Patents

Literature

57results about How to "Large residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

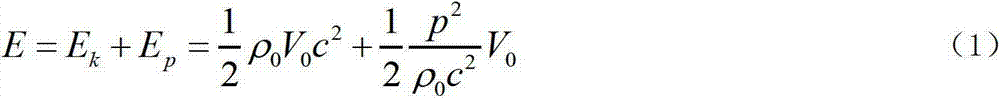

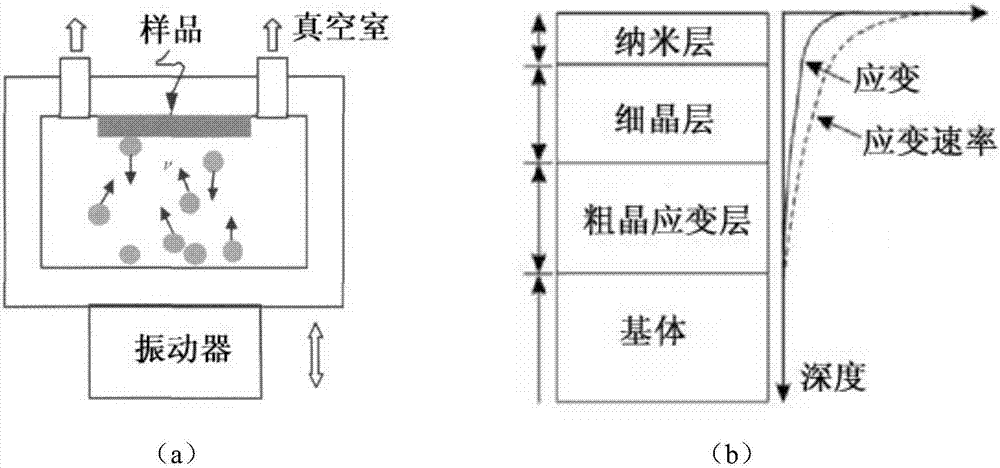

High energy ultrasonic field regulation and control method for residual stress

The invention relates to a high energy ultrasonic field regulation and control method for residual stress. The method is based on the substance of the process of eliminating the residual stress, and mainly utilizes the granule fluctuation energy of the high energy sound wave to offer enough power for dislocation atoms, so that the dislocation atoms can overcome the resistance and reduce lattice distortion by sliding out of the interior of a crystal so as to eliminate the residual stress. According to the method, a formula of the high energy ultrasonic for offering energy for the material is provided, so that a method for selecting a high energy ultrasonic transducer is provided, and the high energy ultrasonic field of the residual stress of metal or nonmetal components is regulated and controlled. According to the method, the processes are simple, effects of the residual stress at the present stage on the usage, stability of the size, the fatigue strength, abrasive resistance and stress corrosion cracking and the like of the component are effectively eliminated, the method has the advantages of high efficiency, energy conservation, environment friendliness and the like, thus having wide application range.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

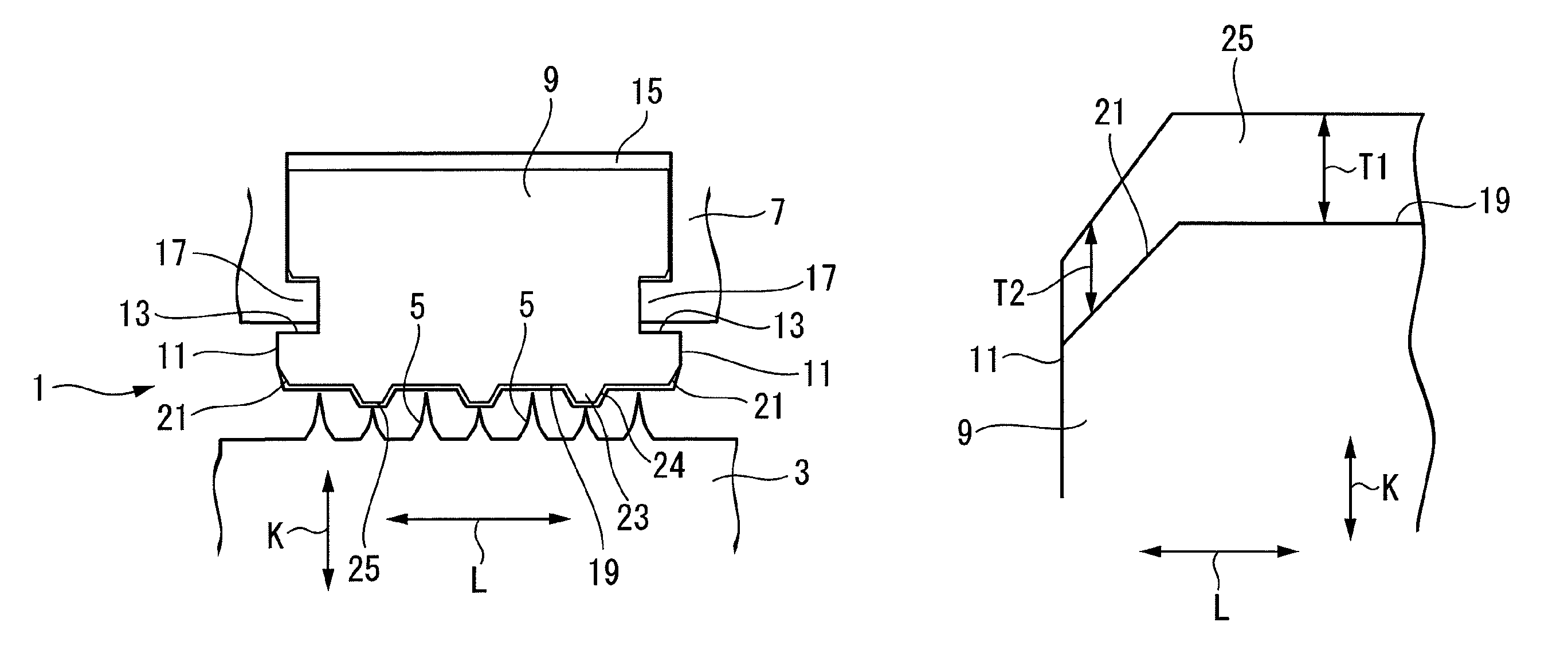

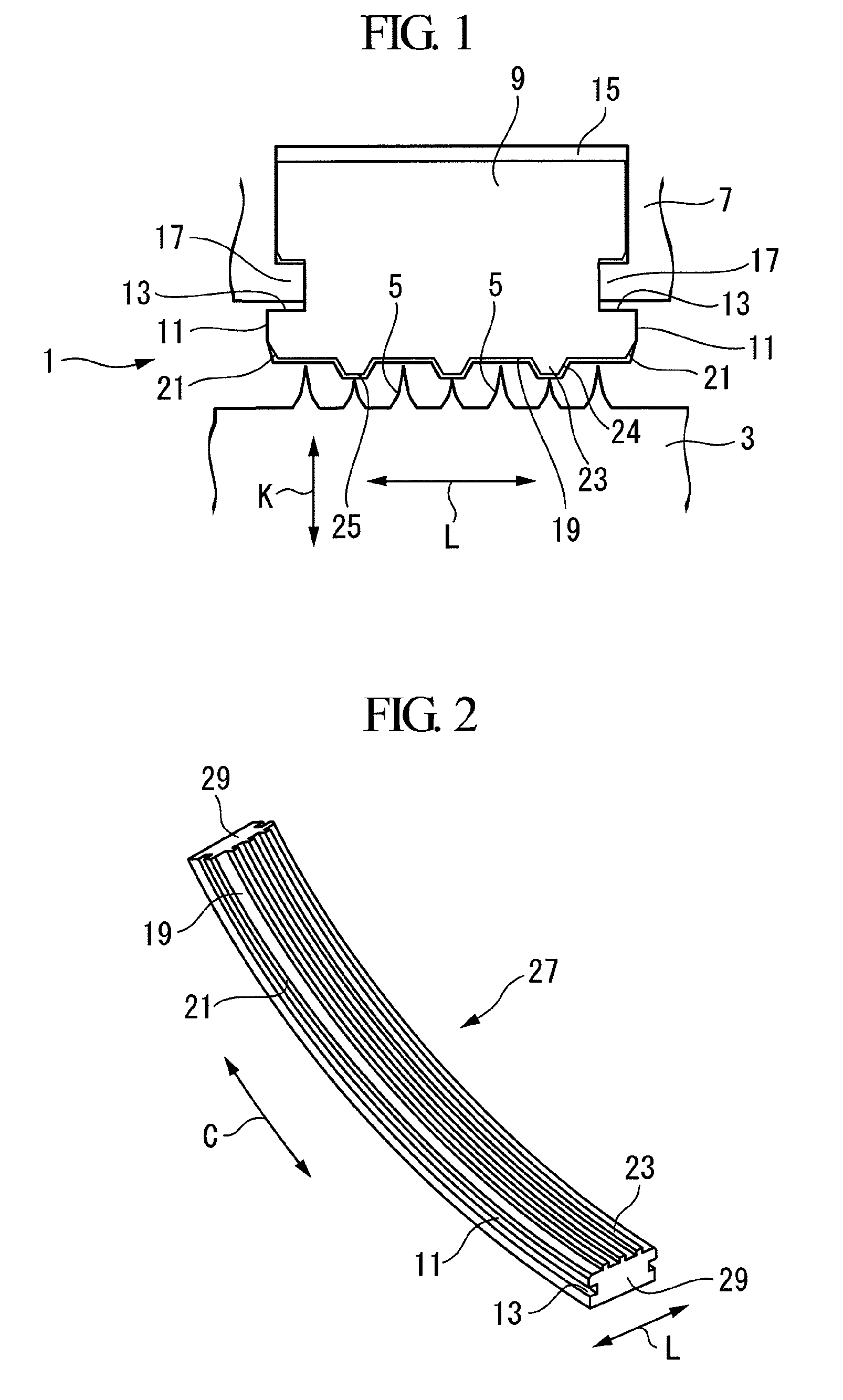

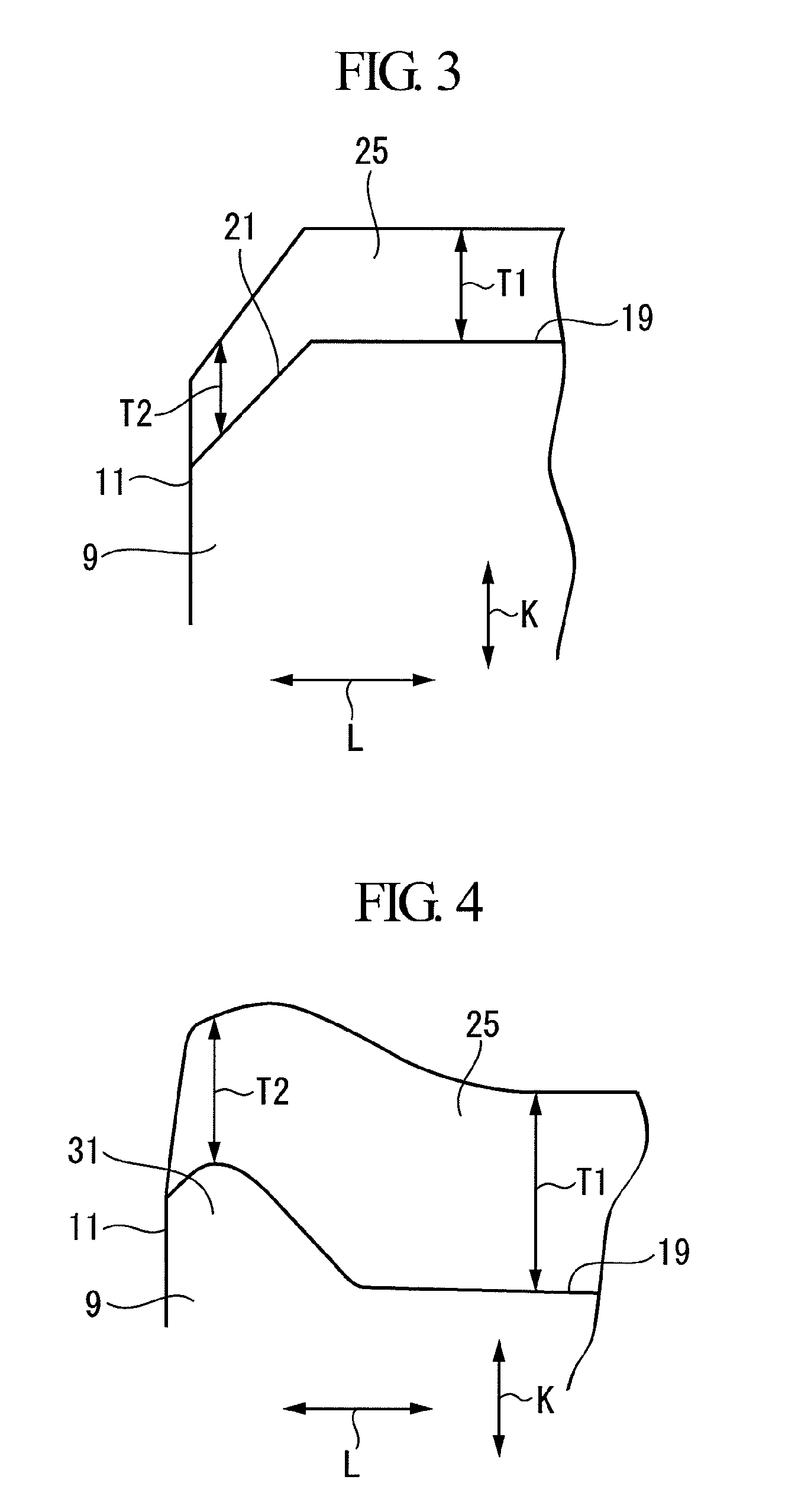

High power fin cold plate radiator and manufacturing method thereof

InactiveCN102231370AReduce distortionNo gapSemiconductor/solid-state device detailsSolid-state devicesActive forceEngineering

The invention relates to a high power fin cold plate radiator and a manufacturing method thereof. Provided is a high power fin cold plate radiator. The radiator is characterized in that it is formed by merging a plurality of radiation cells; the radiation cells are aluminium or copper extrusion moulding uniform cross section bars; the radiation cells are arranged in the width direction; the substrate portion of each adjacent radiation cells uses a stripe-shaped hook to plug with a corresponding slot and the stripe-shaped hook and the slot abut against each to cooperate with an upward or downward inclined plane; when one of the two adjacent radiation cells is impacted with an active force in an up and down direction, the stripe-shaped hook and the slot oppositely slide along the inclined plane to make the adjacent radiation cells become closer so that a clamp structure among the radiation cells is formed and the substrate portions are welded together with a stirring friction welder. The invention is characterized by simple manufacture. The height of the fin can be increased, the thickness of the fin can be reduced, the spacing between the fins after the radiation cells are merged together can be reduced to achieve the requirement of high power fins and 25-time to 40-time fins can be manufactured.

