Patents

Literature

63results about How to "Reduce the difficulty of smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-plasticity medium manganese cold-roll steel sheet and manufacturing method thereof

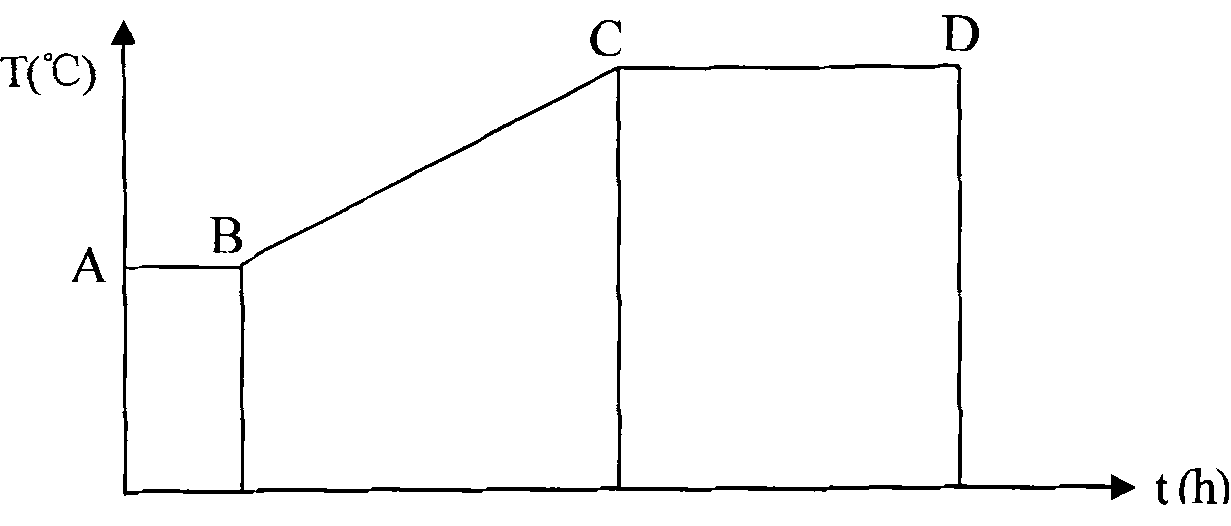

InactiveCN103103438AImprove mechanical propertiesSimple and economical ingredientsTime rangeSheet steel

The invention discloses a high-strength and high-plasticity medium manganese cold-roll steel sheet and a manufacturing method thereof, and belongs to the technical field of metal material manufacturing. The high-strength and high-plasticity medium manganese cold-roll steel sheet comprises the following main components in percentage by mass: 0.15-0.25% of C, 7-8% of Mn, 1.2-1.8% of Si, and less than or equal to 0.05% of Al. The components are smelted and cast into a blank, and then the casting blank is subjected to multi-pass hot rolling so as to obtain a hot-rolled plate; the hot-rolled plate is subjected to intermediate heat treatment two times and two stages of cold rolling; the temperature of the intermediate heat treatment is 80-120 DEG C larger than Ar1, and the heat preservation time is 8 hours and above; in the two stages of cold rolling, the deformation is 30-50%; and the temperature of final heat treatment of the cold-roll steel sheet is Ar1+70 DEG C and above, and the annealing time ranges from 10 minutes to 2 hours. The cold-roll steel sheet disclosed by the invention is simple in preparation method, low in cost, and wide in application prospect. A prepared high-strength and high-plasticity medium manganese cold-roll steel sheet has excellent mechanical properties, and the product of strength and elongation of the cold-roll steel sheet can be up to 44.9 GPa*%.

Owner:UNIV OF SCI & TECH BEIJING

Non-magnetic stainless steel with high strength and toughness, manufacturing method and application thereof

The invention provides non-magnetic stainless steel with high strength and toughness, a manufacturing method and application thereof. The stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.04 percent of C, 0.35 to 0.65 percent of Si, 17.00 to 22.00 percent of Mn, 13.00 to 17.00 percent of Cr, 0.30 to 0.50 percent of Mo, 0.15 to 0.45 percent of Ni, 0.30 to 0.80 percent of N, less than or equal to 0.03 percent of P, less than or equal to 0.005 percent of S, and the balance being Fe and inevitable impurities. The steel improves the rust resistance and corrosion resistance of the stainless steel by adopting a low-carbon and high-chromium content design, reduces the nickel content by replacing the nickel with manganese and nitrogen at the same time, and reduces production cost. The steel is smelted by adopting an EAF, AOD and LF method, the forging process is divided into two temperature stages, the steel is treated by adopting different deformation amounts, and the method is simple and convenient to apply and has good effect. The invention also provides application of the stainless steel in a petroleum drill.

Owner:宝武特种冶金有限公司

Hot rolled ferrite/martensite double phase steel and production method thereof

InactiveCN102517496ALow costReduce the difficulty of surface quality controlDouble phaseUltimate tensile strength

The invention relates to hot rolled ferrite / martensite double phase steel and a production method thereof. The double phase steel comprises the following components, by mass, 0.06-0.10% of C, 1.00-2.00% of Mn, 0.40-0.60% of Si, equal to or less than 0.02% of P, equal to or less than 0.02% of S, 0.08-0.12% of Ti, and the balance Fe and inevitable impurities. The double phase steel provided in the invention contains less than 0.5% of Si, so the surface quality of the steel can be easily controlled; and additionally, the low cost Ti element is added to improve the strength of the steel as a precipitation strengthening element, so costs of steel products are reduced.

Owner:SHOUGANG CORPORATION

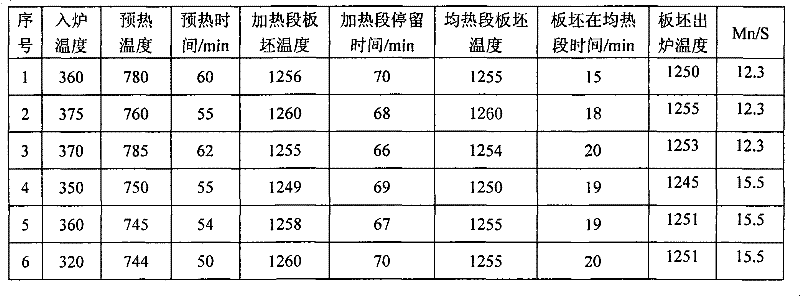

Method for manufacturing thick hot-rolled dual-phase steel based on CSP (Compact Strip Production) process

InactiveCN104593665AGood mechanical propertiesStable mechanical propertiesFurnace temperatureContinuous rolling

The invention discloses a method for manufacturing hot-rolled dual-phase steel based on a CSP (Compact Strip Production) process. The method comprises the following steps: (1) preparing a raw material comprising the following chemical compositions in percentage by weight: 0.055-0.070% of C, 0.40-0.50% of Si, 1.20-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S and the balance of Fe and unavoidable impurities; and (2) sequentially pretreating molten steel, carrying out converter top and bottom combined blowing, refining in an LF, continuously casting thin billet, soaking in a tunnel furnace, continuously rolling by virtue of an F1-F7 seven-stand hot continuous rolling mill group, cooling by virtue of a laminar cooling system, cooling by virtue of an ultra-fast cooling system and coiling. In the method, the out-of-furnace temperature of the continuous casting billet passing through the tunnel soaking furnace is equal to or greater than 1130 DEG C, the initial rolling temperature in the hot continuous rolling step is equal to or greater than 1010 DEG C, the reduction rate in an F1 stand is equal to or greater than 40%, the reduction rate in an F2 stand is equal to or greater than 33.3%, the temperature after the laminar cooling and air cooling is 600-690 DEG C, the temperature after ultra-fast cooling is 150-250 DEG C, the ultra-fast cooling speed is 70-150 DEG C / s. The microstructures of 11.0mm-thickness 590MPa-grade dual-phase steel in the thickness direction, which is produced from a simple low C-Mn-component system in an industrial mass manner, are ferrite and martensite duplex microstructures so that the dual-phase steel is excellent in comprehensive performance.

Owner:NORTHEASTERN UNIV +1

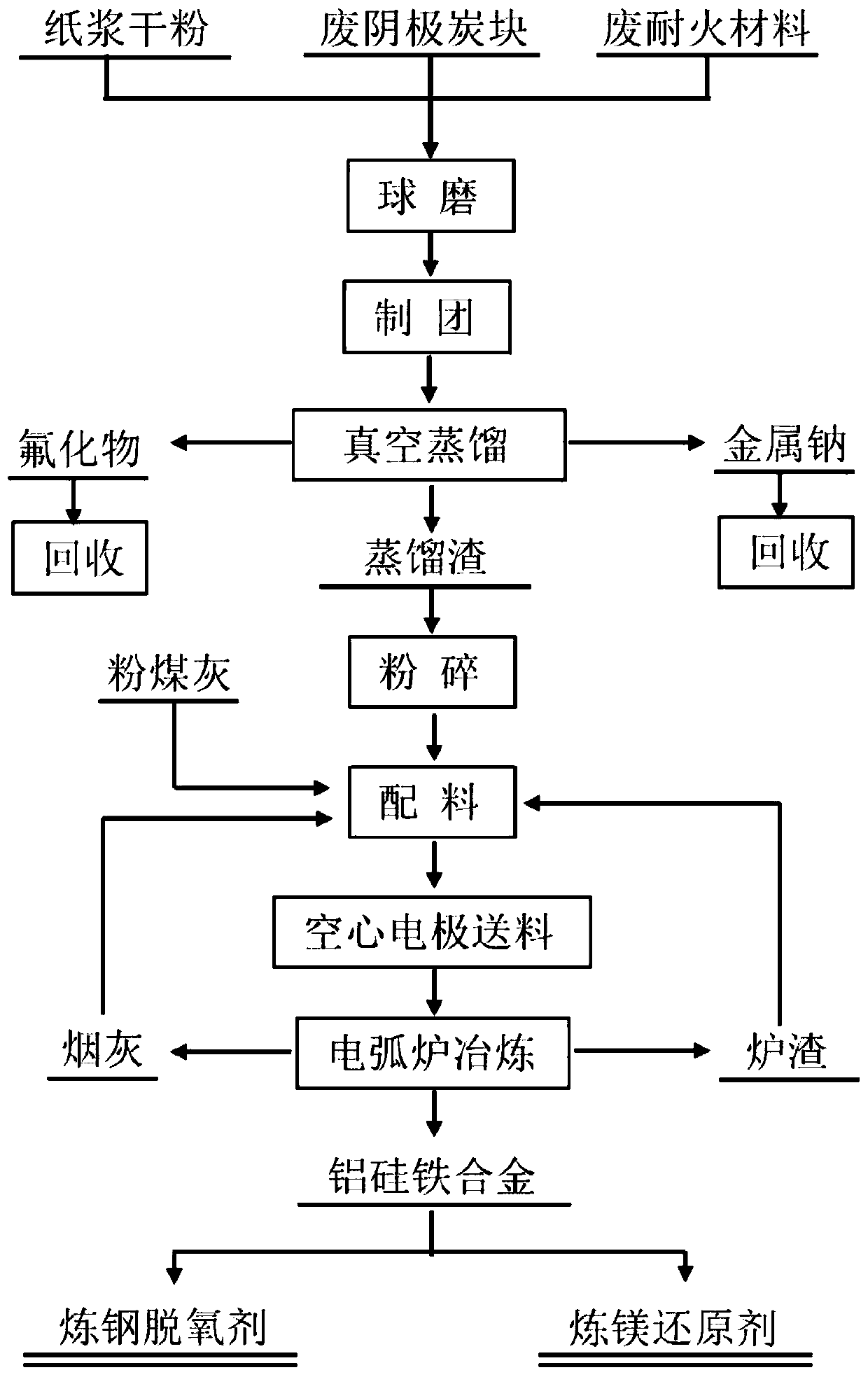

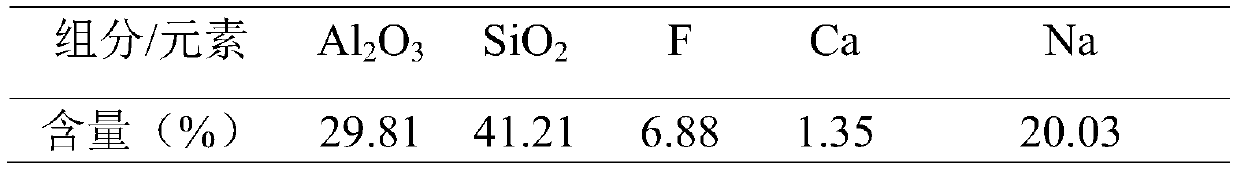

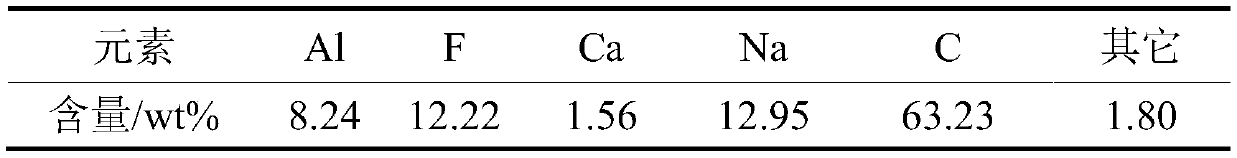

Method for preparing Al-Si-Fe alloy by preprocessing waste fireproof material and carbon thermal reduction

ActiveCN110129506ARealize high temperature volatile separationRealize resource utilizationElectric furnaceGas emission reductionElectric arc furnaceDecomposition

The invention provides a method for preparing an Al-Si-Fe alloy by preprocessing a waste fireproof material and carbon thermal reduction. The method for preparing the Al-Si-Fe alloy by preprocessing the waste fireproof material and carbon thermal reduction comprises the steps that the waste fireproof material, waste negative electrode carbon blocks and paper pulp dry powder are uniformly mixed andmade into powder; then the mixed material is compressed into pellets, high temperature vacuum distillation is conducted so that fluoride in the waste fireproof material and the waste negative electrode carbon blocks volatilize, then the fluoride is separated from the waste fireproof material and the waste negative electrode carbon blocks, and meanwhile, cyanide in the waste negative electrode carbon blocks is decomposed; then distillation residues are smashed and dispensed and mixed with coal ash, and fixed carbon in the waste negative electrode carbon blocks is adopted as a reducing agent inan electric arc furnace so that high temperature reduction can be conducted on a material with aluminum oxide and silicon oxide being the main components, and then the Al-Si-Fe alloy with certain components is prepared; and meanwhile, decomposition of aluminum nitride in aluminum ash and total decomposition of cyanide in the waste negative electrode carbon blocks are completed in the high temperature reduction process, and comprehensive utilization of multiple hazardous wastes and solid wastes is achieved in the same technology.

Owner:NORTHEASTERN UNIV

Low-carbon, low-silicon, cold-rolled and hot-galvanized dual-phase steel for extra-deep drawing and preparation method thereof

InactiveCN104233093AImprove hardenabilityGuaranteed hot-dip galvanizing performanceChemical compositionMo element

The invention relates to low-carbon, low-silicon, cold-rolled and hot-galvanized dual-phase steel for extra-deep drawing and a preparation method thereof. The dual-phase steel comprises chemical components in percentages by mass as follows: 0.035%-0.045% of C, 0.03%-0.05% of Si, 1.3%-1.75% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.008% of S, smaller than or equal to 0.075% of Al, 0.5%-0.68% of Cr, 0.35%-0.5% of Mo and the balance of Fe and unavoidable impurities, wherein the content of P, S and Al is not 0, texture in the {111} / / RD direction in microstructures of the dual-phase steel occupies more than 90 vol.%, the main microstructures adopt ferrite and martensite structures, the tension strength of the dual-phase steel ranges from 485-600 MPa, the elongation is higher than or equal to 32%, and an r value is 2-2.2. The dual-phase steel is matched with the corresponding preparation method. By means of the invention, certain quantity of Cr and Mo elements are added into the low-carbon dual-phase steel, a texture pre-treatment process is adopted, so that the deep drawability of a material is improved remarkably under certain strength condition, and the hot galvanizing performance of the material is improved sufficiently.

