Patents

Literature

37results about How to "High alloy content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Economical non-quenched and non-tempered micro-alloyed plastic die steel plate and making method thereof

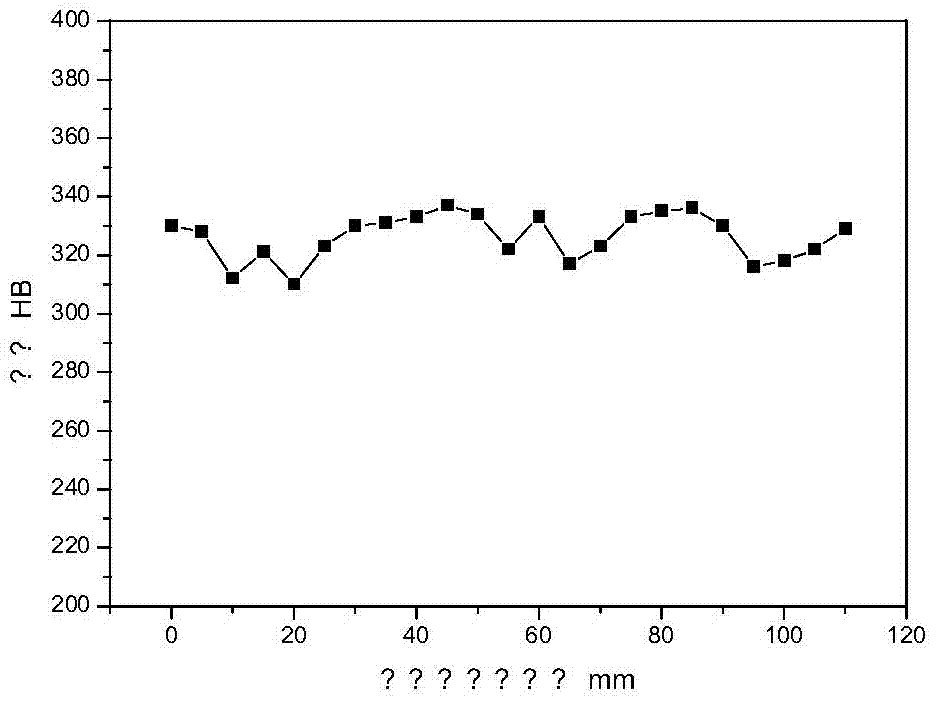

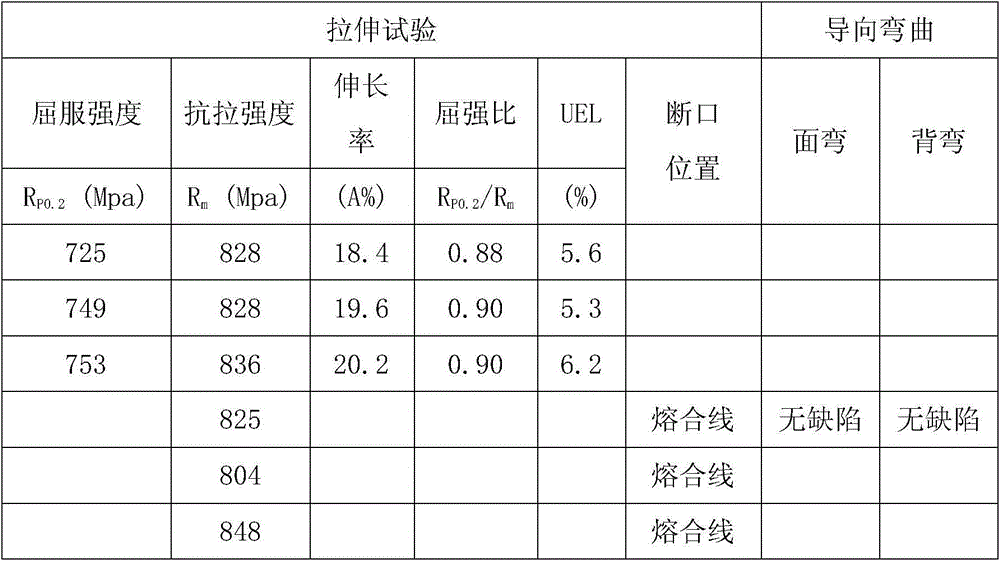

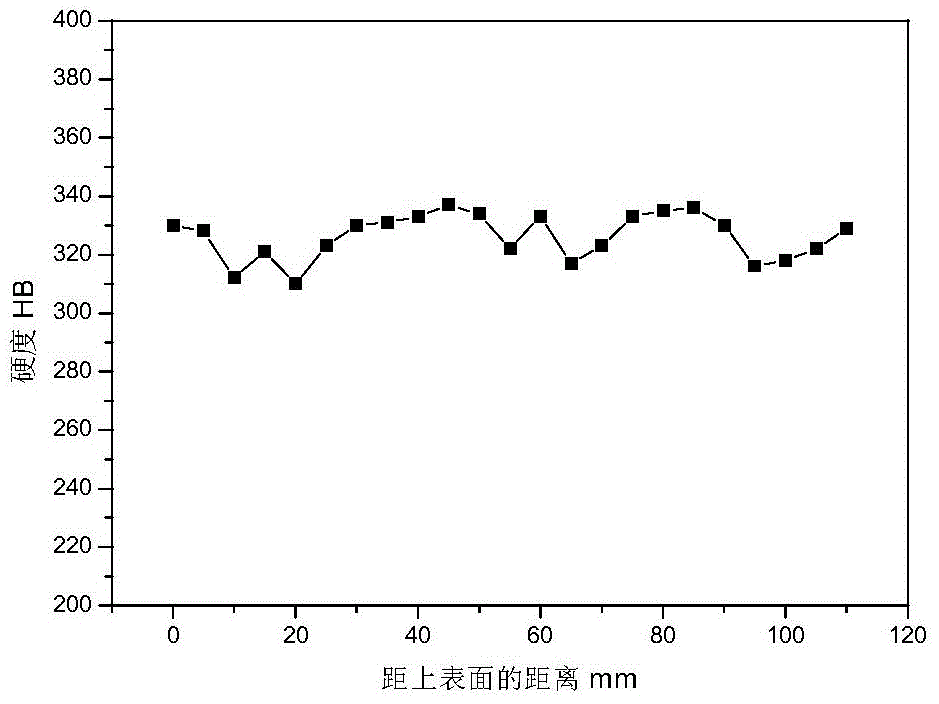

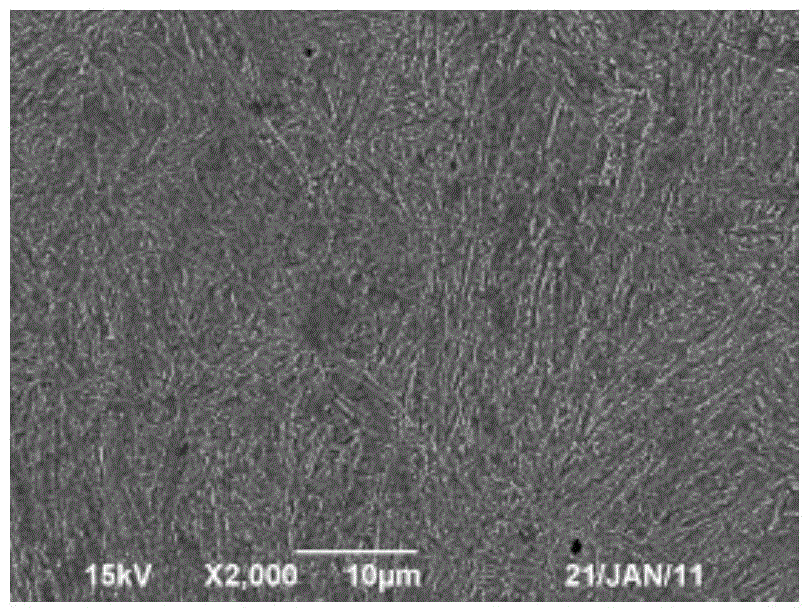

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

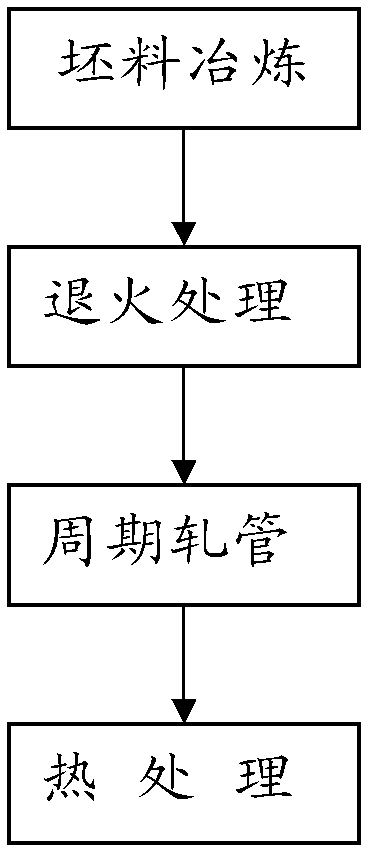

P91 seamless steel pipe and method for manufacturing same

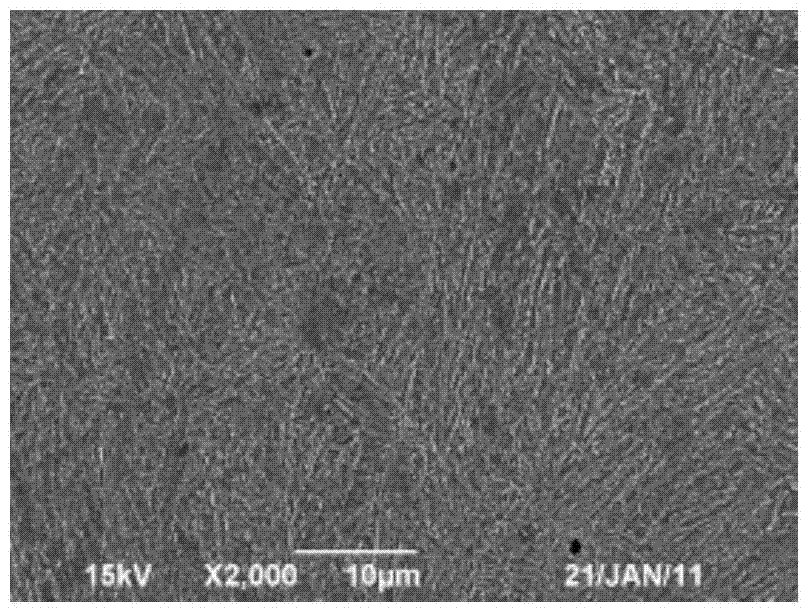

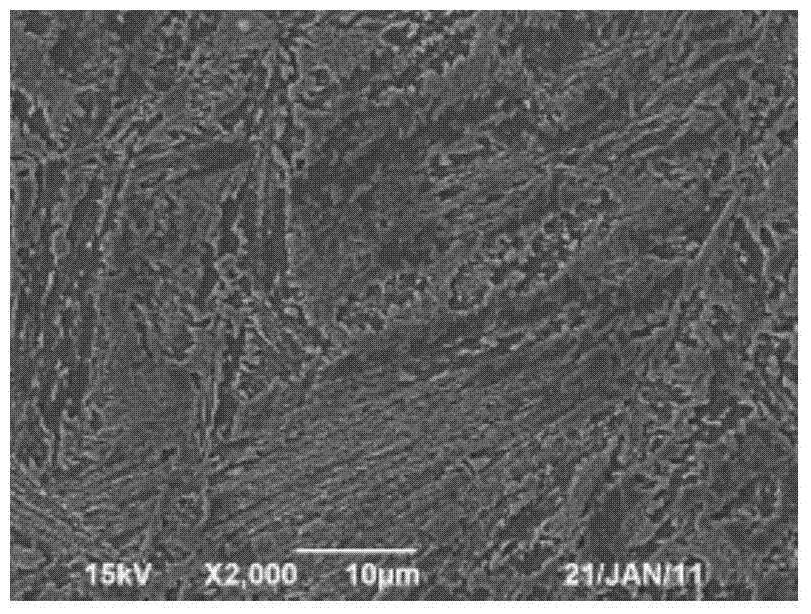

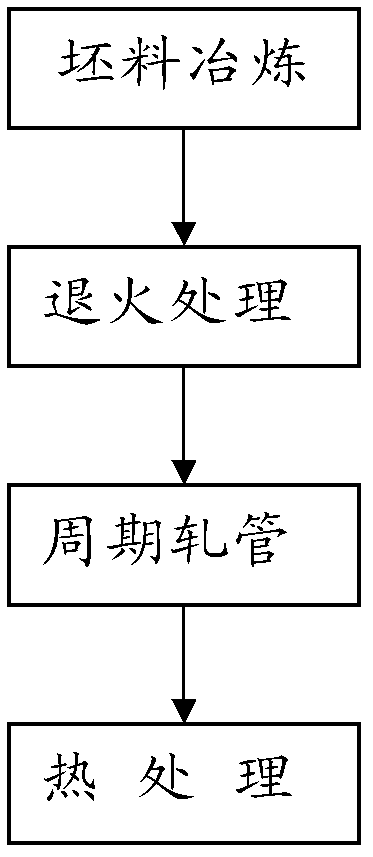

ActiveCN102581555ADense tissueExcellent performanceRigid pipesMetal rolling arrangementsSteel tubeSizing