Owner:苏州三川换热器股份有限公司

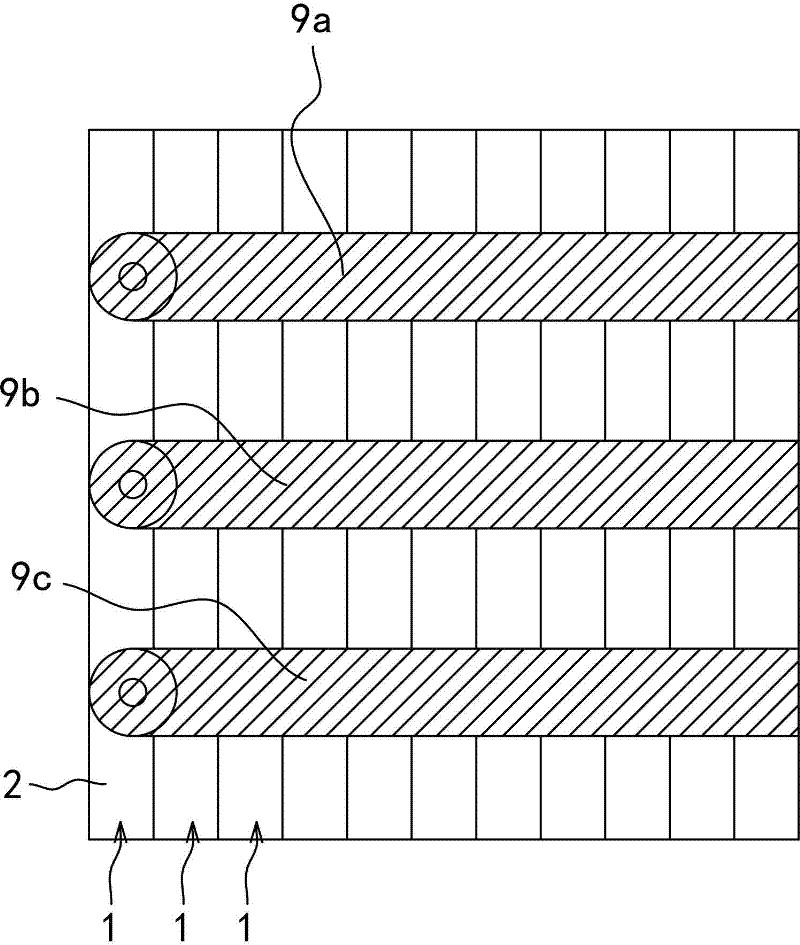

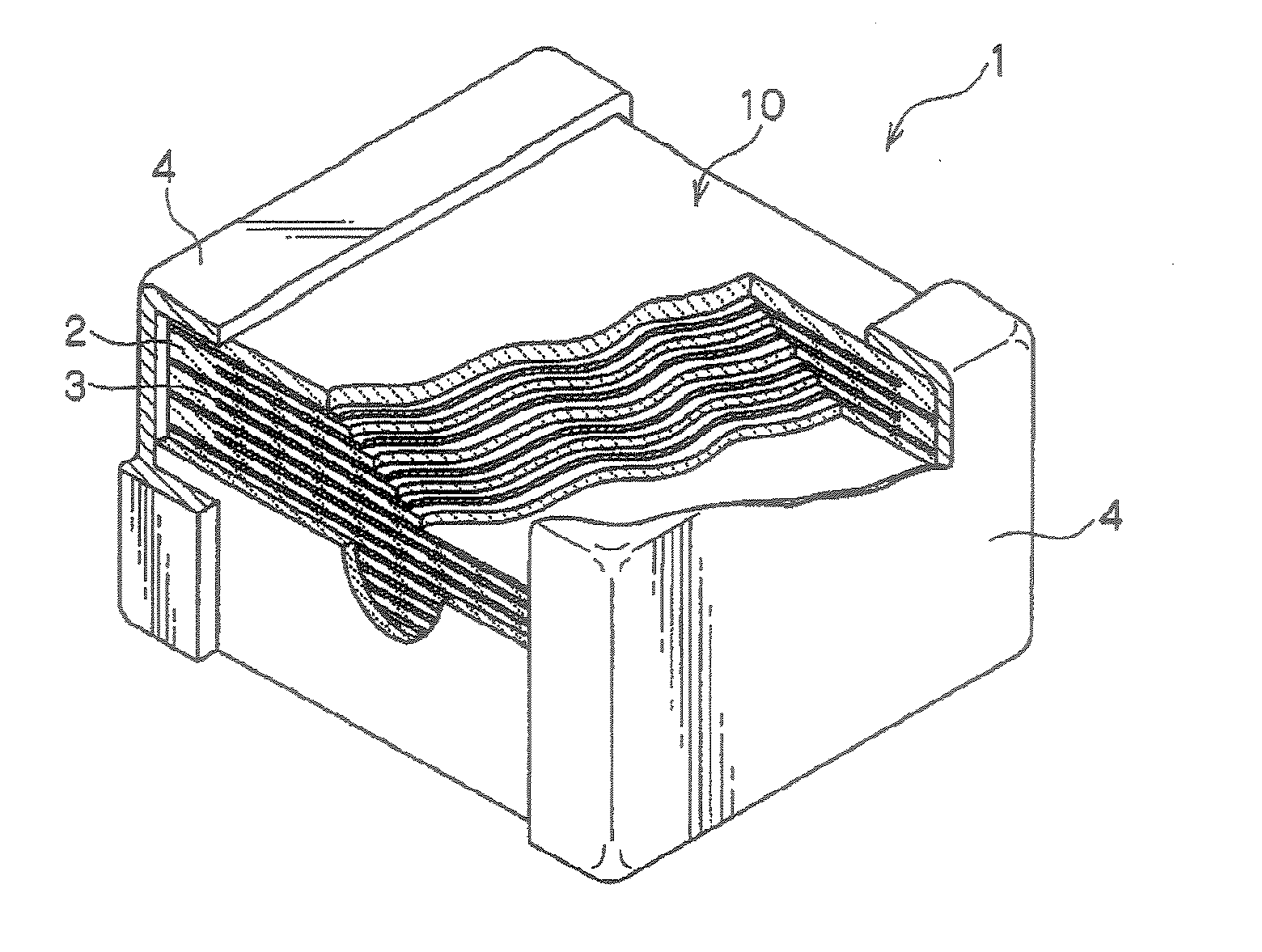

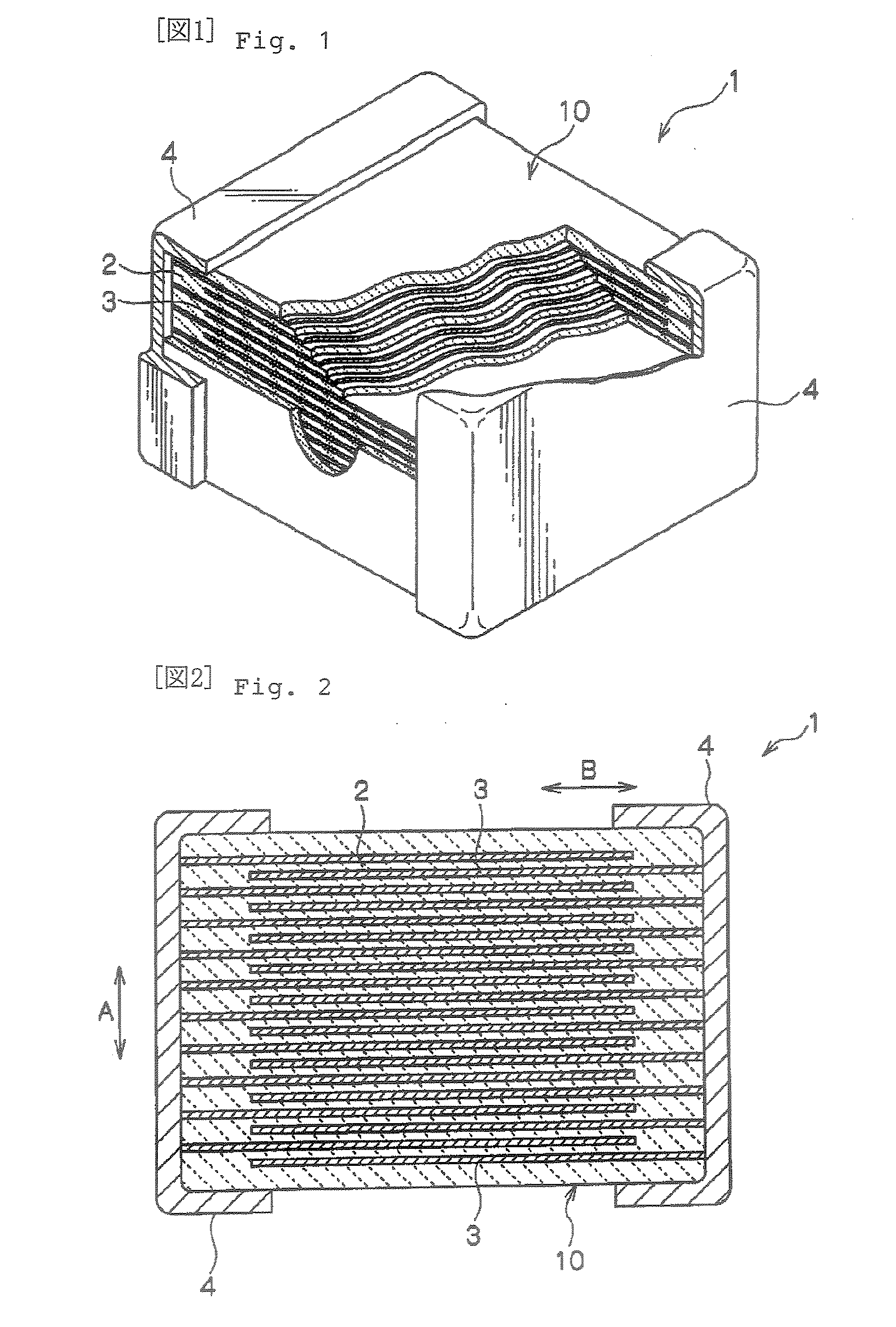

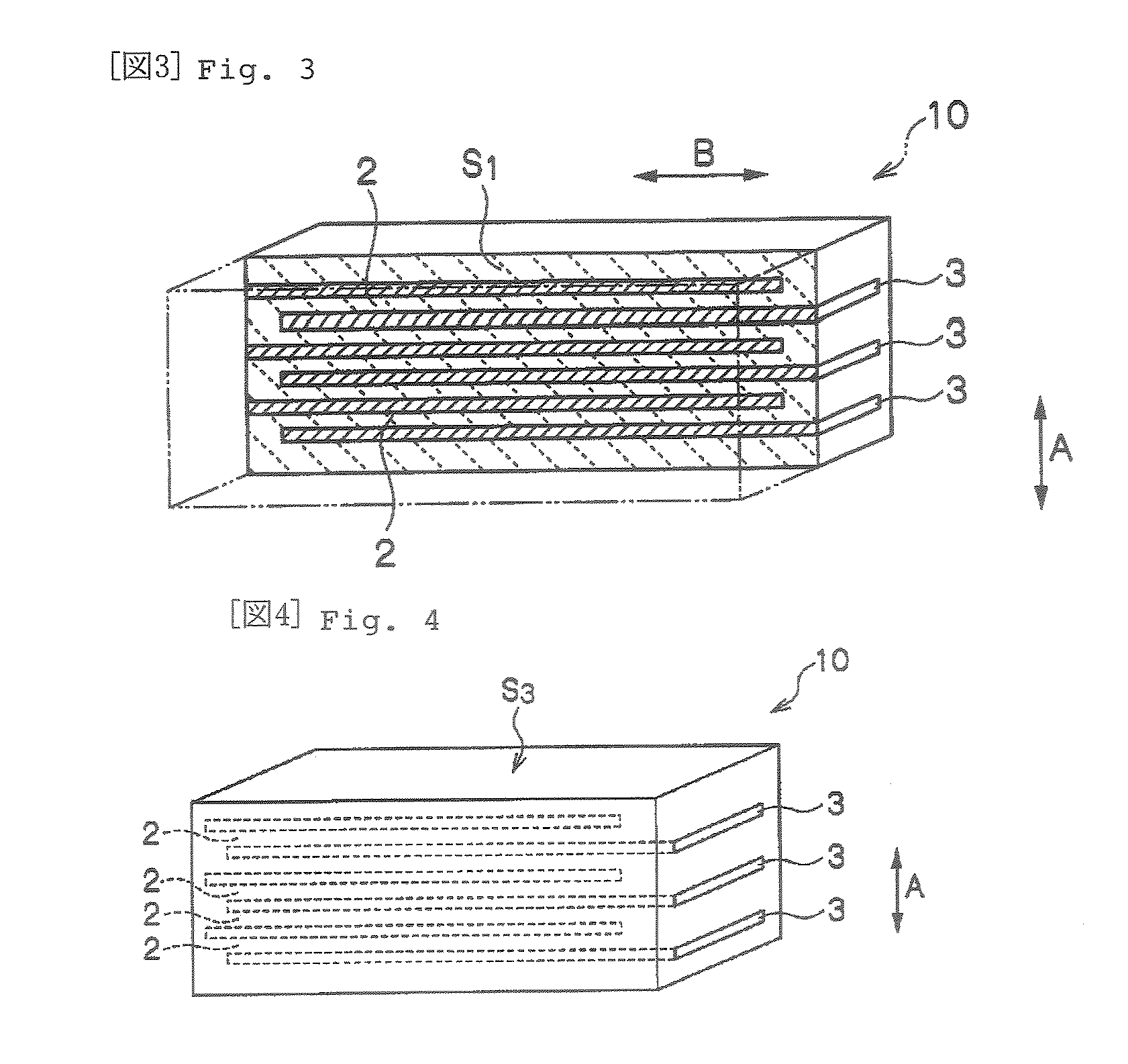

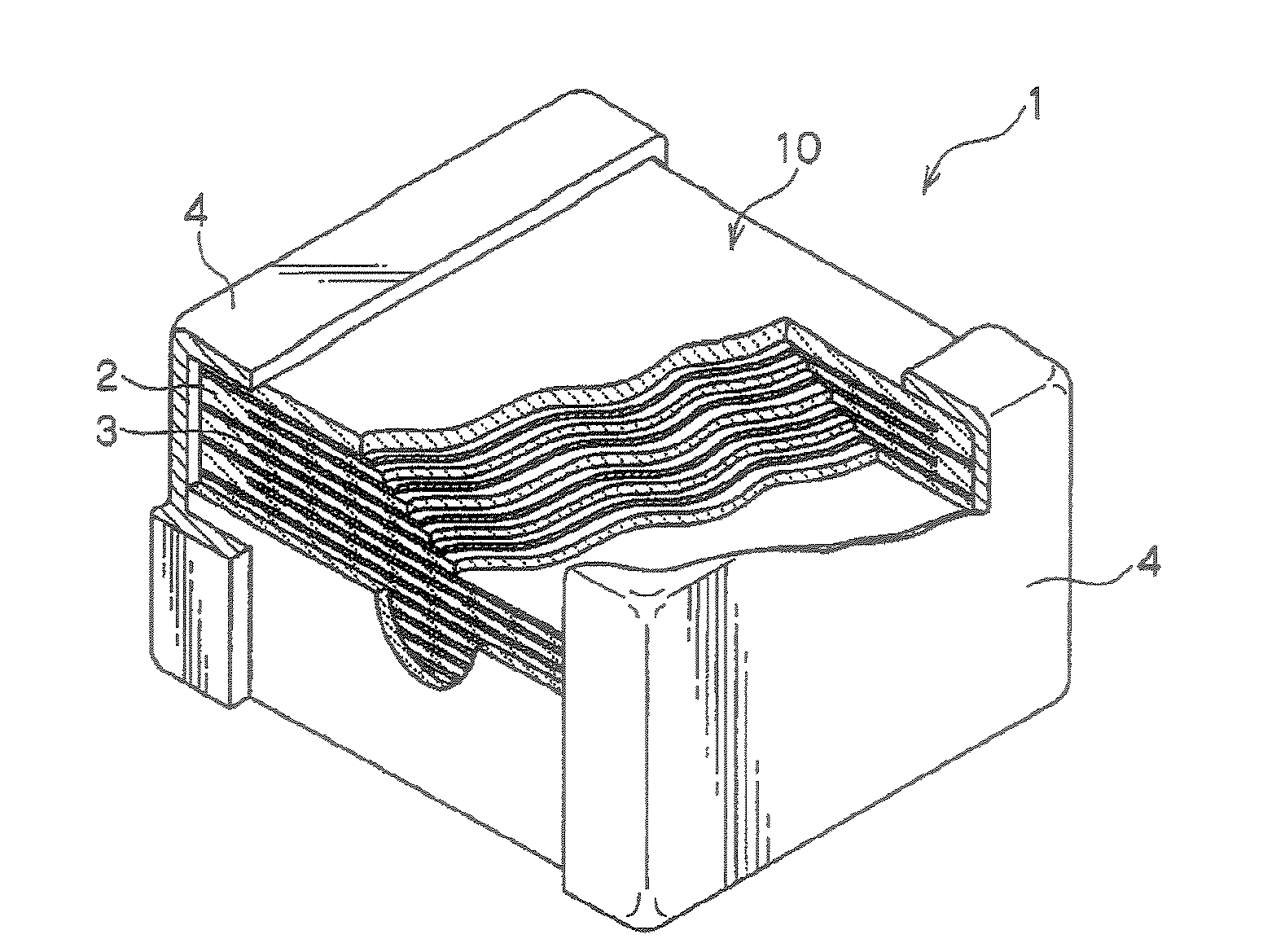

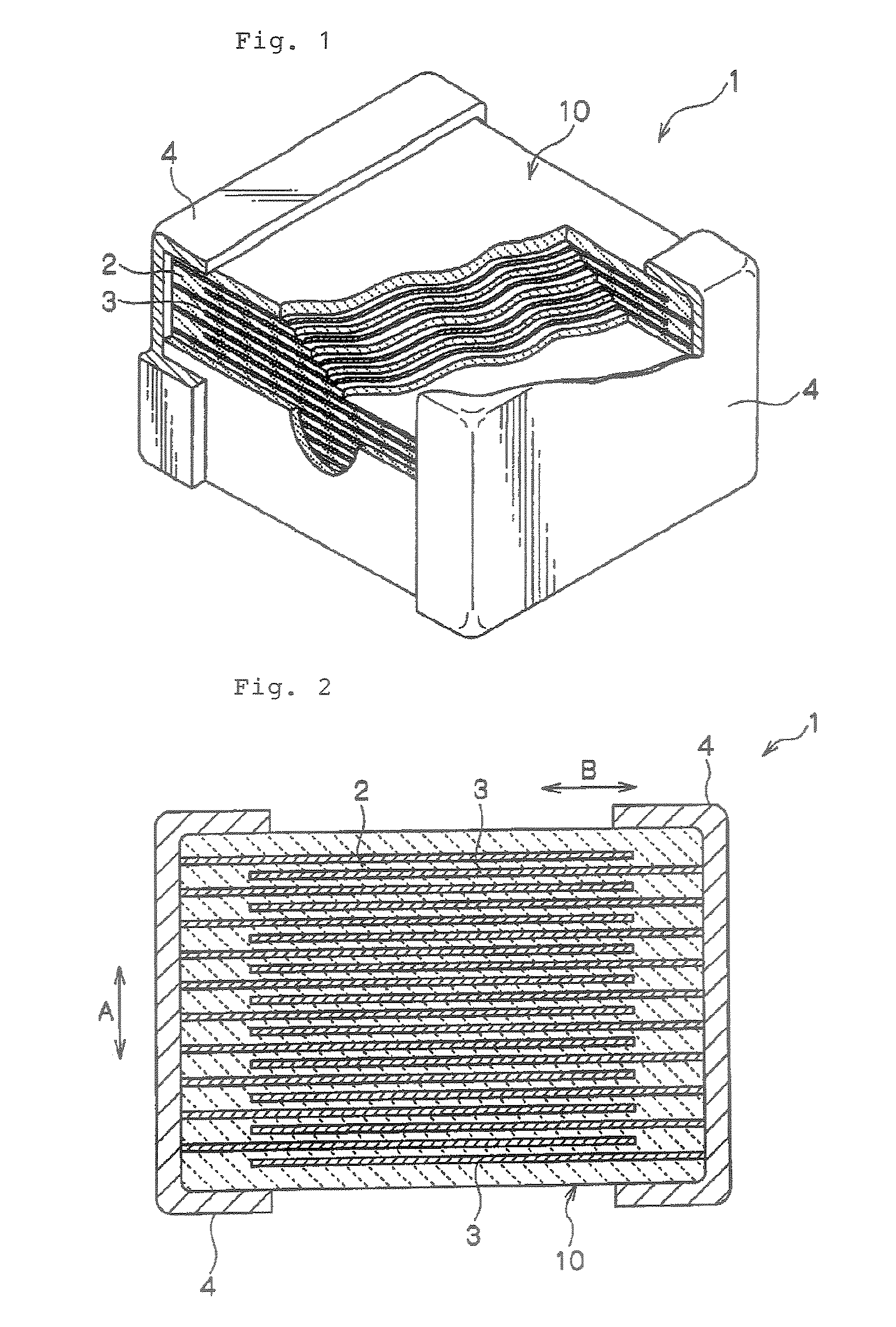

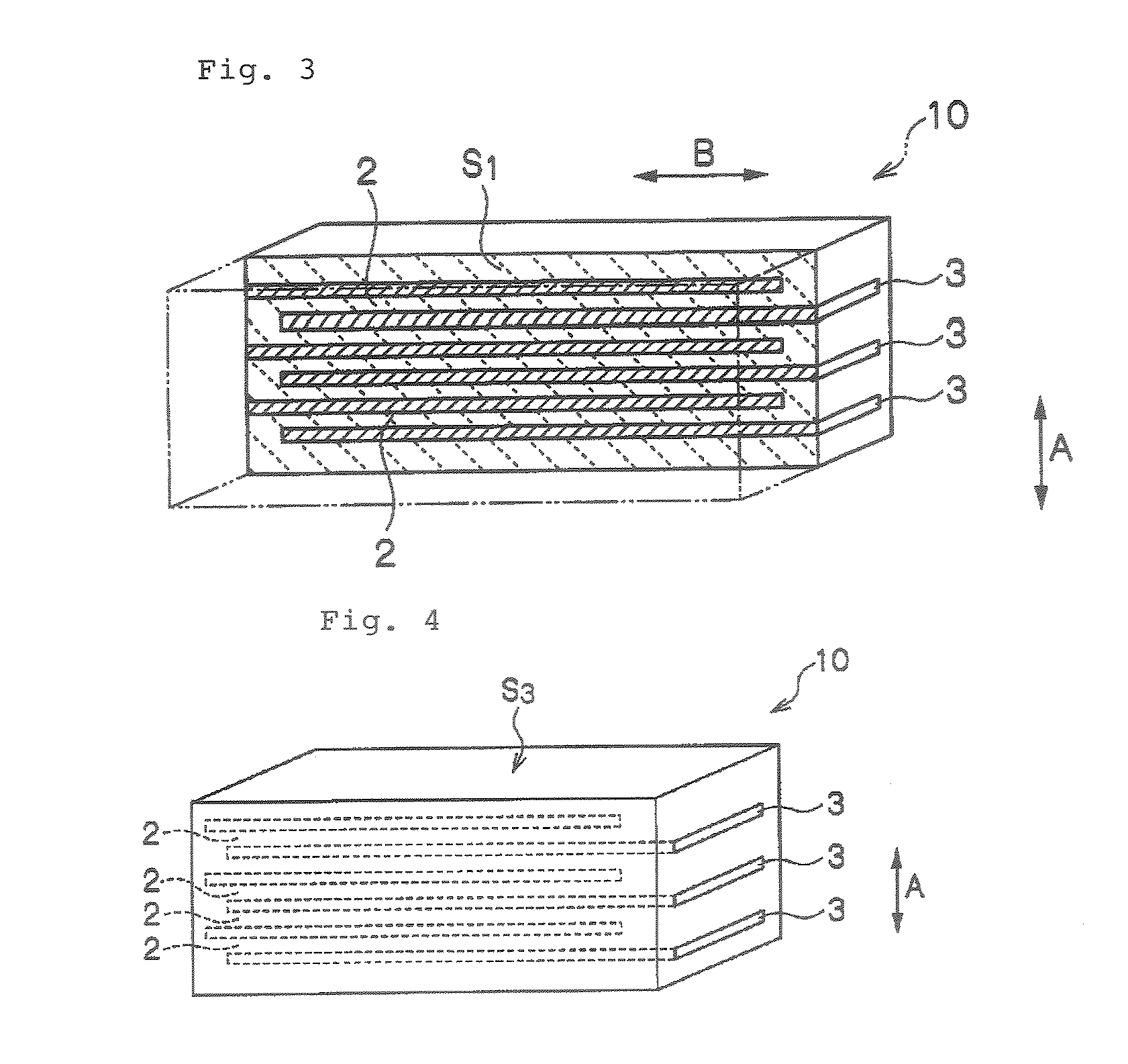

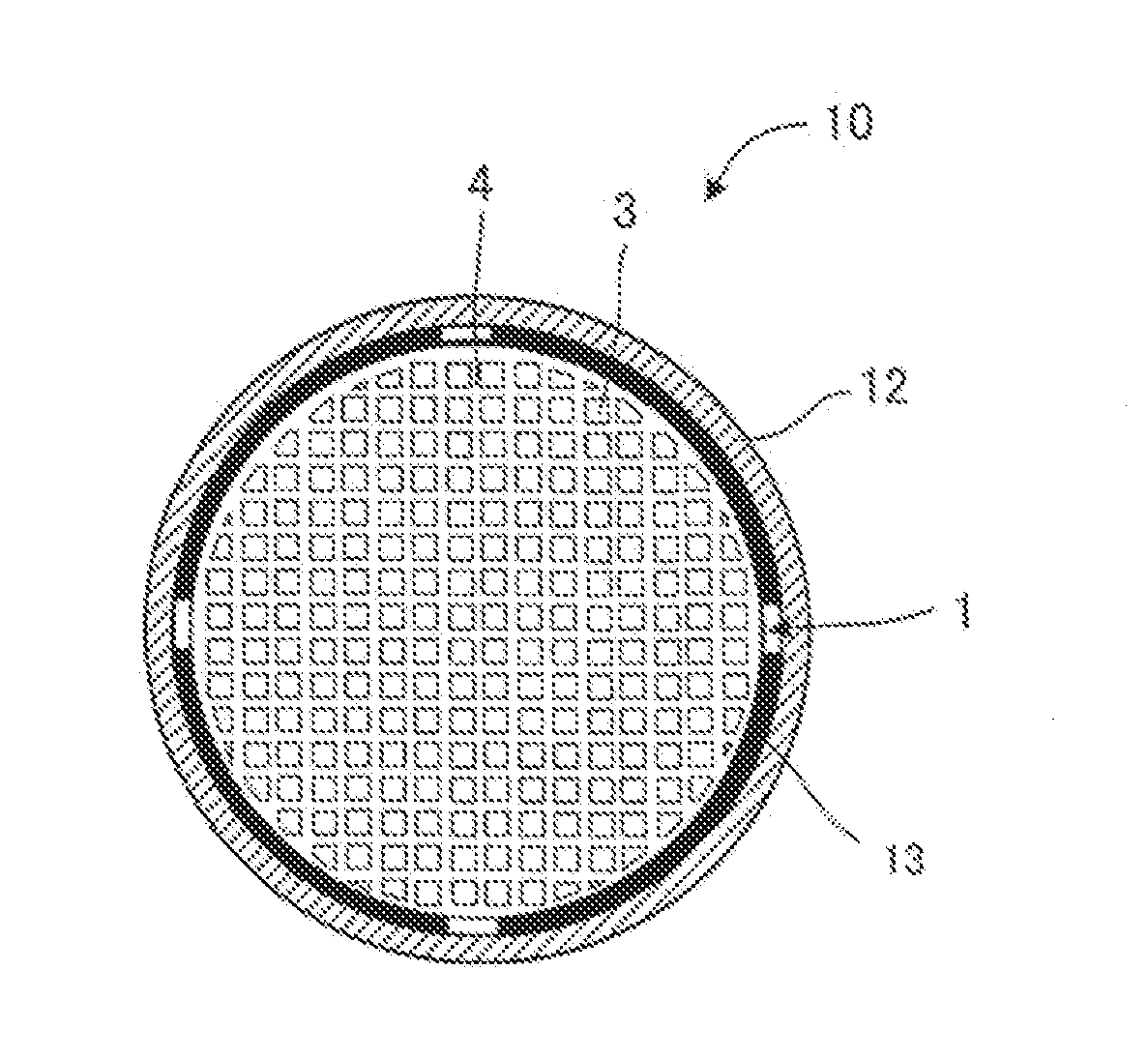

Layered ceramic capacitor

ActiveUS20070139861A1Large capacitanceImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricCapacitanceCeramic capacitor

A multilayer ceramic capacitor having a high dielectric constant, a large capacitance and a high reliability can be obtained by controlling a value of residual stress in it.

Owner:TDK CORPARATION

Layered ceramic capacitor

ActiveUS7595974B2Increase the number of layersLarge capacitanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceCeramic capacitor

A multilayer ceramic capacitor having a high dielectric constant, a large capacitance and a high reliability can be obtained by controlling a value of residual stress in it.

Owner:TDK CORPARATION

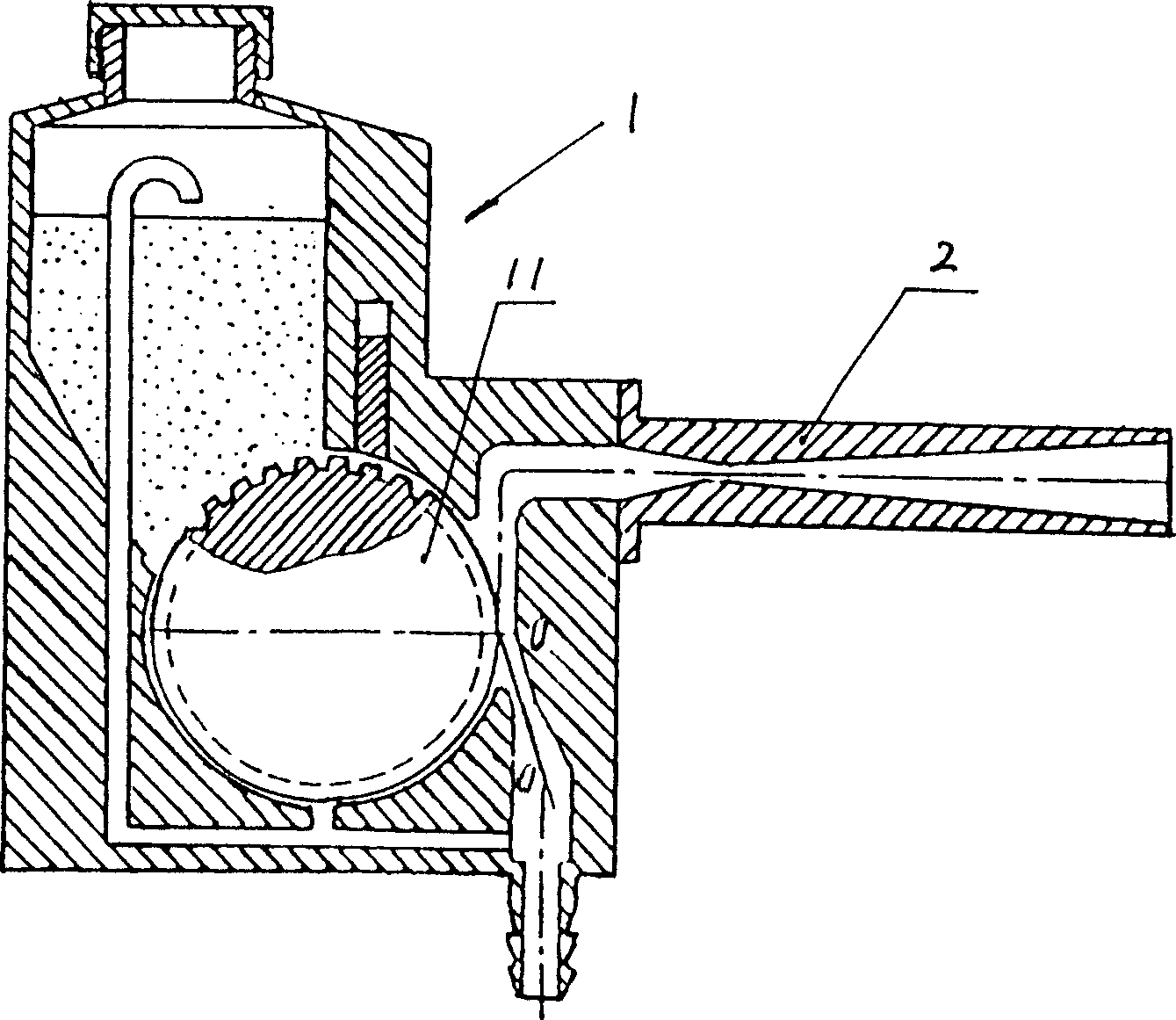

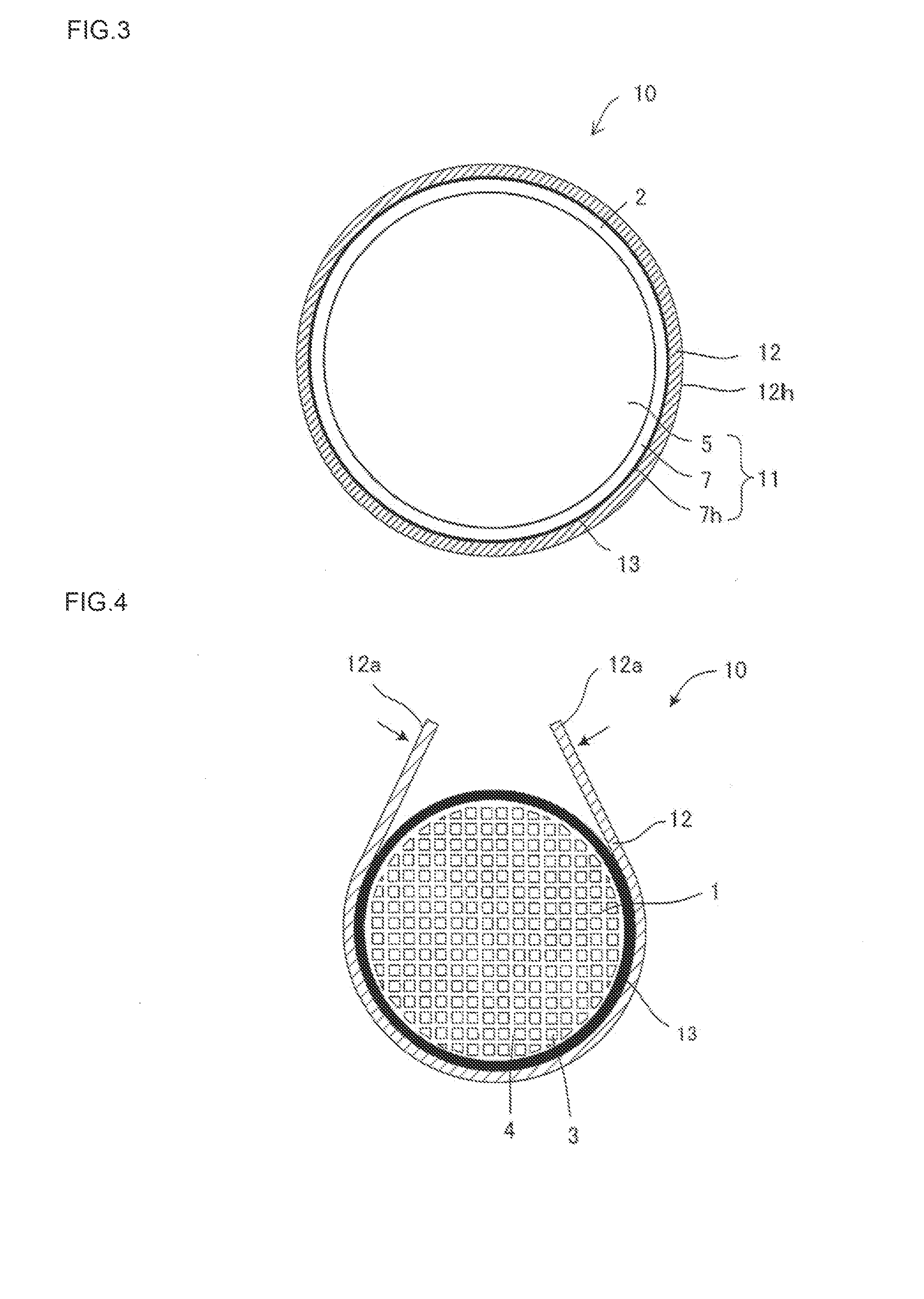

Seal structure

ActiveUS20100164179A1Improve sealingSmall setEngine sealsMolten spray coatingEngineeringMechanical engineering