Owner:朱忠良

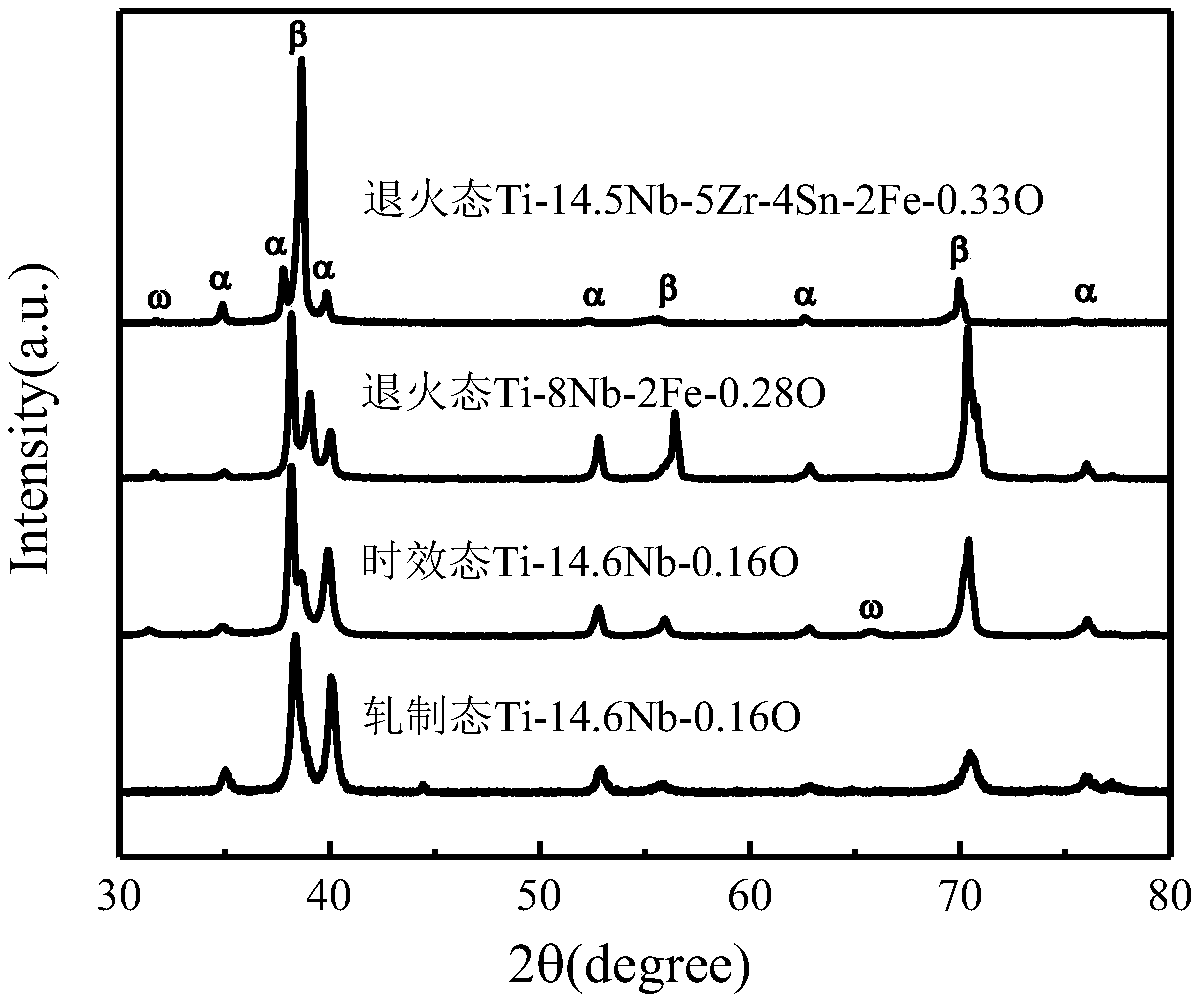

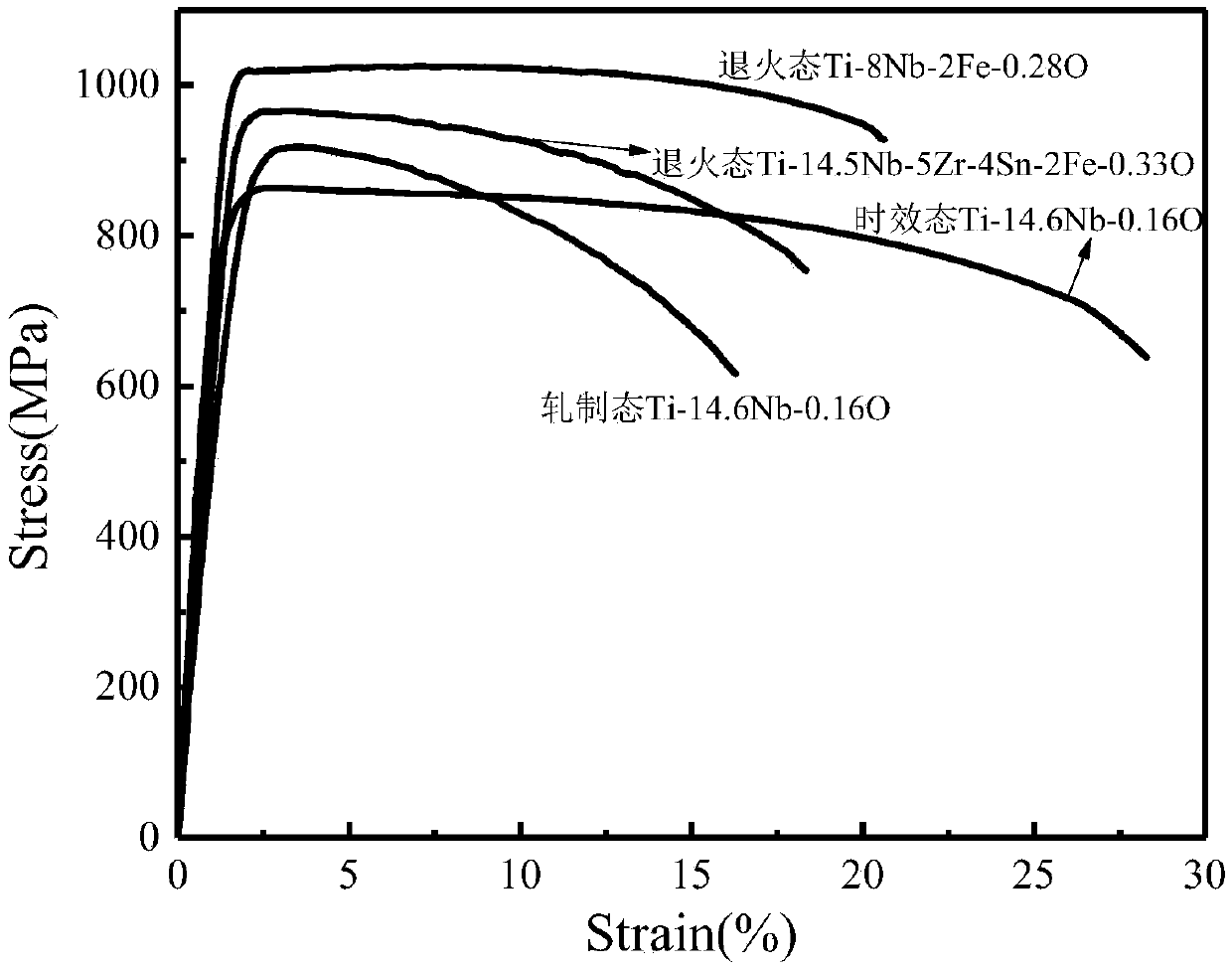

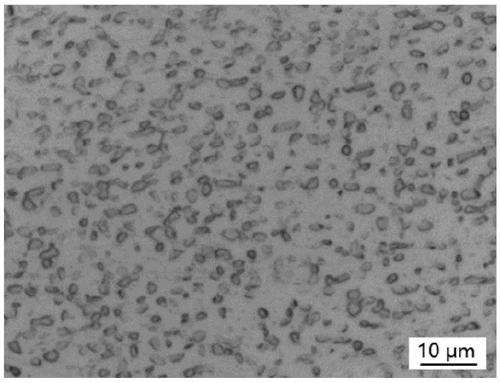

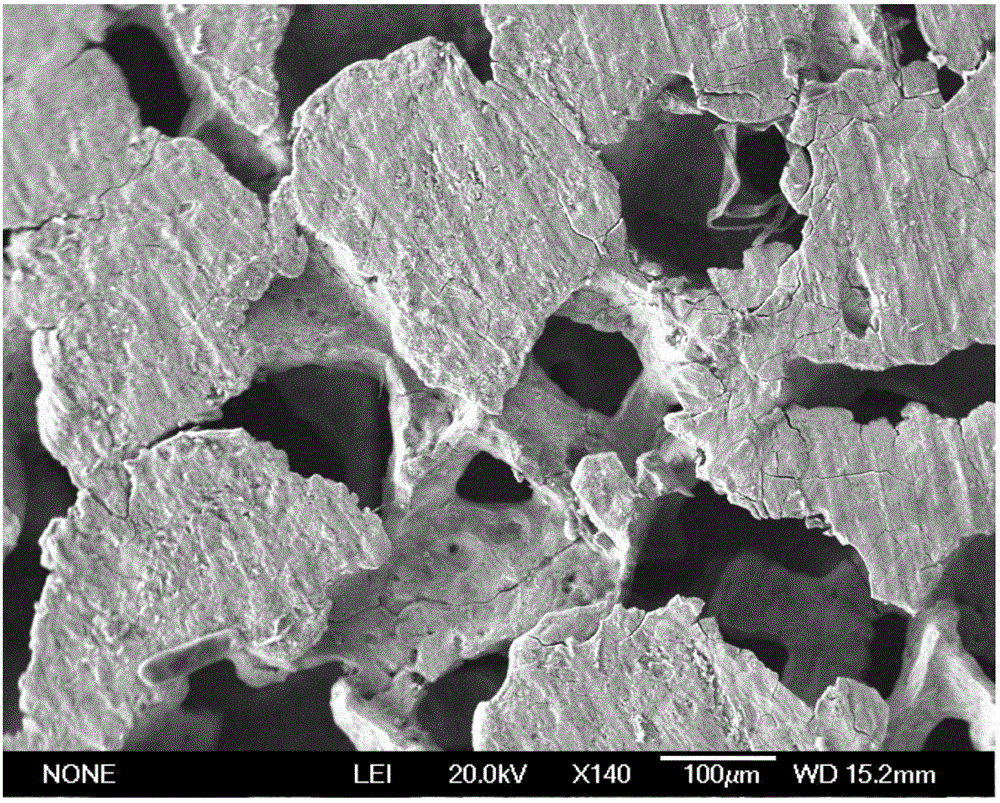

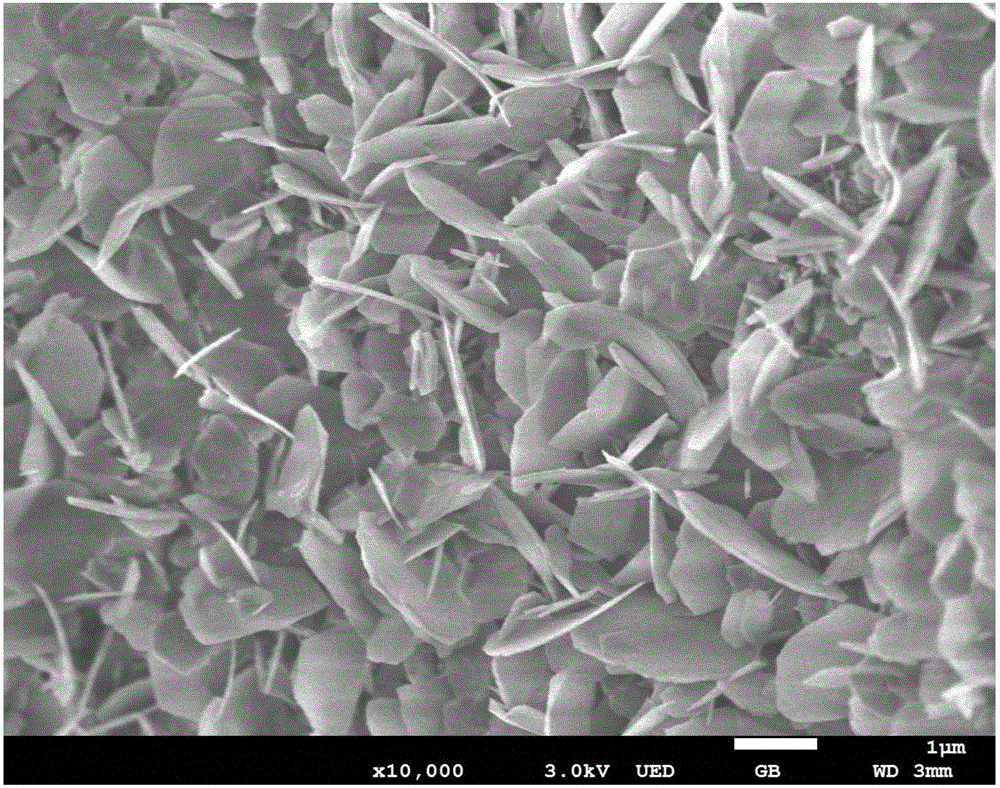

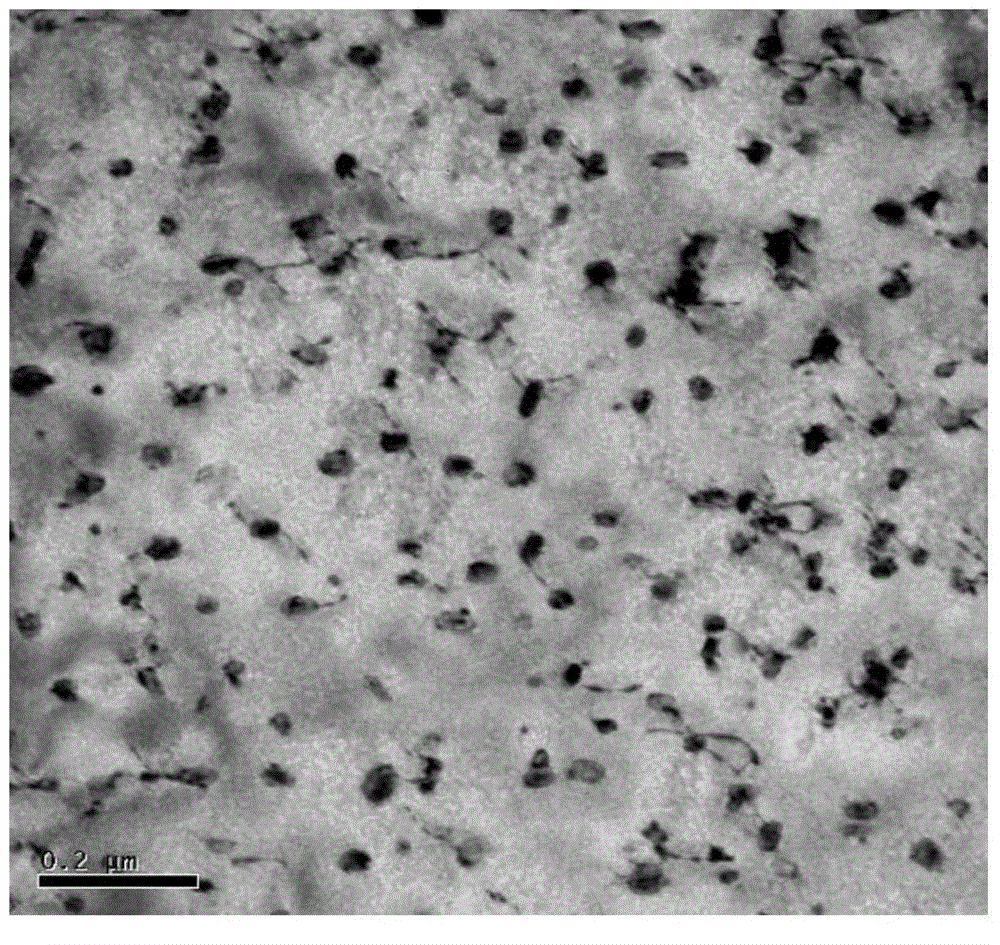

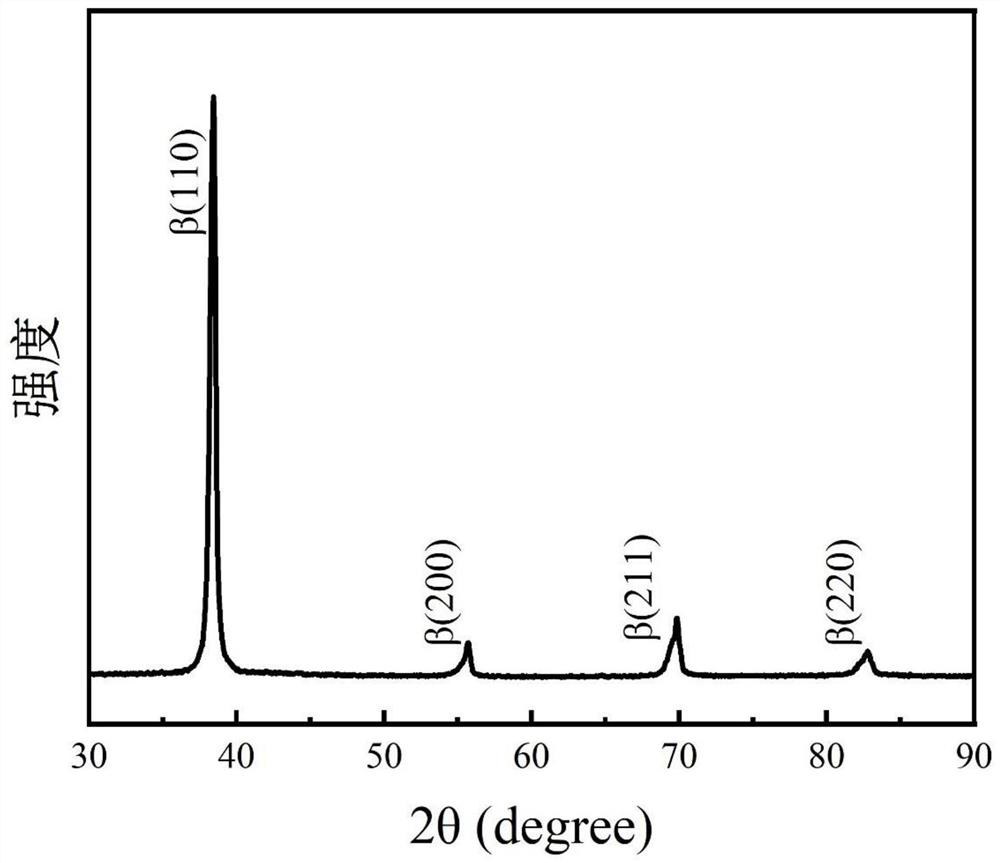

High-elasticity and high-strength titanium alloy and preparing method and application thereof

ActiveCN109628796ASimple ingredientsReduce the difficulty of smeltingResilient modulusValence electron

The invention discloses a high-elasticity and high-strength titanium alloy. The high-elasticity and high-strength titanium alloy comprises 6-18 wt% of Nb, 0.1-0.5 wt% of O and the balance Ti. The average valence electron concentration e / a of the titanium alloy is 4.08-4.12, wherein one value shown in the specification is 2.41-2.44, the other value shown in the specification is 2.80-2.83, the elasticity modulus is 60-80 GPa, the tensile strength is 850 MPa or above, and the structure of the titanium alloy is mainly alpha + beta two phases. The invention further discloses a preparing method andapplication of the high-elasticity and high-strength titanium alloy. The high-elasticity and high-strength titanium alloy has excellent mechanical performance, meanwhile, the smelting difficulty of the high-elasticity and high-strength titanium alloy is low, and important theoretical significance and engineering value are achieved.

Owner:BEIHANG UNIV

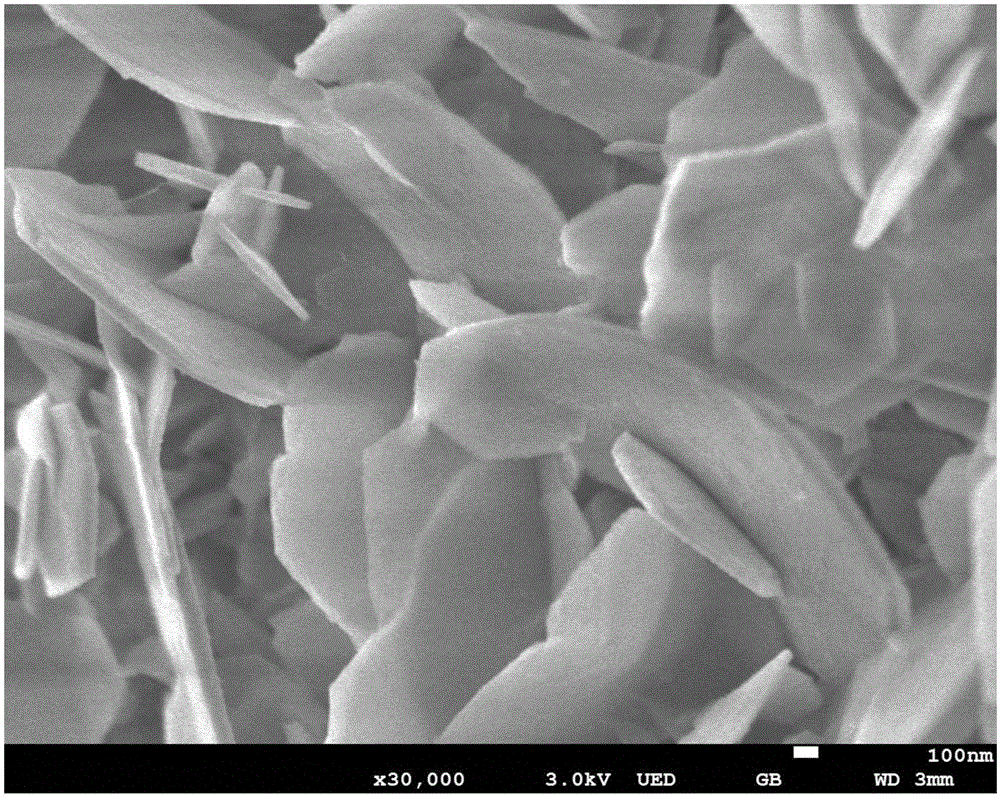

Preparation method for ZnO nanomaterial with hierarchical porous structure

InactiveCN104986793AUniform distribution of macroporesLow melting pointMaterial nanotechnologyZinc oxides/hydroxidesAlloyHierarchical porous

The invention discloses a preparation method for a ZnO nanomaterial with a hierarchical porous structure. The preparation method is characterized in that pure Zn metal and pure Al metal are smelted to obtain a smelted substance, the smelted substance is sucked into a pore-forming agent for suction casting molding, the molded substance is placed in a corrodent after being cleaned to be freely corrode to dealloy, and finally, the dealloyed substance is subjected to oxidation and sintering to obtain the ZnO nanomaterial with the hierarchical porous structure. The ZnO nanomaterial is prepared from non-noble metals and amphoteric metal Zn and amphoteric metal Al are used as two phases of an alloy. The melting points of the two metals are both low, the melting difficulties of the two metals are low, and the costs of the two metals are low; sodium chloride is subjected to sintering, grinding and sieving to form a macroporous pore-forming agent, the operation is simple and convenient, and the cost is low; a NaOH solution is taken as a corrodent during the process of freely corroding to dealloy; the ZnO nanomaterial with the hierarchical porous structure is prepared by adopting a method for freely corroding to dealloy; macropores in the prepared material are uniformly distributed, and the material is integral and complete and owns a certain mechanical property; the product is stable in air, and low in possibility of degeneration.