The invention provides a P91 seamless steel pipe and a method for manufacturing the P91 seamless steel pipe. The method comprises the following steps: smelting a blank: performing smelting, refining, vacuum degassing and round-blank continuous casting on raw materials to obtain the blank; annealing: performing high-temperature diffusion annealing and low-temperature isothermal annealing on the blank; rolling the blank periodically: heating the annealed blank uniformly, hot rolling, perforating, sizing and cooling; and carrying out thermal treatment: heating the blank rolled periodically to 1,040-1,080 DEG C, normalizing, preserving heat, cooling, heating to 750-800 DEG C, performing tempering, preserving heat and cooling to obtain the P91 seamless steel pipe. The content of P in the raw materials is less than or equal to 0.015%, and the content of S content is less than 0.007%. and the diameter phi of the seamless steel pipe is 325-720mm. The P91 seamless steel pipe manufactured by adopting the method is compact in internal structure and excellent in performance. The metal yielding rate and the steel pipe forming yield are improved, the production cost is reduced, and resources are saved.

Owner:HENGYANG VALIN STEEL TUBE

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

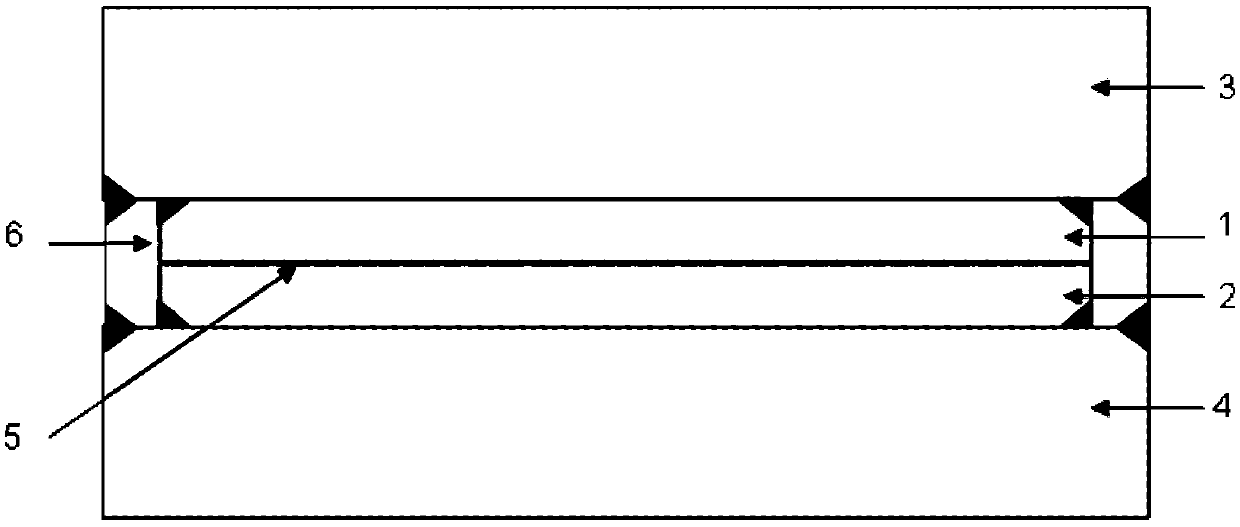

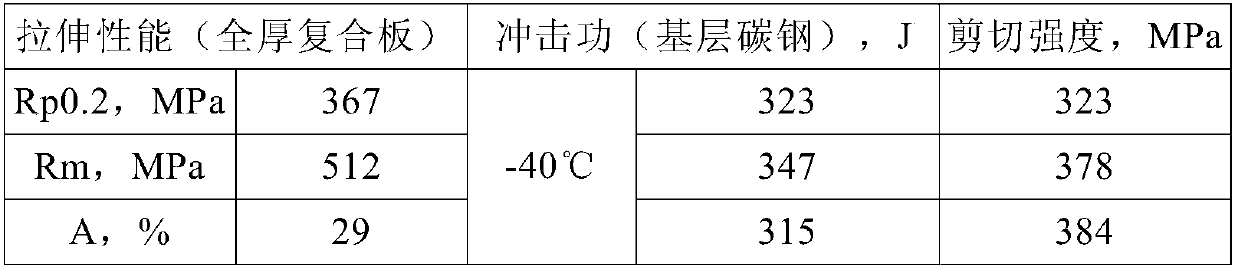

Super double-phase stainless steel composite steel plate and manufacturing method thereof

ActiveCN109532144AIncreased shear strengthHigh bonding strengthFurnace typesHeat treatment furnacesSheet steelDouble phase

The invention relates to a super double-phase stainless steel composite steel plate and manufacturing method thereof. The super double-phase stainless steel composite steel plate has a four-layer structure, wherein, the middle two layers are double-phase stainless steel, and the upper and lower layers are carbon steel; the double-phase stainless steel comprise the following components by weight percentage: less than or equal to 0.03% of C, less than or equal to 1.20% of Mn, less than or equal to 0.80% of Si, 24.0-26.0% of Cr, 6.0-8.0% of Ni, 3.0-5.0% of Mo, 0.24-0.32% of N, and the balance ofFe and inevitable impurities; the carbon steel comprises the following components by weight percentage: 0.03 to 0.12% of C, 0.10 to 0.45% of Si, 0.70 to 1.60% of Mn, less than 0.020% of P, less than 0.025% of S, 0-0.35% of Cu, 0-0.40% of Cr, 0-0.40% of Ni, 0-0.05% of Nb, 0-0.40% of Mo, 0-0.018% of Ti, 0.015-0.045% of Al, and balance of Fe and unavoidable impurities. The composite steel plate of the invention can obtain good structural strength and corrosion resistance. The composite steel plate is the rolled composite plate, which can realize metallurgical bonding of a coating layer and a basematerial, so that the good bonding force can be obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Repair weld composite leveller roll and its production process

InactiveCN1736627AHigh strengthImprove impact resistanceArc welding apparatusOther manufacturing equipments/toolsChemical compositionWorking life

It relates to a pile-up welding composite straightener roll and the preparation technique, belonging to the art of mechanical device, and it especially relates to a straighter roll for a plate hot straightening machine. The straightener roll uses alloy constructional steel 42CrMo wrought-steel as the base metal to prepare mandrel of roll body, and is built-up an operational layer of 5-15mm by thicken on the surface of the roll body, the chemical composition of the deposited material of the operational layer being: C:0.36-0.45%, Cr: 12.00-14.00%, Ni:2.00-2.50%, Mo: 2.00- 3.00%, W: 2.00- 3.00%, Ti: 0.85-1.25%, Si: <=1.50%, Mn: <= 2.00%, P<= 0.035%, and S: <=0.03%. In the technique it uses 1250 type automatic buried arc building-up device, applies bobbing building-up to build up the operation layer of roll body, and uses the 260 weld flux as the welding material. The straightener roll has a long work life and a high strength of roll body, and it can be repaired and reproduced a plural of times.

Owner:UNIV OF SCI & TECH BEIJING

Stainless steel smelting method

ActiveCN101476016AShorten heating timeReduce restore timeElectric furnaceProcess efficiency improvementElectric arc furnaceIntermediate frequency

The invention belonging to the field of smelting relates to a stainless steel smelting method.The invention is characterized in that the method comprises the following steps: 1) electric furnace smelting; 2) a intermediate frequency furnace melting alloy; 3) LF furnace heating; 4) VOD vacuum decarburizing; 5) VOD vacuum reducing and adding aluminum as the reductive in the vacuum state; 6) argon protecting and teeming.According to the invention, by adopting an electric furnace added with a intermediate frequency furnace and adopting a method of adding reductive under a vacuum state, the LF heating and reducing time is shortened, stay time of molten steel in ladle is reduced, steel-making cost is reduced and the manufacture security is improved. The technology has a remarkable economic benefit by producing stainless steel with a high alloy content. The reducing time is shortened from 7 hours primarily to 3-4 hours currently, therefore, the production efficiency is improved greatly, the forgeable pieces producing capability is extended and the economic benefit is remarkable.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Ultra-low hydrogen basic electrode for P92 steel welding

ActiveCN101181768AHigh alloy transition coefficientLow impurity contentWelding/cutting media/materialsSoldering mediaMelting tankSlag

The invention provides an ultra low hydrogen-alkalinity welding rod used for welding a P92 steel, pertaining to the welding field of a material processing engineering. The invention is mainly used for the welding of the P92 steel. No relevant patent or report in literature concerning the manufacture of the P92 steel welding rod has ever been found at home and abroad. The invention is characterized in that formula of coating of the welding rod contains materials based on mass percent of 1-7 percent of ferromanganese, 4-9 percent of ferrosilicon alloy, 1.5-2.5 percent of aluminum, 3-8 percent of nickel powder, 1-4 percent of quartz, 3-6 percent of ferrocolumbium, 0.5-1.0 percent of ferrovanadium, 4.5-6 percent of titanium pigment, 20-30 percent of fluorite and 40-60 percent of marble. The manufactured welding rod has good technique performance and welding technique features of little splash, good fluidity of a molten pool, uniform covered slag, delicate and beautiful welding seam and easy removal of slag, and so on, compared with an imported welding rod. Content of diffusible hydrogen of deposited metal of the welding rod is effectively controlled and the content of the diffusible hydrogen of deposited metal is 1.985mL / 100g, which complies with the requirement of an ultra low hydrogen standard.