Owner:MITSUBISHI POWER LTD

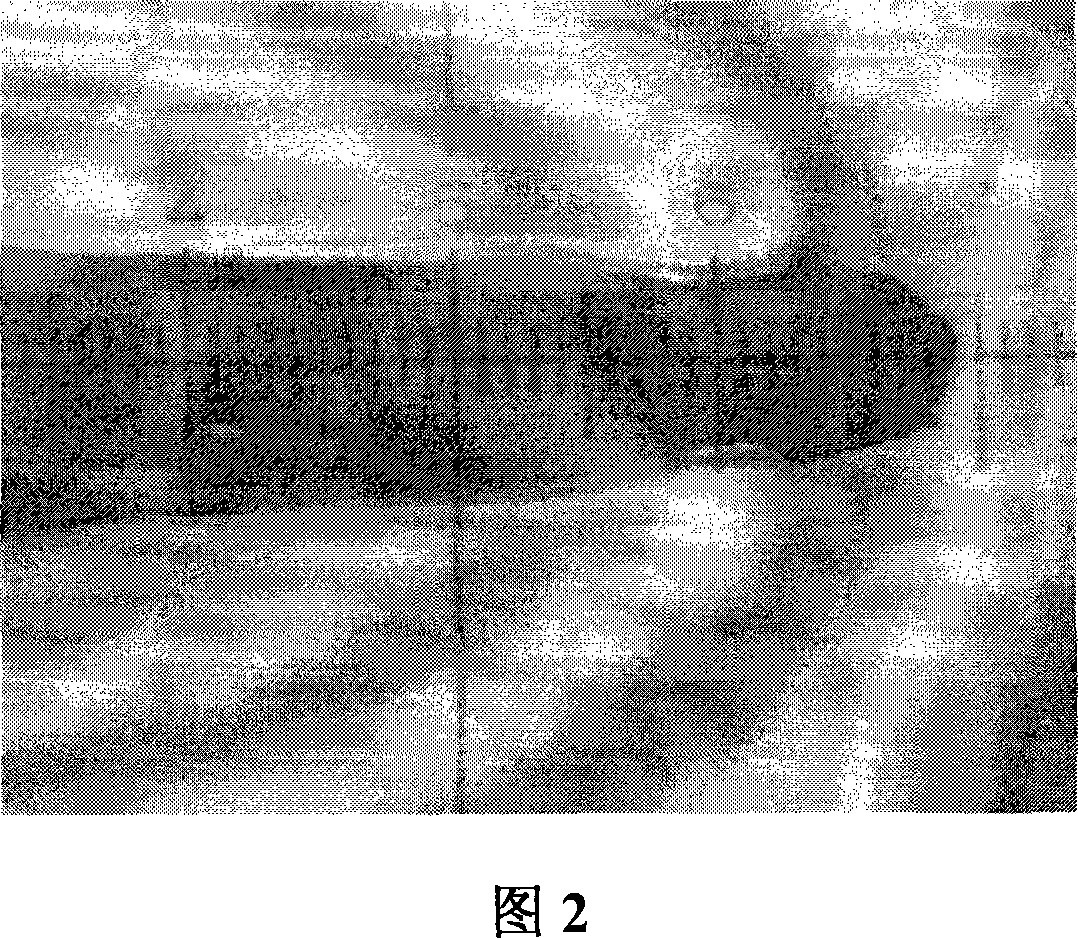

Method for local bonding silicon / glass by laser

InactiveCN101050066AImprove controllabilityStable deliverySemiconductor/solid-state device manufacturingTemperature controlBiological activation

This invention discloses a method for laser local bonding of silicon / glass. The method comprises: washing, performing a first activation, performing a second activation, pre-bonding, and laser heating. After surface activation treatment, glass and silicon wafer can be intimately bonded by laser local bonding without the need for outside force. The method realizes laser local bonding through local high temperature in a certain region, and has a high bonding strength. As a whole, the silicon wafer has a low temperature, and does not have unnecessary temperature gradient or stress field distribution. Thus, the properties of the integrated pressure or temperature sensor are not influenced. The method has such advantages as simple apparatus, easy local temperature control, and high bonding efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

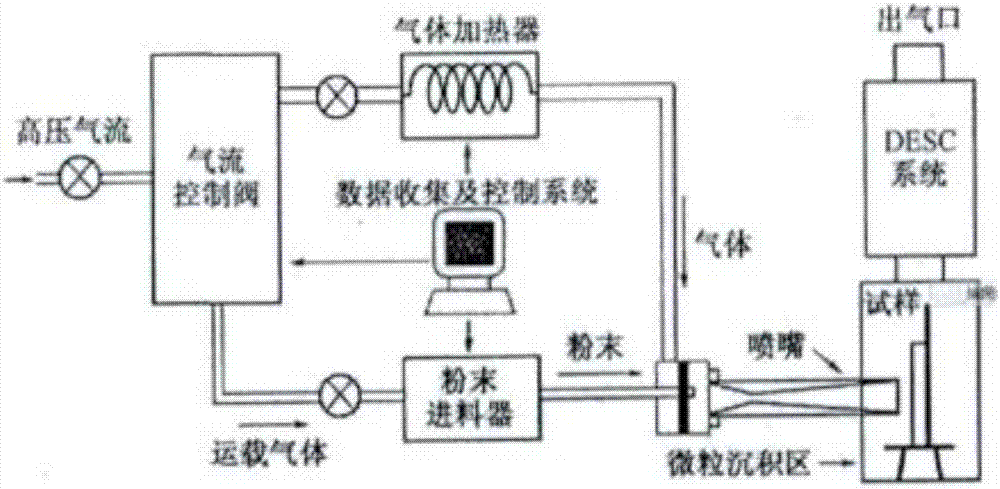

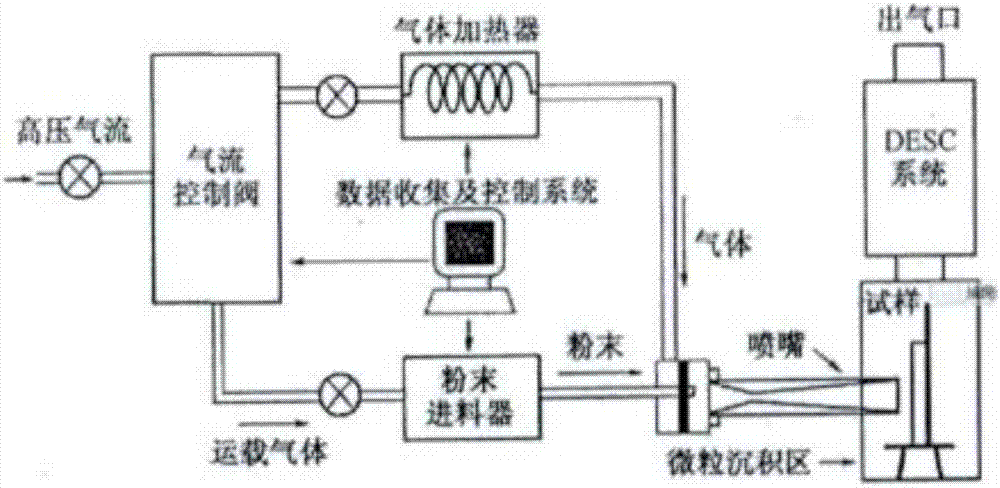

Metal-surface supersonic stress peening method

InactiveCN1438332ALess corrosion resistanceImprove mechanical propertiesRoom temperatureMetallic materials

The invention refers to the intensifying technology of metal surface, especially is metal surface supersonic velocity blasting shot intensifying method, the character is that it uses compressed air to carry metal or nonmetal pills, accelerates the pills to speed of 300-1100 m / s, and the pills strikes the metal surface continuously, forms a remnants tress layer on the surface of the metal, the craft parameters is: the ejecting distance 55-100mm, the pressure of air 2.2-3.0 MPa, the air temperature is room temperature, the flux of air 26-30 g / s, the pills sending voltage 20-30 V, the diameter of pill 50-200 micron.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

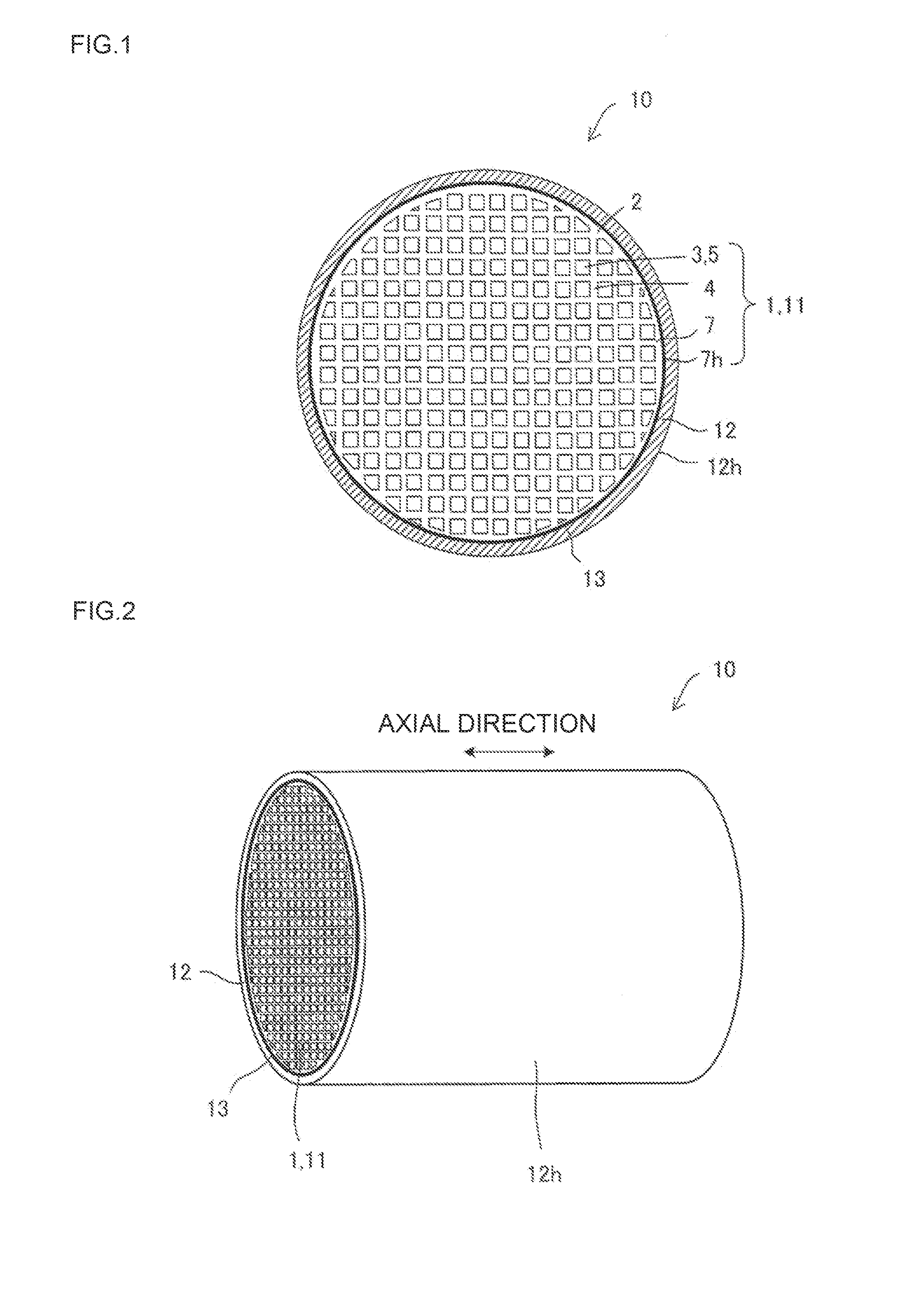

Heat conduction member

ActiveUS20130248159A1Improve thermal conductivityEfficient dischargePhysical/chemical process catalystsInternal combustion piston enginesMetallurgyYoung's modulus

A heat conduction member includes: a cylindrical ceramic body, a metal pipe on the outer periphery side of the cylindrical ceramic body, and an intermediate member held between the cylindrical ceramic body and the metal pipe. The cylindrical ceramic body has passages passing through from one end face to the other end face and allowing the first fluid to flow therethrough. The intermediate member is made of material having at least a part having a Young's modulus of 150 Gpa or less. The first fluid is allowed to flow through the inside of the cylindrical ceramic body while the second fluid having lower temperature than that of the first fluid is allowed to flow on the outer peripheral face side of the metal pipe to perform heat exchange between the first fluid and the second fluid.

Owner:NGK INSULATORS LTD

Production processing method for edge-digging scissors made of Cr12Mo1V1

The invention discloses a production processing method for edge-digging scissors made of Cr12Mo1V1. The production processing method comprises a first step of performing isothermal spheroidizing on a forged piece; a second step of performing rough milling, flaw detection and ingredient detection; a third step of performing destressing tempering, and performing finish milling to dimensions prior to quenching; a fourth step of performing quenching and tempering (enabling workpiece hardness to be HRC 58-62); a fifth step of performing coarse grinding, destressing tempering and semi-precision grinding; a sixth step of utilizing a low-speed wire to perform linear cutting on the arc cutting edge face, and performing precision grinding to obtain a finished product; and a seventh step of performing checking and oil coating, and placing the product in a warehouse. According to the method, cracking of an arc cutting edge during linear cutting can be avoided, and accordingly the edge-digging scissors production pass rate is guaranteed.

