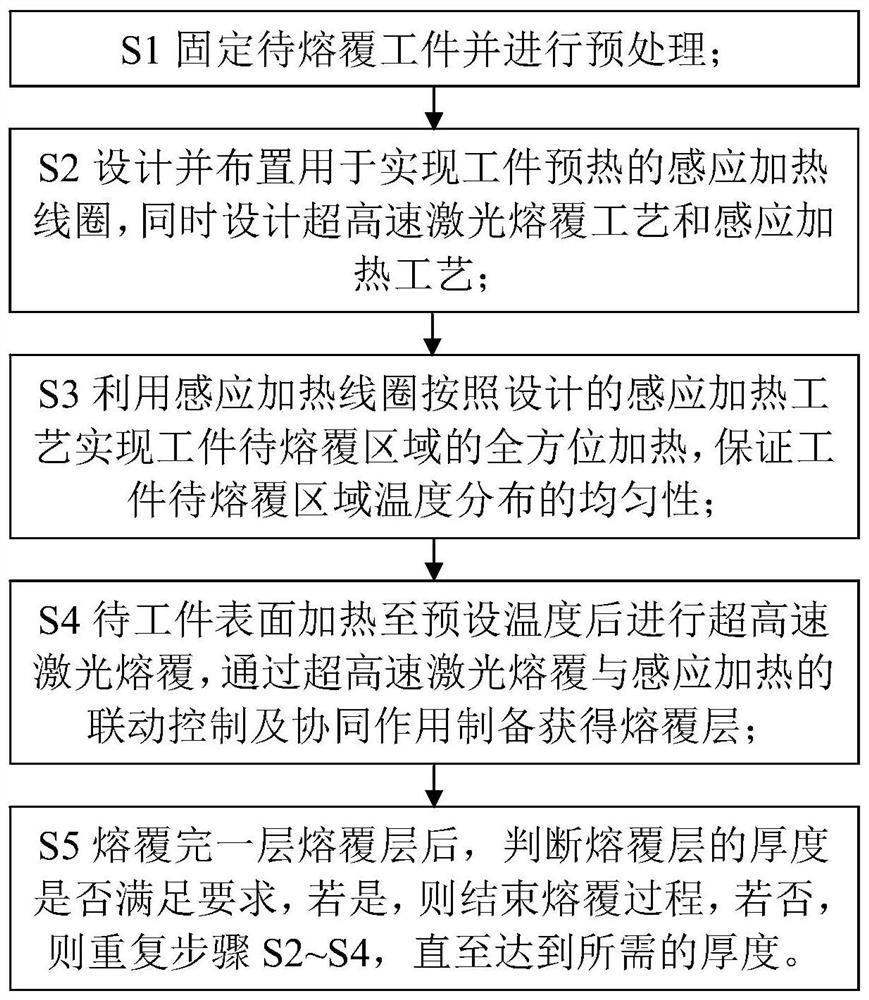

Ultrahigh-speed laser-induction composite cladding method and device

A laser cladding and ultra-high-speed technology, which is applied in the coating process and coating of metal materials, can solve the problems of many influencing factors, high processing costs, and complicated procedures, achieve high deposition accuracy and deposition efficiency, and ensure stable quality The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

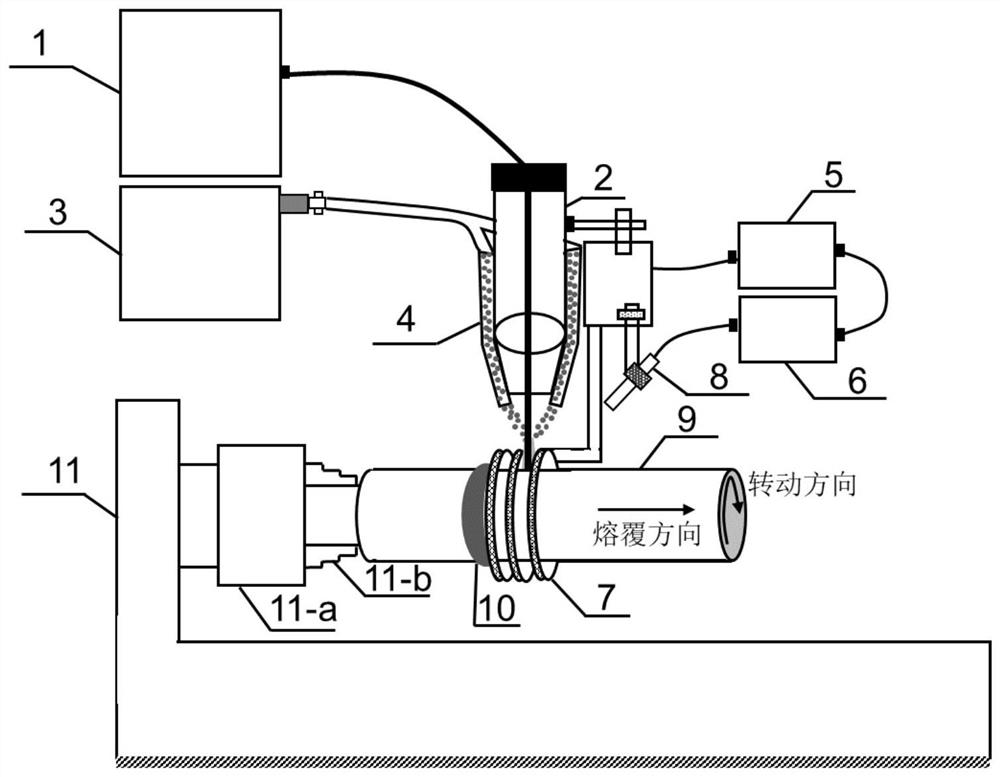

[0092] In this embodiment, ultra-high-speed laser-induction composite cladding is performed on the surface of solid shaft parts. Specifically, a roll with a roll diameter of 245 mm is used as an example for illustration, and it is also applicable to solid shaft parts with other roll diameters.

