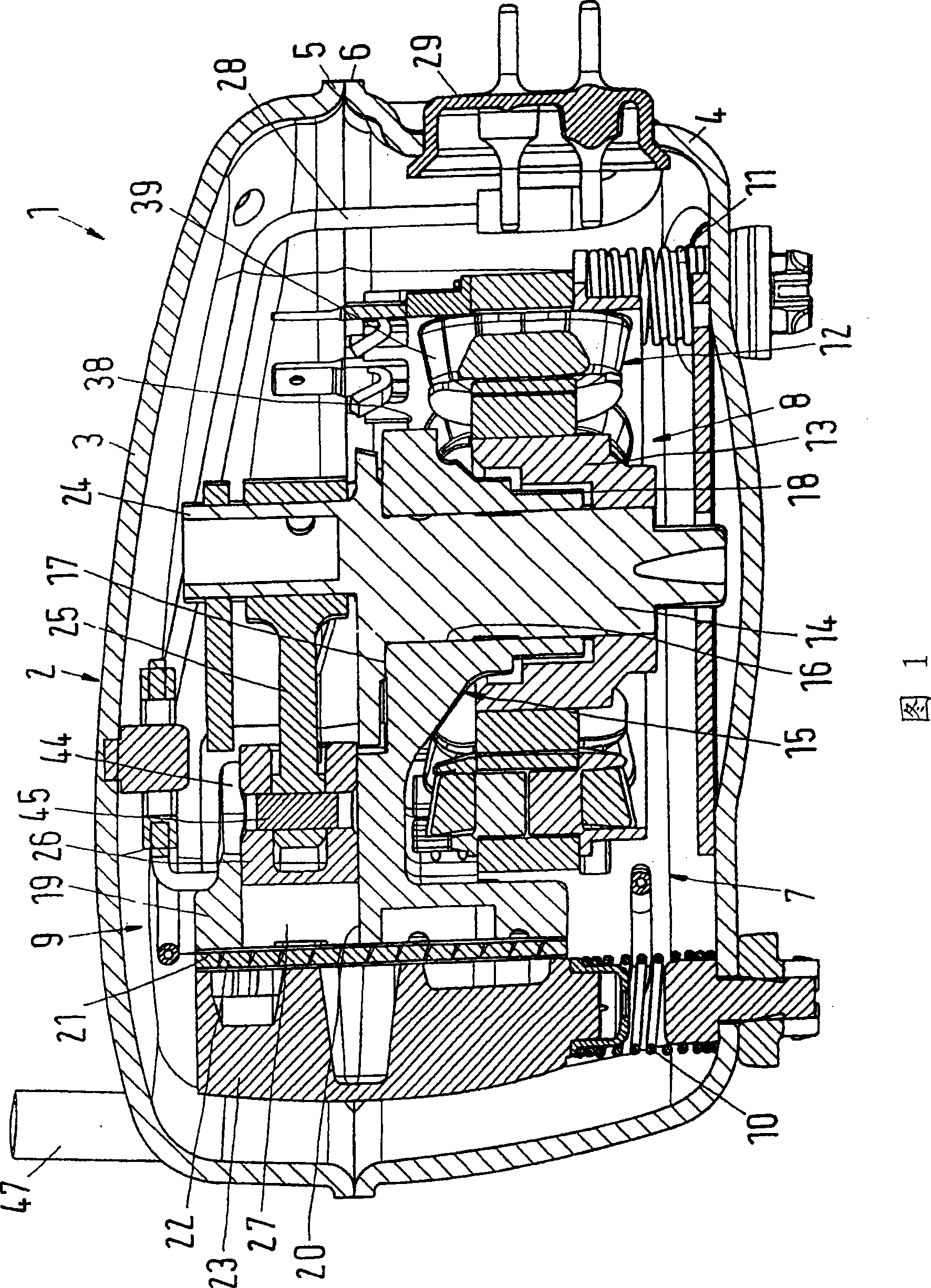

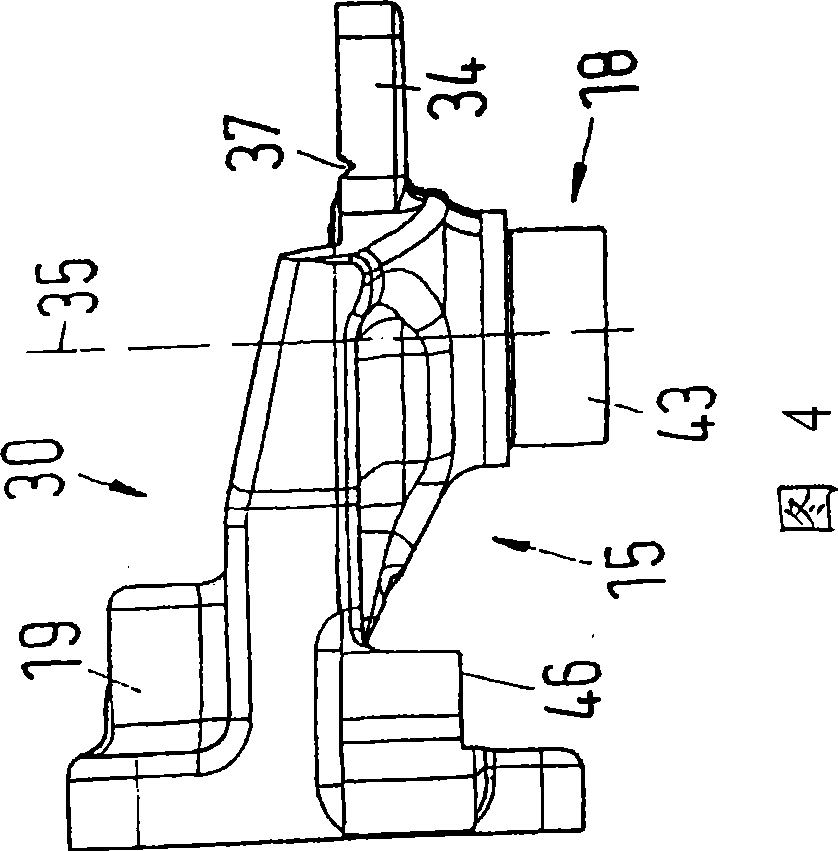

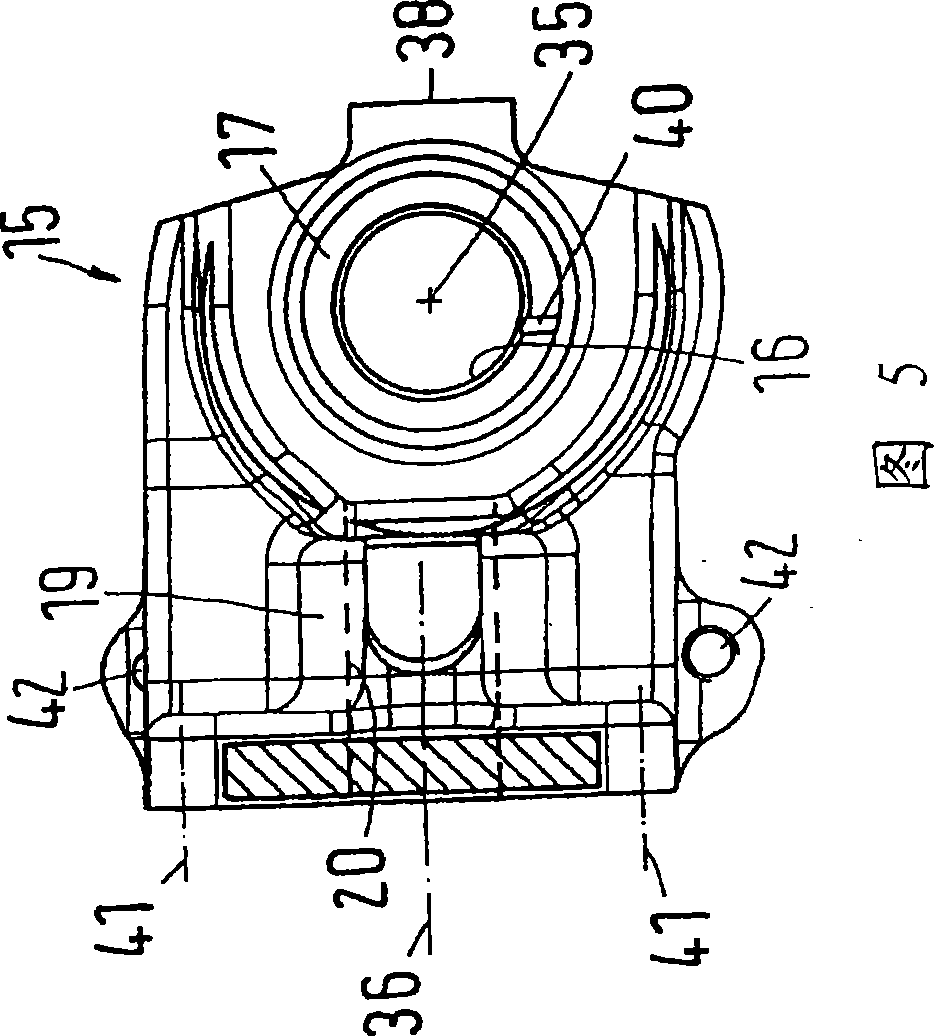

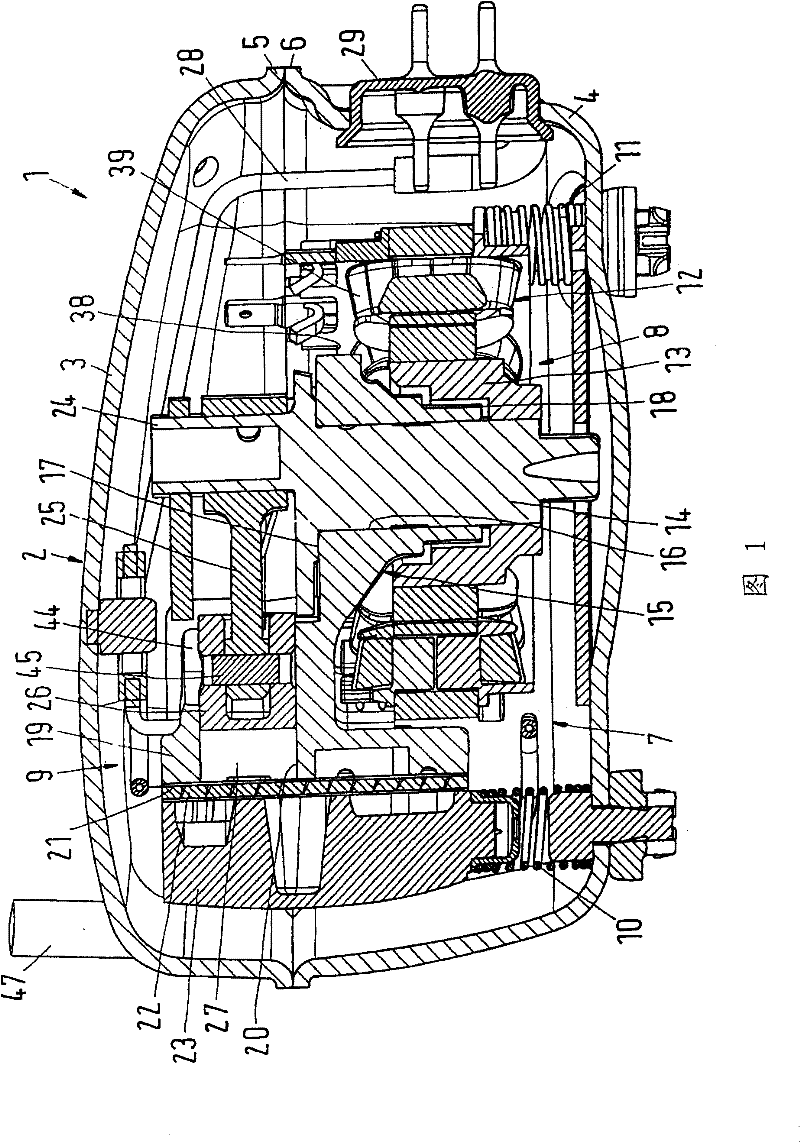

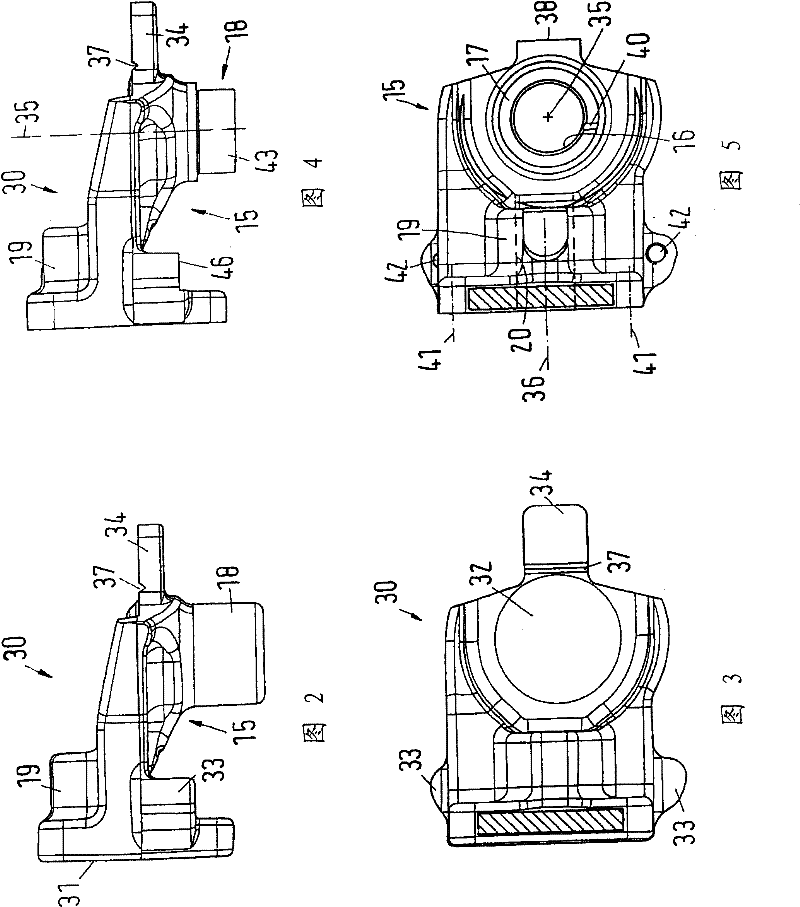

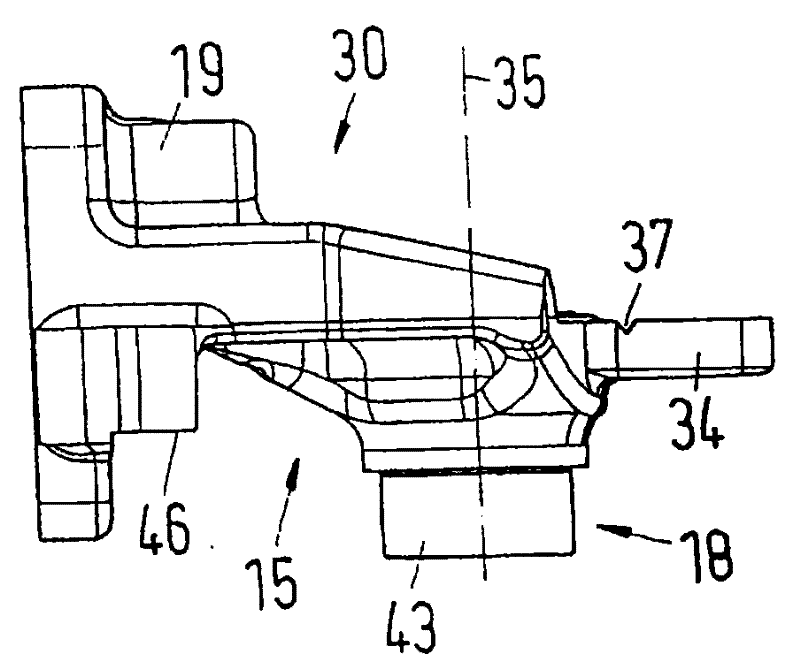

Method and blank for manufacturing a compressor block of a small-type refrigeration appliance

InactiveCN101367164ANo deformationEasy Surface GrindingPositive displacement pump componentsPositive-displacement liquid enginesEngineeringRefrigerant

The invention relates to a method and a blank (30) for manufacturing a compressor block of a small-type refrigeration appliance, in particular to a method and a blank for manufacturing a compressor block of a hermetically enclosed refrigerant compressor arrangement. The blank comprises a handling section (34) and at least two working areas (43, 46). The blank is clamped in a working arrangement at a handling section and is processed during the maintenance of the clamping. The invention is endeavored to reduce the dimensions of the compressor block, though maintaining the opportunity of performing several working steps during one clamping process. For this purpose, the handling section (34) is removed after the processing.