Owner:XIAN UNIV OF TECH

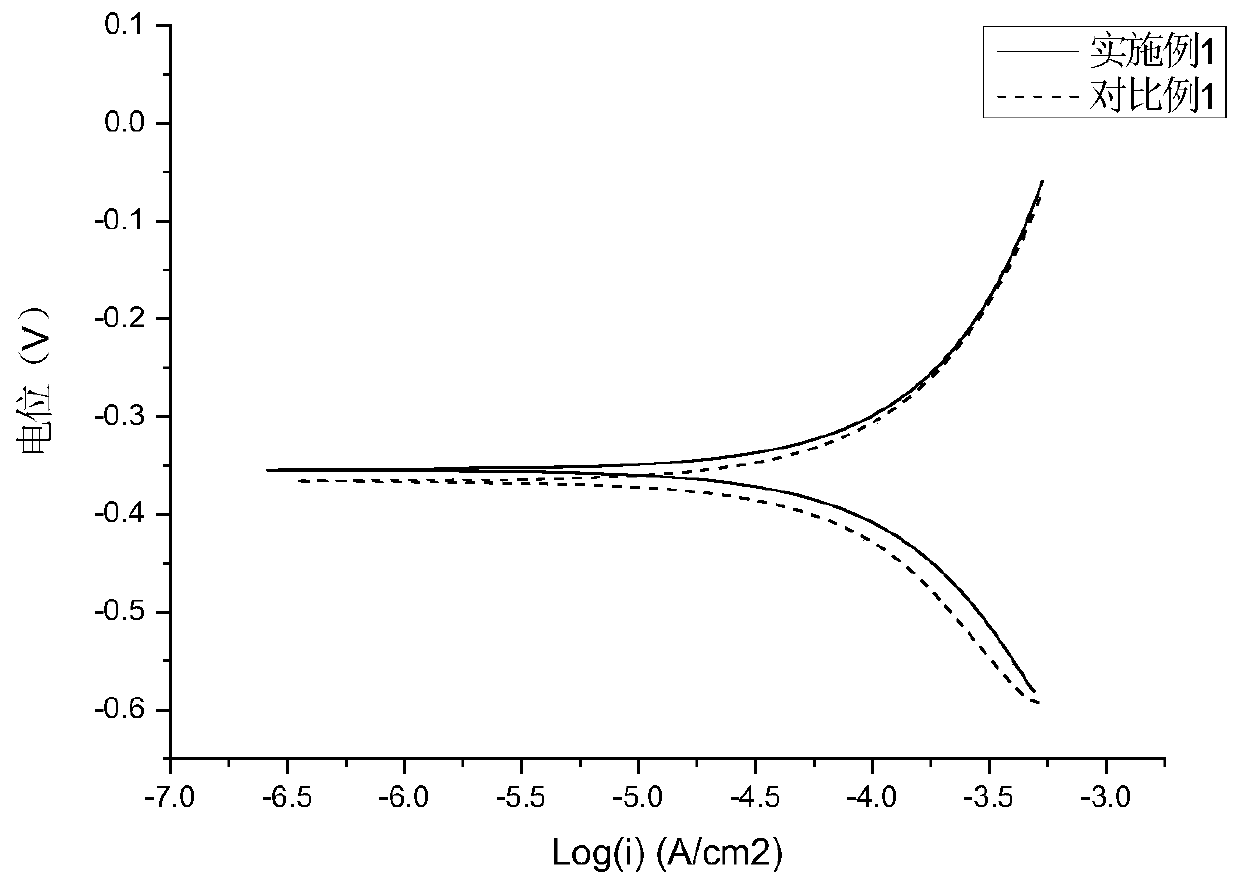

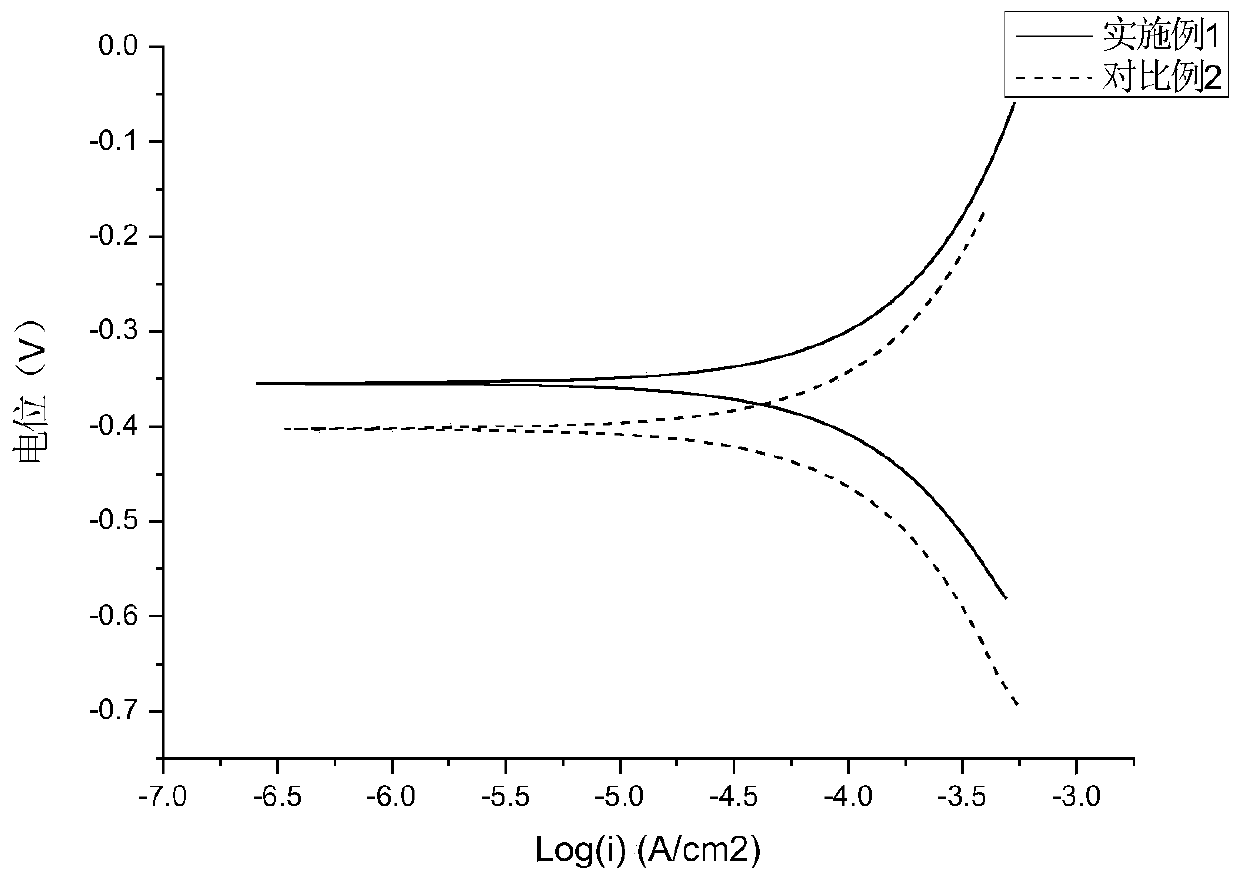

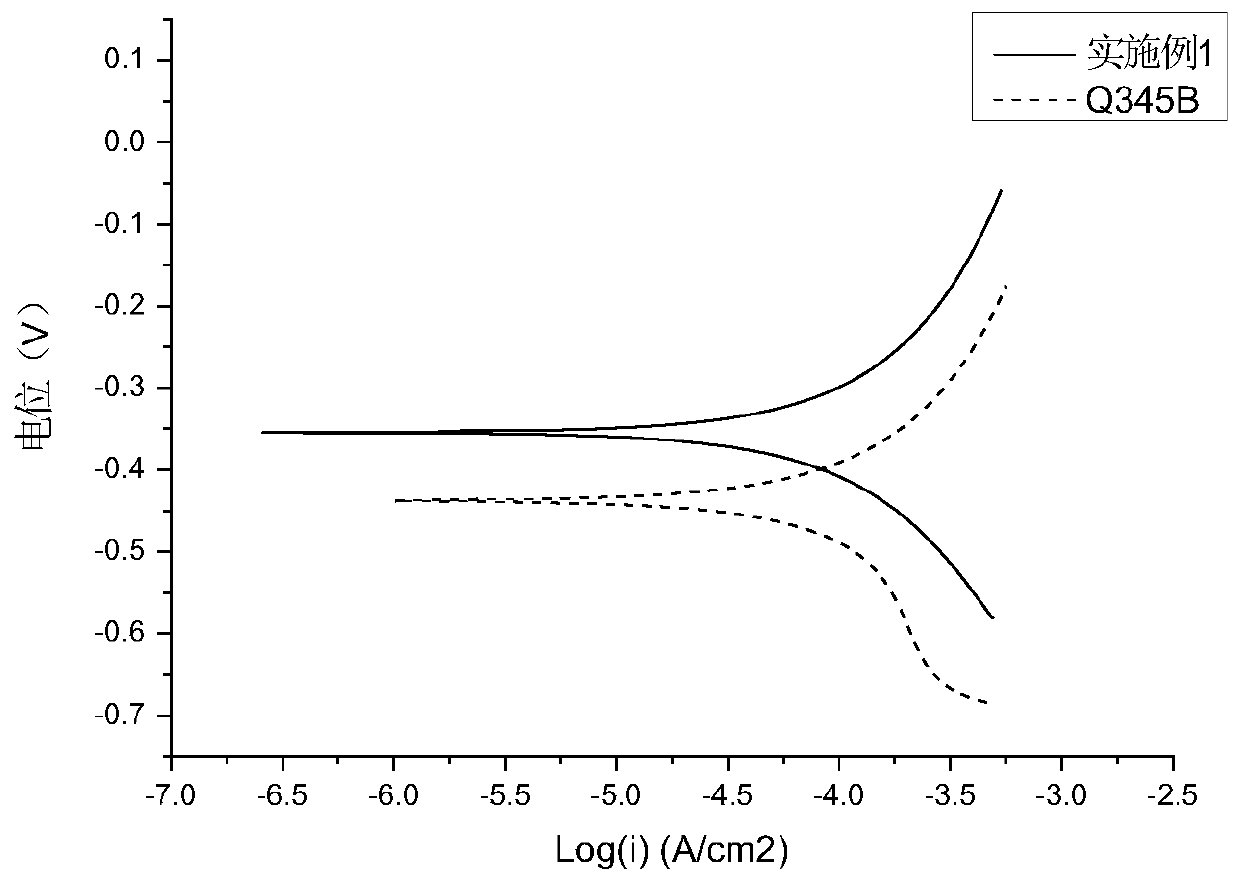

Weather-resistant steel and preparing method thereof

InactiveCN110551947AGood weather resistanceHigh strengthMetal rolling arrangementsChemical compositionLaminar cooling

The invention belongs to the field of ferrous metallurgy and particularly relates to weather-resistant steel and a preparing method thereof. For existing market demands, the weather-resistant steel low in cost and high in quality and the preparing method of the weather-resistant steel are developed. Chemical components of the weather-resistant steel include, by weight, 0.06-0.08% of C, 0.30-0.45%of Si, 1.10-1.25% of Mn, equal to or smaller than 0.020% of P, equal to or smaller than 0.005% of S, 0.20-0.30% of Cu, 0.50-0.60% of Cr, 0.20-0.30% of Ni, 0.020-0.030% of Nb, 0.03-0.05% of Sb, 0.18-0.20% of Al and the balance Fe and inevitable impurities. The preparing method of the weather-resistant steel comprises the steps of smelting, hot rolling, laminar cooling and reeling. The novel elementSb is introduced into the weather-resistant steel, the synergistic effect of the element Sb and the element Al is used for ensuring that the weather-resistant steel has good weather-resistant performance, the weather-resistant performance comparative to that of an S450AW grade can be achieved, and the strength of the weather-resistant steel is high and can reach 450 MPa or above. The content of high-cost alloy elements such as Cr is reduced, cost is reduced, the smelting difficulty is lowered, and the weather-resistant steel and the preparing method thereof are suitable for utilization and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

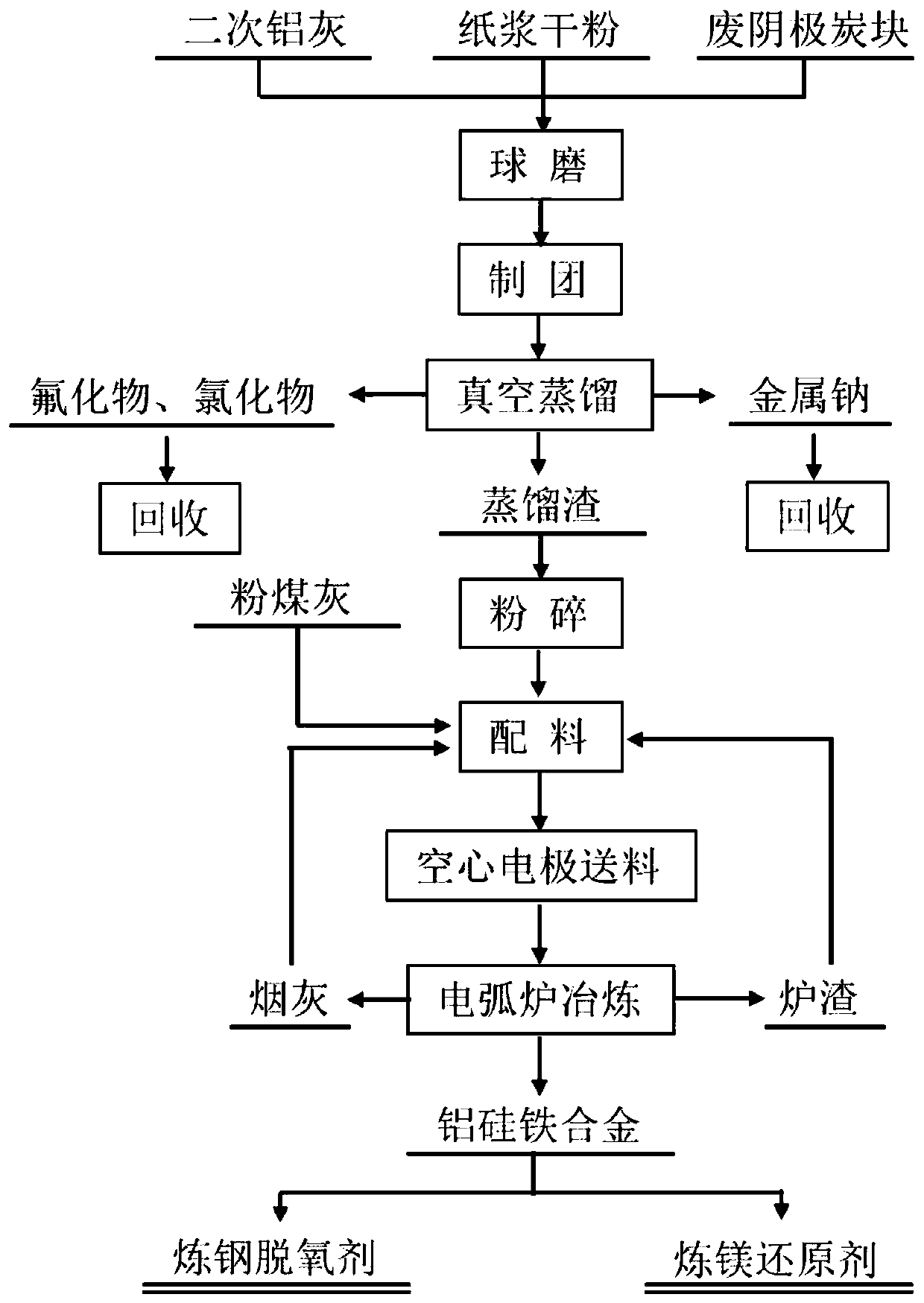

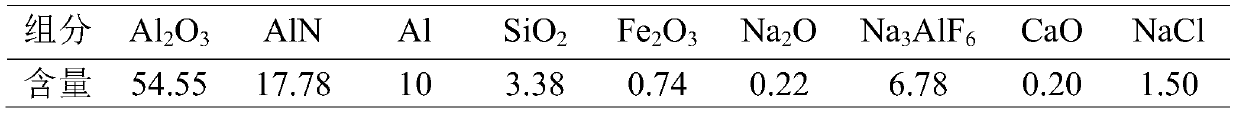

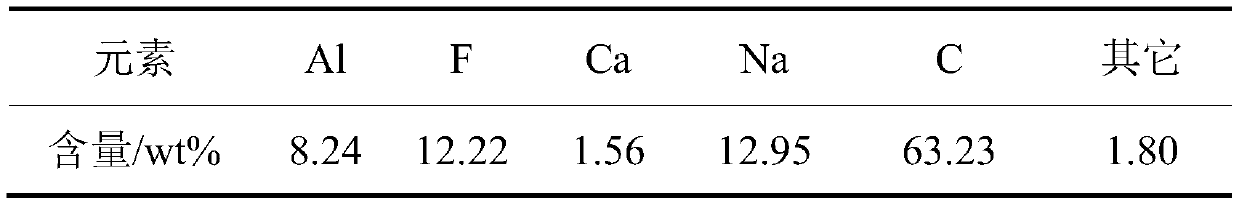

Method for preparing aluminum-silicon-iron alloy by virtue of aluminum-ash pre-treatment carbothermic reduction

ActiveCN110144457ARealize high temperature volatile separationEasy to cause secondary pollutionProcess efficiency improvementElectric arc furnaceDecomposition

The invention provides a method for preparing an aluminum-silicon-iron alloy by virtue of aluminum-ash pre-treatment carbothermic reduction. The method comprises the following steps that secondary aluminum ash, waste cathode carbon blocks and paper pulp dry powder are uniformly mixed and are made into powder, then the mixture is pressed into pellets, and is subjected to high-temperature vacuum distillation, so that fluoride and chloride in the aluminum ash as well as fluoride and metal sodium in the waste cathode carbon blocks are volatilized and then are separated from the aluminum ash and the waste cathode carbon blocks respectively, and meanwhile, cyanide in the waste cathode carbon blocks is decomposed; then distillation residues are smashed, the smashed distillation residues are matched and mixed with fly ash, high-temperature reduction is conducted on a material mainly composed of aluminum oxide and silicon dioxide in an electric arc furnace by taking fixed carbon in the waste cathode carbon blocks as a reducing agent so as to prepare the aluminum-silicon-iron alloy with certain components; and meanwhile, decomposition of aluminum nitride in the aluminum ash and complete decomposition of the cyanide in the waste cathode carbon blocks are completed in the high-temperature reduction process, and the comprehensive utilization of various kinds of dangerous waste and solid waste is realized in the same process.

Owner:NORTHEASTERN UNIV

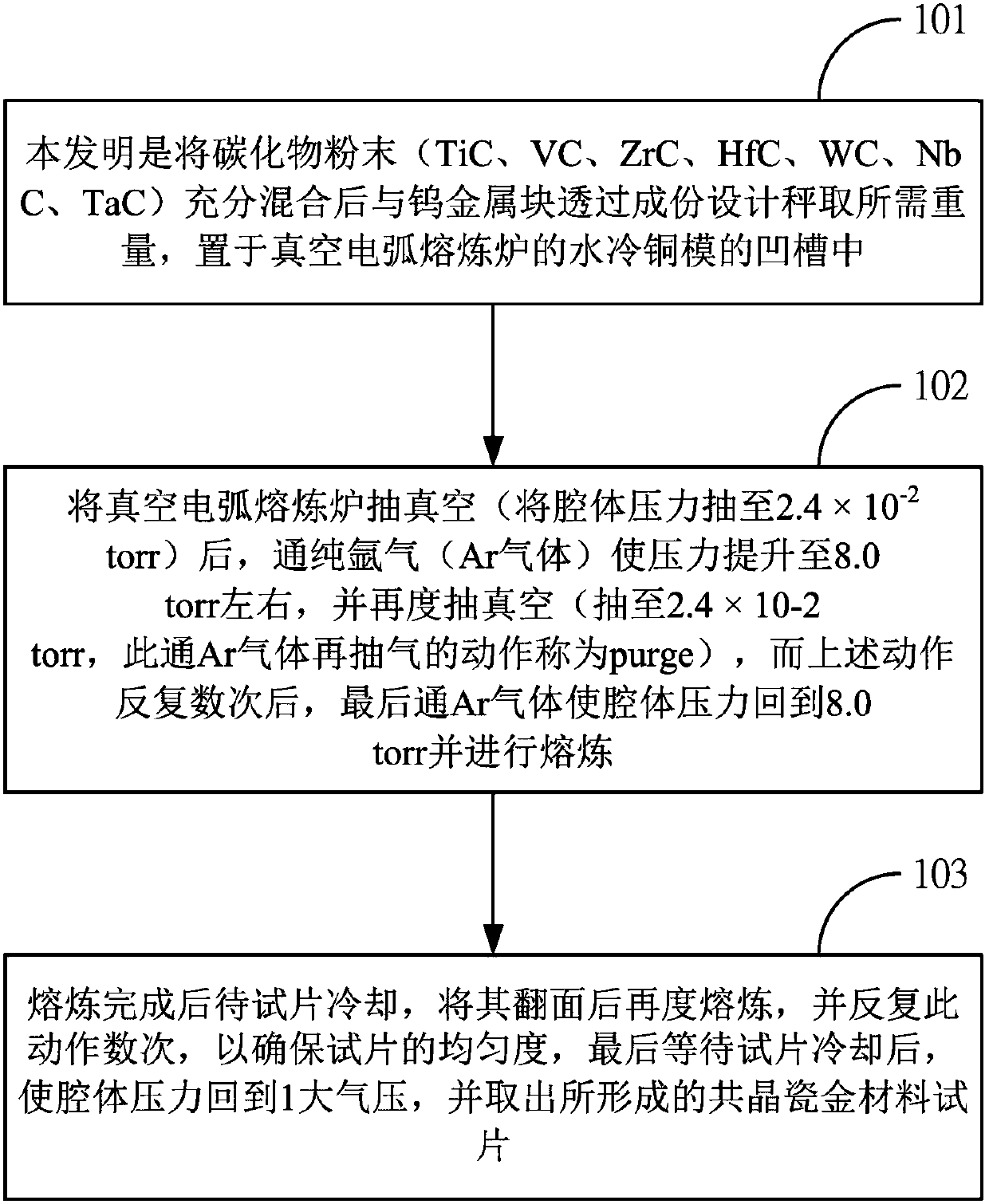

Eutectic cermets

Eutectic cermet materials include at least two carbides and a refractory metal, wherein the carbide is selected from the group of TiC, VC, ZrC, HfC, WC, NbC and TaC, and the refractory metal is tungsten. The disclosed eutectic cermet material prepared is by smelting the carbide and the refractory metal together at a temperature lower than melting temperatures of the carbide and the refractory material. The melting temperature lowered by forming a eutectic composition is to prepare the eutectic cermet materials having a fine lamellar structure. The prepared eutectic cermet materials improve hardness and toughness at use.