Owner:CHINA ELECTRIC POWER RES INST

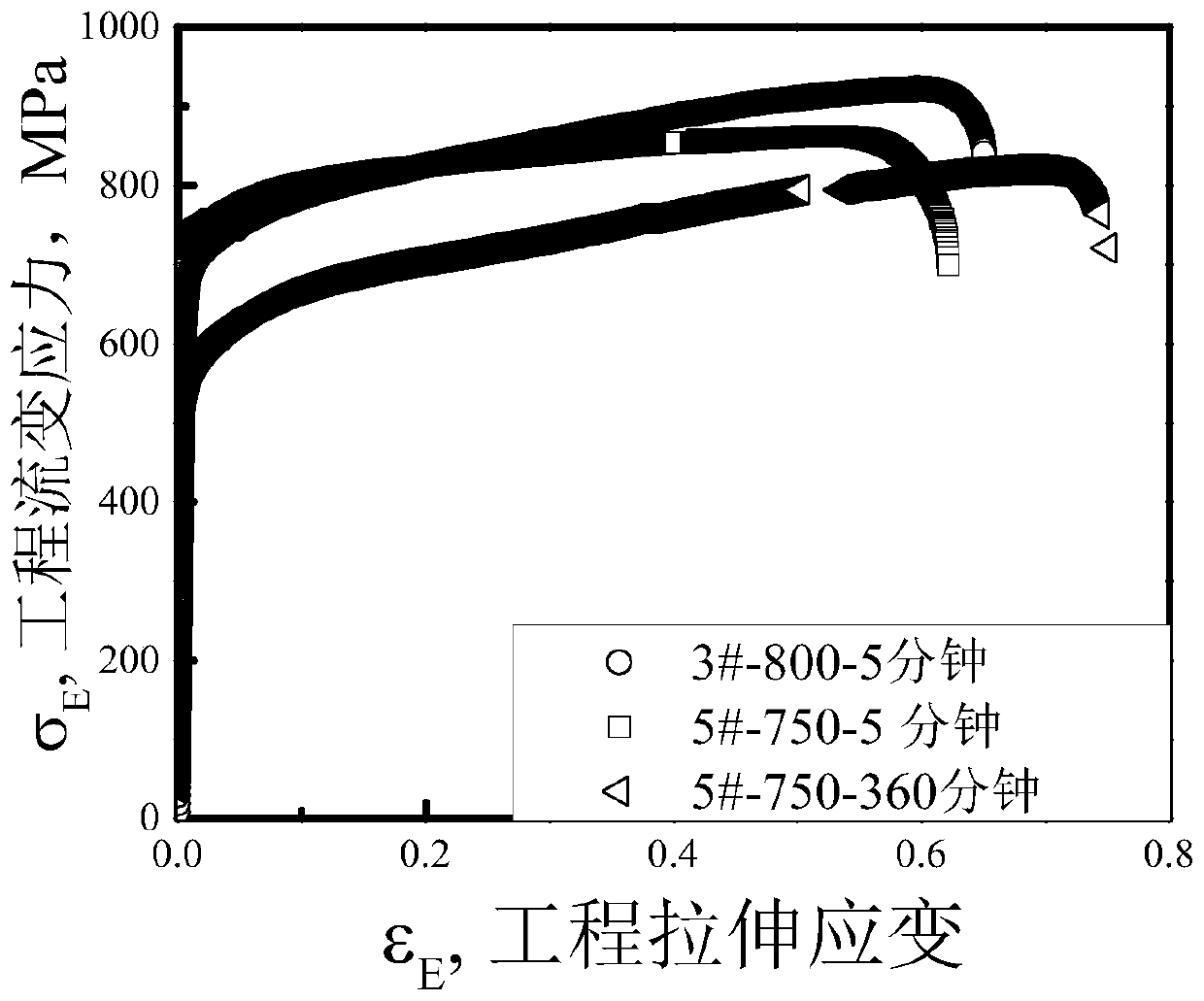

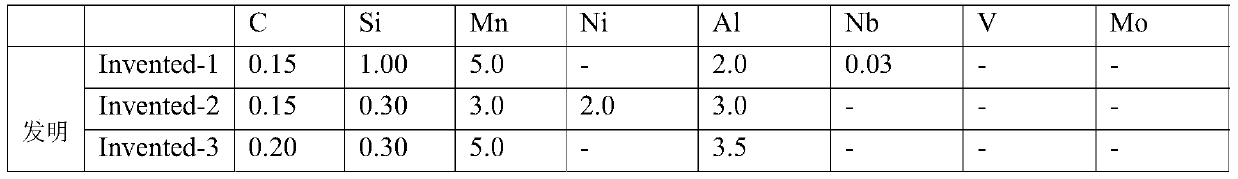

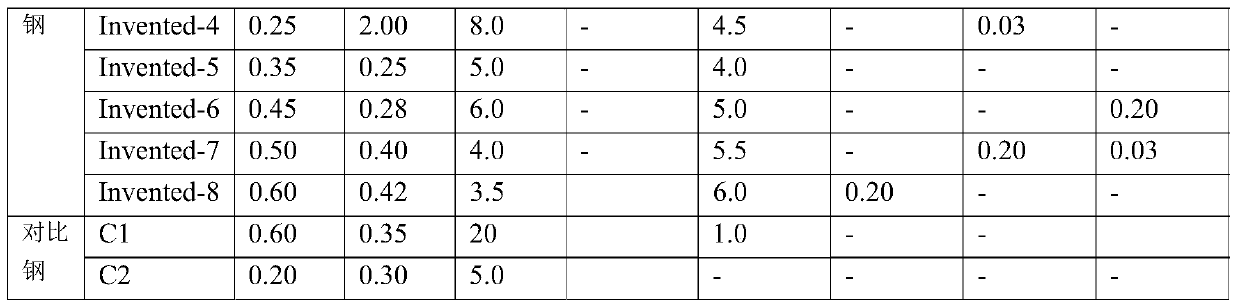

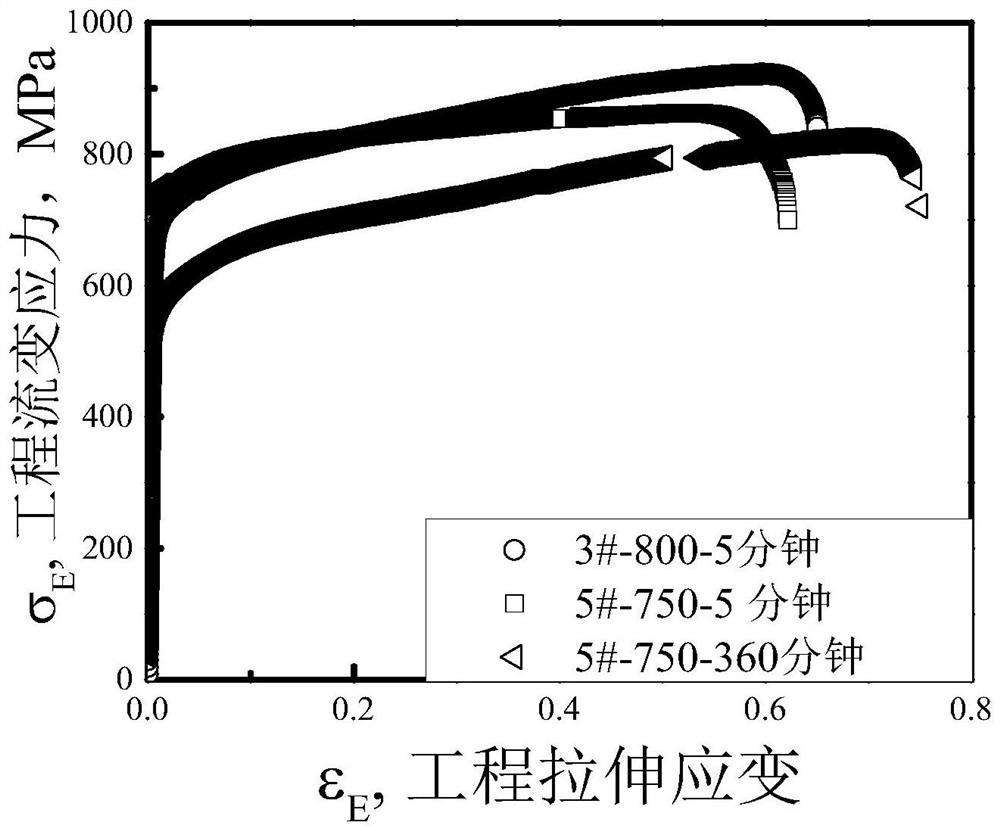

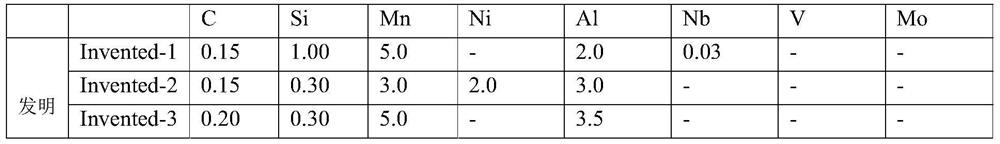

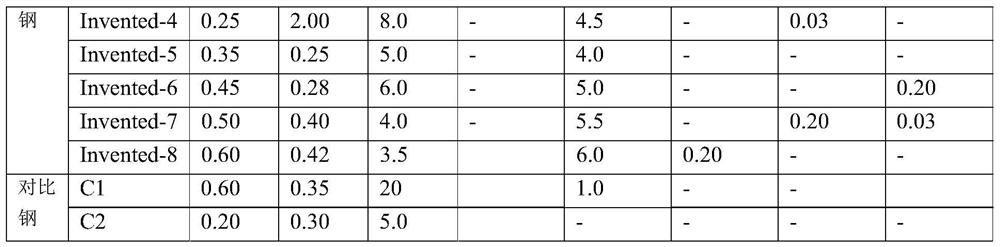

Automobile steel with high toughness and high product of strength and elongation and preparation method thereof

ActiveCN111575580AIncreased strength and plasticityHigh alloy contentMechanical propertyImpact toughness

The invention discloses automobile steel with high toughness and high product of strength and elongation and a preparation method thereof, and belongs to the technical field of preparation of automobile steel with high toughness and high product of strength and elongation. The steel comprises, by weight, 0.15%-0.60% of C, 0%-2.0% of Si, 0%-2.0% of Ni, 3.0-6.0% of Mn, 2.0-6.0% of Al, and the balance of Fe and inevitable impurity elements. On this basis, one or more of the following microalloying elements can be added: by weight, 0-0.10% of Nb, 0-0.10% of V, 0-0.10% of Ti, 0-0.10% of Mo, 0-0.50%of Cu, and 0.0005-0.005% of B. The automobile steel and the preparation method have the advantages that a multi-phase, multi-layer and metastable microstructure is formed through alloying of C, Mn, Al and the like and rolling and annealing of a two-phase region; at -40 DEG C, the V-type impact toughness is not smaller than 120 J, the product of strength and elongation is not lower than 50 GPa%, the cost is far lower than that of traditional high manganese steel, the comprehensive mechanical property is far higher than that of medium manganese steel, and low cost and high performance are achieved. The automobile steel can be applied to the field of white automobile body and transmission part manufacturing in the form of bars or plates.

Owner:CENT IRON & STEEL RES INST

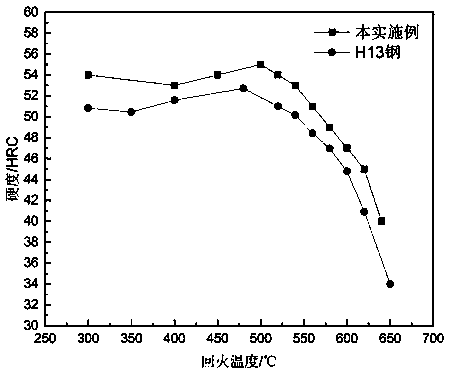

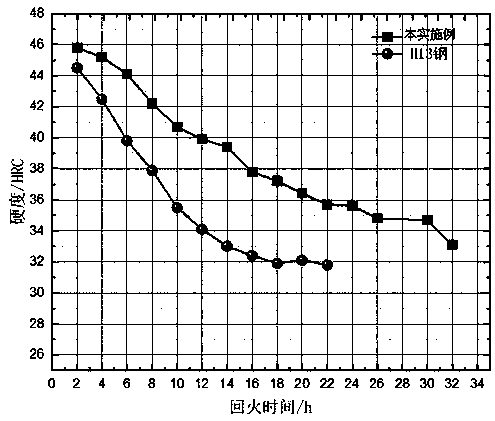

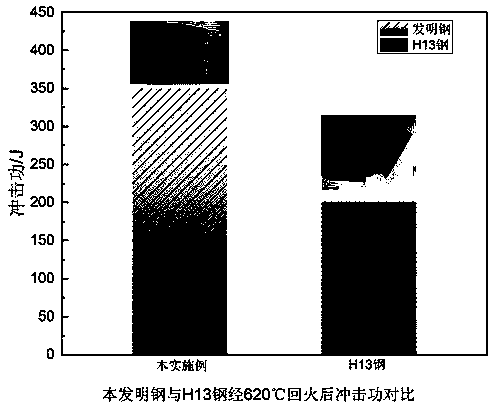

High-manganese low-chromium type hot work die steel and preparation method thereof

The invention relates to high-manganese low-chromium type hot work die steel and a preparation method of the high-manganese low-chromium type hot work die steel, and belongs to the technical field ofhot work die steel. The high-manganese low-chromium type hot work die steel is prepared from, by mass, 0.35-0.45% of C, 0.50-1.20% of Si, 0.60-1.20% of Mn, 3.75-4.50% of Cr, 0.80-1.20% of Mo, 0.30-0.60% of V, 0.50-5.50% of Co, 0.80-3.00% of Ni, less than 0.02% of P, less than 0.02% of S and the balance Fe and inevitable impurities. The high-manganese low-chromium type hot work die steel is prepared through the processes of material preparation, smelting, casting, electroslag remelting, high temperature homogenization treatment, forging, annealing and heat treatment. Compared with existing H13hot work die steel, the high-manganese low-chromium type hot work die steel has higher toughness and higher heat stability.

