Patents

Literature

41results about How to "Low content of alloying elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt less multi element high speed tool steel and its manufacturing method

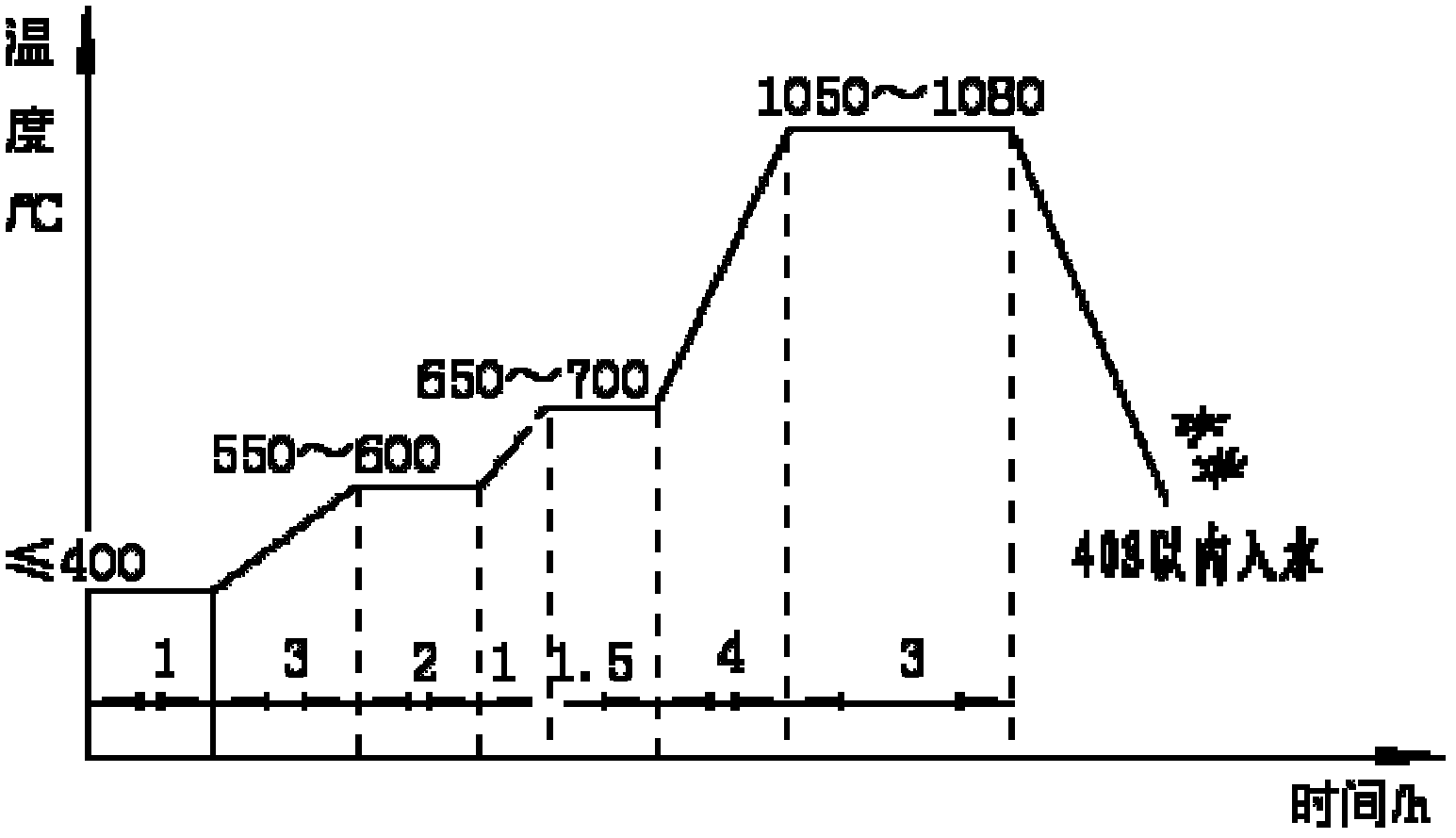

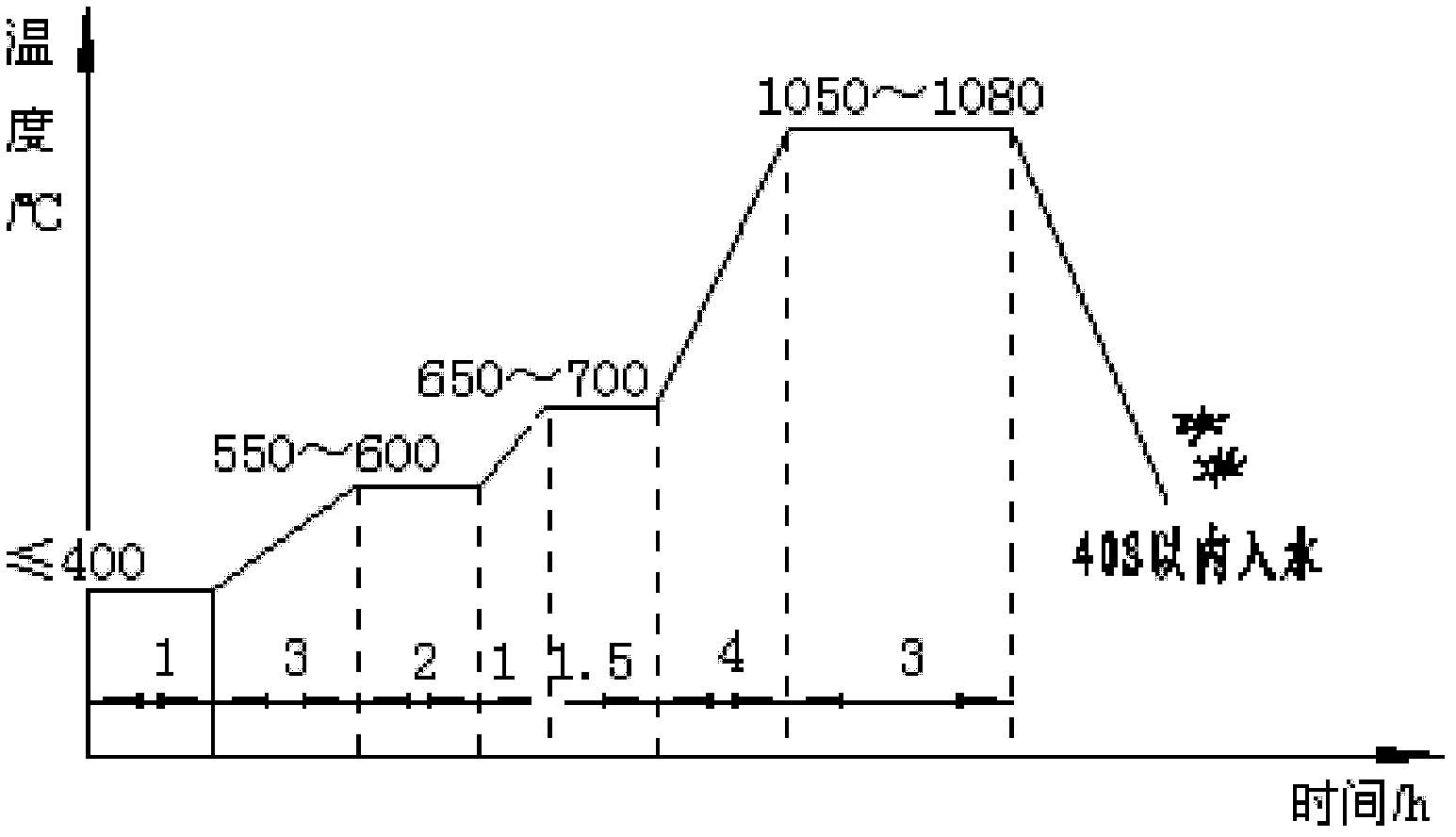

InactiveCN1693527AReasonable range of performanceLow content of alloying elementsFurnace typesHeat treatment furnacesElectrical resistance and conductanceChemical composition

A non-Co multi-element high-speed tool steel contains proportionally C, Si, Mn, S, P, Cr, V, Mo, W, Ni, Nb, Ti, Mg, RE and Fe. Its preparing process includes such steps as smelting by MF furnace, modifying with Y-based RE alloy, centrifugal casting, and heat treating.

Owner:JIUQUAN IRON & STEEL GRP

Novel high carbon high wolfram fast steel rolling roller and preparation process thereof

