Steel for cold extrusion gear shaft and preparation method thereof

A technology of gear shaft and cold extrusion, applied in the field of gear steel, to achieve the effects of inhibiting hardenability, stable hardenability, and low content of residual elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

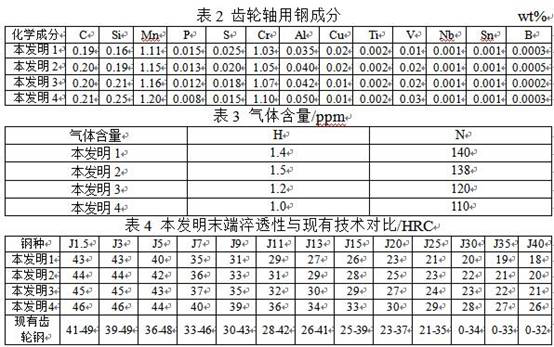

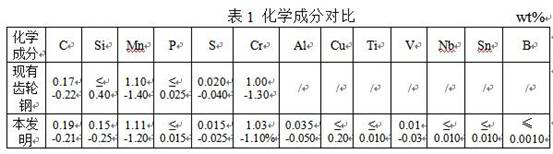

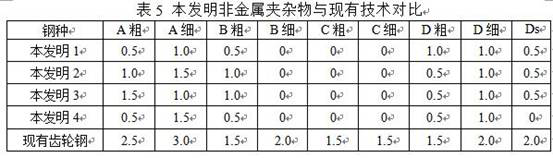

[0042] The chemical composition comparison of the 20MnCr5 gear steel currently used in China and the present invention is shown in Table 1 below.

[0043]

[0044] Prepared by the following production process:

[0045] (1) Hot metal preparation: use S: 0.030%~0.045%, P≤0.12% sulfur-controlled and low-phosphorus molten iron to produce the steel grade of the present invention; the molten iron is not desulfurized, and the sulfur in the molten iron is used to control the S content of the steel;

[0046] (2) Converter smelting: smelting in a top-bottom double blowing converter with a capacity of more than 100 tons, the temperature of molten iron is controlled to be ≥1300°C, and the converter adopts the double-slag method to realize the removal of P, to ensure that the end point of the converter is P≤0.012%, and aluminum cake is added to the tapping. , alloy, pre-melting refining slag, quartz sand, lime for slagging, pre-deoxidation and initial composition adjustment to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com