Method for local bonding silicon / glass by laser

A glass laser and bonding technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of limited application, device pollution, high annealing temperature, etc., and achieve good bonding area selectivity and overall bonding The effect of low temperature and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

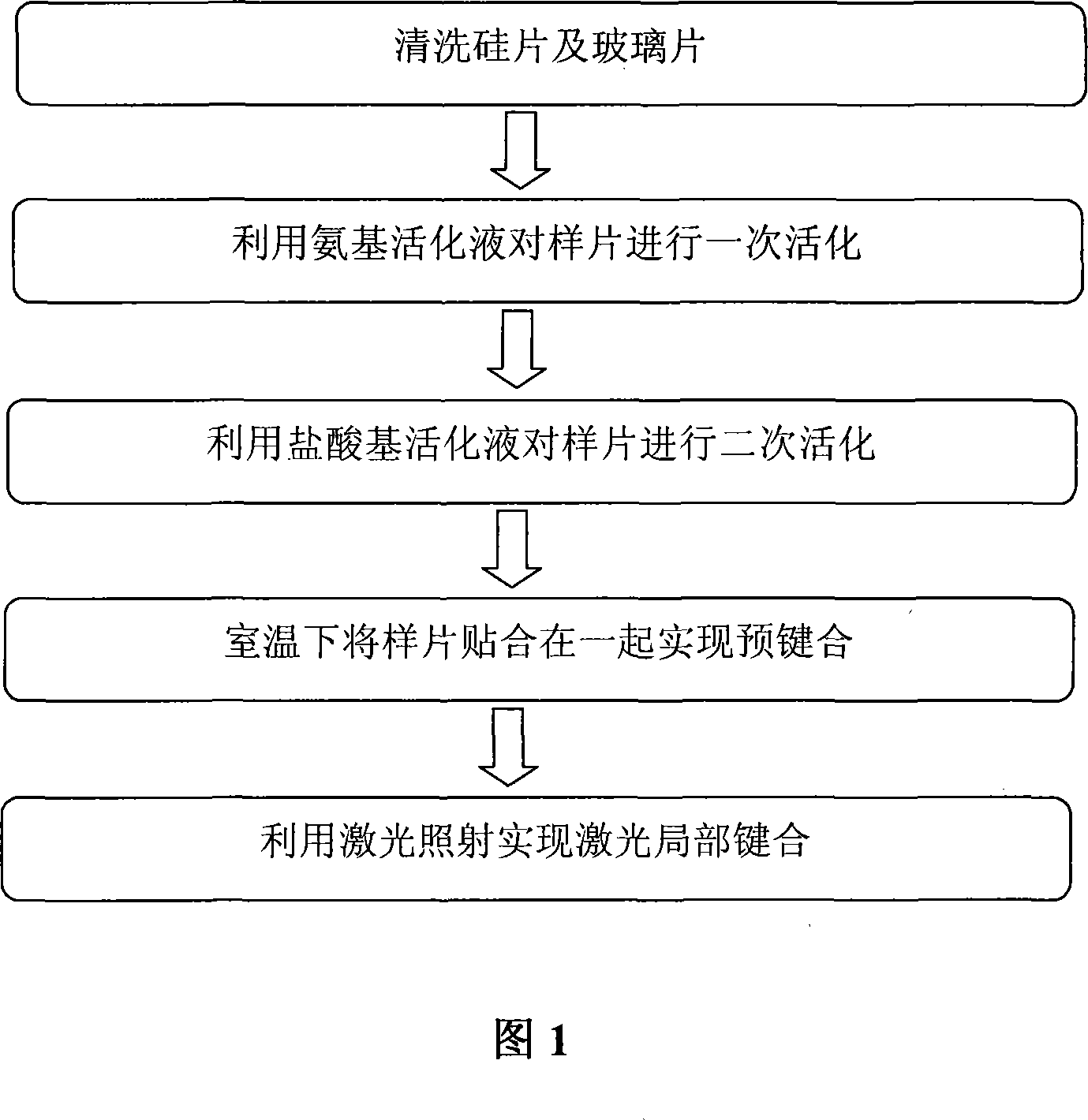

[0031] 1. Clean the sample, soak the sample to be bonded in the cleaning solution (H 2 SO 4 :H 2 o 2 =2:1), control the temperature at 120°C, and wash for 20 minutes;

[0032] 2. Soak the sample to be bonded in the amino activation solution (NH 4 OH:H 2 o 2 :H 2 (0=1:1:5) was activated once, the activation temperature was 70°C, and the sample was activated for 20 minutes;

[0033] 3. Soak the sample to be bonded in hydrochloric acid-based activation solution (HCl:H 2 o 2 :H 2 O=1:1:5) for secondary activation, the activation temperature is 70°C, and the sample is activated for 20 minutes;

[0034] 4. After drying the activated silicon wafer and glass wafer, they are quickly pasted together at room temperature to make them pre-bonded;

[0035] 5. Use the Nd:YAG laser produced by Rofin-Sinar, Germany, and adopt the continuous laser emission method for local laser bonding. The laser parameters selected for bonding are: laser power 75W, wavelength 1064nm, spot diameter...

Embodiment 2

[0038] 1. Sample cleaning. Soak the sample to be bonded in the cleaning solution (H 2 SO 4 :H2 o 2 =2:1), control the temperature at 120°C, and wash for 20 minutes;

[0039] 2. Activate the sample once. Soak the sample to be bonded in the amino activation solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:5), the activation temperature is 70°C, and the sample is activated for 20 minutes;

[0040] 3. Perform secondary activation on the sample. Soak the sample to be bonded in a hydrochloric acid-based activation solution (HCl:H 2 o 2 :H 2 O=1:1:5), the activation temperature is 70°C, and the sample is activated for 20 minutes;

[0041] 4. Sample pre-bonding. After the silicon wafer and the glass wafer are blown dry, they are quickly bonded together at room temperature, and pre-bonding occurs;

[0042] 5. Local laser bonding. The laser power is 90W, the wavelength is 1064nm, the spot diameter is 200μm, and the laser scanning speed is 10mm / s.

[0043] Figure 5 is a diagram of th...

Embodiment 3

[0045] 1. Sample cleaning. Soak the sample to be bonded in the cleaning solution (H 2 SO 4 :H 2 o 2 =4:1), control the temperature at 50°C, and wash for 30 minutes;

[0046] 2. Activate the sample once. Soak the sample to be bonded in the amino activation solution (NH 4 OH:H 2 o 2 :H 2 O=1:1:3), the activation temperature is 50°C, and the sample is activated for 30 minutes;

[0047] 3. Perform secondary activation on the sample. Soak the sample to be bonded in a hydrochloric acid-based activation solution (HCl:H 2 o 2 :H 2 O=1:1:3), the activation temperature is 50°C, and the sample is activated for 30 minutes;

[0048] 4. Sample pre-bonding. After the silicon wafer and the glass wafer are blown dry, they are quickly bonded together at room temperature, and pre-bonding occurs;

[0049] 5. Local laser bonding. The laser power is 25W, the wavelength is 1064nm, the spot diameter is 200μm, and the laser scanning speed is 0.5mm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com