Non-magnetic stainless steel with high strength and toughness, manufacturing method and application thereof

A high-strength, high-toughness, manufacturing method technology, applied in the field of non-magnetic high-strength and high-toughness stainless steel, can solve the problems of high equipment requirements and high production costs, and achieve the effects of enhancing corrosion resistance, satisfying non-magnetic properties, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

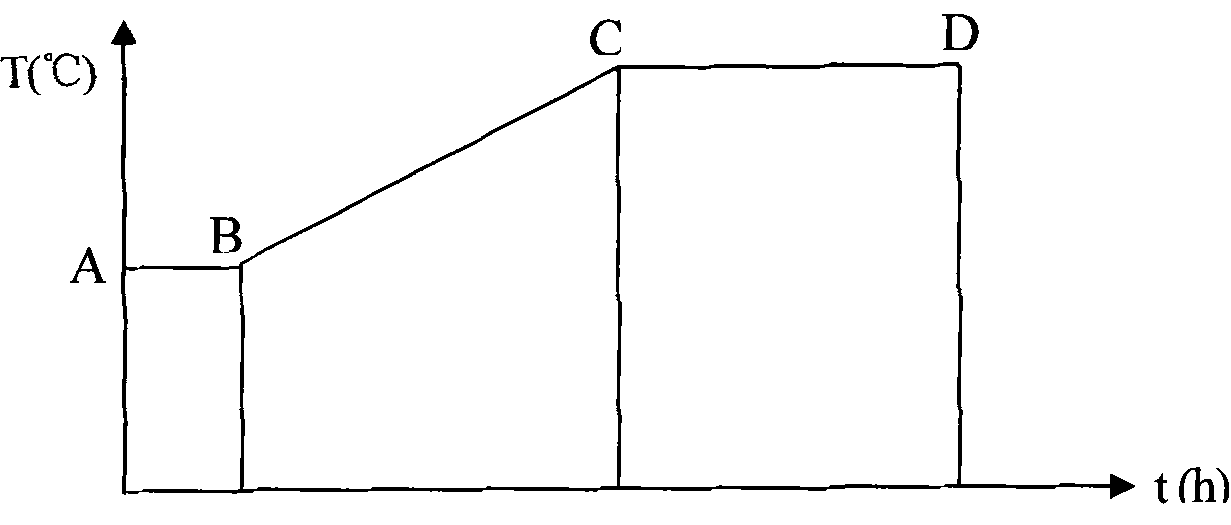

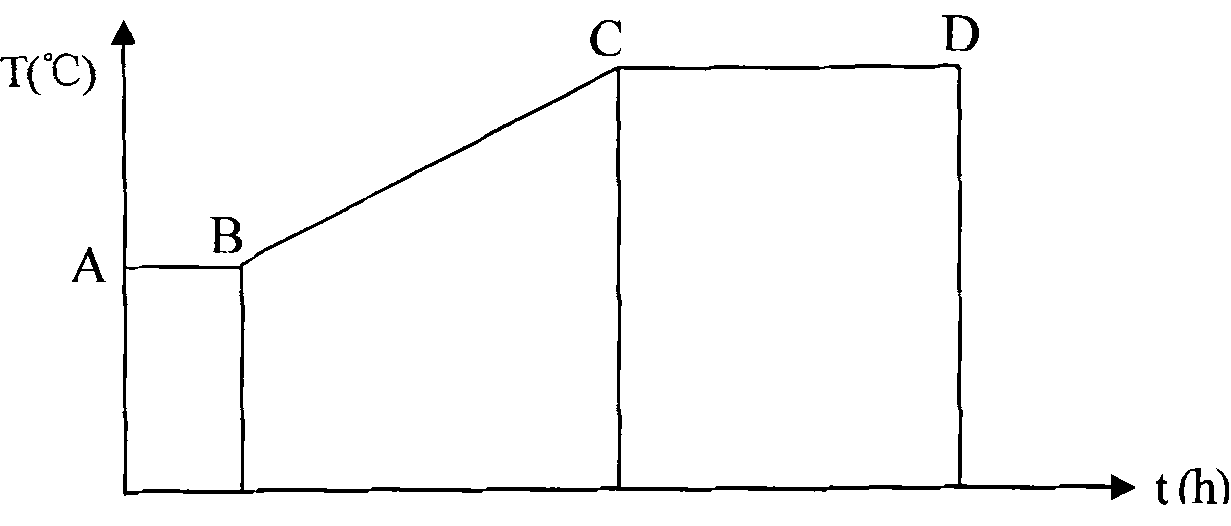

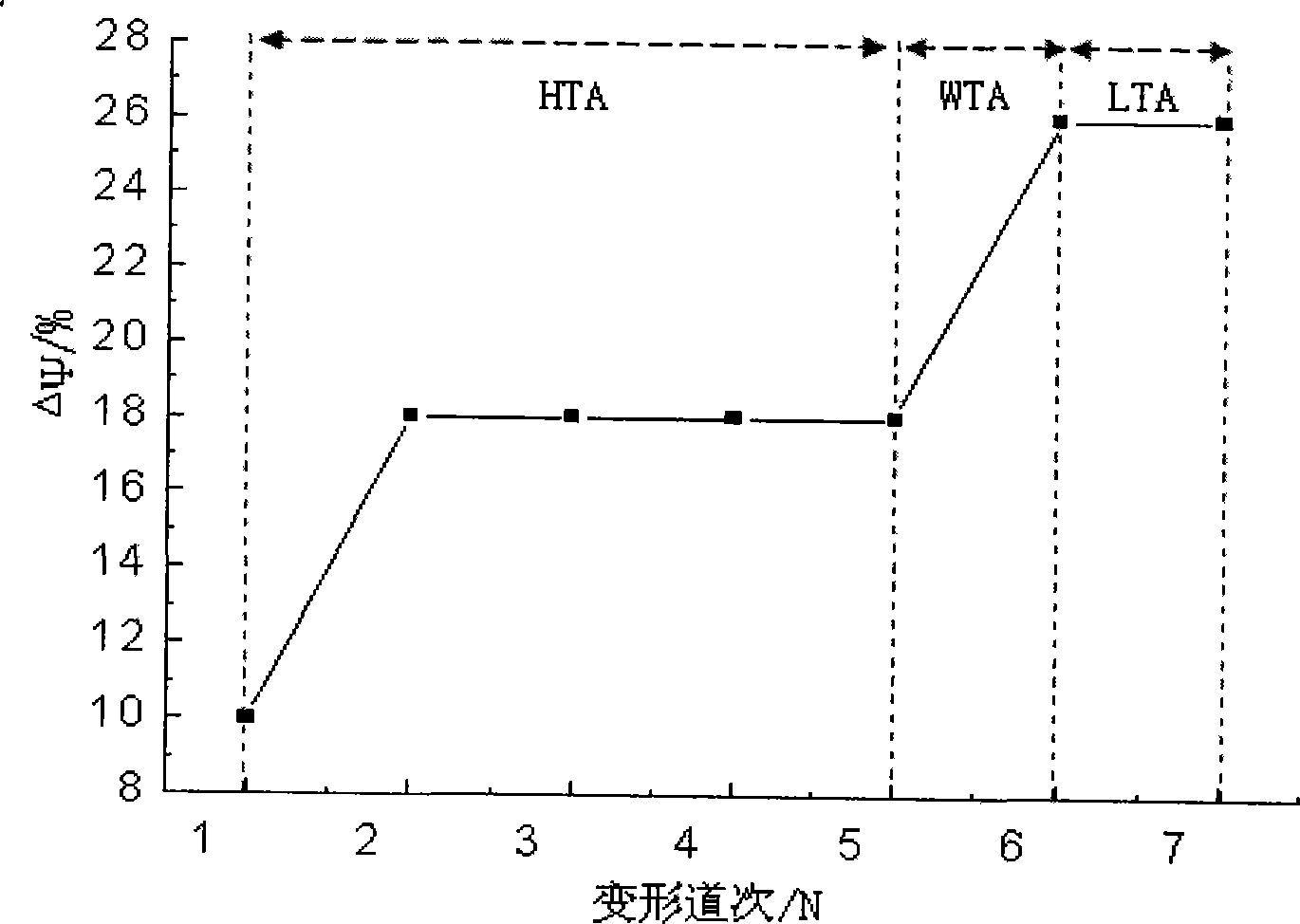

Image

Examples

Embodiment 1

[0066] In this embodiment, the chemical composition mass percentage of steel is: C: 0.036; Si: 0.50; Mn: 19.92; Cr: 13.31; Mo: 0.38; Ni: 0.39; N: 0.40; P: 0.019; The balance is Fe and unavoidable impurities.

[0067] Steel is manufactured as follows:

[0068] Electric furnace smelting: When the melt is about to be cleared, blow oxygen appropriately to boost the melting; the tapping temperature is higher than 1630°C;

[0069] AOD smelting: mixed with rough smelting molten steel, the carbon content is controlled in the range of 0.80-1.2;

[0070] Mix the manganese in the molten steel to 6.0-10.0%. In the oxidation period of AOD smelting, blow nitrogen all the time, and at the same time blow oxygen to decarburize until the carbon content is not higher than 0.03%, enter the reduction period to raise the temperature of molten steel to 1650-1720°C, and continue to blow nitrogen to the nitrogen content after the manganese content is fully prepared Stop blowing nitrogen at about 0....

Embodiment 2

[0075] The chemical composition mass percentage of steel in this embodiment is: C: 0.030; Si: 0.40; Mn: 19.20; Cr: 13.30; Mo: 0.32; Ni: 0.20; N: 0.38; Fe and unavoidable impurities.

[0076] Others are the same as embodiment 1. The mechanical properties and magnetic permeability results of the steel in this example are shown in Table 6.

Embodiment 3

[0078] The chemical composition mass percentage of steel in this embodiment is: C: 0.036; Si: 0.56; Mn: 19.32; Cr: 14.00; Mo: 0.40; Ni: 0.36; N: 0.43; Fe and unavoidable impurities.

[0079] Others are the same as embodiment 1. The mechanical properties and magnetic permeability results of the steel in this example are shown in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com