A welding wire for 9cr-3w-3co martensitic heat-resistant steel and its application in gtaw welding process

A welding process, heat-resistant steel technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc. High temperature creep lasting strength and other issues, to achieve the effect of widening the heat treatment process window, reducing the difficulty of smelting, and improving the high temperature creep lasting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

[0064] According to the composition range of the welding wire of the present invention, several groups of examples are made on the welding wire of the present invention, and comparative examples are given.

[0065] Table 1 The chemical composition (wt%) of welding wire of embodiment 1-3 and comparative example 1-2

[0066]

[0067]

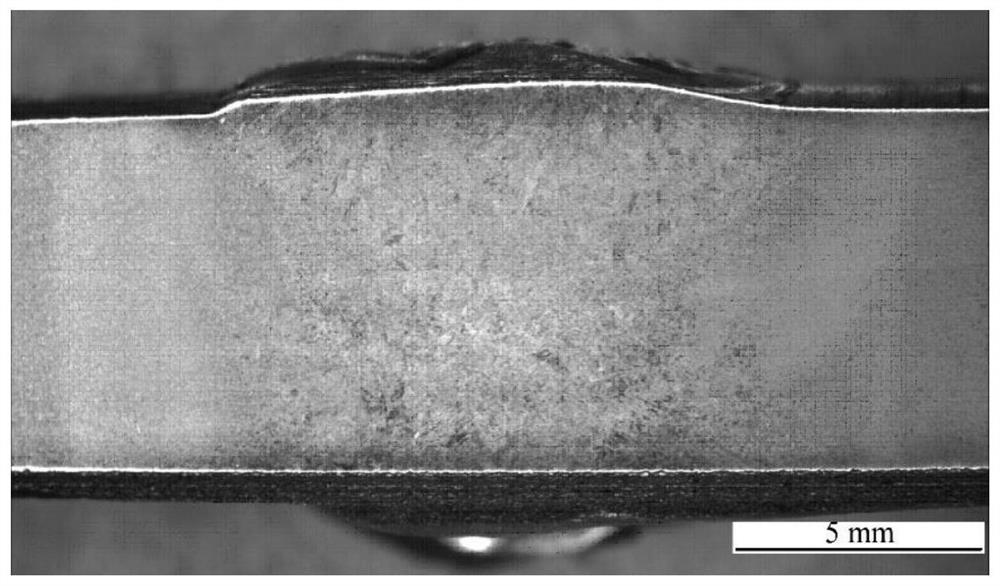

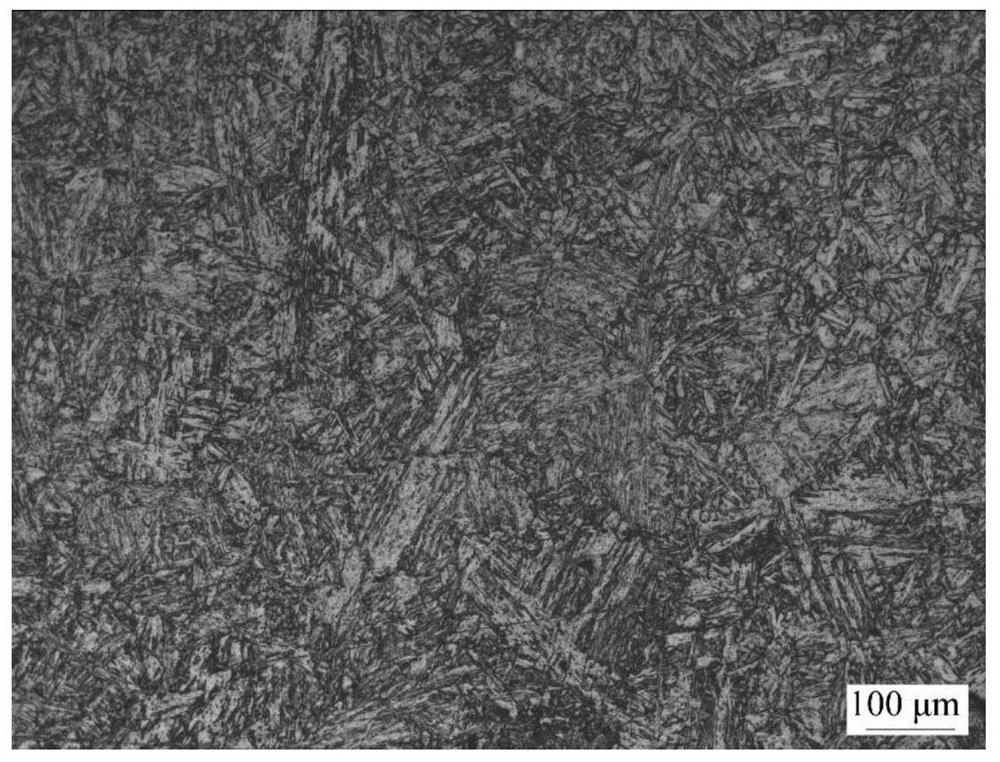

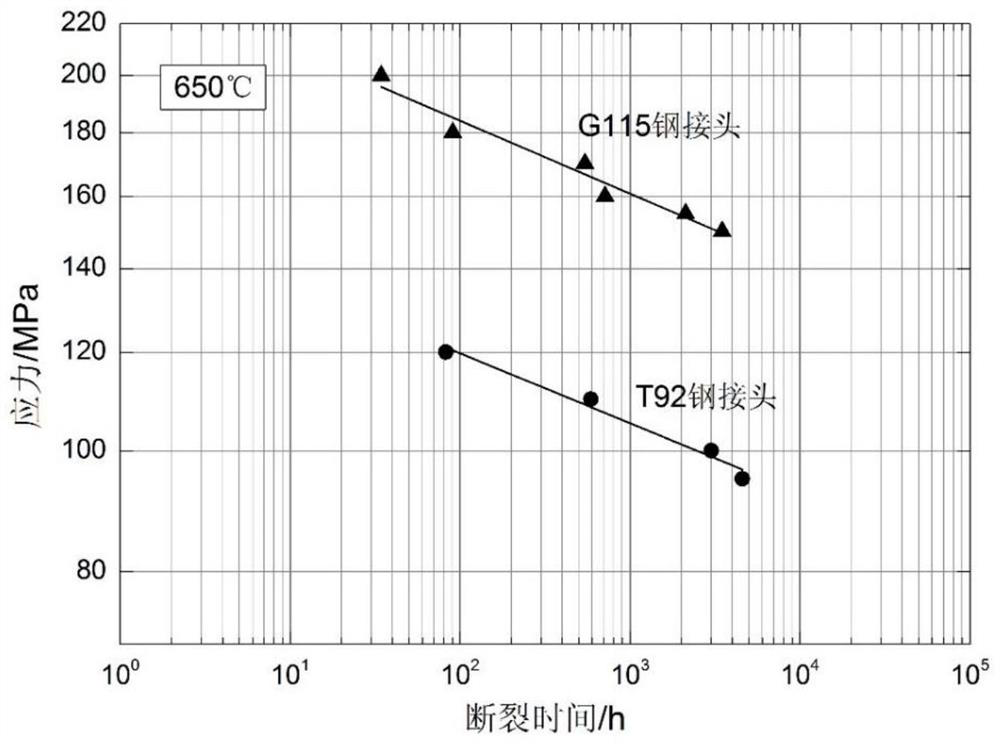

[0068] The deposited metal phase transition point test sample of welding wire was prepared by hot wire automatic GTAW method. The process conditions were: welding wire diameter 1.0mm, preheating temperature 150°C, interlayer temperature 150-250°C, welding current 200A, welding voltage 10V, welding speed 100mm / min, hot wire voltage 4.5V. Test of Weld Metal by Thermal Expansion A C1 point, the results are shown in Table 2. It can be seen that by controlling the content of Cu and Ni at a low level,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com