Method for eliminating re-crystallization tendency of laser 3D printed single-crystal high-temperature alloy

A technology of 3D printing and high-temperature alloys, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of eliminating the tendency of recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

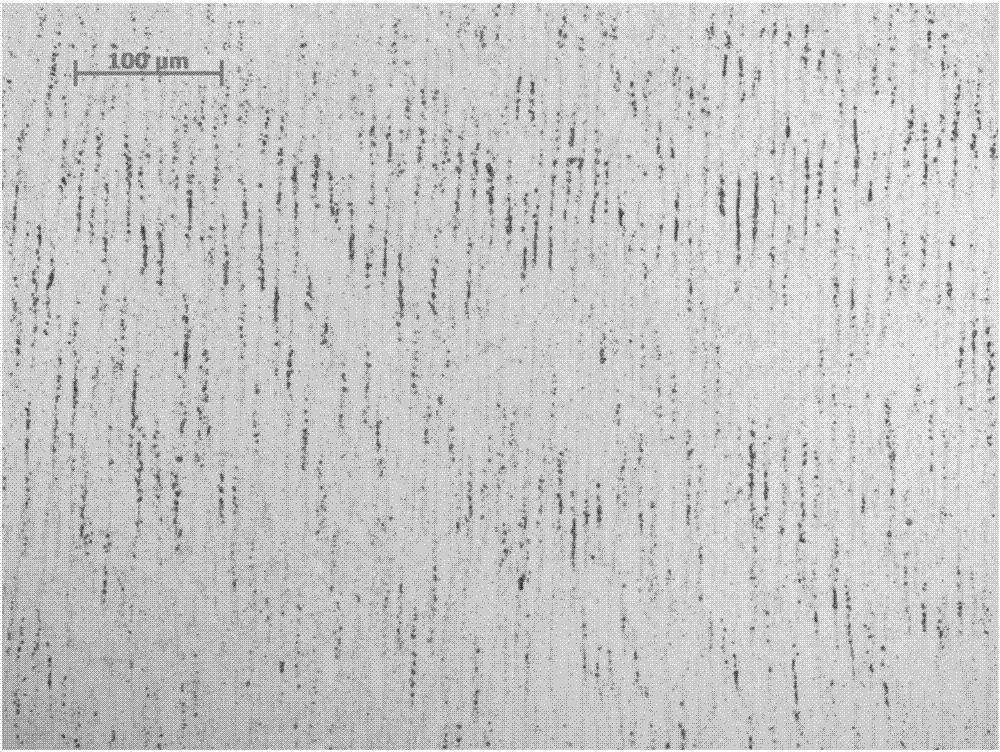

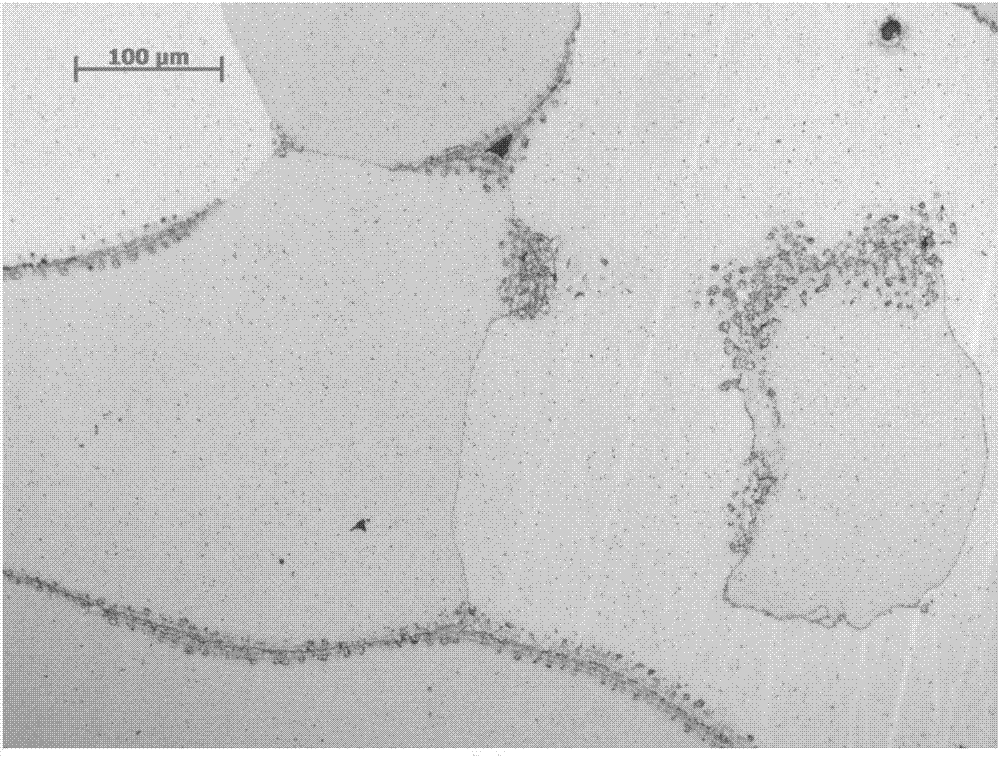

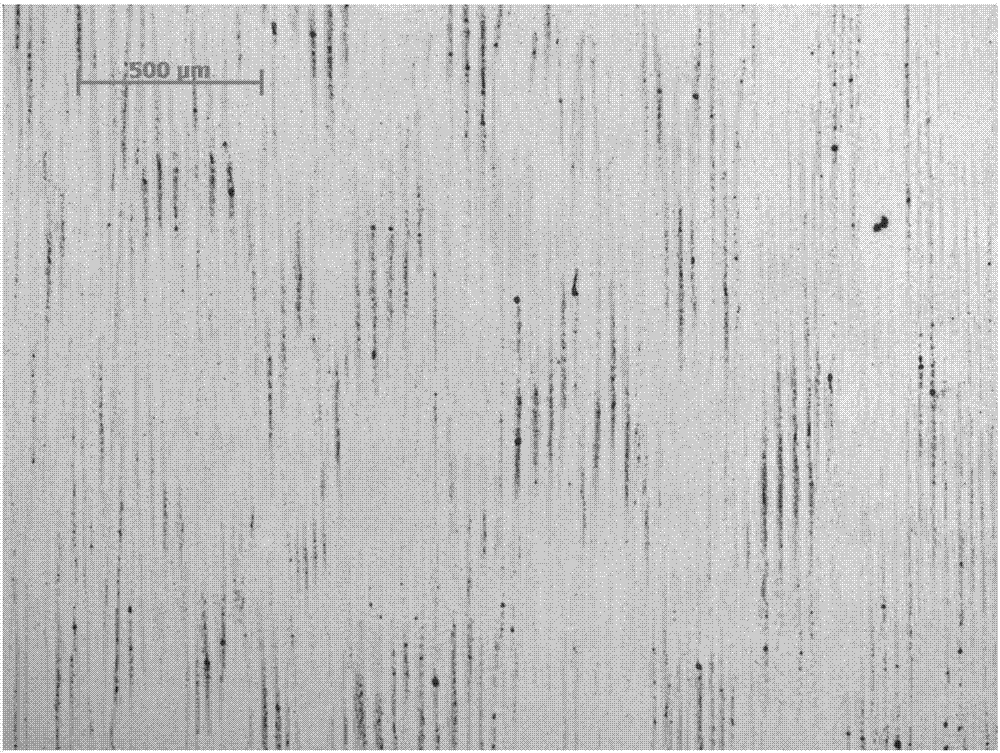

[0054] This example is to eliminate its recrystallization tendency in the process of laser 3D printing superalloy DD499. Laser 3D printing with coaxial powder feeding is performed on a single crystal superalloy substrate with a length of 2 cm × width of 1 cm × height of 1 cm. The surface of the substrate is the crystallographic [001] plane. During the laser forming process, the thickness of the printing layer is lower than the growth height of the dendrites in the [001] direction, and the pass spacing is smaller than the area width of the dendrites in the [001] direction. Print layer thickness and pass spacing to ensure the success of epitaxial growth. The sample uses an in-situ preheating process during the printing process, so that the preheating temperature in the low-temperature area of the sample is higher than 950°C during the printing process, and the temperature gradient in the sample during the printing process is about 150K / cm. Such as image 3 As shown, the dend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com