Method for conducting magnetron sputtering on surface of Al2O3 ceramic matrix to coat Al2O3 ceramic matrix with nanometer copper film

A magnetron sputtering plating and ceramic substrate technology, applied in the field of metal surface coating, can solve the problems of low purity, strict pretreatment requirements, poor film uniformity, etc., achieve high conductivity and improve the bonding force between coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

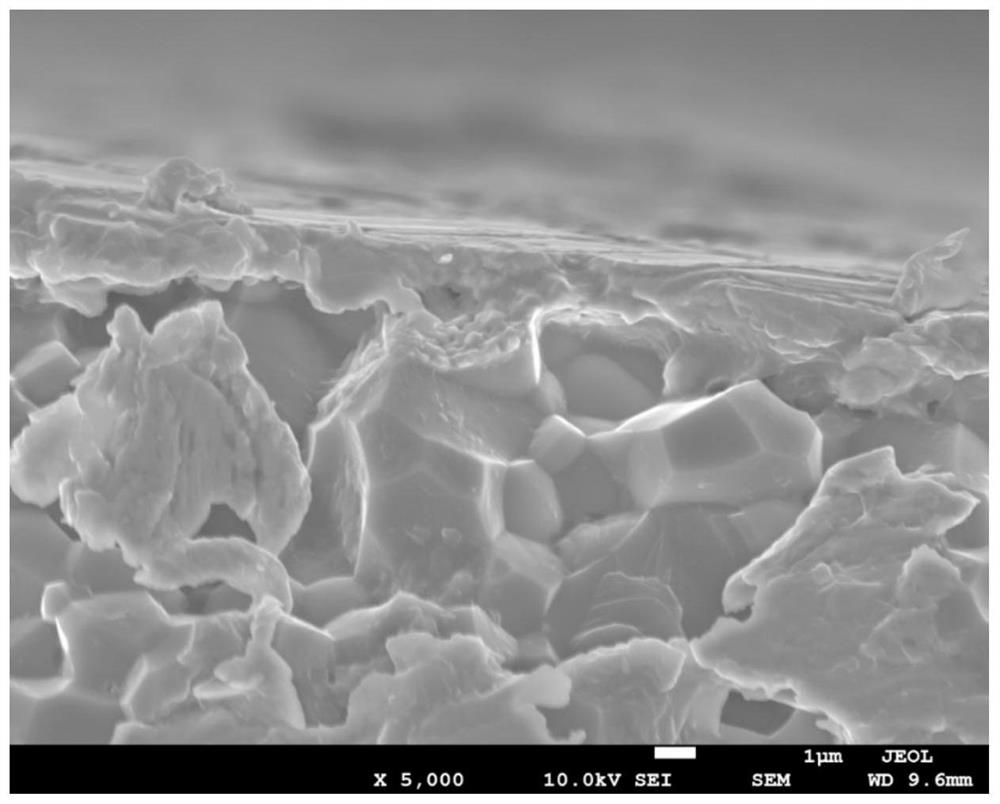

[0027] a in Al 2 o 3 The method for magnetron sputtering nano-scale copper film plating on ceramic substrate surface, it comprises the following steps:

[0028] (1) Sample treatment: Al 2 o 3The ceramic substrate was ultrasonically cleaned in acetone for 10 minutes, then ultrasonically cleaned twice with ethanol, taken out and dried;