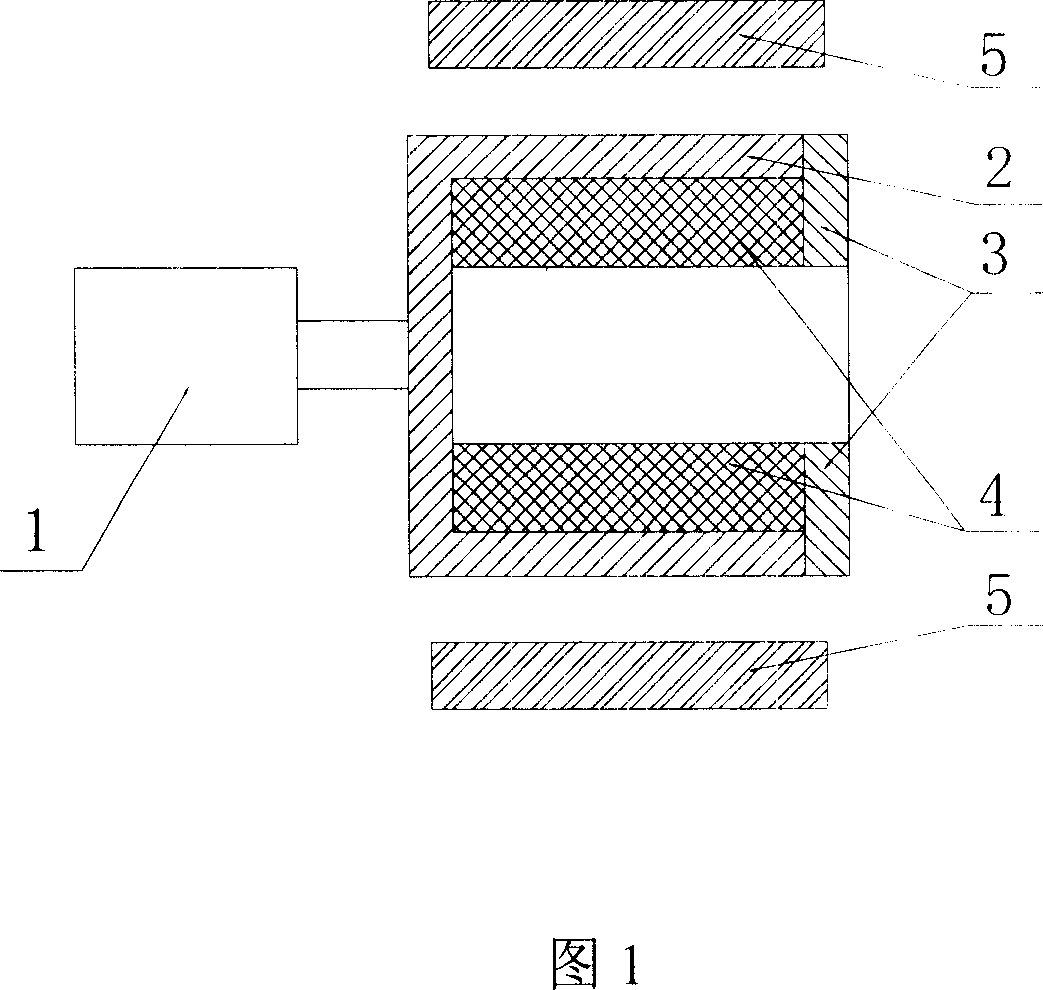

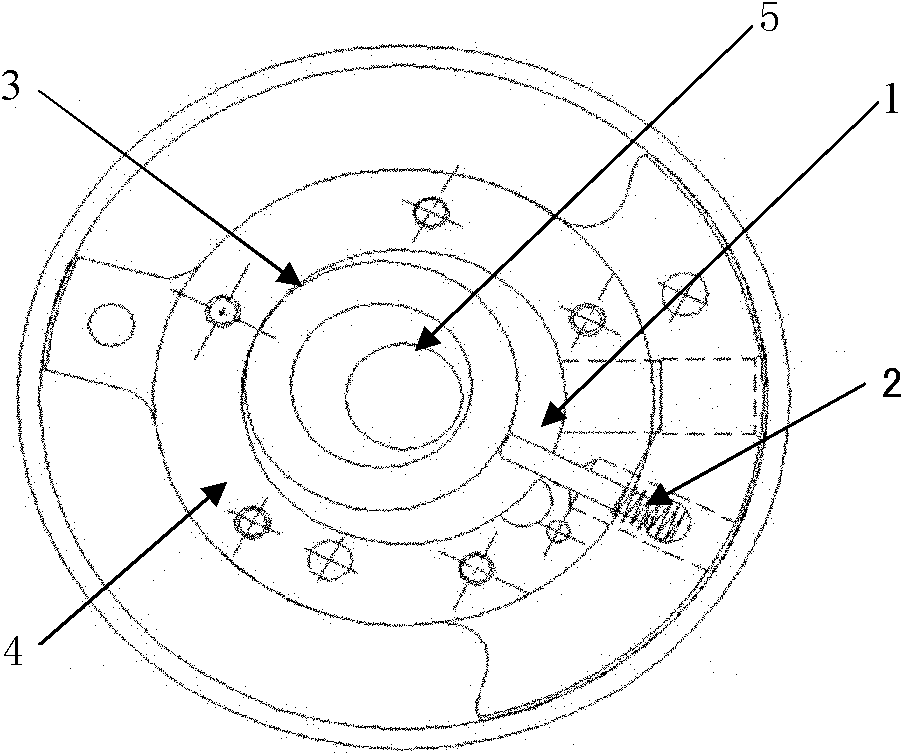

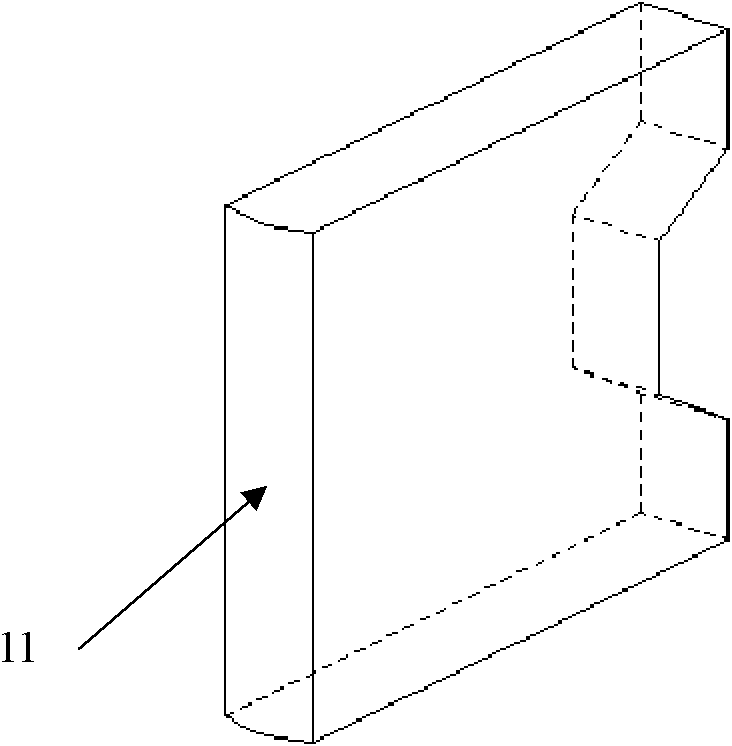

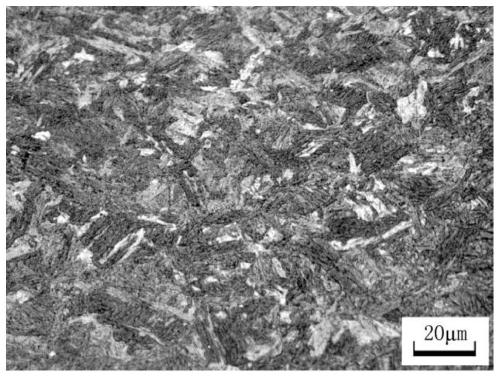

The present invention discloses one kind of new high carbon and high tungsten high speed steel roll and its making process, and belongs to the field of high speed steel roll making technology. The high carbon and high tungsten high speed steel roll contains C 2.0-3.0 wt%, W 6.0-18.0 wt%, V 2.0-4.0 wt%, Mo 1.0-3.0 wt%, Cr 3.0-9.0 wt%, Si less than 1.2 wt%, and Mn less than 1.2 wt%, and possesses MC type composite carbide of V and W. The making process of the high carbon and high tungsten high speed steel roll includes heating high carbon and high tungsten high speed steel to 1580-1620 deg.c before deoxidizing, casting at 1400-1500 deg.c and rotary forming while adding stable magnetic field of 0.05-0.25 T to the centrifuging casting mold and rotating the casting mold at 600-1800 rpm speed.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa

ActiveCN102644034AAdd lessReduce manufacturing costMetal rolling arrangementsSurface layerWeather resistance

The invention discloses a cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa. The high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa comprises the following components in percentage by mass: 0.06-0.12% of C, 0.30-0.60% of Si, 0.80-1.20% of Mn, 0.010-0.030% of P, 0.001-0.015% of S, 0.20-0.35% of Cu, 0.20-0.40% of Cr, 0.15-0.30% of Ni, 0.040-0.060% of Nb, 0.003-0.030% of Als, and the balance of iron and residual trace impurities. The H-shaped steel rolling technology comprises the steps of: heating with a casting blank heating furnace, rolling with a cogging mill, rolling with a universal mill and two-segment quick cooling after the rolling. In the invention, by adopting a two-segment quick cooling method after the hot rolling of the H-shaped steel and by use of a refined crystalline strengthening, precipitation strengthening and phase change strengthening mechanism, the H-shaped steel organization state with single-phase bainite on the surface layer and complex-phase organization inside and with small grains is obtained, the addition of the alloy elements is obviously reduced, the productioncost is lowered, the weather resistance of the H-shaped steel is improved, the welding performance of the steel is enhanced, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

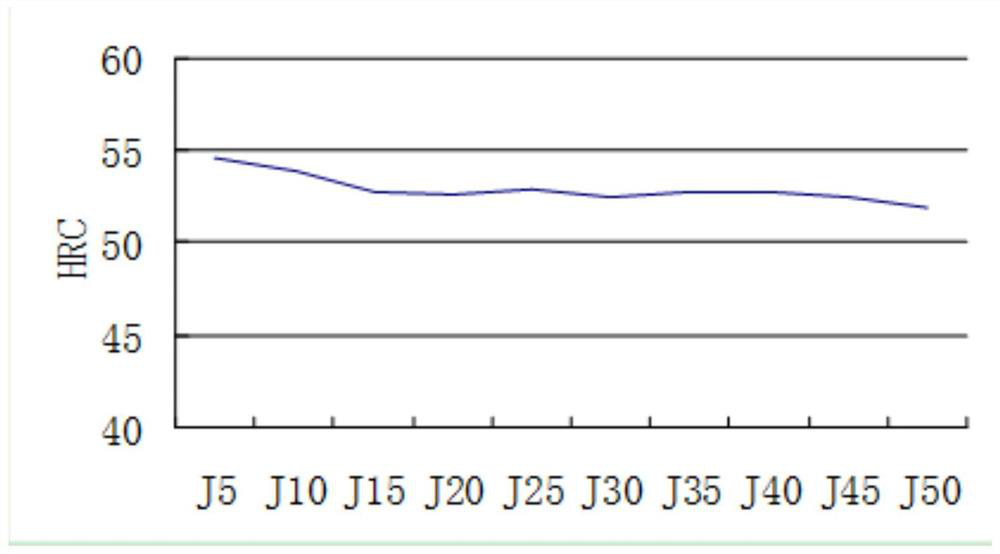

Slide block for rotary type compressor and manufacturing method thereof

ActiveCN102174936AHigh hardnessImprove toughnessRotary/oscillating piston pump componentsLiquid fuel engine componentsHardnessPre treatment

The invention discloses a slide block for a rotary type compressor and a manufacturing method thereof. The slide block which meets the requirement is manufactured by the following steps of: performing pretreatment on GCr15 or GCr15SiMn bearing steel serving as a material; performing cold rolling; cutting; performing heat treatment and dimension stability treatment, and the like. In the invention,the material is selected reasonably, and a proper heat treatment process is achieved, so that the material selection range of the slide block for the rotary type compressor is enlarged, the content of alloy elements of the material is low, the requirement on rare elements is reduced, loads to the environment are reduced, and the raw material cost of the slide block is reduced simultaneously; and a manufacturing process is simple, manufacturing cost is low, and the obtained slide block has high hardness, high toughness and high abrasion resistance and can meet the using requirement of the conventional rotary type compressor.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

Method for cooling low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling

ActiveCN102676919AAdd lessReduce manufacturing costMetal rolling arrangementsHigh intensityHeating furnace

The invention discloses a method for cooling a low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling, wherein the low-alloy hot-rolled H-shaped steel with the yield strength of 550MPa comprises following components by mass: 0.13-0.18% of C, 0.30-0.50% of Si, 1.40-1.60% of Mn, not more than 0.025% of P, not more than 0.025% of S, 0.10-0.12% of V, 0.010-0.014% of N, 0.003-0.030% of Als, and the balance of iron and residual trace impurities; a rolling process of the H-shaped steel is as follows: heating casting blank in a heating furnace, performing rolling by a cogging mill, performing rolling by a universal rolling mill and quickly cooling the steel in two-stage manner after rolling; the method adopts the two-stage quick cooling method after the H-shaped steel is hot-rolled, so that the high-temperature H-shaped steel is cooled to proper temperature at short time; by using the cooling method after colling, texture state of the H-shaped steel with fine crystal particles and complex phase texture is obtained, adding amount of the alloy elements is drastically reduced, production cost is notably reduced when requirement of high-strength performance is satisfied, and welding performance of the steel and production efficiency are improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Cooling after rolling method for low-alloy hot-rolled H-steel with yield strength up to 500MPa

The invention discloses a cooling after rolling method for low-alloy hot-rolled H-steel with yield strength up to 500MPa. The low-alloy hot-rolled H-steel with the yield strength up to 500MPa comprises the following components in weight percentage: 0.08-0.14 percent of C, 0.30-0.50 percent of Si, 1.20-1.40 percent of Mn, not greater than of 0.025 percent of P, not greater than 0.020 percent of S, 0.025-0.050 percent of Nb, 0.003-0.030 percent of Als and the balance of ferrum and residual trace impurities. An H-steel rolling process comprises the following steps of: heating a casting blank in a heating furnace, rolling by a roughing mill, rolling by a universal rolling mill, and performing two-stage rapid cooling after rolling is ended. According to the cooling after rolling method for the low-alloy hot-rolled H-steel with the yield strength up to 500MPa, through adopting a two-stage rapid cooling method after hot rolling is performed on the H-steel, the H-steel with higher temperature can be cooled to the proper temperature in a short time. By adopting the cooling after rolling method, an H-steel texture with fine grains and a multiphase structure can obtained, thereby, the additive amount of alloying elements is greatly reduced; and while the high-strength performance requirement is met, the production cost can be obviously reduced, the welding performance of the steel is improved, and the production efficiency is also increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

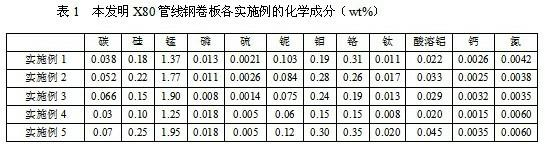

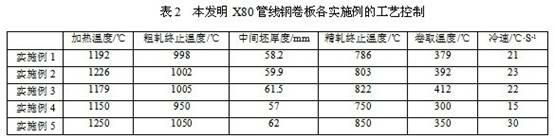

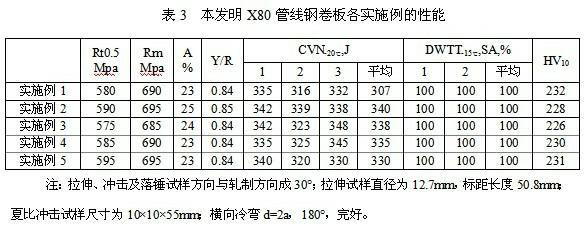

X80 pipeline steel coil with low cost and high toughness and production method thereof

The invention relates to an X80 pipeline steel coil with low cost and high toughness and a production method thereof, belonging to the technical field of low-alloy steel. The X80 pipeline steel coil comprises the following chemical components by percent: 0.03-0.07 percent of C, 0.10-0.25 percent of Si, 1.25-1.95 percent of Mn, at most 0.018 percent of P, at most 0.005 percent of S, 0.06-0.12 percent of Nb, 0.15-0.30 percent of Mo, 0.008-0.020 percent of Ti, 0.15-0.35 percent of Cr, 0.020-0.045 percent of Als, 0.0015-0.0035 percent of Ca, at most 0.0060 percent of N and the balance of Fe and inevitable impurities. The X80 pipeline steel coil disclosed by the invention has the advantages of simple component design and low production cost, and a lot of precious metal resources are saved. Meanwhile, the X80 pipeline steel coil has higher mechanical property and good impact toughness and has a wide market promotion prospect.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

