Eutectic cermets

A technology of gold materials and crystal porcelain, which is applied in the field of eutectic ceramic gold engineering materials, can solve the problems of complex manufacturing process and high cost, and achieve the effects of good hardness stability, high toughness performance, and good high-temperature hardness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings.

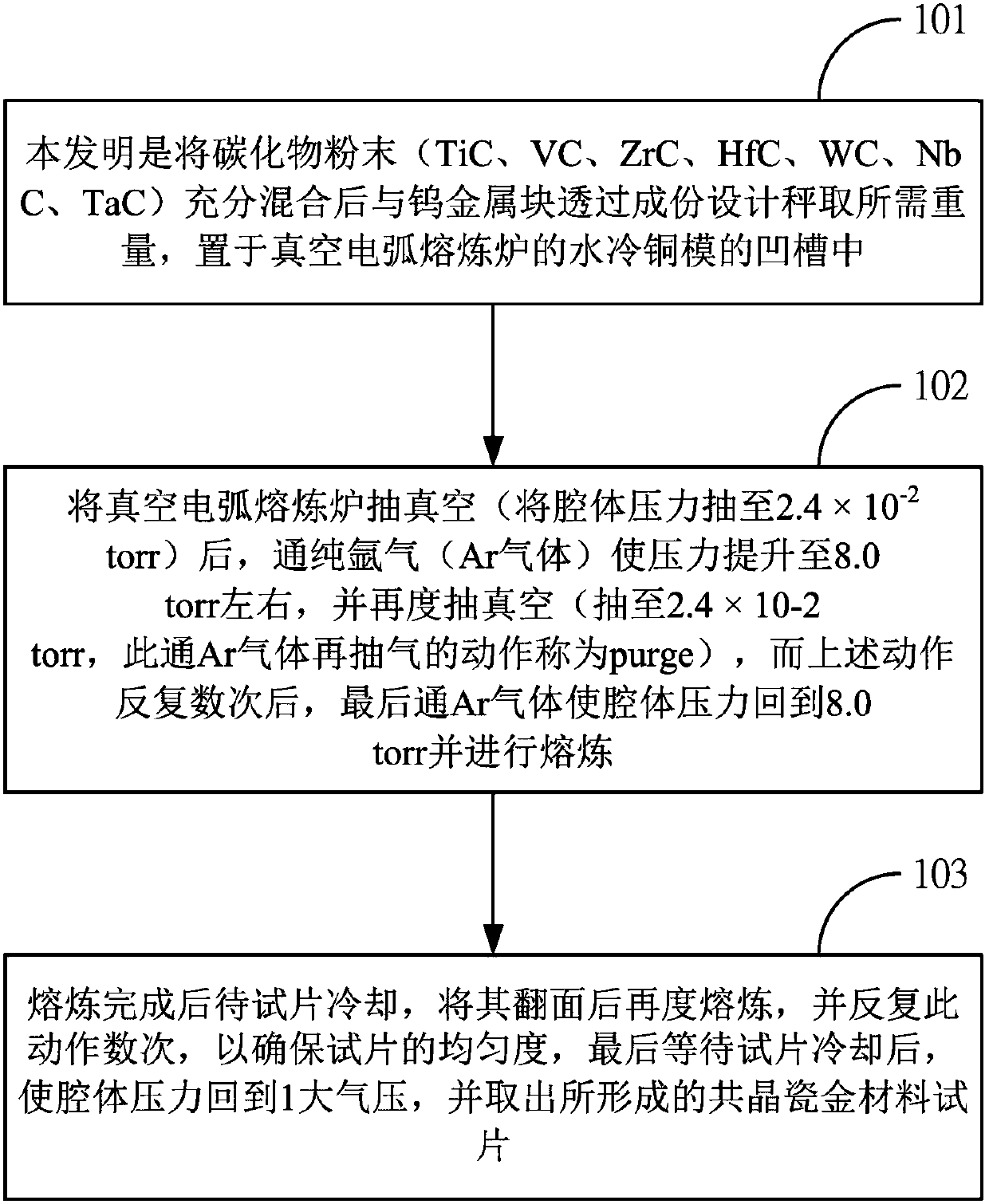

[0027] see figure 1 , its preparation method is as follows:

[0028] (1) In the present invention, the carbide powder (TiC, VC, ZrC, HfC, WC, NbC, TaC) is fully mixed with the tungsten metal block to weigh the required weight through the composition design, and placed in the water cooling of the vacuum arc melting furnace. 101 in the groove of the copper mold;

[0029] (2) Vacuumize the vacuum arc melting furnace afterwards (pump the chamber pressure to 2.4×10 -2 torr), pass pure argon (Ar gas) to increase the pressure to about 8.0torr, and then evacuate again (pump to 2.4×10-2torr, this action of passing Ar gas and then pumping is called purge), and the above action After repeated several times, Ar gas was finally passed to bring the chamber pressure back to 8.0torr and sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com