Patents

Literature

1900 results about "Re crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

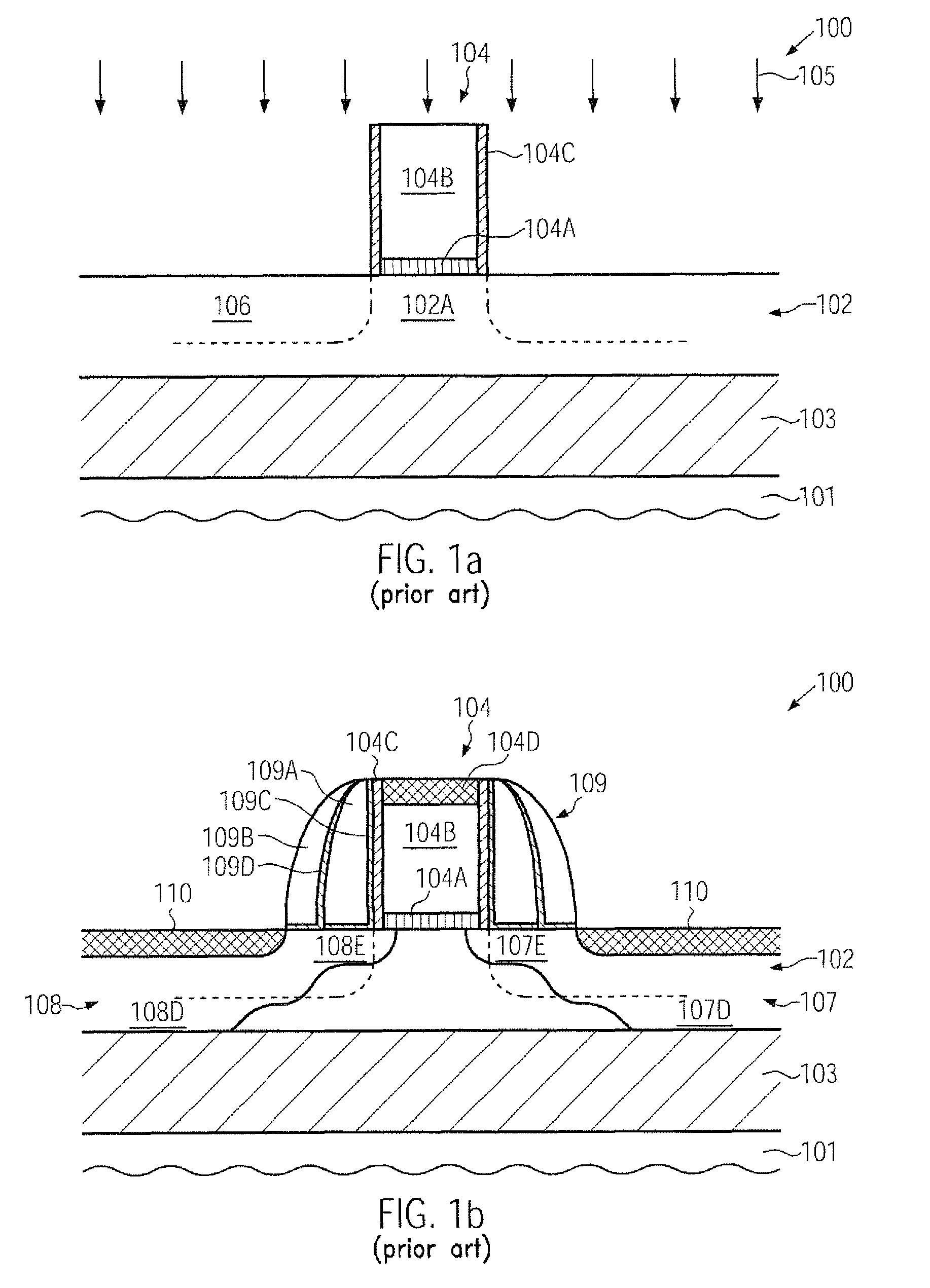

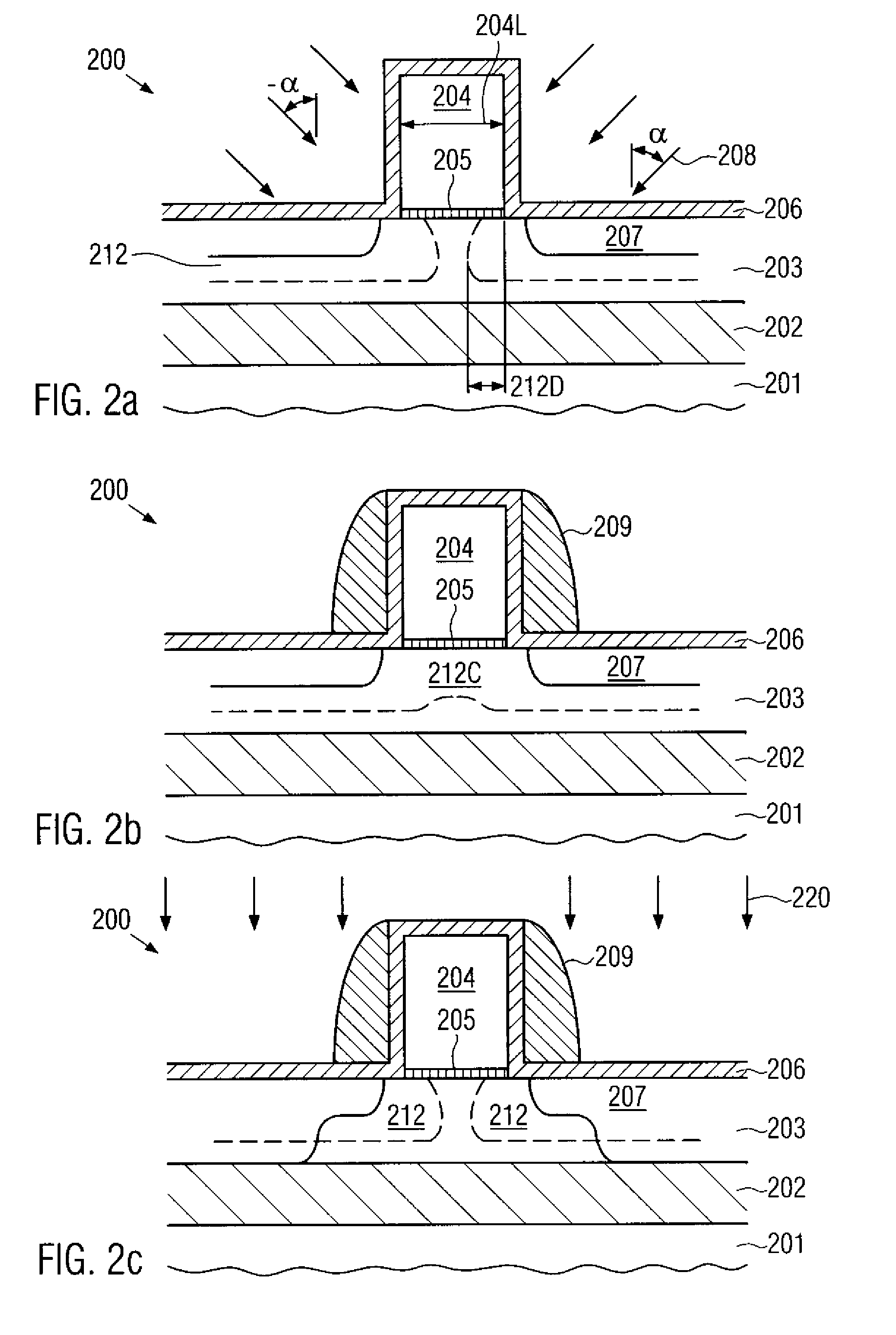

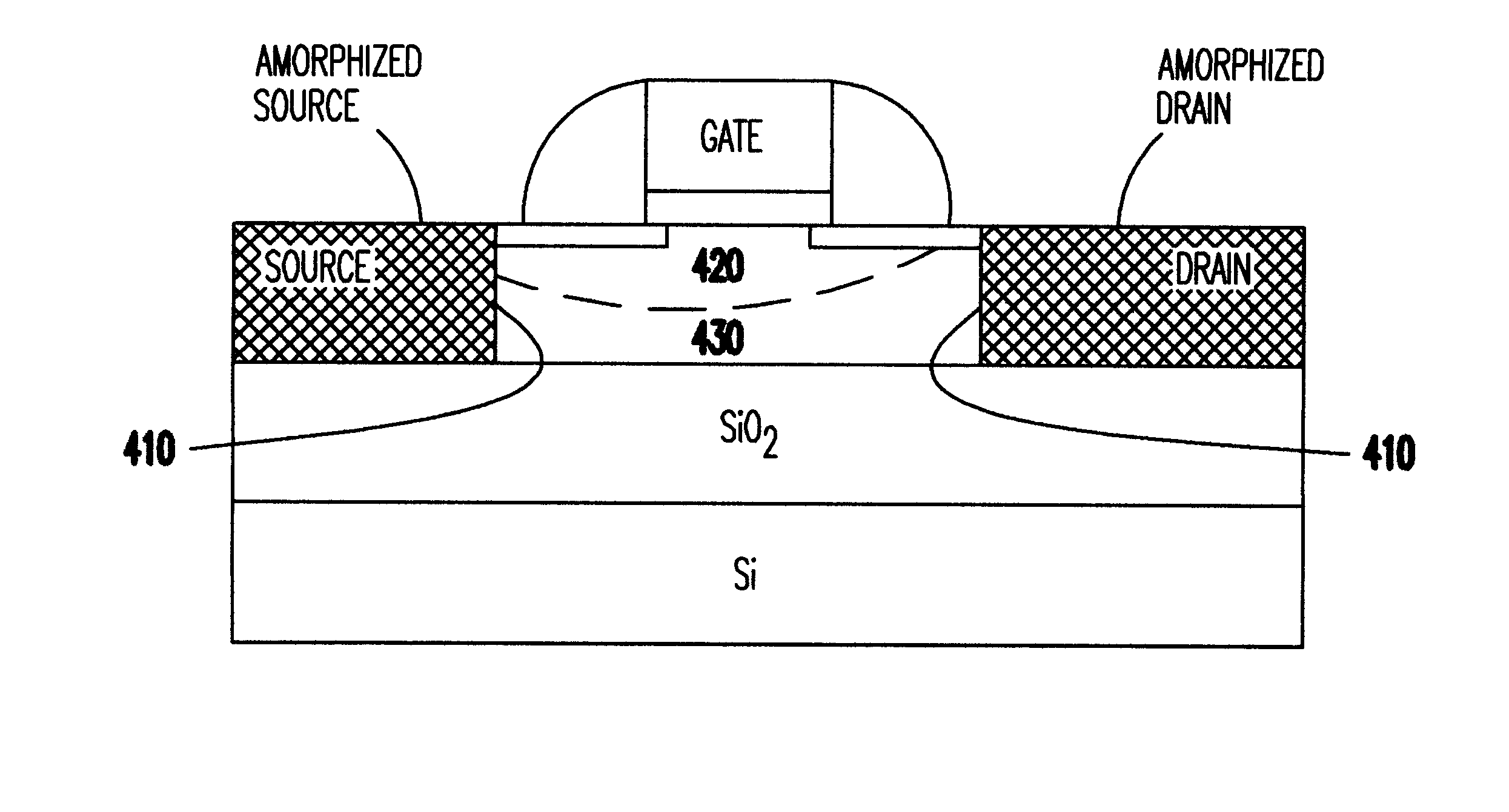

Drive current increase in transistors by asymmetric amorphization implantation

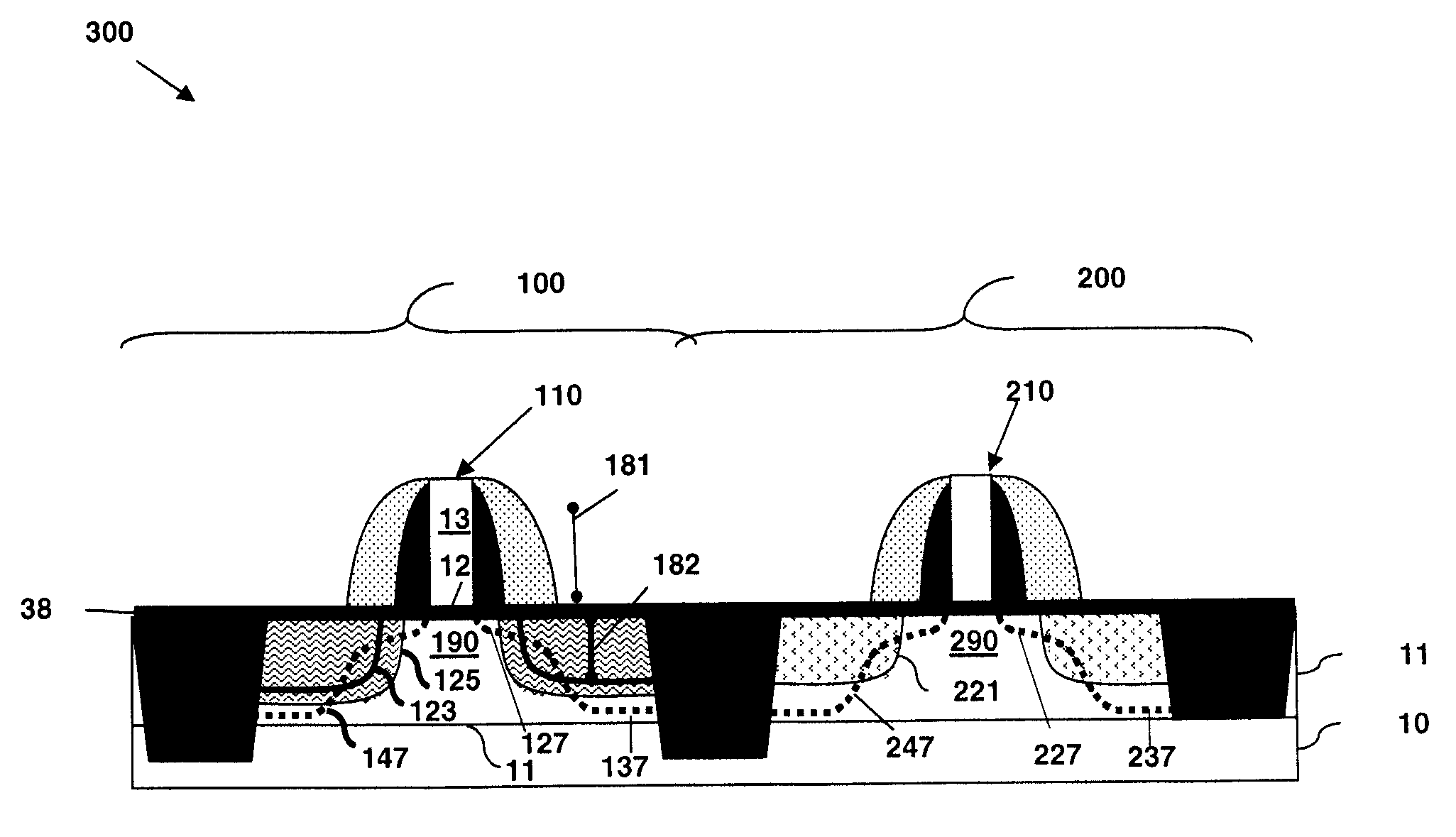

ActiveUS7855118B2Increased complexityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentNon symmetric

By providing a substantially non-damaged semiconductor region between a pre-amorphization region and the gate electrode structure, an increase of series resistance at the drain side during the re-crystallization may be reduced, thereby contributing to overall transistor performance, in particular in the linear operating mode. Thus, symmetric and asymmetric transistor architectures may be achieved with enhanced performance without unduly adding to overall process complexity.