Owner:SECOP GMBH

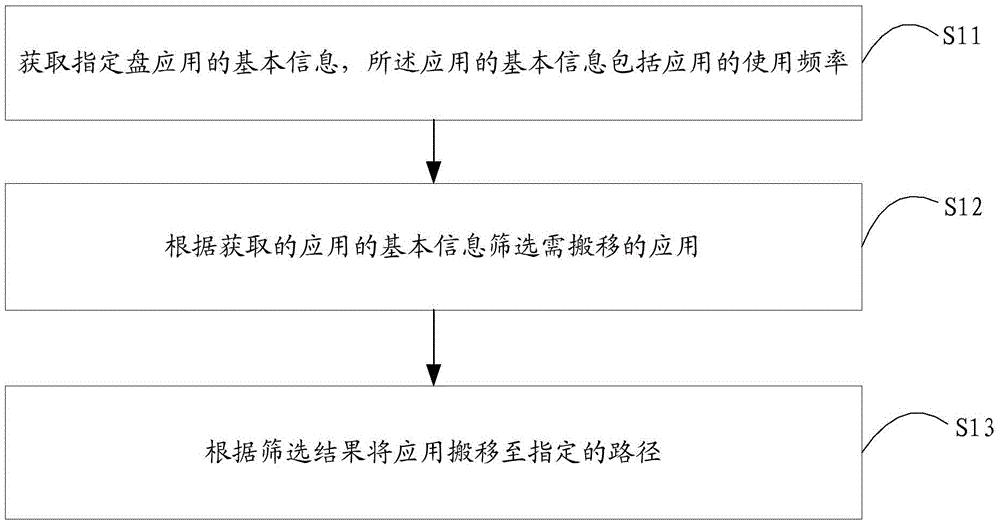

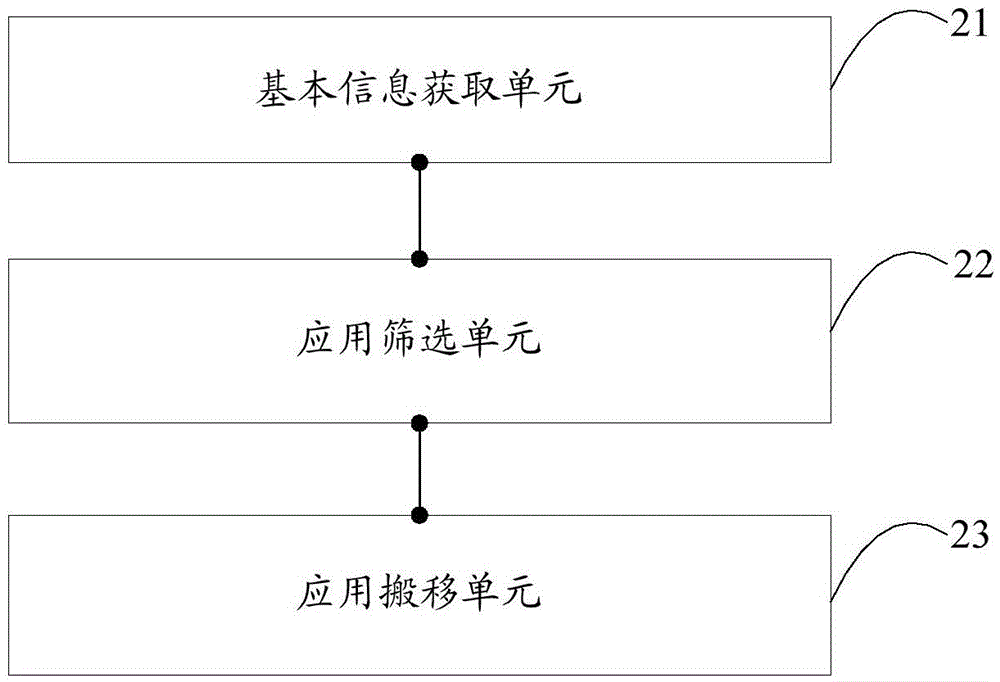

Application moving method and device

InactiveCN105550026AConducive to normal operationEnough free spaceProgram initiation/switchingFrequency of useSoftware engineering

The invention is applied to the field of computers, and provides an application moving method and device. The method comprises the following steps: obtaining basic information of an application in an appointed disk, wherein the basic information of the application includes the use frequency of the application; screening the application to be moved according to the obtained basic information of the application; and moving the application to an appointed path according to the screening result. The embodiment of the invention can ensure that the appointed disk has enough residual space; and thus, normal operation of the system is easily carried out.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

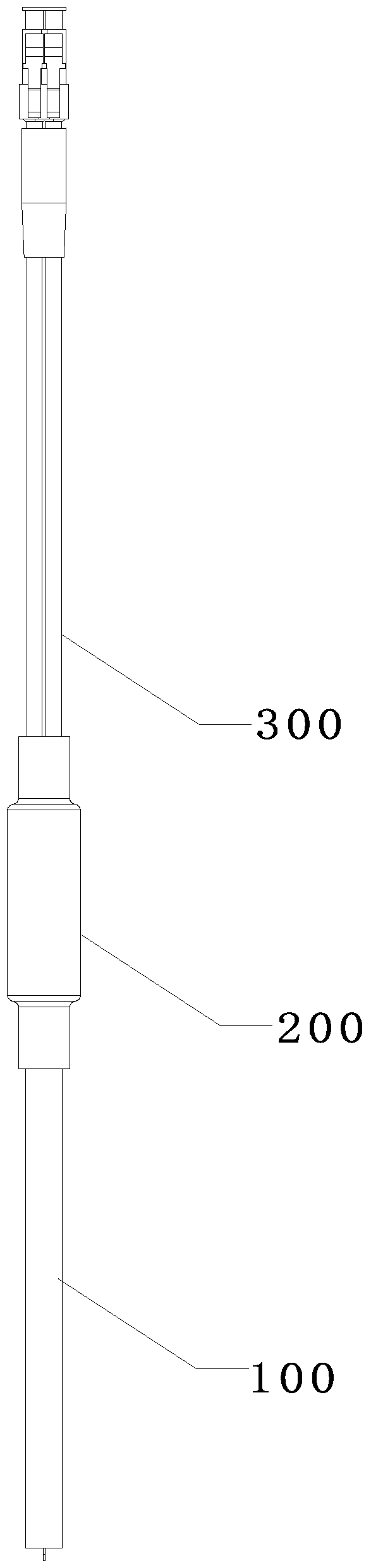

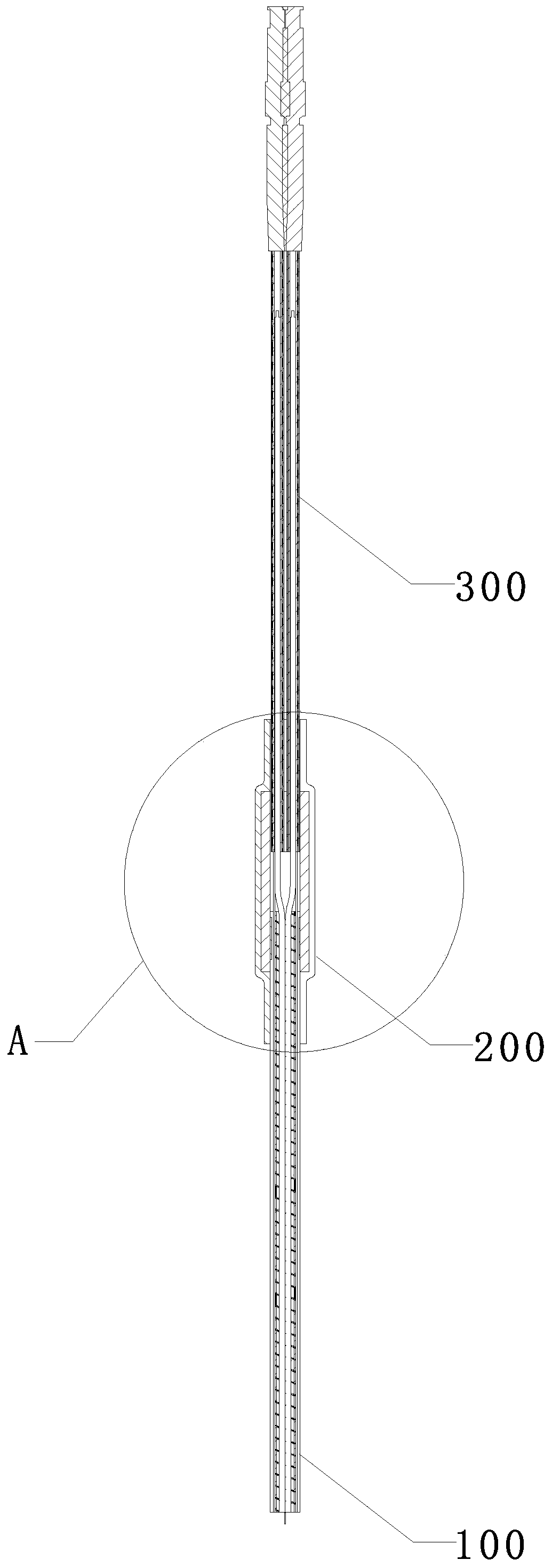

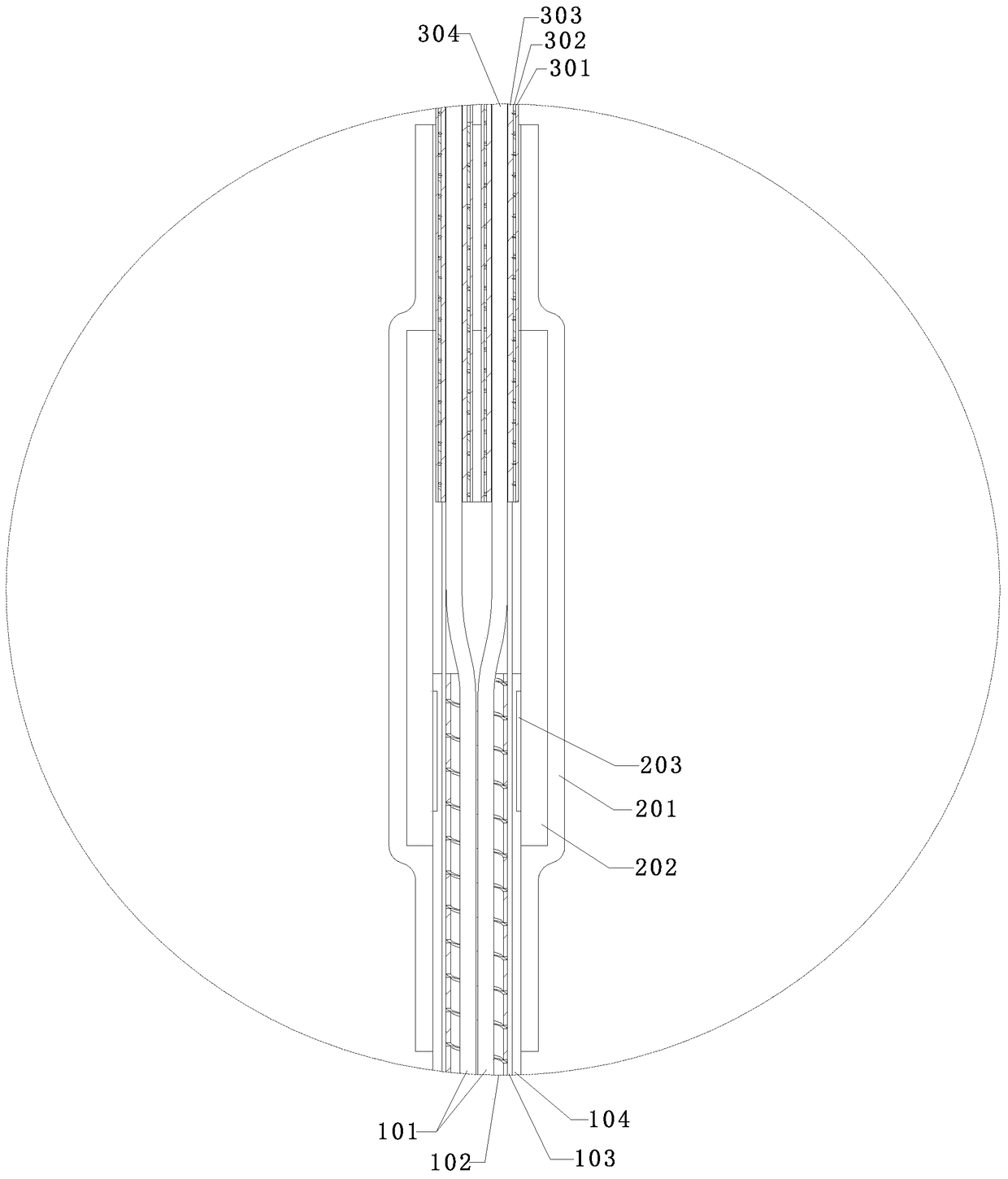

Optical cable branch line protection structure

ActiveCN105301717BEfficient use ofEnough free spaceFibre mechanical structuresEngineeringSingle-core

The present invention discloses an optical cable branching protection structure. The optical cable branching protection structure comprises: a main optical cable, a plurality of sub-optical cables formed by branching the main optical cable, and a deconcentrator sleeved at the outside of the branching of the main optical cable and a plurality of sub-optical cables. A junk ring bush compressing a coating layer sleeves the outside of the main optical cable section, and the sub-optical cable sections have no a junk ring bush. Aramid fibers are located between the coating layer and the steel pipe, and the movement of the aramid fibers may be effectively utilized to make optical fibers in the main optical cable have enough free activity space, so that the optical fibers have enough length to satisfy various usage environment and the optical performance and signal transmission effect of the optical fibers are ensured. According to the invention, single core fibers and aramid fibers are located in the steel pipe, the steel pipe and the coating layer are integrated into one body to fix with a thermoplastic pipe, and the length of the outer coating layer may be determined; and when a branching is made, length of each single core sub-optical fiber is controllable, and the length consistency of the branch sub-optical fiber may be effectively ensured.