Owner:TAIER HEAVY IND

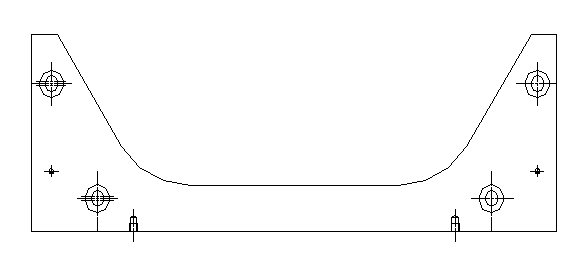

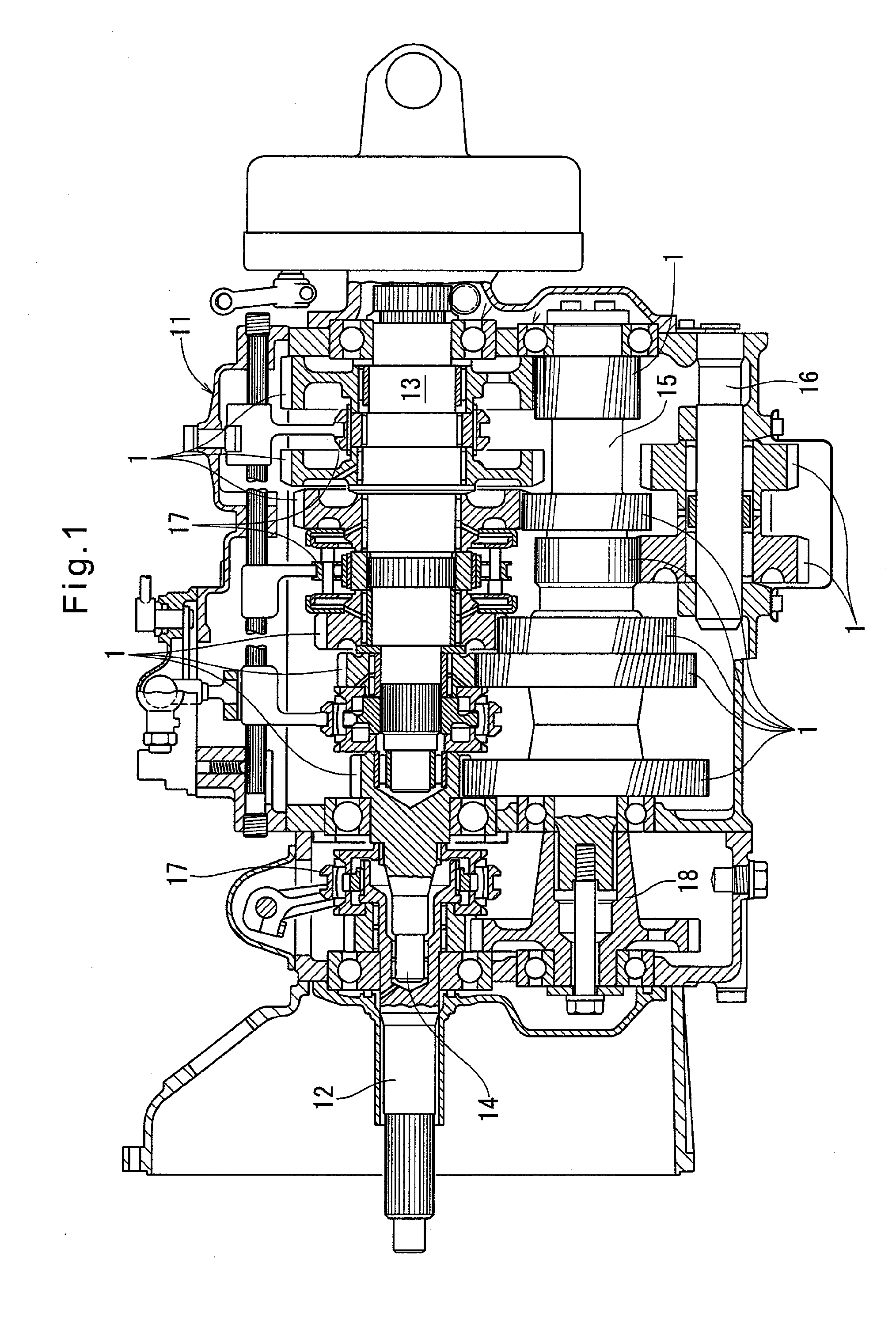

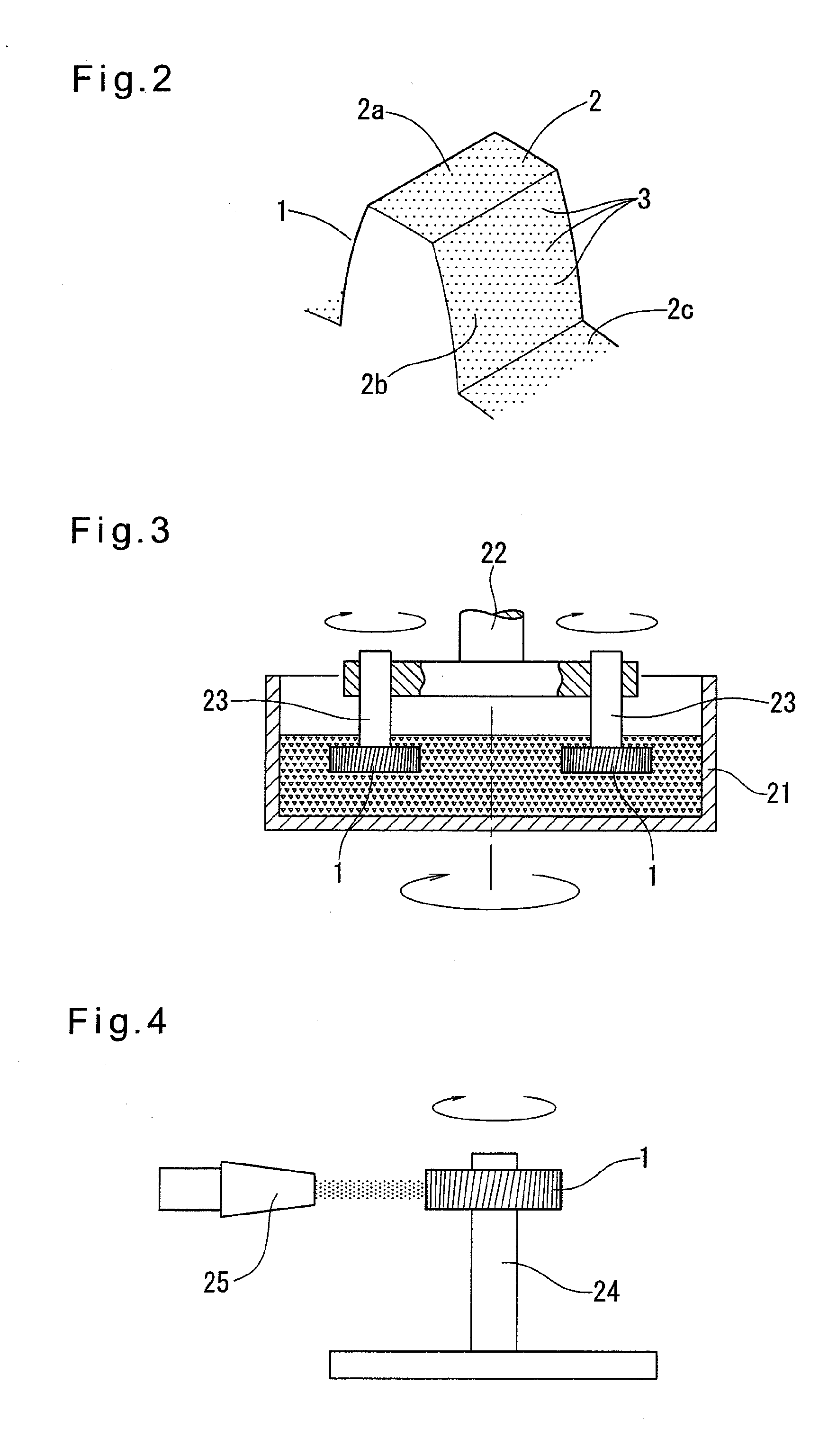

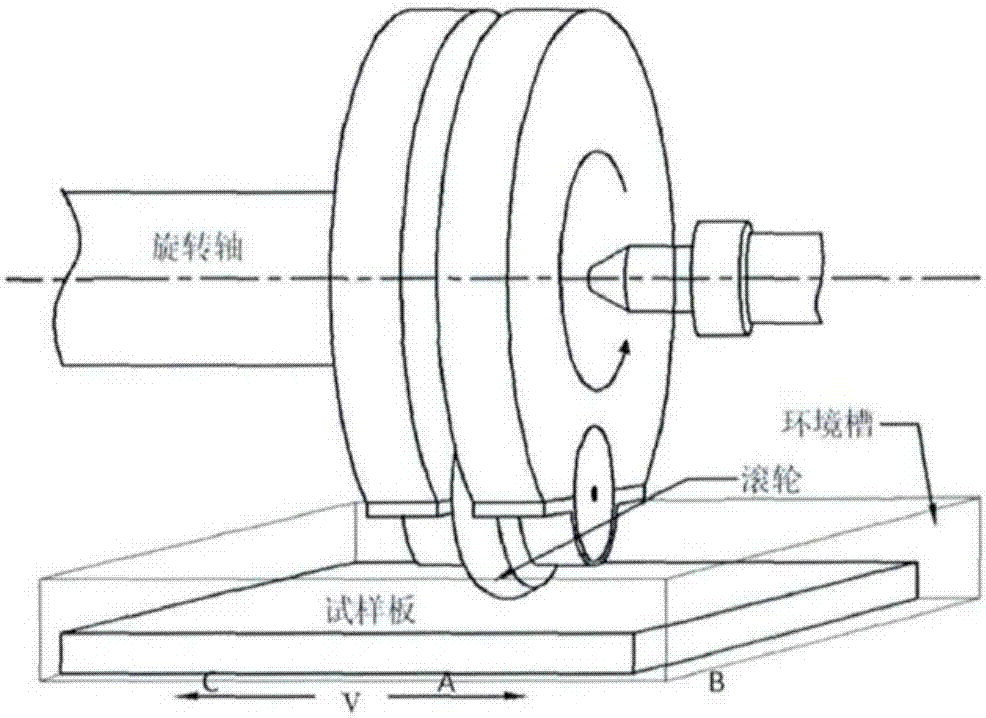

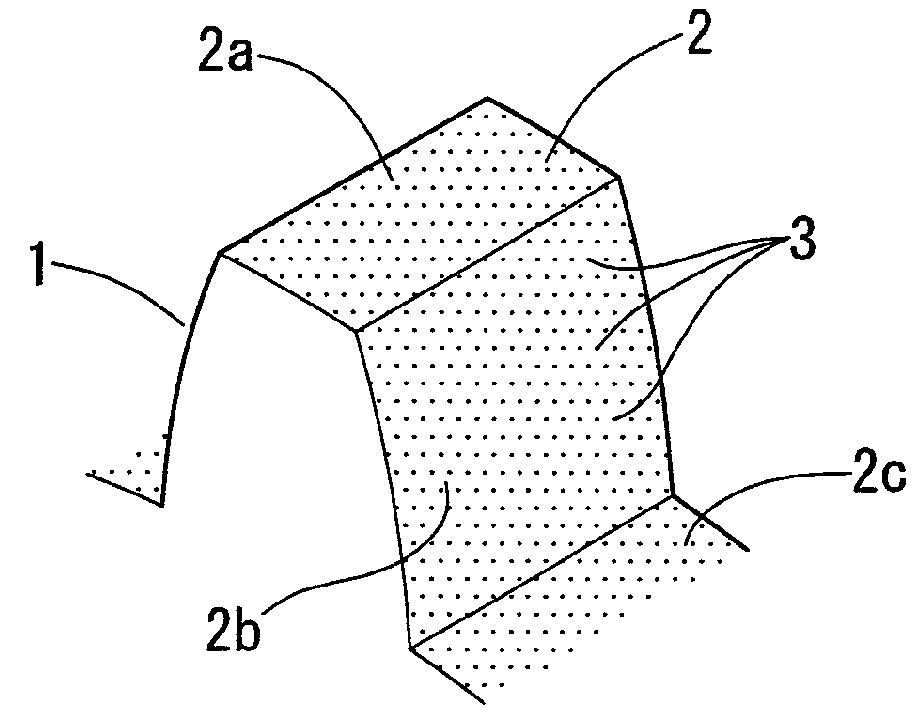

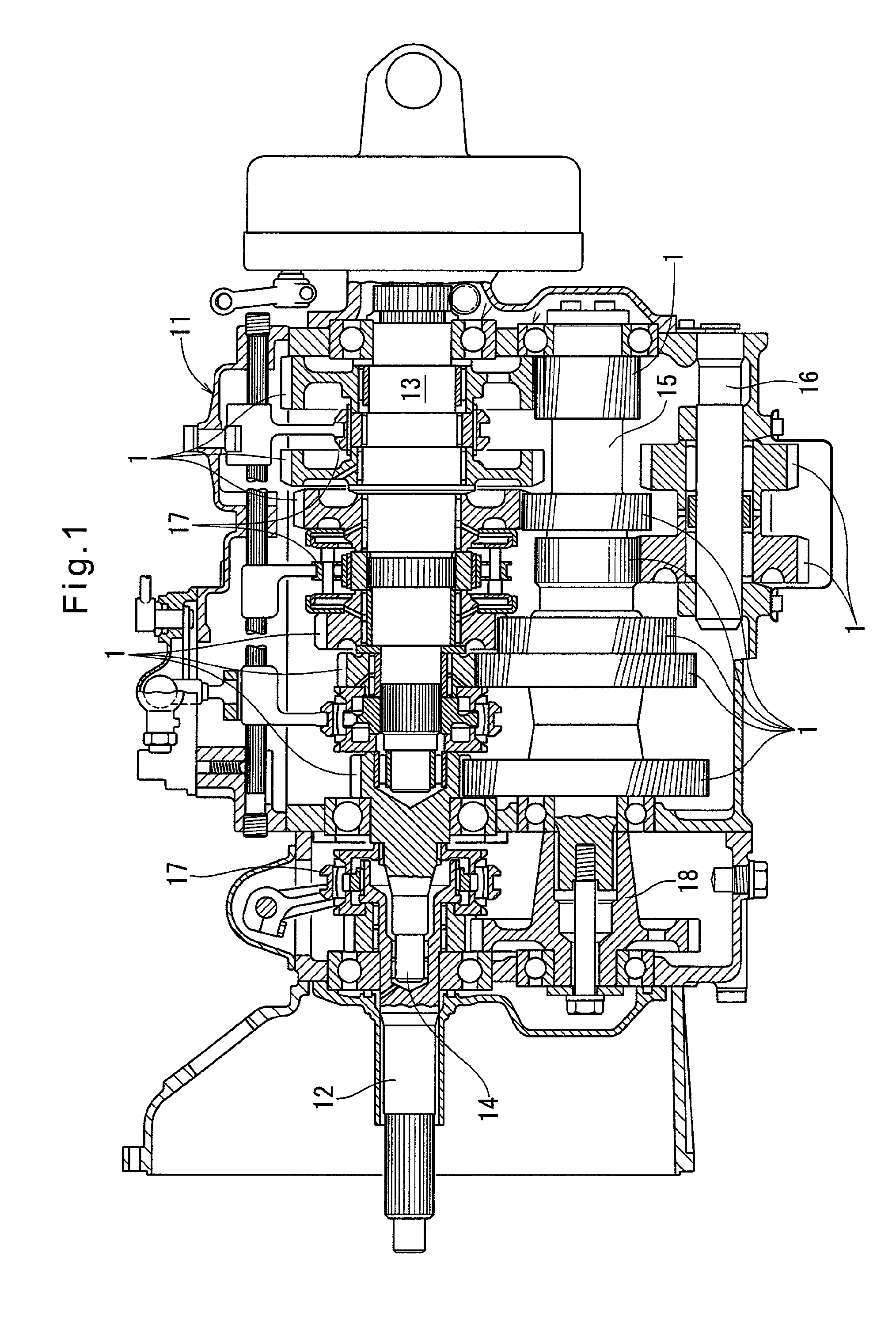

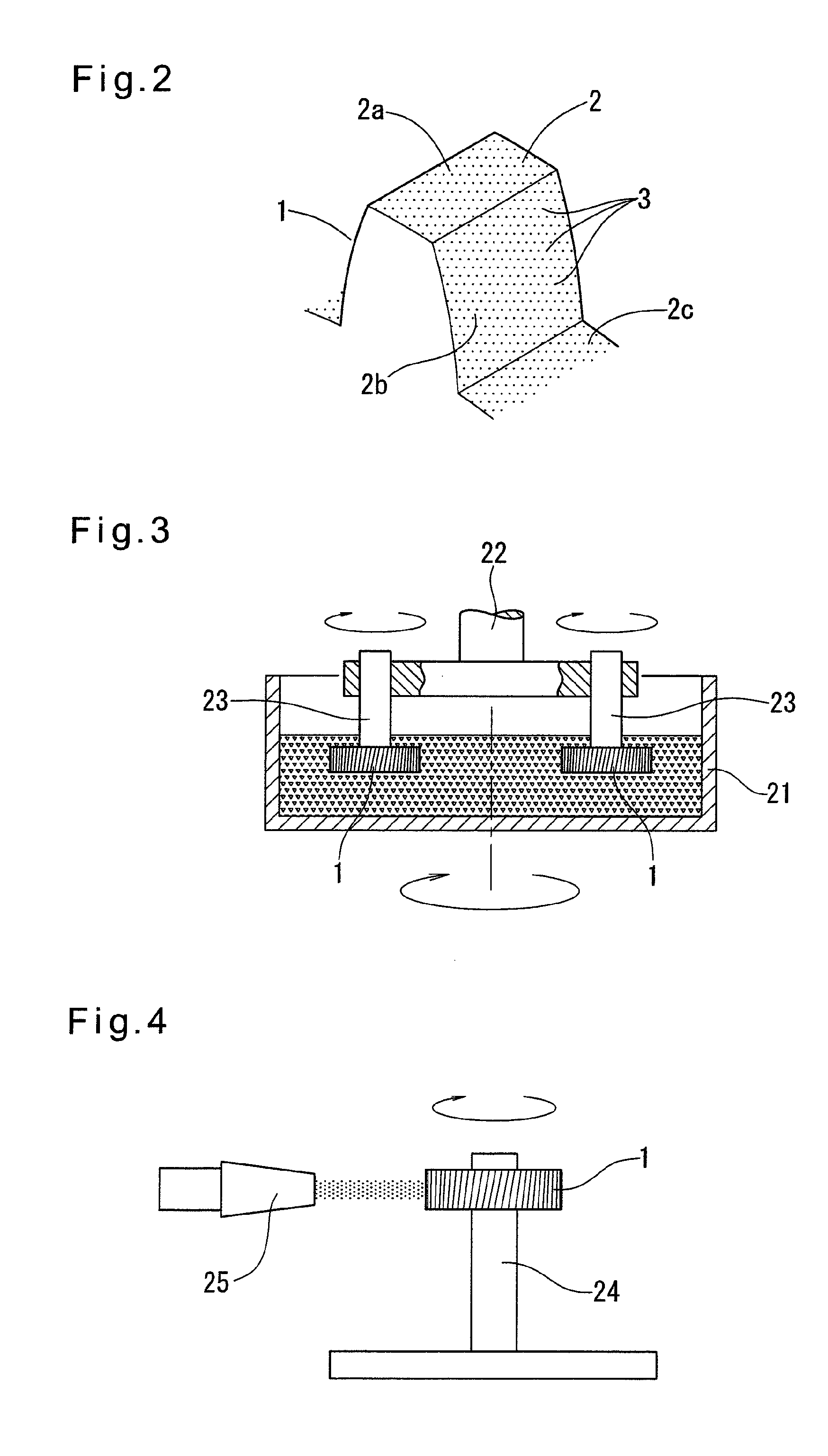

Gear

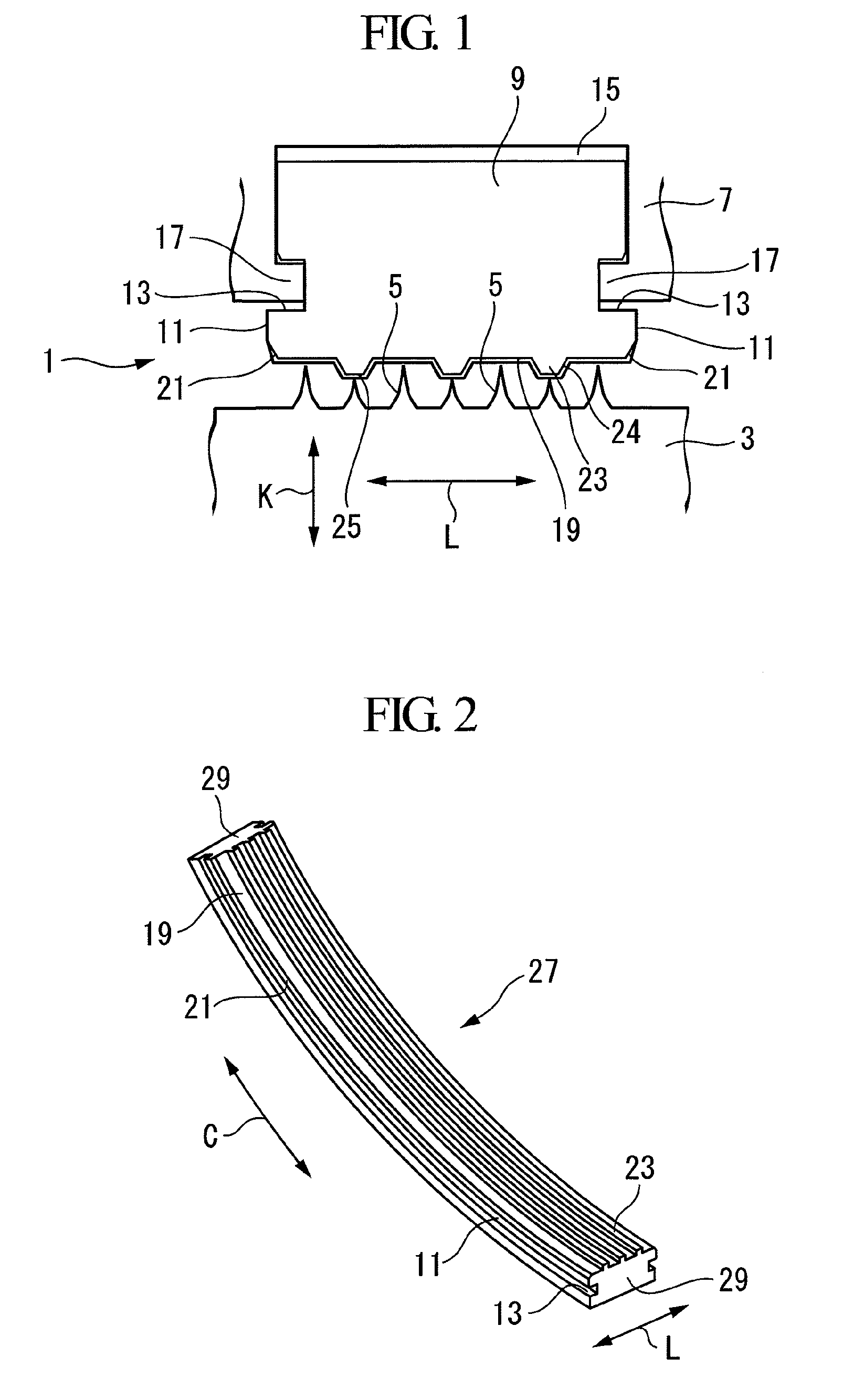

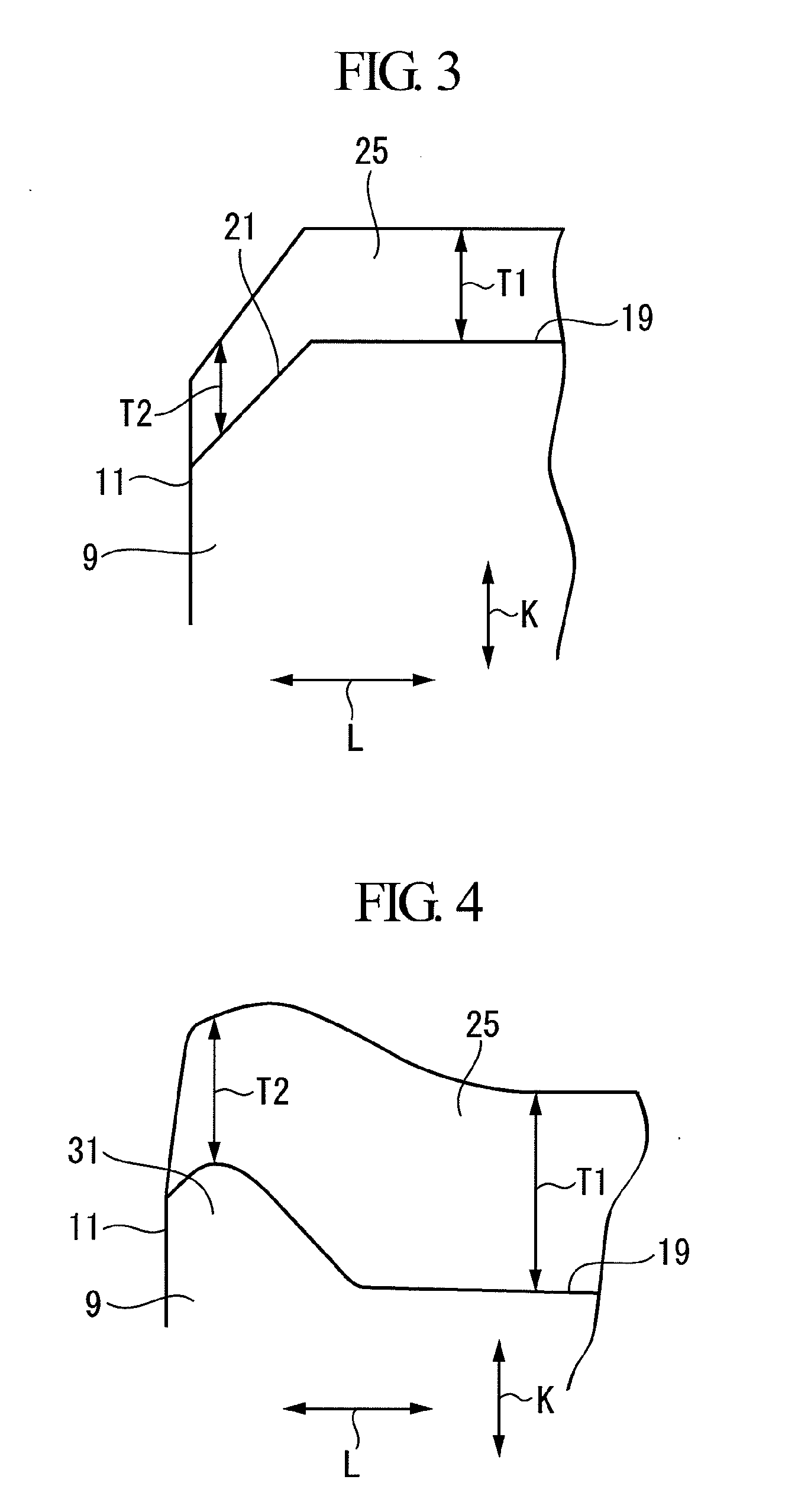

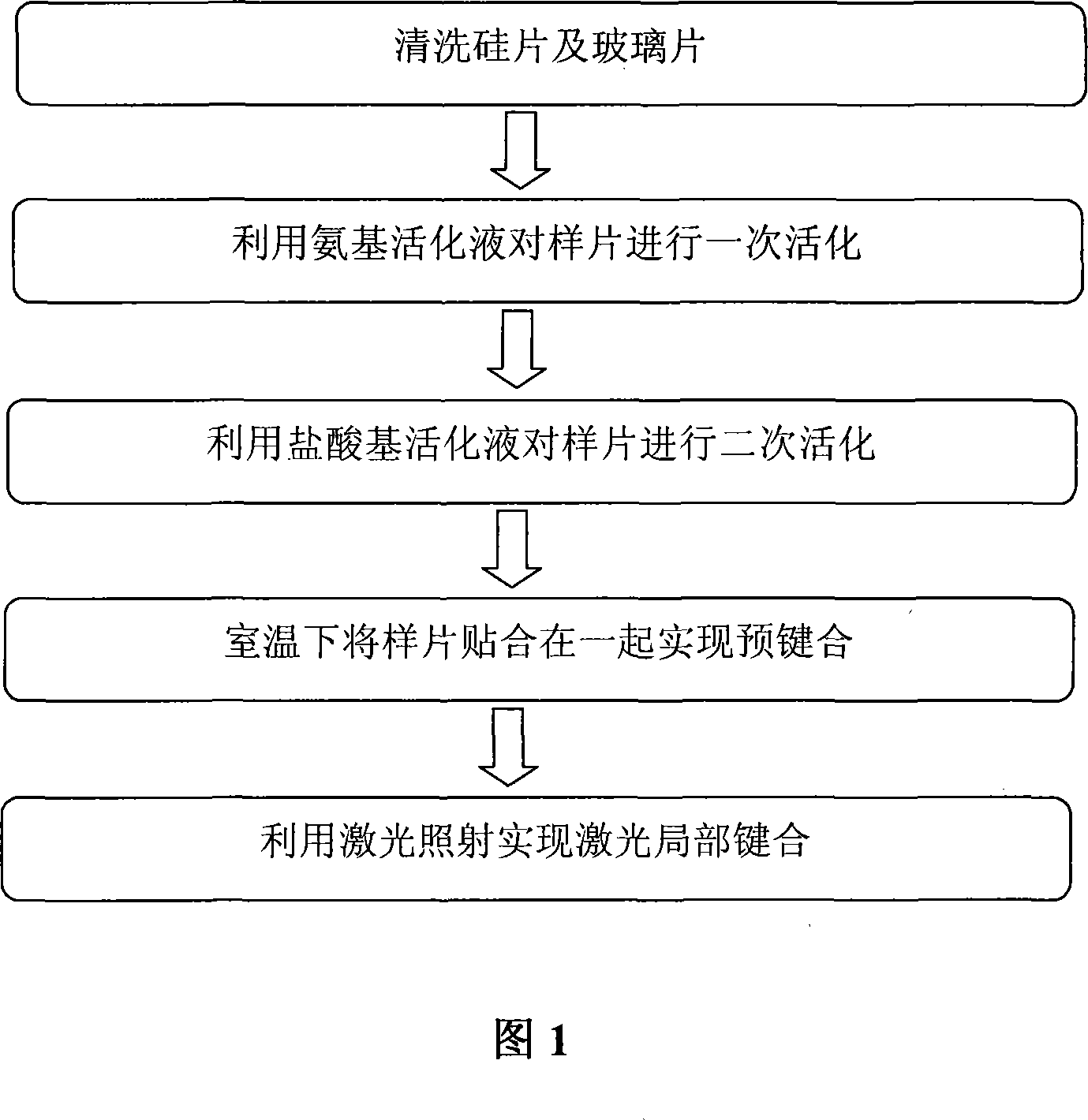

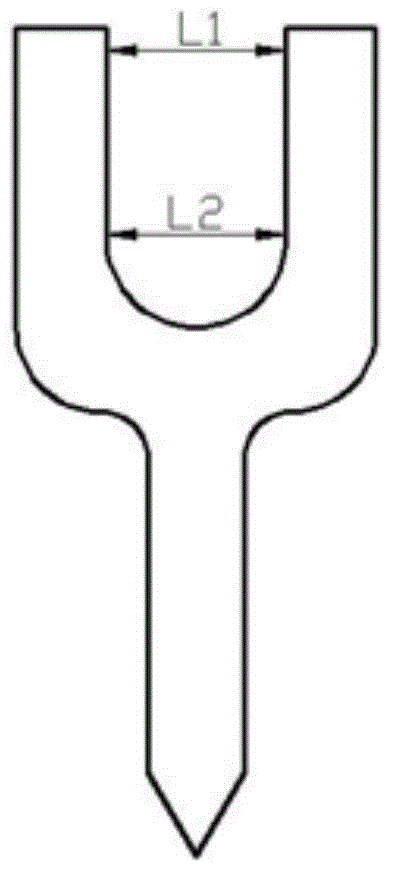

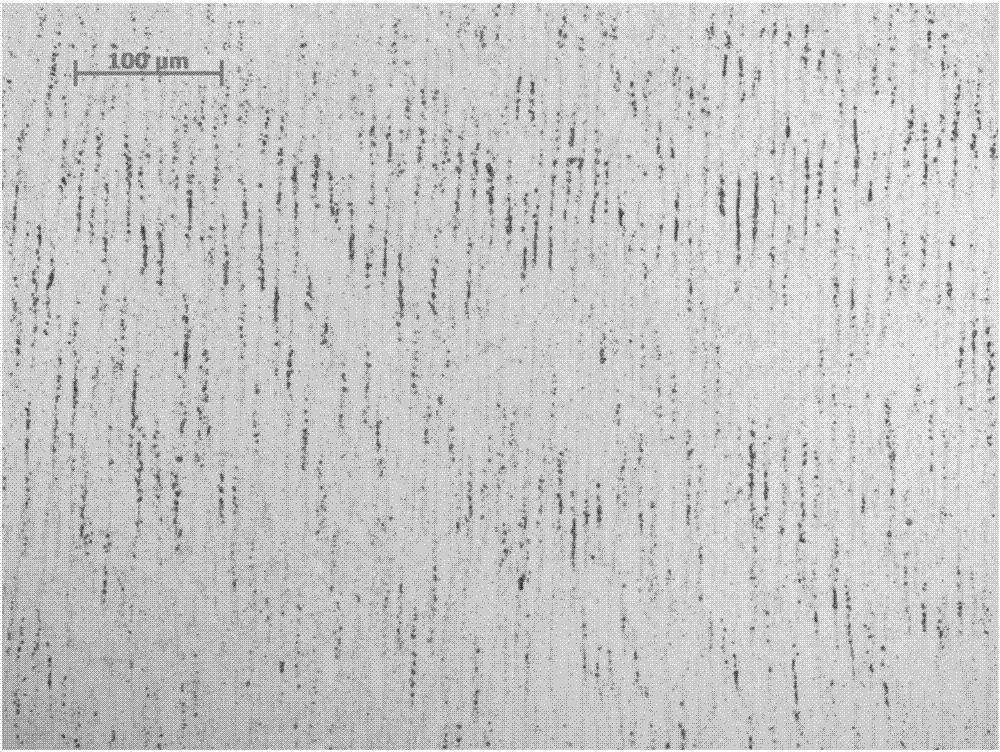

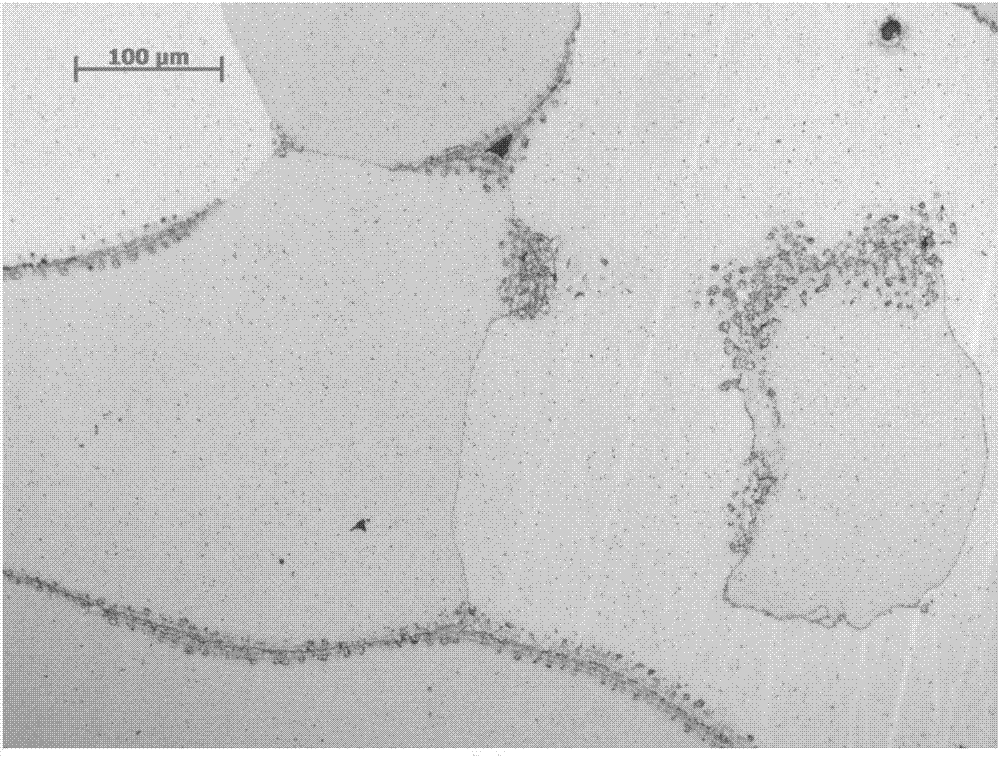

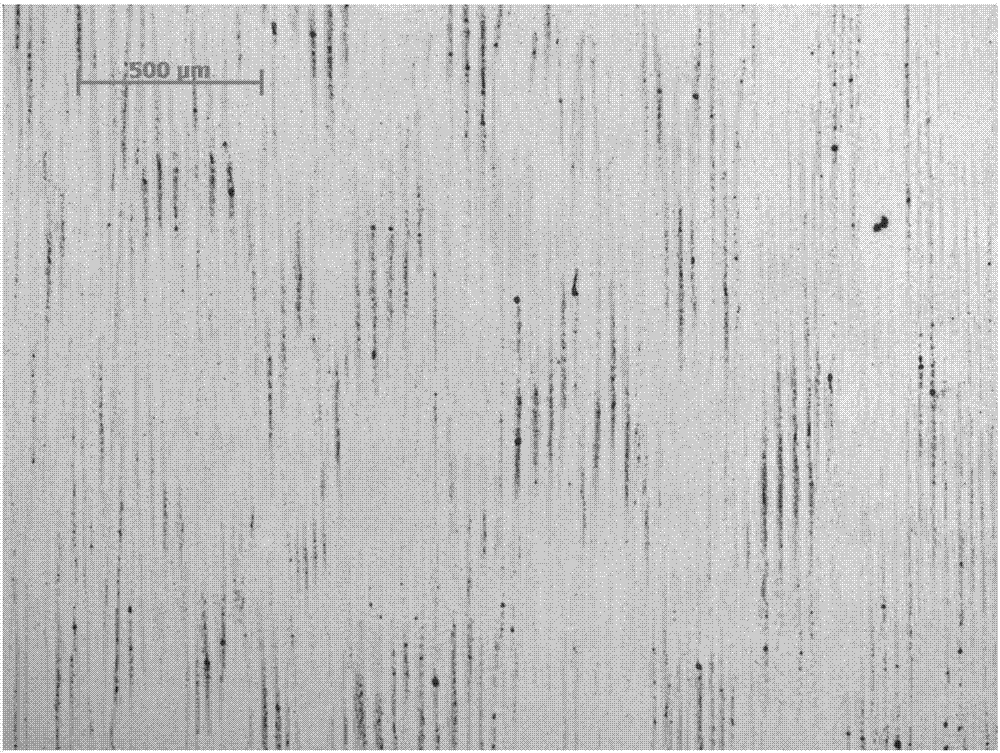

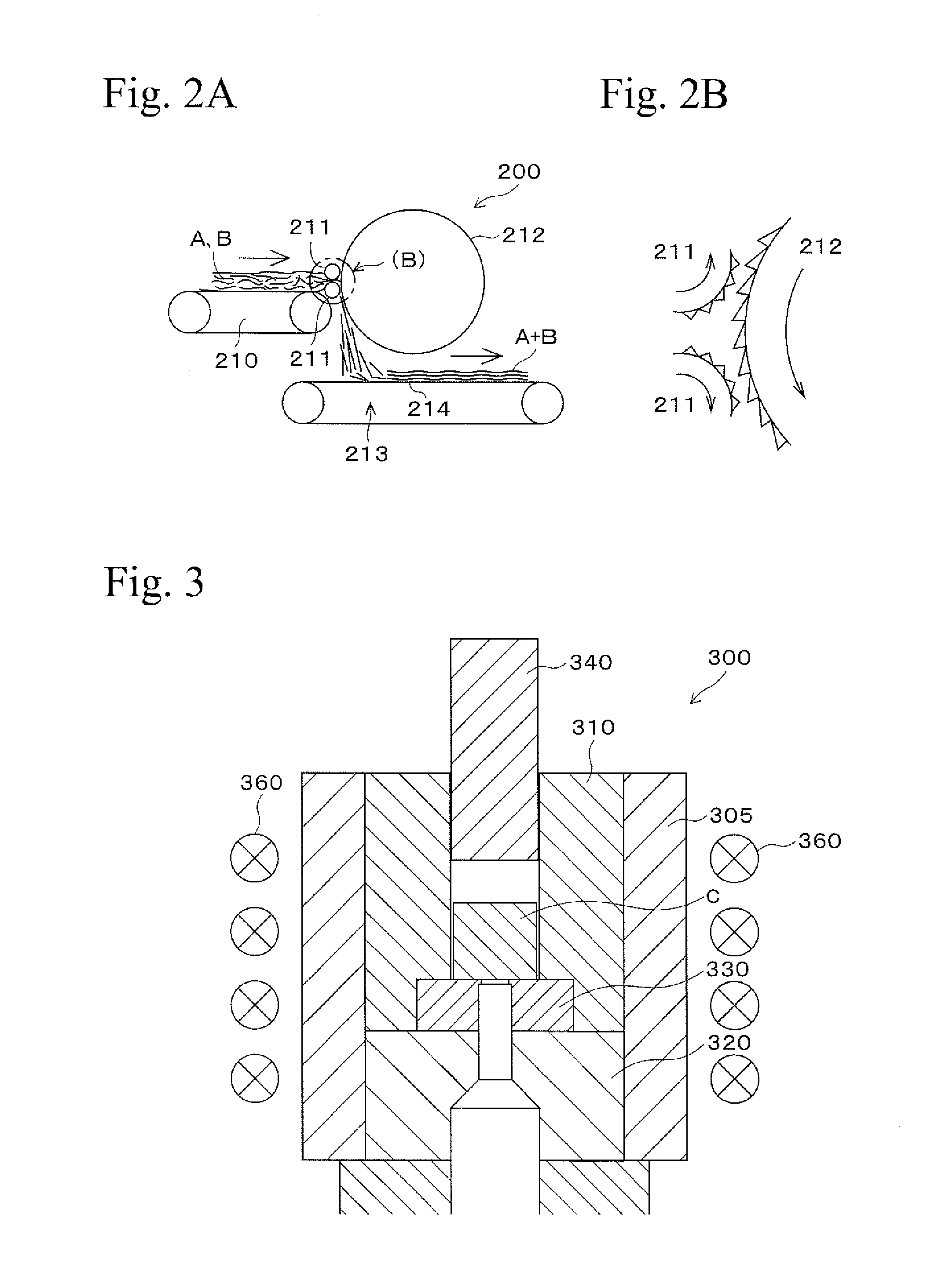

ActiveUS20100300229A1Reduce the number of stepsLarge residual stressPolishing machinesPortable liftingGear wheelEngineering

The invention aims to improve not only the resistance to abrasion and scoring, but also the fatigue strength against pitting and chipping, without increasing the number of steps of the manufacturing process.The tooth face 2 of the gear is smoothed by gyro polishing. In the thus smoothed tooth face 2, a multitude of microscopic recesses 3 are randomly formed by liquid honing in which microscopic hard particles are collided with the tooth surface together with liquid. By the liquid honing, a large compressive residual stress is produced on the tooth face 2. This improves not only the resistance to abrasion and scoring, but also the fatigue strength against pitting and chipping, without increasing the number of steps of the manufacturing process.

Owner:NTN CORP

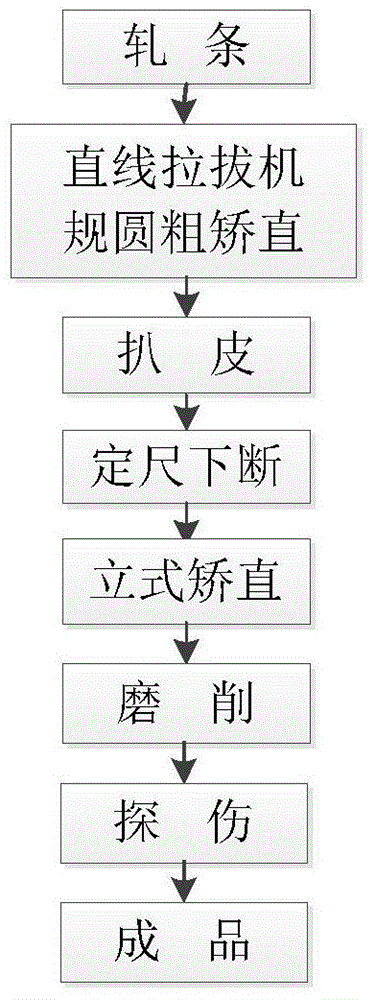

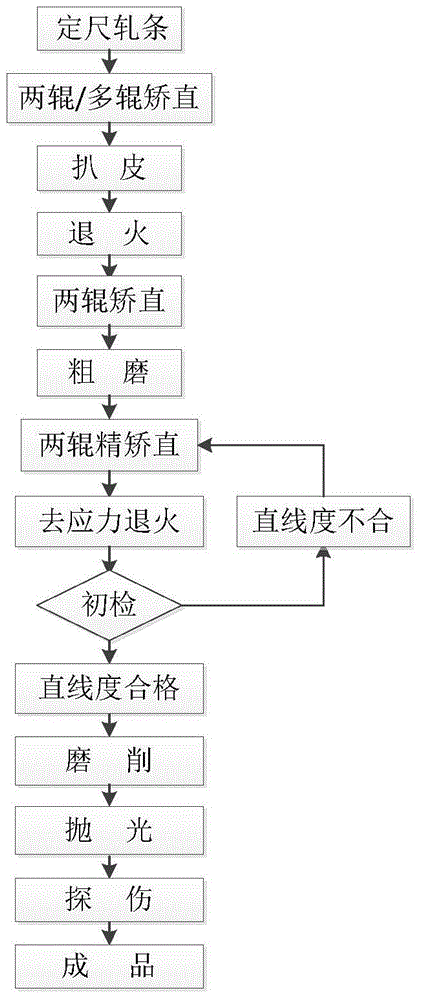

Preparation method of titanium alloy bar for pedicle screw

ActiveCN104056872AEasy to prepareSuitable for mass production and processingCenterless grindingElectric heating

The invention discloses a preparation method of a titanium alloy bar for a pedicle screw. The preparation method comprises the following steps: firstly, performing rounding coarse straightening treatment on original rolled bar blanks by adopting a straight drawbench, then removing surface defects by using a flaying machine, simultaneously performing sizing determining operation at a discharge hole, straightening in a vertical electrothermal straightening mode, and finally, performing centerless grinding treatment to obtain a finished bar. According to the preparation method of the titanium alloy bar for the pedicle screw, the rounding coarse straightening treatment is performed on the rolled bar blanks by adopting the straight drawbench, and a traditional two-roll or multi-roll straightening rounding mode is replaced, so as to prevent residual stress due to coarse straightening; the residual stress generated by traditional two-roll or multi-roll fine straightening is removed by utilizing the vertical straightening mode, and the problem of necking caused by unbalanced stress of a U-shaped groove of the pedicle screw due to excessive inner stress of the titanium alloy bar prepared in the prior art is solved; the preparation method has the advantage of simplicity and is suitable for mass production and machining.

Owner:西安赛特思迈钛业有限公司

Method for eliminating re-crystallization tendency of laser 3D printed single-crystal high-temperature alloy

ActiveCN107119325ALarge residual stressSolve crackingPolycrystalline material growthAdditive manufacturing apparatusSingle crystal superalloySingle crystal

The invention discloses a method for eliminating re-crystallization tendency of a laser 3D printed single-crystal high-temperature alloy, belonging to the field of manufacturing of laser additives and preparation of the single-crystal high-temperature alloy. By utilizing laser 3D printing as a production technology, the epitaxial growth of the laser-formed dendritic structure on a single-crystal high-temperature alloy base material can be realized through controlling technological parameters. In addition, the temperature field of the printing process is controlled so that the residual stress of the 3D printed single-crystal high-temperature alloy parts is at a lower level, and the re-crystallization tendency of the laser 3D printed single-crystal high-temperature alloy is thoroughly eliminated. The method can be used for preparing large-size single-crystal high-temperature alloy without re-crystallization tendency, and single-crystal high-temperature alloy blades can be prepared by using laser 3D printing on the basis.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Seal structure

ActiveUS8240675B2Great advantageLarge residual stressEngine sealsMolten spray coatingEngineeringMechanical engineering

Owner:MITSUBISHI POWER LTD

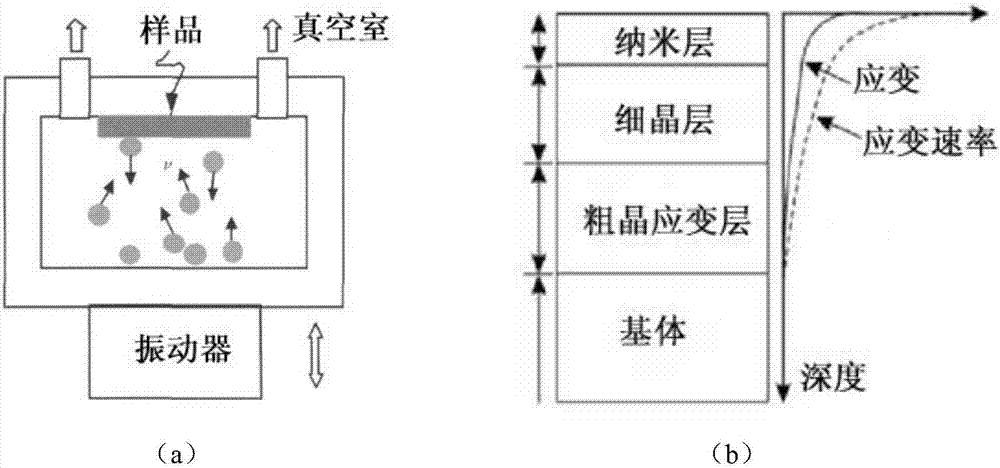

Metal material surface strengthening method based on mixed surface nanocrystallization technology

