A thin coal seam shearer drum

A technology for shearer drums and thin coal seams, which is applied to cutting machinery, earthwork drilling, etc., can solve problems such as irreparable and poor coal loading performance of thin coal seam drums, so as to improve service life, increase coal loading rate, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

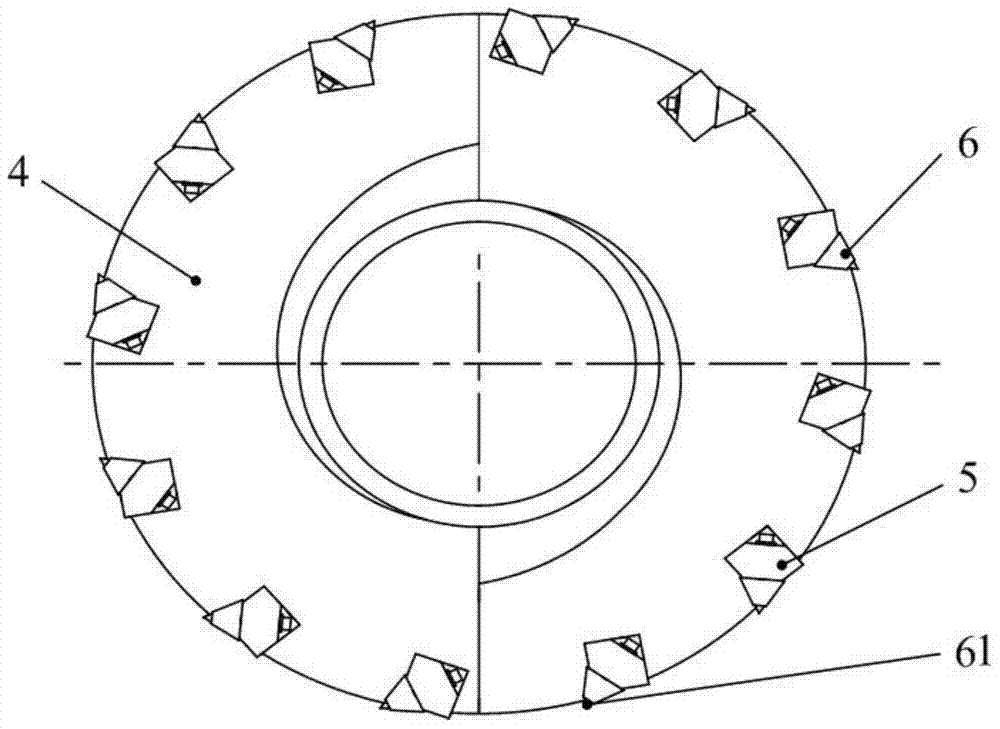

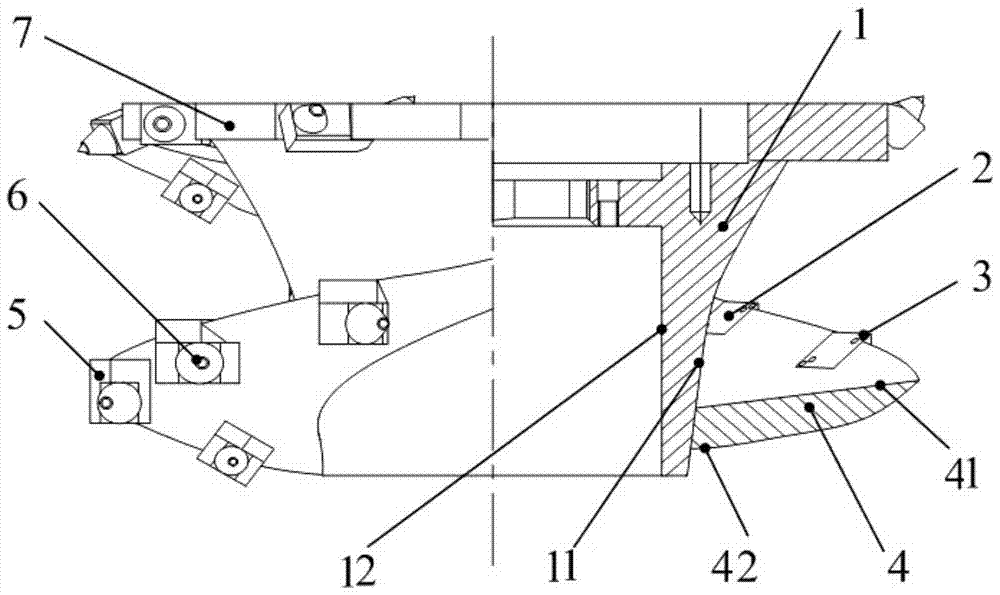

[0019] Such as figure 2 As shown, a thin coal seam shearer drum includes an end plate 7, a drum hub 1, a helical blade 4, a tooth holder 5, and a tooth 6. The drum has a compact structure and is suitable for any thin coal seam drum shearer in terms of installation and use.