[0093] This embodiment adopts as figure 2 For the implementation of the device shown, the motion control unit uses a four-axis CNC machine tool. The specific implementation steps include:

[0094] (1) Select Ni60 alloy powder with a particle size of 25 μm to 60 μm as the cladding material, and the base material is high-carbon alloy steel. The workpiece is fixed on the rotary table 11a of the CNC machine tool using a three-jaw chuck 11b, and a grinding machine or Sandpaper is used to polish the area to be clad on the surface of the workpiece to remove surface rust and pollutants, or use laser cleaning equipment to remove surface rust and pollutants;

[0095] (2) A multi-turn annular i...

Embodiment 2

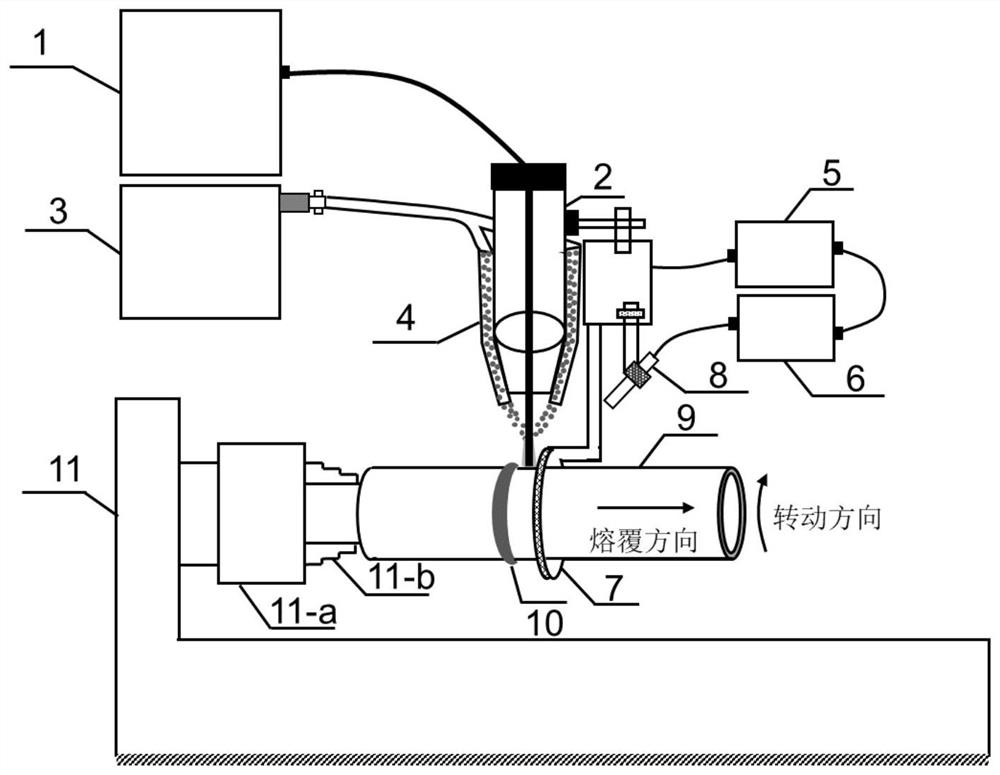

[0100] In this embodiment, ultra-high-speed laser-induction composite cladding is performed on the outer surface of tubular hollow parts. Specifically, a pipe with a diameter of 100 mm and a wall thickness of 8 mm is used as an example for illustration, and it is also applicable to tubular parts with other diameters and wall thicknesses.

[0101] This embodiment adopts as image 3 For the implementation of the device shown, the motion control unit uses a four-axis CNC machine tool. The specific implementation steps include:

[0102] (1) Ni-based alloy-WC cermet composite powder is selected as the cladding material, wherein the Ni alloy is Ni60 alloy powder with a particle size of 25 μm to 60 μm, and the WC is cast WC with a particle size of 20 μm to 50 μm. The two are mixed by mechanical mixing. The base material is ordinary low-carbon steel; the workpiece is fixed on the rotary table 11a of the CNC machine tool with a three-jaw chuck 11b, and the area to be clad on the surfac...

Embodiment 3

[0109] In this embodiment, ultra-high-speed laser-induction composite cladding is performed on the inner surface of the tubular hollow part, and the induction coil is installed inside the workpiece. Specifically, a pipe with a diameter of 200 mm and a wall thickness of 10 mm is used as an example for illustration, and it is also applicable to tubular components with other diameters and wall thicknesses.

[0110] This embodiment adopts as Figure 4 For the implementation of the device shown, the motion control unit uses a four-axis CNC machine tool. The specific implementation steps include:

[0111] (1) Select Co-based alloy-WC cermet composite powder as the cladding material, wherein the Co-based alloy is Stellite12 alloy powder with a particle size of 25 μm to 60 μm, and the WC is cast WC with a particle size of 20 μm to 50 μm. The two are mixed by mechanical mixing , the base material is ordinary low-carbon steel; use a three-jaw chuck to fix the workpiece on the CNC machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com