InactiveCN106929777AImprove the problem of large surface roughnessEase of industrial applicationMicrometerMetallic materials

The invention provides a metal material surface strengthening method based on the mixed surface nanocrystallization technology. The method comprises the steps that the surface of a metal material sample is ground and polished; supersonic speed microparticle bombardment surface nanocrystallization treatment is carried out, a nanometer layer with the thickness not smaller than 50 micrometers is formed on the surface of the base material to be welded, the average size of surface nanometer crystals is not larger than 50 nm, the surface roughness is larger than 3 micrometers, and the surface microhardness is larger than 250 HV; and the surface of the metal material sample is subjected to surface mechanical rolling. By means of the method, the surface roughness of the surface-nanocrystallized metal material can be greatly improved.

Owner:ROCKET FORCE UNIV OF ENG

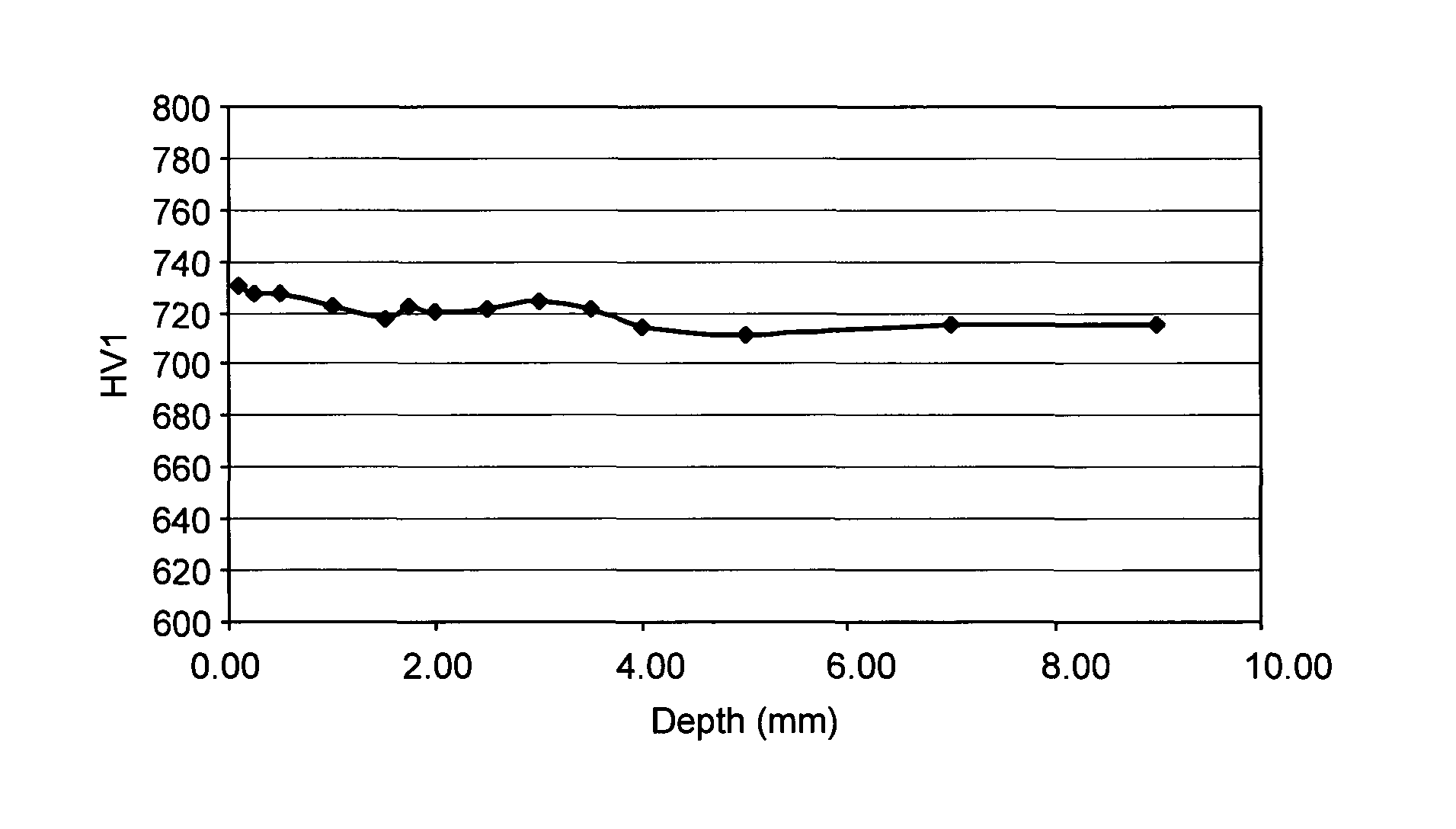

Titanium alloy member and production method therefor

InactiveUS20140212319A1High strengthImprove fatigue resistanceTransportation and packagingMetal-working apparatusSurface layerSintered titanium

A high strength titanium alloy member with superior fatigue resistance, and a production method therefor, are provided. The production method includes preparing a raw material made of titanium alloy, nitriding the raw material to form a nitrogen-containing raw material by generating a nitrogen compound layer and / or a nitrogen solid solution layer in a surface layer of the raw material, mixing the raw material and the nitrogen-containing raw material to yield a nitrogen-containing mixed material, sintering the nitrogen-containing mixed material to obtain a sintered titanium alloy member by bonding the material together and uniformly diffusing nitrogen in solid solution from the nitrogen-containing raw material to the entire interior portion of the sintered titanium alloy member, hot plastic forming and / or heat treating the sintered titanium alloy member to obtain a processed member, and surface treating the processed member to provide compressive residual stress.

Owner:NHK SPRING CO LTD

Manufacturing method of surface nanometer gradient layer of metal material

InactiveCN107419077AImprove the problem of large surface roughnessEase of industrial applicationMicrometerMetallic materials

The invention provides a method for preparing a nano-gradient layer on the surface of a metal material. The surface of a metal material sample is ground and polished; 50μm nano-layer, the average size of the surface nano-grains is not greater than 50nm, the surface roughness is greater than 3μm, and the surface microhardness is greater than 250HV; then the surface of the metal material sample is mechanically rolled; The surface of the sample is treated to finally reduce the surface roughness of the material to 0.01-0.2 μm, and the surface microhardness is greater than 300HV. The invention can greatly improve the surface roughness of the metal material after surface nanometerization.

Owner:XIAN UNIV OF TECH

Heat treatment method of large heat-resistant high alloy steel castings

The invention relates to a heat treatment method of large heat-resistant high alloy steel castings in the technical field of steel casting heat treatment. The heat treatment method of the large heat-resistant high alloy steel castings includes the process of high-temperature diffusion annealing, gating and risering system cutting, normalizing air cooling, primary tempering and secondary tempering,and it is set that carbon arc air gouging dressing is performed on the surfaces of the castings between the primary tempering and the secondary tempering. The method solves the problem that the largeheat-resistant high alloy steel castings with a ZG12Cr9Mo1CoNiVNbNB material are prone to cracking in the heat treatment process, and makes various normal temperature and high temperature mechanicalproperties of the steel castings meet the using requirement.

Owner:RUGAO OUTONG MACHINERY FITTINGS

Glass-fiber-reinforced thermoplastic resin molding product, and production method therefor

A glass-fiber-reinforced thermoplastic resin molding product is provided, which includes a thermoplastic resin, a fibrous filler dispersed in the thermoplastic resin, and at least one of a dye and a pigment having an average particle diameter of at most 30 nm, the fibrous filler including:(A) 40 to 80% of glass fibers each having a length of not less than 0.05 mm and less than 0.5 mm;(B) 15 to 40% of glass fibers each having a length of not less than 0.5 mm and less than 1.0 mm;(C) 2 to 30% of glass fibers each having a length of not less than 1.0 mm and less than 3.0 mm; and(D) at most 1% of glass fibers each having a length of not less than 3.0 mm.

