Alumina ceramic-wear resistant steel composite material and preparation method thereof

A technology of alumina ceramics and composite materials, which is applied in the field of wear-resistant steel matrix modification, can solve the problems of complex process complexity, large residual stress at the interface, poor chemical stability, etc., and achieves good wear resistance, high connection strength, improved Wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

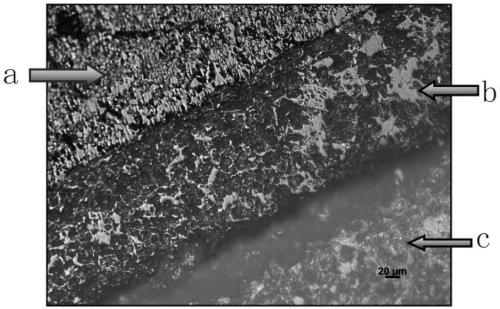

Image

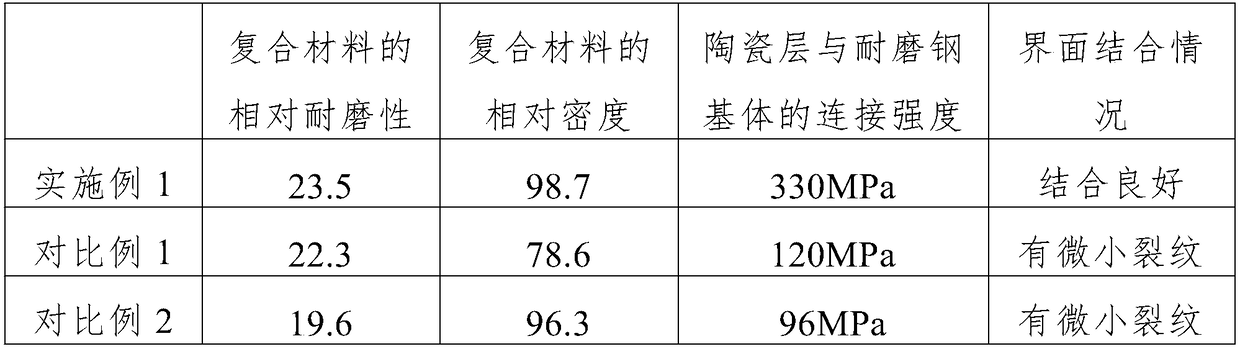

Examples

Embodiment 1

[0022] The composite material of alumina ceramics and wear-resistant steel in this embodiment includes a wear-resistant steel substrate, a ceramic layer and an enamel layer, the enamel layer is located in the middle of the wear-resistant steel substrate and the ceramic layer, and the thickness of the enamel layer is 5 mm; The thickness of the ceramic layer is 20mm; the enamel layer includes the following components in mass percentage: SiO 2 50%, B 2 o 3 16%, Na 2 O 12%, K 2 O 6%, CoO 1.5%, NiO 1.5%, balance Al 2 o 3 ; The ceramic layer comprises the following components in mass percentage: TiO 2-x 4%, CuO2%, the balance is Al 2 o 3 .

[0023] This embodiment also provides the method for the above-mentioned composite material of alumina ceramics and wear-resistant steel, the method comprising the following steps:

[0024] Step 1. Pretreatment of the wear-resistant steel substrate: decarburize the wear-resistant steel substrate at a temperature of 940°C for 15 minutes,...

Embodiment 2

[0043] The composite material of alumina ceramics and wear-resistant steel in this embodiment includes a wear-resistant steel substrate, a ceramic layer and an enamel layer, the enamel layer is located in the middle of the wear-resistant steel substrate and the ceramic layer, and the thickness of the enamel layer is 1mm; The thickness of the ceramic layer is 5mm; the enamel layer includes the following components in mass percentage: SiO 2 40%, B 2 o 3 20%, Na 2 O 15%, K 2 O 1%, CoO 1%, NiO 1%, the balance is Al 2 o 3 ; The ceramic layer comprises the following components in mass percentage: TiO 2-x 10%, CuO10%, the balance is Al 2 o 3 .

[0044] This embodiment also provides the method for the above-mentioned composite material of alumina ceramics and wear-resistant steel, the method comprising the following steps:

[0045]Step 1. Pretreatment of the wear-resistant steel substrate: decarburize the wear-resistant steel substrate at a temperature of 910°C for 10 minute...

Embodiment 3

[0054] The composite material of alumina ceramics and wear-resistant steel in this embodiment includes a wear-resistant steel substrate, a ceramic layer and an enamel layer, the enamel layer is located in the middle of the wear-resistant steel substrate and the ceramic layer, and the thickness of the enamel layer is 5 mm; The thickness of the ceramic layer is 35mm; the enamel layer includes the following components in mass percentage: SiO 2 60%, B 2 o 3 5%, Na 2 O 1%, K 2 O 10%, CoO 5%, NiO 5%, the balance is Al 2 o 3 ; The ceramic layer comprises the following components in mass percentage: TiO 2-x 1%, CuO 1%, the balance is Al 2 o 3 .

[0055] This embodiment also provides the method for the above-mentioned composite material of alumina ceramics and wear-resistant steel, the method comprising the following steps:

[0056] Step 1. Pretreatment of the wear-resistant steel substrate: decarburize the wear-resistant steel substrate at a temperature of 940°C for 20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com