Owner:SHENZHEN ACE ARMORED CABLE CO

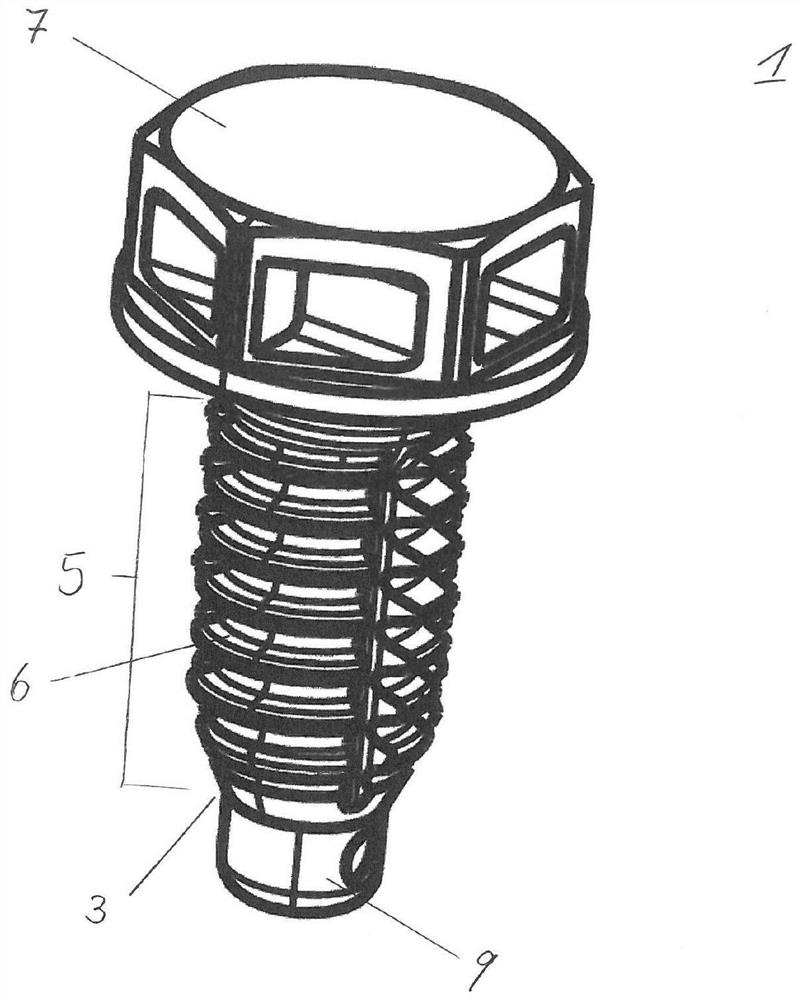

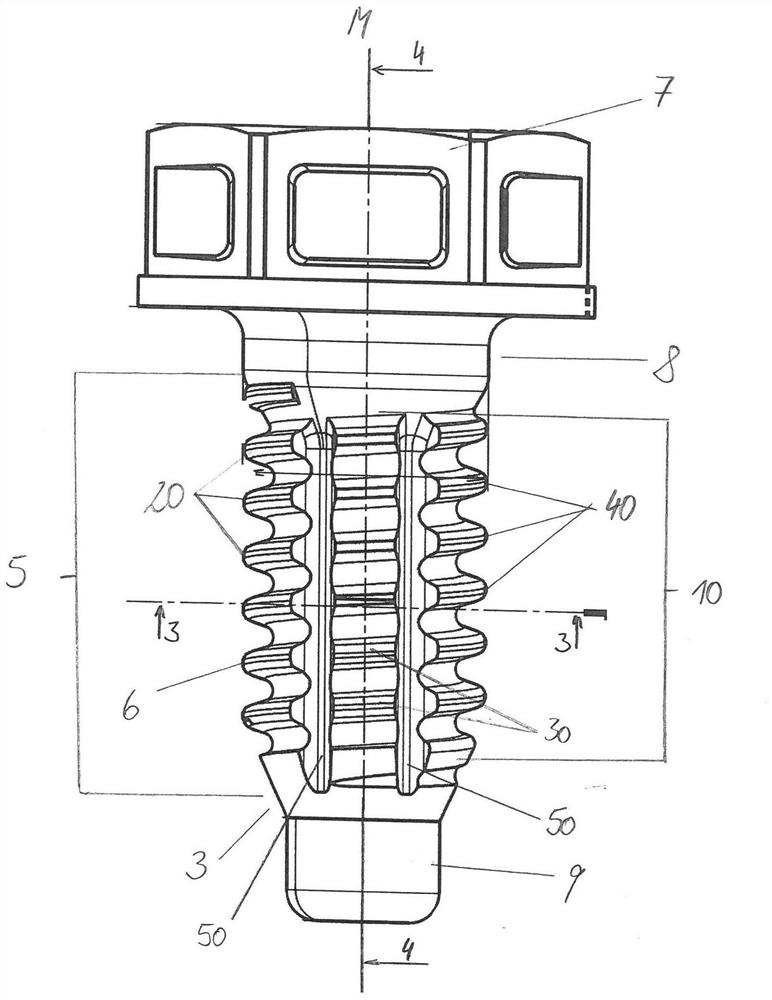

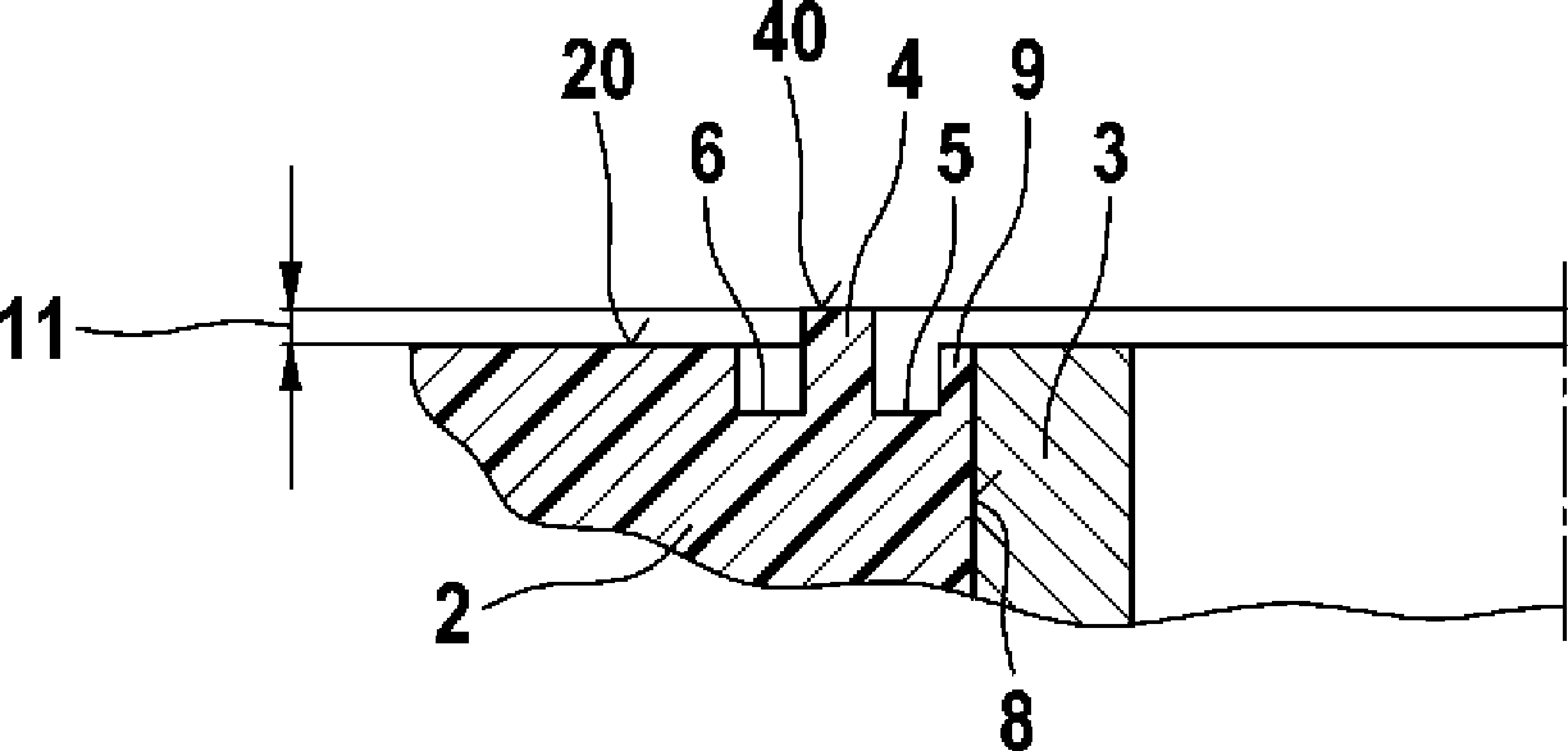

Threaded element, connection assembly comprising the element and method of manufacturing both

The invention relates to a threaded element made of plastic, a connection assembly comprising a support part made of plastic, said threaded element made of plastic being screwed into said support part by creating a reverse thread, a A method of making said connection, and a method of making said threaded element. The threaded element features an axial piece in which the circumferential winding of the threaded turn is interrupted by at least two chip flutes. The resulting coiled region forms a cutting web and a restraining web, wherein the cutting web extends radially beyond the restraining web.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

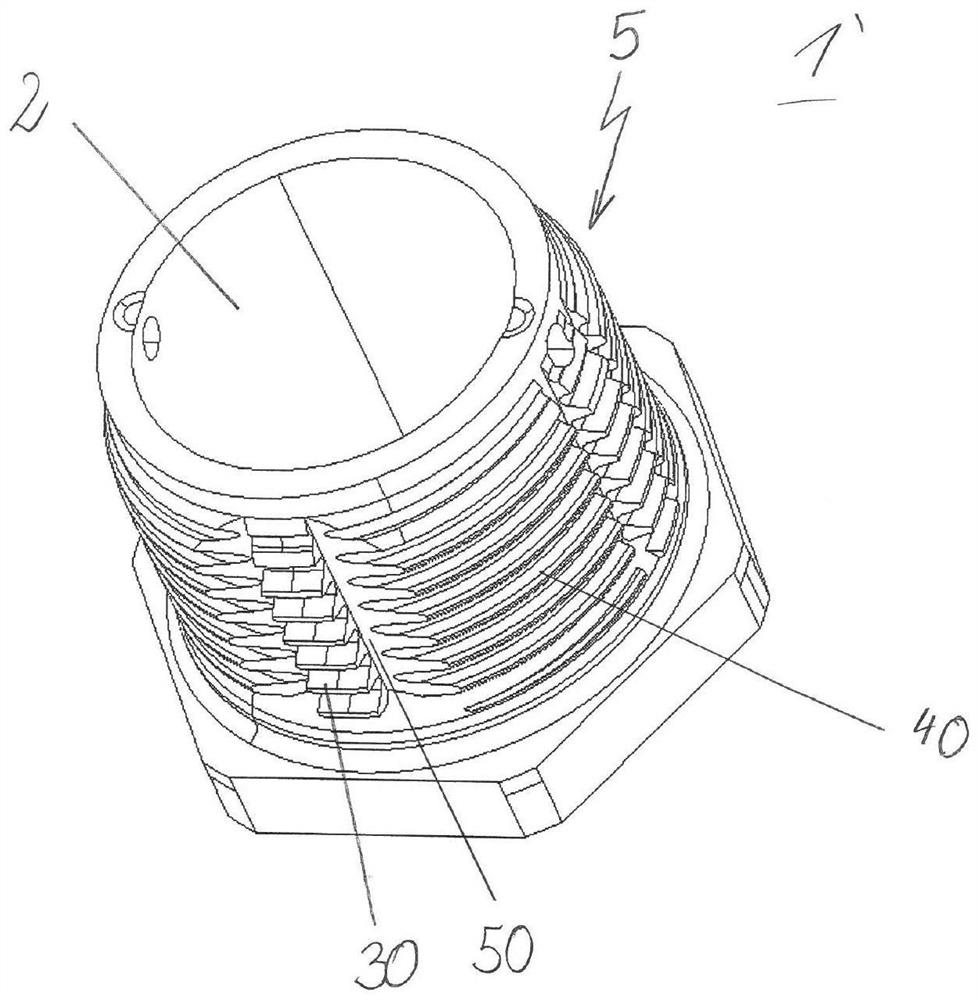

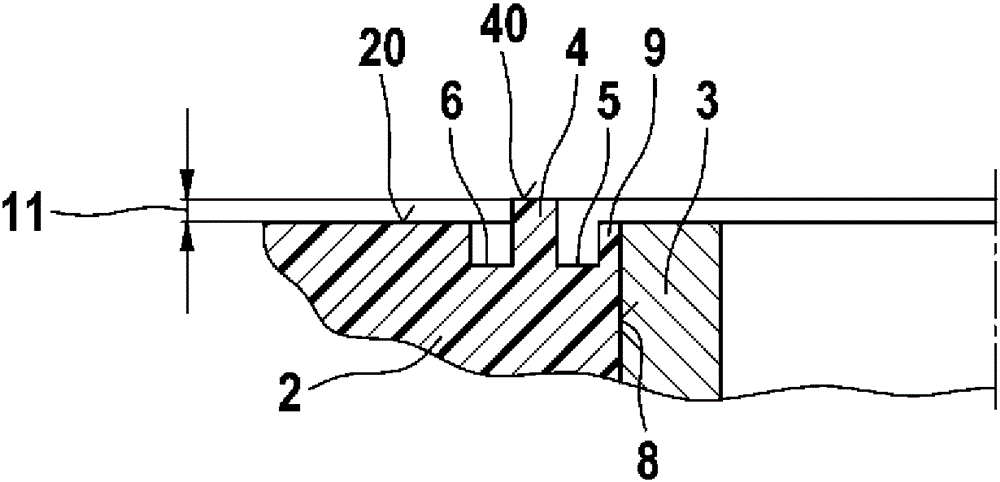

Ignition apparatus with improved sealing properties

InactiveCN103038840ANo corrosionNo peelingTransformers/reacts mounting/support/suspensionTransformersIgnition coilEngineering

The invention relates to an ignition apparatus for an internal combustion engine, comprising: a housing (2) for accommodating an ignition coil and further components of the ignition apparatus, wherein the housing (2) has a passage hole (8); and a screw-on bushing (3) which is arranged in the passage hole (8), wherein the housing (2) has a sealing contour (4; 14) on an outer face of an opening of the passage hole (8), wherein the sealing contour (4; 14) is arranged so as to run all the way around the opening of the passage hole (8), and wherein the screw-on bushing (3) is designed without a corrosion-protection coating.

Owner:ROBERT BOSCH GMBH

Method for realizing all-day in-and-out toll-by-time charging of gymnasium

InactiveCN111754668AAttractiveFree timeIndividual entry/exit registersBuying/selling/leasing transactionsComputer scienceOperations research

The invention discloses a method for realizing all-day in-and-out toll-by-time charging of a gymnasium. The invention belongs to the technical field of unmanned shops. The method comprises the steps that an automatic access control system, an account opening system, a user identification system, a private teaching and group lesson reservation pushing system, a charging system and a settlement system are arranged in a gymnasium, an intelligent full-self-service fitness new mode is achieved through cooperation of the systems, annual cards are not needed, code scanning is conducted for entrance,payment is realized if people are leaving, charging according to minutes is realized, 24-hour business and no marketing are achieved; the method provided by the invention has the advantages of free time, self-service selection, low operation cost and low user use cost.