Owner:陈瑞凯

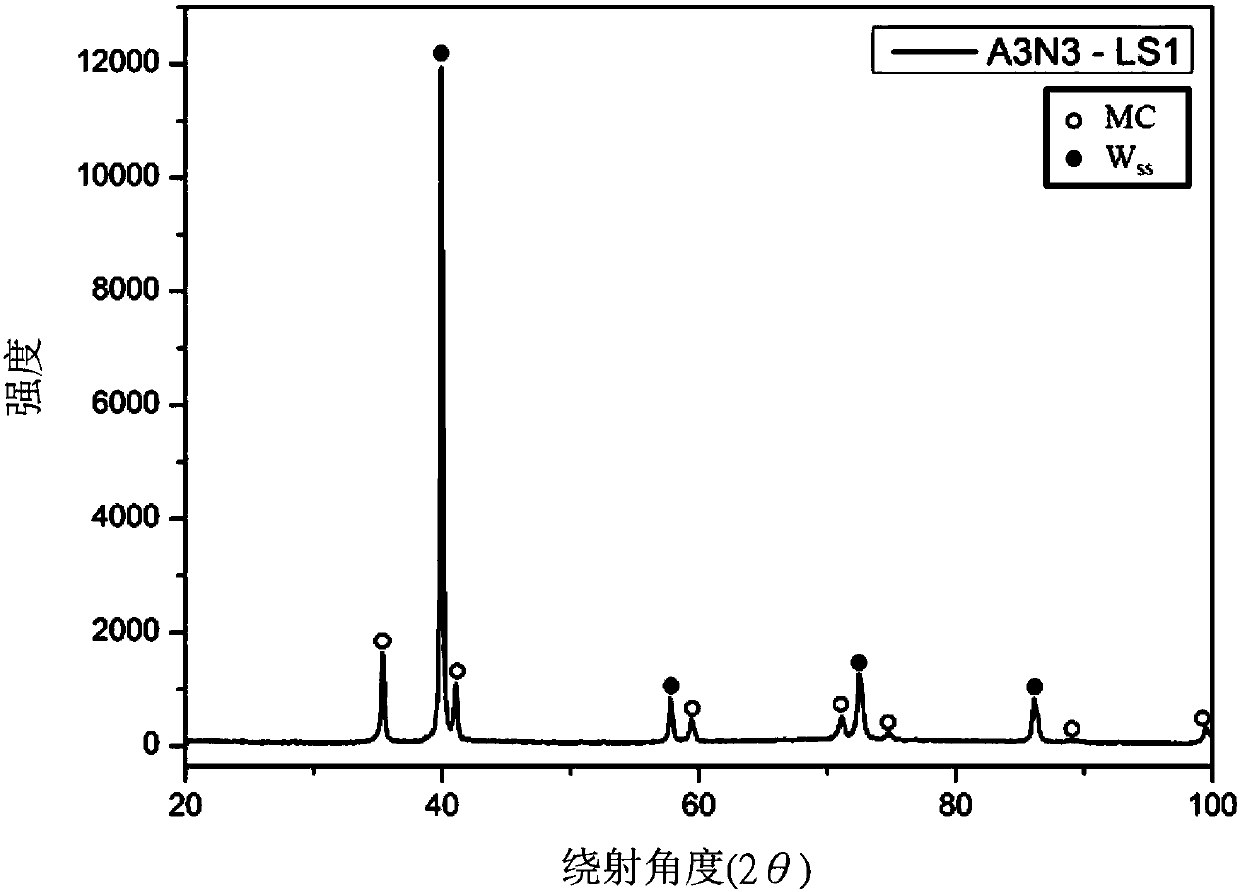

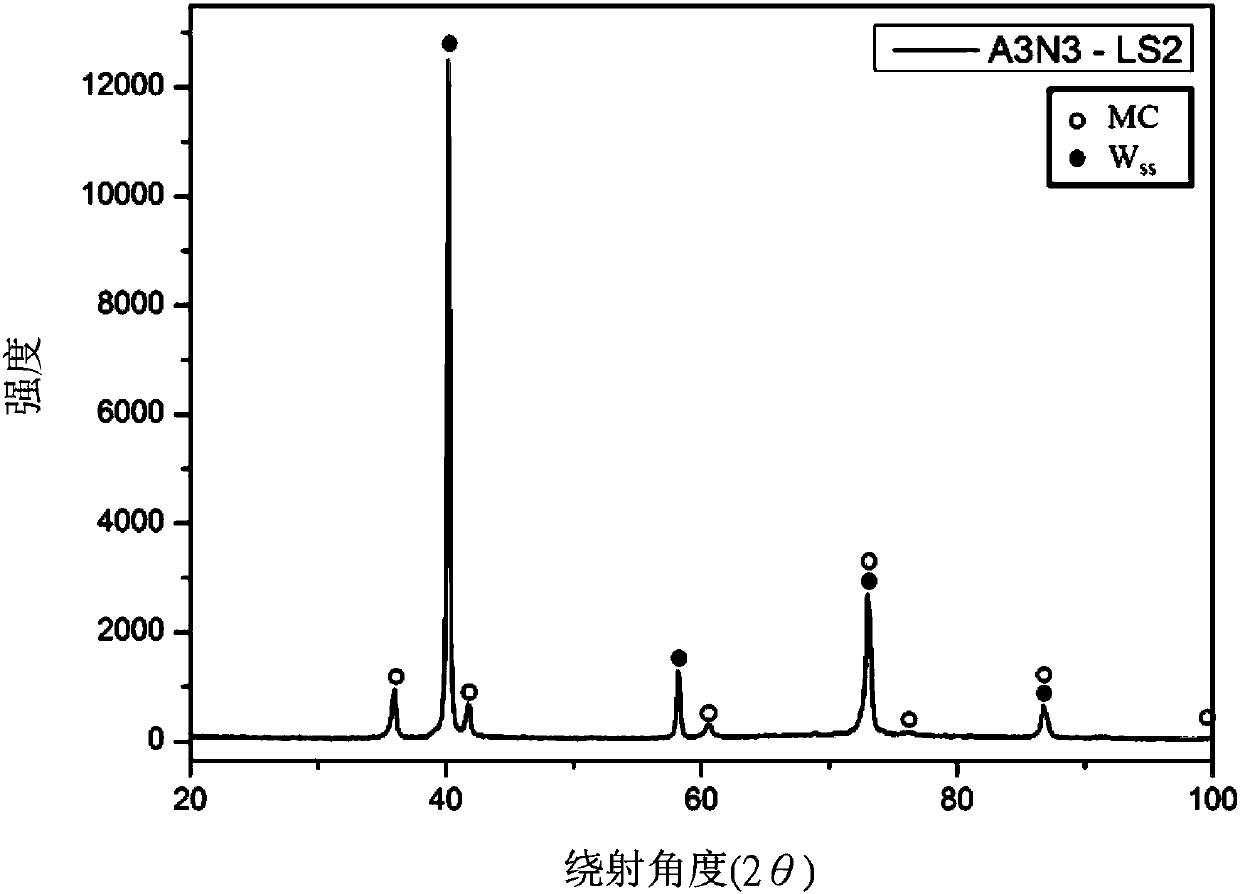

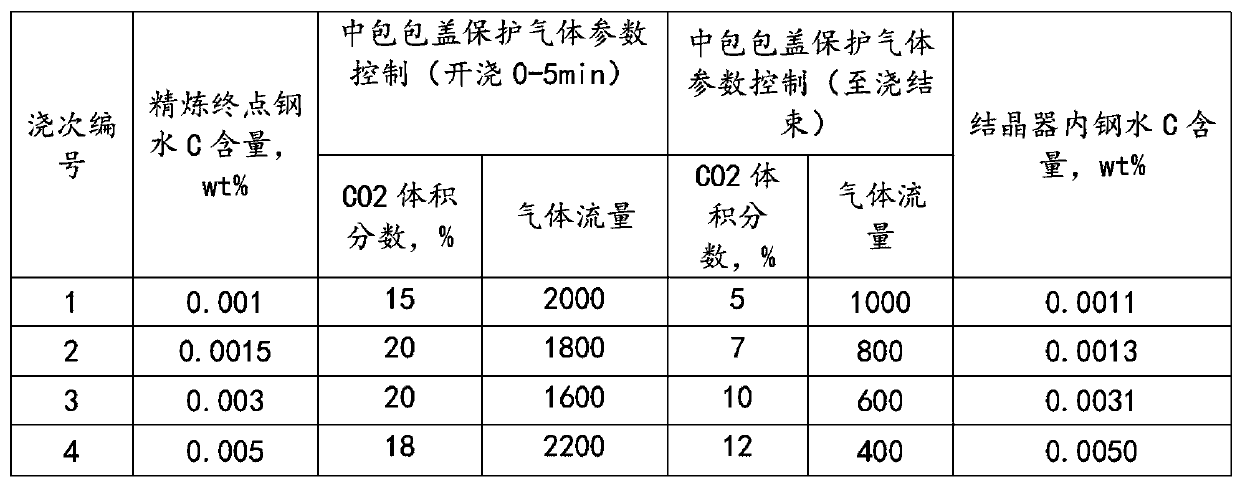

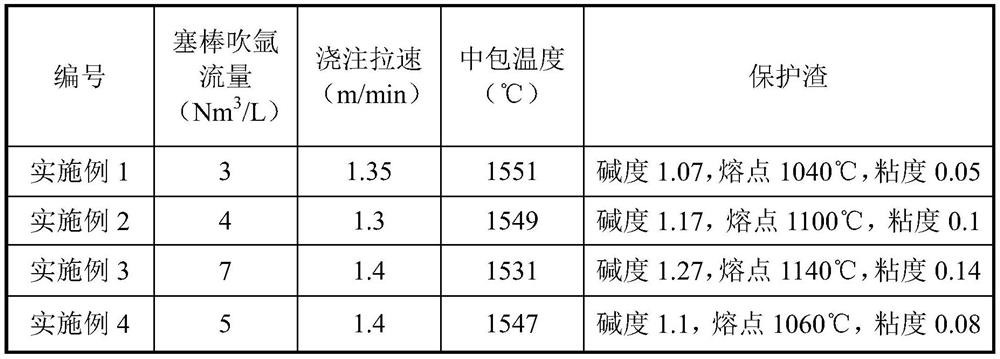

Tundish protection casting method for ultra-low carbon steel

ActiveCN110976787AReduce the difficulty of smeltingReduce carbon removal pressureCarbon steelTundish

The invention discloses a tundish protection casting method for ultra-low carbon steel. The tundish protection casting method comprises the following steps that S1, ultra-low carbon steel is cast, andduring casting, a tundish cover blowing device blows out mixed gas of carbon dioxide and argon; S2, when casting is started for 0-5min, the flow of the carbon dioxide gas in the mixed gas of the carbon dioxide and the argon blown out by the tundish cover blowing device is 1500-2500Nl / min; and S3, after the casting time is 5min, casting is finished, the volume fraction of the carbon dioxide gas is5%-15%, and the gas flow is 200-1500Nl / min. According to the method, the 5%-30% carbon dioxide gas is mixed in the tundish cover protection gas argon, the carbon dioxide gas enters molten steel to react, and carbon monoxide bubbles float up in the molten steel to be discharged. The carbon dioxide gas can consume carbon in the steel under the casting temperature condition, the concentration of thegenerated carbon monoxide gas is extremely low, and the carbon monoxide gas is fully burnt out when escaping out of a tundish, and the safety problem cannot be caused.

Owner:SHOUGANG CORPORATION

Non-magnetic stainless steel with high strength and toughness, manufacturing method and application thereof

The invention provides non-magnetic stainless steel with high strength and toughness, a manufacturing method and application thereof. The stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.04 percent of C, 0.35 to 0.65 percent of Si, 17.00 to 22.00 percent of Mn, 13.00 to 17.00 percent of Cr, 0.30 to 0.50 percent of Mo, 0.15 to 0.45 percent of Ni, 0.30 to 0.80 percent of N, less than or equal to 0.03 percent of P, less than or equal to 0.005 percent of S, and the balance being Fe and inevitable impurities. The steel improves the rust resistance and corrosion resistance of the stainless steel by adopting a low-carbon and high-chromium content design, reduces the nickel content by replacing the nickel with manganese and nitrogen at the same time, and reduces production cost. The steel is smelted by adopting an EAF, AOD and LF method, the forging process is divided into two temperature stages, the steel is treated by adopting different deformation amounts, and the method is simple and convenient to apply and has good effect. The invention also provides application of the stainless steel in a petroleum drill.

Owner:宝武特种冶金有限公司

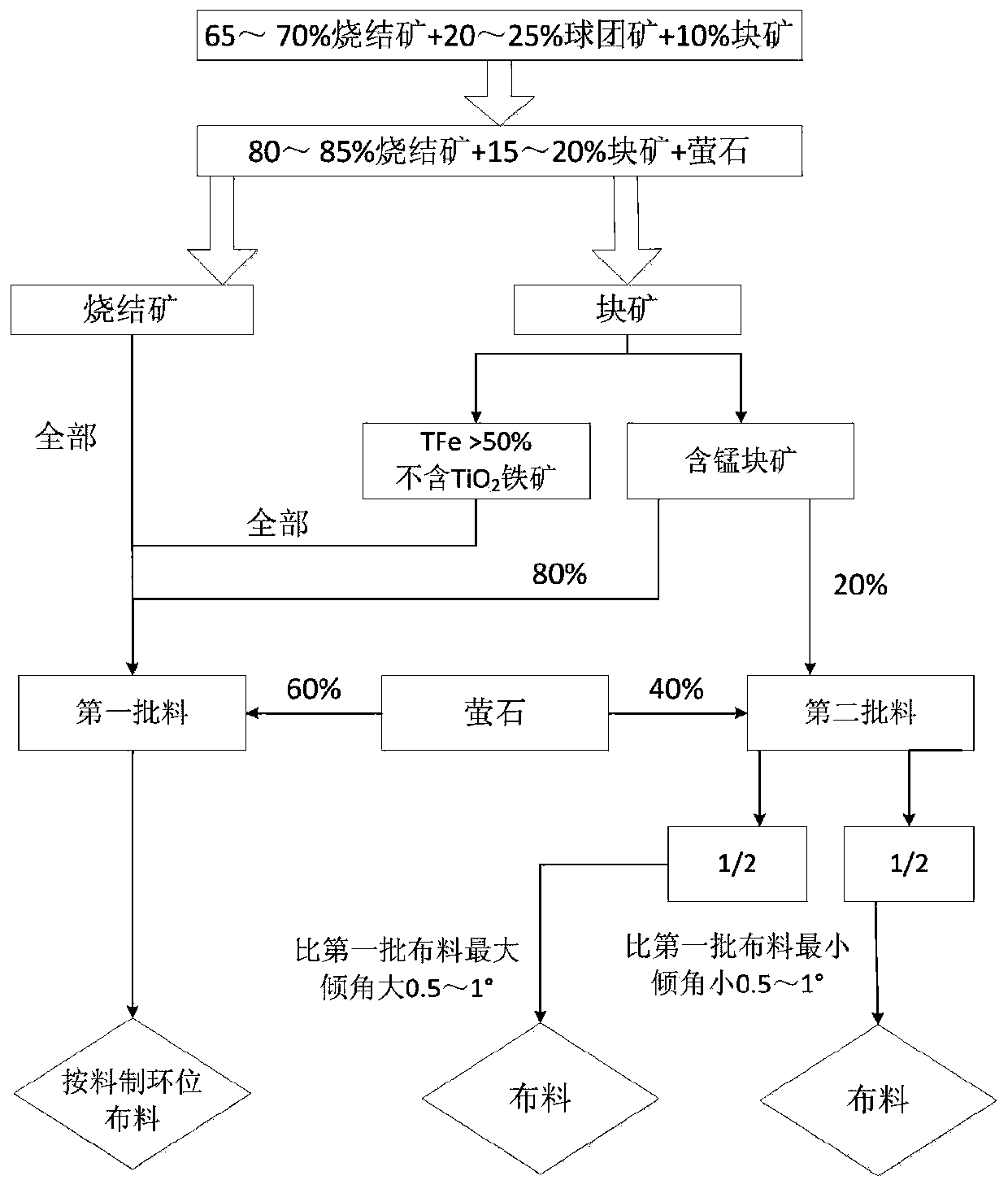

Vanadium-titanium magnetite blast furnace smelting method

ActiveCN110724776AImprove breathability and liquid permeabilityImprove metallurgical performanceBlast furnace detailsBlast furnace smeltingTitanomagnetite

The invention discloses a vanadium-titanium magnetite blast furnace smelting method, and belongs to the technical field of blast furnace smelting. The vanadium-titanium magnetite blast furnace smelting method is provided to eliminate the situation that furnace conditions of vanadium-titanium magnetite blast furnace smelting is not smooth. By adjusting magnetite distribution, a slagging system, a heat system and an air supply system, the fluidity of slag iron is improved, the working state of a furnace cylinder is stabilized, the gas permeability and liquid permeability of a material column areimproved, reasonable distribution of blast furnace gas flow is promoted, and rapid recovery of the furnace conditions of a blast furnace is promoted.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

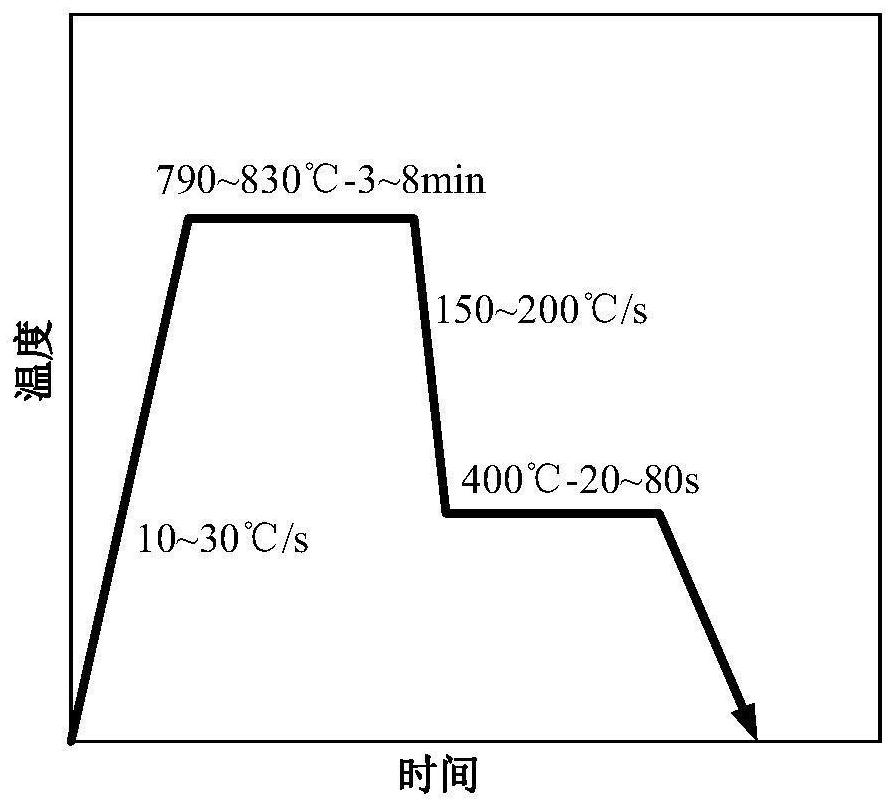

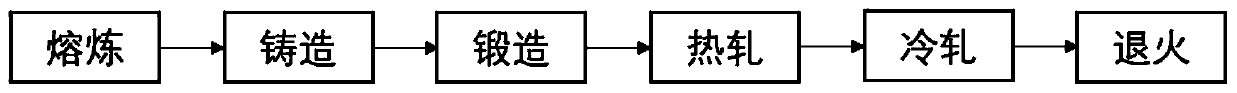

Aluminum-containing cold rolling ultrahigh strength steel as well as preparation method and application thereof

