Coal mining machine and method for improving mining rate of thin coal seam

A technology of mining efficiency and thin coal seam, applied in cutting machinery, earthwork drilling, slitting machinery, etc., can solve the problem of low mining efficiency of thin coal seam, and achieve the goal of improving coal loading rate, improving safety and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

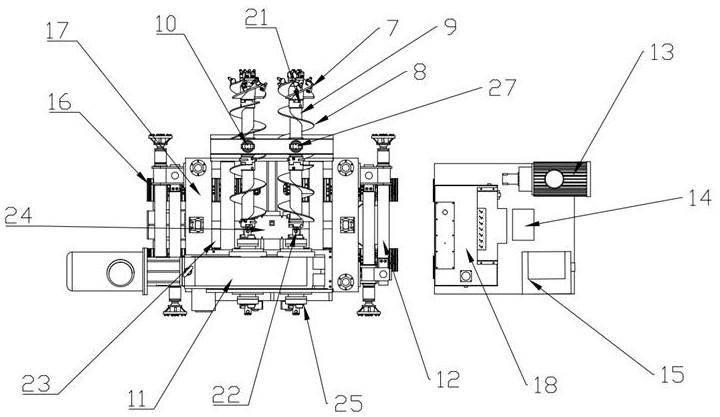

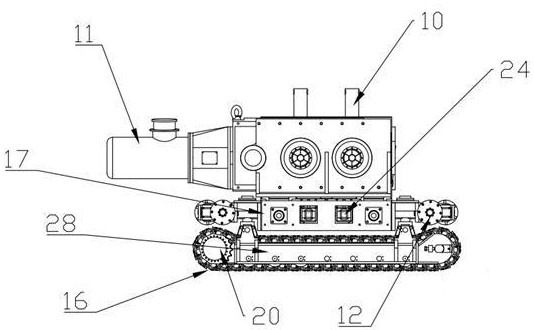

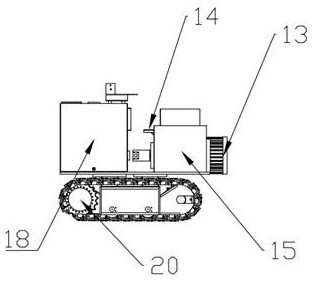

[0030] Below in conjunction with accompanying drawing this coal shearer is described in further detail.

[0031] Such as Figure 1 to Figure 4 As shown, a machine suitable for mining thin coal seams, including crawler 16, crawler chassis 28, hydraulic cylinder 27, small bevel gear assembly 2, large bevel gear assembly 3, oil pump motor 13, reducer 11, pin shaft I21 , pin shaft II 22, guide shaft 23, fixed oil cylinder 12, gearbox 6, tunneling head 7, cutting head 4, drill pipe 9, rotary blade 8, travel motor 20, fuel tank 18, electric control switch 15, oil pump motor 13, Drilling frame 10, operating table 14, pushing oil cylinder 24, hydraulic motor 25, moving clamp seat 34, frame 17, drilling barrel 35 and coal retaining plate 5.

[0032] This kind of coal mining machine with a high coal mining rate is provided with a driving device, and the driving device includes two driving heads 7, and the tails of the driving heads 7 are respectively connected to the ends of two drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com