Owner:KUNMING UNIV OF SCI & TECH

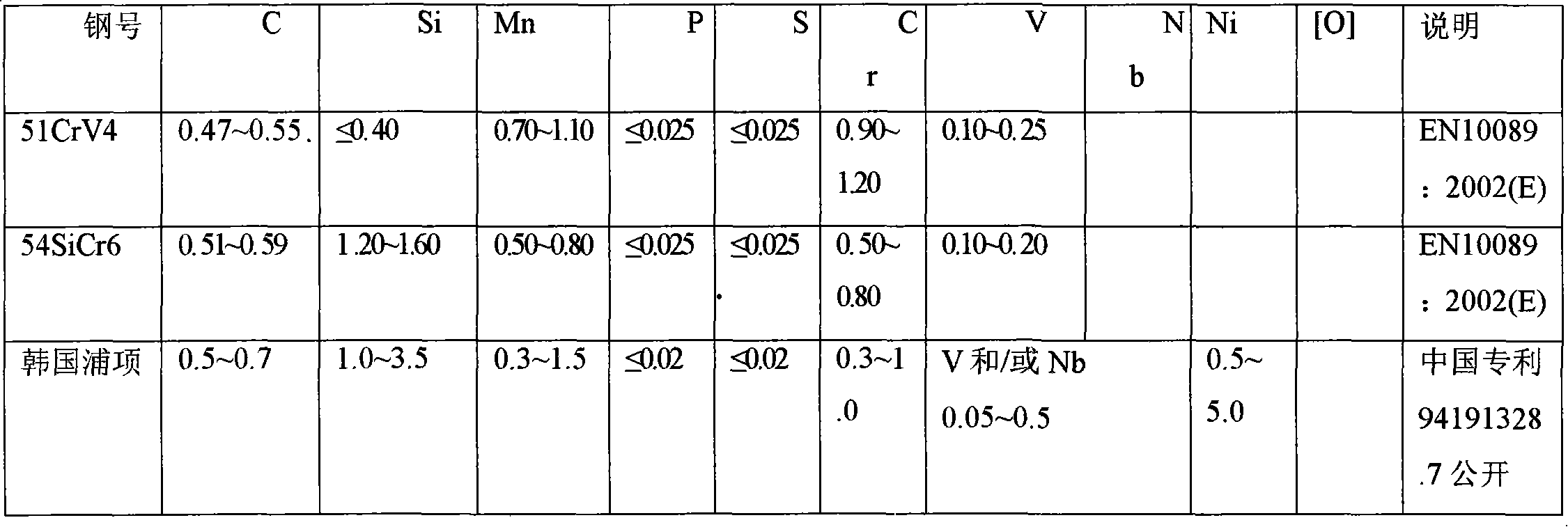

Big-wire diameter suspension helical spring material and preparation method thereof

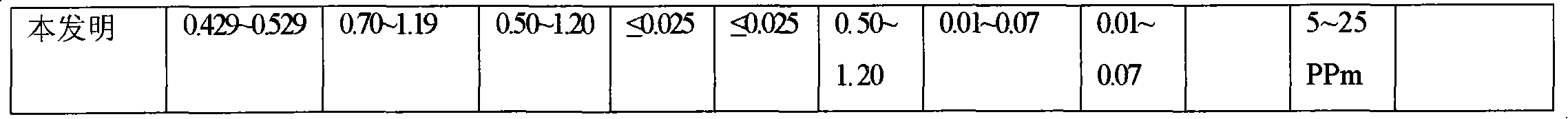

InactiveCN101619418ALow antioxidantLow decarbonization effectFurnace typesHeat treatment furnacesAlloyHigh intensity

The invention relates to a big-wire diameter suspension helical spring material, which comprises the following chemical components in percentage by weight: 0.429 to 0.529 percent of C, 0.70 to 1.19 percent of Si, 0.50 to 1.20 percent of Mn, 0.50 to 1.20 percent of Cr, 0.01 to 0.07 percent of V, 0.01 to 0.07 percent of Nb, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 5 to 25ppm of O, and the balance of Fe and inevitable impurities. The big-wire diameter suspension helical spring material has technical properties of low decarburization, high strength and high plasticity, has a low alloy content and is a good material for making a helical spring of a suspension having a big wire diameter of a medium or heavy vehicle and also for making a suspension helical spring of a car, a vehicle torsion bar spring and a stock stabilizer, and also a good material used for making a high-strength spring steel wire and an oil tempering spring steel wire.

Owner:孙心红

Heat treatment method of large heat-resistant high alloy steel castings

The invention relates to a heat treatment method of large heat-resistant high alloy steel castings in the technical field of steel casting heat treatment. The heat treatment method of the large heat-resistant high alloy steel castings includes the process of high-temperature diffusion annealing, gating and risering system cutting, normalizing air cooling, primary tempering and secondary tempering,and it is set that carbon arc air gouging dressing is performed on the surfaces of the castings between the primary tempering and the secondary tempering. The method solves the problem that the largeheat-resistant high alloy steel castings with a ZG12Cr9Mo1CoNiVNbNB material are prone to cracking in the heat treatment process, and makes various normal temperature and high temperature mechanicalproperties of the steel castings meet the using requirement.