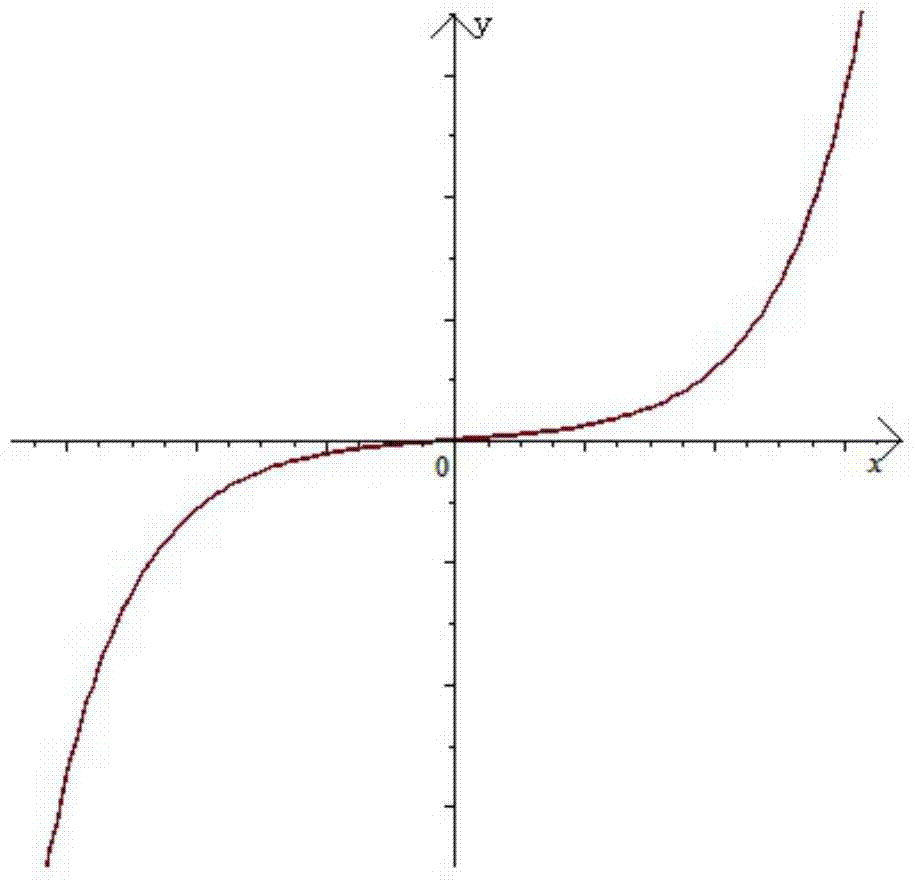

[0020] The diameter of the drum hub 1 increases in a hyperbolic sine form from the bottom of the drum to the end plate 7, so that the outer contour line 11 of the drum hub meets the space requirements of the coal flow in the drum during the drum coal transportation process, and the diameter of the drum hub 1 is from the bottom of the drum to the end. The increase in the direction of disc 7 in the form of hyperbolic sine is the best test effect, and other forms of diameter increase are not as good as hyperbolic sine in improving the coal charging performance of the drum. Such as image 3 The pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com