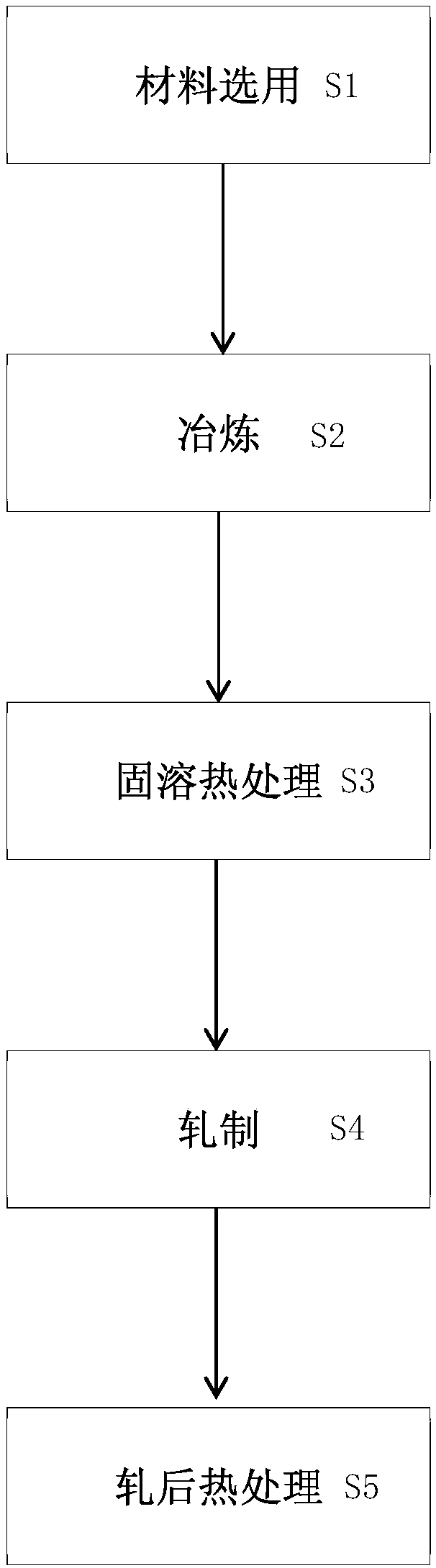

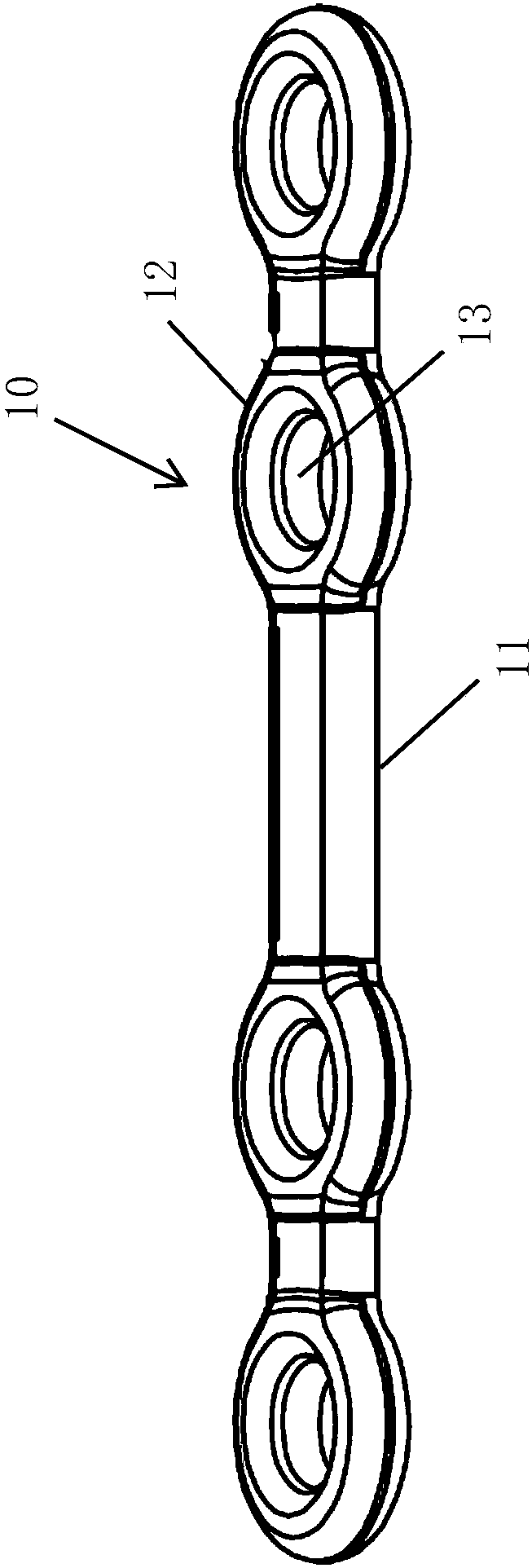

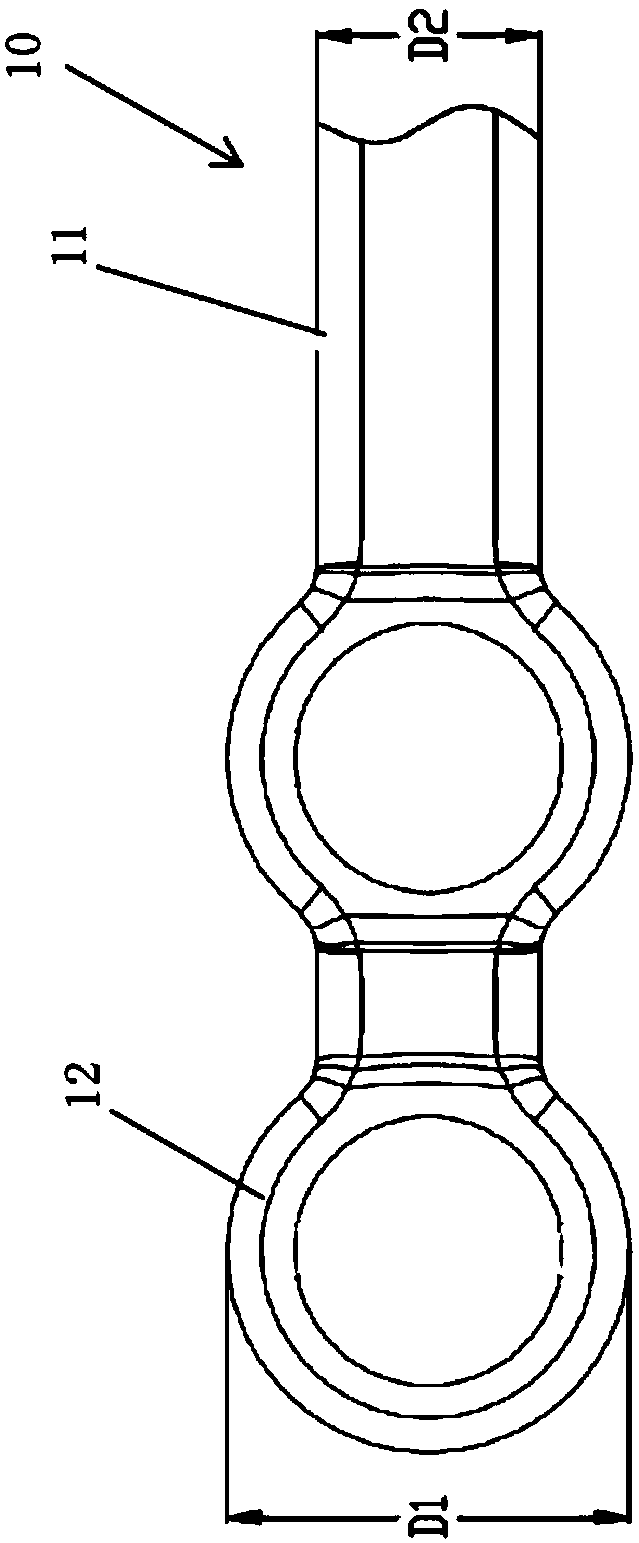

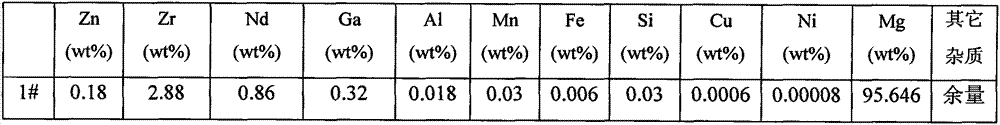

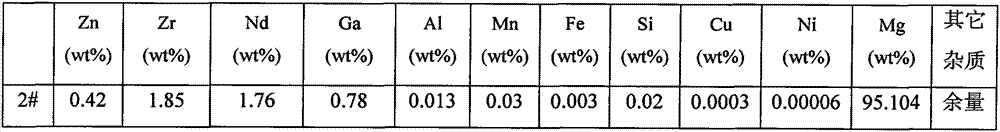

Low-alloyed degradable miniature inner fixed assembly, magnesium alloy preparation method and magnesium alloy material

PendingCN108236495ALow content of alloying elementsLow impurity contentFastenersBone platesMagnesium alloySmelting

The invention discloses a low-alloyed degradable miniature inner fixed assembly, a magnesium alloy preparation method and a magnesium alloy material. The low-alloyed magnesium alloy material which ismicro in impurity content and low in degrading rate is obtained by means of the preparation methods of smelting, solution heat treatment and the like. Different strength and plasticity are matched bymeans of adjusting and rolling and post-rolling annealing process of the magnesium alloy material, so as to prepare medical implant miniature inner fixed assemblies which have different demands on strength and plasticity.

Owner:西安卓恰新材料科技有限公司

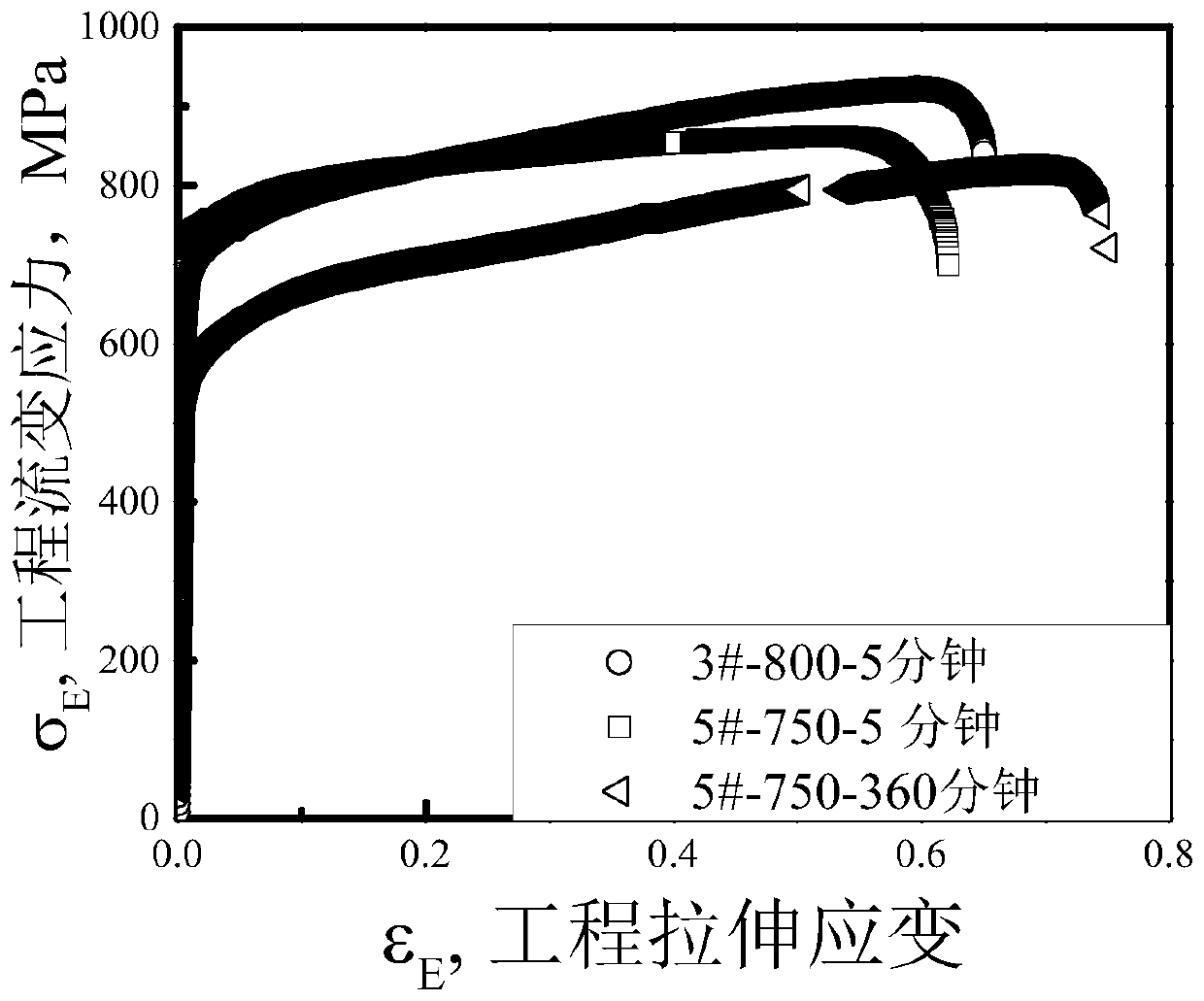

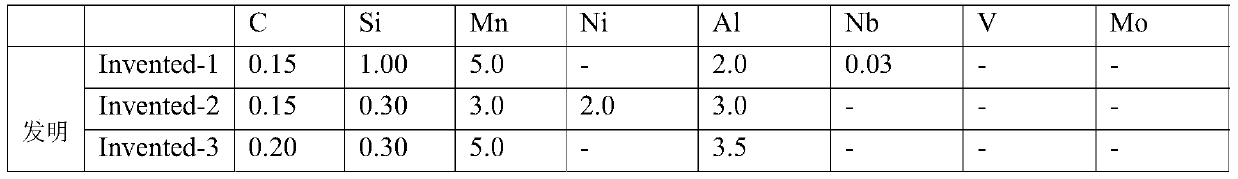

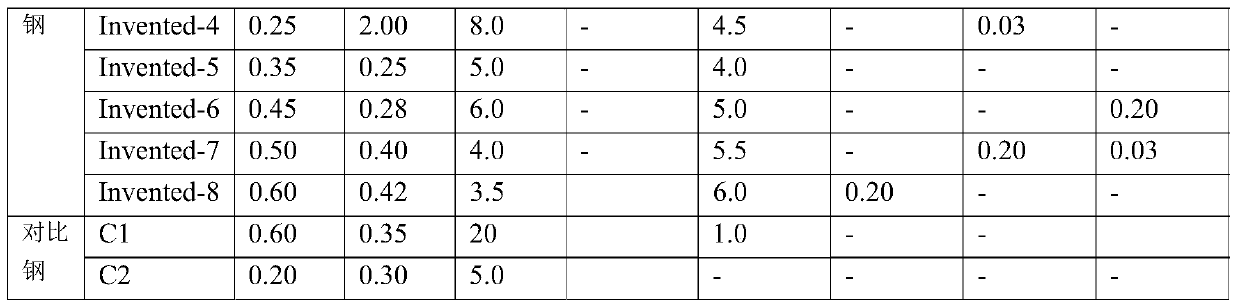

Automobile steel with high toughness and high product of strength and elongation and preparation method thereof

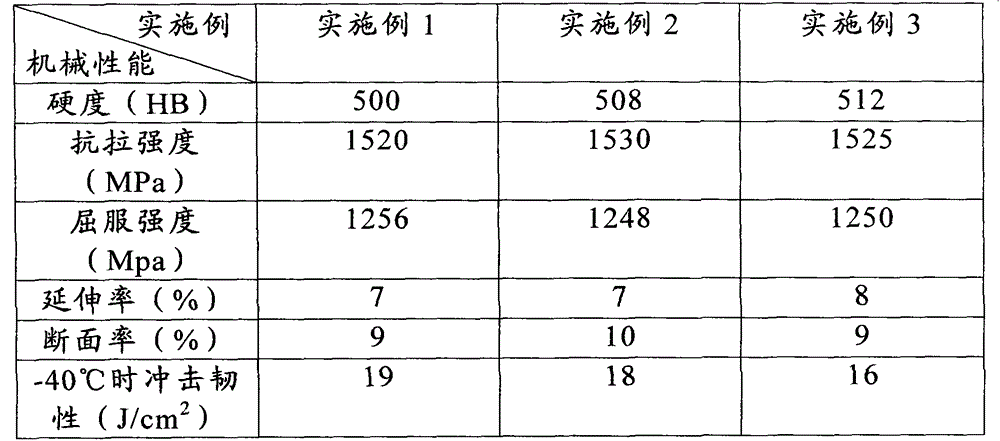

ActiveCN111575580AIncreased strength and plasticityHigh alloy contentMechanical propertyImpact toughness

The invention discloses automobile steel with high toughness and high product of strength and elongation and a preparation method thereof, and belongs to the technical field of preparation of automobile steel with high toughness and high product of strength and elongation. The steel comprises, by weight, 0.15%-0.60% of C, 0%-2.0% of Si, 0%-2.0% of Ni, 3.0-6.0% of Mn, 2.0-6.0% of Al, and the balance of Fe and inevitable impurity elements. On this basis, one or more of the following microalloying elements can be added: by weight, 0-0.10% of Nb, 0-0.10% of V, 0-0.10% of Ti, 0-0.10% of Mo, 0-0.50%of Cu, and 0.0005-0.005% of B. The automobile steel and the preparation method have the advantages that a multi-phase, multi-layer and metastable microstructure is formed through alloying of C, Mn, Al and the like and rolling and annealing of a two-phase region; at -40 DEG C, the V-type impact toughness is not smaller than 120 J, the product of strength and elongation is not lower than 50 GPa%, the cost is far lower than that of traditional high manganese steel, the comprehensive mechanical property is far higher than that of medium manganese steel, and low cost and high performance are achieved. The automobile steel can be applied to the field of white automobile body and transmission part manufacturing in the form of bars or plates.