Owner:广东菲鸟体育文化有限公司

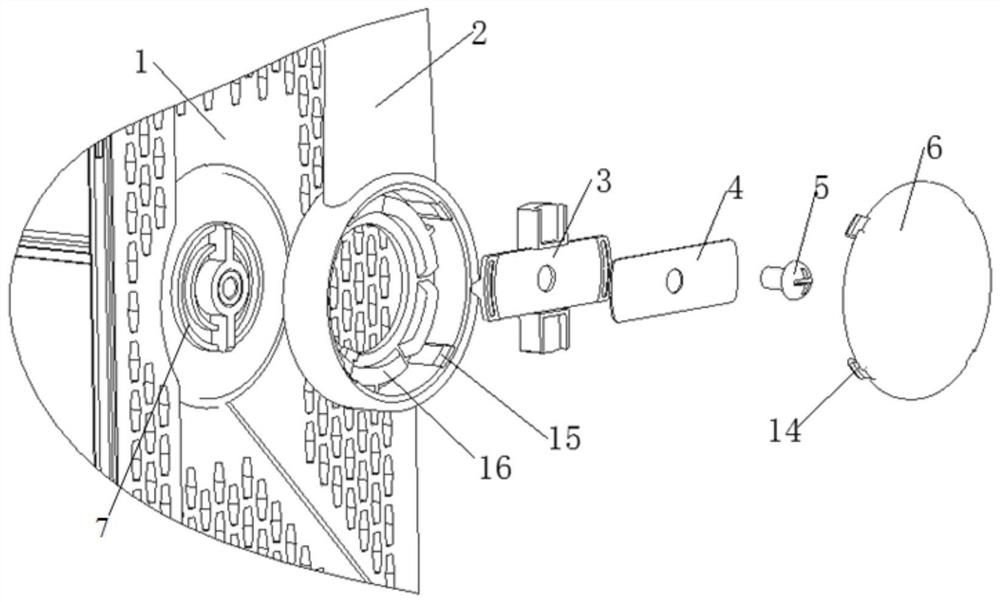

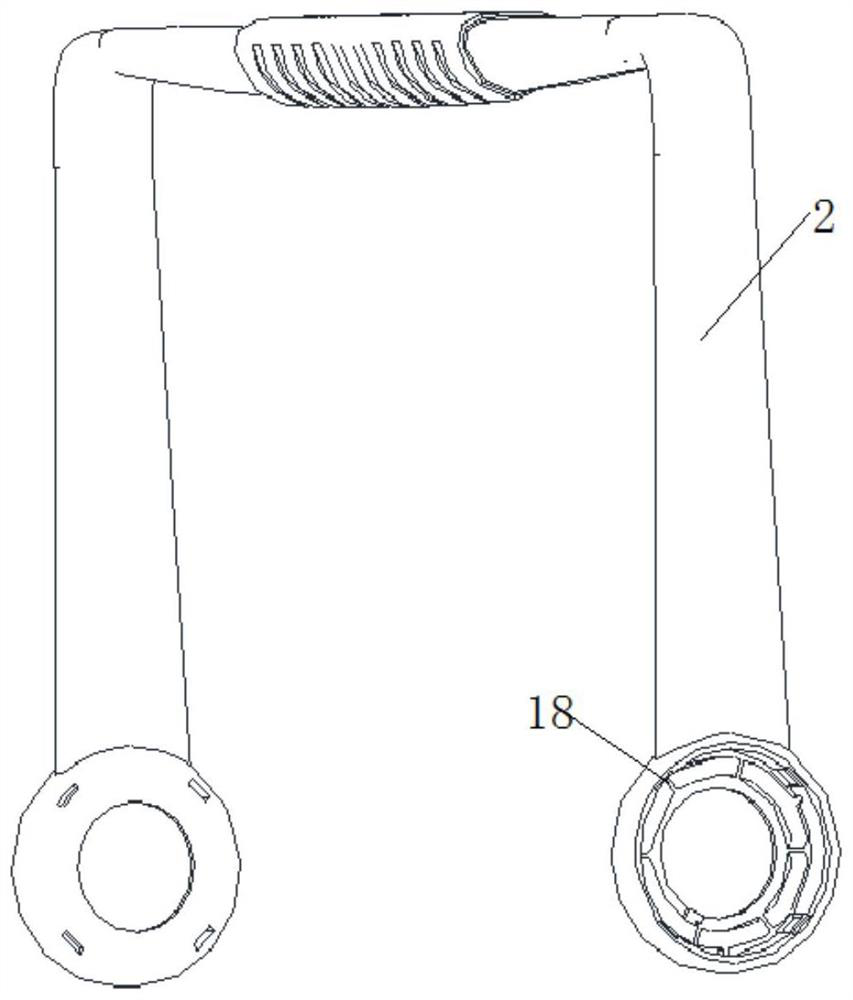

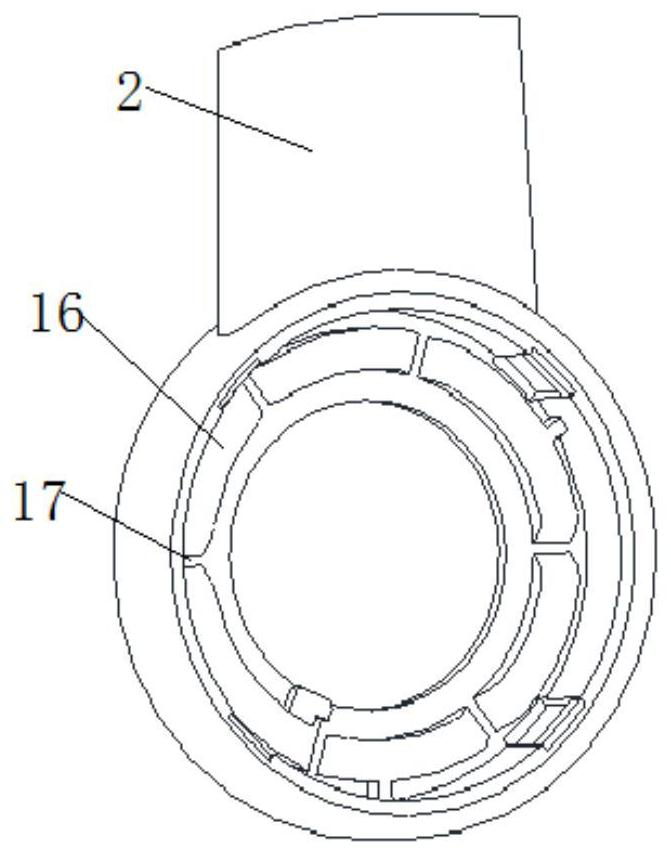

Handle structure for portable instrument, portable instrument and use method

ActiveCN110260902BGuaranteed gearVersatileMeasurement apparatus caging devicesMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a handle structure for a portable instrument, a portable instrument and a use method, which solve the problems of single handle structure and function, complicated setting and poor reliability in the prior art, and have the advantages of realizing the fixing of multiple gear handles. The beneficial effects of meeting the needs of portable use are as follows: a handle structure for a portable instrument, comprising a handle, one end of the handle is a circular ring part for engaging with a casing, the handle can be rotated relative to the casing, and the circular ring A groove is set in the inner part, a plurality of fixing blocks are arranged in the groove, and a clamping slot is formed between two adjacent fixing blocks; a limit pressure block, one side of the limit pressure block is provided with a limit that can cooperate with the clamping groove Protruding, and the limit pressure block can cooperate with the shell; the pressure piece, the pressure piece is arranged on the other side of the limit pressure block, the pressure piece is connected with the shell through the locking piece, and the locking piece passes through the limit Position pressure block and groove setting of the ring part.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Method and blank for manufacturing a compressor block of a small-type refrigeration appliance

InactiveCN101367164BSmall sizeEnough free spacePositive displacement pump componentsPositive-displacement liquid enginesRefrigerantRefrigeration

The invention relates to a method and a blank (30) for manufacturing a compressor block of a small-type refrigeration appliance, in particular to a method and a blank for manufacturing a compressor block of a hermetically enclosed refrigerant compressor arrangement. The blank comprises a handling section (34) and at least two working areas (43, 46). The blank is clamped in a working arrangement at a handling section and is processed during the maintenance of the clamping. The invention is endeavored to reduce the dimensions of the compressor block, though maintaining the opportunity of performing several working steps during one clamping process. For this purpose, the handling section (34) is removed after the processing.

Owner:SECOP GMBH

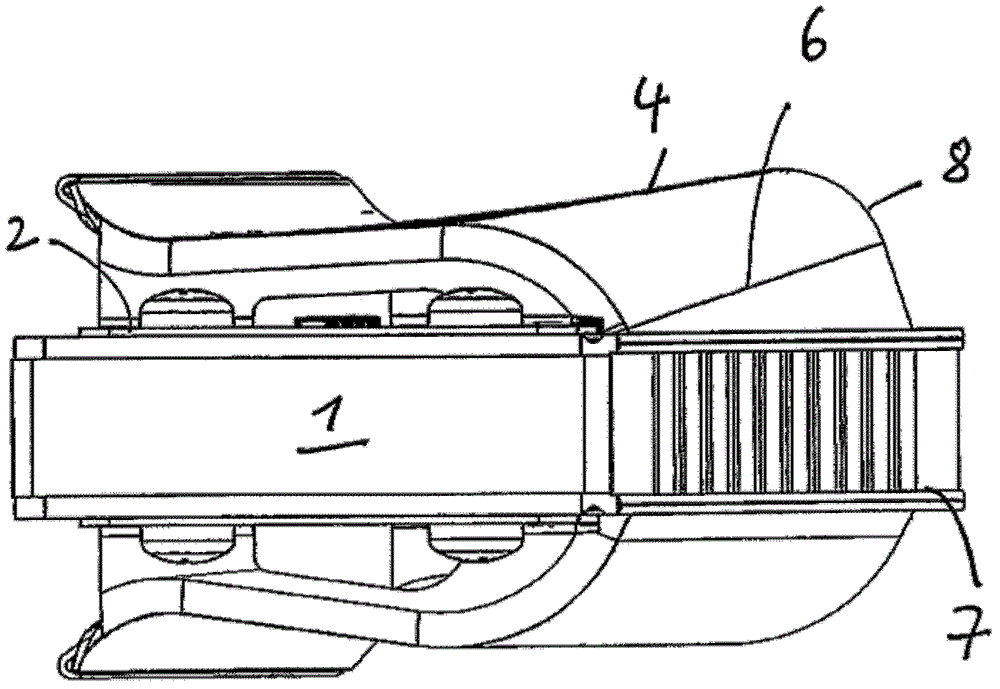

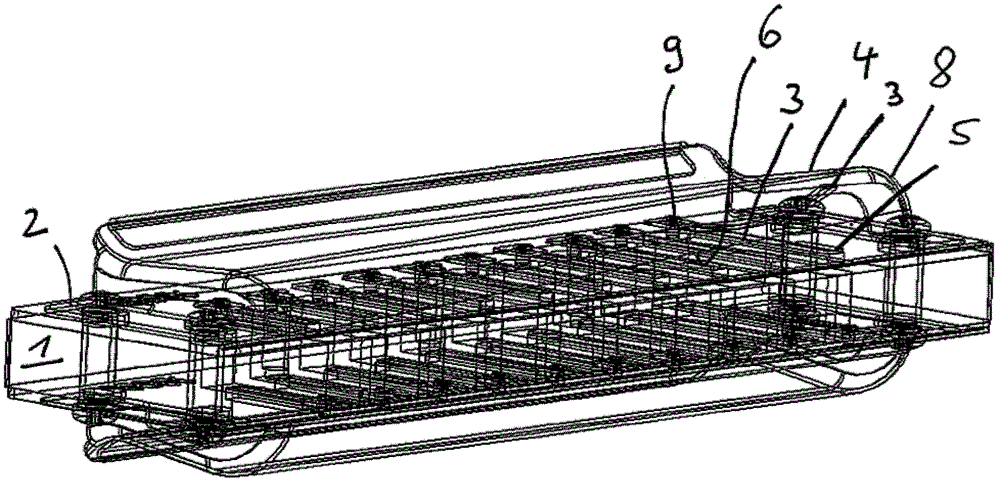

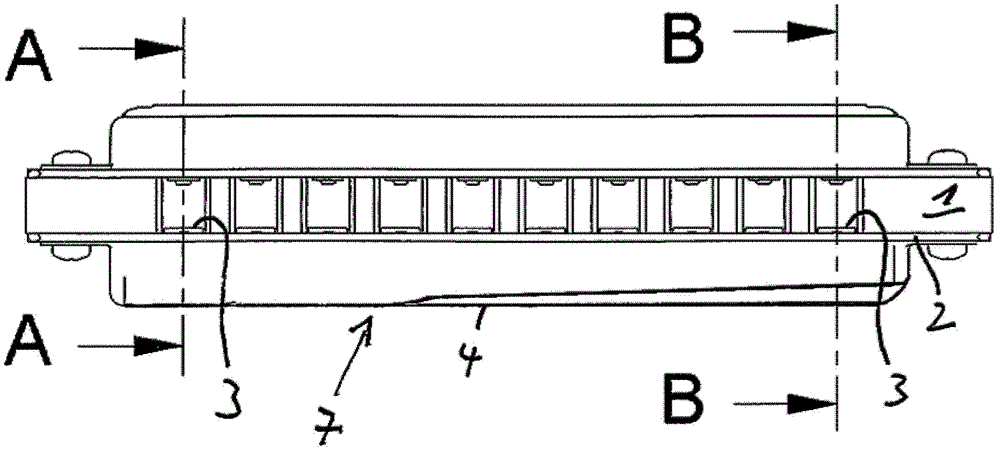

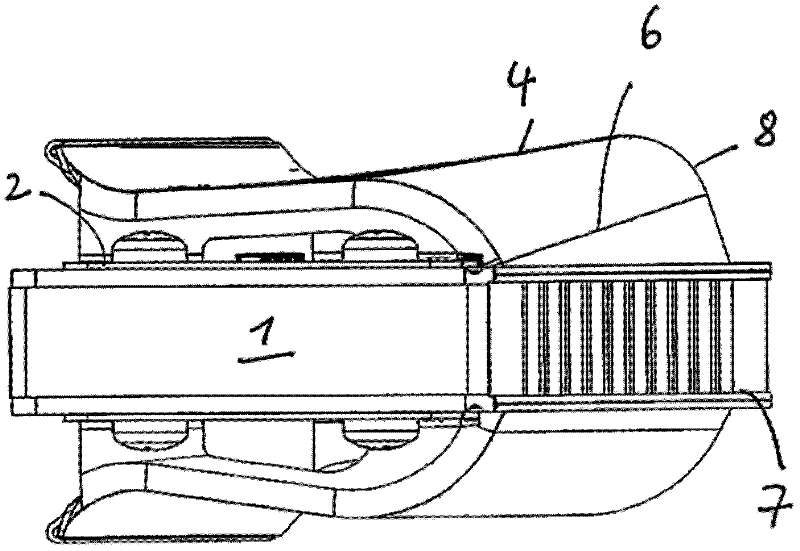

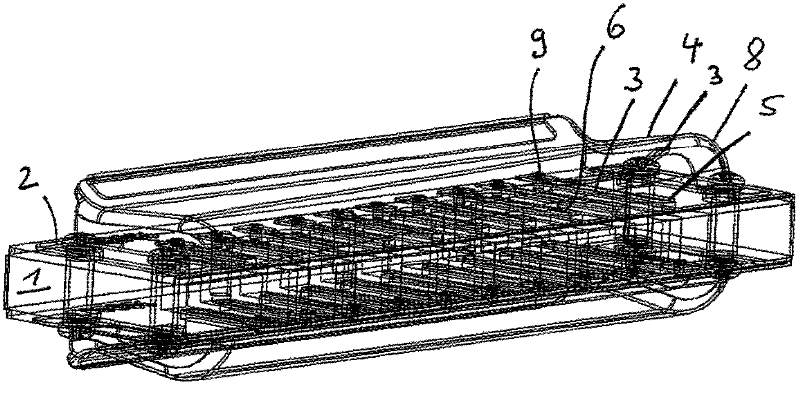

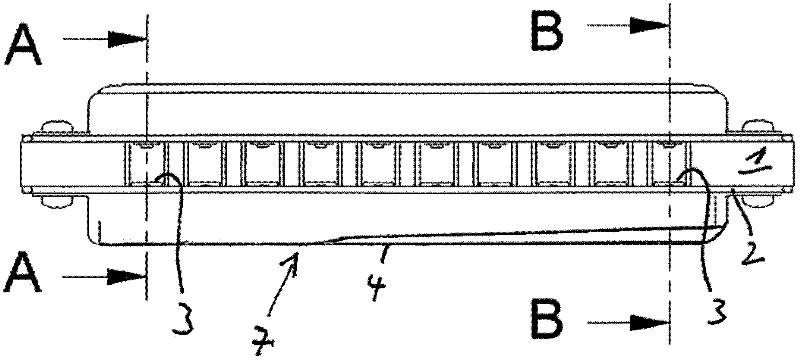

Mouth organ

ActiveCN102298920BEnough free spaceImprove gripWind musical instrumentsMouth pieceStructural engineering

#CMT# # / CMT# The mouth organ has a comb (1) on which a tuning plate (2) with tuning guides over lies. The tuning guides are fixed on the outer side tuning plate and are coverd by a cover (4) arranged on the tuning plate (2). One of the tuning guides has a pendulum mass on its head for a deep note. The swing width of the pendulum mass determines a clear roof headway of the cover, against which the cover falls monopitch roof shaped. #CMT#USE : # / CMT# Mouth organ. #CMT#ADVANTAGE : # / CMT# The mouth organ has a comb on which a tuning plate with tuning guides over lies. The tuning guides are fixed on the outer side tuning plate and are coverd by a cover arranged on the tuning plate, and hence ensures an efficient mouth organ with improved sound volume. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a schematic perspective view of a mouth organ. 1 : Comb 2 : Tuning plate 4 : Cover 6 : Segment 7 : Mouth piece side.