Owner:ADVANCED MICRO DEVICES INC

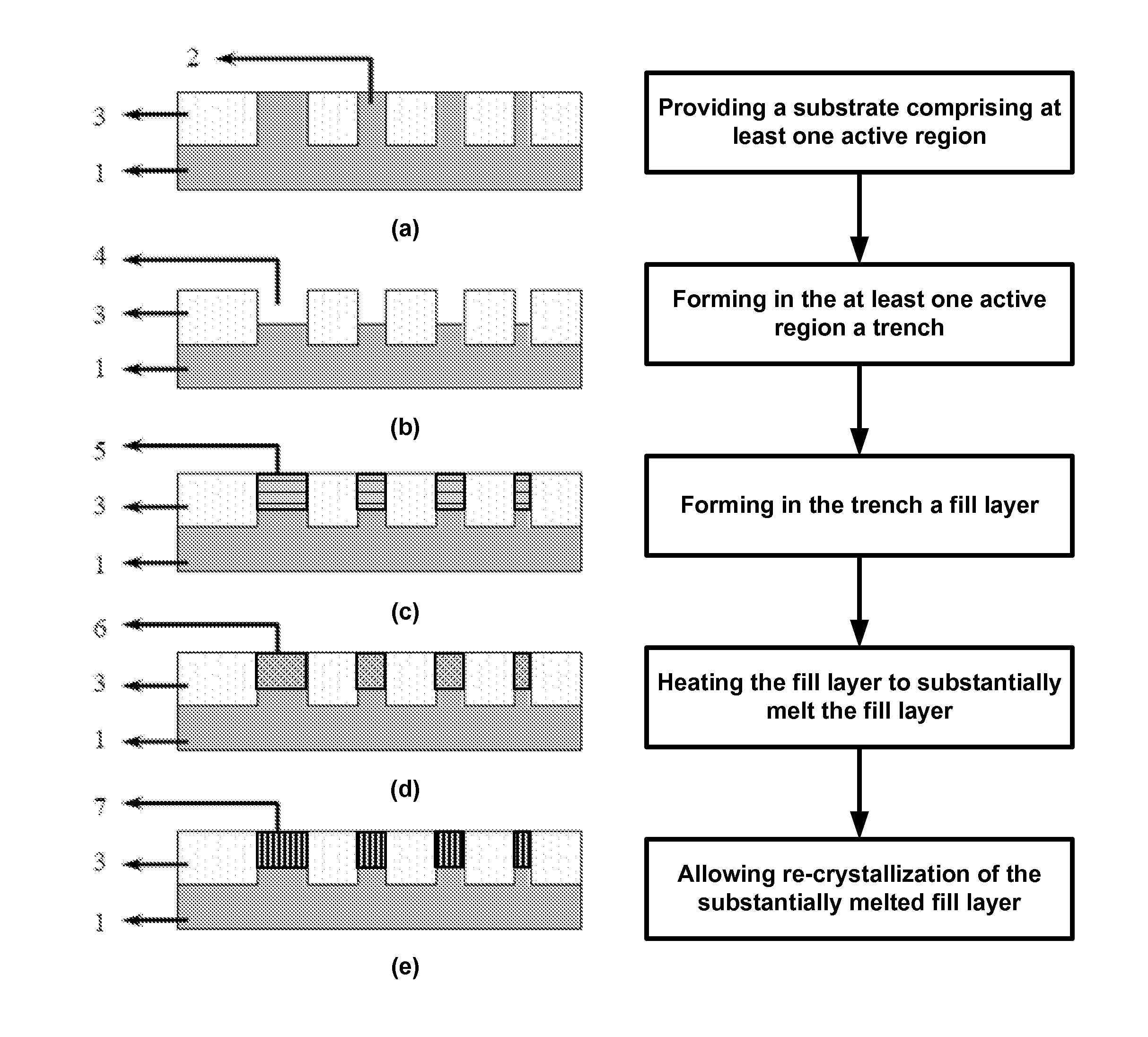

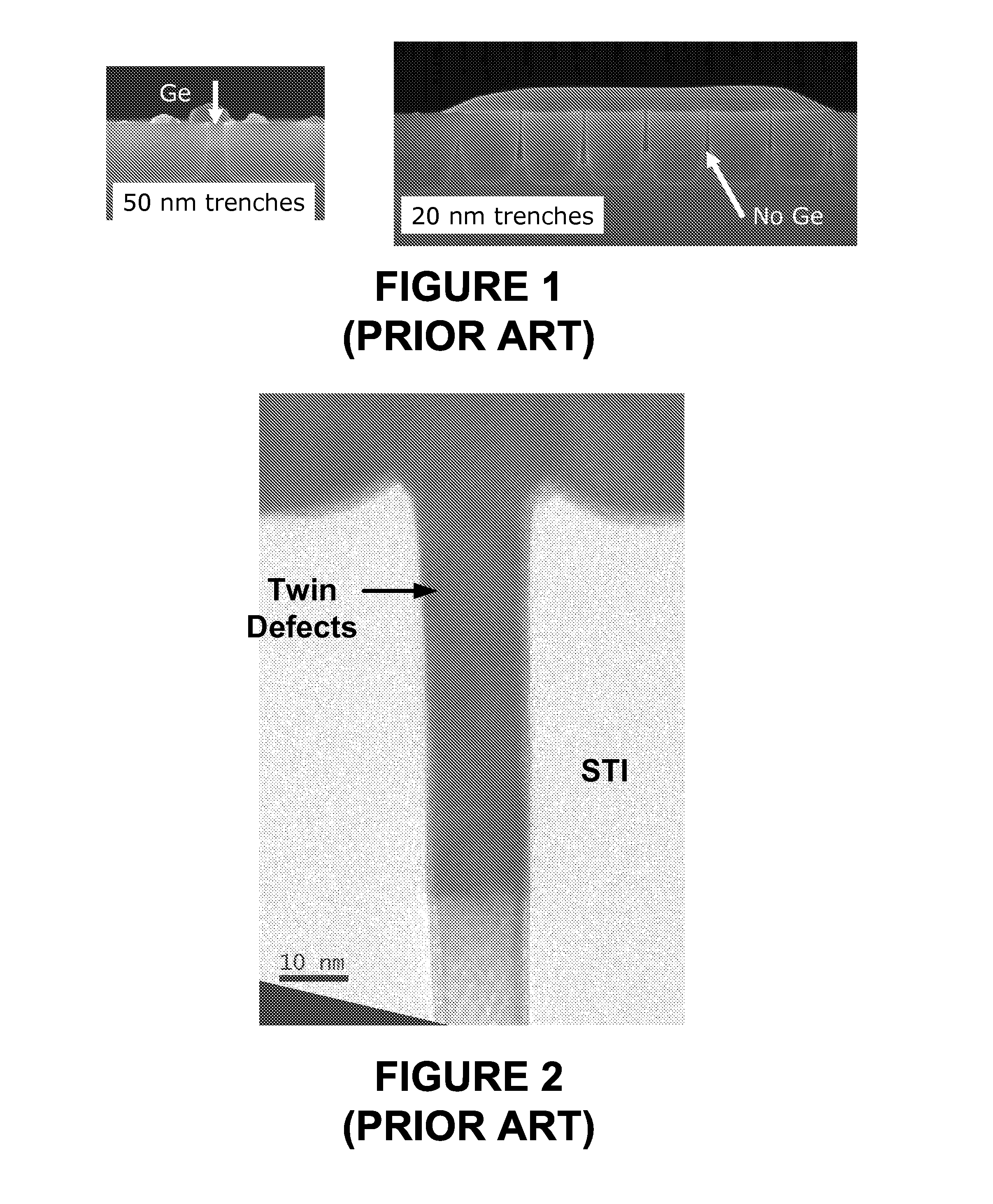

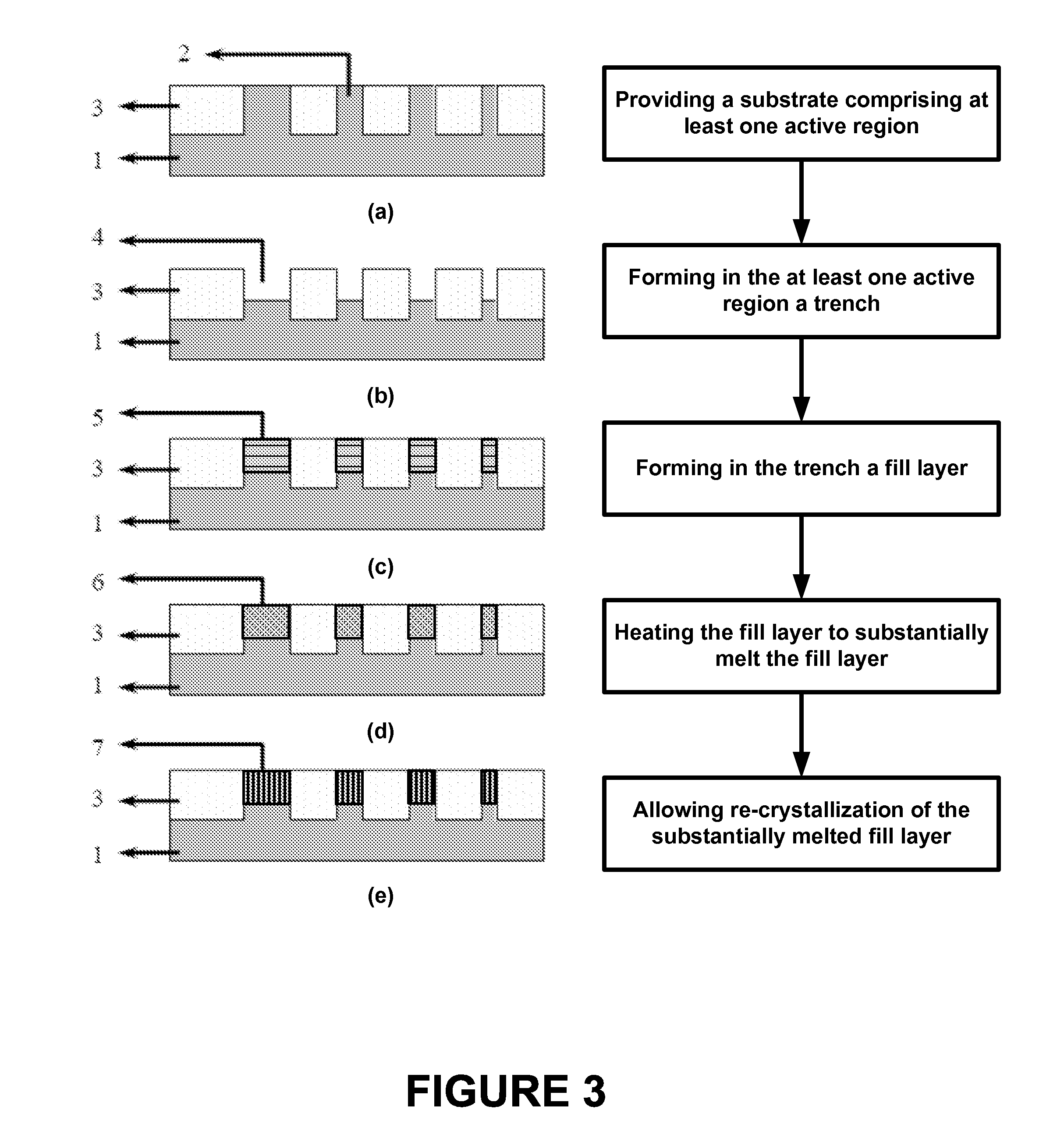

Method of Forming Mono-Crystalline Germanium or Silicon Germanium

InactiveUS20110097881A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalOptoelectronics

A method is presented for forming mono-crystalline germanium or silicon germanium in a trench. In an embodiment, the method comprises providing a substrate comprising at least one active region that is adjacent to two insulating regions, forming in the active region a trench having a width of less than 100 nm, and forming in the trench a fill layer at a temperature of less than 450° C. that comprises germanium or silicon germanium and substantially fills the trench. The method further comprises heating the fill layer to a temperature sufficient to substantially melt the fill layer and allowing re-crystallization of the substantially melted fill layer, thereby forming mono-crystalline germanium or silicon germanium in the trench. In an embodiment, the method further comprises forming a mono-crystalline germanium or silicon germanium fin by removing at least a portion of the insulating regions. The mono-crystalline fin may be comprised in a fin field-effect-transistor (finFET).