Owner:CENT IRON & STEEL RES INST

Wear-resistant hammer head for crusher and production method thereof

InactiveCN102634734AHigh hardnessTough enoughFoundry mouldsFurnace typesWear resistantEvanescent mode

The invention relates to a wear-resistant hammer head for a crusher, and a production method of the wear-resistant hammer head, and belongs to a wear-resistant hammer head for a crusher, and a production method of the wear-resistant hammer head. The invention aims at mainly solving the technical problems of that the wear resistance is poor and the service life is short in the prior art. According to the technical scheme, the wear-resistant hammer head for the crusher comprises the following raw materials by weight percent: 0.9-1.2% of C, 11.0-14.0% of Mn, 0.3-0.7% Si, 0.1-0.5% Cr, less than or equal to 0.3% of Mo, less than 0.1% of V, less than or equal to 0.1% of Ti, less than or equal to 0.04% of P and S, 0.1-0.4% of Re, 0.3-0.6% of No.1 Tieshen, and the balance of Fe. The production method comprises the steps of: manufacturing an evanescent mode-manufacturing a sand mould-smelting alloy-conducting modification-pouring-cleaning-conducting thermal treatment. According to the wear-resistant hammer head and the production method, the rigidity is high, the toughness is enough, the wear resistance is improved greatly, the service life is prolonged by one time compared with the original service life, and the wear-resistant hammer head is especially applicable to non-strong-impaction working conditions.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cast aluminum alloy applied to automobile suspension bracket and preparation method of cast aluminum alloy

The invention discloses cast aluminum alloy applied to an automobile suspension bracket. The cast aluminum alloy comprises the following chemical components in percentage by weight: 6-7% of Si, 3-4% of Cu, 0.05-0.12% of Re (La, Ce) and the balance of Al, wherein Re (La, Ce) comprises the following components in percentage by weight: 33% of La and 66% of Ce. The cast aluminum alloy is a novel material which is prepared by adding La-Ce mixture rare earth on the basis of the components of aluminum alloy with the brand number being ZL107, and strictly controlling the lower limit of a main alloy element in the national standard range and the content of impurity element Fe; the rare earth elements are added in a manner of Al-Re intermediate alloy. The suspension bracket produced by using the material is good in strength, good in anti-fatigue performance and relatively high in specific strength.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Casting medium alloy steel for cold stamping mould of automobile

The invention relates to casting medium alloy steel for a cold stamping mould of an automobile. The casting medium alloy steel is characterized by comprising the following chemical components in percentage by weight: 0.50-0.65% of C, 0.90-1.20% of Si, 0.60-0.90% of Mn, 4.50-5.50% of Cr, 0.75-0.90% of Mo, 0.70-0.80% of V, less than or equal to 0.02% of S or less than or equal to 0.03% of P. The casting medium alloy steel has high wear resistance and strong toughness, is low in production cost, is easy to process, has the overall quenching hardness of HRC59-62 and can meet the use requirements of the mould.

Owner:CHINA FIRST AUTOMOBILE +1

Steel for high-pressure oil pipe, high-pressure oil pipe and preparation method of high-pressure oil pipe

ActiveCN107747035ALow content of alloying elementsReduce manufacturing costFurnace typesHeat treatment furnacesChemical compositionCarbide

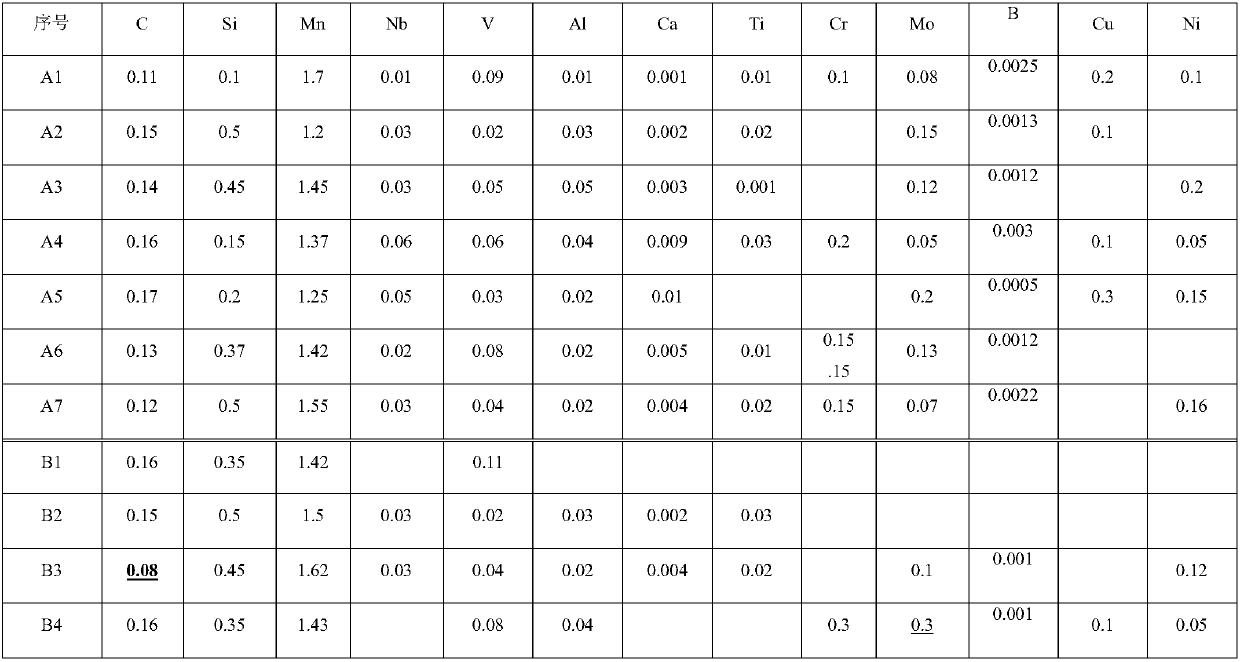

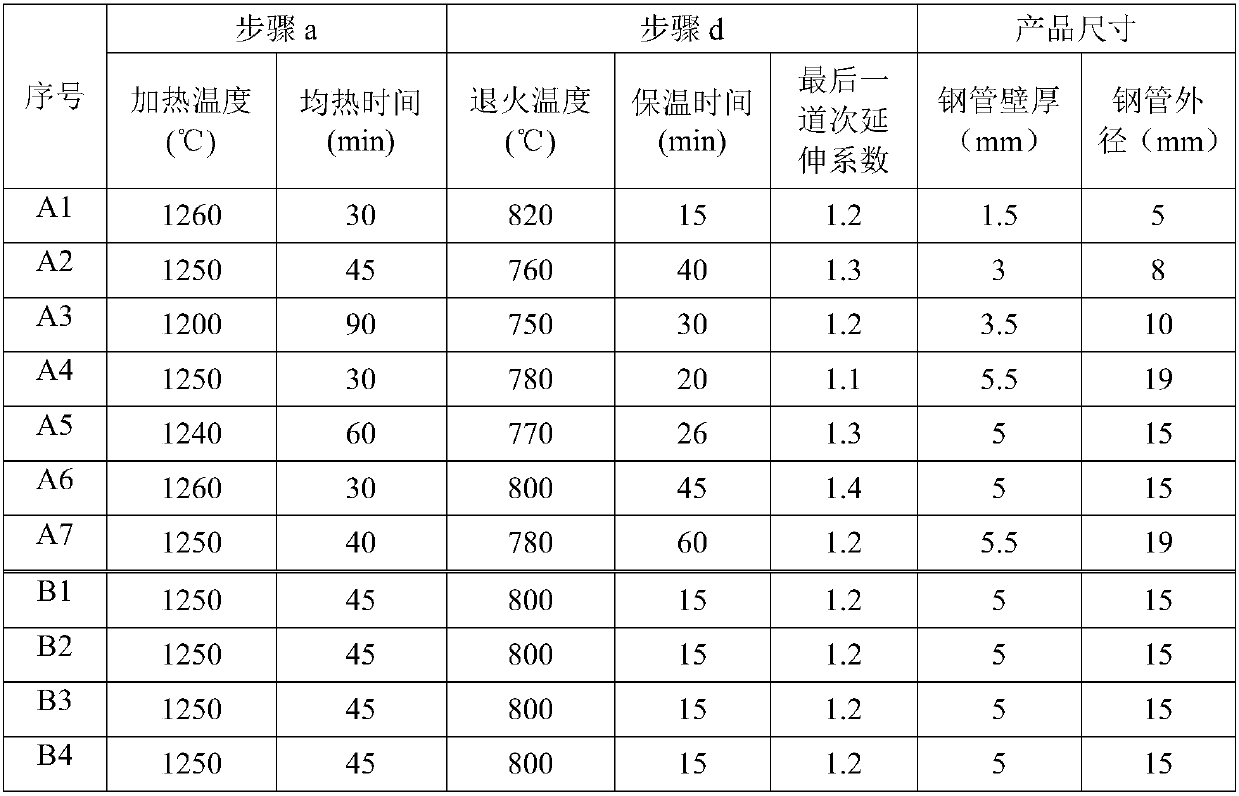

The invention discloses steel for a high-pressure oil pipe, the high-pressure oil pipe and a preparation method of the high-pressure oil pipe. The steel for the high-pressure oil pipe is composed of the chemical components of, by mass, 0.11%-0.17% of C, 0.1%-0.5% of Si, 1.2%-1.7% of Mn, 0.01%-0.05% of Al, 0.01%-0.06% of Nb, 0.02%-0.09% of V, 0.05%-0.2% of Mo, 0.0005%-0.003% of B, not larger than 0.03% of Ti, not larger than 0.2% of Cr, not larger than 0.2% of Ni, not larger than 0.3% of Cu, 0.001%-0.01% of Ca and the balance Fe and other inevitable impurities, wherein the chemical components meet the relationship expression that 4<(B*Mo) / (C*Mn)*10<4> <12. The structure of the steel for the high-pressure oil pipe is ferrite + dispersive distribution carbide + tempered sorbite, the steel forthe high-pressure oil pipe can reach the high performance grade of 670 MPa and over, and the performance cost ratio of the steel for the high-pressure oil pipe is high .