Owner:SUMITOMO RIKO CO LTD

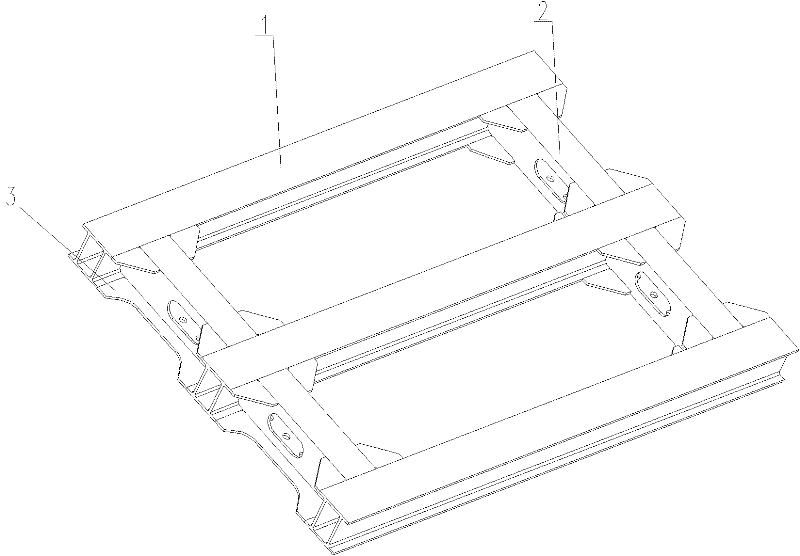

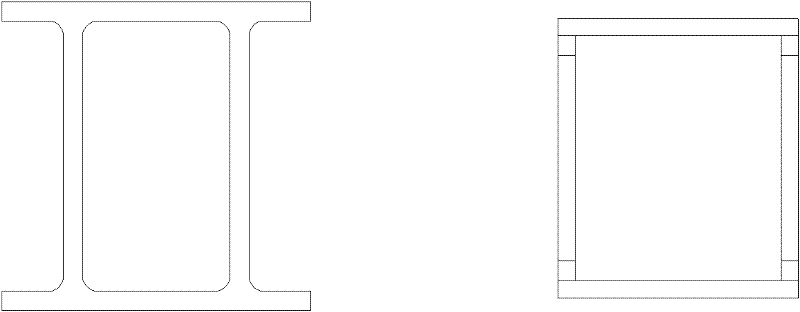

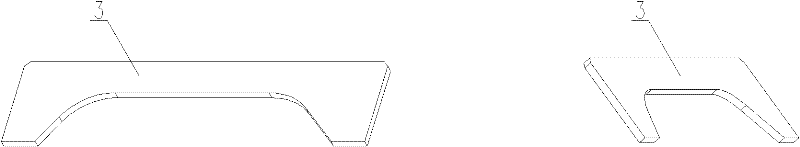

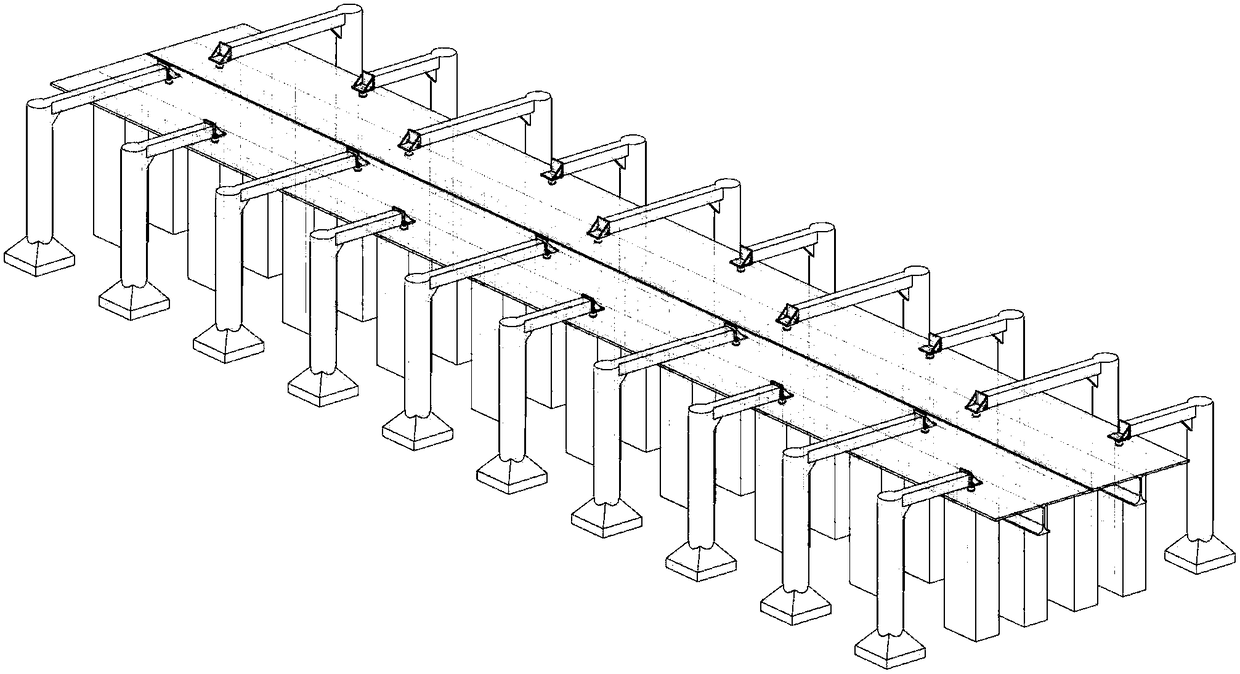

Railway vehicle tractive transformer hanging beam

InactiveCN102543363AReduce stress levelsImprove fatigue lifeTransformers/reacts mounting/support/suspensionCross connectionEngineering

The invention relates to a railway vehicle tractive transformer hanging beam, which is of a frame type hanging structure. By means of welding connection between the structure of three transverse beams and the structure of four longitudinal beams, entire rigidity and mechanical strength of the hanging beam are improved, and using requirements of European standards for bearing load on abnormal working conditions are met. The hanging beam comprises a plurality of transverse beams and longitudinal beams in cross connection. The plurality of transverse beams keep parallel to each other, the plurality of longitudinal beams keep parallel to each other, and connection ends between the transverse beams and the longitudinal beams are welded. The transverse beams and the longitudinal beams are defined according to the directions in which the beams and a vehicle body form during installation, either transverse or longitudinal. A stiffening plate is connected between every two adjacent transverse beams. The transverse beams and the longitudinal beams adopt the welding connection mode, the stiffening plates are used for auxiliary reinforcement, and strength of the entire hanging beam is improved to bear acceleration load specified in EN12663 standards.

Owner:CRRC QINGDAO SIFANG CO LTD

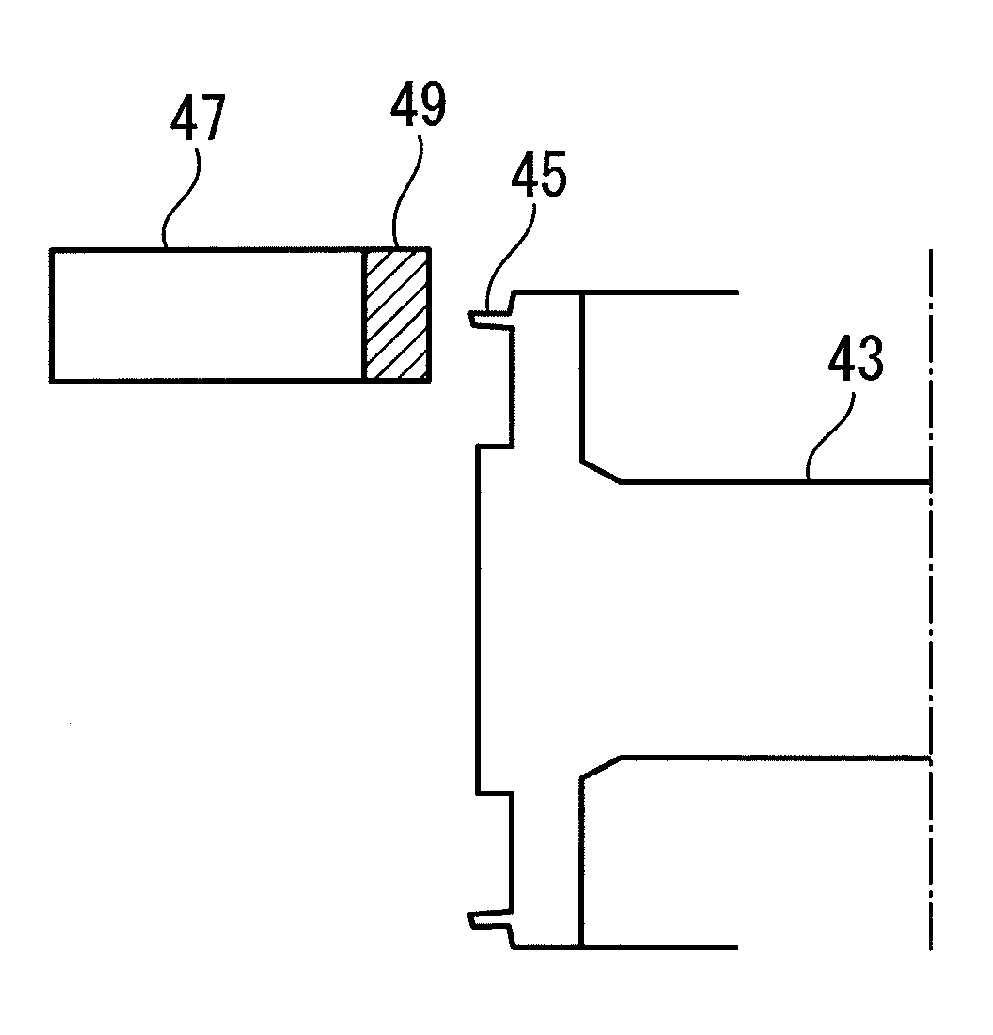

Gear

ActiveUS8100027B2Reduce the number of stepsLarge residual stressPolishing machinesPortable liftingGear wheelEngineering

The invention aims to improve not only the resistance to abrasion and scoring, but also the fatigue strength against pitting and chipping, without increasing the number of steps of the manufacturing process.The tooth face 2 of the gear is smoothed by gyro polishing. In the thus smoothed tooth face 2, a multitude of microscopic recesses 3 are randomly formed by liquid honing in which microscopic hard particles are collided with the tooth surface together with liquid. By the liquid honing, a large compressive residual stress is produced on the tooth face 2. This improves not only the resistance to abrasion and scoring, but also the fatigue strength against pitting and chipping, without increasing the number of steps of the manufacturing process.

Owner:NTN CORP

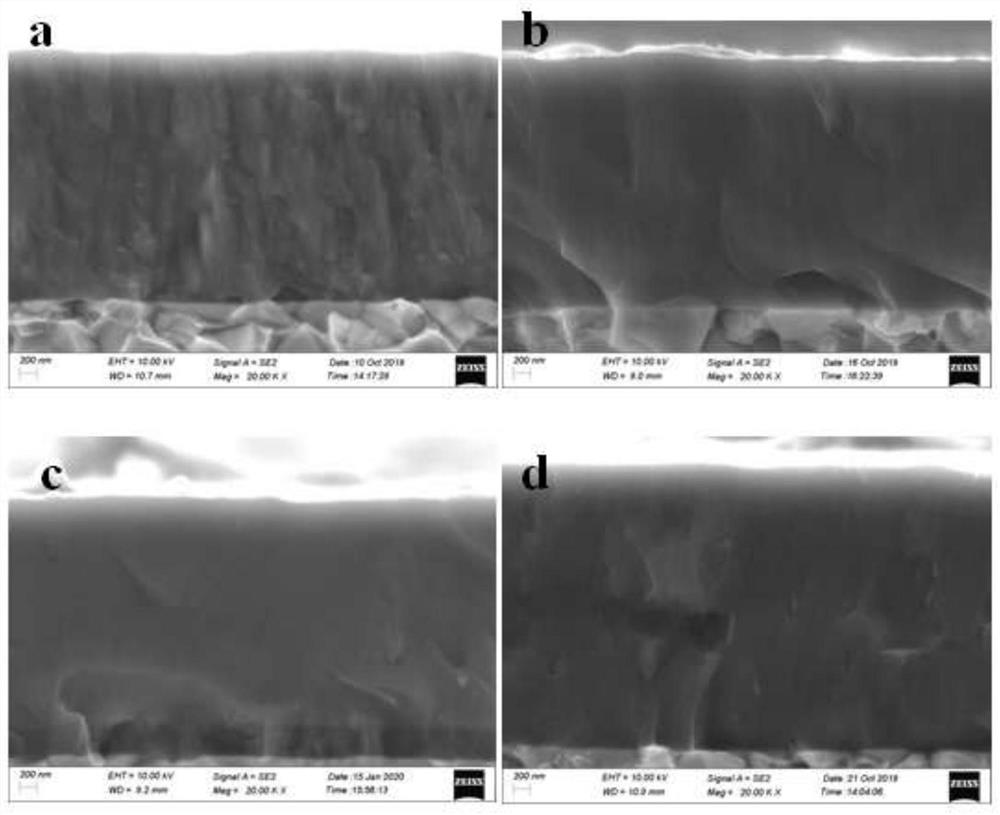

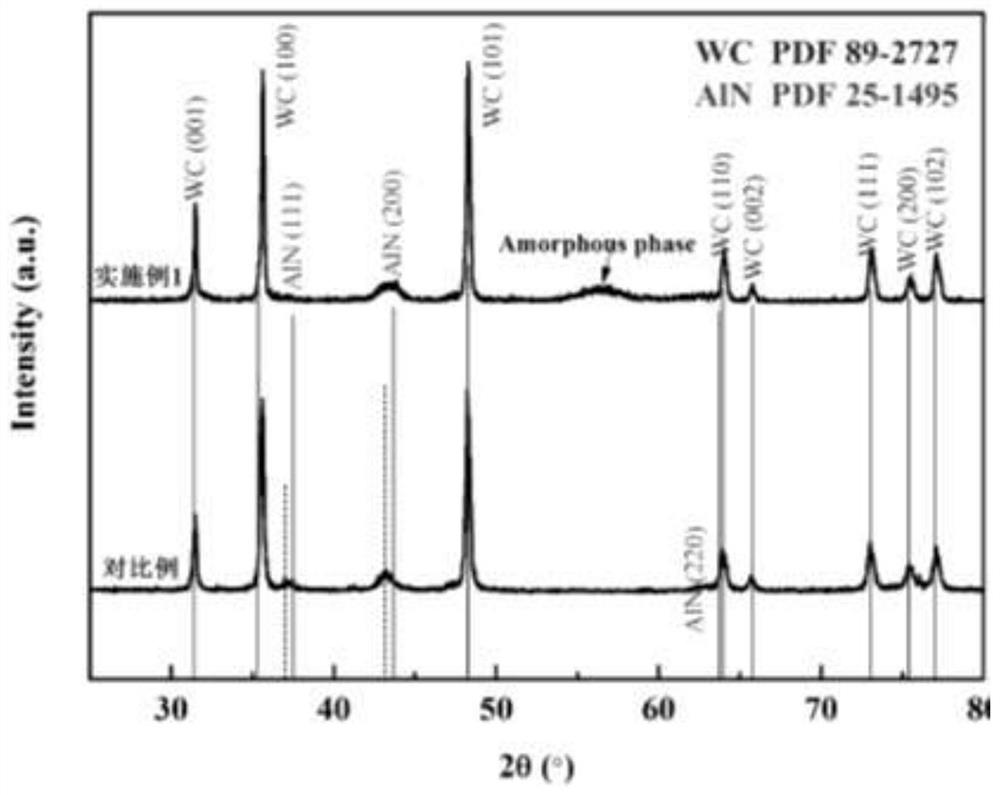

Nanocrystalline amorphous composite coating, preparation method thereof and cutter

ActiveCN111910159ASmall elastic modulus changesLittle changeVacuum evaporation coatingSputtering coatingWear resistanceSi element

The invention provides a TiAl (Nb, Si, C) N-containing nanocrystalline amorphous composite coating, a preparation method thereof and a cutter. The composite coating is a nanocrystalline amorphous TiAl(Nb, Si, C) N coating formed by physical vapor deposition. The TiAlN composite coating with a hardening and wear-resistant Si element, a toughening Nb element and an antifriction C element co-doped in an optimal proportion maintains the characteristics of excellent comprehensive performance and no short plate and good 'wooden barrel effect' of a TiAlN-based coating, meanwhile, the adhesive force,wear resistance and high-temperature stability of the coating can be greatly improved, and the integration of toughness and wear resistance of the coating is realized. The preparation method is simple in process, easy to operate in actual production, low in production cost and suitable for large-scale popularization.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

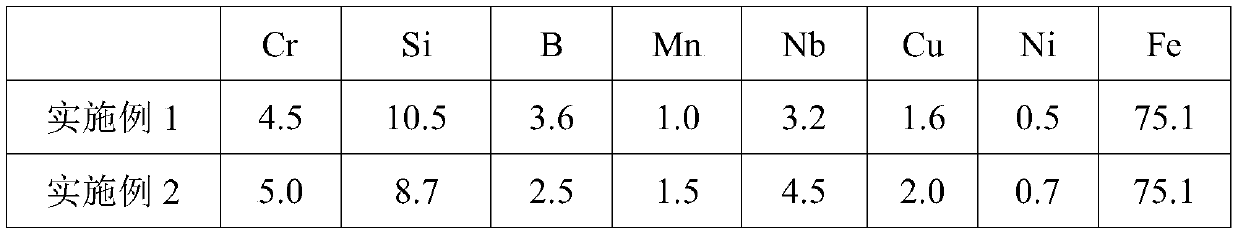

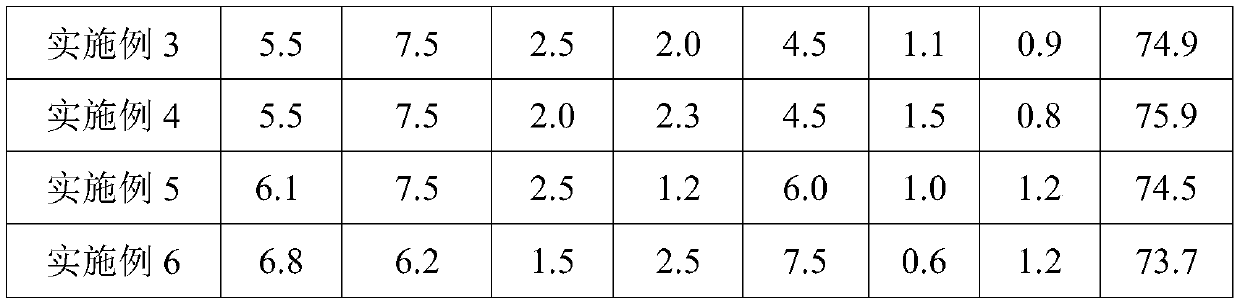

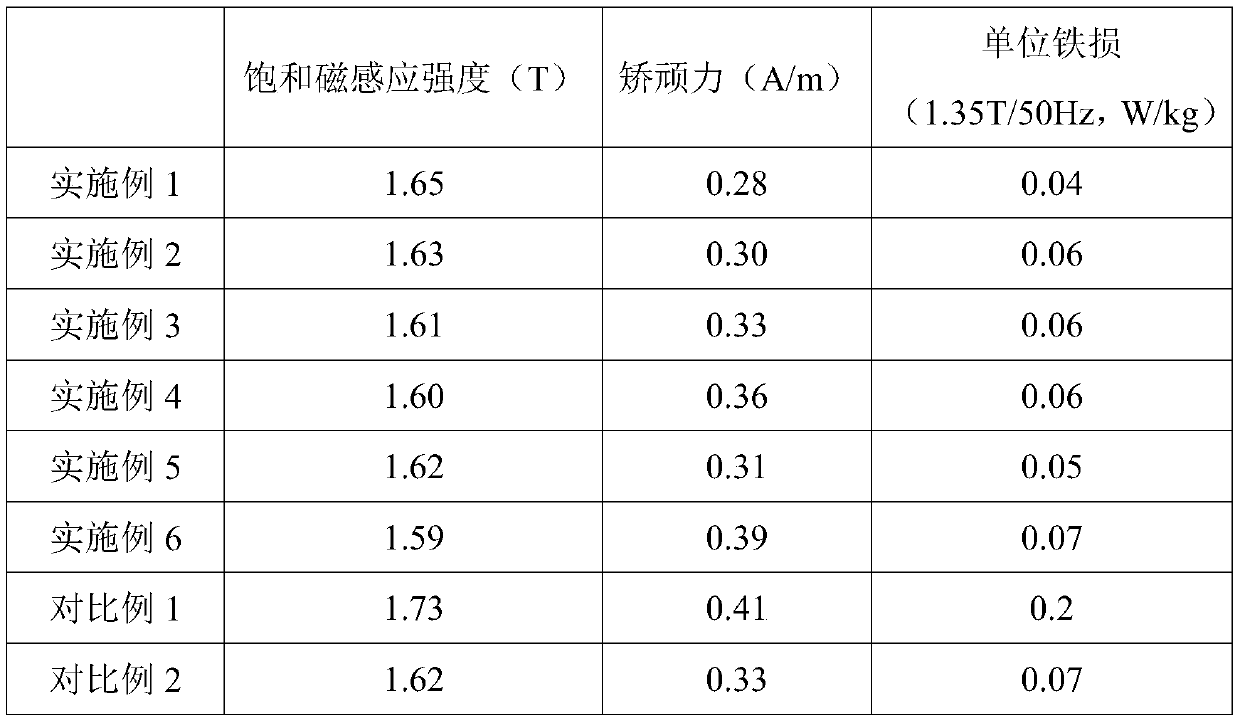

Anti-rust nanocrystal alloy and fabrication method thereof

ActiveCN109754973AOptimized formulaExcellent anti-rustInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationThermal treatment

The invention provides an anti-rust nanocrystal alloy and a fabrication method thereof, and belongs to the technical field of magnetic material preparation. The anti-rust nanocrystal alloy comprises the following element constituents based on percent by mass: 4.5-6.8% of Cr, 6.2-10.5% of Si, 1.5-3.6% of B, 1.0-2.5% of Mn, 3.2-7.5% of Nb, 0.6-2.0% of Cu and 0.5-1.2% of Ni with the balance being Fe.By optimizing alloy element constituents and proportion and improving a thermal treatment mode, the nanocrystal alloy product compatible with excellent anti-rust performance and favorable soft magnetic performance is obtained.