Owner:RUGAO OUTONG MACHINERY FITTINGS

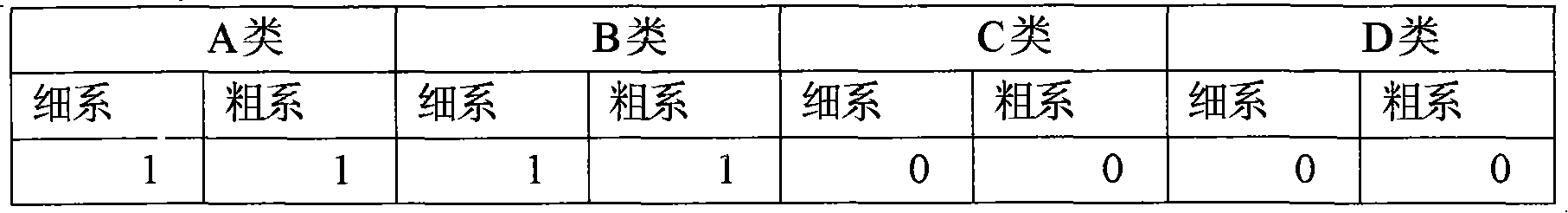

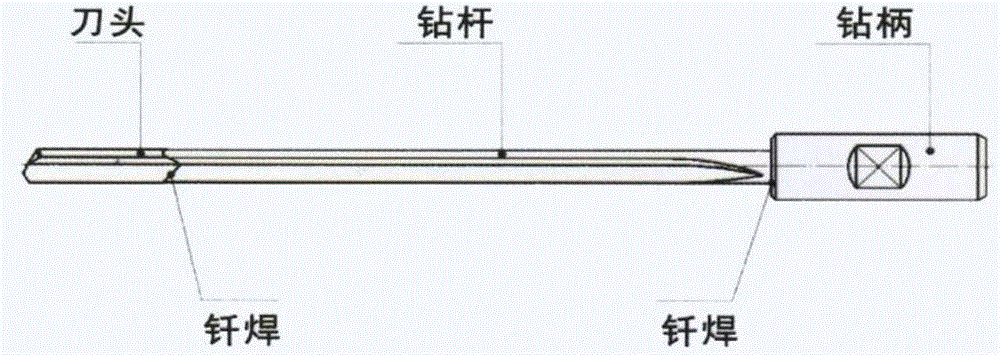

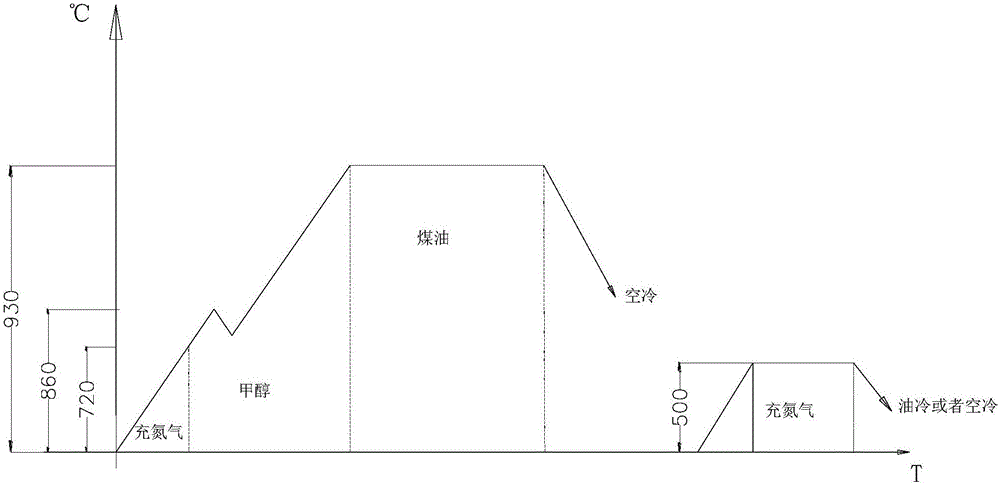

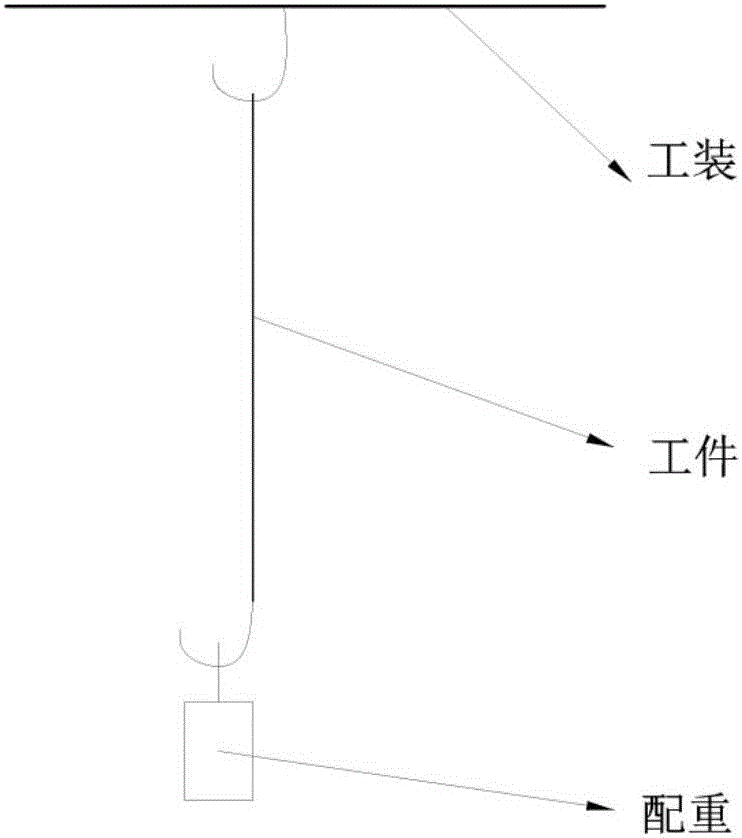

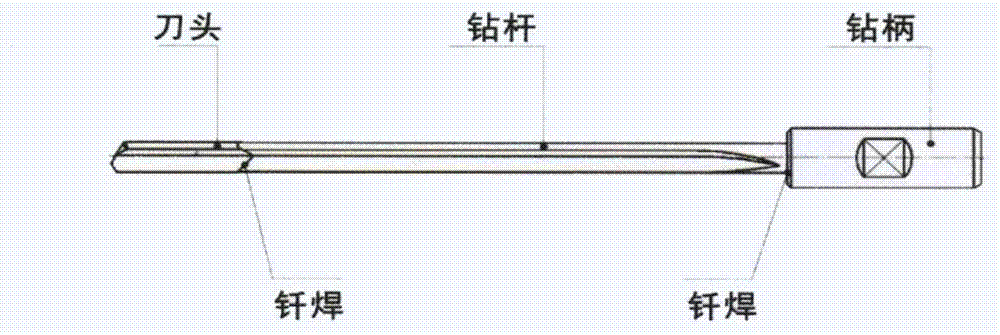

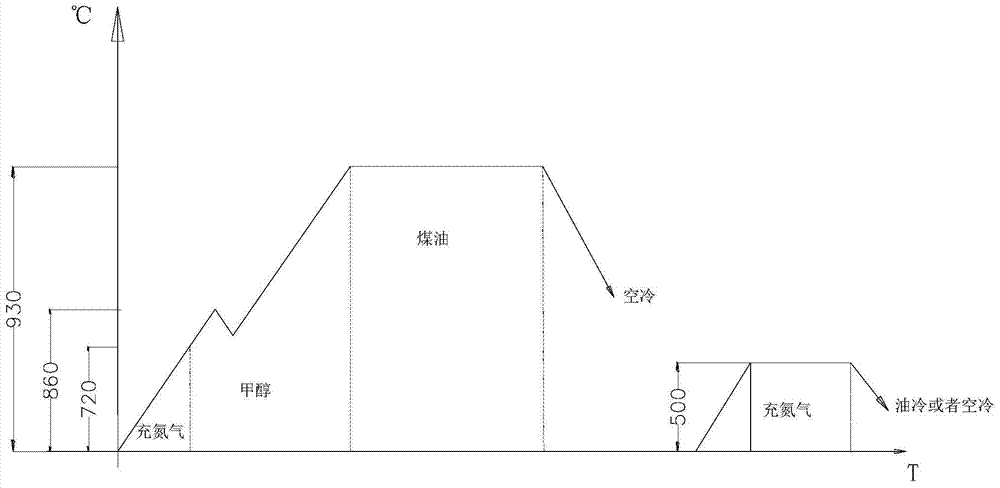

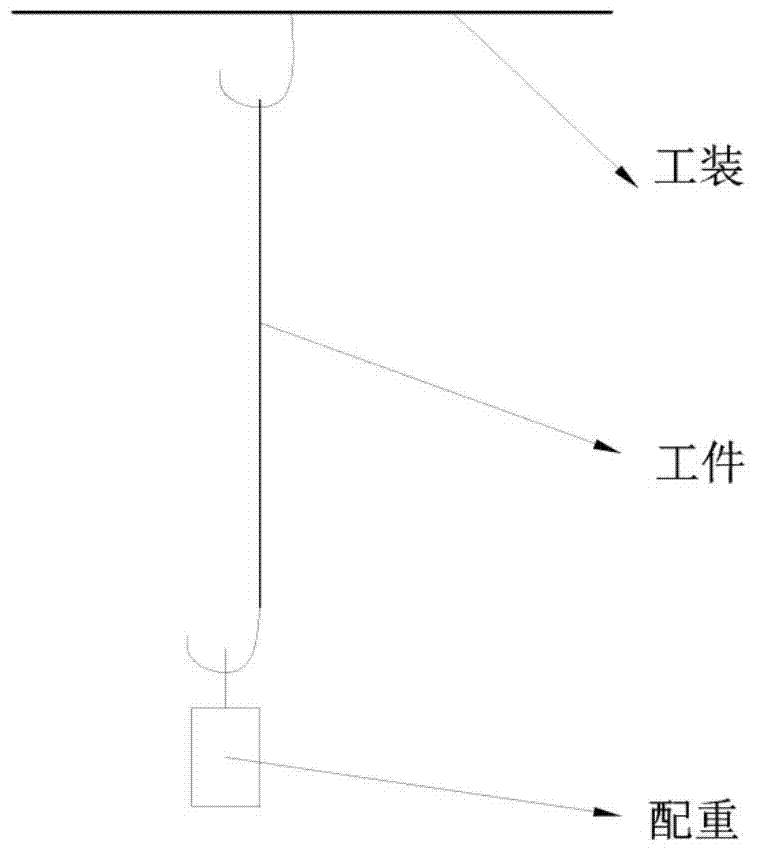

Strengthening, toughening and straightening process for deep hole machining gun-drill drill rod

ActiveCN105063323AHigh alloy contentHigh strengthSolid state diffusion coatingFurnace typesShielding gasQuenching

The invention relates to the technical field of machining methods of deep hole machining equipment, in particular to a strengthening, toughening and straightening process for a deep hole machining gun-drill drill rod. The process includes the following steps that 1) material selection, pipe manufacturing and forming are conducted, and superior alloy steel or tool steel or carburizing steel is selected and machined to form the deep hole machining gun-drill drill rod before heat treatment; 2) heat treatment strengthening, toughening and straightening are integrated, the deep hole machining gun-drill drill rod before heat treatment is vertically hung on a tool, a balance weight is hung at the bottom end of the deep hole machining gun-drill drill rod, and carburizing, quenching, balance weight automatic straightening or quenching and automatic straightening are conducted; and 3) tempering, straightening and cooling are conducted. Compared with the prior art, the superior alloy steel or tool steel or carburizing steel is selected as raw materials, through heat treatment of a controlled atmosphere furnace, a vacuum furnace and a high-frequency furnace and under the gravity effect of the balance weight, automatic straightening or carburizing steel carburizing and quenching are conducted, the carbon content is increased, and toughness is enhanced; heat treatment strengthening, toughening and straightening are integrated, and automatic straightening is achieved in the tempering process.

Owner:佛山市云昇金属科技有限公司

Carbon dioxide arc welding wire with small diameter of 1.6 mm and high alloy content

InactiveCN105195925AHigh alloy contentWelding/cutting media/materialsSoldering mediaTemperature resistanceFlux-cored arc welding

The invention relates to a carbon dioxide arc welding wire with the small diameter of 1.6 mm and the high alloy content. The welding wire comprises 1.6-mm welding wire skin and a flux core. The welding wire is characterized in that the flux core is prepared from 1.5%-6% of C, 0.5%-2% of Si, 0.5%-20% of Mn, 10%-25% of Cr, 0%-8% of Ni, 0%-5% of Mo, 0%-7% of Co, 0%-5% of Nb, 0%-10% of V, 0%-2% of W, 0%-10% of Ti and the balance B. According to the carbon dioxide arc welding wire with the small diameter of 1.6 mm and the high alloy content, by means of the formula, multiple alloy elements are contained, the alloy content is high, the welding wire is especially suitable for the occasions needing the high temperature resistance, corrosion resistance, abrasion resistance and impact resistance, and the usage occasion of the flux core welding wire is wider.

Owner:SHANGHAI SMILE SPECIAL ALLOY MATERIALS

Austenitic stainless steel continuous tube with low carbon and high strength and preparation method thereof

The invention discloses an austenitic stainless steel continuous tube with low carbon and high strength and a preparation method thereof. The austenitic stainless steel continuous tube comprises the components in percentage by mass: at most 0.03% of C, at most 1.00% of Si, 4.00-8.00% of Mn, at most 0.050% of P, at most 0.005% of S, 18-20% of Cr, 3-5.0% of Ni, 1.2-3.5% of Cu, 0.20-0.30% of N, at most 0.3% of Mo and the rest Fe and unavoidable impurities. The preparation method comprises the steps of (1) manufacturing a coil plate; (2) longitudinally shearing the coil plate and lengthening a steel band; and (3) forming the steel band, using laser welding, conducting rapid cooling after welding, and thus obtaining the stainless steel continuous tube. The produced continuous tube has high strength, low cost and good corrosion resistance by optimizing the alloy content and improving the manufacturing process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

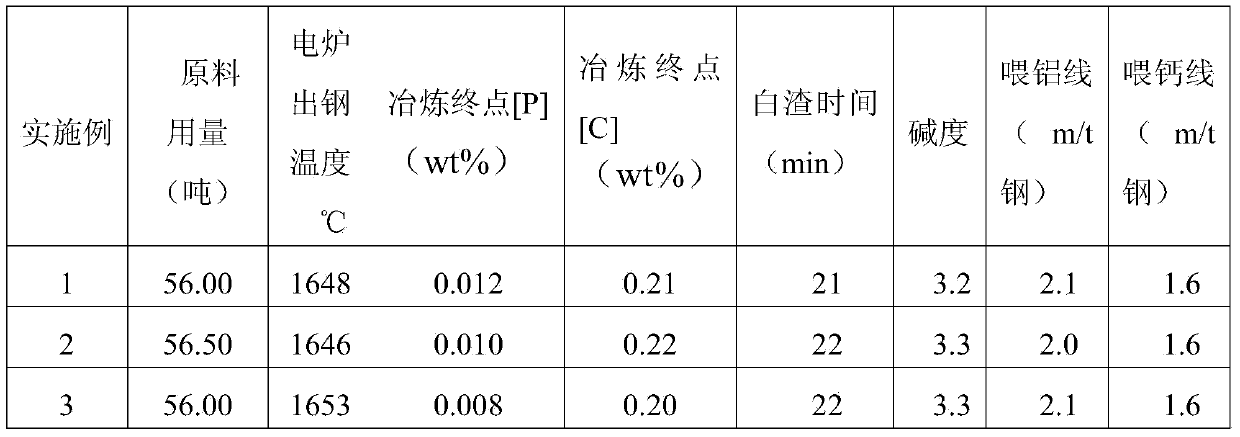

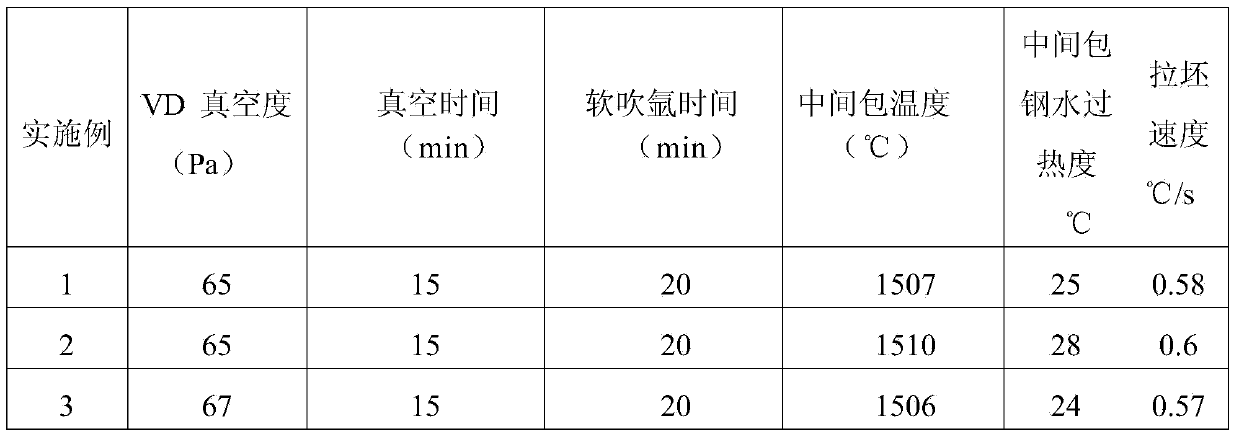

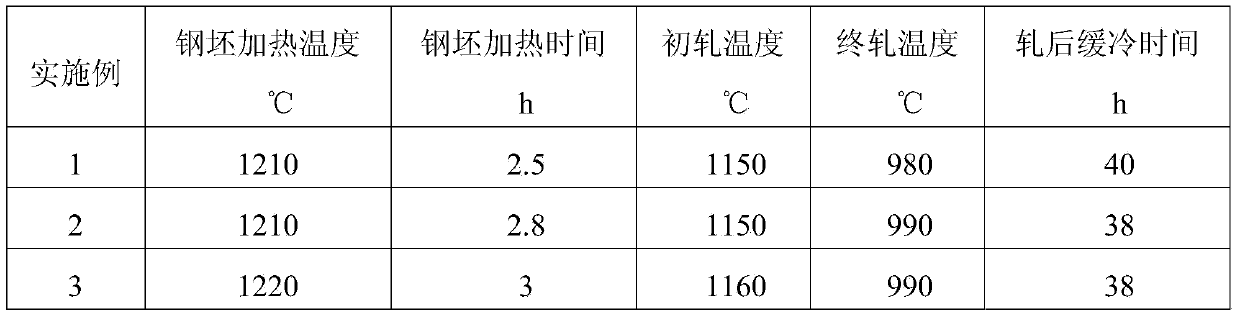

Steel for chemical equipment fastener and production method thereof

The invention discloses steel for a chemical equipment fastener and a production method thereof. The steel for the chemical equipment fastener comprises, by weight, 0.49-0.52% of C, 0.20-0.25% of Si, 0.85-1.00% of Mn, 0.95-1.10% of Cr, 0.15-0.20% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020-0.060% of Alt and the balance Fe and unavoidable impurities. The production method comprises electric furnace smelting, LF external refining, VD furnace vacuum treatment, continuous casting and rolling. Compared with the existing medium C-Cr-Mo steel, the steel provided by the invention has better comprehensive mechanical properties and high-temperature stability and has a certain corrosion resistance.