Owner:SHANGHAI UNIV

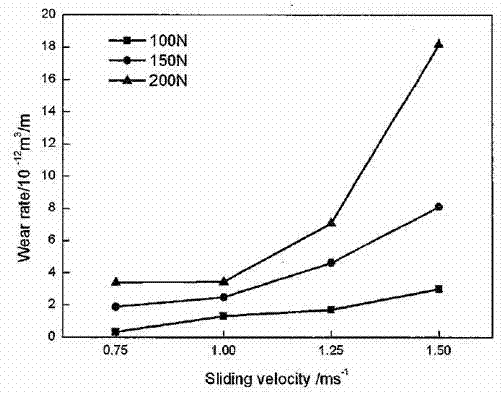

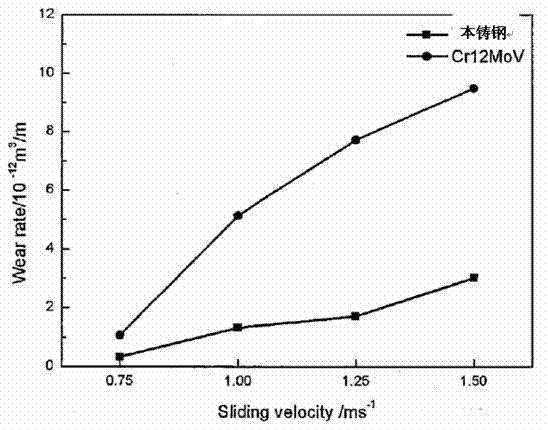

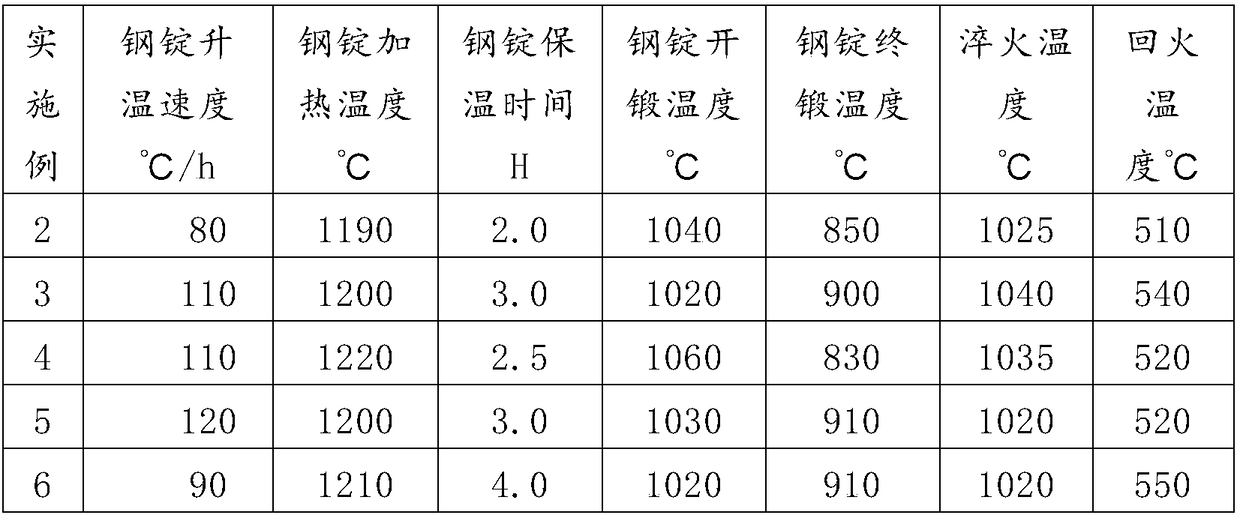

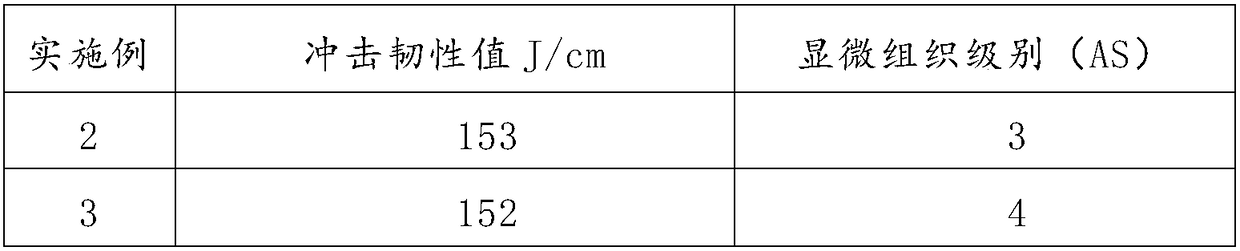

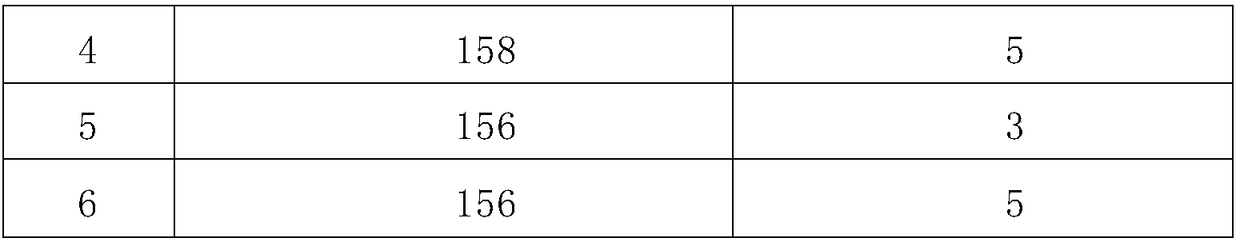

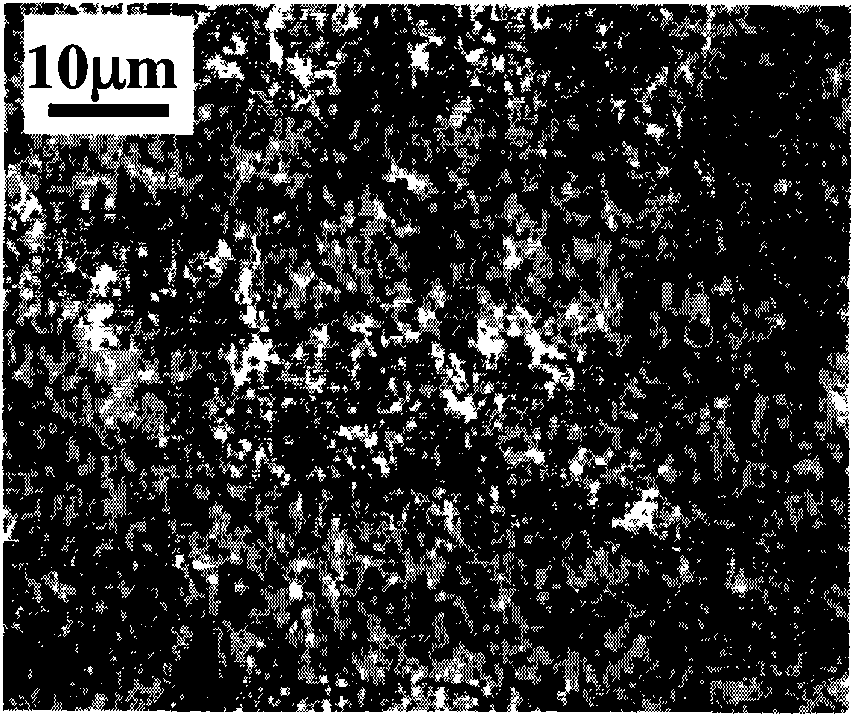

High impact toughness cold work die steel and preparation method thereof

The invention provides high impact toughness cold work die steel and a preparation method thereof. The die steel includes the following elements, by weight percent, 0.45-0.50% of C, 0.10-0.30% of Si,0.40-0.60% of Mn, 4.80-5.30% of Cr, 2.20-2.40% of Mo, and 0.50-0.90% of V, with the balance being iron and unavoidable impurity elements. The preparation method includes smelting a steel ingot, and taking the steel ingot as a consumable electrode to perform electroslag remelting so that a liquid metal can be obtained; cooling the liquid metal to an electroslag ingot; performing forging processingafter keeping the electroslag ingot under 1190-1220 DEG C for 2-4 hours; and performing quenching and tempering in order to obtain high impact toughness cold work die steel. The alloy element component design of the cold work die steel is to suitably reduce C and Cr and increase Mo and V on the basis of Cr<12>MoV, so that eutectic carbide can be reduced and refined, grains can be refined, and goodmicrostructures can be obtained.

Owner:宝武特种冶金有限公司

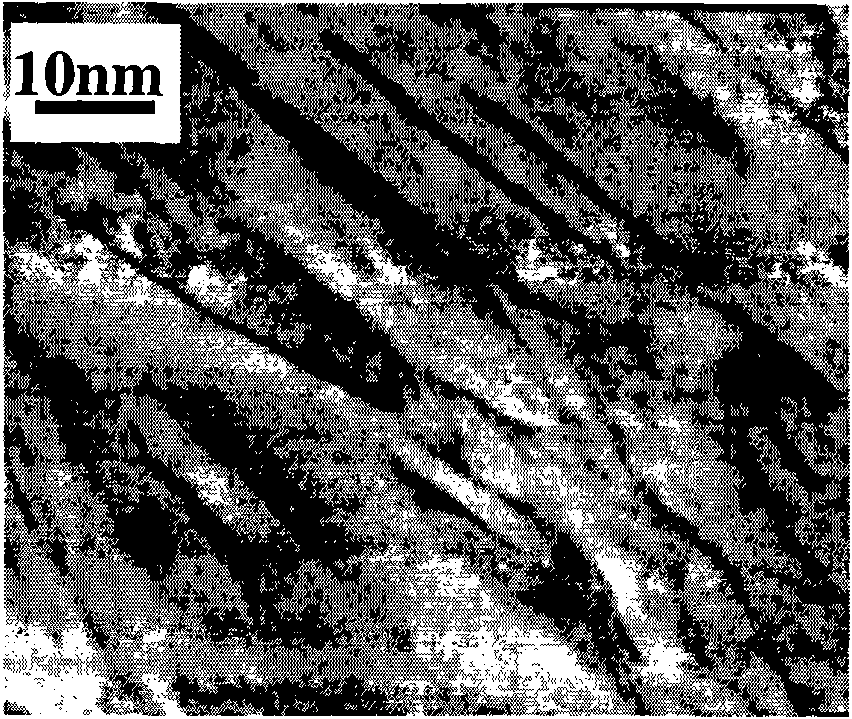

Ultra-high strength hot rolling wire rod of 2200 Mpa level and manufacture method thereof

ActiveCN101586208ALow content of alloying elementsSave resourcesTemperature control deviceWork treatment devicesWire rodChemical composition

The invention provides an ultra-high strength hot rolling wire rod of 2200 Mpa level and a manufacture method thereof. The ultra-high strength hot rolling wire rod of 2200 Mpa level comprises the following chemical components by weight percentage: 0.40 to 0.60 percent of C, 2.5 to 4.0 percent of Si, 3.0 to 5.0 percent of Mn, 0.40 to 0.60 percent of Mo, and the balance of Fe and unavoidable impurities. The invention adopts Mn-Si-Mo line components, and obtains the hot rolling wire rod taking a nanometer scale martensite structure as the characteristic through purification smelting, forging, rough rolling, finish rolling and the silking technology with the width of a martensite slab of about 5 to 15 nm. The ultra-high strength hot rolling wire rod has the steel yield strength no less than 1900 Mpa, the tensile strength no less than 2200 Mpa, the yield ratio no less than 0.85 percent, the elongation no less than 8.0 percent and the reduction of area no less than 40 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

Cooling after rolling method for high-weather fastness hot-rolled H-steel with yield strength up to 550MPa

The invention discloses a cooling after rolling method for high-weather fastness hot-rolled H-steel with yield strength up to 550MPa. The high-weather fastness hot-rolled H-steel with the yield strength up to 550MPa comprises the following components in weight percentage: 0.06-0.12 percent of C, 0.30-0.60 percent of Si, 1.25-1.50 percent of Mn, 0.010-0.030 percent of P, 0.001-0.015 percent of S, 0.20-0.35 percent of Cu, 0.20-0.40 percent of Cr, 0.15-0.30 percent of Ni, 0.10-0.12 percent of V, 0.008-0.014 percent of N, 0.003-0.030 percent of Als and the balance of ferrum and residual trace impurities. An H-steel rolling process comprises the following steps of: heating a casting blank in a heating furnace, rolling by a roughing mill, rolling by a universal rolling mill, and performing two-stage rapid cooling after rolling is ended. According to the cooling after rolling method for the high-weather fastness hot-rolled H-steel with the yield strength up to 550MPa, through adopting a two-stage rapid cooling method after hot rolling is performed on the H-steel and by utilizing a refined crystalline strengthening mechanism, a precipitation strengthening mechanism and a phase change strengthening mechanism, an H-steel texture which is provided with single-phase bainite on the surface layer, is of a multiphase structure inside and has fine grains is obtained, thereby, the additive amount of alloying elements is reduced, the production cost is obviously reduced, the welding performance of the steel is improved, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

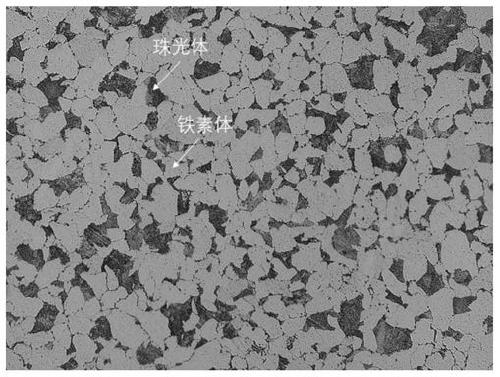

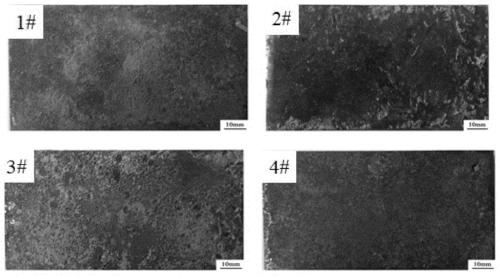

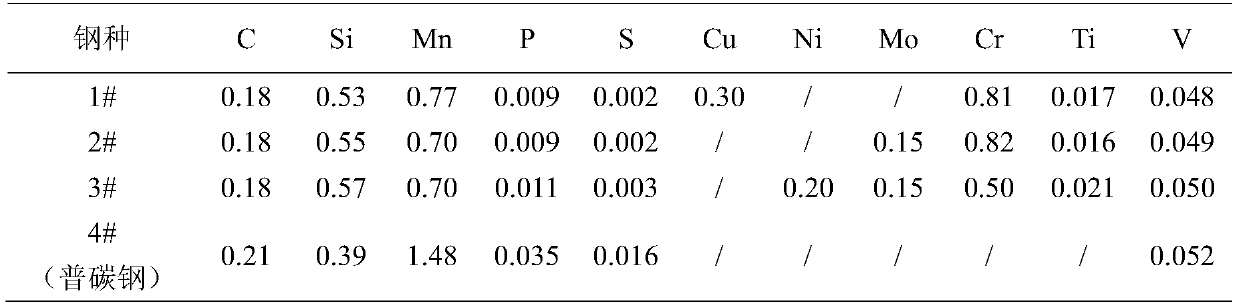

Steel for anti-corrosion steel bar for tropical ocean atmospheric environment concrete structure and production method thereof

The invention discloses an anti-corrosion steel bar for a tropical ocean atmospheric environment concrete structure and a production method thereof, and belongs to the technical field of anti-corrosion materials. The steel bar comprises the following chemical components in percentage by weight: C: 0.16-0.21%, Si: 0.35-0.65%, Mn: 0.70-1.20%, P: less than or equal to 0.030%, S: less than or equal to0.030%, Cr: 0.40-1.00%, Cu: less than or equal to 0.35, Ni: less than or equal to 0.45%; Mo: 0.10-0.20%, Ti: less than or equal to 0.025%, V: 0.030-0.050%, N: less than or equal to 0.0080%, and the balance Fe and inevitable impurities. A small amount of alloy elements are added on the basis of the carbon steel bar, and through optimization of the content and proportion of the alloy elements, thenovel steel bar with excellent corrosion resistance is obtained. The steel for the anti-corrosion steel bar meets the requirements of mechanical performance and welding performance of the tropical marine atmospheric environment concrete structure, the corrosion resistance of the steel bar is 2-4 times that of HRB400E steel bars, and the durability of the reinforced concrete structure can be effectively prolonged.