Owner:和莱乐器有限责任公司

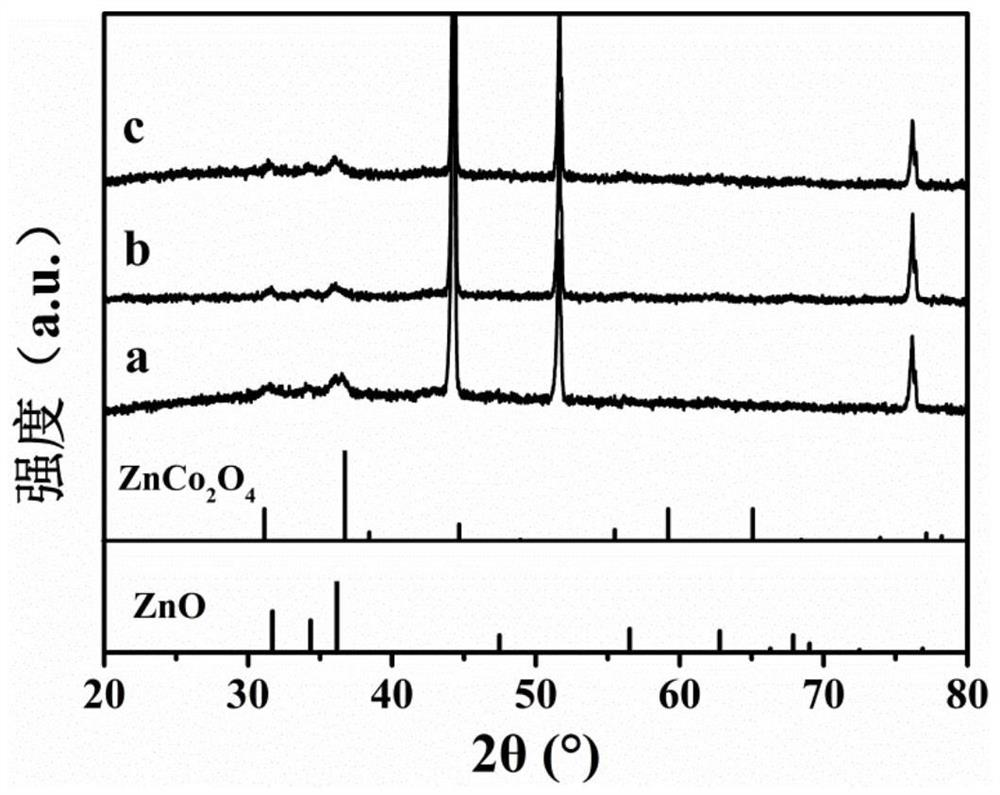

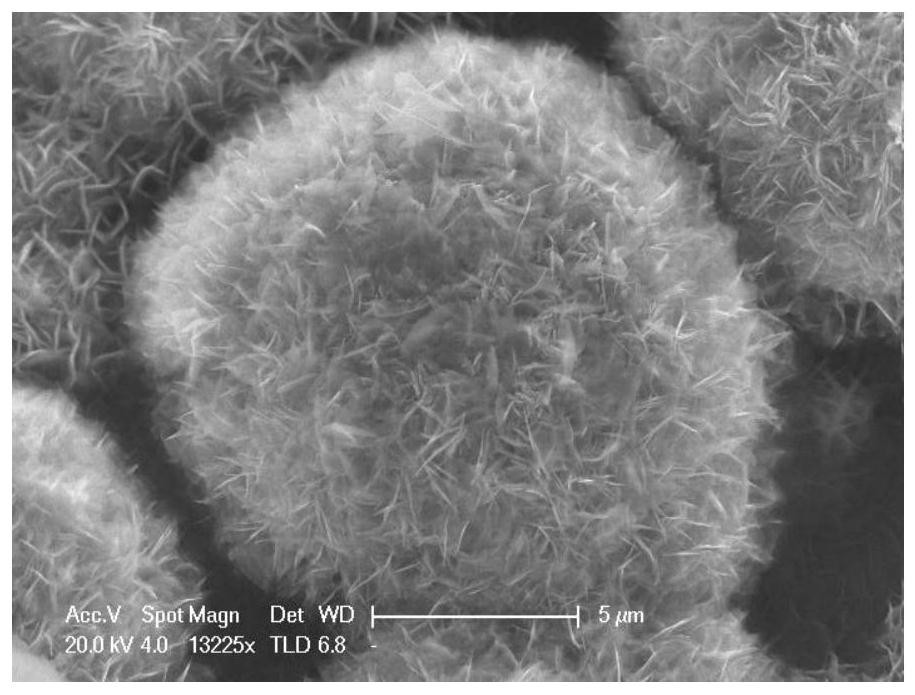

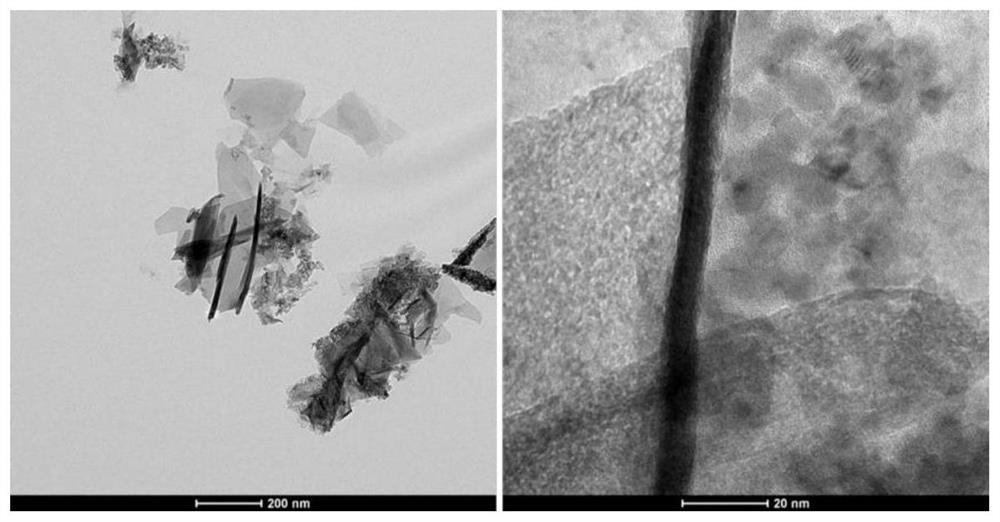

Self-supporting bimetal-based electrode material and preparation method and application thereof

PendingCN114400147ASimple structureReasonable structureHybrid capacitor electrodesHybrid/EDL manufactureNickel substrateActive site

The invention discloses a self-supporting bimetal-based electrode material and a preparation method and application thereof, the material is of a core-shell structure, the core is ZnCo2O4-ZnO loaded on a foamed nickel substrate, and the shell is CoS deposited on the surface of a ZnCo2O4-ZnO compound. The method comprises the following steps: pretreating foamed nickel; growing a ZnxCo1-x (OH) 2 precursor on the foamed nickel in situ, and calcining to obtain ZnCo2O4-ZnO; coS is deposited on the surface of ZnCo2O4-ZnO (at) C through an electro-deposition method, and the composite material is obtained. The material forms a stable three-dimensional structure, has a relatively high specific surface area and a large number of active sites, and is in full contact with electrolyte, and an enough free space is formed in the material, so that a long-term Faraday reaction can be effectively relieved; relatively high energy density and relatively long cycle life are shown; the preparation method is simple in process, low in cost and high in reproducibility.

Owner:SOUTHEAST UNIV

A method and device for solving android terminal not booting

ActiveCN105068844BEnough free spaceSolve the problem of not being able to bootProgram loading/initiatingComputer terminalTerminal system

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A thin coal seam shearer drum

ActiveCN105134206BIncrease coal loading rateConform to the law of distributionCutting machinesSpiral bladeEngineering

The invention discloses a drum of a thin coal seam shearer, which is composed of an end disc, a spiral blade, a drum hub, a pick and a gear seat, etc., and the diameter of the drum hub increases in a hyperbolic sine form from the bottom of the drum to the end disc. The angle between the section of the helical blade and the inner cylinder of the hub is non-right angle, the coal-facing surface of the helical blade is an arc surface, and the pick seat is fixed on the coal-facing surface of the helical blade by bolts, so that only the alloy head of the pick is exposed Outside the envelope of the helical blade. According to the movement and distribution rules of the coal body during the process of being shipped, the drum combines the main reasons for the wear and tear failure of the current drum, and combines the special hub contour line of the present invention, the arc-shaped skewed spiral blade and the detachable pick tooth seat, so that The coal loading rate of the drum is increased by more than 20%, and the life of the drum is increased by more than 6%. It is suitable for mining thin coal seams with a coal seam thickness of less than 1.3 meters and a strike angle of less than 20°. The drum has the advantages of compact structure, convenient use, good coal charging effect and long service life.