Owner:LAIWU IRON & STEEL GRP

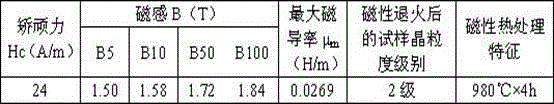

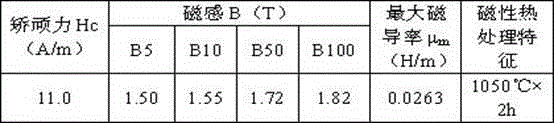

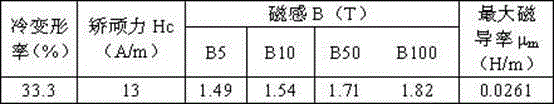

Manufacturing method of low-coercive force electromagnetic pure ion cold-rolled sheet

ActiveCN103205548BRapid demagnetizationLow coercivityFurnace typesHeat treatment furnacesThin slabAlloy

The invention relates to a manufacturing method of a low-coercive force electromagnetic pure ion cold-rolled sheet. The manufacturing method comprises the following steps in sequence: I. manufacturing of a sheet billet with optimal components, to be specific, a. during smelting, controlling C, N, O and S elements and impurity contents thereof, increasing the Al alloy content in steel, and reducing the S content in steel, and b. continuous casting of the sheet billet; II. hot rolling of steel coils, to be specific, a. the heating temperature of the sheet billet is 1160-1200 DEG C; b. hot rolling and finishing rolling at a high temperature, rolling the sheet billet into a hot-rolled steel sheet with the thickness of 1.5mm-7.0mm at 860-1000 DEG C, c. curling at a high temperature, wherein the curing temperature of the hot-rolled steel sheet is 700 DEG C to 800 DEG C; III. cold rolling and molding, wherein the total amount of deformation during cold rolling is 30%-40%; IV. annealing a single sheet by adopting a nitrogen protective cover type furnace, and carrying out heat preservation for 6-8 hours at 540-560 DEG C; and V. magnetism heat treatment, to be specific, carrying out magnetic heat treatment on a test sample for magnetism detection by adopting a vacuum or atmosphere protective anti-oxidation heat treatment furnace at 1000-1100 DEG C for no less than 2 hours of heat preservation. The low-coercive force of the low-coercive force electromagnetic pure ion cold-rolled sheet manufactured by the method is 11-20A / m.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Process for producing die steel by utilizing converter continuous casting mode

ActiveCN103160635AHigh alloy contentImprove purityTemperature control deviceManufacturing convertersEconomic benefitsHigh pressure water

The invention discloses a process for producing die steel by utilizing a converter continuous casting mode. The process comprises a steel making continuous casting process and a steel rolling process. The steel making continuous casting process comprises the following process steps of: converter smelting, LF (Ladle Furnace) refining, continuous casting, slow cooling and other process steps; and the steel rolling process comprises the following process steps of: heating, scale removal by using high pressure water, rolling, straightening, stacking, slow cooling and other steps. By using the die steel produced by the invention, the contents of gas and occluded foreign substances in the die steel can be reduced, the thermal stress and the structural stress for slowing a steel blank down are eliminated, a thick and nonuniform cast structure inside the steel blank is improved, and the problems of flaw detection disqualification and finished product crack of the die steel are solved. By using the process, the aim of producing the die steel by using a converter is achieved, the production cost is reduced, and the economic benefit is increased.

Owner:冀南钢铁集团有限公司

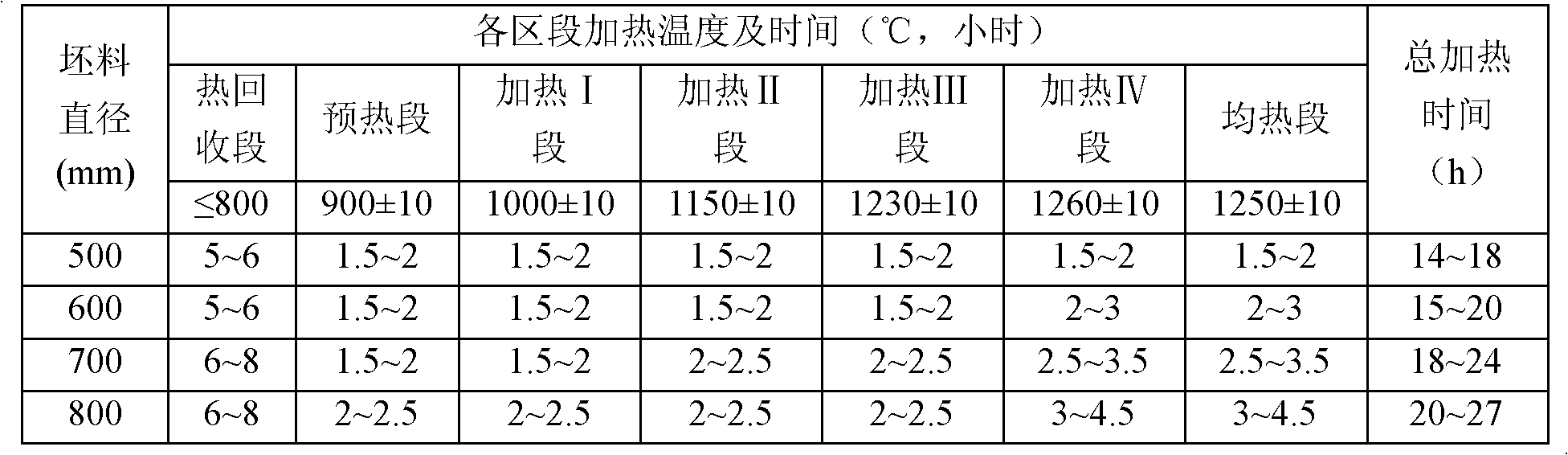

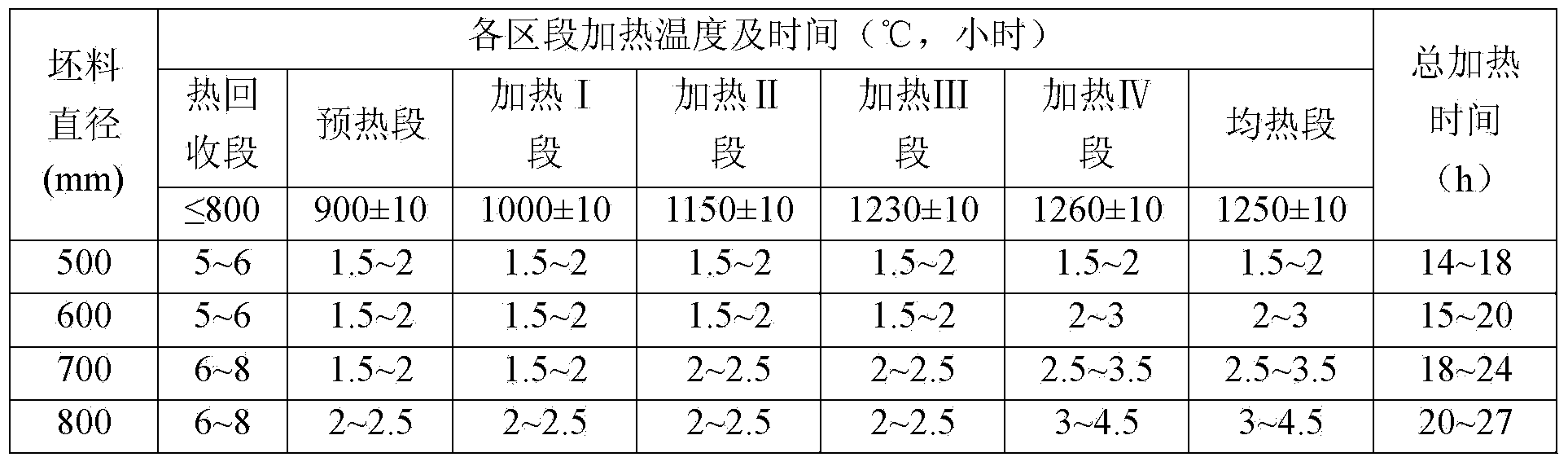

P91 seamless steel pipe and method for manufacturing same

ActiveCN102581555BHigh alloy contentDense tissueRigid pipesMetal rolling arrangementsIsothermal annealingThermal treatment

The invention provides a P91 seamless steel pipe and a method for manufacturing the P91 seamless steel pipe. The method comprises the following steps: smelting a blank: performing smelting, refining, vacuum degassing and round-blank continuous casting on raw materials to obtain the blank; annealing: performing high-temperature diffusion annealing and low-temperature isothermal annealing on the blank; rolling the blank periodically: heating the annealed blank uniformly, hot rolling, perforating, sizing and cooling; and carrying out thermal treatment: heating the blank rolled periodically to 1,040-1,080 DEG C, normalizing, preserving heat, cooling, heating to 750-800 DEG C, performing tempering, preserving heat and cooling to obtain the P91 seamless steel pipe. The content of P in the raw materials is less than or equal to 0.015%, and the content of S content is less than 0.007%. and the diameter phi of the seamless steel pipe is 325-720mm. The P91 seamless steel pipe manufactured by adopting the method is compact in internal structure and excellent in performance. The metal yielding rate and the steel pipe forming yield are improved, the production cost is reduced, and resources are saved.

Owner:HENGYANG VALIN STEEL TUBE

Stainless steel smelting method

ActiveCN101476016BShorten heating timeReduce restore timeProcess efficiency improvementElectric furnaceSteelmakingEconomic benefits

The invention belonging to the field of smelting relates to a stainless steel smelting method.The invention is characterized in that the method comprises the following steps: 1) electric furnace smelting; 2) a intermediate frequency furnace melting alloy; 3) LF furnace heating; 4) VOD vacuum decarburizing; 5) VOD vacuum reducing and adding aluminum as the reductive in the vacuum state; 6) argon protecting and teeming.According to the invention, by adopting an electric furnace added with a intermediate frequency furnace and adopting a method of adding reductive under a vacuum state, the LF heating and reducing time is shortened, stay time of molten steel in ladle is reduced, steel-making cost is reduced and the manufacture security is improved. The technology has a remarkable economic benefit by producing stainless steel with a high alloy content. The reducing time is shortened from 7 hours primarily to 3-4 hours currently, therefore, the production efficiency is improved greatly, the forgeable pieces producing capability is extended and the economic benefit is remarkable.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Production method for one-steel multi-grade pipeline steel blank

The invention discloses a production method for a one-steel multi-grade pipeline steel blank, and relates to the technical field of steel smelting. Pipeline steel is mainly used for petroleum pipelineconveying and natural gas pipeline conveying, a pipeline product is designed through a low-carbon component system with a C content of less than 0.080% according to the use need stability and safetyof the product, and a component design with components which are applicable to many pipeline grades is carried out on the product according to the product yield requirement and the product performancerequirement, so that the smelting brands of the pipeline product are effectively reduced, production scheduling is benefited, and a blank stock is reduced; and through the design thought, the numberof pipeline steel types is effectively reduced, the steel types for pipelines are reduced to be more than 30 from the previous number of more than 50, and moreover, the replacement usability of the steel types is greatly improved, stocked blanks are effectively controlled, and the production operation rate of a steel plant is increased.

Owner:NANJING IRON & STEEL CO LTD

Manufacturing method of roller

InactiveCN108480402AEvenly distributedHigh strengthRollsMetal rolling arrangementsInterference fitHigh volume manufacturing

The invention discloses a manufacturing method of a roller. A roller ring of the roller is cast at twice through a centrifugal casting method. The alloy content of an outer-layer material of the roller is higher than that of an inner-layer material of the roller. A roller core of the roller is manufactured through a forging method. The roller core and an inner hole of the roller ring are combinedinto a whole through interference fit. The manufacturing method of the roller comprises the steps of centrifugal compound casting of the roller ring, forging of the roller core, heat treatment of theroller ring and combination of the roller core and the roller ring. According to the roller produced by the manufacturing method, the outer layer of the roller ring is high in alloy content and high in hardness, the inner layer of the roller ring is low in alloy content and simple in heat treatment, the roller core is manufactured through the forging method and suitable for large-batch production,heat treatment is separately carried out after casting of the roller ring is completed, the technology is simple, the effect is better compared with overall heat treatment, the roller core is fixed in the roller ring through interference fit after manufacturing is completed, the roller ring can be separately replaced after being abraded, and the cost is saved. In the using process of the roller manufactured through the manufacturing method, the roller face is not likely to produce cracks, the rolled steel plate edge is good in quality, and the rolling period of the roller is long.