Owner:ANGANG STEEL CO LTD +1

High-strength and high-plasticity magnesium alloy material and preparation method thereof

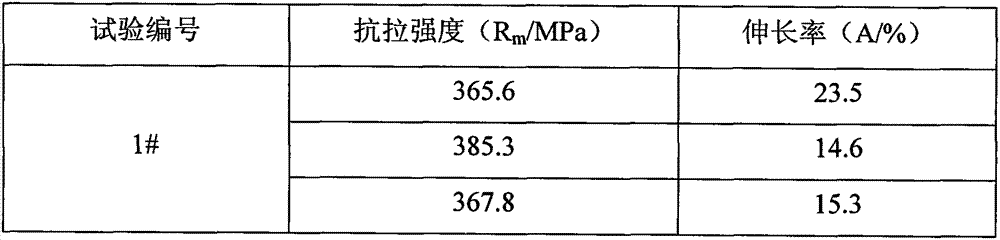

InactiveCN102787264AHigh strength and high plasticityHigh strengthRoom temperatureMechanical property

The present invention relates to a high-strength and high-plasticity magnesium alloy material and a preparation method thereof. The alloy material comprises the following components, by weight: 0.5-3.Swt% of Nd, 0.2-1.2wt% of Ga, 1.5 -4.5wt% of Zr, 0.1-1.0wt% of Zn; impurity elements comprising no more than 0.02wt% of Al, no more than 0.05wt% of Mn, no more than 0.01wt% of Fe, no more than 0.05wt% of Si, no more than 0.001wt% of Cu, no more than 0.001wt% of Ni and no more than 0.05v% of other impurity elements; and the balance of Mg. The preparation method comprises steps of: heating pure magnesium and pure Zn in an industrial line-frequency induction melting furnace to higher than 400 DEG C and introducing argon at 1-2.0L / min for protection; heating to 720+ / -10 DEG C; insulating for 15-30 m to completely melt the metal materials; insulating for 20min after melting; successively adding a piece of Mg-Nd intermediate alloy and a piece of Mg-Ga intermediate alloy; insulating for 10-15 min after melting; adding a piece of Mg-Zr intermediate alloy; and insulating for 3-5 min after melting. The invention has the following advantages: raw materials have wide sources; and the high-strength and high-plasticity magnesium alloy material, with mechanical properties at room temperature reaching Rm no less than 350MPa and A no less than 12%, is prepared through alloying scientific formula design of Zn, Nd, Ga and Zr, and rolling and heat treatment.

Owner:刘利涛 +1

High-plasticity-toughness low-alloy ultrahigh-strength steel and preparation method

The invention provides high-plasticity-toughness low-alloy ultrahigh-strength steel and a preparation method, and relates to the technical field of engineering materials. The high-plasticity-toughnesslow-alloy ultrahigh-strength steel comprises the following chemical components in percentage by mass: 0.30-0.43% of C, 0.50-1.60% of Mn, 0.80-2.00% of Si, 0.80-1.50% of Cr, 2.50-3.50% of Ni, 0.50-1.50% of W, 0.20-0.80% of Mo, 0.05-0.20% of V, 0.01-0.20% of Nb, not greater than 0.005% of S, not greater than 0.010% of P, not greater than 0.050% of Al, and the balance Fe. The mechanical performanceof the steel material reaches the design index; the steel material can replace G50 and DT300 steel materials in a certain field; and the steel material is higher in hardenability, and can satisfy thelarge-specification requirements on the steel material.

Owner:上海佩琛金属材料有限公司

Cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa

ActiveCN102644034BAdd lessReduce manufacturing costMetal rolling arrangementsWeather resistanceSurface layer

The invention discloses a cooling-after-rolling method of high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa. The high-weather resistance hot-rolling H-shaped steel with yield strength of 500MPa comprises the following components in percentage by mass: 0.06-0.12% of C, 0.30-0.60% of Si, 0.80-1.20% of Mn, 0.010-0.030% of P, 0.001-0.015% of S, 0.20-0.35% of Cu, 0.20-0.40% of Cr, 0.15-0.30% of Ni, 0.040-0.060% of Nb, 0.003-0.030% of Als, and the balance of iron and residual trace impurities. The H-shaped steel rolling technology comprises the steps of: heating with a casting blank heating furnace, rolling with a cogging mill, rolling with a universal mill and two-segment quick cooling after the rolling. In the invention, by adopting a two-segment quick cooling method after the hot rolling of the H-shaped steel and by use of a refined crystalline strengthening, precipitation strengthening and phase change strengthening mechanism, the H-shaped steel organization state with single-phase bainite on the surface layer and complex-phase organization inside and with small grains is obtained, the addition of the alloy elements is obviously reduced, the production cost is lowered, the weather resistance of the H-shaped steel is improved, the welding performance of the steel is enhanced, and the production efficiency is increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for producing thin abrasion-resistant steel through DQ technology

ActiveCN111349759ACurl shape controllableEasy to shapeFurnace typesHeat treatment furnacesHeat conservationAustenite

The invention discloses a method for producing thin abrasion-resistant steel through a DQ technology. The method comprises the following steps of smelting, rough rolling, finish rolling and DQ which are conducted in sequence; during smelting, a cast blank is heated to 1220-1280 DEG C, and heat preservation is conducted for 2-4 h for sufficient austenitizing; the rough rolling temperature is 1050+ / -30 DEG C; the initial temperature of finish rolling is 1020+ / -20 DEG C, the final temperature is 860+ / -20 DEG C, the passing speed of a steel plate is 1.8-3.5 m / s, and the thickness is 4-12 mm; and during DQ, after finish rolling is completed, direct quenching is conducted in a single phase cooling mode, the rate of cooling upper water to cooling lower water is 60-80 / 65-85, the cooling rate is 40-80 DEG C / s, the cooling time is 4-8 s, and then, cooling of the encryption section is conducted for 3-6 s. The production technology is simple, the efficiency is high, the cost is low, the comprehensive performance of the type of steel is excellent, the tensile strength of the steel is higher than or equal to 1200 MPa, and the impact energy is larger than or equal to 50 J at the temperature of -40 DEG C.

Owner:武汉钢铁有限公司

Method for cooling low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling

ActiveCN102676919BAdd lessReduce manufacturing costMetal rolling arrangementsHigh intensityHeating furnace

The invention discloses a method for cooling a low-alloy hot-rolled H-shaped steel with yield strength of 550MPa after rolling, wherein the low-alloy hot-rolled H-shaped steel with the yield strength of 550MPa comprises following components by mass: 0.13-0.18% of C, 0.30-0.50% of Si, 1.40-1.60% of Mn, not more than 0.025% of P, not more than 0.025% of S, 0.10-0.12% of V, 0.010-0.014% of N, 0.003-0.030% of Als, and the balance of iron and residual trace impurities; a rolling process of the H-shaped steel is as follows: heating casting blank in a heating furnace, performing rolling by a cogging mill, performing rolling by a universal rolling mill and quickly cooling the steel in two-stage manner after rolling; the method adopts the two-stage quick cooling method after the H-shaped steel is hot-rolled, so that the high-temperature H-shaped steel is cooled to proper temperature at short time; by using the cooling method after colling, texture state of the H-shaped steel with fine crystal particles and complex phase texture is obtained, adding amount of the alloy elements is drastically reduced, production cost is notably reduced when requirement of high-strength performance is satisfied, and welding performance of the steel and production efficiency are improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN100386461CFlexible structureAdaptableTemperature control deviceHeat treatment process controlOxygenCopper

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

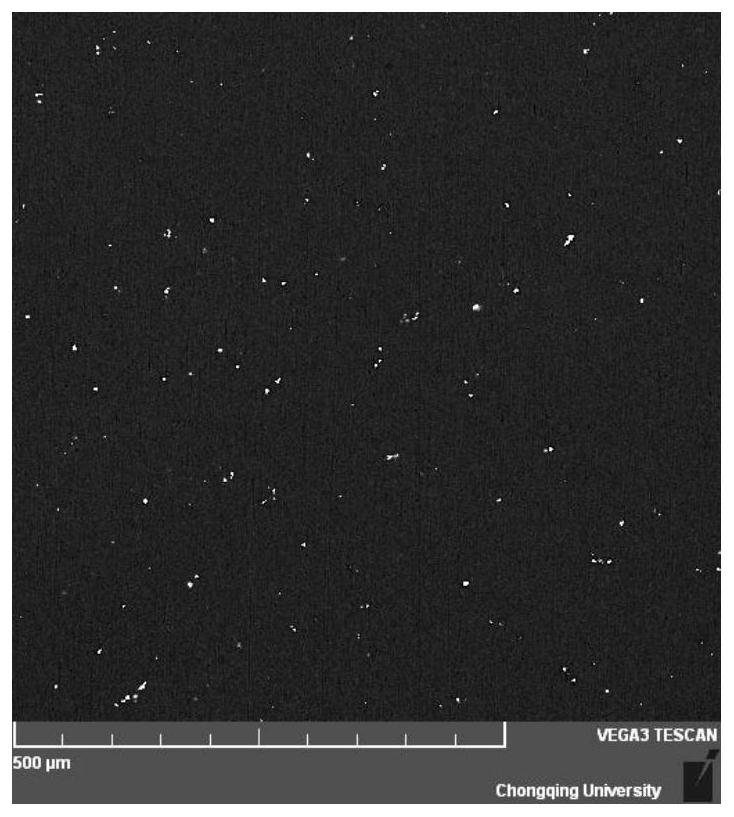

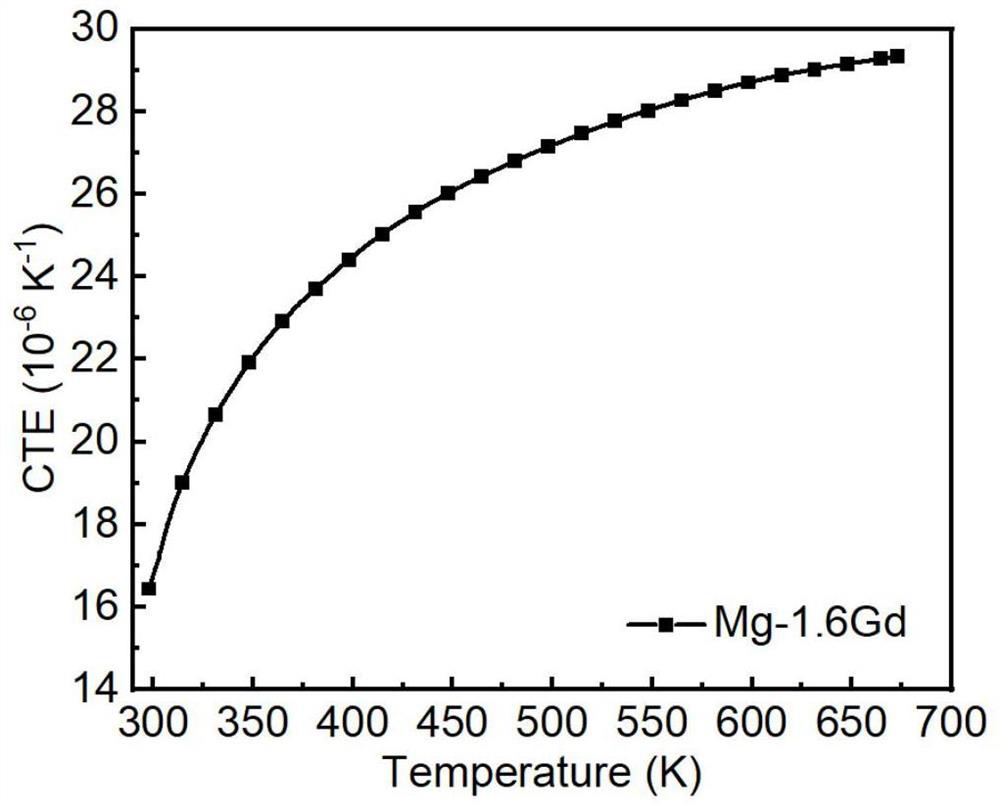

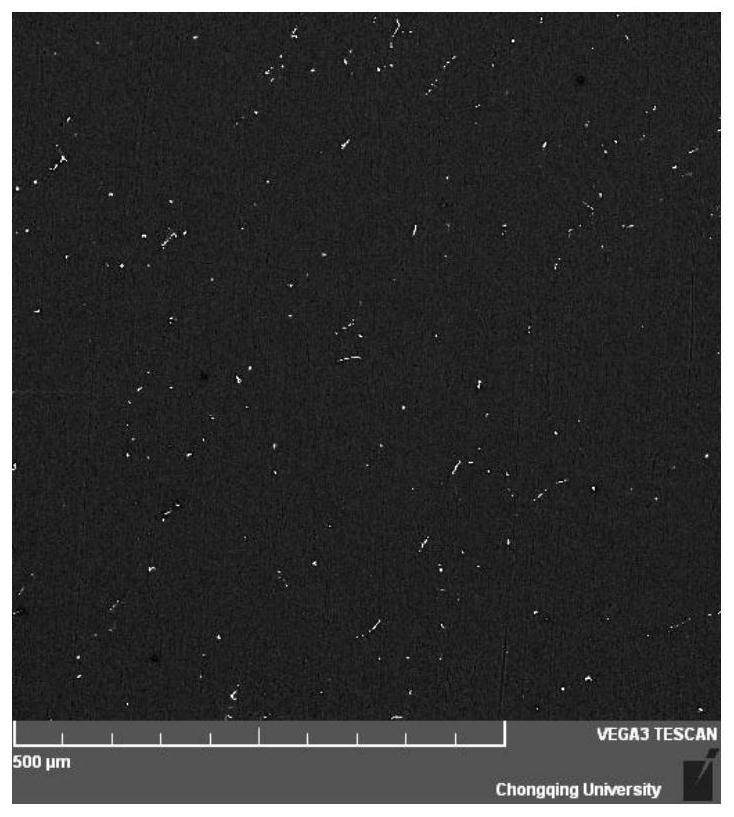

Novel low-expansion binary magnesium alloy and preparation method thereof

ActiveCN114672711AReduce the content of the second phaseReduce stress concentrationSolution treatmentThermal dilatation

The invention discloses a novel low-expansion binary magnesium alloy and a preparation method thereof, the magnesium alloy comprises the following components in percentage by mass: 1.6-15.5% of Gd and the balance of magnesium and inevitable impurity elements, and the thermal expansion coefficient of the magnesium alloy at room temperature is 15.7 * 10 <-6 > K <-1 >-16.4 * 10 <-6 > K <-1 >. By adopting the mode of combining accurate control of the content of the Gd element and the solution treatment process, the content of a second phase in the alloy is greatly reduced, meanwhile, a large number of phase interfaces are prevented from being generated with a magnesium matrix, and the thermal expansion coefficient of the magnesium alloy is effectively reduced. The Mg-Gd alloy not only has a low thermal expansion coefficient, but also has good plastic processing performance, the potential of the Mg-Gd alloy serving as a repair welding material or an electronic element material is greatly improved, the engineering field where magnesium alloy can be applied is expanded, meanwhile, a new research direction is provided for research on preparation of low-expansion magnesium alloy, and the Mg-Gd alloy has great significance.