Owner:SHANDONG UNIV OF SCI & TECH

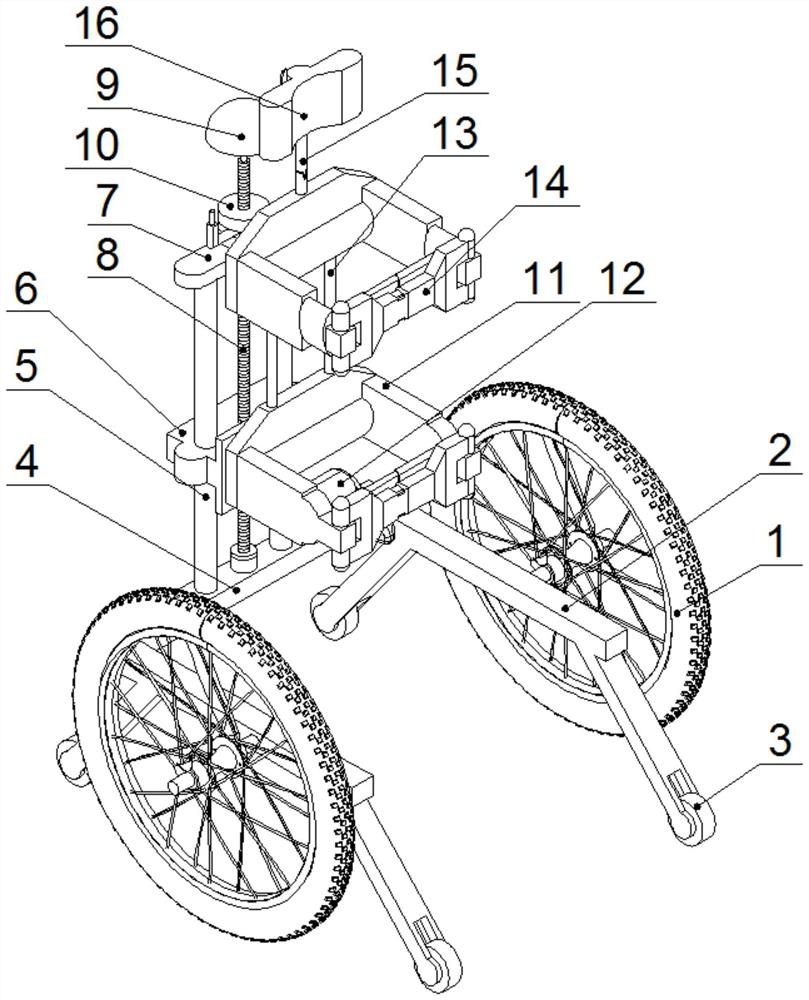

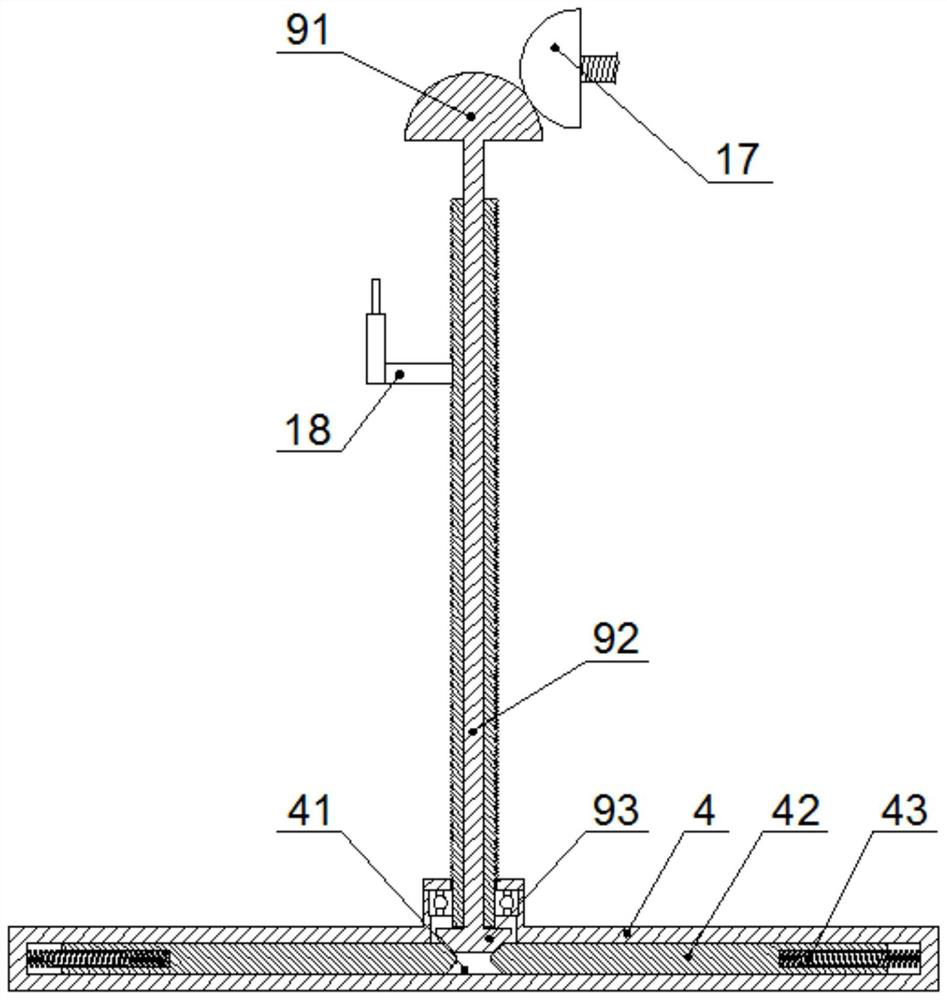

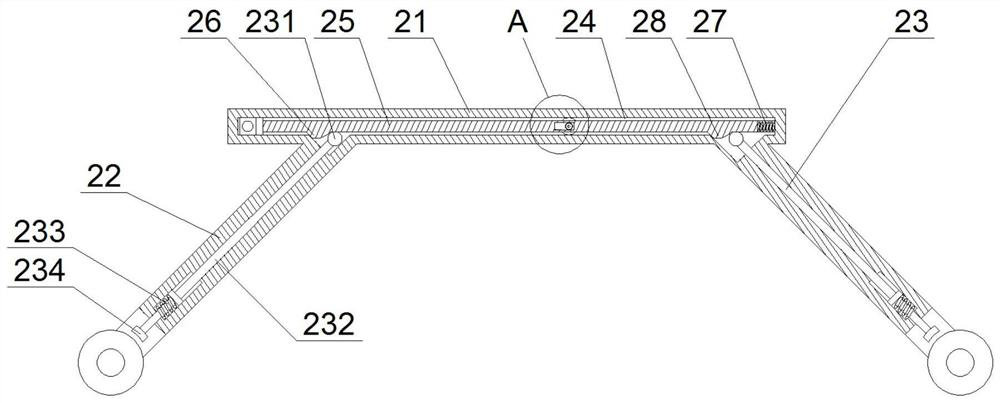

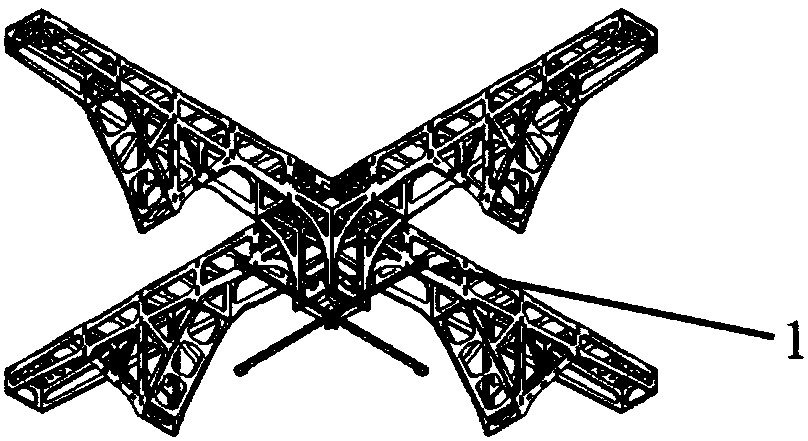

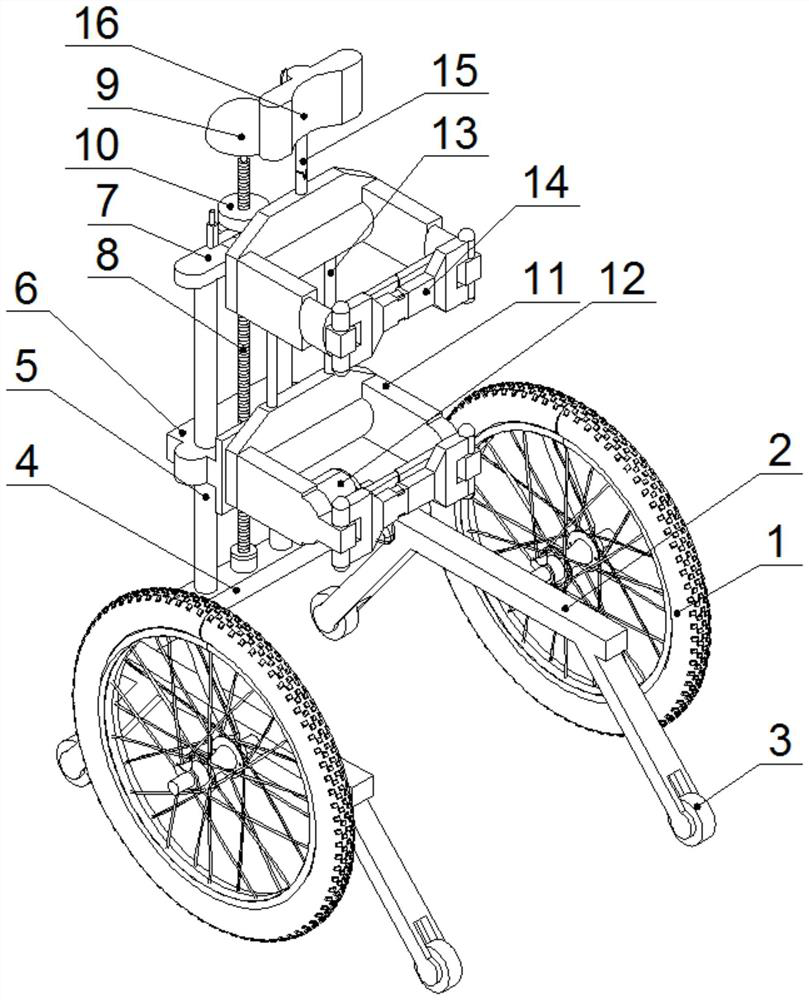

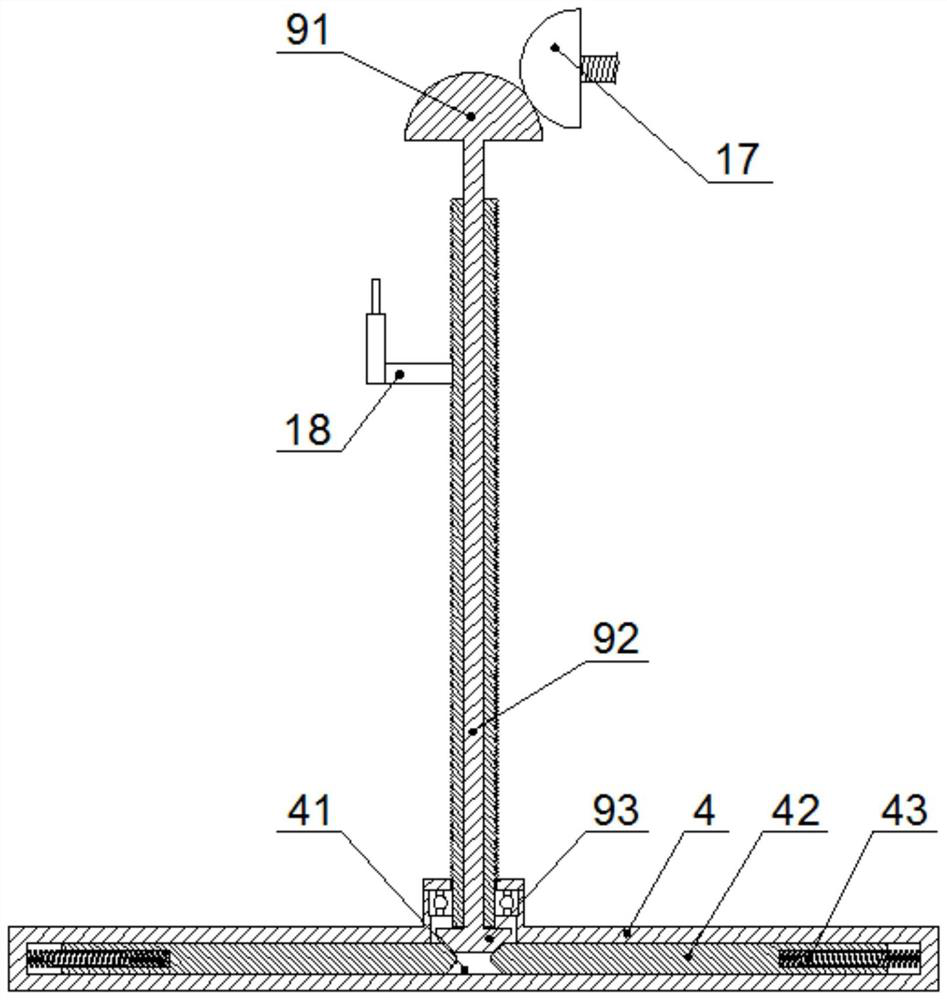

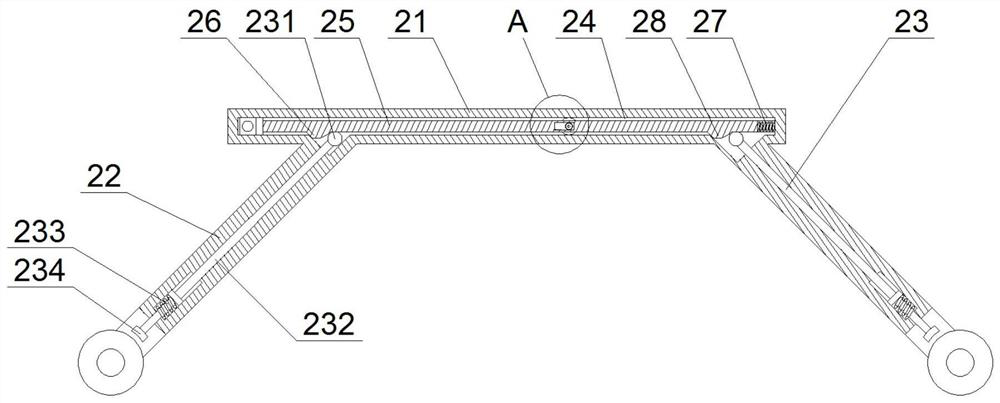

Child walking trainer

The invention discloses a child walking trainer which comprises two side support sets and a cross beam fixed between the two side support sets, wherein large walking wheels are installed on the sides,away from each other, of the two side support sets, two trundles are arranged at the bottom of each side support set, a supporting plate is fixed to the upper surface of the cross beam through two vertical sliding rods, a sliding seat capable of sliding is arranged on the sliding rods, a mounting plate is fixed to the front side of the sliding seat, a supporting seat and a waist positioner are mounted on the front side of the mounting plate, a chest positioner is mounted on the upper surface of the waist positioner through a supporting rod, a head support pillow is mounted on the upper surface of the chest positioner through a supporting hinge rod, a lead screw is mounted between the supporting plate and the cross beam, and the screw rod is matched with the sliding seat through the screwhole. By arranging the adjustable waist positioner and the adjustable chest positioner which are used for fixing or positioning the waist and the chest of a child respectively, a stable acting point is formed, the child can move synchronously and stably with the whole walking device through body movement, and therefore the hands of the child are liberated.

Owner:四川省康复辅具技术服务中心

Ignition device with improved sealing performance

InactiveCN103038840BEasy to manufactureLow costTransformers/reacts mounting/support/suspensionTransformersIgnition coilEngineering

The invention relates to an ignition apparatus for an internal combustion engine, comprising: a housing (2) for accommodating an ignition coil and further components of the ignition apparatus, wherein the housing (2) has a passage hole (8); and a screw-on bushing (3) which is arranged in the passage hole (8), wherein the housing (2) has a sealing contour (4; 14) on an outer face of an opening of the passage hole (8), wherein the sealing contour (4; 14) is arranged so as to run all the way around the opening of the passage hole (8), and wherein the screw-on bushing (3) is designed without a corrosion-protection coating.

Owner:ROBERT BOSCH GMBH

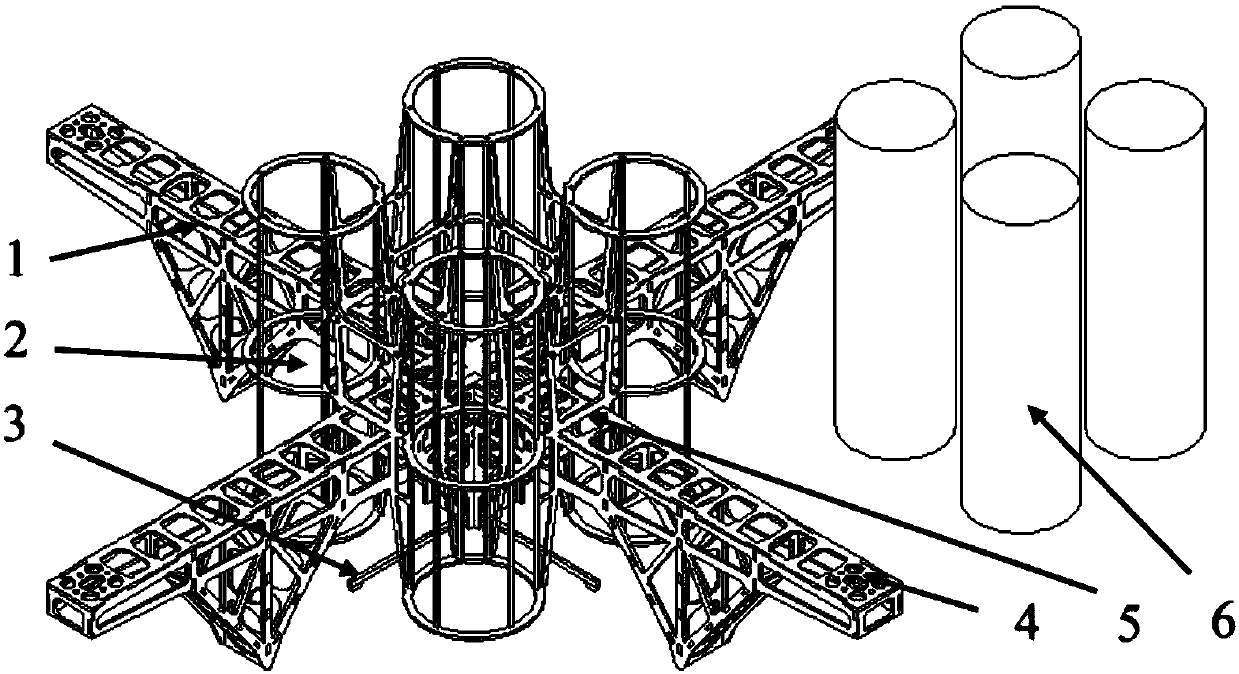

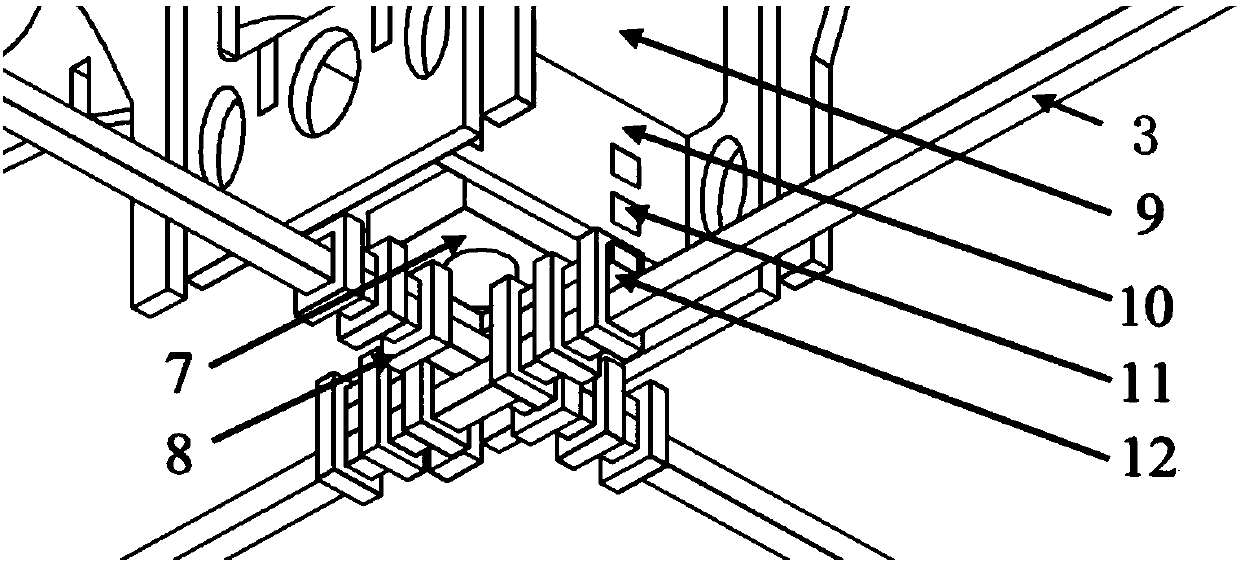

Multi-bin type minitype container quadrotor transporting unmanned aerial vehicle

InactiveCN107600413AImprove transportation efficiencyWith structural stabilityAircraft componentsLaunching weaponsJet aeroplaneUncrewed vehicle

The invention relates to unmanned aerial vehicles, in particular to a multi-bin type minitype container quadrotor transporting unmanned aerial vehicle. By utilizing the characteristic of a quadrotor plane that an enough usable space is left between every two adjacent shafts, four detachable cargo bins which are connected in pairs to form a whole are mounted among four shafts of a vehicle body, andopening and closing of the four bin doors are controlled through a steering engine fixed to the position below a small storage warehouse in the middle of the vehicle body. In this way, the transporting efficiency of the quadrotor transporting plane is improved greatly, the effective space of the plane is utilized sufficiently, and the transporting unmanned aerial vehicle has the characteristic ofbeing stable in structure. Meanwhile, container type transporting is adopted, four minitype containers can be transported through one time flying, and the minitype containers can be loaded with different cargos.