Owner:安徽智磁新材料科技有限公司

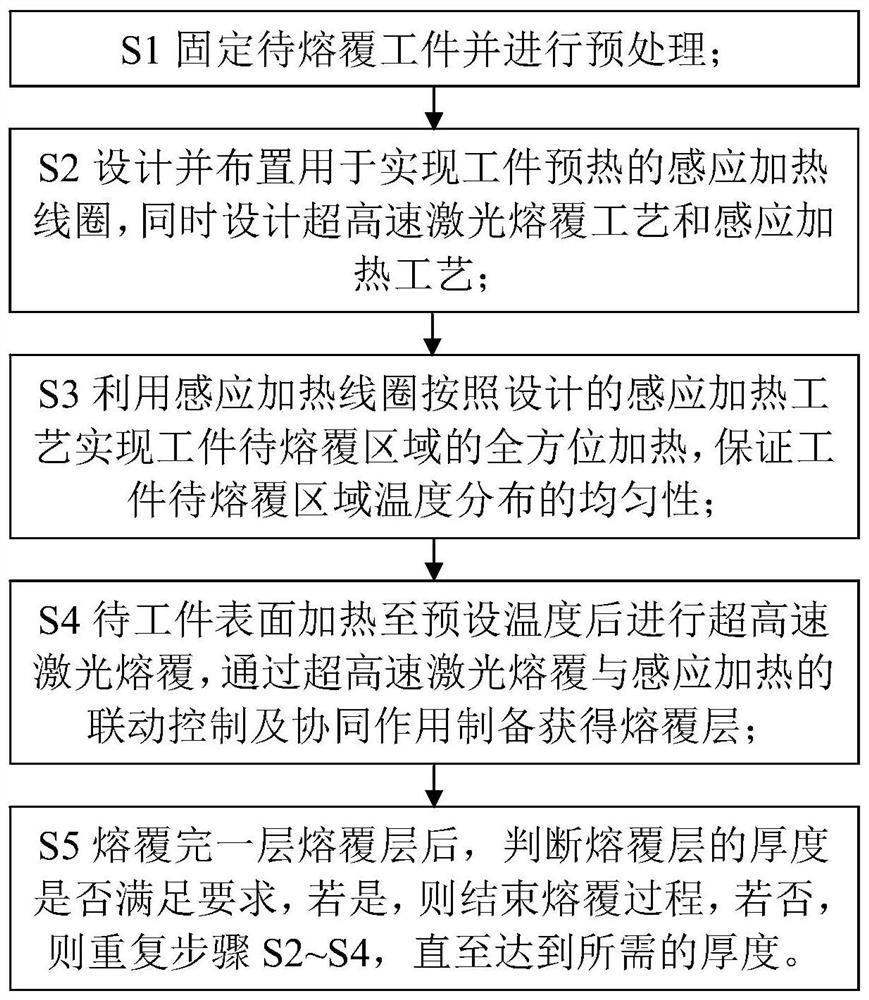

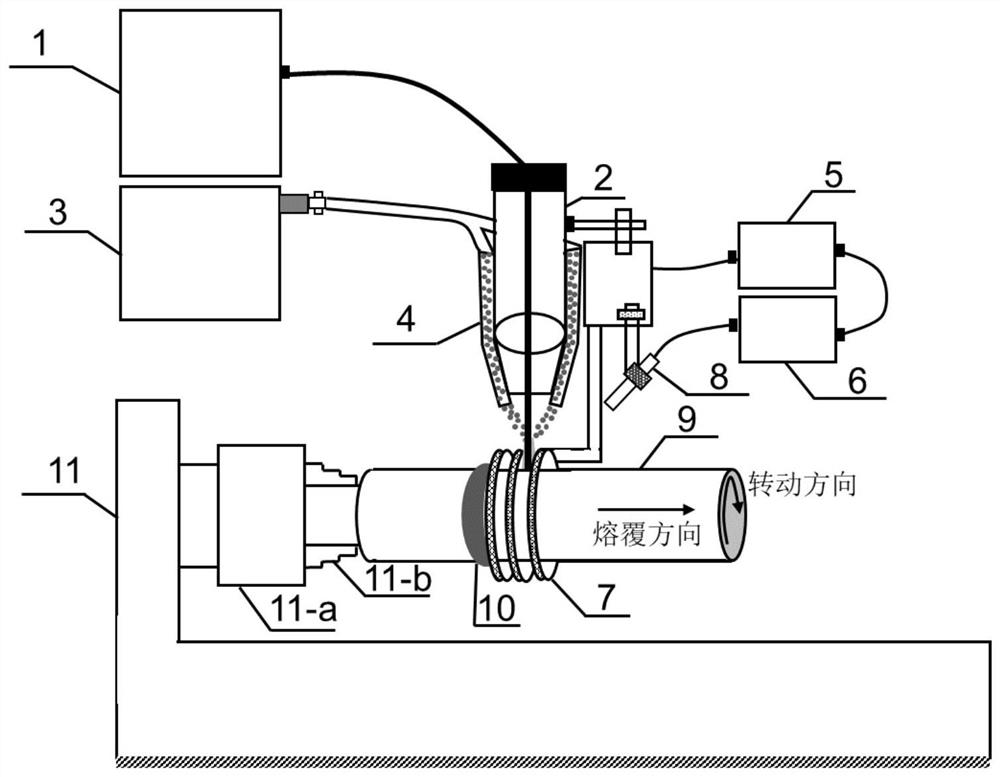

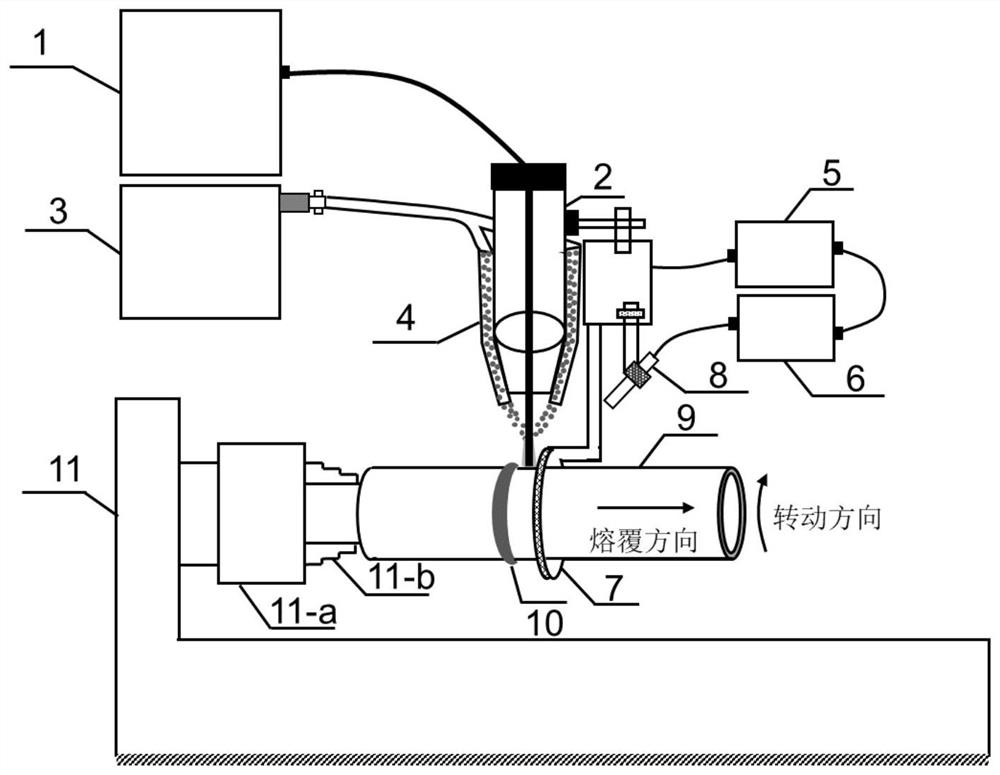

Ultrahigh-speed laser-induction composite cladding method and device

ActiveCN111676477AHigh precisionQuality improvementIncreasing energy efficiencyMetallic material coating processesUltra high speedAlloy

The invention belongs to the field of surface coating processing, and particularly discloses an ultrahigh-speed laser-induction composite cladding method and device. Aiming at a workpiece to be cladded as a processing object, the ultrahigh-speed laser-induction composite cladding device is provided with an induction heating coil used for realizing the fact of preheating the workpiece, the induction heating coil is arranged nearby the workpiece to be cladded, a area to be cladded of the workpiece is heated to a set temperature through the shape of the induction heating coil and the spatial arrangement of the induction heating coil relative to the workpiece to be cladded; and carrying out ultrahigh-speed laser-induction composite cladding above the area to be cladded of the workpiece by adopting ultrahigh-speed laser cladding and induction heating modes, so that interaction effect between a laser beam spot and a powder beam flow is carried out at a target position of a cladding area to heat a alloy powder to a molten drop or semi-molten drop state, and the alloy powder is sprayed to a micro molten pool on the preheated surface of the workpiece in a liquid or semi-solid form so as toprepare a required cladding layer. By means of the ultrahigh-speed laser-induction composite cladding method and device, high-precision, high-performance and metallurgical-defect-free ultra-efficientdeposition of the metal cladding layers of various materials can be achieved on the surface of a metal component.

Owner:武汉飞能达激光技术有限公司

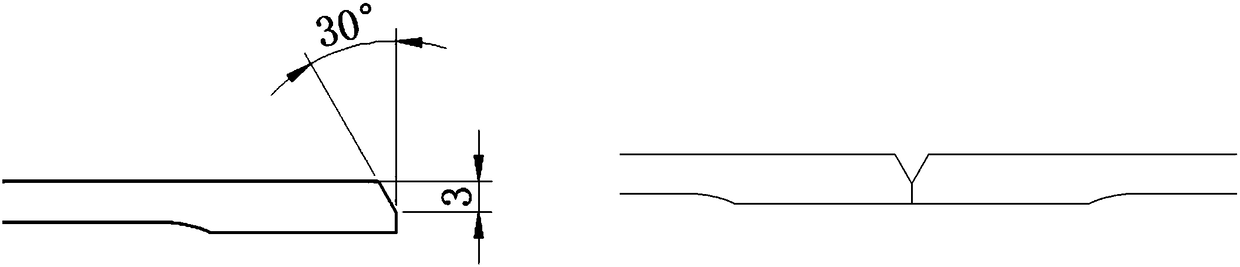

Automatic welding method for aluminum alloy thin plates

ActiveCN108544062ALarge residual stressImprove welding effectWelding/cutting auxillary devicesArc welding apparatusButt jointLarge deformation

The invention belongs to the technical field of welding, and relates to an automatic welding method for aluminum alloy thin plates. The automatic welding method comprises the steps of pre-welding preparation for equidistant cutting of the aluminum alloy thin plates, pre-treatment of a groove at the butt joint of the aluminum alloy thin plates, uniform clamping of a hydraulic clamping tool for thealuminum alloy thin plates, welding of the aluminum alloy thin plates after being clamped by the automatic welding method and post-welding shaping of small-scale flame repairing. The problems that inthe prior art, relatively large residual stress is prone to being generated when MIG is adopted to weld the aluminum alloy thin plates, large deformation of the base metal is generated after the completion of the welding, and subsequent shaping can be used for fine-tuning but the result is still not satisfactory are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

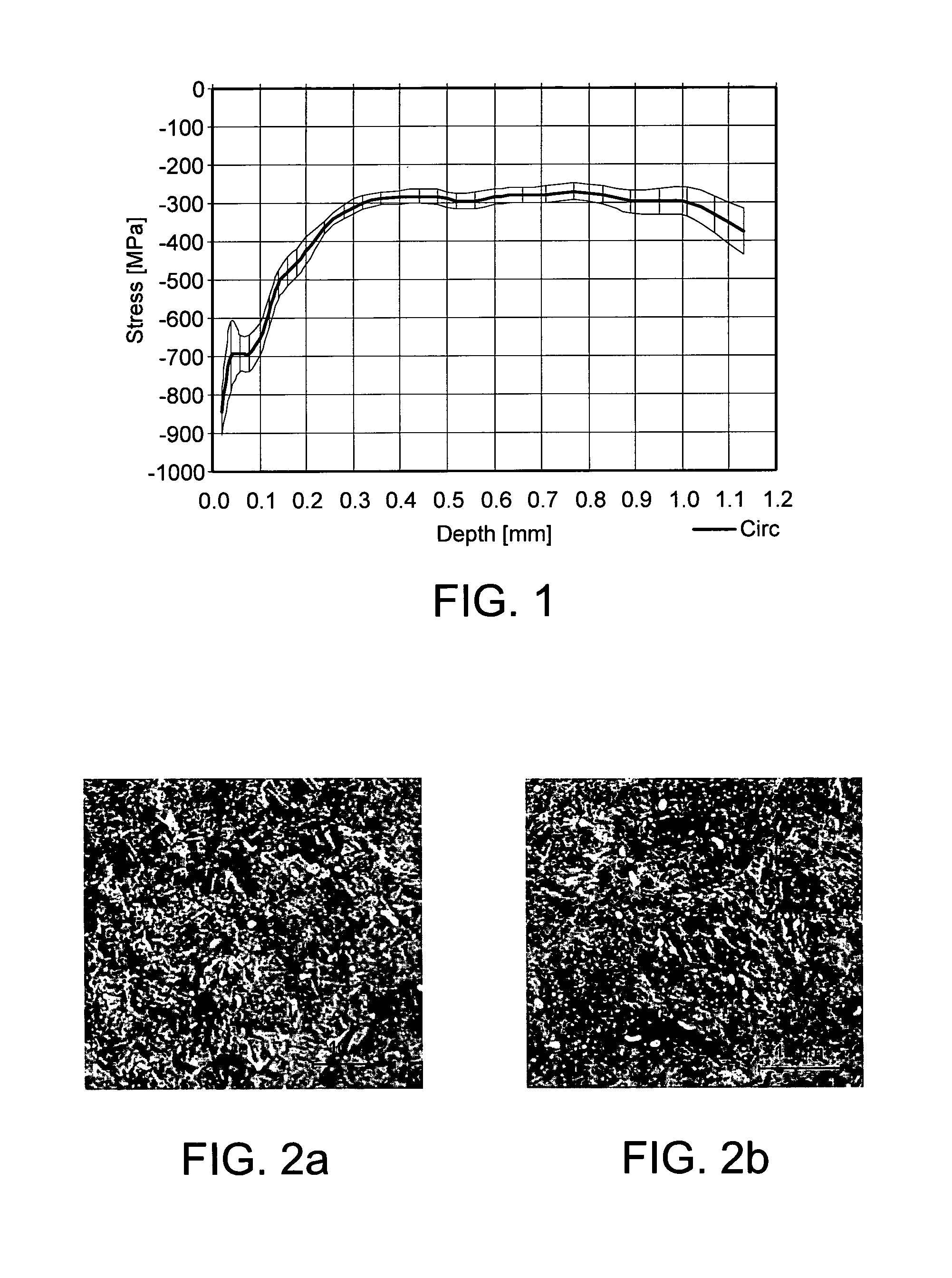

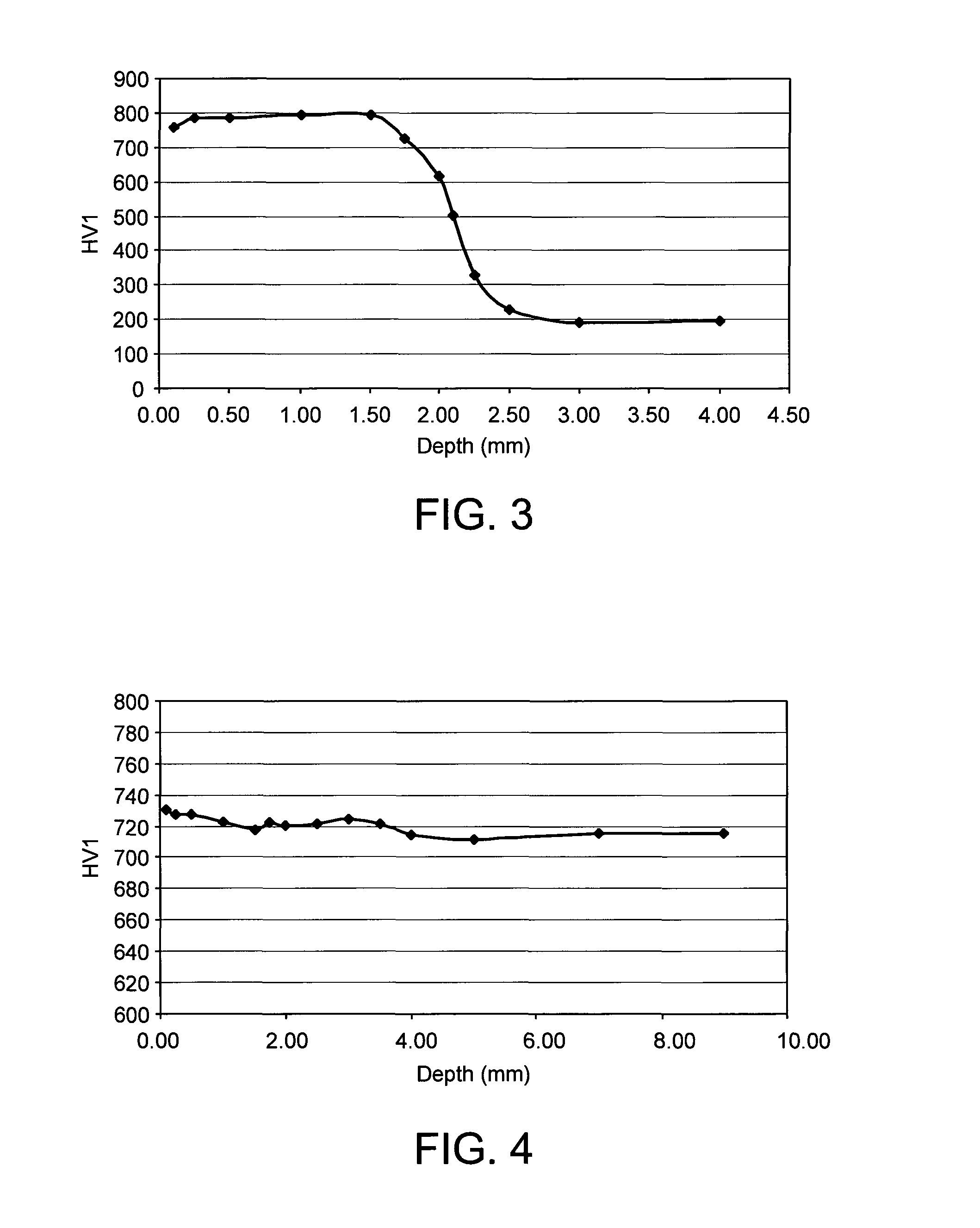

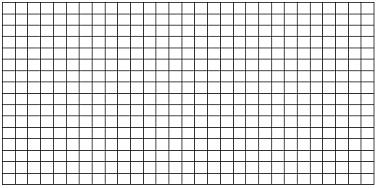

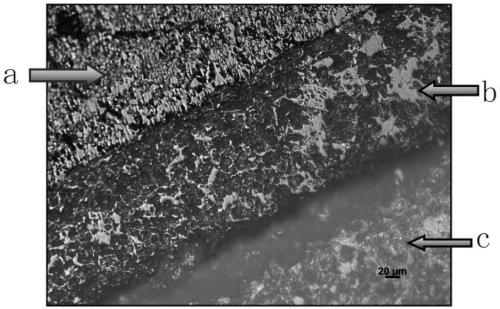

Method of heat treating a steel bearing component

InactiveUS8562767B2Increased thermal strainLarge residual stressBearing componentsFurnace typesChemical compositionPhysical chemistry

A bearing component formed from a bearing steel, wherein the component has an outer surface and comprises through-hardened bainite and / or martensite and has a substantially homogeneous chemical composition, at least a part of the bearing component having a compressive residual stress profile comprising −25 to −1000 MPa at the near surface, wherein the near surface is defined as a region 500 microns or less below the outer surface.

Owner:AB SKF

Manufacture method of mesh transparent electrode

InactiveCN102468378AImprove reliabilityQuality improvementSemiconductor devicesPower flowProtection layer

The invention relates to a manufacture method of a mesh-like transparent electrode, which is characterized by the following steps of: firstly, depositing a GaN material in an epitaxial growth process of an LED (Light-Emitting Diode); secondly, depositing a transparent electrode layer after the LED epitaxial growth; and finally, manufacturing the deposited transparent electrode layer to be a mesh-like layer. The mesh-like transparent electrode layer with a high dielectric constant is used as a current expansion layer and a stress buffering layer; therefore, the luminous efficiency is improved and the reliability of the device is further improved simultaneously. And more importantly, the invention can remove the larger residual stress existing inside an LED epitaxial wafer in the future, thereby preventing an LED protection layer from releasing and improving the entire quality of the LED.

Owner:HAIDIKE NANTONG OPTOELECTRONICS TECH CO LTD

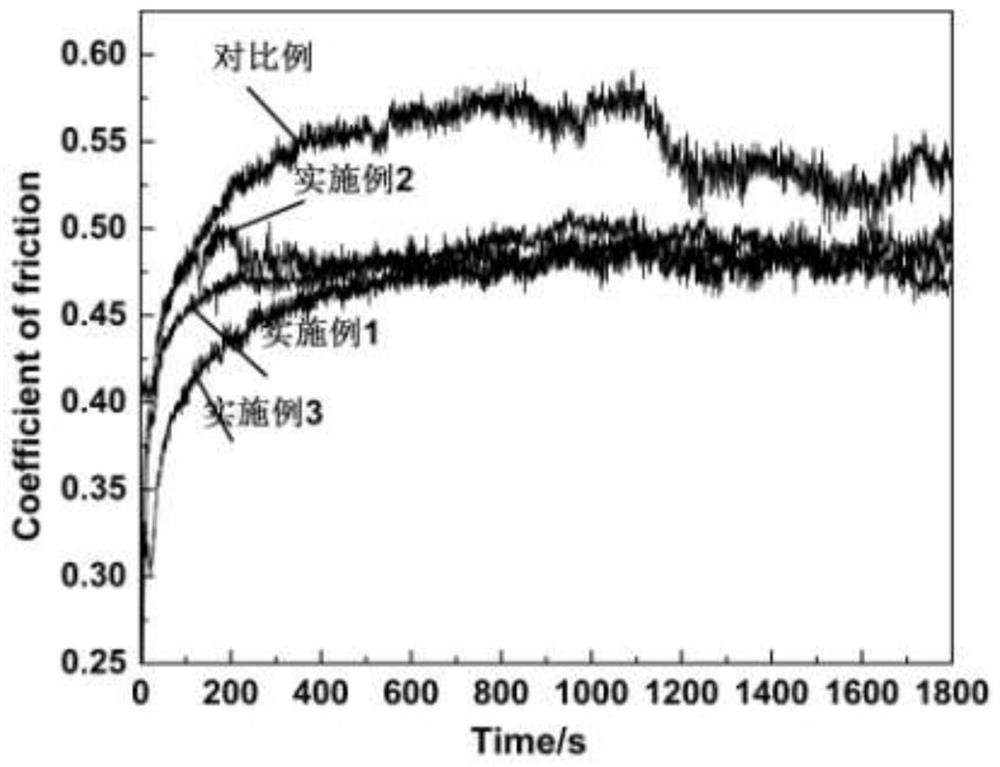

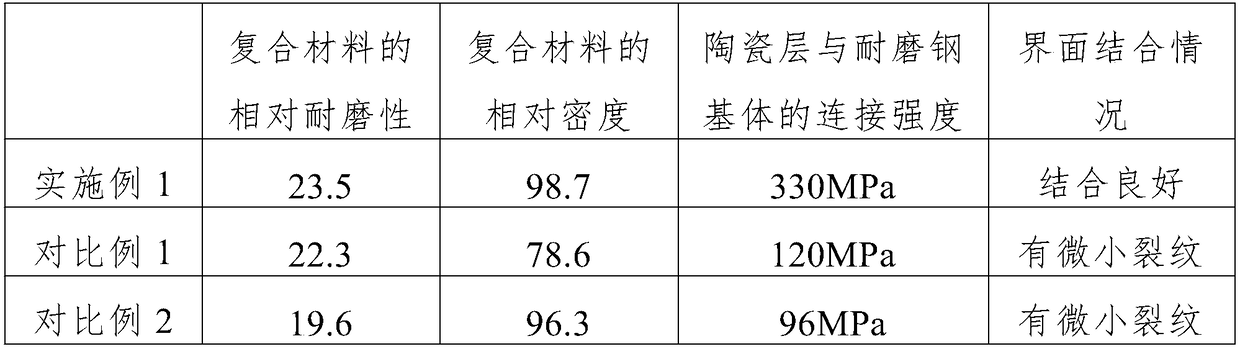

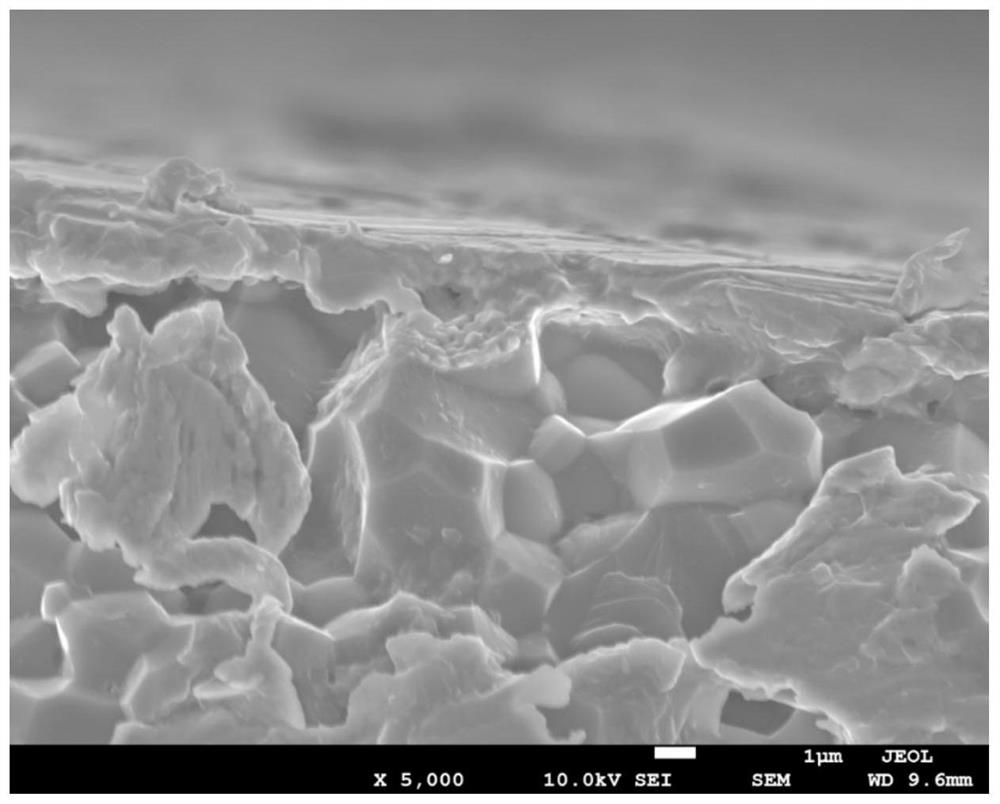

Alumina ceramic-wear resistant steel composite material and preparation method thereof

The invention provides an alumina ceramic-wear resistant steel composite material which comprises a wear resistant steel matrix, a ceramic layer and an enamel layer; and the enamel layer is arranged between the wear resistant steel matrix and the ceramic layer. The invention also provides a preparation method of the alumina ceramic-wear resistant steel composite material. The preparation method comprises the following steps of performing decarburization treatment on the wear resistant steel matrix to obtain the wear resistant steel matrix, preparing enamel powder and ceramic particle, then sequentially putting the materials in a lapping tool, and performing bi-directional compression and normal pressure sintering to obtain the alumina ceramic-wear resistant steel composite material. For the alumina ceramic-wear resistant steel composite material provided by the invention, the enamel layer can wet the ceramic layer and can improve the wettability with the wear resistant steel matrix toform chemical bond bonding; a part of the enamel powder is charged in pores of the ceramic layer, so that bubbles are difficultly formed between the wear resistant steel matrix and the enamel layer; and TiO2-x and CuO in the ceramic layer can lower the sintering temperature as sintering aids, prevent the wear resistant steel matrix from oxidizing, improves the preparation efficiency and lowers thepreparation cost.

Owner:JIAMUSI UNIVERSITY

Method for conducting magnetron sputtering on surface of Al2O3 ceramic matrix to coat Al2O3 ceramic matrix with nanometer copper film

InactiveCN112410742AImprove bindingImprove conductivityVacuum evaporation coatingSputtering coatingSputteringHigh wear resistance

The invention provides a method for conducting magnetron sputtering on the surface of an Al2O3 ceramic matrix to coat the Al2O3 ceramic matrix with a nanometer copper film. According to the method, byconducting magnetron sputtering to coat the Al2O3 ceramic matrix with the nanometer copper film, protection of the film for the matrix is better, and good electrical conductivity and film-matrix adhesion are achieved; and the produced coat (film) is dense and flat, the hardness is high, the wear resistance is good, a wear rate decreases, and the high-temperature oxidation resistance is enhanced,so that the microstructure of the material (Al2O3 ceramic matrix) is improved, the comprehensive performance of the material (Al2O3 ceramic matrix) is improved, and meanwhile, the film has a good electrical property.