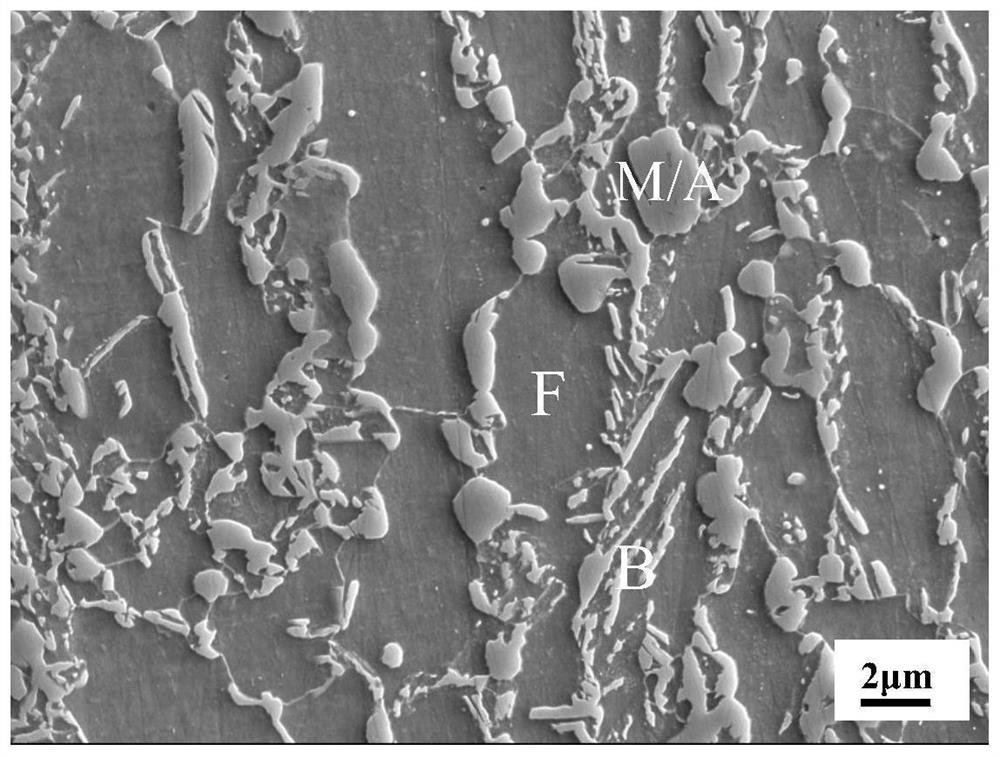

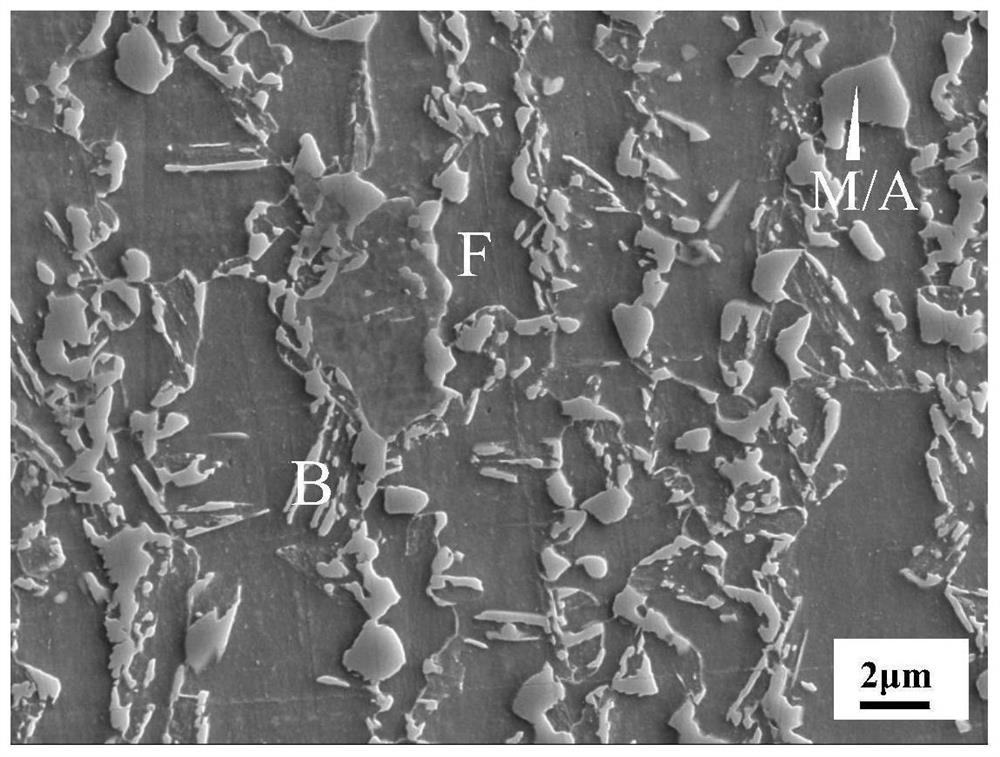

The invention discloses aluminum-containing cold rolling ultrahigh strength steel as well as a preparation method and application thereof and belongs to the technical field of material thermal treatment. The cold rolling ultrahigh strength steel is composed of polygonal ferrite, bainite and martensite / austenite islands; the martensite / austenite islands are composed of twin crystal martensite and retained austenite; the cold rolling ultrahigh strength steel is obtained through short overaging treatment; the time of short overaging treatment is 20-80 s, and the temperature of short overaging treatment is 400 DEG C; the preparation method comprises the following steps: smelting, forging, hot rolling, cold rolling, and thermal treatment; and during the thermal treatment process, two-phase region annealing is adopted to raise the temperature to 790-830 DEG C at the heating rate of 10-30 DEG C / s, thermal insulation is carried out for 3-8 minutes, the temperature is cooled to 400 DEG C at therate of 80-150 DEG C / s, then, short overaging treatment is carried out for 20-80 s, and the temperature is cooled to the room temperature. With adoption of the preparation method, high-strength and high-plasticity automobile steel is prepared through short overaging treatment, so that production energy consumption is greatly reduced, the cost is decreased, and the product competitiveness is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

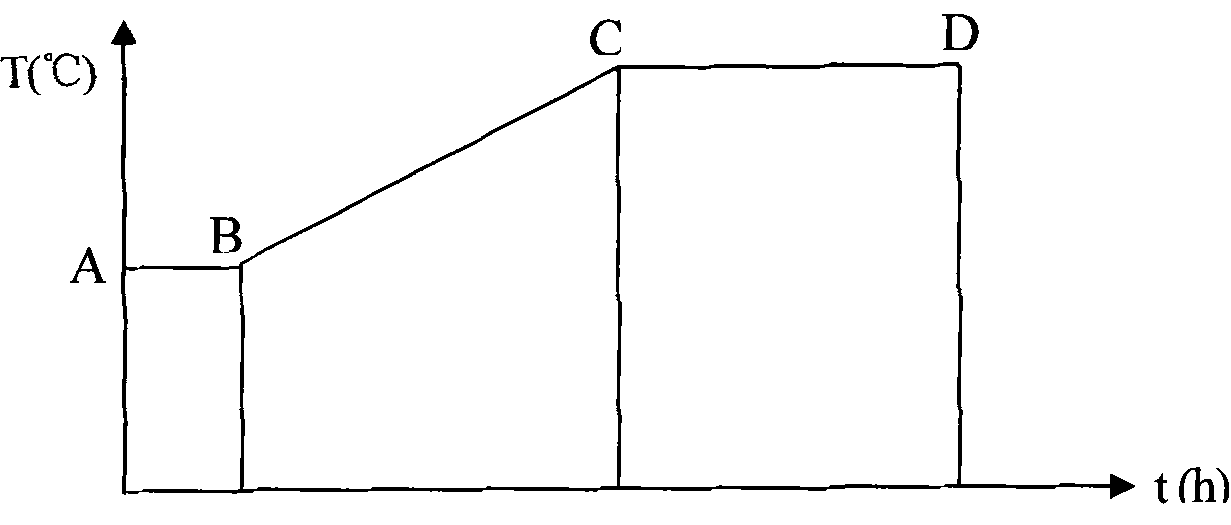

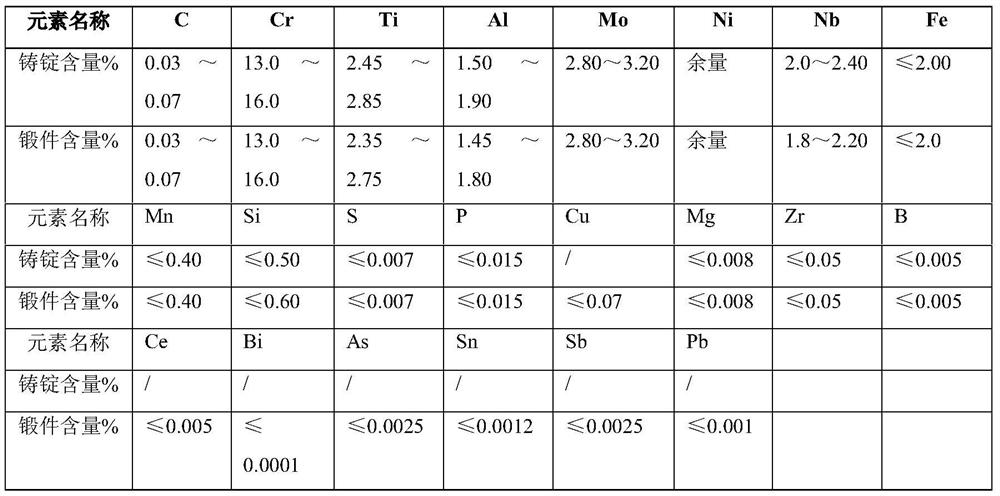

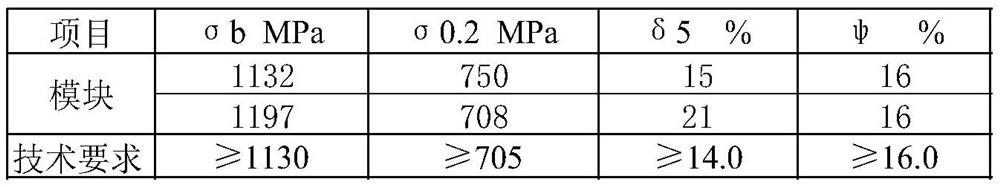

Preparation method of GH4698 high-temperature alloy mold

ActiveCN112410618AWide range of chemical compositionReduce the difficulty of smeltingIngotSuperalloy

The invention relates to a preparation method of a GH4698 high-temperature alloy mold, and belongs to the technical field of alloy materials. The preparation method of the GH4698 high-temperature alloy mold comprises the following steps: heating a cast ingot to the temperature of 1160-1180 DEG C for first forging, wherein the total deformation in the forging process is below 20%; heating the castingot to the temperature of 1160-1180 DEG C for second forging, wherein the total deformation in the forging process is below 25%; heating the cast ingot to the temperature of 1160-1180 DEG C for third forging, wherein the total deformation in the forging process is below 35%; peeling the cast ingot after third forging to obtain a bar; carrying out three-time upsetting on the obtained bar at the temperature of 1140-1160 DEG C to finish module manufacturing, wherein the upsetting deformation of the bar is not higher than 40% during three-time upsetting; after upsetting is completed, rounding the bar to eliminate bulging influence; and carrying out heat treatment and finish machining to obtain the GH4698 high-temperature alloy mold. By the mold prepared by the method, the cost is greatly reduced.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

