A receiving device and a belt conveyor

A material receiving device and receiving hopper technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of limited effect and complicated operation, and achieve the effect of alleviating the impact of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

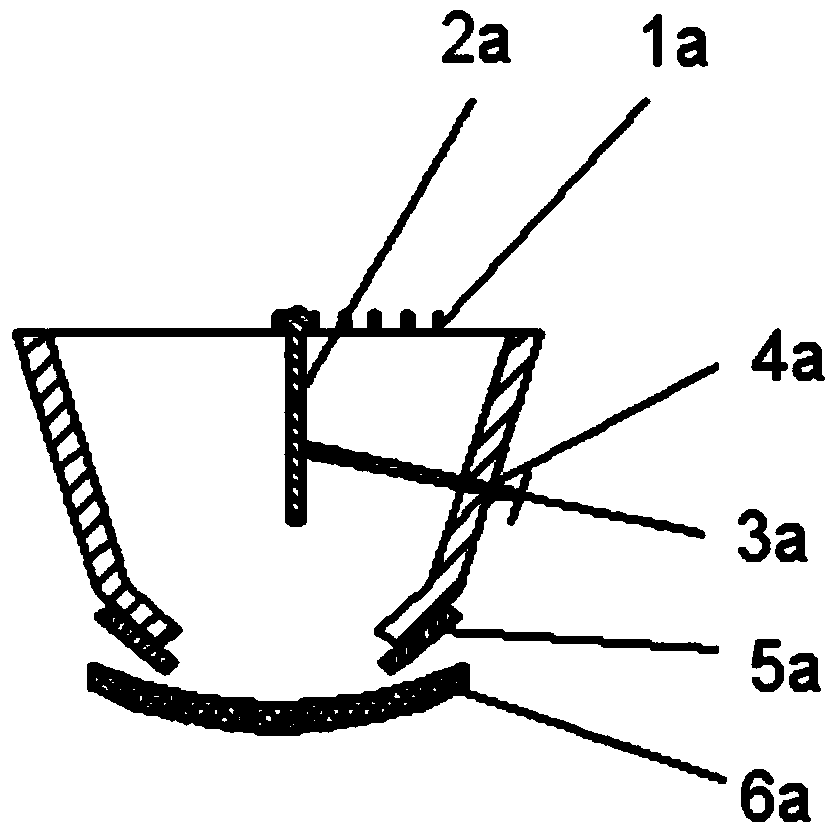

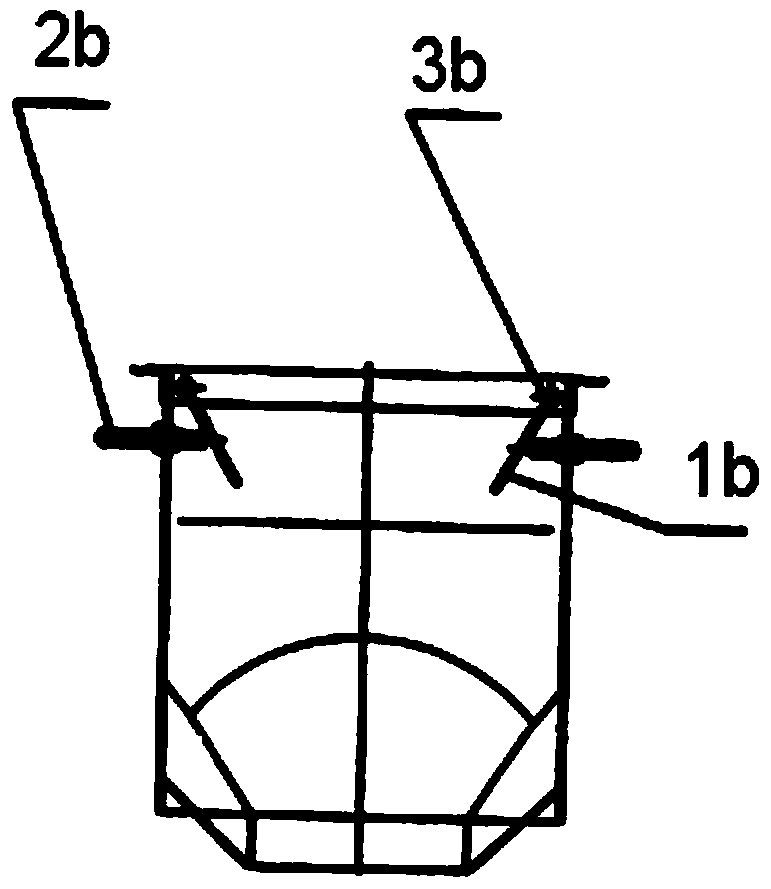

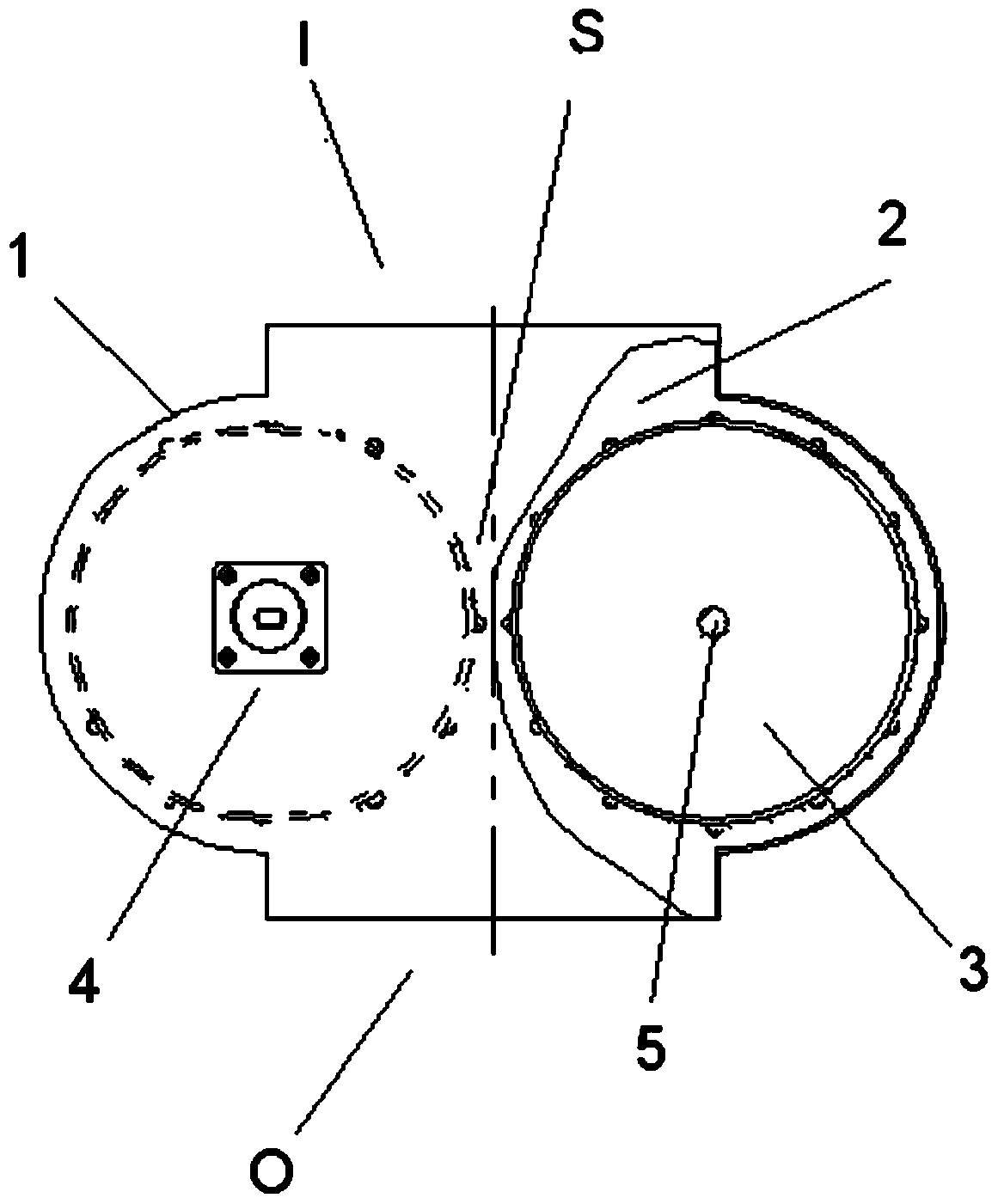

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0026] image 3 A specific embodiment of a receiving device provided by the present invention is shown. The material receiving device includes: a material receiving hopper 1, and at least one group of roller groups 2 arranged in the material receiving hopper 1, the material receiving hopper 1 has an inlet I and an outlet O in a vertical direction, and the roller group 2 includes two There are two cylinders 3 with the same radius and the rotating shafts 5 on the same horizontal line. A gap S is formed between the two cylinders 3 for materials to pass through, and the gap S is aligned with the outlet O; a rotation restraining mechanism 4 is also included. The rotation inhibiting mechanism 4 can inhibit the rotation of the drums 3 during the rotation of the two drums 3. Therefore, when the material enters the S, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com