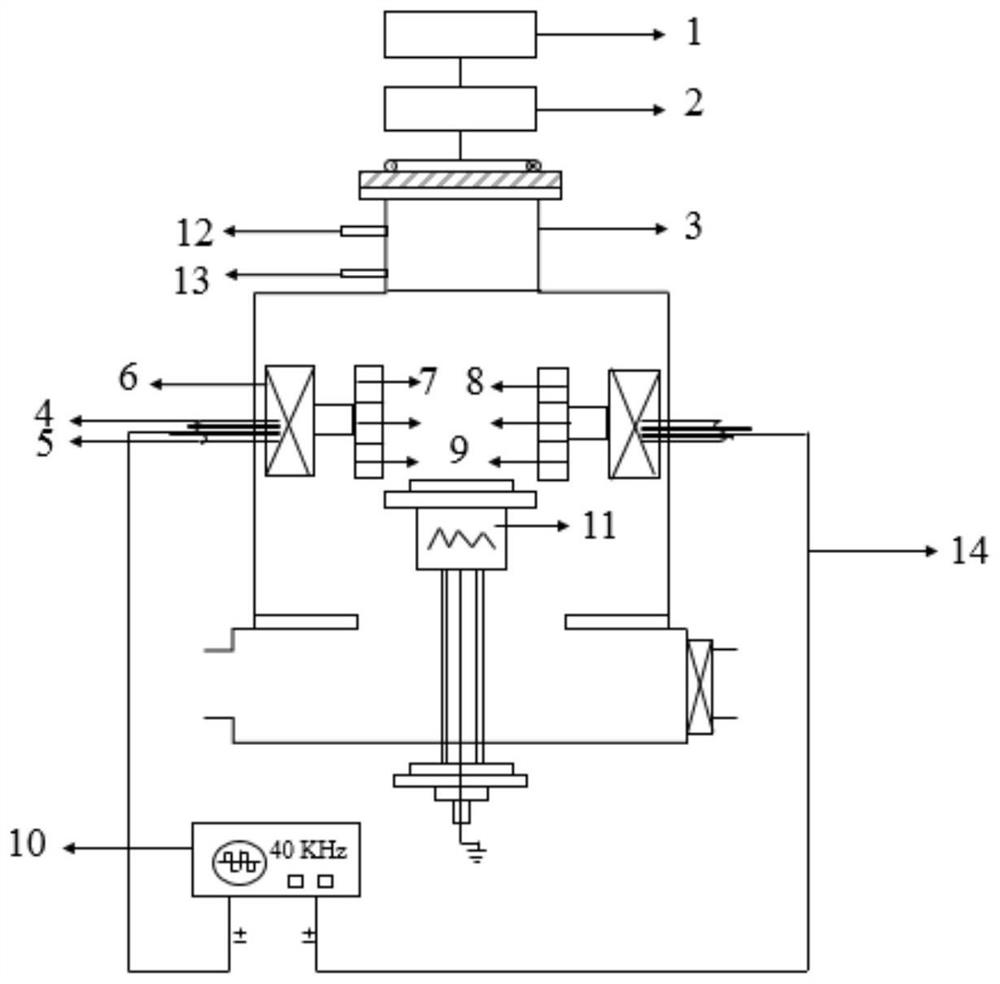

[0029] (2) Equipment preparation: use a magnetron sputtering coating machine, select three Cu, Al and Ni simple substance targets with a purity of 99.99%, and the working gas is Ar gas with a purity of 99.99%, N 2 gas.

[0030] (3) The sample processed in step (1) is put into the furnace, and the air pressure in the vacuum chamber is pumped to 3×10 -3 Pa, filled with argon sputtering gas, ion bombardment for 10min, argon gas flow rate 20sccm, sputtering pressure 0.9Pa, plasma source power 1000W, turn on auxiliary heating, and raise the temperature to 350°C.

[0031] (4) Deposit the Al transition layer: turn on the magnetron sputtering Al t...

Embodiment 2

[0040] a in Al 2 o 3 The method for magnetron sputtering nanoscale copper film plating on ceramic substrate surface, it comprises the following steps: (1) sample processing: Al 2 o 3 The ceramic substrate was ultrasonically cleaned in acetone for 10 minutes, then ultrasonically cleaned twice with ethanol, taken out and dried;

[0041] (2) Equipment preparation: use a magnetron sputtering coating machine, select three Cu, Al and Ni simple substance targets with a purity of 99.99%, and the working gas is Ar gas with a purity of 99.99%, N 2 gas.

[0042] (3) The sample processed in step (1) is put into the furnace, and the air pressure in the vacuum chamber is pumped to 3×10 -3 Pa, filled with argon sputtering gas, ion bombardment for 10min, argon gas flow rate 10sccm, sputtering pressure 0.7Pa, plasma source input power 200W, turn on auxiliary heating, and raise the temperature to 350°C.

[0043] (4) Deposit the Al transition layer: turn on the power supply of the magnetron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com