Owner:CHONGQING UNIV

Method for improving overall performance of multi-phase steel with hot-rolled deformation substructure

The invention particularly relates to a method for improving the overall performance of multi-phase steel with a hot-rolled deformation substructure. According to the technical scheme, the method includes the steps that low-carbon steel subjected to rough rolling is precisely rolled within the section of Ac3-910 DEG C at first, and the precise-rolling reduction rate is accumulated to be 60%-100%;then the temperature is lowered to 540-710 DEG C at the speed of 80-150 DEG C / s; afterwards, heat preservation lasts for 5-12s or air cooling lasts for 5-12s; and finally laminar cooling is conductedto an indoor temperature. The low-carbon steel comprises, by weight, 0-0.10% of C, 0.5%-1.6% of Mn, 0-0.35% of Si, 0-0.030% of Nb, 0.02%-0.06% of Al, 0-0.75% of Cr, 0-0.048% of P, 0-0.005% of S and the balance iron and inevitable impurities. The method for improving the overall performance of the multi-phase steel with the hot-rolled deformation substructure is simple in technology, the content ofthe alloy elements is low, and the overall performance of the obtained multi-phase steel is good.

Owner:WUHAN UNIV OF SCI & TECH

Hot rolling wire rod of 1800 MPa level for low-alloy structure and manufacture method thereof

ActiveCN101586209ALow content of alloying elementsSave resourcesTemperature control deviceWire rodChemical composition

The invention provides a hot rolling wire rod of 1800 MPa level for a low-alloy structure and a manufacture method thereof. The hot rolling wire rod of 1800 MPa level for the low-alloy structure comprises the following chemical components by weight percentage: 0.30 to 0.40 percent of C, 2.0 to 3.0 percent of Si, 2.5 to 4.0 percent of Mn, 0.30 to 0.40 percent of Mo, and the balance of Fe and unavoidable impurities. The invention adopts Mn-Si-Mo line components, and produces a medium carbon hot rolling wire rod which takes fine acicular martensite structure as the characteristic through purification smelting, rough rolling, finish rolling and the controlled cooling technology. The hot rolling wire rod has the steel yield strength no less than 1600 Mpa, the tensile strength no less than 1800 Mpa, the yield ratio no less than 0.80 percent, the elongation no less than 9.0 percent and the reduction of area no less than 40 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

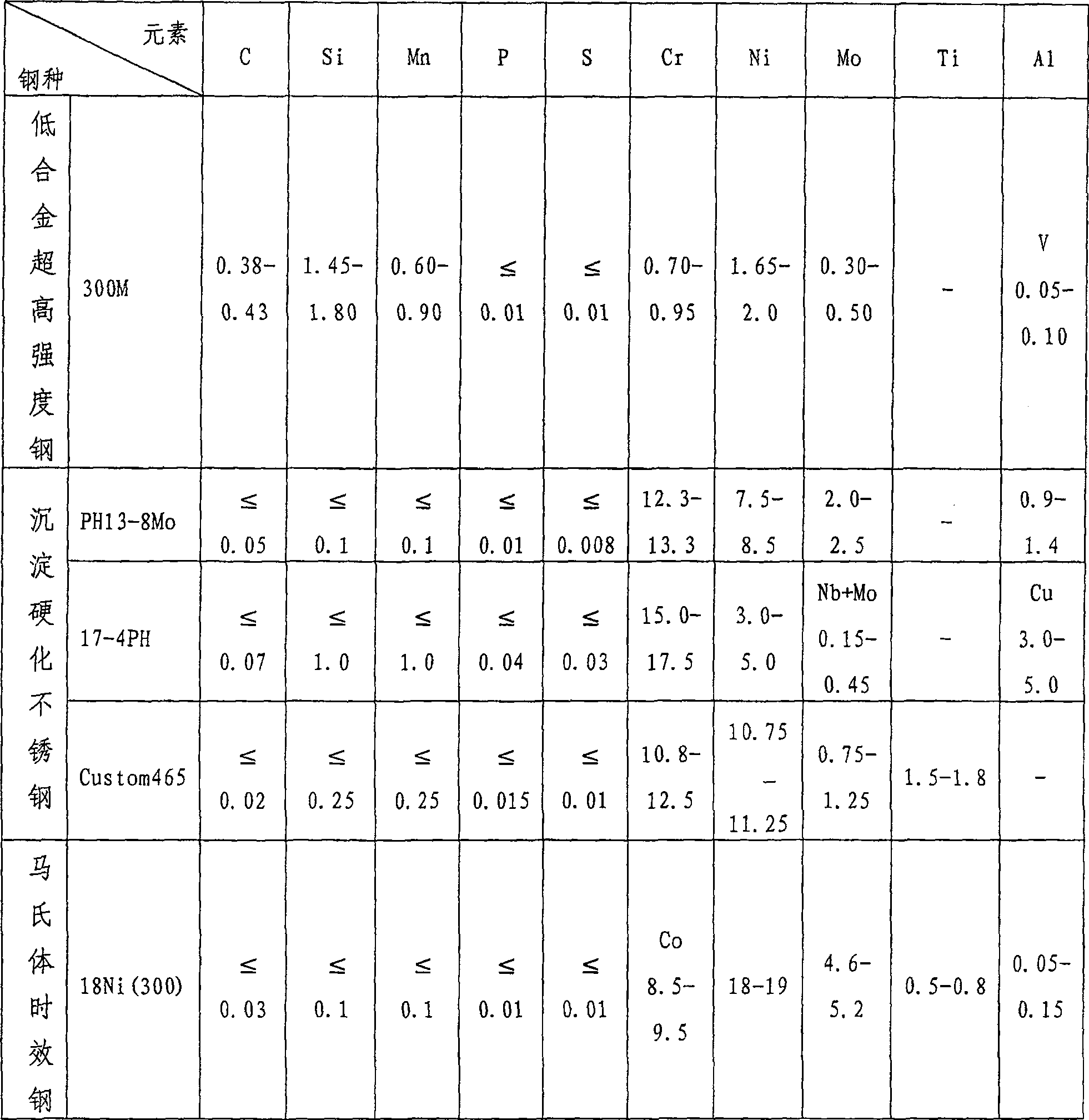

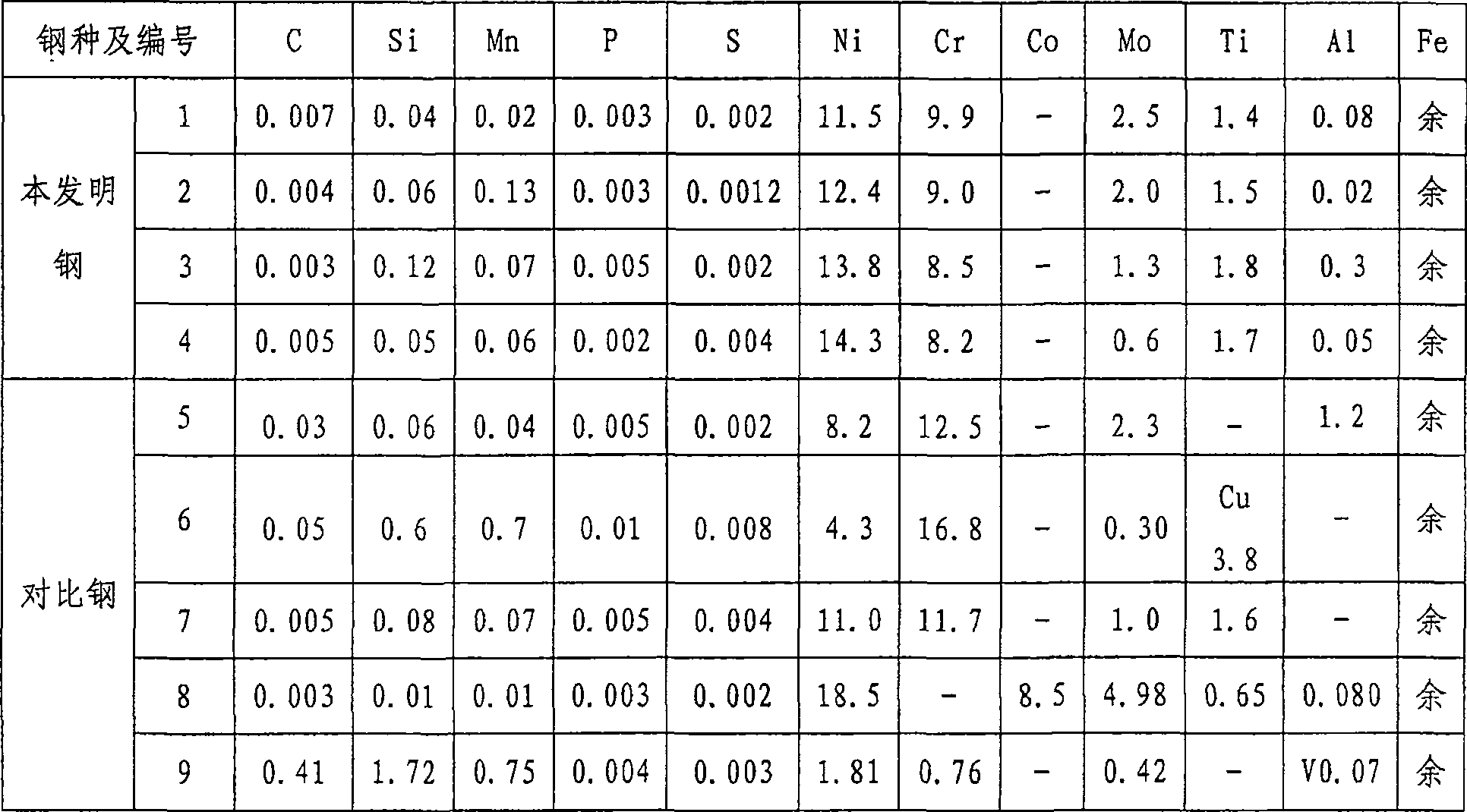

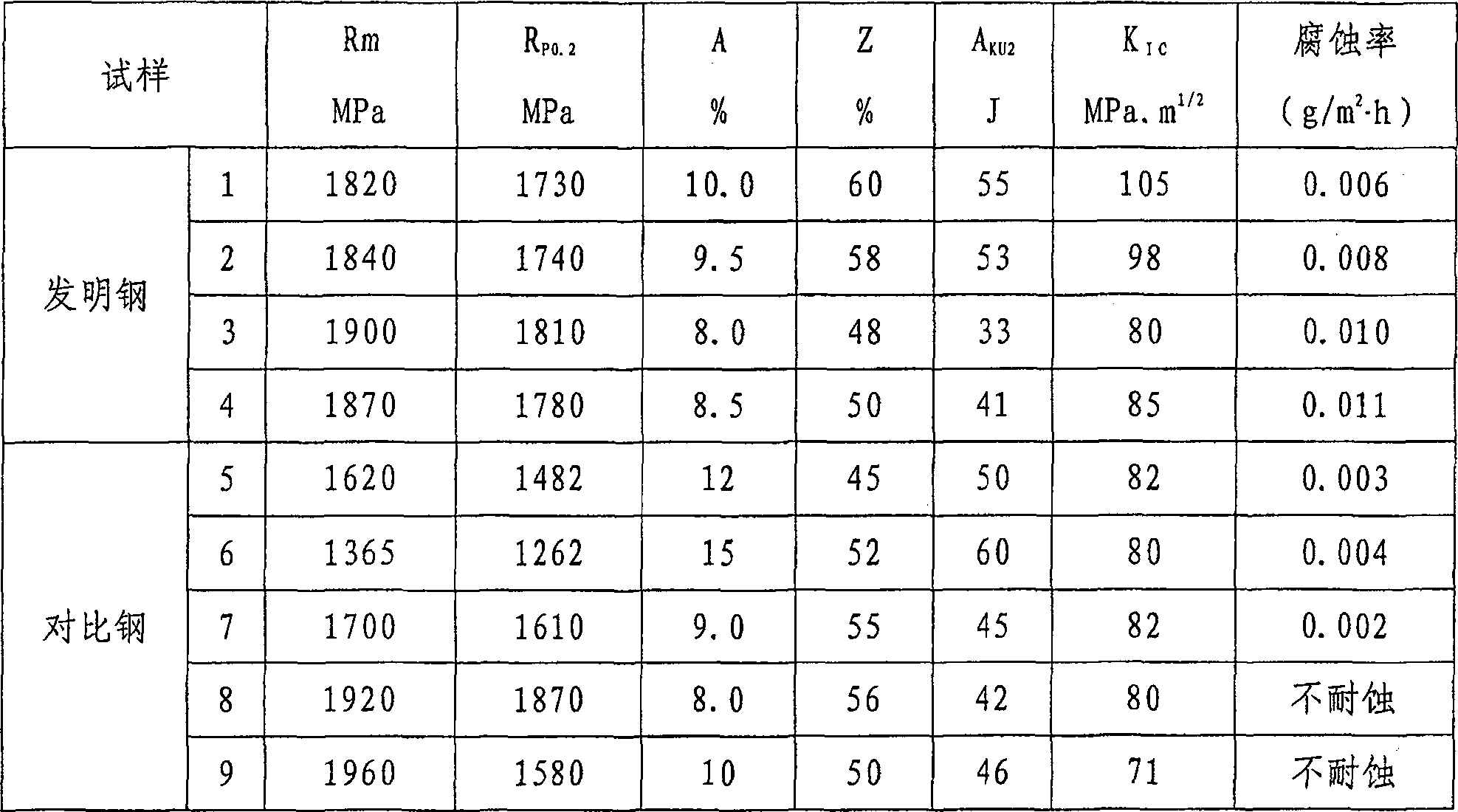

Corrosion resistant structural steel with ultra high strength

This invention relates to an ultrahigh-strength and corrosion-resistant structural steel, whose chemical composition is: C less than or equal to 0.02 wt.%, Si less than or equal to 0.15 wt.%, Mn less than or equal to 0.15 wt.%, S less than or equal to 0.01 wt.%, P less than or equal to 0.01 wt.%, Cr 8.0-10.0 wt.%, Ni 11.5-14.5 wt.%, Mo 0.5-2.5 wt.%, Ti 1.0-2.0 wt.%, Al 0.02-0.5 wt.%, and Fe as balance. The strength of the structural steel is 1800-1900 MPa. The structural steel has such advantages as low cost, high strength, high fracture toughness, and high corrosion resistance.