Owner:JIANGSU LIDIAN MACHINE TOOL TECH CO LTD

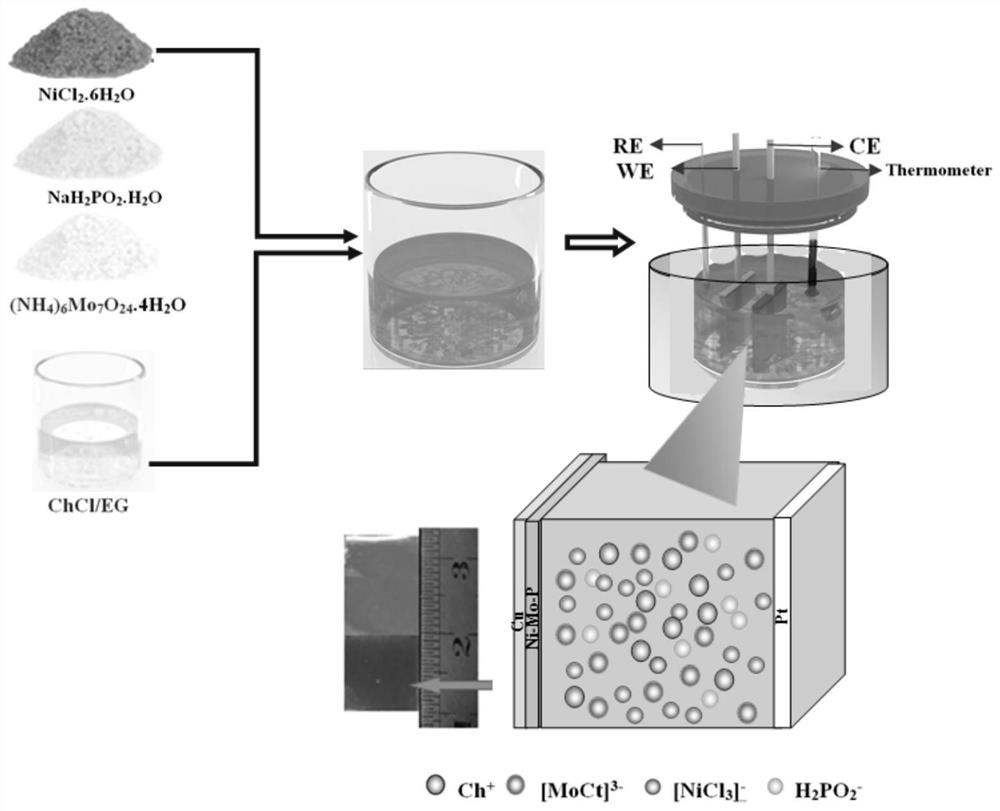

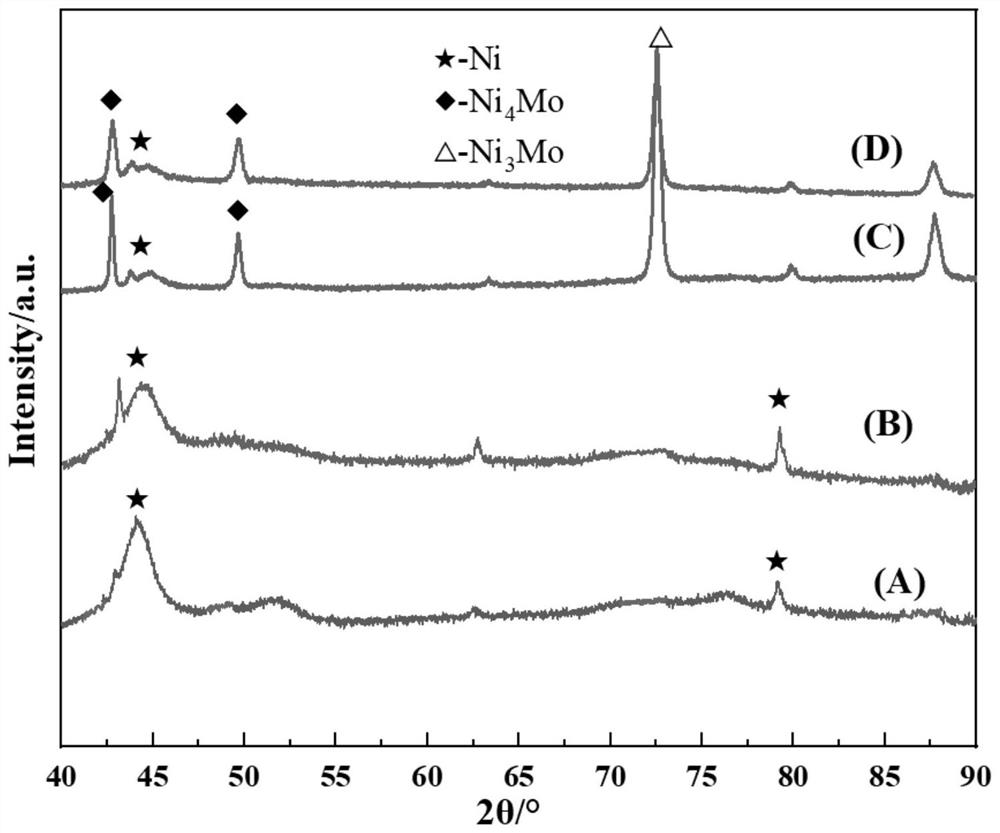

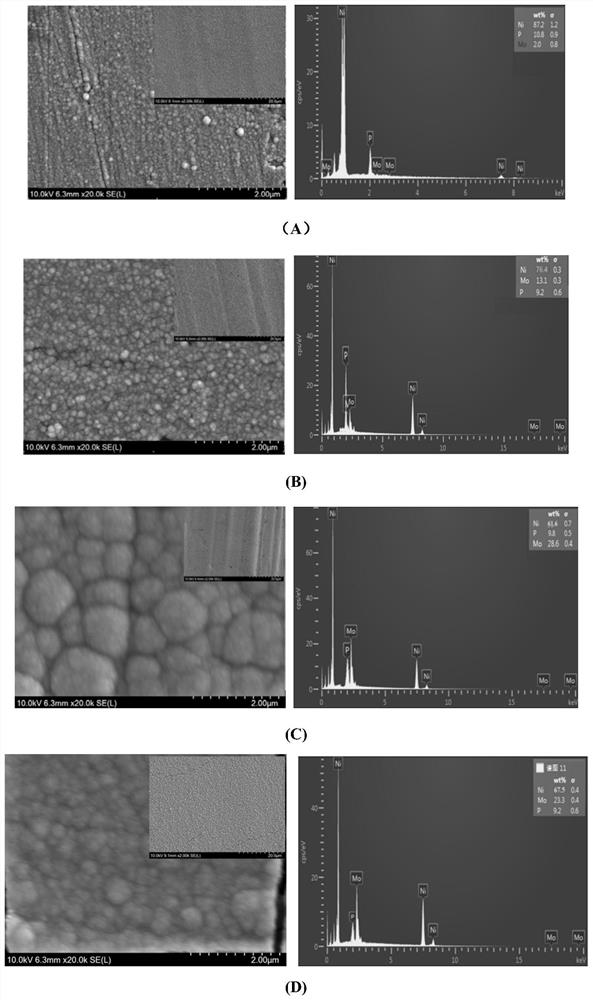

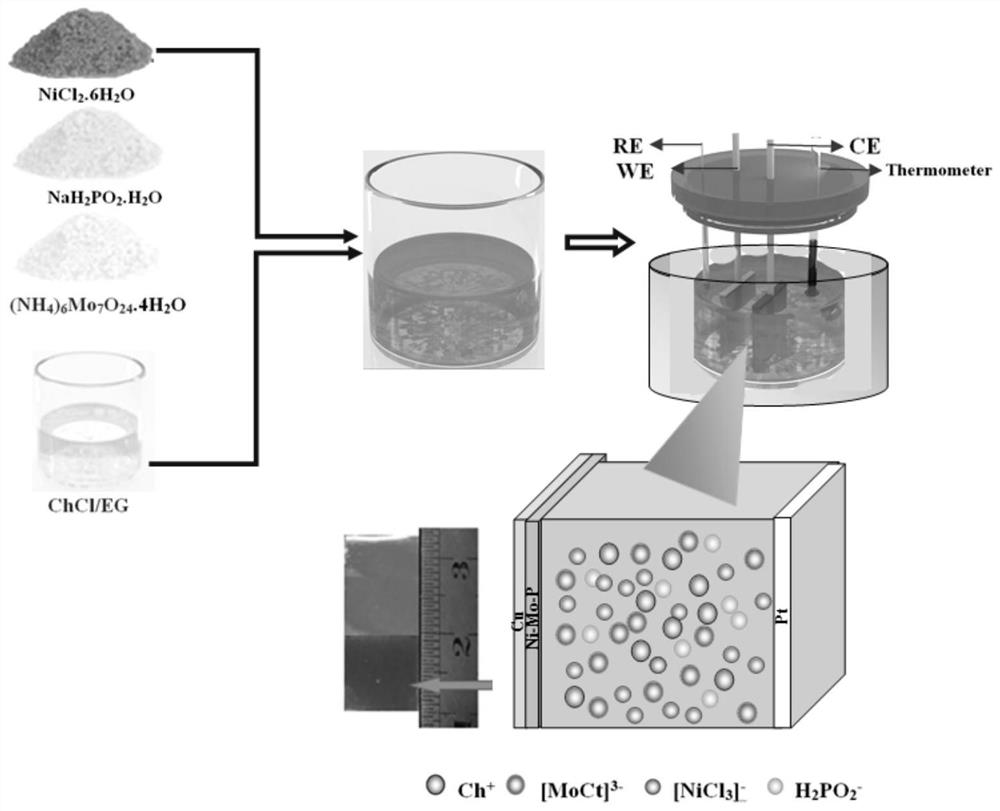

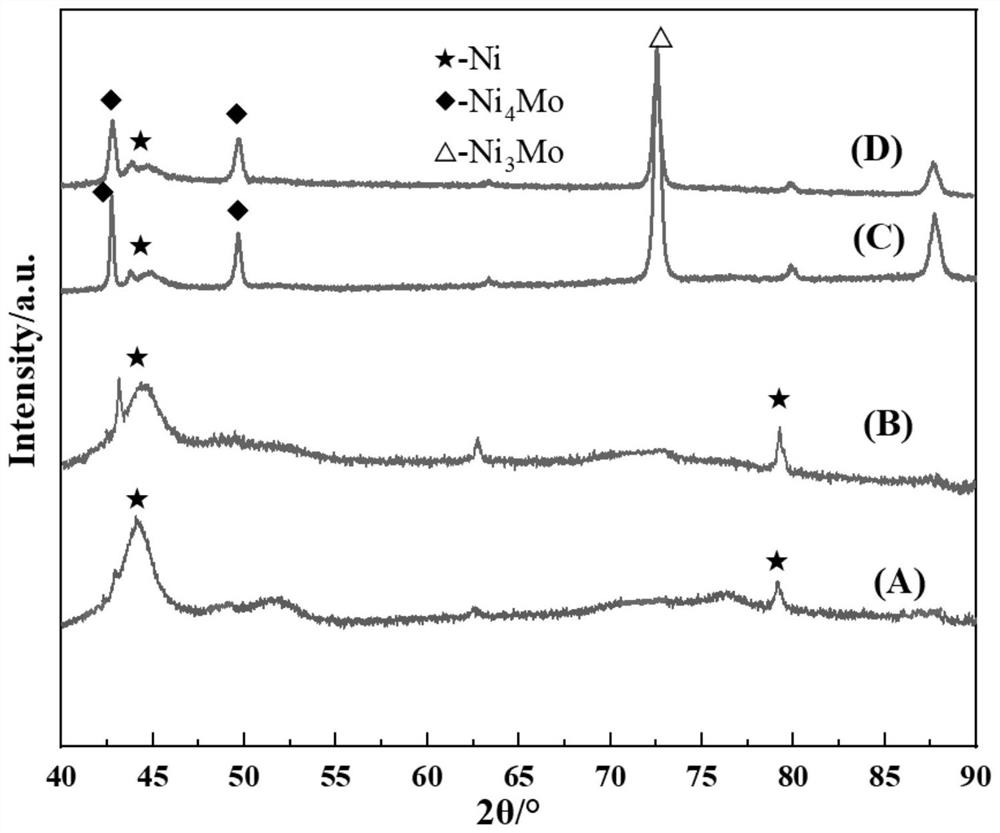

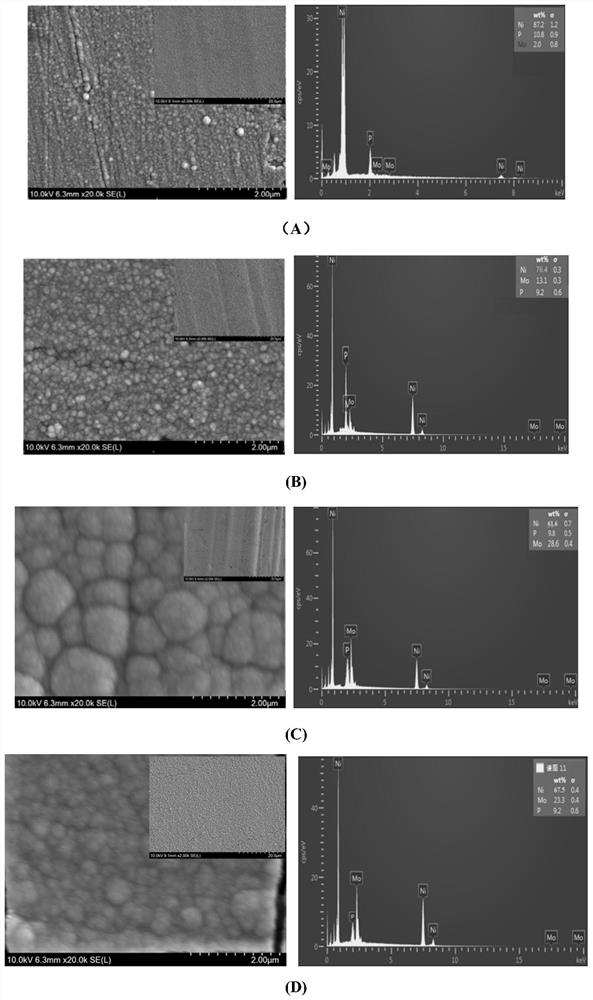

Method for preparing Ni-Mo-P nano alloy film electrode through ionic liquid electro-deposition

ActiveCN113430532ASimple manufacturing processWide electrochemical windowElectrodesNickel saltPhosphate

The invention relates to a method for preparing a Ni-Mo-P nano alloy film electrode by utilizing ionic liquid electro-deposition. The method successfully solves the problems of low current efficiency, high waste liquid yield, coarse film tissue, high hydrogen-induced defects and the like in the traditional method for preparing a nickel-based alloy film electrode by utilizing aqueous solution electrodeposition. The method for preparing the Ni-Mo-P nano alloy film electrode through ionic liquid electro-deposition comprises the following steps that a phosphate, citric acid, a molybdenum salt and a nickel salt are added into an ionic solvent formed by mixing choline chloride and ethylene glycol, and an ionic plating solution is obtained; a brass sheet is used as a substrate, the Ni-Mo-P nano-alloy film electrode is prepared on the brass sheet in an electro-deposition mode through a constant current method, wherein the phosphate is NaH2PO2, the molybdenum salt is (NH4) 6Mo7O24, the nickel salt is NiCl2, and the temperature of a plating solution is 60-80 DEG C, the current density is 5-50 mA / cm < 2 >, and the electro-deposition time is 3-7 min. The Ni-Mo-P alloy film electrode prepared by the preparation method disclosed by the invention has good hydrogen evolution catalytic performance (eta 200 is equal to 169mV, and b is equal to 51.2 mV / dec).

Owner:SUZHOU UNIV

Quenching method for large-specification working roller of high-alloy cold-work die steel

ActiveCN107760849AHigh surface hardnessHigh heart toughnessFurnace typesIncreasing energy efficiencyAlloyHardness

The invention discloses a quenching method for a large-specification working roller of high-alloy cold-work die steel, and belongs to the steel processing field. The quenching method comprises the following steps: performing continuous induction thermal treatment on the working roller, quickly rising the temperature of the surface of the working roller to 1020-1100 DEG C, and performing fog cooling when the temperature is risen to a preset temperature; continuously performing fog cooling for 50-70 minutes; and guaranteeing a re-heating temperature to be not higher than 100 DEG C. The quenchingmethod disclosed by the invention is free of pollution, is low in requirement on needed equipment; surface hardness of the working roller is great, toughness of the core part of the working roller ishigh, a transitional layer is transitional in a gradient mode at uniform reducing hardness, loading requirements are met, continuous induction quenching of the roller body is realized while cracks are avoided, a thermal treatment success rate is increased, and production cost is reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

A method of manufacturing x100 high steel grade large diameter thick wall longitudinal submerged arc welded pipe

ActiveCN103521549BImprove solderabilityUniform elongationArc welding apparatusX-rayHydrostatic pressure

The invention discloses a manufacturing method of an X100 high-steel-grade large-opening-diameter thick-wall longitudinal submerged-arc welded pipe. The manufacturing method comprises steel plate ultrasonic inspection, edge milling, edge pre-bending, JCO forming, pre-welding, inner welding, outer welding, welding line X-ray inspection, steel pipe diameter expanding, hydrostatic pressure testing, welding line ultrasonic inspection, pipe end X-ray inspection, chamfering, pipe end magnetic particle testing, and appearance quality inspection. A refined welding process comprises inner and outer welding four-wire submerged-arc automatic welding. The X100 high-steel-grade large-opening-diameter thick-wall longitudinal submerged-arc welded pipe manufactured by the method not only has the characteristics of high low-temperature impact toughness, good welding joint mechanical properties and the like, but also has relatively high pipe body uniform elongation rate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

An economical non-quenched and tempered micro-alloyed plastic mold steel plate and its manufacturing method

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

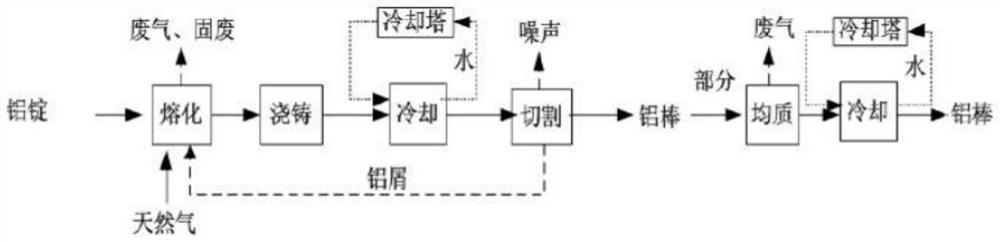

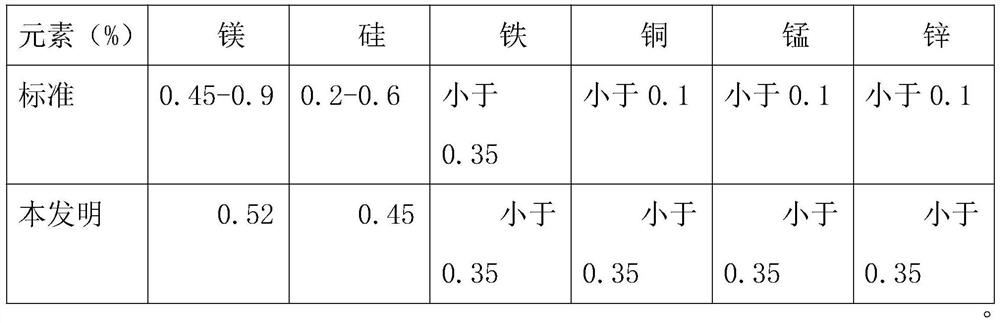

Aluminum profile casting process