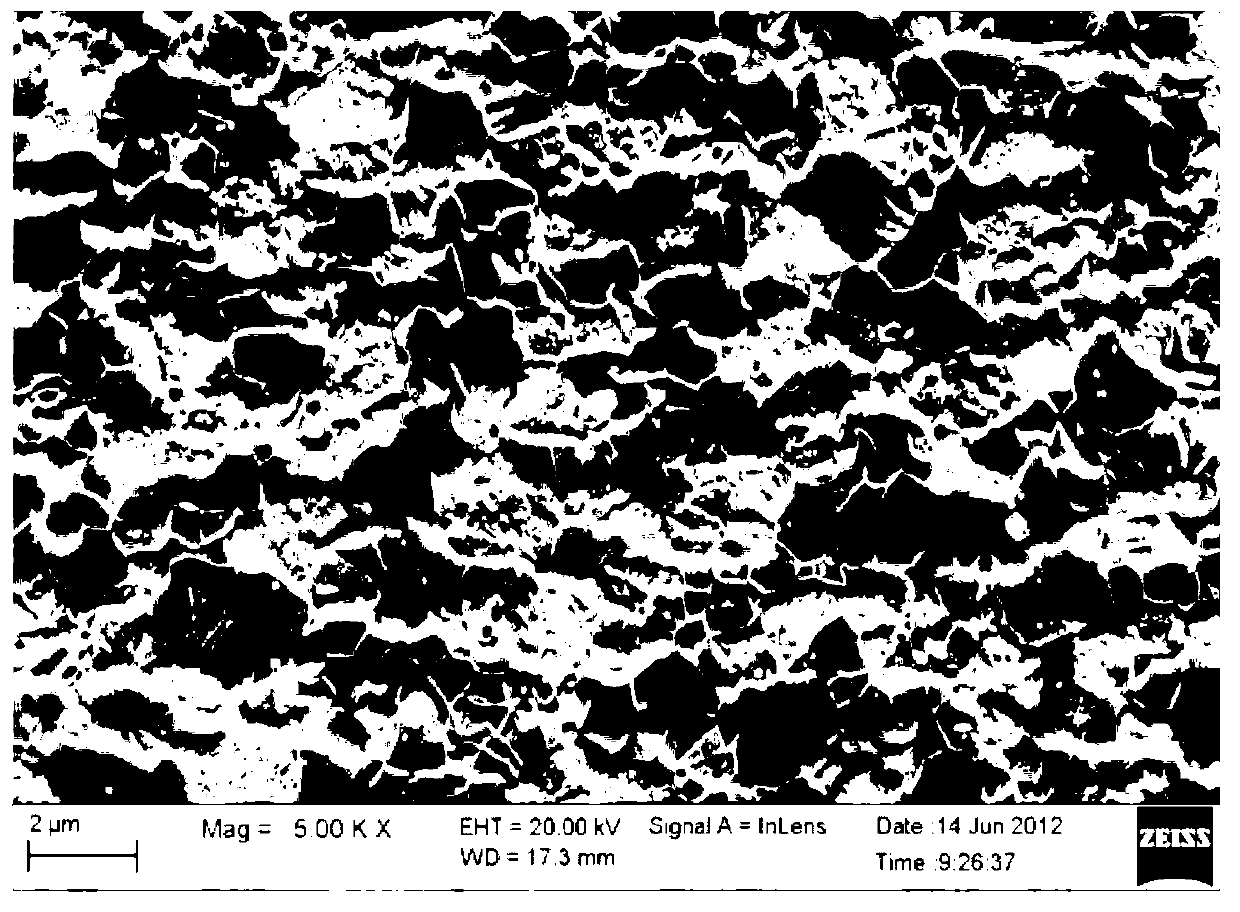

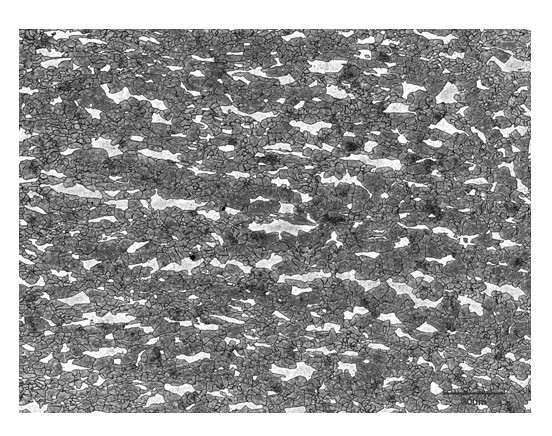

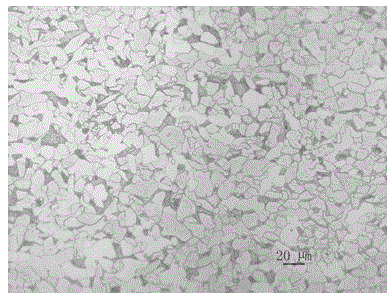

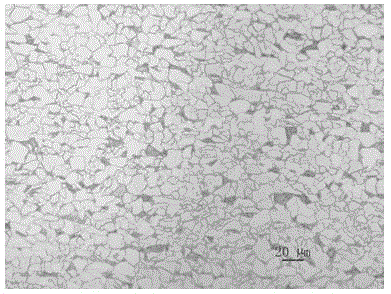

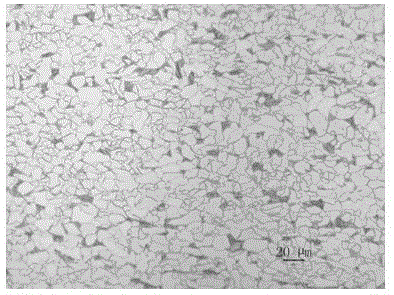

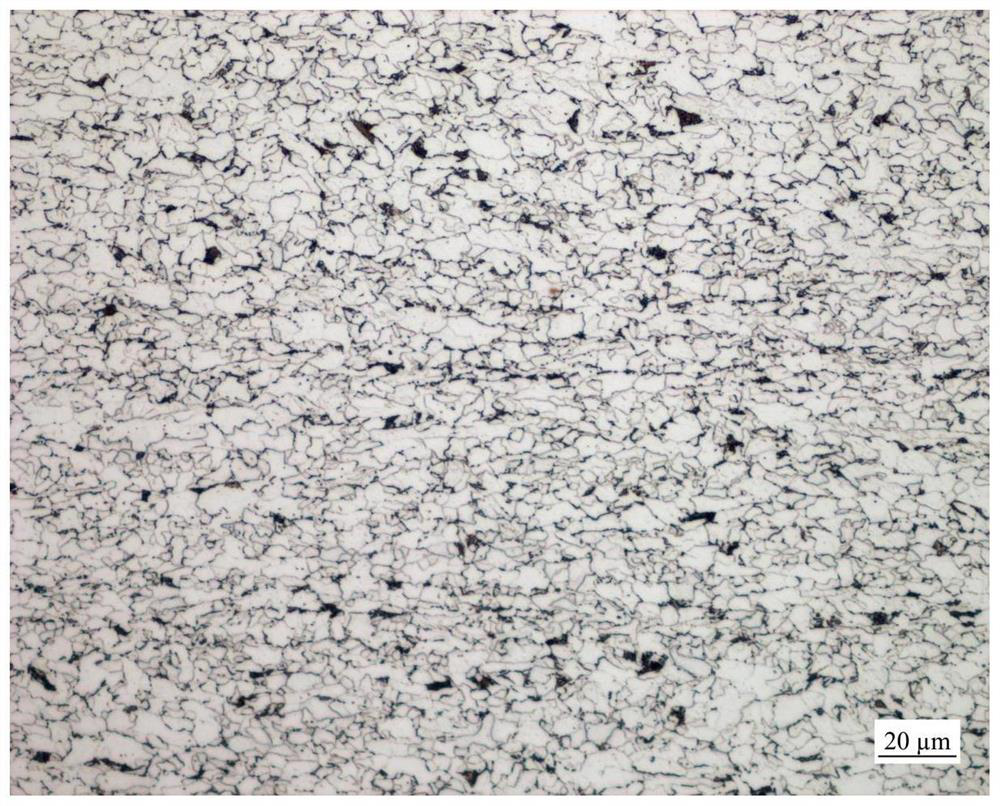

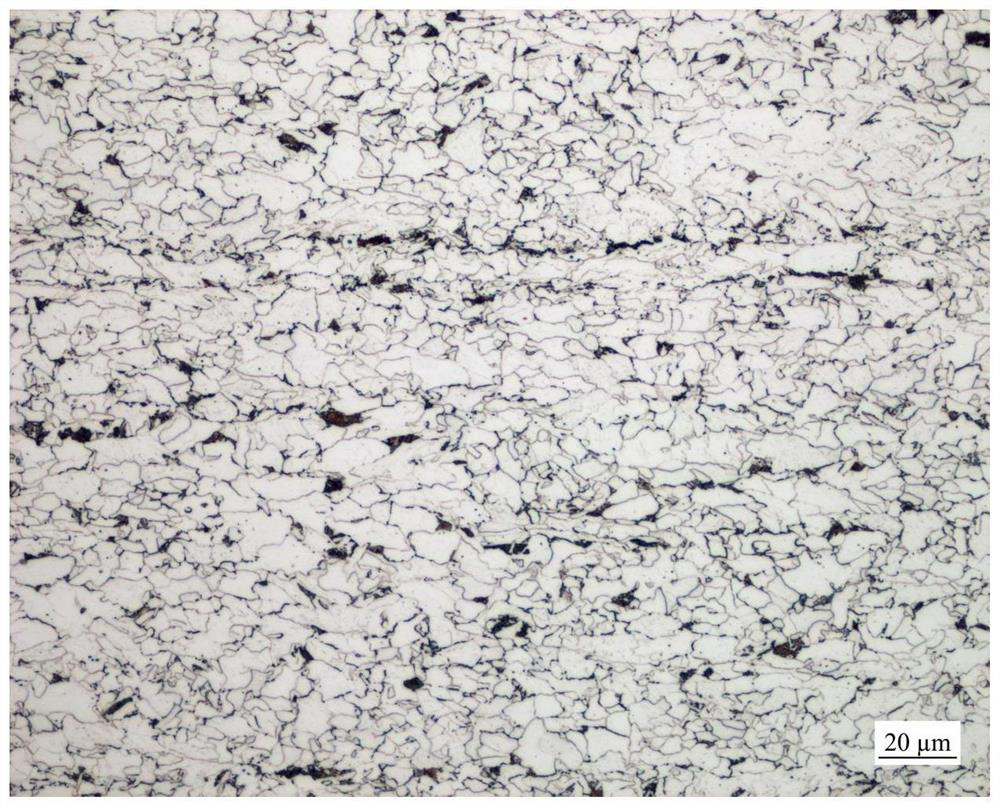

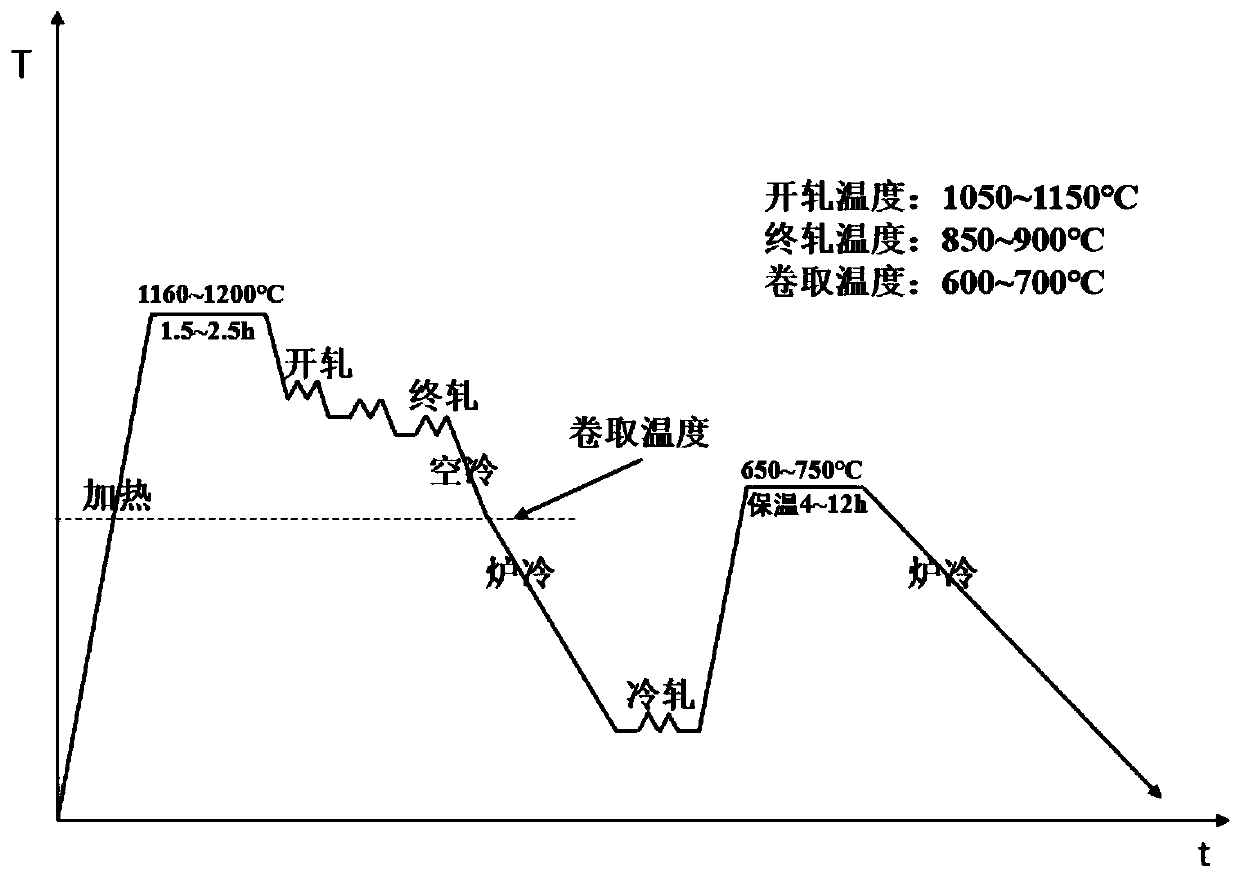

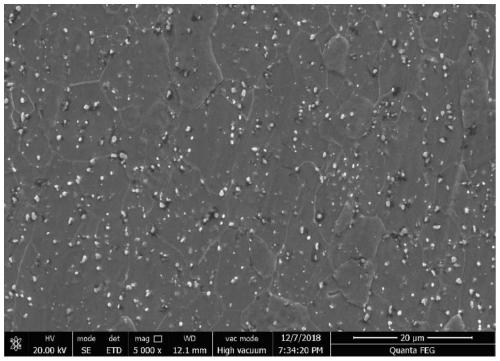

A kind of cake-shaped grain deep-drawing dual-phase steel plate and preparation method thereof

The invention discloses a cake-shaped crystal grain deep-draw double-phase steel plate and a preparation method thereof, belonging to the field of a metal material rolling technology. The cake-shaped crystal grain deep-draw double-phase steel plate comprises the chemical components by weight percent: 0.01-0.05% of C, 0.1-0.4% of Si, 1.2-1.7% of Mn, 0.1-0.4% of Cr, 0.03-0.07% of Als, 0.003-0.006% of N, less than or equal to 0.02% of P, less than or equal to 0.01% of S and the balance of Fe and unavoidable trace impurities. The preparation method of the steel plate comprises the steps of firstly, smelting raw material and refining the raw material in a heating steel ladle; casting the refined raw material into a plate blank by continuous casting, and then carrying out hot rolling on the plate blank; carrying out acid pickling and then rolling the plate blank into a sheet by cold rolling; carrying out cover annealing, cooling to the room temperature and then carrying out continuous annealing; finally, carrying out overaging treatment and cooling the product to the room temperature to obtain the cake-shaped crystal grain deep-draw double-phase steel plate. Compared with a piece of equiaxed grain double-phase steel with the same performances, the cake-shaped crystal grain deep-draw double-phase steel plate has better stamping forming property. Compared with the existing deep-draw double-phase steel, the cake-shaped crystal grain deep-draw double-phase steel plate is low in production cost, higher in practicability and better in plate shape and surface quality.

Owner:安徽工业大学科技园有限公司

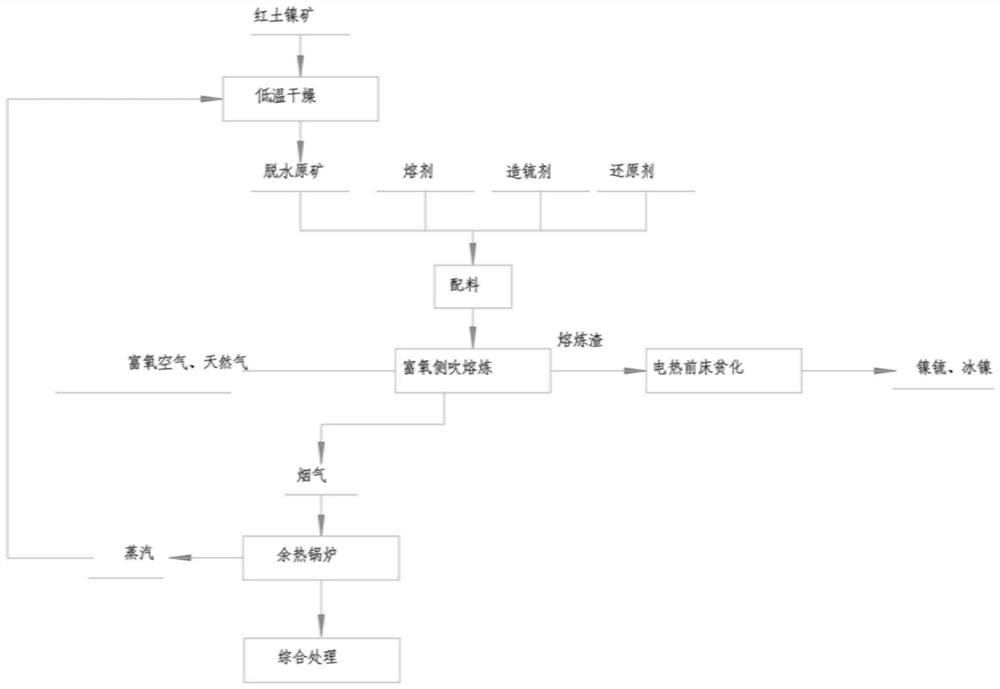

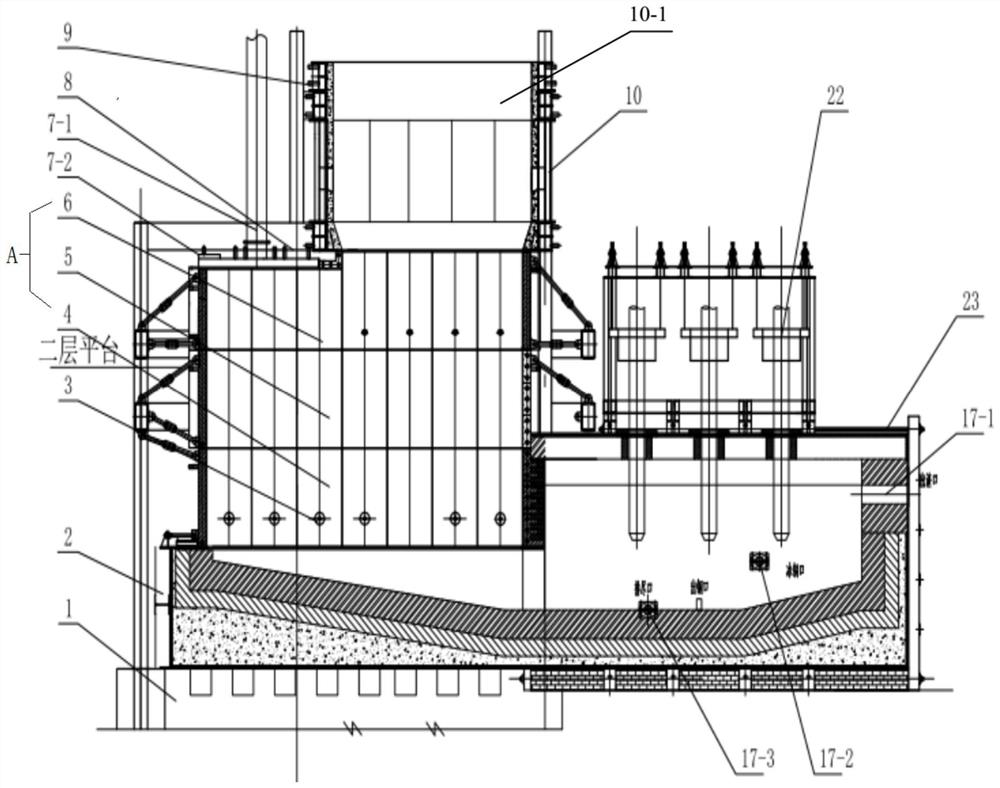

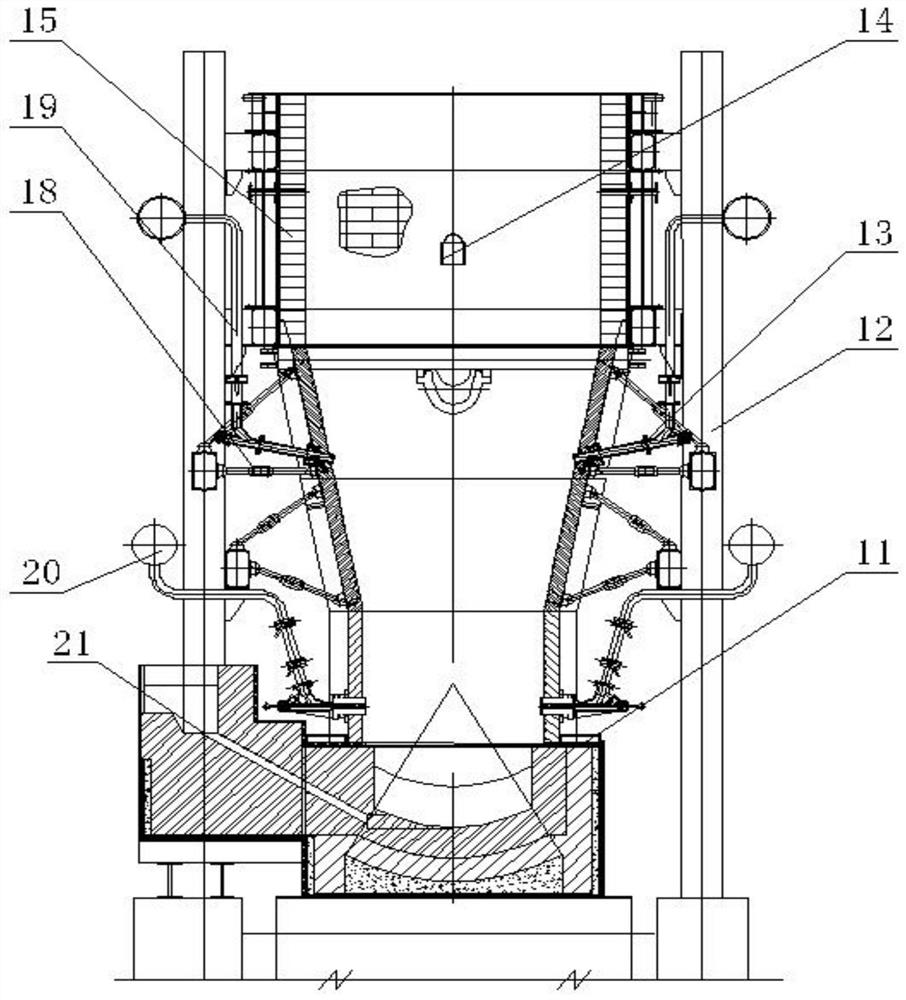

Smelting furnace and smelting method for extracting valuable metals from laterite-nickel ore

InactiveCN111996391ASimple smelting processLess economic valueCharge manipulationCharge treatment typeMining engineeringLaterite

The invention relates to a smelting furnace and a smelting method for extracting valuable metals from laterite-nickel ore. The smelting furnace comprises a furnace body with a furnace chamber, the furnace body is sequentially divided into a hearth section, a furnace body section and a furnace top section from bottom to top; the bottom side of the hearth section is in communication with an electricheating fore well, the electric heating fore well is provided with a deslagging port and a siphon port, the position of the inner end of the siphon port is lower than the position of the inner end ofthe deslagging port, and the bottom area of an inner cavity of the electric heating fore well is 1 / 2-3 / 2 of the bottom area of an inner cavity of the hearth section; the inner bottom face of the hearth section inclines in the direction where the electric heating fore well is located, and the included angle between the inner bottom face of the hearth section and the horizontal plane is 5degrees-20degrees. After the laterite-nickel ore, the additive, the flux and the like are mixed, the mixture can be directly smelted in a smelting furnace, pelletizing treatment is not needed, and the smeltingprocess is simplified. The smelting furnace can be used for carrying out direct, efficient and low-energy-consumption oxygen-enriched smelting on the low-grade laterite-nickel ore to generate nickelmatte, nickel matte and the like with economic values.

Owner:湖南锐异资环科技有限公司

Axle housing steel for cold stamping of 590mpa thick specification and preparation method thereof

The invention discloses an axle housing steel for cold stamping with a thickness of 590 MPa and a preparation method thereof, and belongs to the technical field of hot continuous rolling strip production. 590MPa grade axle housing steel for cold stamping, its chemical composition is: C0.07‑0.10%, Si0.05‑0.10%, Mn1.50‑1.60%, P≤0.020%, S≤0.008%, Nb0. 030‑0.040%, V0.07‑0.10%, N0.010‑0.015%, Als 0.015‑0.050%, and the balance is Fe and inevitable impurities. The preparation method is as follows: smelting into slabs according to the chemical composition of the axle housing steel for cold stamping with a thickness of 590 MPa, and sequentially heating the slabs, rough rolling, finishing rolling, coiling and cooling, to obtain a slab for cold stamping with a thickness of 590 MPa. Axle steel. The product of the invention has yield strength ≥460MPa, tensile strength ≥590MPa, elongation after fracture ≥20%, full-size-40°C impact energy KV2 ≥80J, and can effectively solve the problem of high production cost of existing high-strength axle housing steel .