Owner:XIAMEN UNIV

A kind of children's walker

The invention discloses a children's walker, which comprises two sets of side supports and a beam fixed between the two sets of side supports. The sides of the two sets of side supports away from each other are equipped with large walking wheels, and the bottom of each set of side supports is provided with There are two casters, and the support plate is fixed on the upper surface of the beam through two vertical sliding rods. The sliding rod is provided with a slidable sliding seat. The front side of the sliding seat is fixed with a mounting plate, and the front side of the mounting plate is installed with a support Seat and waist positioner, the chest positioner is installed on the upper surface of the waist positioner through the support rod, the brain drag pillow is installed on the upper surface of the chest positioner through the support hinge rod, and the screw rod and the screw rod are installed between the support plate and the beam Cooperate with the sliding seat through the thread hole. In the present invention, adjustable waist locators and chest locators are respectively used to fix or position the children's waist and chest, thereby forming a stable focus point, and the child can move synchronously and stably with the entire walker through the movement of the trunk, thereby Free children's hands.

Owner:四川省康复辅具技术服务中心

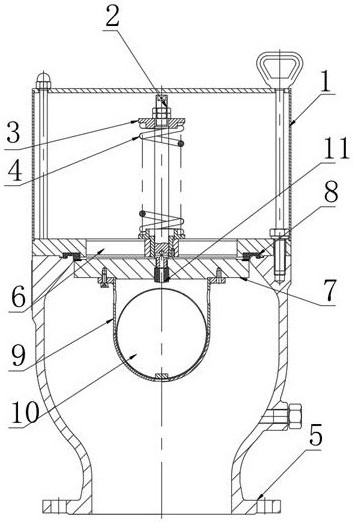

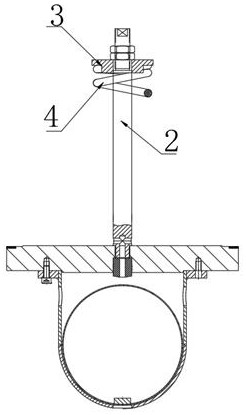

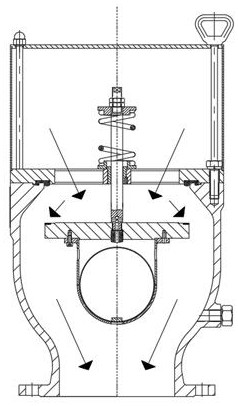

Integrated gas injection micro-exhaust valve

PendingCN112361064ADon't worry about failureAir supply pressure is adjustableOperating means/releasing devices for valvesLift valveThermodynamicsExhaust valve

The invention discloses an integrated gas injection micro-exhaust valve. The integrated gas injection micro-exhaust valve comprises a protective cover, the bottom end of the protective cover is connected with a gas injection valve body through a bolt, a guiding shaft is installed in the protective cover, a limiting block is connected to the top of the guiding shaft through a bolt, and a spring isconnected to the bottom end of the limiting block; and a gas injection valve cover is connected to the top end of the gas injection valve body, a micro-exhaust valve seat is connected to the position,below the guiding shaft, of the gas injection valve cover, a gas injection valve element is connected to the bottom end of the gas injection valve cover, and the bottom end of the gas injection valveelement is connected with a micro-exhaust ball basket through a bolt. The gas injection micro-exhaust valve adopts an integrated structure and is composed of a gas inlet part and a micro-exhaust partlocated in the valve body. The gas injection micro-exhaust valve is simple in structural design, reliable in work and durable, the starting pressure of negative pressure gas suction is determined through the spring, the position of the limiting block can be adjusted through double nuts on the upper portion so that the stroke of the spring can be controlled to achieve the effect that the gas supplementing pressure can be adjusted, meanwhile, the spring is not in water, and spring failure caused by water erosion does not need to be worried about.

Owner:WATTS VALVE CHANGSHA

Storage space monitoring method and device, electronic terminal, storage medium

ActiveCN109656885BMonitor usageEnough free spaceFile access structuresFile/folder operationsComputers technologyInode

The disclosure provides a storage space monitoring method and device, an electronic terminal, and a computer-readable storage medium, belonging to the technical field of computers. The method is applied to an electronic terminal, and includes the following steps: starting a monitoring process for a storage space, wherein the storage space includes a data area and an index node area, the data area is used for storing files, and the index node area is used for Store the index information of the file; obtain the index node occupancy rate through the monitoring process, and the index node occupancy rate is the ratio of the occupied index nodes in the index node area to all index nodes; if the index node occupancy rate exceeds the preset threshold, the storage space is cleaned up. The disclosure can realize the monitoring and management of the index node area of the storage space, can effectively monitor the abnormal occupancy of the storage space, and improve the monitoring efficiency.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

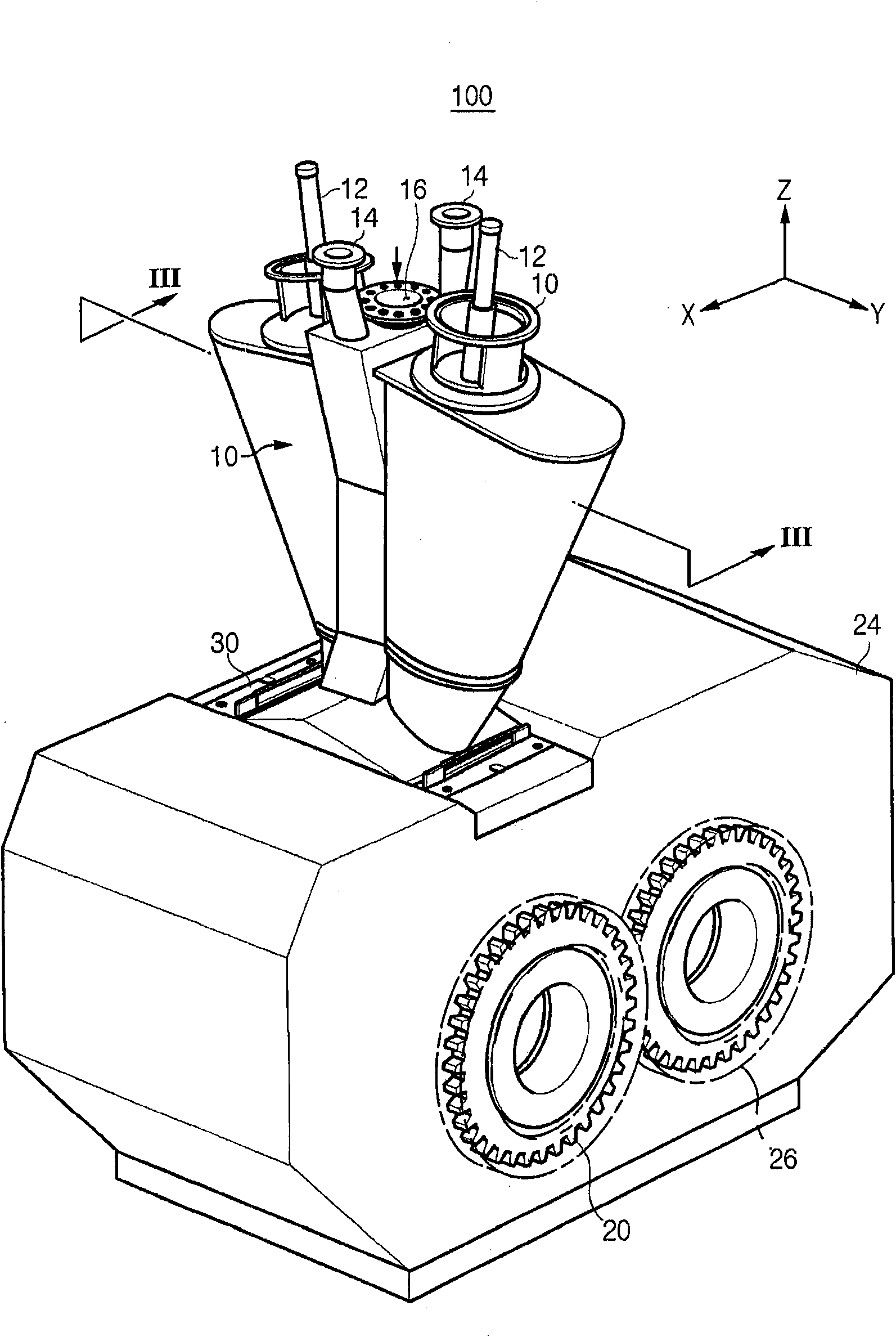

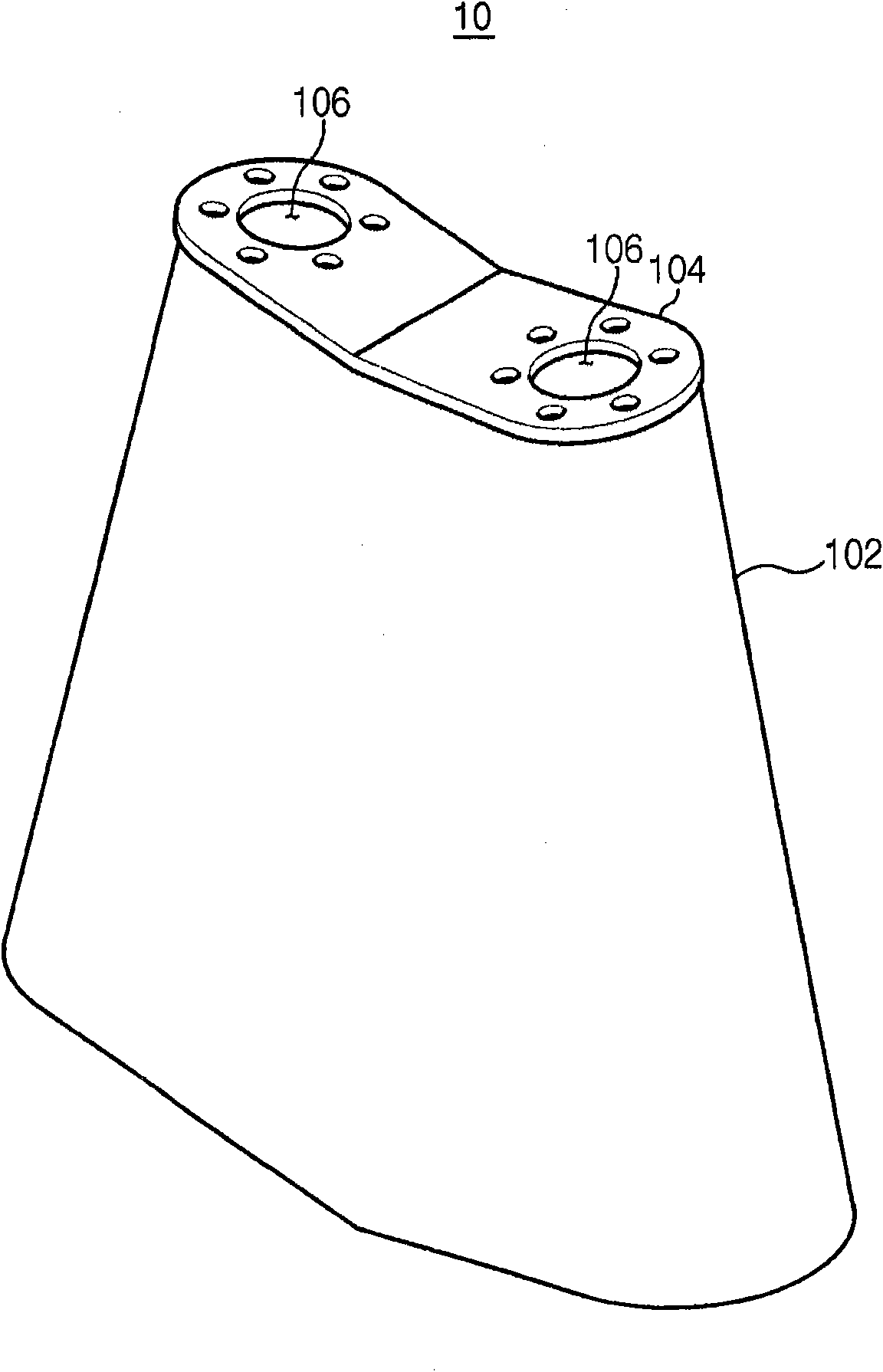

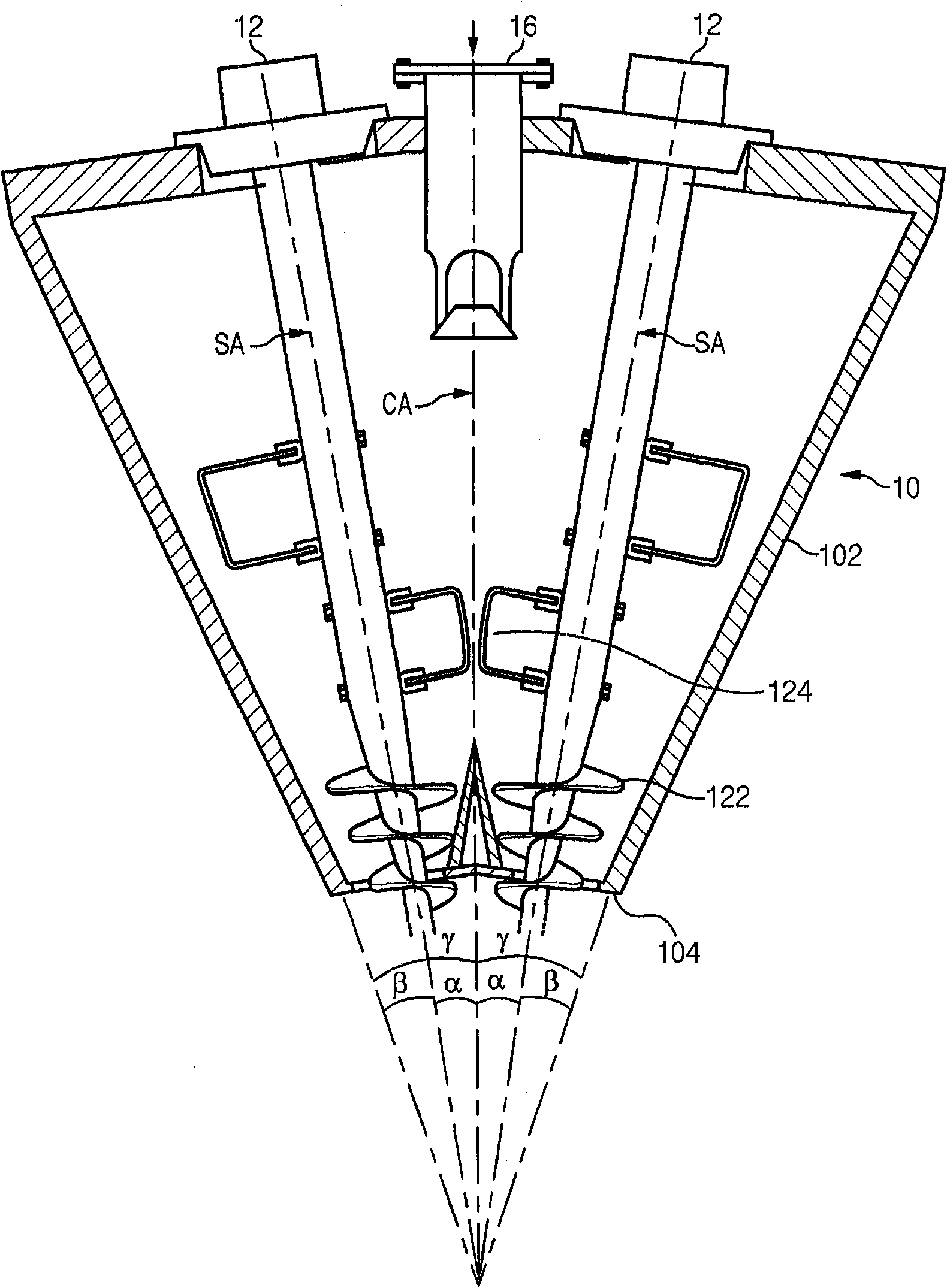

Apparatus for manufacturing compacted irons of reduced materials comprising fine direct reduced irons and apparatus for manufacturing molten irons provided with the same

An apparatus for manufacturing compacted iron for manufacturing reduced materials containing fine reduced iron into compacted iron and an apparatus for manufacturing molten iron provided with the sameare provided. The apparatus for manufacturing compacted iron includes i) a charging hopper into which reduced materials containing fine reduced iron are charged, and ii) a pair of rollers that form agap therebetween by being spaced apart from each other and that press the reduced materials containing fine reduced iron that are discharged from the charging hopper and pass through the gap, therebymanufacturing the compacted iron. The above-described charging hopper includes i) a surface of a wall, and ii) an integrated lower surface that is connected to the surface of the wall and is directedtoward the pair of rollers. In addition, at least one discharging opening is formed on the integrated lower surface to discharge the reduced materials containing fine reduced iron to the pair of rollers.