Owner:CENT IRON & STEEL RES INST

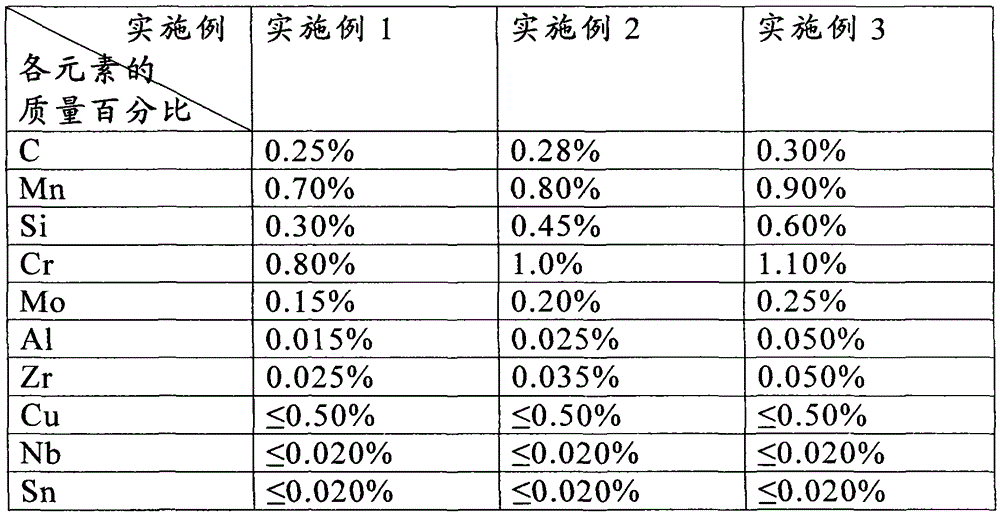

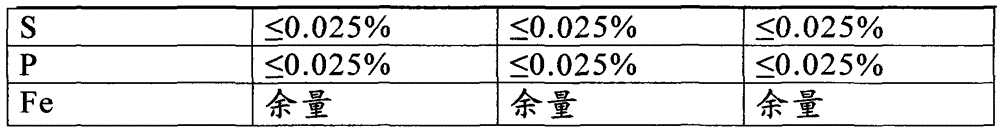

A kind of wear-resistant liner and its preparation method

InactiveCN103114245BImprove mechanical propertiesImprove wear resistanceFurnace typesHeat treatment furnacesWear resistantMechanical property

The invention discloses a wear-resistant lining board and a preparation method thereof. The invention solves the problems of high cost and the like in the wear-resistant lining board in the prior art. The wear-resistant lining board comprises the following component elements in percentage by mass: 0.25%-0.30% of C, 0.70%-0.90% of Mn, 0.30%-0.60% of Si, 0.8%-1.10% of Cr, 0.15%-0.25% of Mo, 0.015%-0.050% of Al, 0.025%-0.050% of Zr, at most 0.50% of Cu, at most 0.020% of Nb, at most 0.020% of Sn and the balance of Fe and inevitable impurity. The invention also provides a preparation method of the wear-resistant lining board, which comprises the following steps: proportioning, casting, casting head cutting and heat treatment. The wear-resistant lining board disclosed by the invention has the advantages of low cost, favorable mechanical properties and long service life.

Owner:NINGBO HUADIAN CAST STEEL

Ultrafine-grain steel pipe and process for manufacturing the same

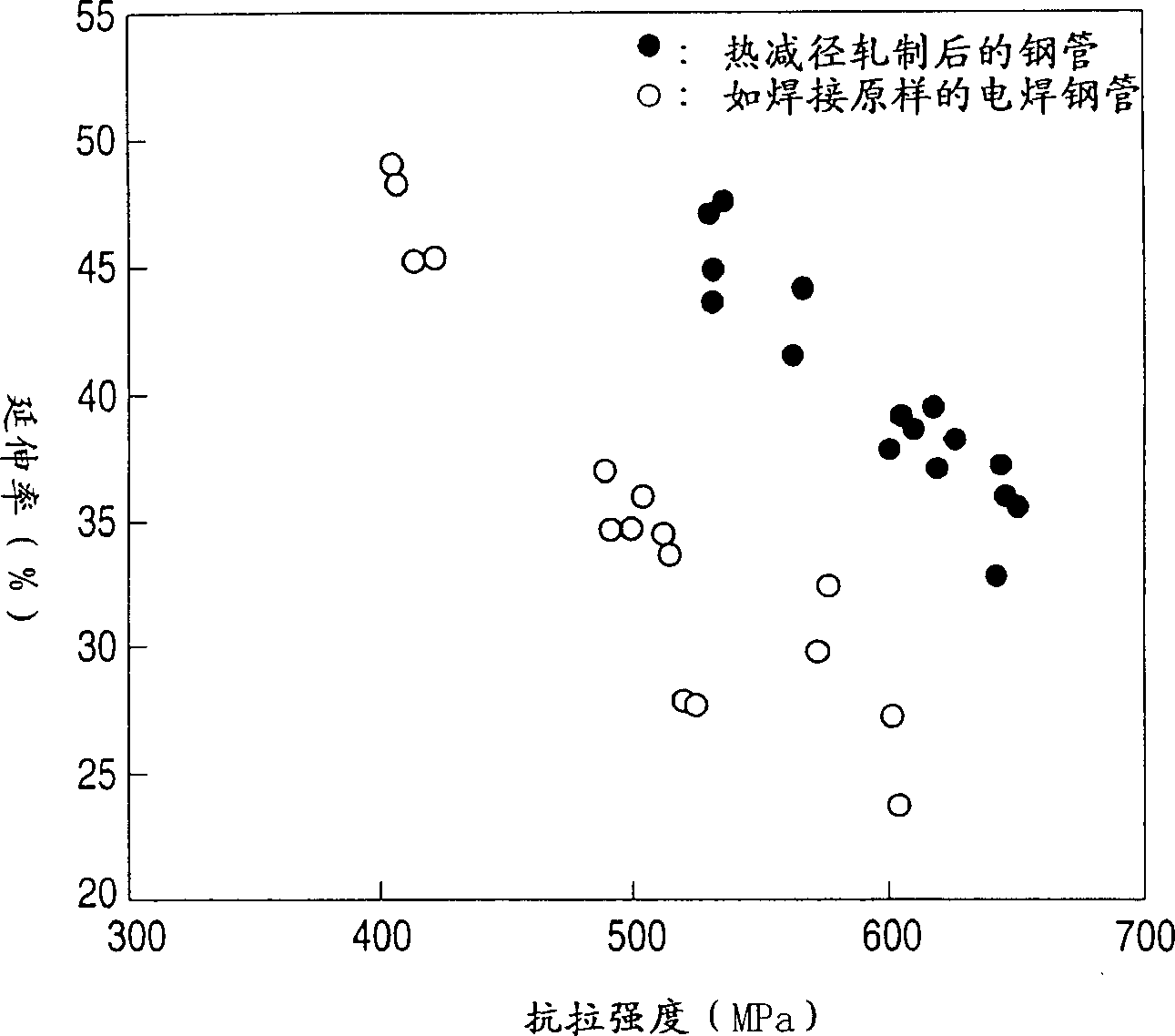

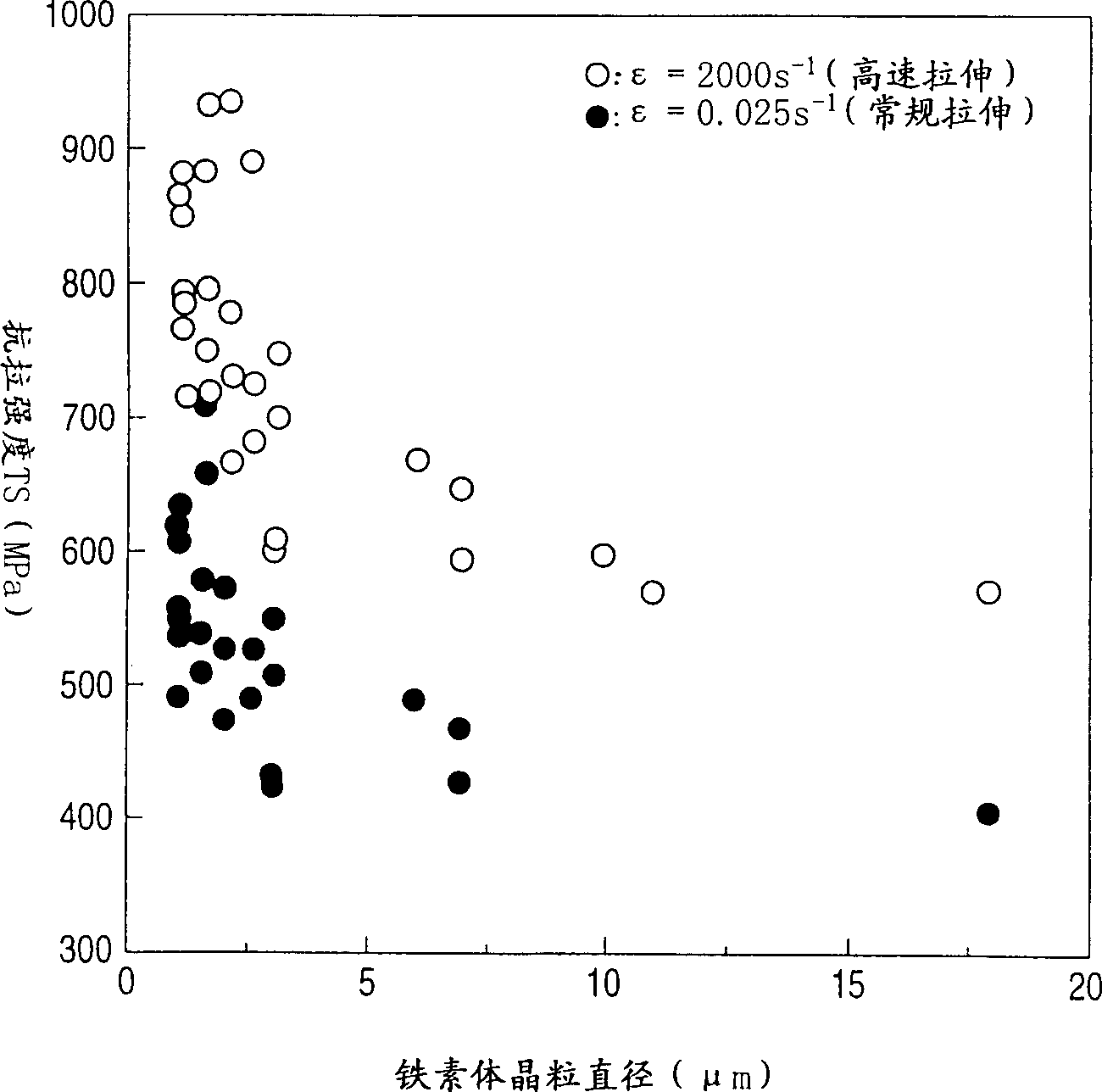

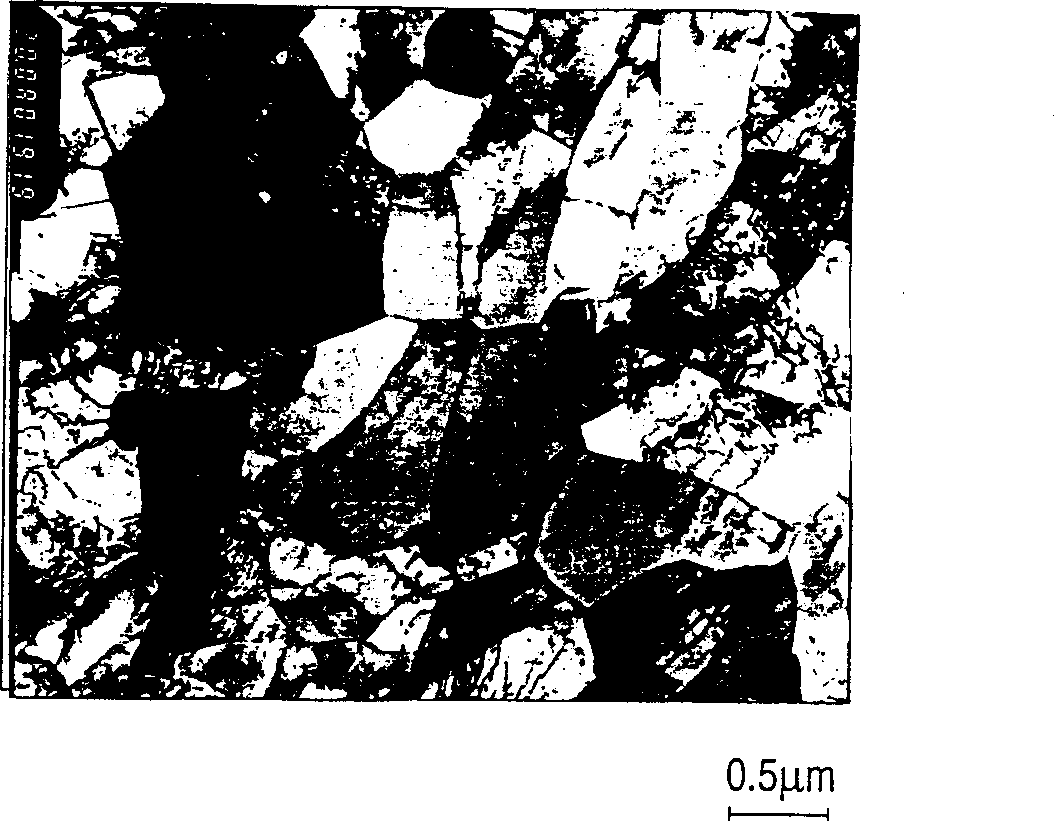

InactiveCN1082561CImprove ductilityHigh strengthMetal rolling arrangementsReduction ratioUltimate tensile strength

A steel pipe containing fine ferrite crystal grains, which has excellent toughness and ductility and good ductility-strength balance as well as superior collision impact resistance, and a method for producing the same are provided. A steel pipe containing super-fine crystal grains can be produced by heating a base steel pipe having ferrite grains with an average crystal diameter of di (mum), in which C, Si, Mn and Al are limited within proper ranges, and if necessary, Cu, Ni, Cr and Mo, or Nb, Ti, V, B, etc. are further added, at not higher than the Ac3 transformation point, and applying reducing at an average rolling temperature of thetam (DEG C) and a total reduction ratio Tred (%) within s temperature range of from 400 to Ac3 transformation point, with di, thetam and Tred being in a relation satisfying a prescribed equation.

Owner:KAWASAKI STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com