Owner:东莞市烽元科技有限公司 +1

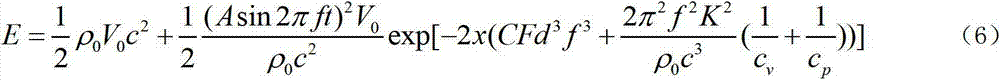

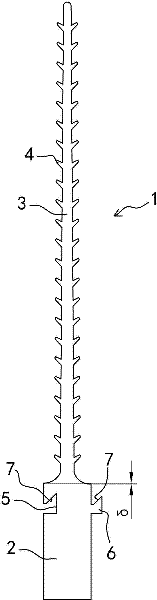

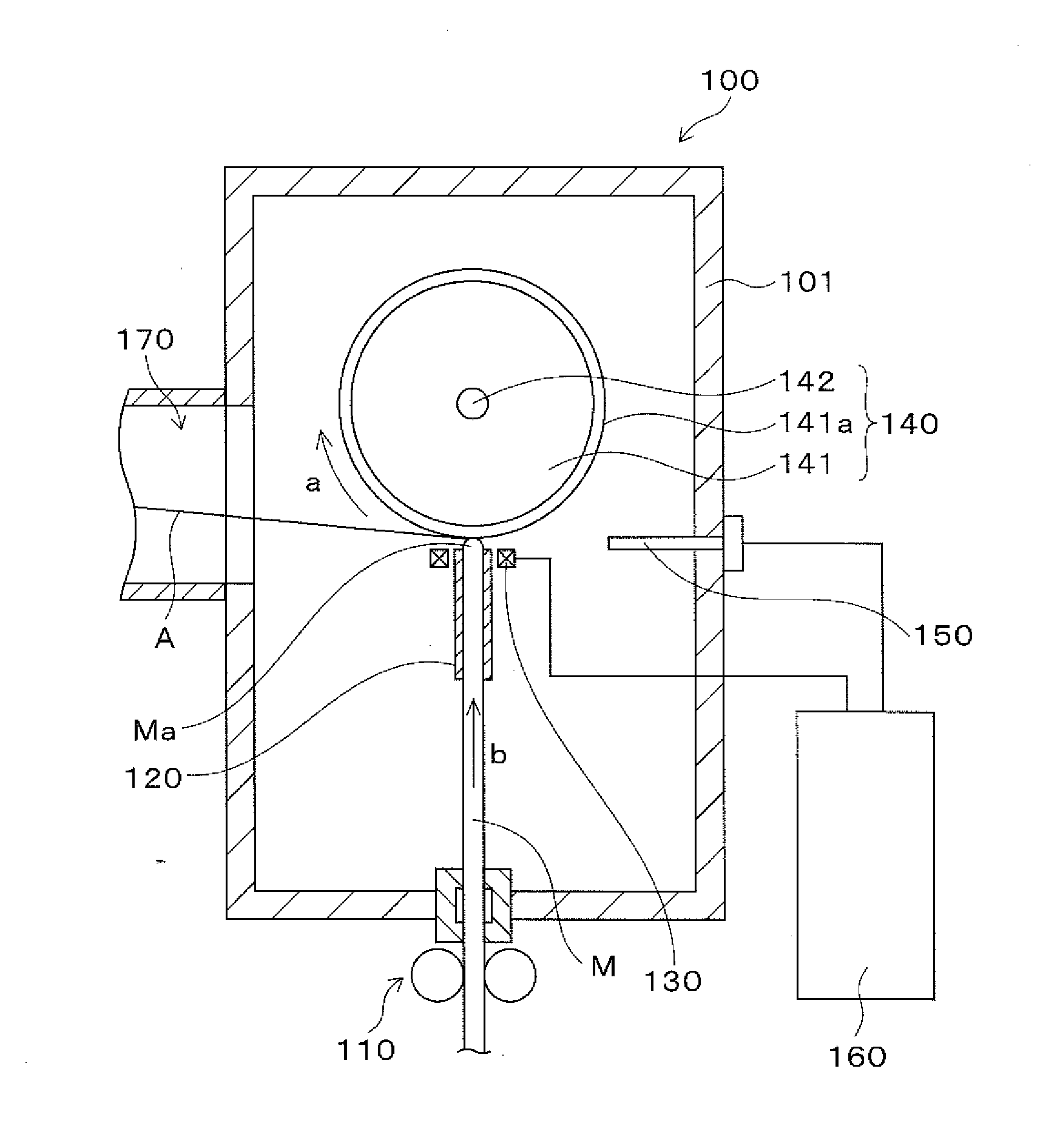

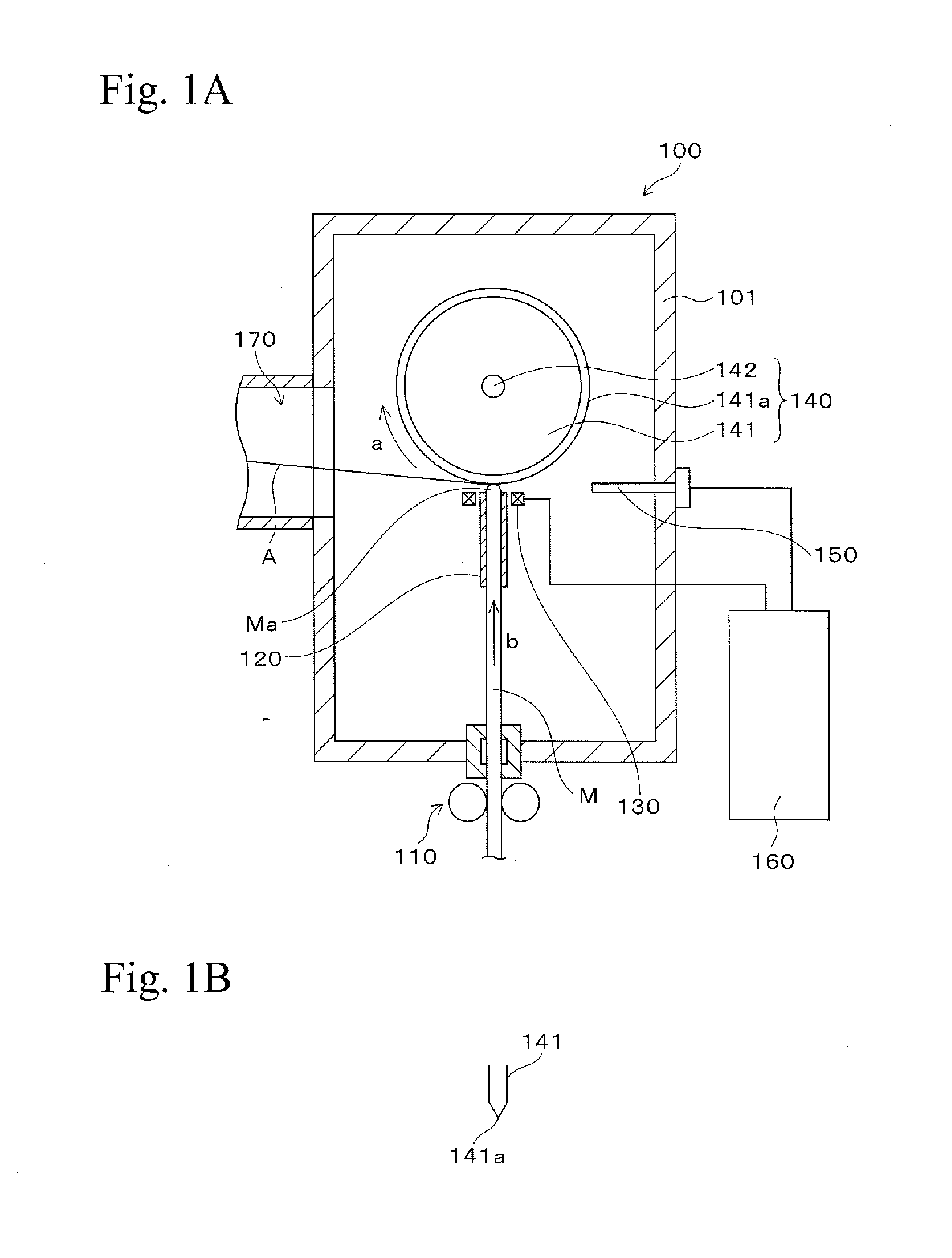

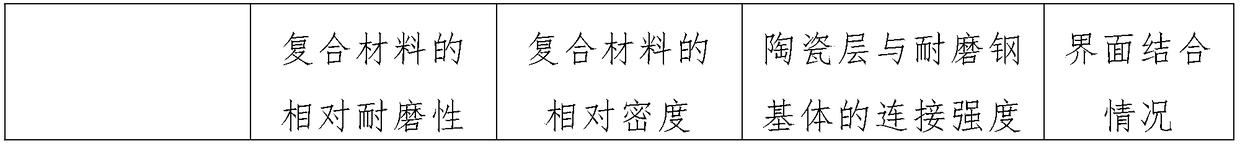

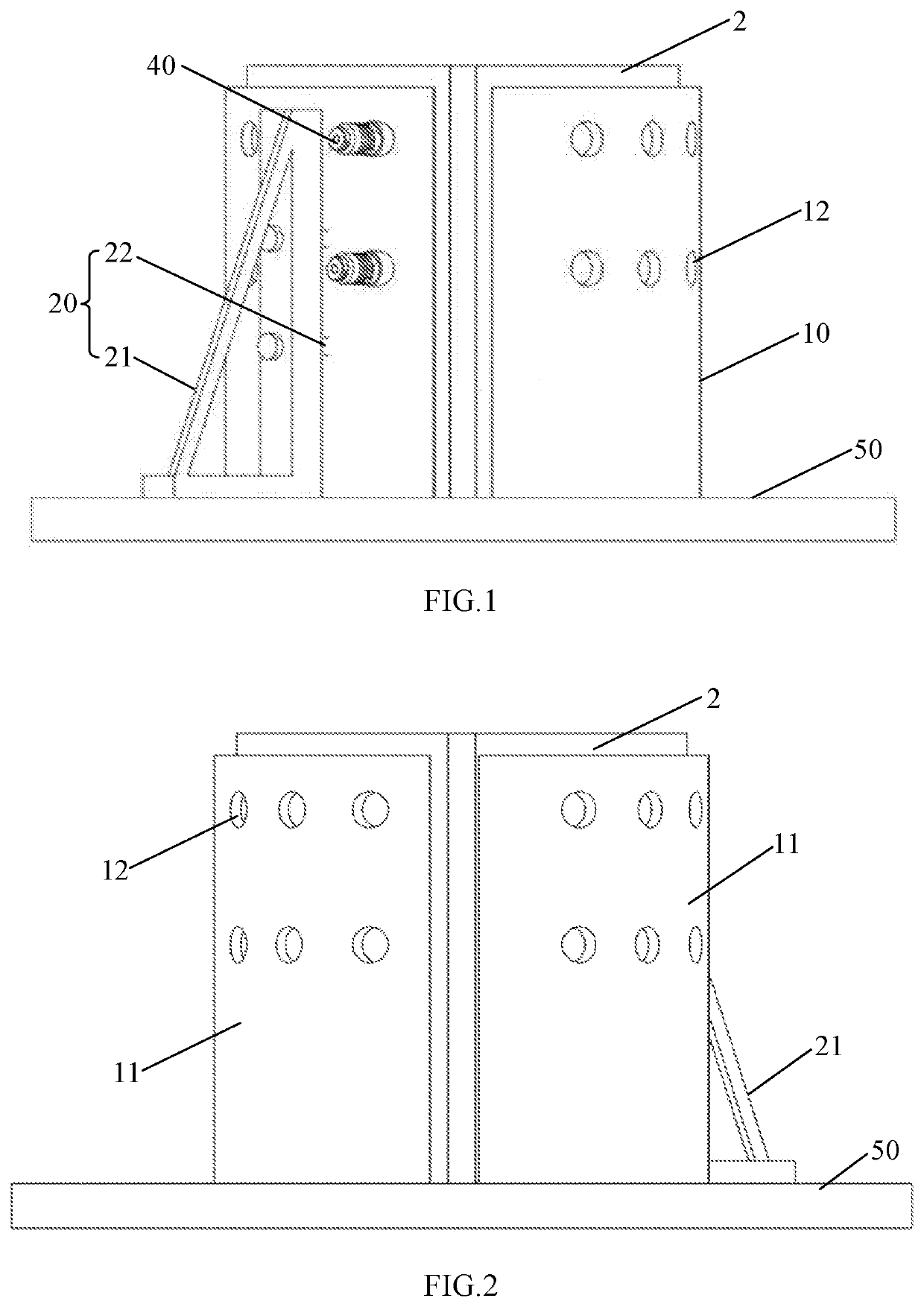

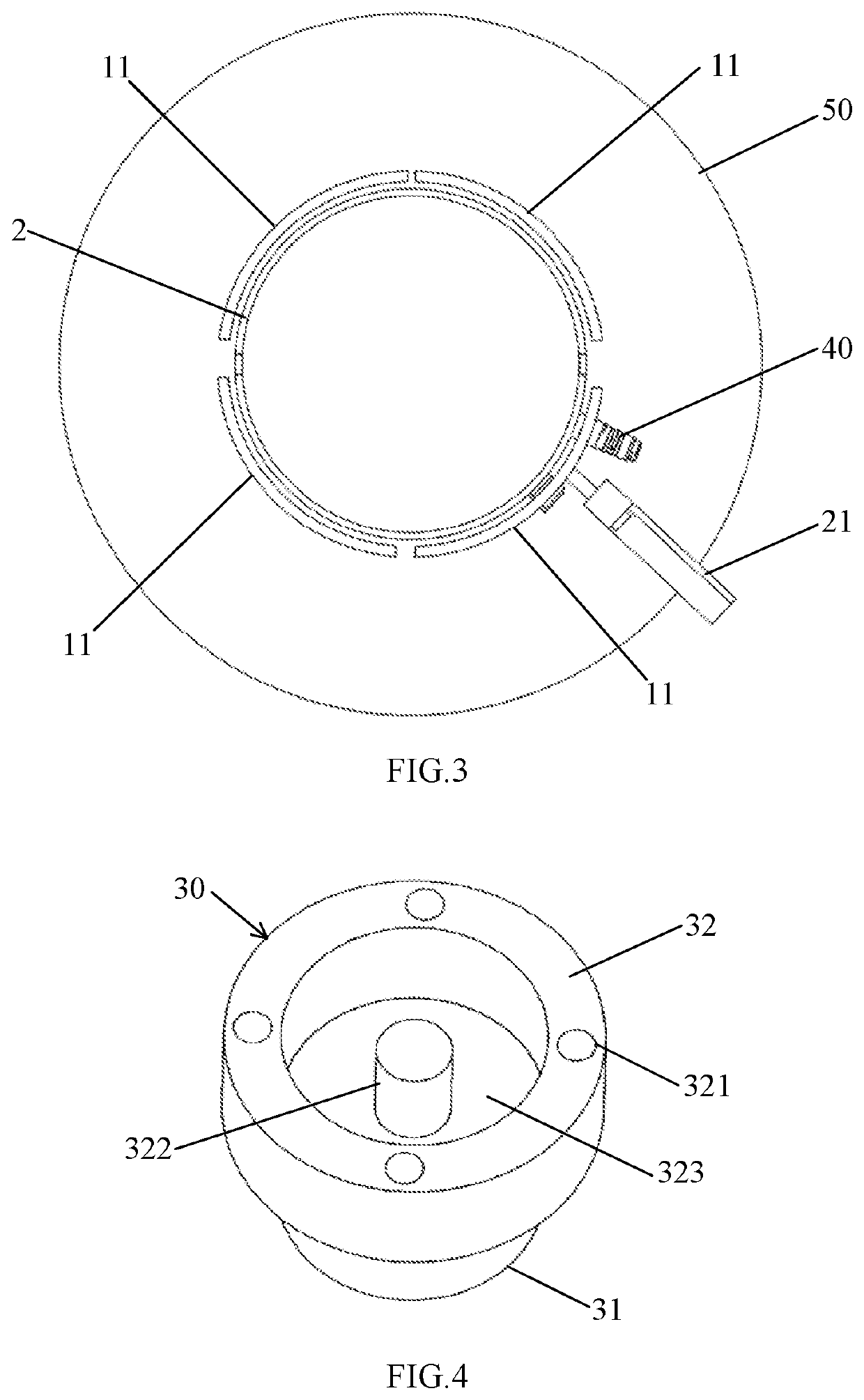

Device and method for reducing and homogenizing residual stress of a component by array of high-energy elastic waves

ActiveUS20210086309A1High impact strengthReduce and homogenize residual stressMechanical vibrations separationWelding apparatusSignal amplifierMechanical engineering

A device and method for reducing and homogenizing residual stress of a component by an array of high-energy elastic waves. The device includes a tubular body consisting of at least two elements, multiple first through holes and a clamping device provided on an outer side of the tubular body. Exciters are connected with exciting wedges so that an end face of each of the exciting wedges is closely coupled to a surface of the component. A connection portion is coupled to an emitting end of each of the exciters, where the axis of the emitting end coincides with a normal line at a pressed surface of the component A multi-channel signal amplifier is electrically connected to each of the exciters and a multi-channel excitation control module is electrically connected to the multi-channel signal amplifier.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

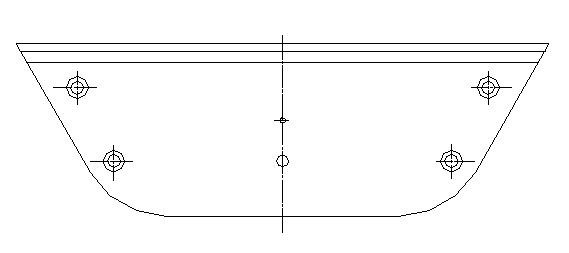

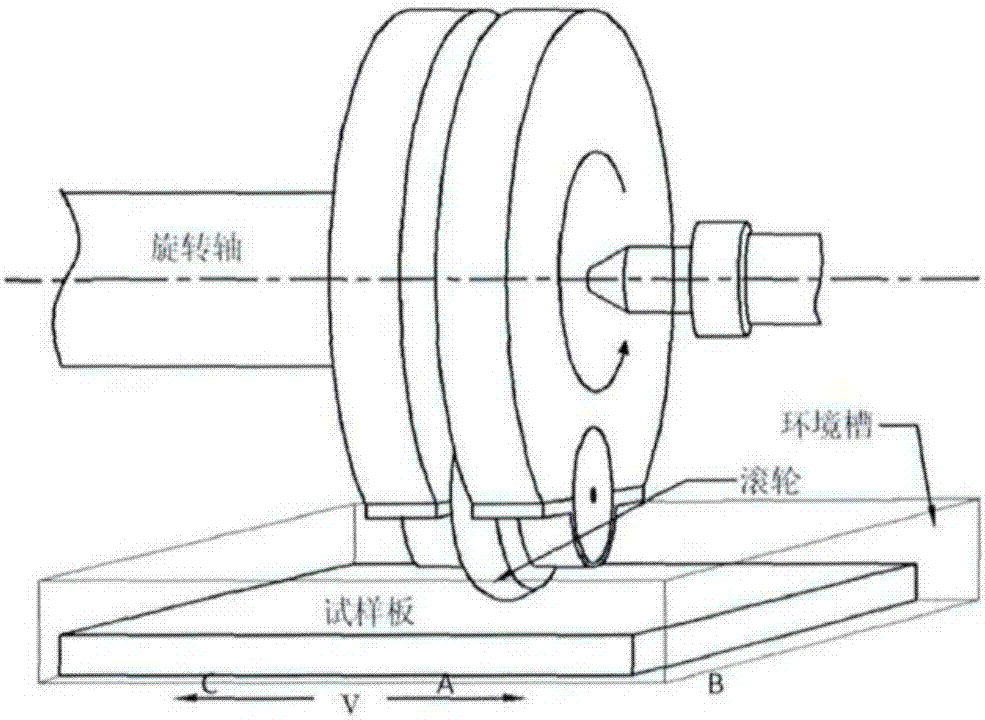

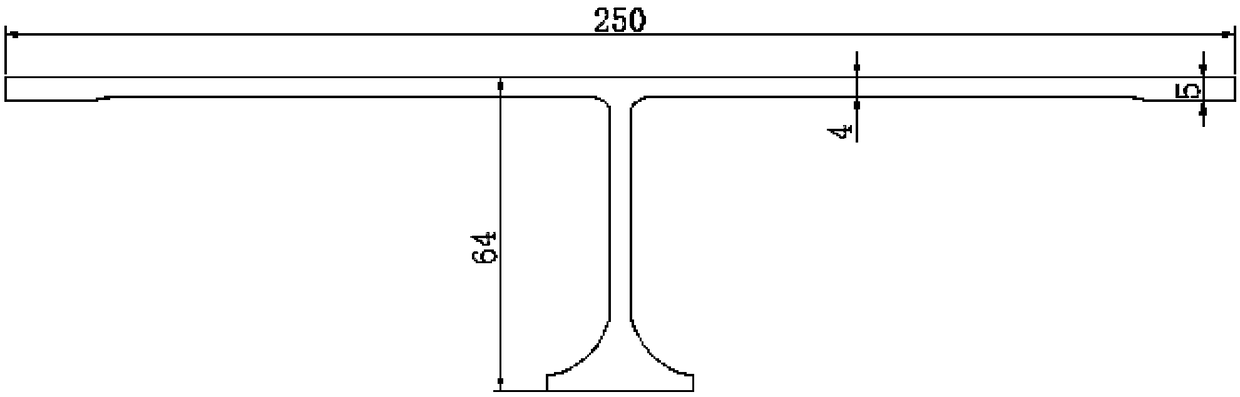

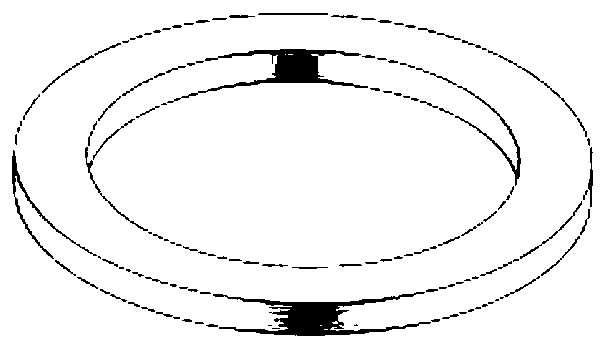

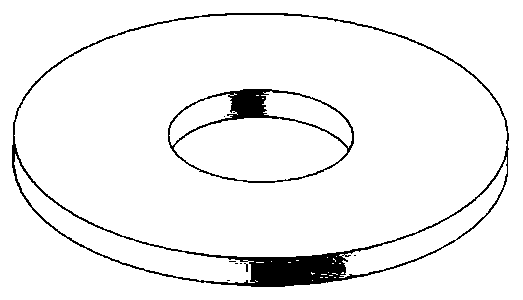

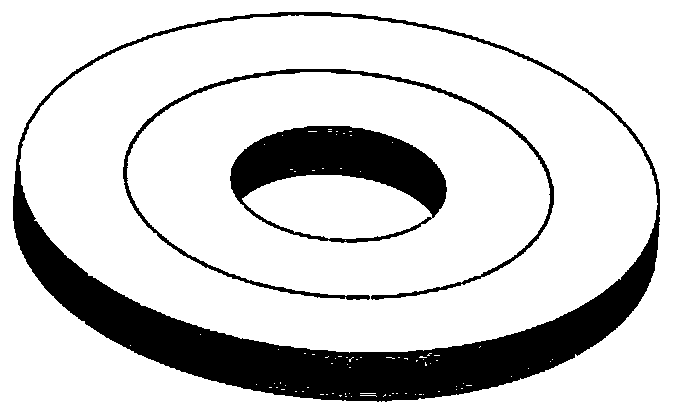

Characterization method for size stability after welding forming

ActiveCN111515566ABig restraintLarge residual stressWelding apparatusElasticity measurementMechanical engineeringBoundary line

The invention discloses a characterization method for size stability after welding forming. The characterization method includes the following steps that firstly, a large circular-ring-shaped weldingpart and a small circular-ring-shaped welding part are manufactured, wherein the inner diameter of the large welding part is equal to the outer diameter of the small welding part; secondly, the smallwelding part is sleeved with the large welding part, the large welding part and the small welding part are integrally welded through the welding technology, and therefore a welding forming sample is formed; thirdly, an opening is formed in the radius direction of the welding forming sample and is perpendicular to the surface of the welding forming sample; and fourthly, the linear distance parameter between opposite two points of the circumference of the boundary line of the upper surfaces of the two sides of the opening is detected in a fixed time interval, and the deflection change parametersof the welding forming sample is detected. By means of the characterization method, the size stability condition of the welding parts along time after welding forming can be detected rapidly, accurately and conveniently.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com