Metal-surface supersonic stress peening method

A metal surface, shot peening technology, applied in the field of metal surface strengthening, can solve the problems of thin strengthening layer thickness, low strengthening efficiency, and no related reports on shot peening of metal materials, etc. , Improve the effect of shot peening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The base material is 316L stainless steel pipe, and the projectile is Al 2 o 3 (The particle size of the projectile is about 150 microns) Use compressed air to carry the projectile, inject gas through the Lava nozzle to accelerate the projectile to 300-1100m / s, and continuously bombard the surface of the metal material to produce a residual compressive stress layer on the metal surface. The process parameters are as follows:

[0016] The spray distance is 70mm, the gas pressure is 3.0MPa, the gas temperature is room temperature, the gas flow rate is 30g / s, the power consumption is 12kW, the shot feeding voltage is 30V, the shot peening time is 6 minutes, and the average thickness of the surface strengthening layer is 75 microns according to X-ray diffraction analysis. about.

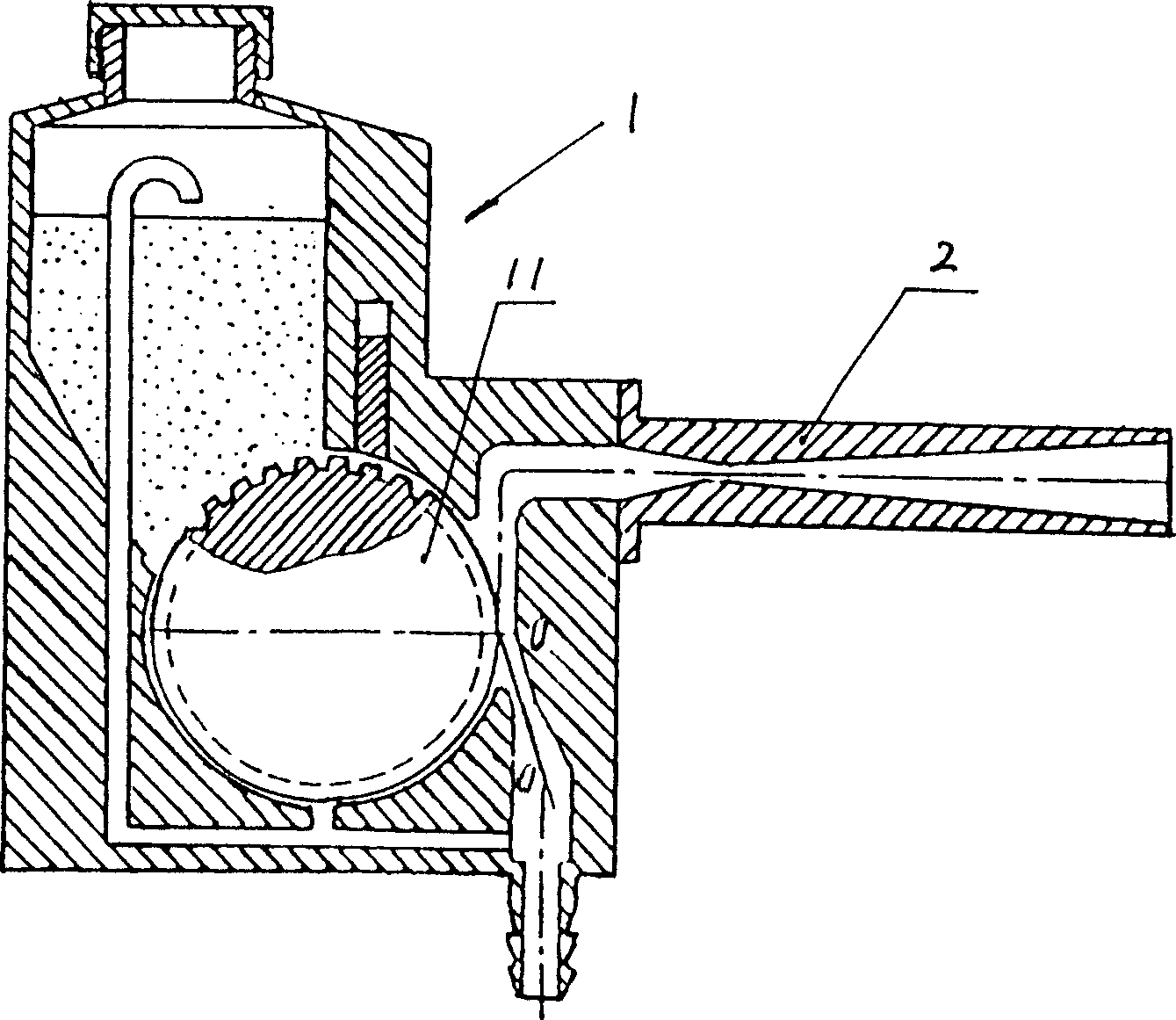

[0017] This embodiment adopts as figure 1 The supersonic spraying device shown is a Russian patent, and the patent numbers are respectively 1674585 (1991), 1603581 (1993), 1618778 (1993), 177307...

Embodiment 2

[0019] The difference from Example 1 is:

[0020] The matrix material is a carbon steel test piece, and the projectile adopts steel shot (about 100 microns), and the process parameters are as follows:

[0021] The spraying distance is 55mm, the gas pressure is 2.5MPa, the gas temperature is room temperature, the gas flow rate is 28g / s, the power consumption is 10kW, the shot feeding voltage is 25V, and the shot peening time is 10 minutes. According to X-ray diffraction analysis, the average thickness of the surface strengthening layer reaches 75 Microns or so.

Embodiment 3

[0023] The difference from Example 1 is:

[0024] The base material is a mold steel test piece, and the projectile uses nylon particles (about 200 microns). The process parameters are as follows:

[0025] The spray distance is 100mm, the gas pressure is 2.2MPa, the gas temperature is room temperature, the gas flow rate is 26g / s, the power consumption is 8kW, the shot feeding voltage is 20V, the shot peening time is 15 minutes, and the average thickness of the surface strengthening layer is 70 microns according to X-ray diffraction analysis. about.

[0026] In addition, the device used in the present invention can also adopt the cold air power spraying device in the Chinese patent application (application number is 01128130.8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com