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

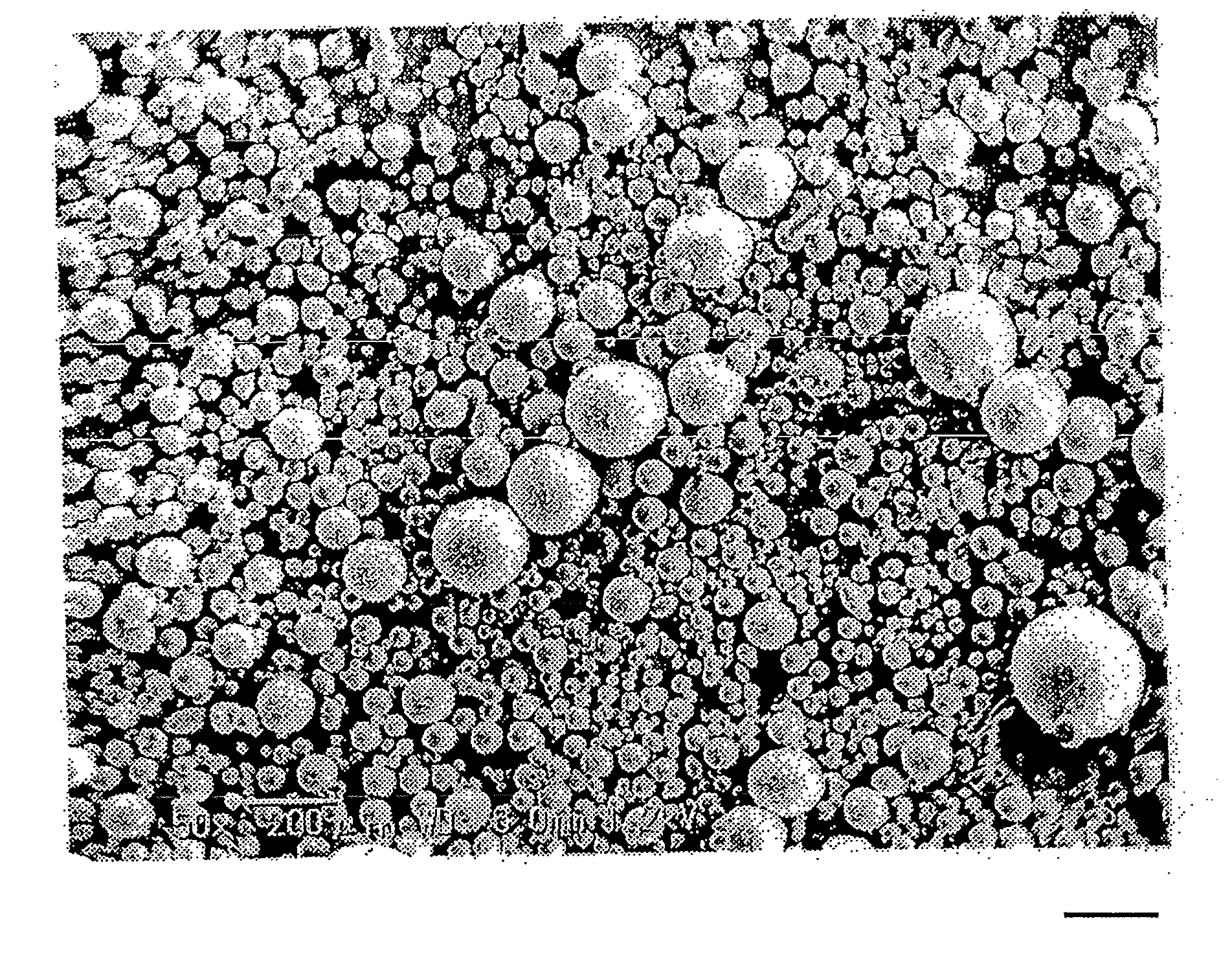

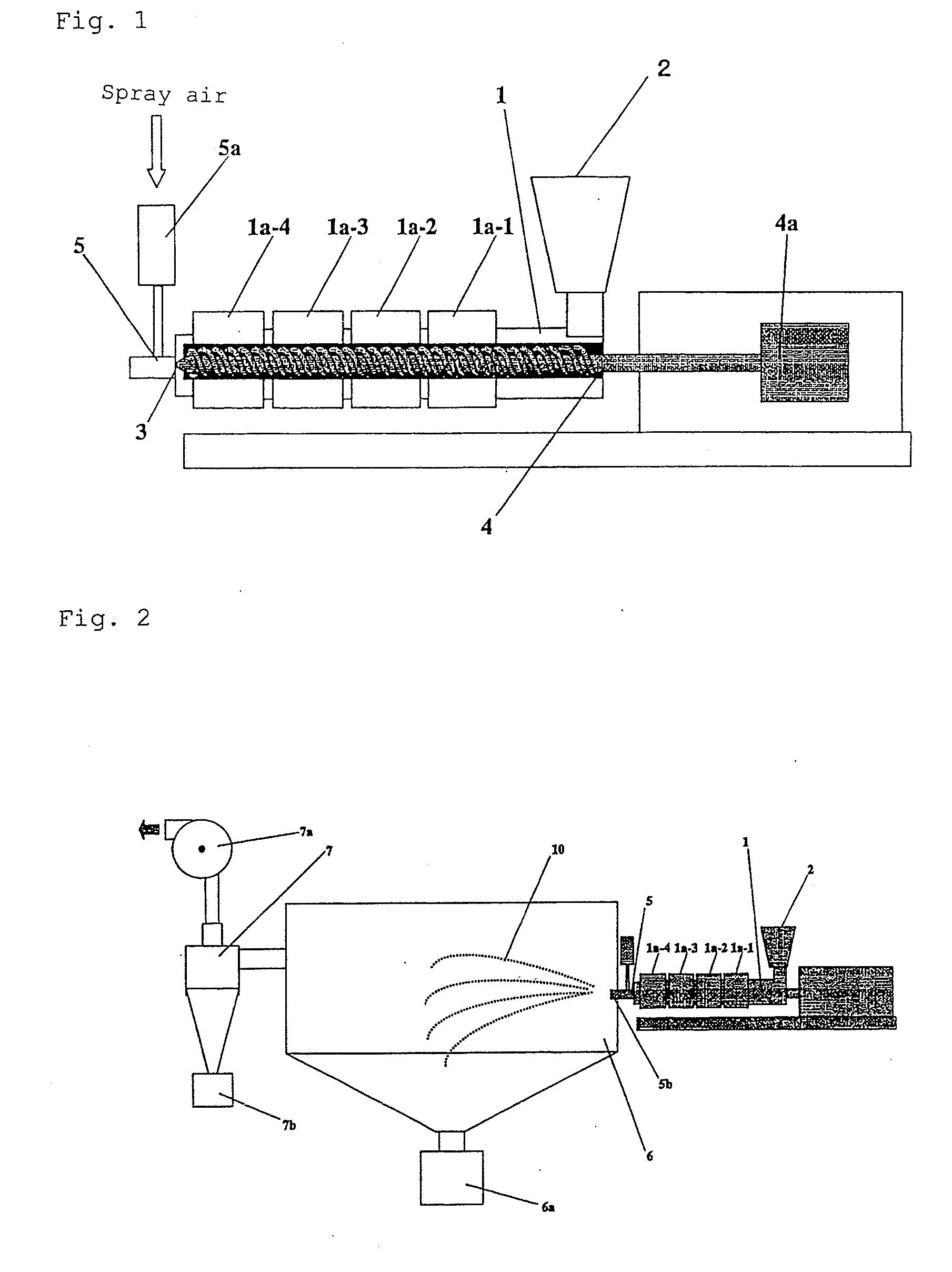

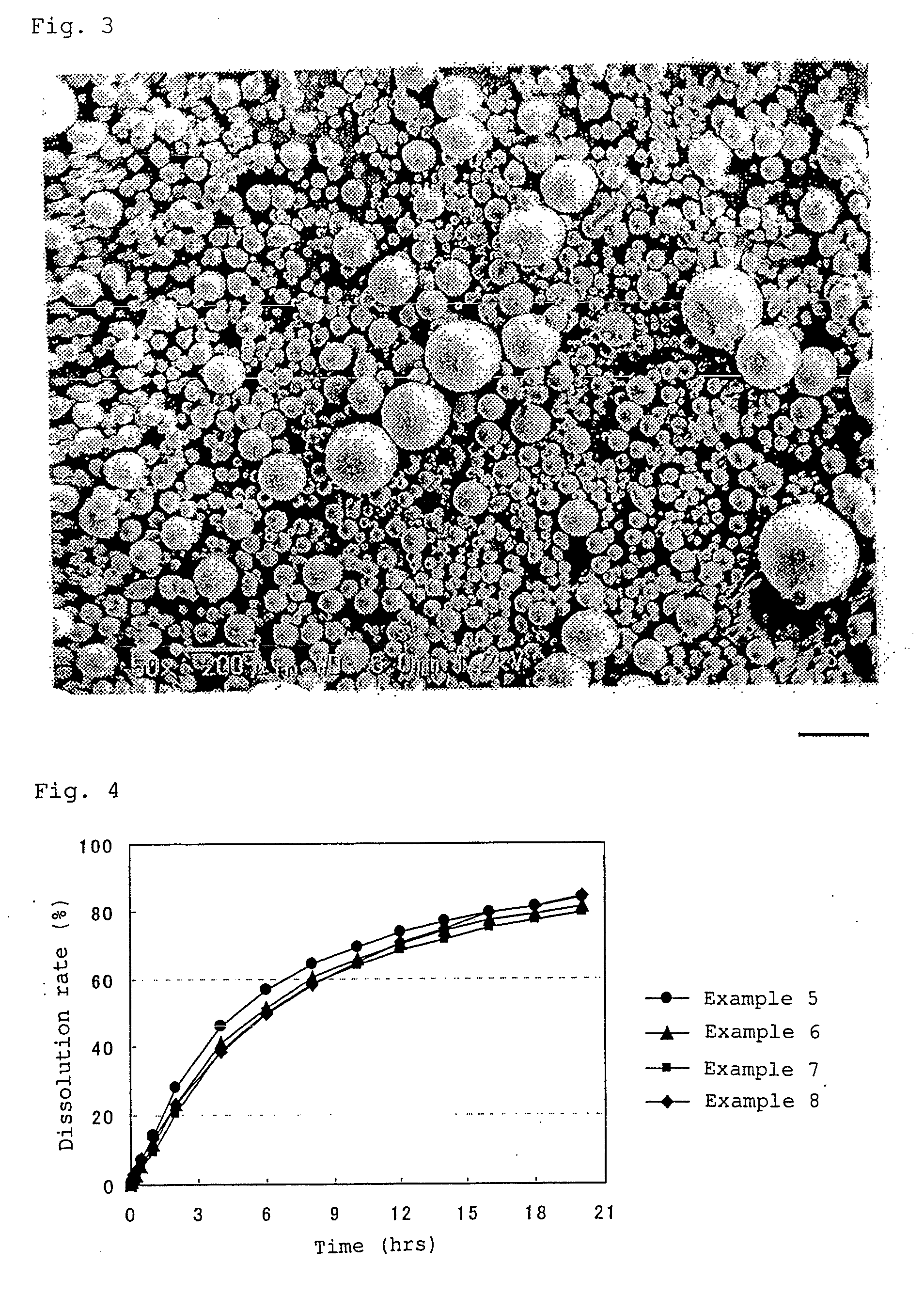

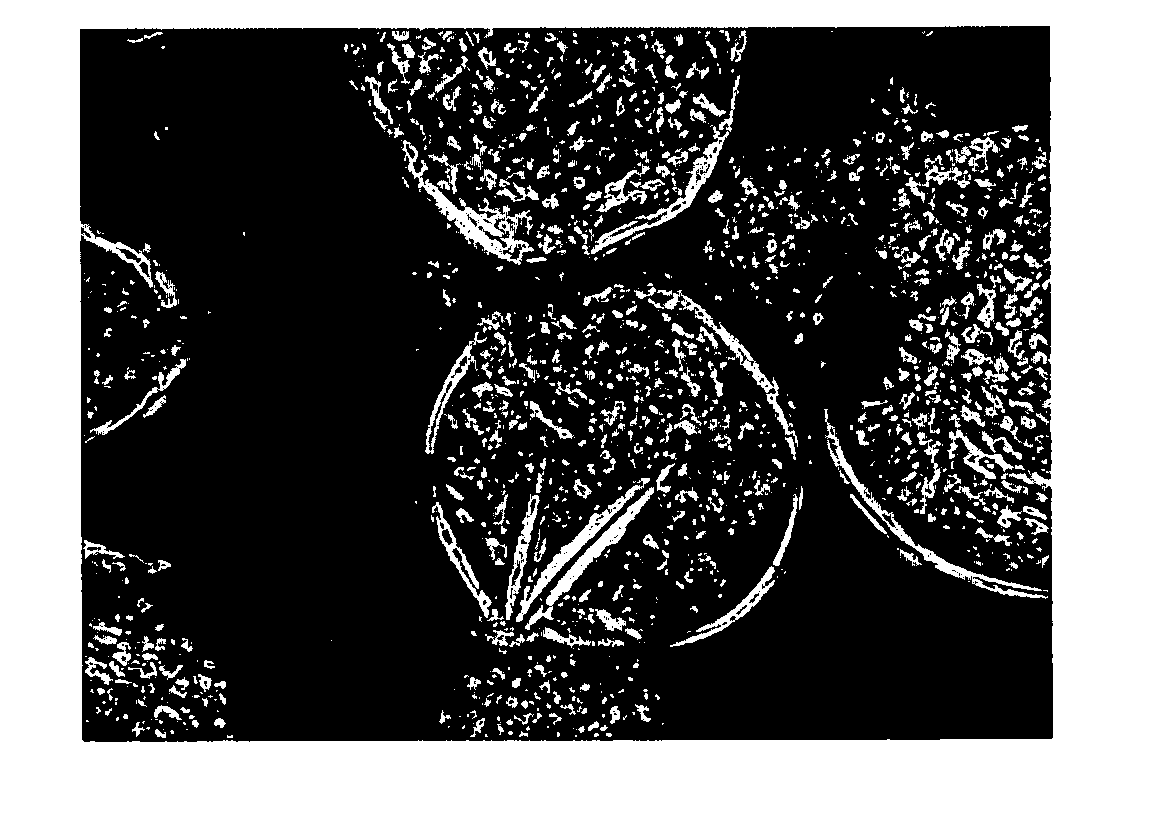

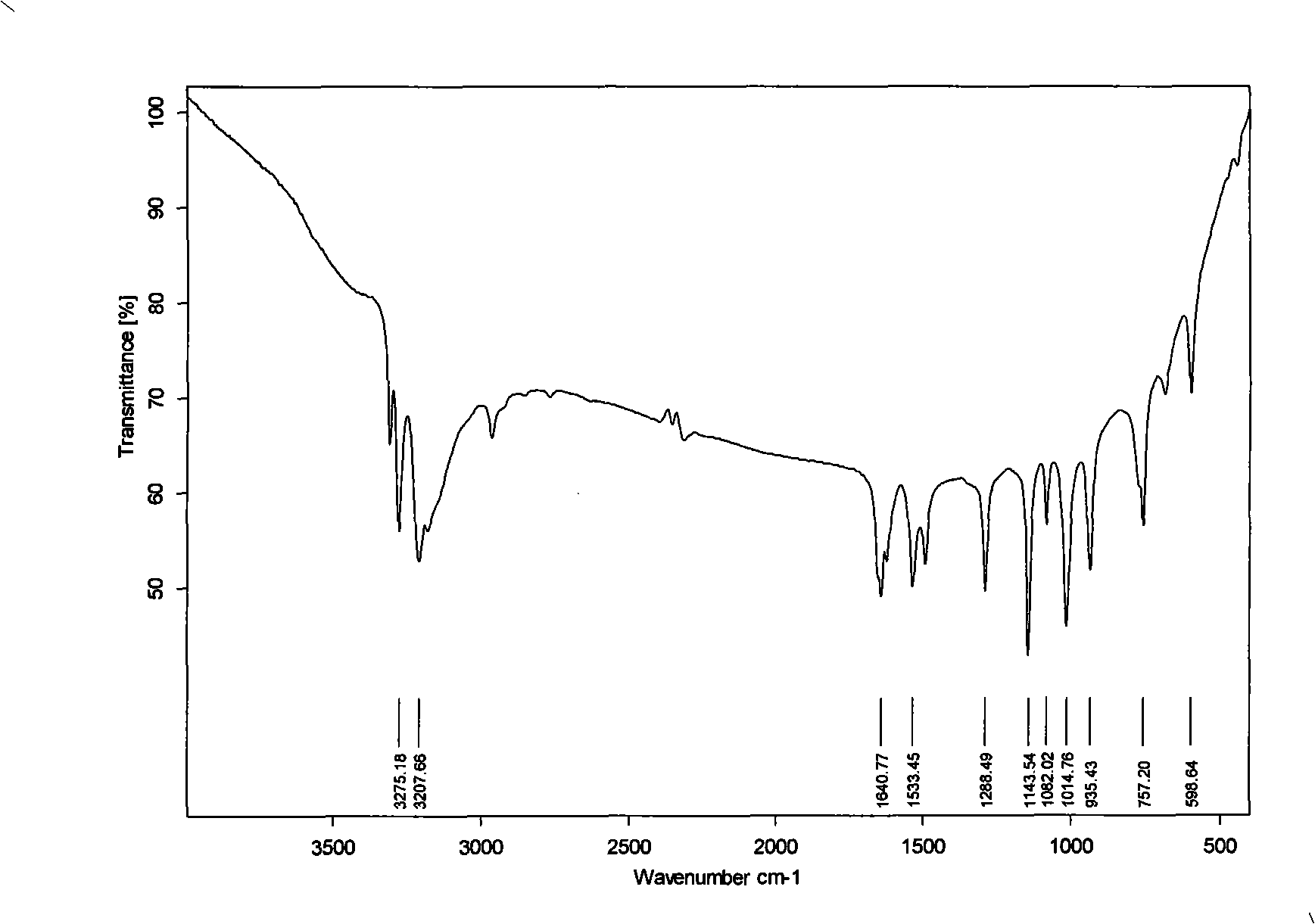

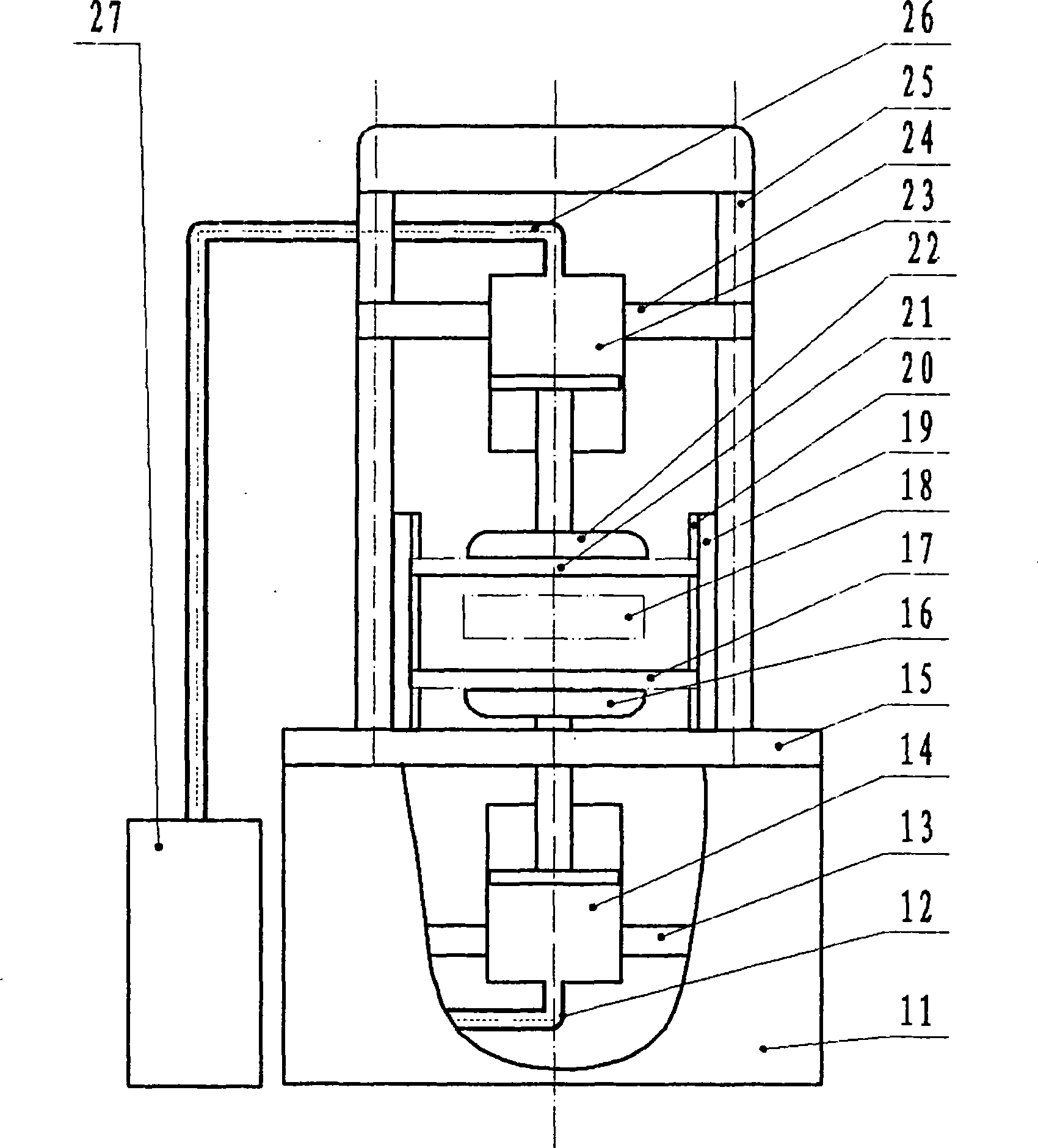

Method of producing drug-containing wax matrix particles, extruder to be used in the method and sustained-release preparation containing cilostazol

InactiveUS20090047357A1Easy to produceSolve low usagePowder deliveryBiocideSpray nozzleSustained-Release Preparations

The present invention aims to provide a method for producing, by a simple method, drug-containing wax matrix granules, particularly drug-containing wax matrix granules having an average particle diameter of 1 mm or lower, while avoiding liquid blockage due to the recrystallization of a molten drug during the period from a melting step to a spray step.Drug-containing wax matrix granules having at least one wax and at least one drug are produced by the following steps (i) and (ii): (i) supplying the at least one drug and the at least one wax to an extruder in which the temperature of a barrel and the temperature of a die are adjusted to be higher than the melting point of the at least one wax; and (ii) while melting and kneading the at least one drug and the at least one wax in the extruder to give a molten kneaded drug and wax, spraying the molten kneaded drug and wax into an atmosphere having a temperature lower than the melting point of the wax from a spray nozzle directly mounted onto a die provided at a top end of the barrel of the extruder, thereby forming the mixture into granules.

