Hot rolled ferrite/martensite double phase steel and production method thereof

A hot-rolled dual-phase steel and production method technology, applied in the field of steel rolling, can solve the problems of high production cost and complicated process of hot-rolled ferrite/martensitic dual-phase steel, reduce the difficulty of surface quality control, and solve the problem of production The effect of high cost and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

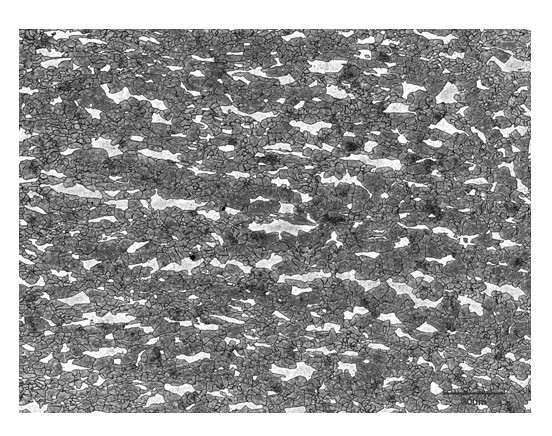

Image

Examples

Embodiment 1

[0024] The smelted molten steel conforming to the composition scheme described in Component 1 in Table 1 was cast into billets, and then the billets were heated up to 1200°C with the furnace and kept for 0.5h before rolling. Among them, the starting rolling temperature of the austenite recrystallization zone is 1180°C, and the deformation amount is 65%; the starting rolling temperature of the austenite non-recrystallization zone is 930°C, the billet deformation amount is 35%, and the final rolling temperature is 800°C. After the steel plate is rolled, it is warmed in the air. After the temperature reaches 600°C, water cooling is started. The cooling rate of water cooling is 45°C / s, and it is cooled to 300°C, reaching the coiling temperature, and then coiled.

Embodiment 2

[0026] The smelted molten steel conforming to the composition scheme described in component 2 in Table 1 was cast into billets, and then the billets were heated up to 1200°C with the furnace and kept for 0.5h before rolling. Among them, the starting rolling temperature of the austenite recrystallization zone is 1150°C, and the deformation is 60%; the starting rolling temperature of the austenite non-recrystallization zone is 910°C, the billet deformation is 40%, and the final rolling temperature is 780°C. After the steel plate is rolled, it is warmed in the air. After the temperature reaches 580°C, water cooling is started. The cooling rate of water cooling is 50°C / s, and it is cooled to 250°C, reaching the coiling temperature, and then coiled.

Embodiment 3

[0028] The smelted molten steel conforming to the composition scheme described in Component 3 in Table 1 was cast into billets, and then the billets were heated up to 1200°C with the furnace and kept for 0.5h for rolling. Among them, the starting rolling temperature of the austenite recrystallization zone is 1100°C, the deformation amount is 50%; the starting rolling temperature of the austenite non-recrystallization zone is 910°C, the billet deformation amount is 50%, and the final rolling temperature is 750°C. After the steel plate is rolled, it is warmed in the air. After the temperature reaches 550°C, water cooling is started. The cooling rate of water cooling is 60°C / s, and it is cooled to 210°C, reaching the coiling temperature, and then coiled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com