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

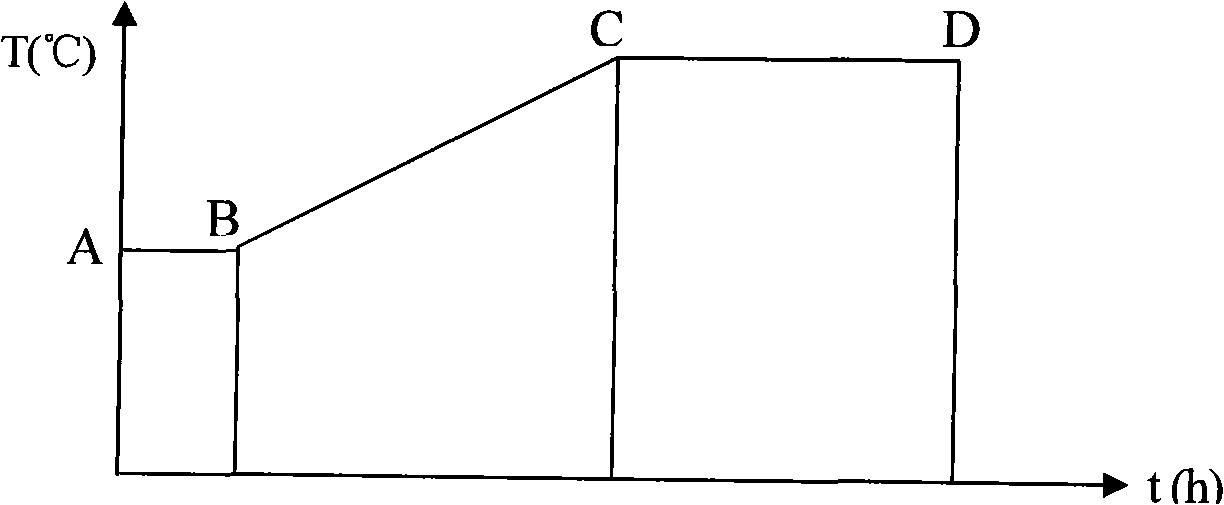

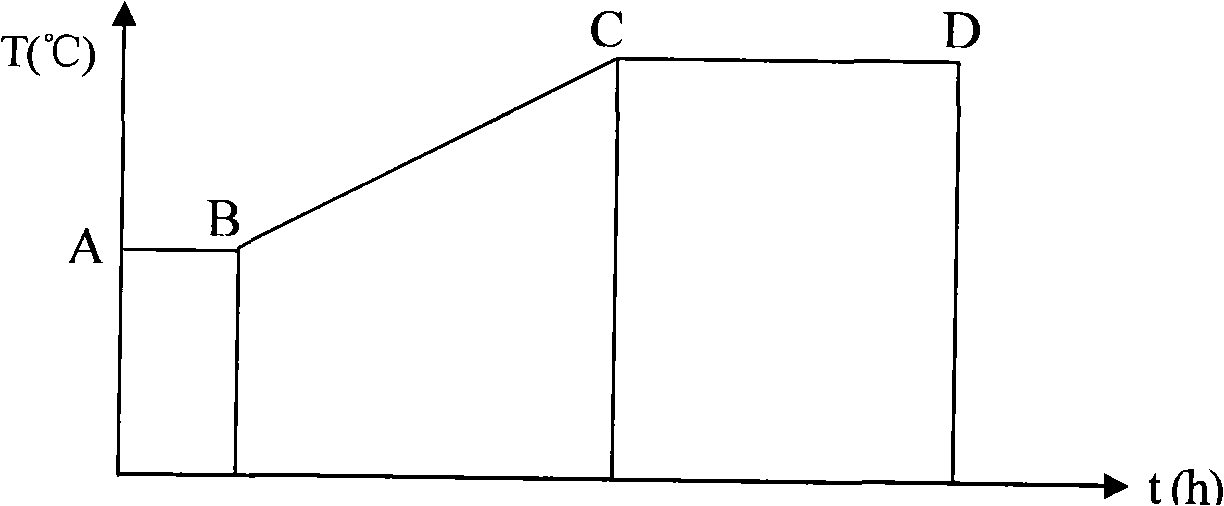

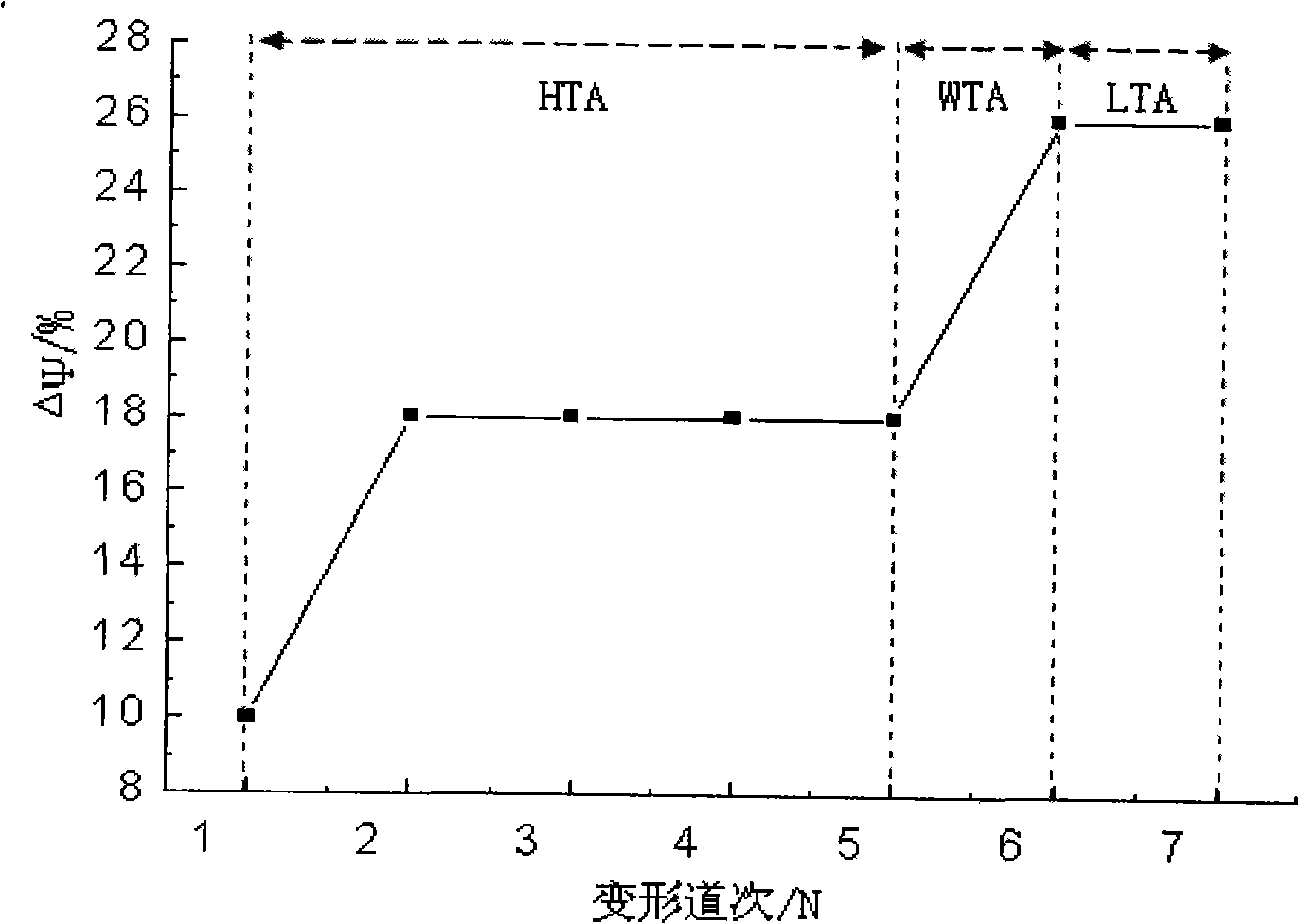

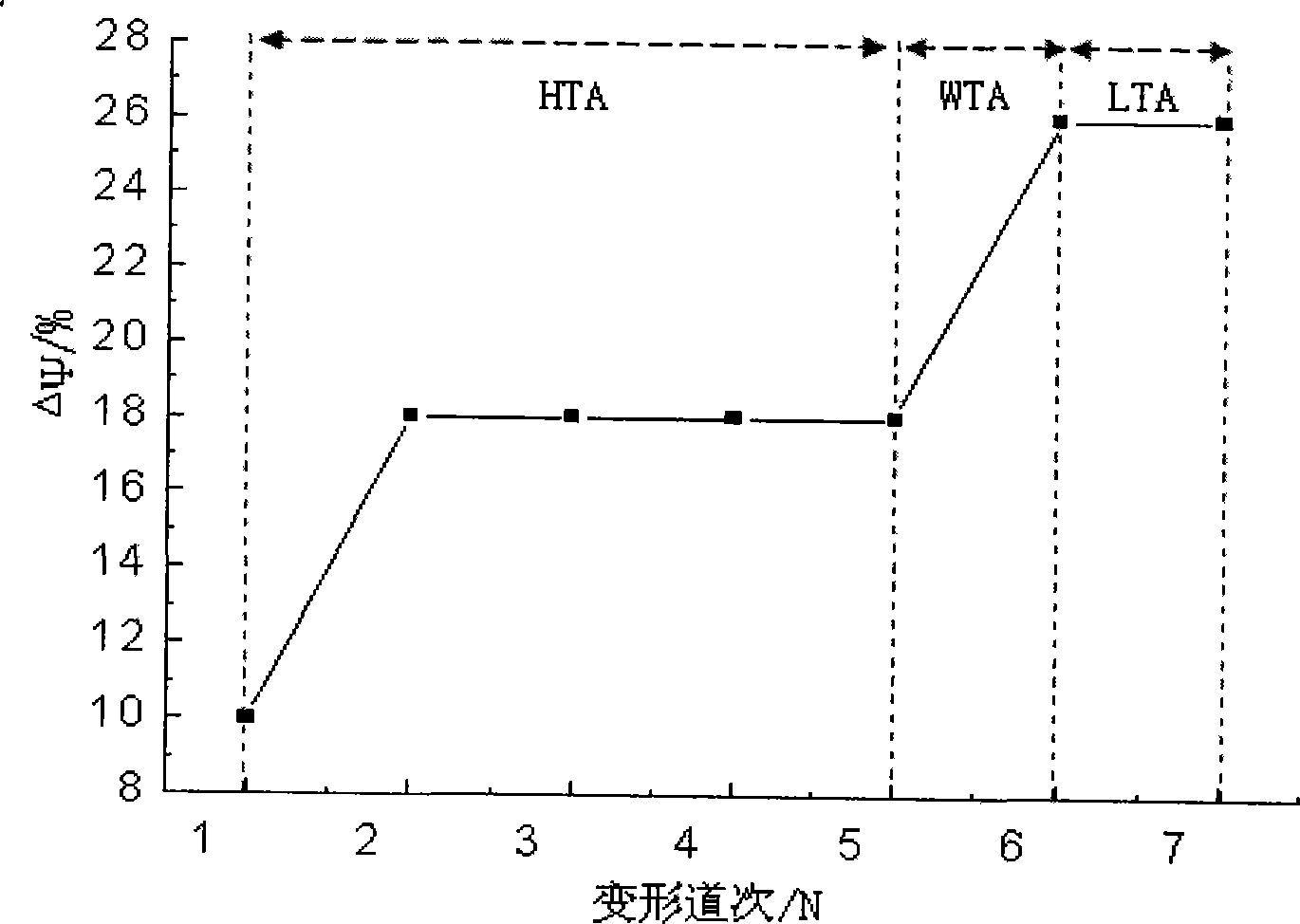

Rolling method for high silicon steel thin strip

The invention discloses a rolling method for a high silicon steel thin strip. The method comprises the following steps: 1) hot rolling: heating a high silicon steel cast strip which is prepared by a twin roll strip continuous casting process and 2 to 4 mm in thickness as a raw material to 900 to 1100 DEG C under a protection atmosphere, and performing at least one-pass hot rolling till the thickness is 1 to 1.2 mm, wherein the total reduction rate of the hot rolling is 50 to 60 percent; 2) warm rolling: heating the high silicon steel hot cast strip treated in the previous step to 320 to 500 DEG C, and performing at least one-pass hot rolling till the thickness is 0.4 to 0.5 mm, wherein the total reduction rate of the warm rolling is 50 to 70 percent; 3) acid pickling: removing oxide on thesurface of the high silicon steel warm cast strip for cleaning the surface; 4) cold rolling at room temperature: performing multi-pass cold rolling on the high silicon steel warm cast strip subjectedto acid pickling at room temperature with a small reduction rate, wherein the reduction rate of each pass of cold rolling is not larger than 25 percent till the required high silicon steel finished product thickness is reached. By adopting the method, the high silicon steel thin strip has high surface quality, good plate shape and superior annealed magnetic performance.

Owner:武汉钢铁有限公司

Smelting method for medium-carbon stainless steel

The invention relates to a smelting method of medium carbon stainless steel. The method includes steps of electric furnace smelting and refining and vacuum processing. During the electric furnace smelting, the tapping P is controlled not larger than 0.015 percent; the electric furnace outputs the steel without slag; the temperature of a large ladle is controlled between 1580 DEG C and 1630 DEG C; the ladle is excellent in argon blowing; after a stationary ladle is refined, the temperature of the molten steel is raised simultaneously when deoxidation and the temperature is controlled between 1580 DEG C and 1650 DEG C; ferrochrome iron is added by 4 to 6 batches; during the refining process, large argon blowing is carried out until the alloy is completely smelt and uniformed, the other components are adjusted to the target values; the slag amount is enlarged during refining, white slag is maintained; then the medium carbon stainless steel is obtained through post treatment. In the method, the chromium recycling rate of the molten steel can reach more than 97 percent; the [P] content of the molten steel is controlled within 0.015 percent. Simultaneously the method is simply operated, convenient and practical, reduces the smelting difficulty, shortening the smelting period and reducing the production cost; besides, the method has a certain reference meaning to the smelting of a plurality of steel with high alloy.

Owner:WUYANG IRON & STEEL

Method for increasing nitrogen content in steel

PendingCN113337679ATo meet the different needs of nitrogen contentHigh nitrogen contentManufacturing convertersAlloyTotal nitrogen

The invention provides a method for increasing the nitrogen content in steel, the method comprises the following steps that at the last stage of converter smelting, an initial oxygen step of oxygen-nitrogen mixed blowing is set according to a turning point of decarburization rate reduction at the last stage of blowing; the oxygen-nitrogen ratio, the nitrogen blowing time and the total nitrogen blowing amount are set according to the steel grade nitrogen requirement; when blowing reaches the initial oxygen step of oxygen-nitrogen mixed blowing, nitrogen and oxygen are blown into molten steel at the same time according to the oxygen-nitrogen ratio through an oxygen lance, and nitrogen blowing lasts for the nitrogen blowing time to reach the total nitrogen blowing amount; and during converter tapping, silicon-vanadium alloy is added into the molten steel for nitrogen fixation. The nitrogen content in the molten steel can be remarkably increased, the nitrogen content in the molten steel after tapping can reach 80-120 ppm so as to meet different requirements of different steel types for the nitrogen content under different process routes, nitrogen-containing alloy (HRB400E) is completely replaced, or nitrogen-containing alloy (HRB500E) is partially replaced, and the alloy cost and the smelting difficulty are reduced under the condition that the requirements for the nitrogen content and the strength of twisted steel are met.

Owner:CHONGQING IRON & STEEL CO LTD

Low-carbon and high-chromium steel slab and continuous efficient production method thereof

ActiveCN114000047ASolve the bottleneck problem of long smelting cycleSolve the problem of non-self-citation when opening and pouringProcess efficiency improvementManganeseTitanium

The invention discloses a low-carbon and high-chromium steel slab and a continuous efficient production method thereof, and belongs to the field of steelmaking continuous casting. The low-carbon and high-chromium steel slab comprises the following chemical components in percentage by weight: 0.02-0.04% of carbon; 0.1-0.3% of silicon; 0.2-0.5% of manganese; 0.020% or less of phosphorus; 0.005% or less of sulfur; 0.02-0.06% of aluminum; 0.2-0.4% of nickel; 0.3-0.5% of copper; 4.0-4.7% of chromium; 0.01- 0.03% of titanium; 0.0080% or less of nitrogen; 0.0040% or less of oxygen; 0.00025% or less of hydrogen; 0.0010-0.0035% of calcium, and the balance of iron and inevitable impurities. According to the production method, the smelting procedures of molten iron pretreatment, converter smelting, RH vacuum treatment, LF refining and continuous casting are adopted. The defects that in the prior art, the production cost of low-carbon high-chromium steel is generally high, and continuous and efficient production is difficult to achieve are overcome, high-pulling-speed continuous casting of nine furnaces or above can be achieved through reasonable process layout and reasonable distribution of loads of all the working procedures, and full-working-procedure efficient production is achieved.

Owner:MAANSHAN IRON & STEEL CO LTD

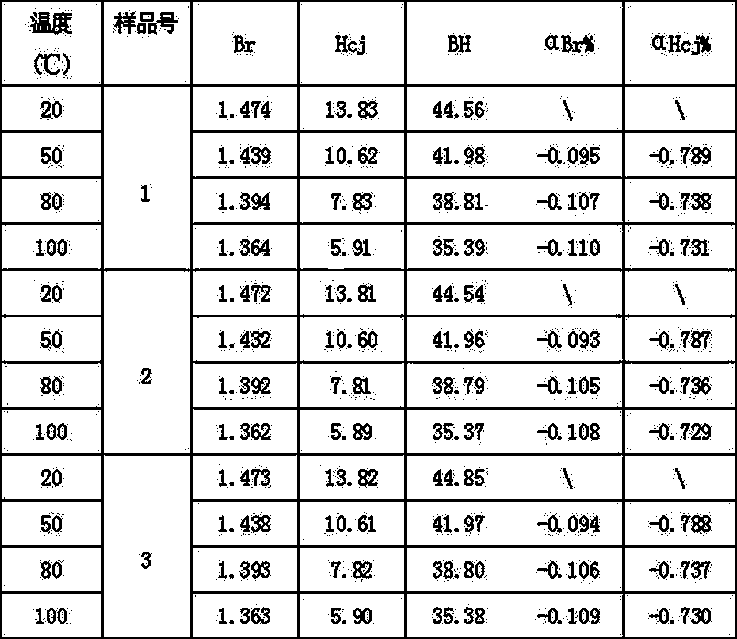

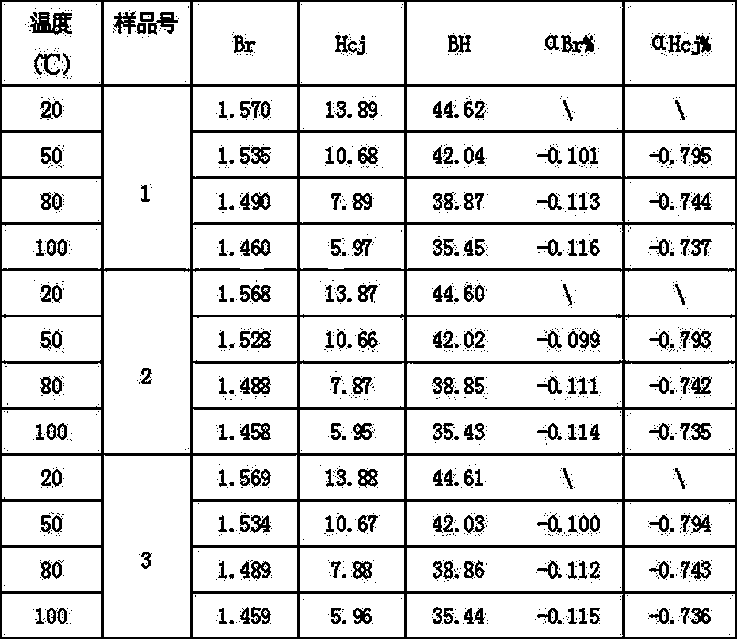

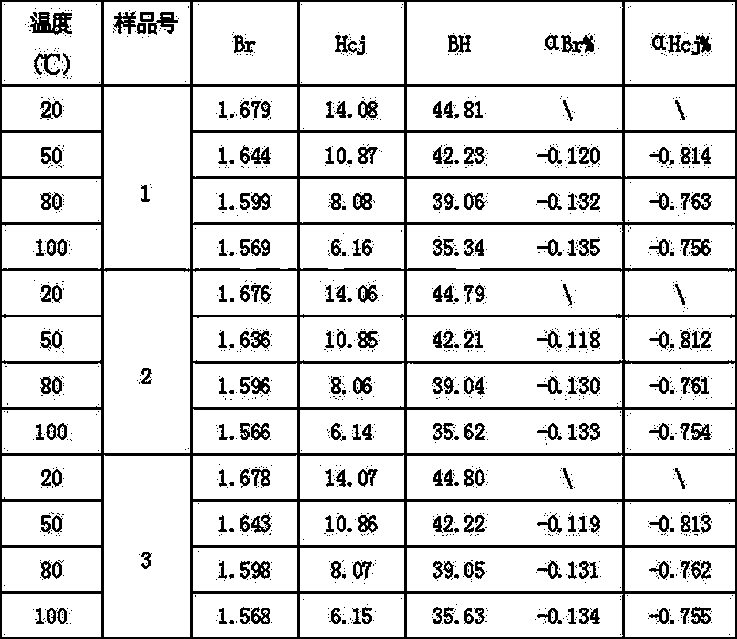

Dysprosium-iron-praseodymium-neodymium magnetic steel with high performance

InactiveCN103811142AExcellent magnetic propertiesImprove processing strengthMagnetic materialsDysprosiumAlloy

The invention discloses dysprosium-iron-praseodymium-neodymium magnetic steel with high performance. The dysprosium-iron-praseodymium-neodymium magnetic steel comprises the following components in percent by weight: more than or equal to 0.022% and less than or equal to 0.036% of C, less than or equal to 0.45% of Mn, more than or equal to 1.00% and less than or equal to 2.00% of Dy, more than or equal to 12.50% and less than or equal to 13.50% of Ni, more than or equal to 2.50% and less than or equal to 3.00% of Mo, more than or equal to 21.00% and less than or equal to 22.50% of Cr, more than or equal to 1.90% and less than or equal to 6.00% of Si, more than or equal to 0.30% and less than or equal to 0.50% of Al, more than or equal to 0.10% and less than or equal to 0.15% of Cu, less than or equal to 0.015% of P, less than or equal to 0.010% of S, more than or equal to 0.40% and less than or equal to 0.70% of Nb, less than or equal to 0.1% of Ga, 28-29% of praseodymium-neodymium alloy 1#, 10-20% of dysprosium-iron alloy 2# and the balance of Fe and other inevitable trace impurities. The dysprosium-iron-praseodymium-neodymium magnetic steel disclosed by the invention has the advantages that the praseodymium-neodymium alloy 1# and the dysprosium-iron alloy 2# are adopted for adjusting and controlling the content of dysprosium, praseodymium and neodymium in the magnetic steel, so that the quality and the quality stability of a magnetic-steel product are improved.

Owner:NINGBO HONGLEI MAGNETICS

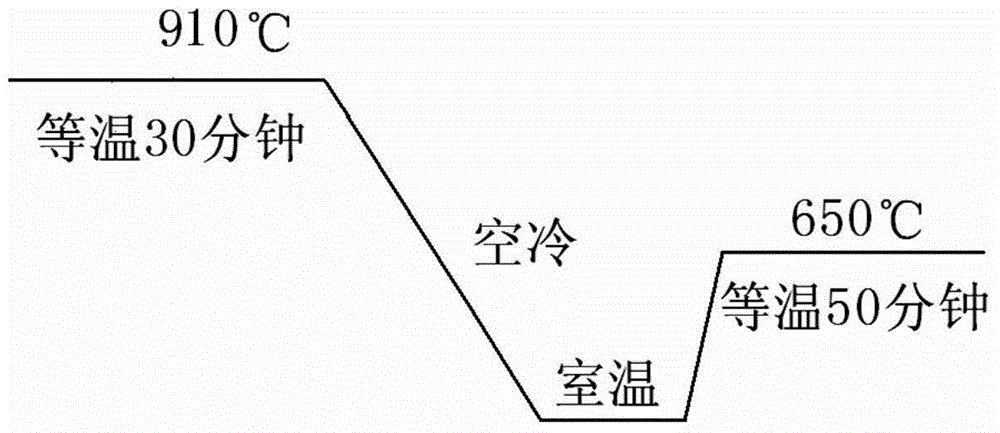

Ultralow carbon copper-containing automobile high-strength cold-rolled steel plate and manufacturing method thereof

ActiveCN106319363AReduce smelting costReduce the difficulty of smeltingReduction rateRoom temperature

The invention discloses an ultralow carbon copper-containing automobile high-strength cold-rolled steel plate and a manufacturing method thereof. The chemical component in steel comprises, by weight, 0.004%-0.006% of C, 0.001%-0.003% of N, 0.2%-1.0% of Si, 0.2%-1.0% of Mn, 0-0.015% of P, 0-0.015% of S, 0.02%-0.04% of Als, 1.2%-2.4% of Cu and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that the thickness of a continuous casting blank is controlled to be 350 mm or below; the hot rolling heating temperature is 980 DEG C-1050 DEG C, heat preservation is conducted for 30-60 min, the initial rolling temperature is 950 DEG C-1000 DEG C, the finish rolling temperature is 820 DEG C-880 DEG C, and the coiling temperature is 500 DEG C-550 DEG C; and the cold rolling reduction rate is not lower than 65%, the annealing heating temperature is 890 DEG C-920 DEG C, heat preservation is conducted for 20-40 min, the continuous casting blank is cooled to the room temperature at the speed of being not lower than 20 DEG C / s, and then aging is conducted for 30-60 min at the temperature of 550 DEG C-680 DEG C. The cold-rolled steel plate is low in production cost and excellent in corrosion resistance.