Owner:浦项股份有限公司

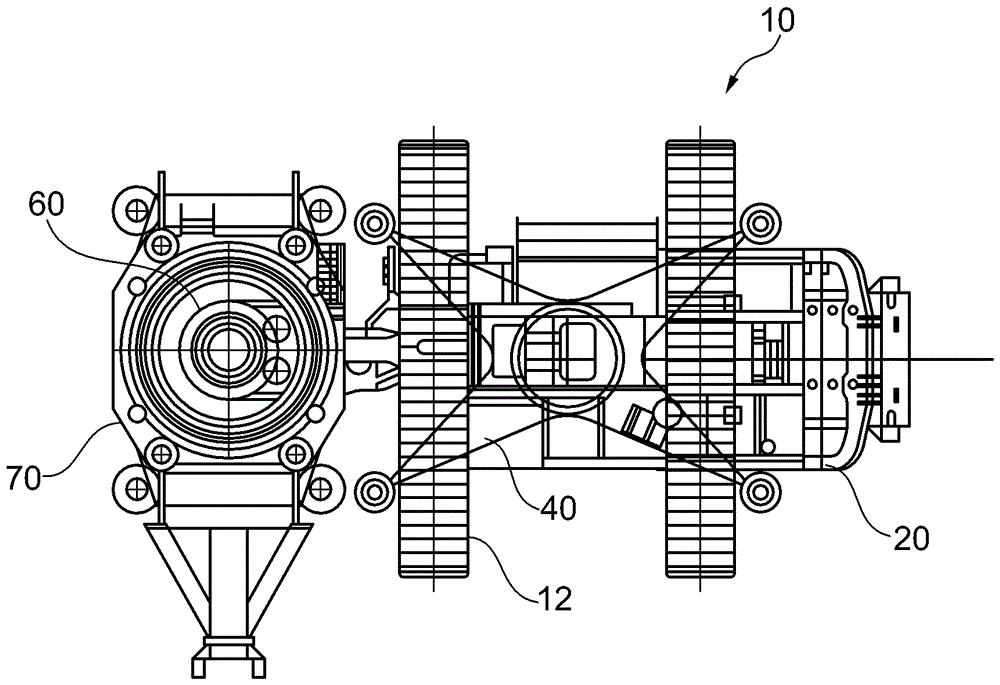

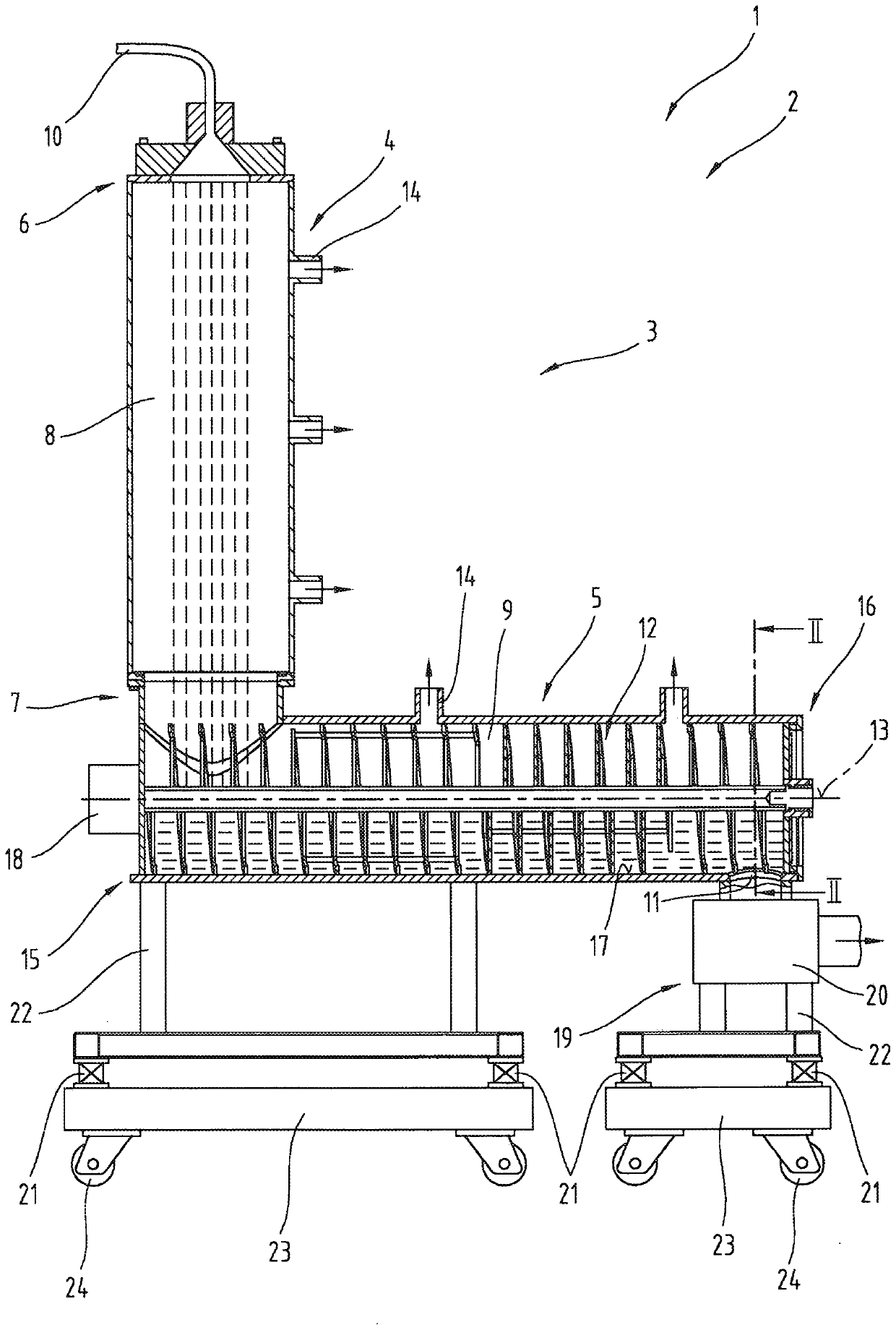

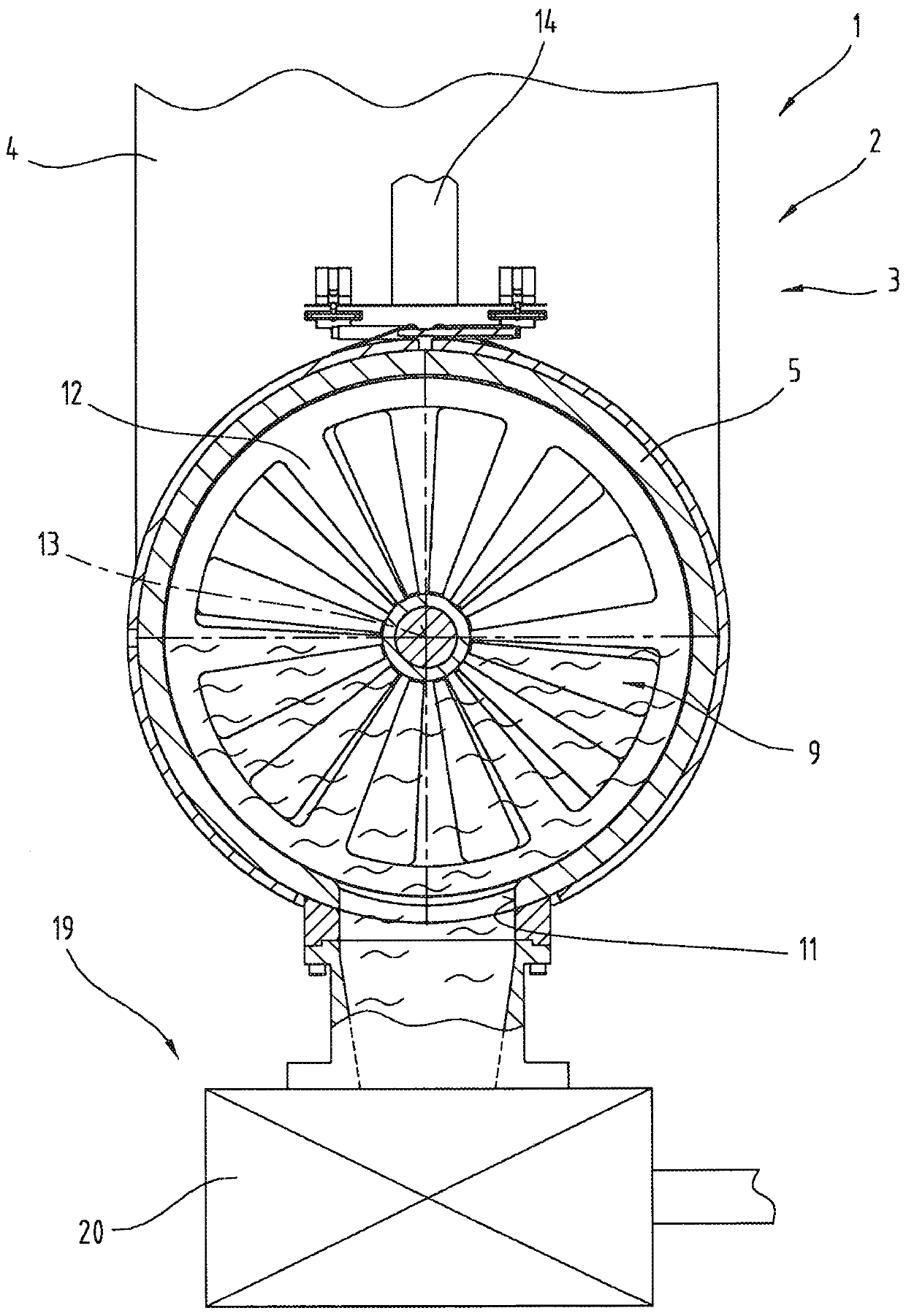

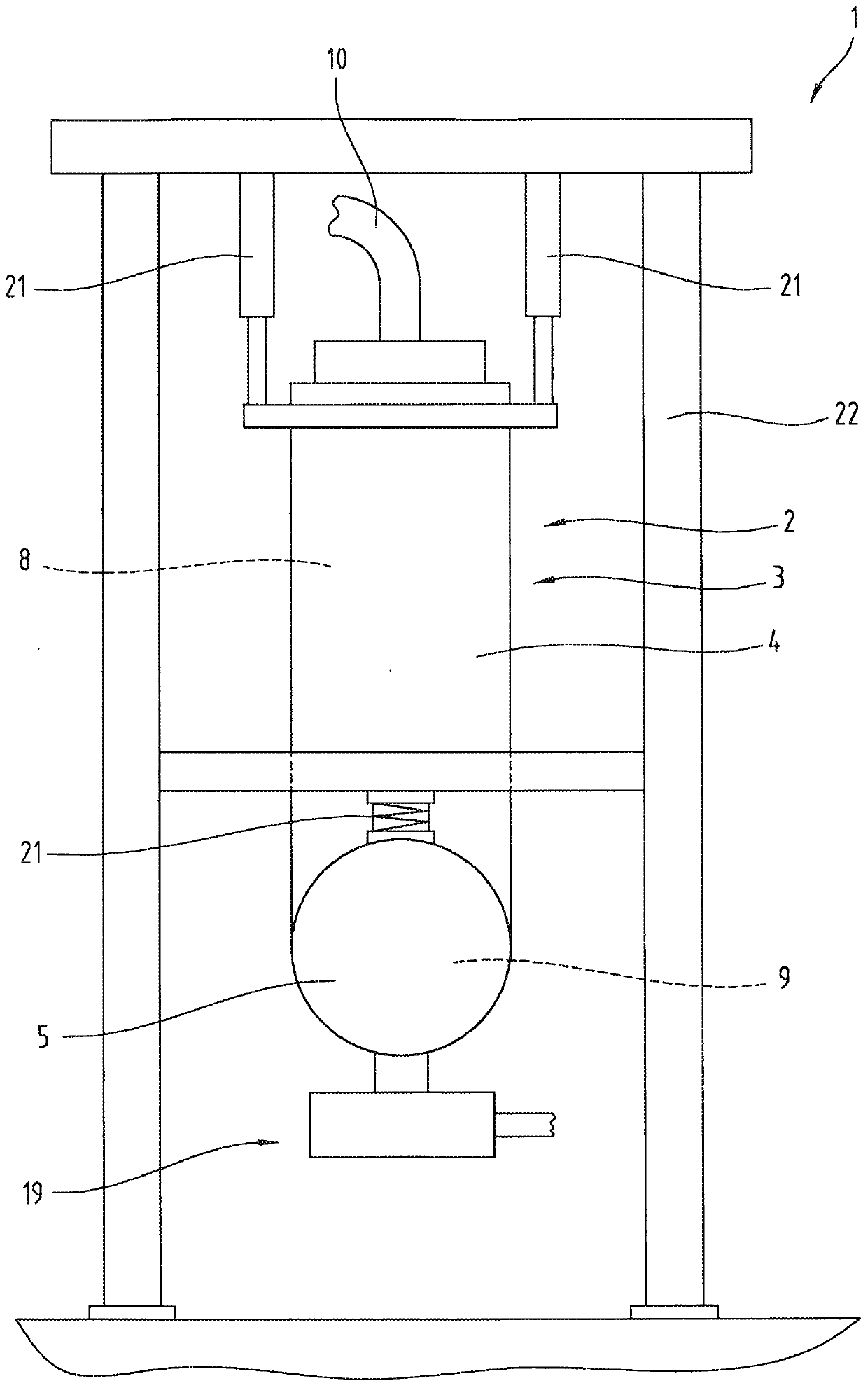

Apparatus and method for processing plastic melts

ActiveCN108349113BQuality improvementImprove productivityTransportation and packagingRotary stirring mixersProcess engineeringMechanical engineering

The invention relates to a plant and a method for processing plastic melts, said plant having a reactor (2) comprising a reactor housing (3) comprising first and second Two reactor housing parts (4, 5); the mixing element (12) is arranged in the second reactor housing part (5) and is rotatably mounted on the second reactor housing part about an axis of rotation (13) Above; the reactor together with the unloading device (19) is supported on the placement surface with at least one weighing device (21) connected in the middle.

Owner:NEXT GENERATION RECYCLINGMASCHEN

Mouth organ

The invention discloses a mouth organ which comprises a comb (1); a tuning plate (2) with tuning guides (3) support on at least one side. The tuning guides (3) are fixed on the outer side tuning plate (2) and are coverd by a cover (4) arranged on the tuning plate (2). One of the tuning guides (3) has a pendulum mass (5) on its head for a deep note. The swing width (X) of the pendulum mass (5) determines a clear roof headway (Y) of the cover, against which the cover falls monopitch roof shaped.

Owner:和莱乐器有限责任公司

Rolling bearing cage and manufacturing method thereof

ActiveCN103443485BStop stopImprove carrying capacityRolling contact bearingsShaftsRolling-element bearingEngineering

The invention relates to a rolling bearing cage (12) with two side rings (2) and a plurality of cage connecting beams (1), wherein the side rings (2) and the cage connecting beams (1) form a plurality of Cage cavity (8). In order to make the rolling bearing cage (12) particularly light and stable, the invention provides that, in the corners (10) of the cage pockets (8), recesses (3) are formed respectively, which are directed towards their radial center (7 ) is reduced or reduced, no stop surface for the associated rolling element ( 9 ) is formed here. Furthermore, the invention relates to a method for producing a rolling bearing cage (12) according to the invention, in which it is provided that a plurality of cage pockets (8) are milled into a solid cage blank, wherein the cage pockets (8) The corners (10) of the are milled in such a way that, in the cage pockets, recesses (3) are formed in each case, which taper or become smaller towards their radial center (7), without forming for the associated rolling elements (9) stop surface.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com