A specific manufacturing method of the aluminum profile casting technology comprises the following steps that S1, firstly, burdening and charging are conducted, and raw materials are prepared; s2, the raw materials are poured into a casting furnace to be smelted; s3, deslagging the raw materials, and adjusting components; s4, refining the raw materials; s5, casting treatment; and S6, saw cutting and homogenizing treatment are carried out. The smelting and refining steps are adopted, waste gas is exhausted through nitrogen in the refining process, meanwhile, slagging-off is conducted after smelting and refining are completed every time, in the raw material slagging-off process, feeding is conducted again according to the analysis result, components are adjusted, the components are rapidly stirred and mixed, the alloy content of a product is overall increased, and the product is high in quality.

Owner:JIANGSU WEIYE ALUMINUM MATERIAL

Toughening and Straightening Technology of Gun Drilling Drill Rod for Deep Hole Processing

ActiveCN105063323BHigh alloy contentHigh strengthSolid state diffusion coatingFurnace typesShielding gasCarburizing

The present invention relates to the technical field of processing methods for deep hole processing equipment, in particular to the process of toughening and straightening gun drill rods for deep hole processing, comprising the following steps: 1) material selection, pipe making and forming, selecting high-quality alloy steel, tool steel or Carburized steel, processed into a deep hole processing gun drill pipe before heat treatment; 2) heat treatment strengthening and toughening and straightening integration, the deep hole processing gun drill pipe before heat treatment is hung vertically on the tooling, deep The counterweight is mounted on the bottom end of the hole processing gun drill drill pipe for carburizing, quenching, self-alignment of the counterweight or quenching and self-straightening; 3) tempering, straightening, and cooling. Compared with the prior art, this The invention uses high-quality alloy steel, tool steel or carburizing steel as raw materials, and through heat treatment in a protective gas furnace, vacuum furnace, and high-frequency furnace, under the gravity of the counterweight, self-alignment or carburizing and quenching of carburizing steel improves The carbon content is lowered, the toughness is strengthened; the heat treatment is strengthened and toughened and straightened, and the tempering process is self-aligned.

Owner:佛山市云昇金属科技有限公司

Process for producing die steel by utilizing converter continuous casting mode

ActiveCN103160635BHigh alloy contentImprove purityTemperature control deviceManufacturing convertersEconomic benefitsHigh pressure water

The invention discloses a process for producing die steel by utilizing a converter continuous casting mode. The process comprises a steel making continuous casting process and a steel rolling process. The steel making continuous casting process comprises the following process steps of: converter smelting, LF (Ladle Furnace) refining, continuous casting, slow cooling and other process steps; and the steel rolling process comprises the following process steps of: heating, scale removal by using high pressure water, rolling, straightening, stacking, slow cooling and other steps. By using the die steel produced by the invention, the contents of gas and occluded foreign substances in the die steel can be reduced, the thermal stress and the structural stress for slowing a steel blank down are eliminated, a thick and nonuniform cast structure inside the steel blank is improved, and the problems of flaw detection disqualification and finished product crack of the die steel are solved. By using the process, the aim of producing the die steel by using a converter is achieved, the production cost is reduced, and the economic benefit is increased.

Owner:冀南钢铁集团有限公司

A kind of method utilizing ionic liquid electrodeposition to prepare ni-mo-p nano-alloy film electrode

ActiveCN113430532BSimple manufacturing processWide electrochemical windowElectrodesNickel saltPhosphate

The invention relates to a method for preparing Ni-Mo-P nano-alloy thin film electrodes by electrodeposition of ionic liquids. The method successfully solves the problems of low current efficiency, high output of waste liquid and thin film Coarse tissue and high hydrogen-induced defects. The method for preparing Ni-Mo-P nano-alloy film electrode by ionic liquid electrodeposition comprises the following steps, adding phosphate, citric acid, molybdenum salt, nickel salt respectively in the ionic solvent that choline chloride and ethylene glycol mix, obtain ion Plating solution; using a brass sheet as a substrate, Ni-Mo-P nano-alloy thin film electrodes are prepared by electrodeposition on the brass sheet by a constant current method, wherein the phosphate is NaH 2 PO 2 , Molybdenum salt is (NH 4 ) 6 Mo 7 o 24 , nickel salt is NiCl 2 , the bath temperature is 60-80°C; the current density is 5-50mA / cm 2 , The electrodeposition time is 3-7min. The Ni-Mo-P alloy film electrode prepared by the present invention has good hydrogen evolution catalytic performance (η 200 =169mV, b=51.2mV / dec).

Owner:SUZHOU UNIV

A kind of high-strength toughness and high-strength plasticity automobile steel and its preparation method

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com