Owner:ANGANG STEEL CO LTD

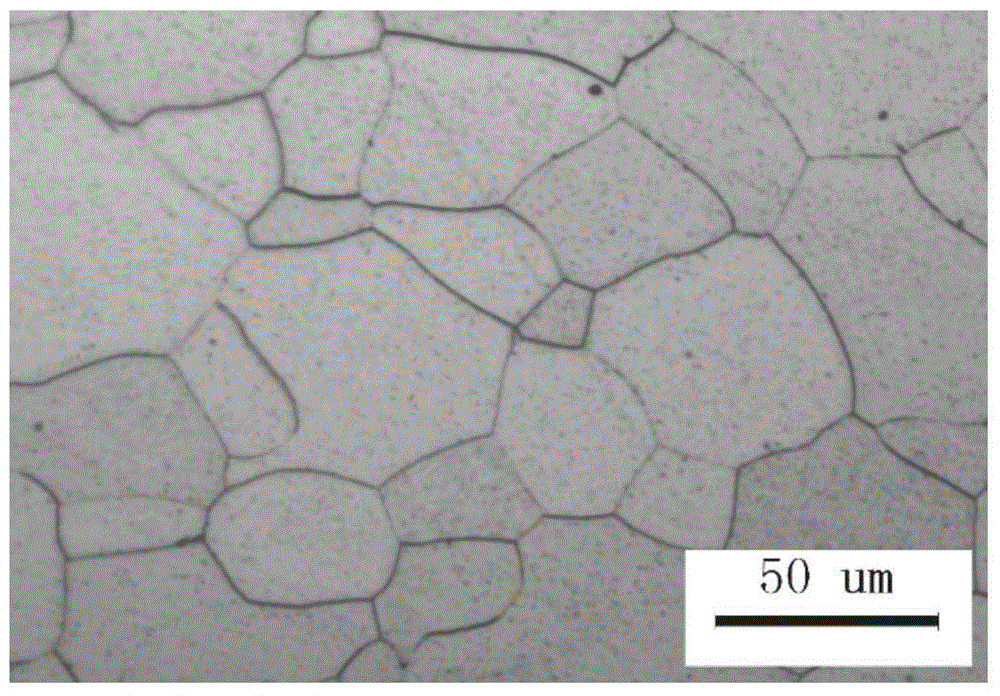

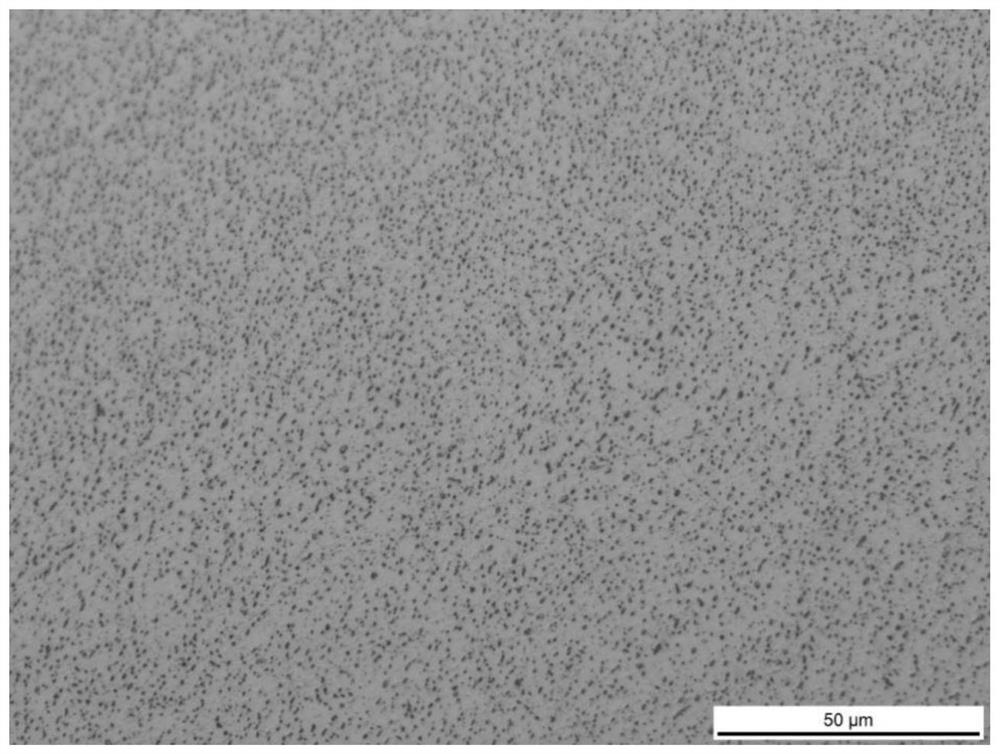

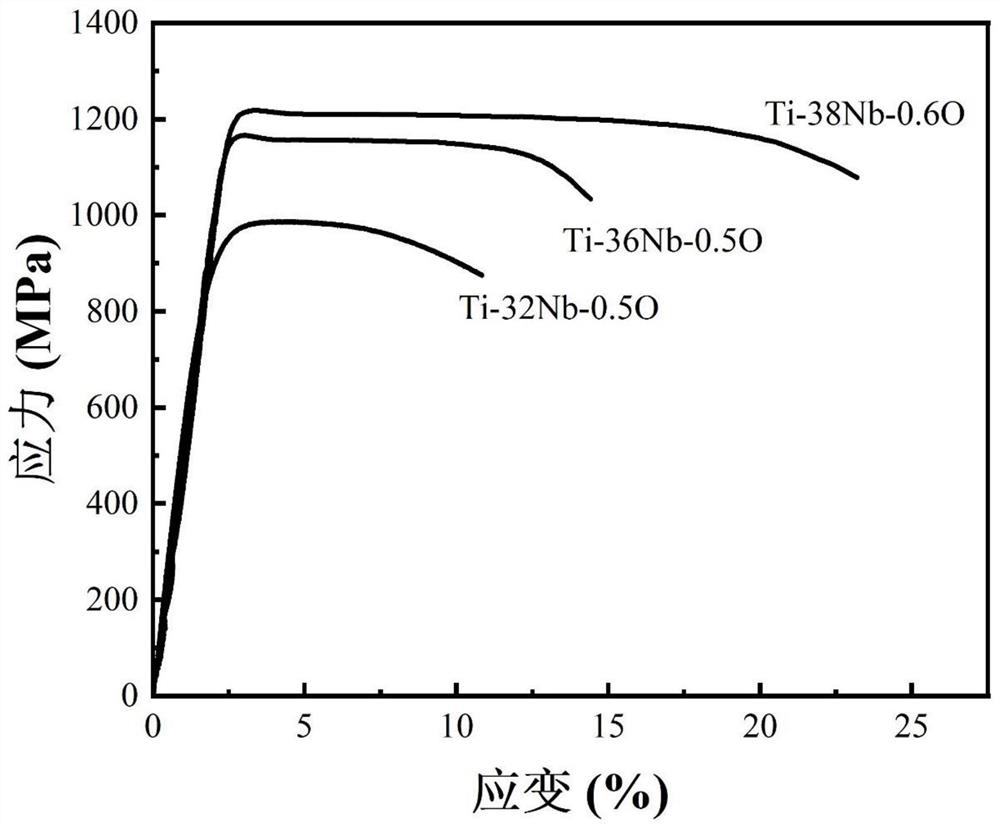

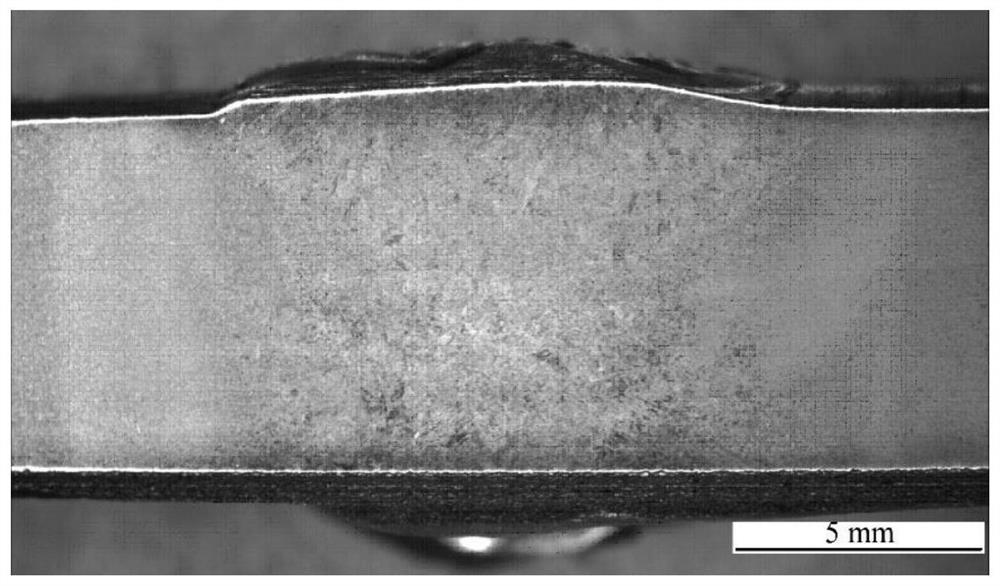

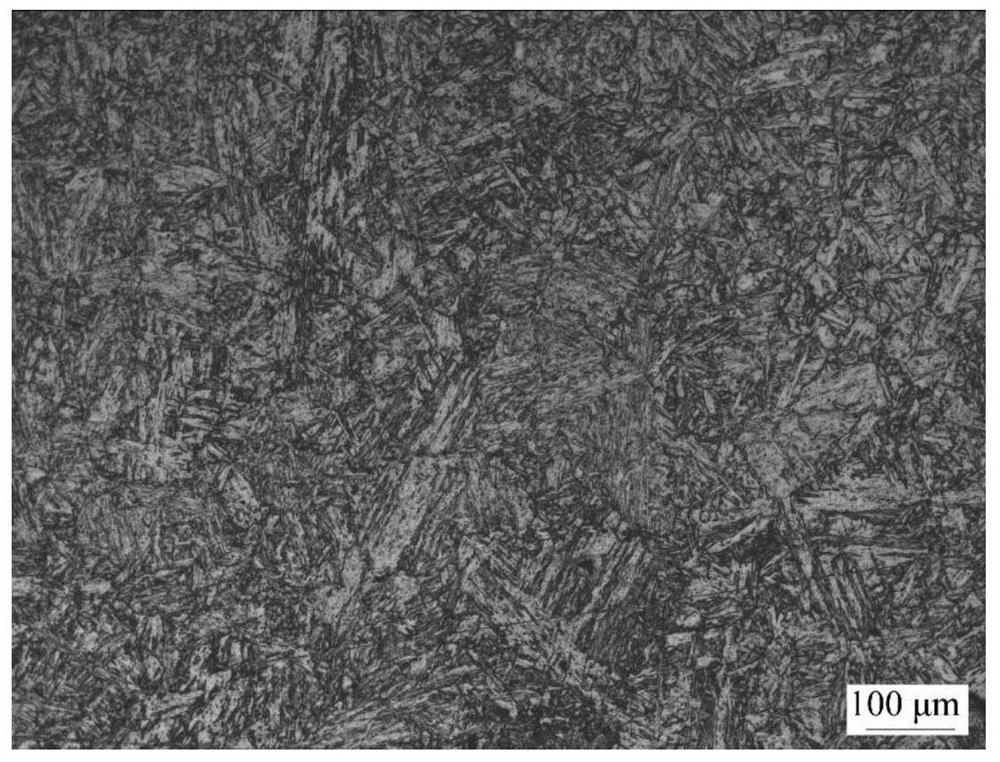

A kind of biomedical tinb base titanium alloy and preparation method thereof

This invention discloses a biomedical titanium alloy and a preparation method thereof. The titanium alloy contains three elements of Ti, Nb and O, and the composition includes 31-39wt% Nb, 0.4-0.8wt% O and the balance of Ti and other components. Inevitable impurities; through heat treatment, the content of α-phase in the alloy structure is finally controlled to be no more than 15%, and the Nb content of β-phase is 38-40%; the elastic modulus of the alloy is 50-65GPa, and the tensile strength is above 900MPa. The low-modulus and high-strength titanium alloy of the invention has high oxygen content, can reduce the cost of deoxygenation in the smelting preparation process, has excellent mechanical properties, and has important theoretical significance and engineering value.

Owner:BEIHANG UNIV

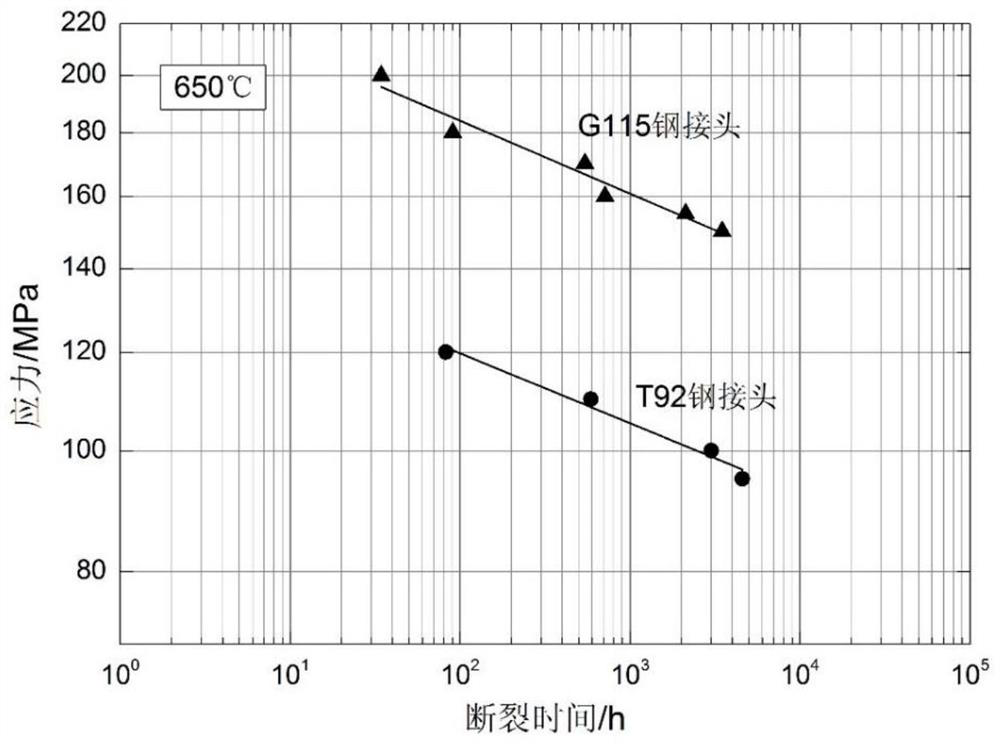

A welding wire for 9cr-3w-3co martensitic heat-resistant steel and its application in gtaw welding process

ActiveCN111843284BReduce the difficulty of smeltingImprove high temperature creep resistanceWelding/cutting media/materialsSoldering mediaChemical compositionMartensite

The invention provides a welding wire for 9Cr-3W-3Co martensitic heat-resistant steel and its application in GTAW welding process. In terms of mass percentage, the chemical composition of the welding wire is: C: 0.05-0.12%, Si: 0.50% or less, Mn: 1.0% or less, P: 0.01% or less, S: 0.008% or less, Ni: 0.20% or less, Cr: 8.50-9.50%, W: 2.50-3.0%, Co: 2.50-3.50%, Nb: 0.03-0.07%, V: 0.15-0.25%, N: 0.03-0.07%, B: 0.004% or less, Cu: 0.10% Below, Ti: 0.01% or less, Al: 0.03% or less, and the rest are Fe and unavoidable impurities. The A of the welding wire GTAW weld metal C1 High point, high impact toughness of weld and excellent high temperature creep strength.

Owner:WUHAN UNIV

Smelting method for medium-carbon stainless steel

The invention relates to a smelting method of medium carbon stainless steel. The method includes steps of electric furnace smelting and refining and vacuum processing. During the electric furnace smelting, the tapping P is controlled not larger than 0.015 percent; the electric furnace outputs the steel without slag; the temperature of a large ladle is controlled between 1580 DEG C and 1630 DEG C;the ladle is excellent in argon blowing; after a stationary ladle is refined, the temperature of the molten steel is raised simultaneously when deoxidation and the temperature is controlled between 1580 DEG C and 1650 DEG C; ferrochrome iron is added by 4 to 6 batches; during the refining process, large argon blowing is carried out until the alloy is completely smelt and uniformed, the other components are adjusted to the target values; the slag amount is enlarged during refining, white slag is maintained; then the medium carbon stainless steel is obtained through post treatment. In the method, the chromium recycling rate of the molten steel can reach more than 97 percent; the [P] content of the molten steel is controlled within 0.015 percent. Simultaneously the method is simply operated,convenient and practical, reduces the smelting difficulty, shortening the smelting period and reducing the production cost; besides, the method has a certain reference meaning to the smelting of a plurality of steel with high alloy.

Owner:WUYANG IRON & STEEL

Method for eliminating edge fault of aluminium killed steel with low manganese-sulfur ratio and low carbon

ActiveCN101912875BEliminate quality impactMeet the requirements of a low-carbon economyTemperature control deviceWork treatment devicesSulfurStrip steel

The invention relates to a method for eliminating an edge fault of aluminium killed steel with low manganese-sulfur ratio and low carbon, belonging to the technical field of steel rolling. The method comprises the following technological steps of: cooling an offline plate blank in an insulating pit, or slowly cooling by stacking; controlling the atmosphere in a heating furnace and the residence time in each stage, the temperature and the total residence time in the furnace of the plate blank; rolling in an equivalent width mode or widening mode; and adjusting a scale removing mode and a layercooling mode. The invention has the advantage of eliminating the influence of Mn / S on the quality of steel edges by optimizing heating and rolling technologies under the premise of not increasing extra equipment and investment. Compared with the prior art for eliminating the influence of Mn / S on the quality of band steel edges by increasing the content of Mn or reducing the content of S in the plate blank, the invention can greatly reduce production cost and smelting difficulty. The method is economical and effective, meets the requirements of low carbon and economy of green steel, and is especially applicable to the production of low-carbon aluminium killed steel with 10-30 Mn / S.

Owner:首钢股份公司迁安钢铁公司

A kind of cold-rolled low-alloy high-strength air-cooled strengthened steel for automobiles and its preparation method

ActiveCN109972058BGood casting performanceGood welding performanceUltimate tensile strengthAlloy steel

The invention provides cold-rolled low-alloy high-strength air-cooled strengthened steel for an automobile and a preparation method, and belongs to the technical field of alloy steel preparation. Thestrengthened steel comprises, by mass percent, 0.05%-0.15% of C, 1.0%-2.0% of Mn, 0.05%-0.25% of Si, 0.20%-1.0% of Cr, 0.05%-0.3% of Mo, 0.01%-0.06% of Al, 0.01%-0.10% of Nb, 0.01%-0.10% of V, 0.01%-0.10% of Ti, 0.001%-0.006% of B, smaller than 0.03% of P, smaller than 0.03% of S and the balance Fe and unavoidable impurities. The strengthened steel is obtained through the steps that after raw material preparing, smelting and pouring are conducted to obtain a plate blank, the plate blank is heated, multiple passes of hot rolling deformation is conducted after homogenization treatment is conducted, air cooling is conducted till the temperature reaches rolling temperature, rolling is conducted till the temperature reaches the room temperature, cold rolling is conducted after acid pickling, and finally annealing treatment is conducted. The obtained cold-rolled annealing plate has the yield strength of being lower than 350 MPa and the tensile strength of being lower than 500 MPa, has the good cold forming performance and can be machined into complex automobile parts.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com