Owner:OTSUKA PHARM CO LTD

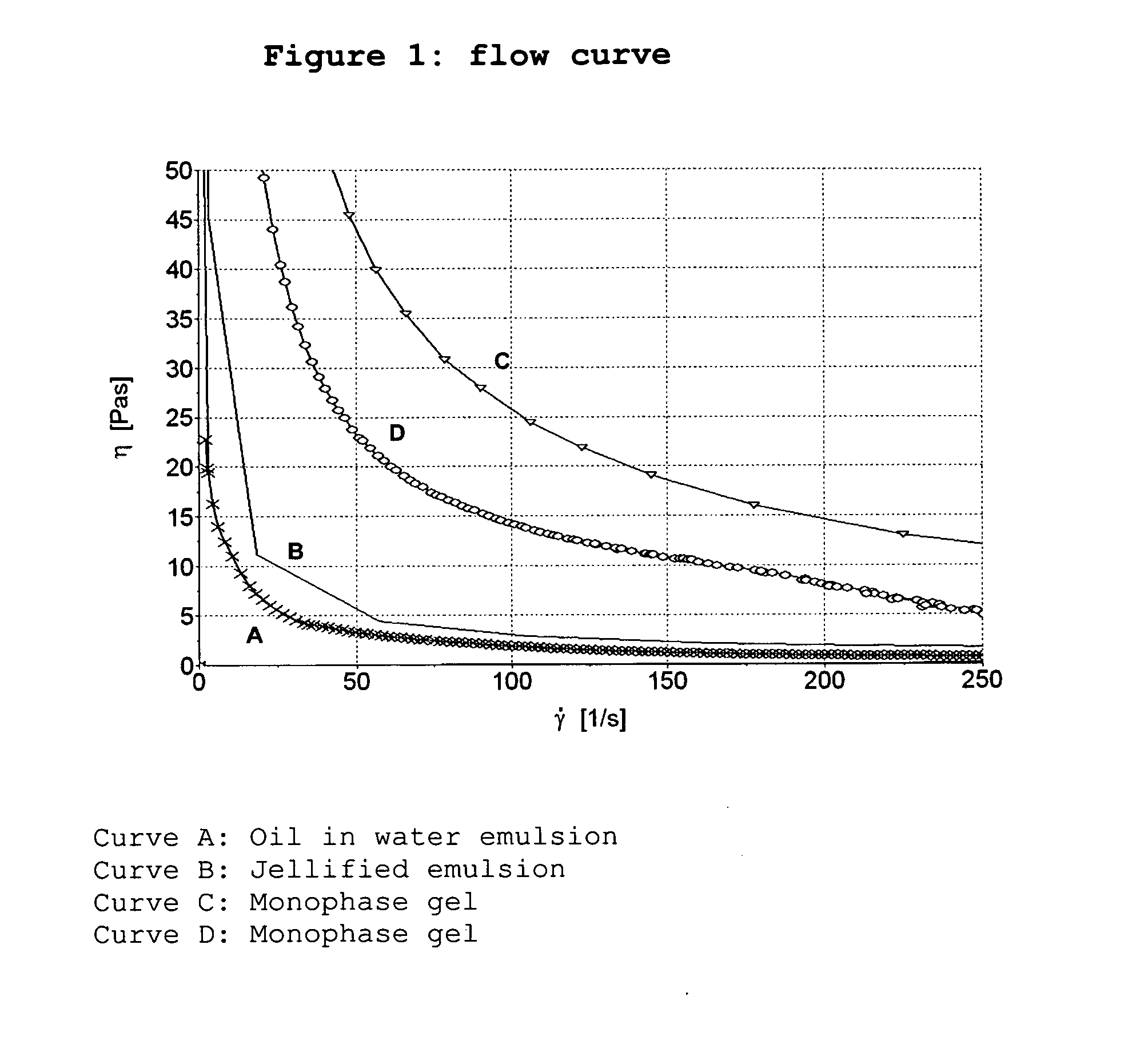

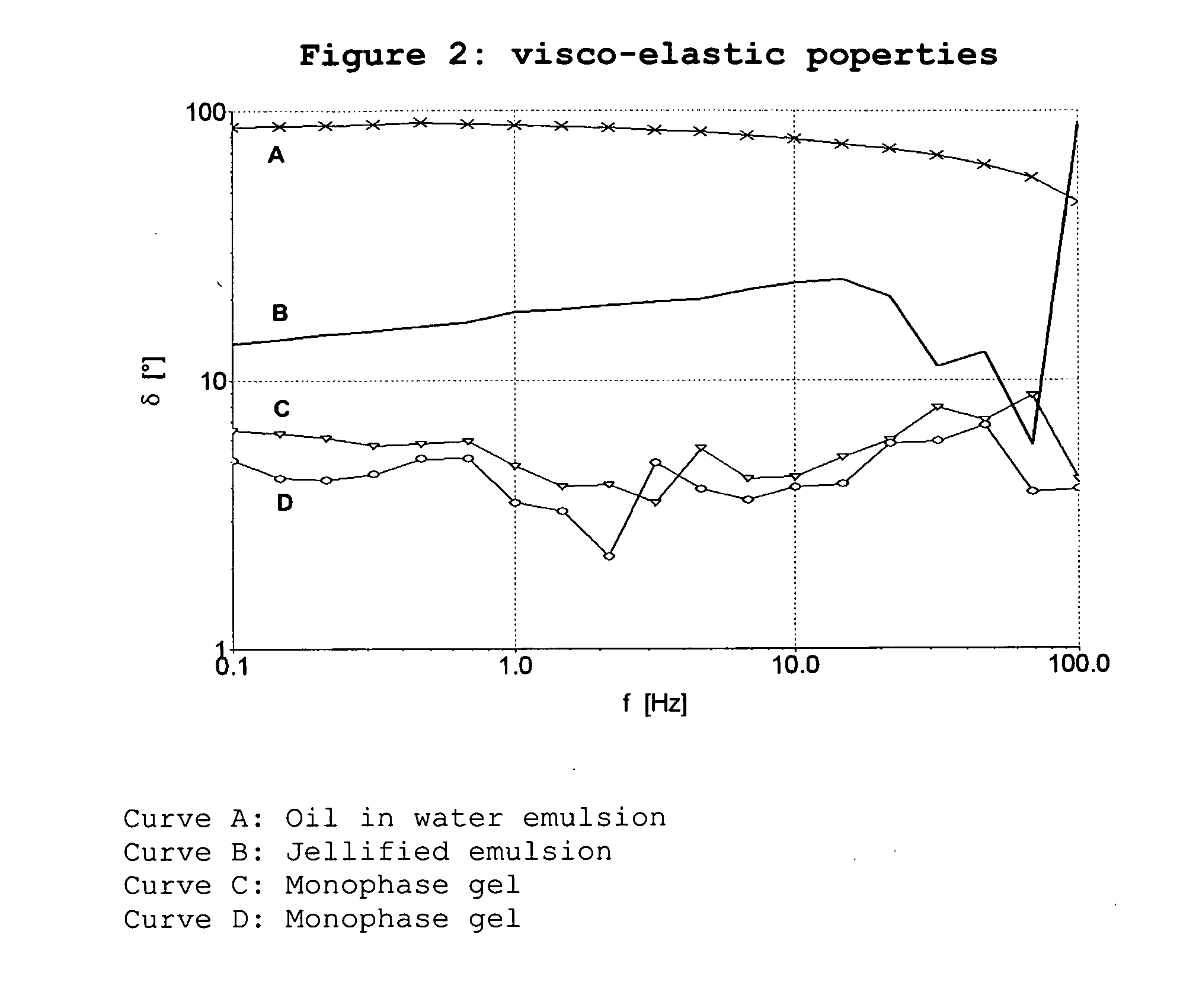

Modified release emulsions for application to skin or vaginal mucosa

Modified release oil in water emulsions that delivers drugs to a target tissue. The emulsions according to the present invention contain the lipophilic active ingredient completely dissolved into the hydrophobic internal phase stabilised by a polymeric surfactant. The presence of this polymer around the hydrophobic droplets avoids the migration of the active ingredient into the external hydrophilic phase and, consequently, its re-crystallization.

Owner:POLICHEM SA

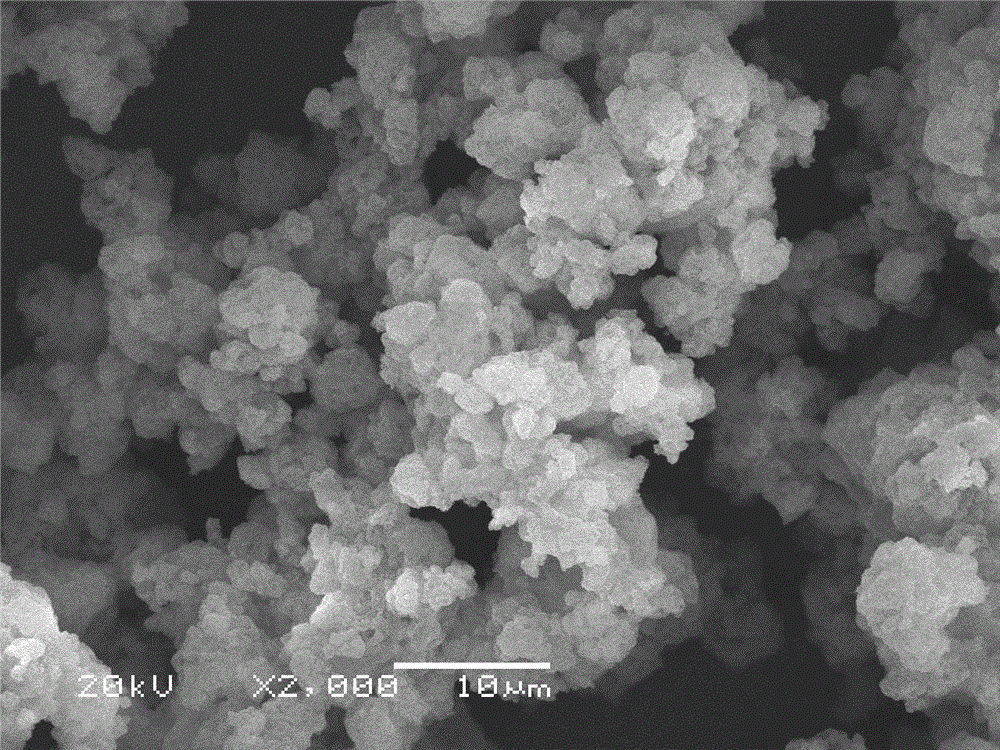

Method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum

The invention provides a method for preparing alpha semi-hydrated gypsum by utilizing desulfurized gypsum, comprising the technological steps of purification, crystal transforming reaction, oriented crystallization, washing and separation, and drying and pulverization. The method concretely comprises the following steps of: enhancing the taste of calcium sulfate dlhy in the desulfurized gypsum to be greater than 95% through a purification treatment; dissolving and recrystallizing the desulfurized gypsum at 70 to 98 DEG C under the normal pressure through adding prepared habit modifiers, transforming into the alpha semi-hydrated gypsum and then carrying out oriented crystallization on the alpha semi-hydrated gypsum to form a short column-shaped alpha semi-hydrated gypsum crystal under the function of an oriented crystal type stabilizer, wherein the length-diameter ratio of the short column-shaped alpha semi-hydrated gypsum crystal is less than 1:3, the 2h breaking strength is greater than 6.5 MPa, the compression strength is greater than 23 MPa, the dry breaking strength is greater than 25 MPa, and the dry compression strength is greater than 53 MPa. The method can be widely used in the fields of ceramics, automobiles, precise casting, heterogenic casting and the like.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

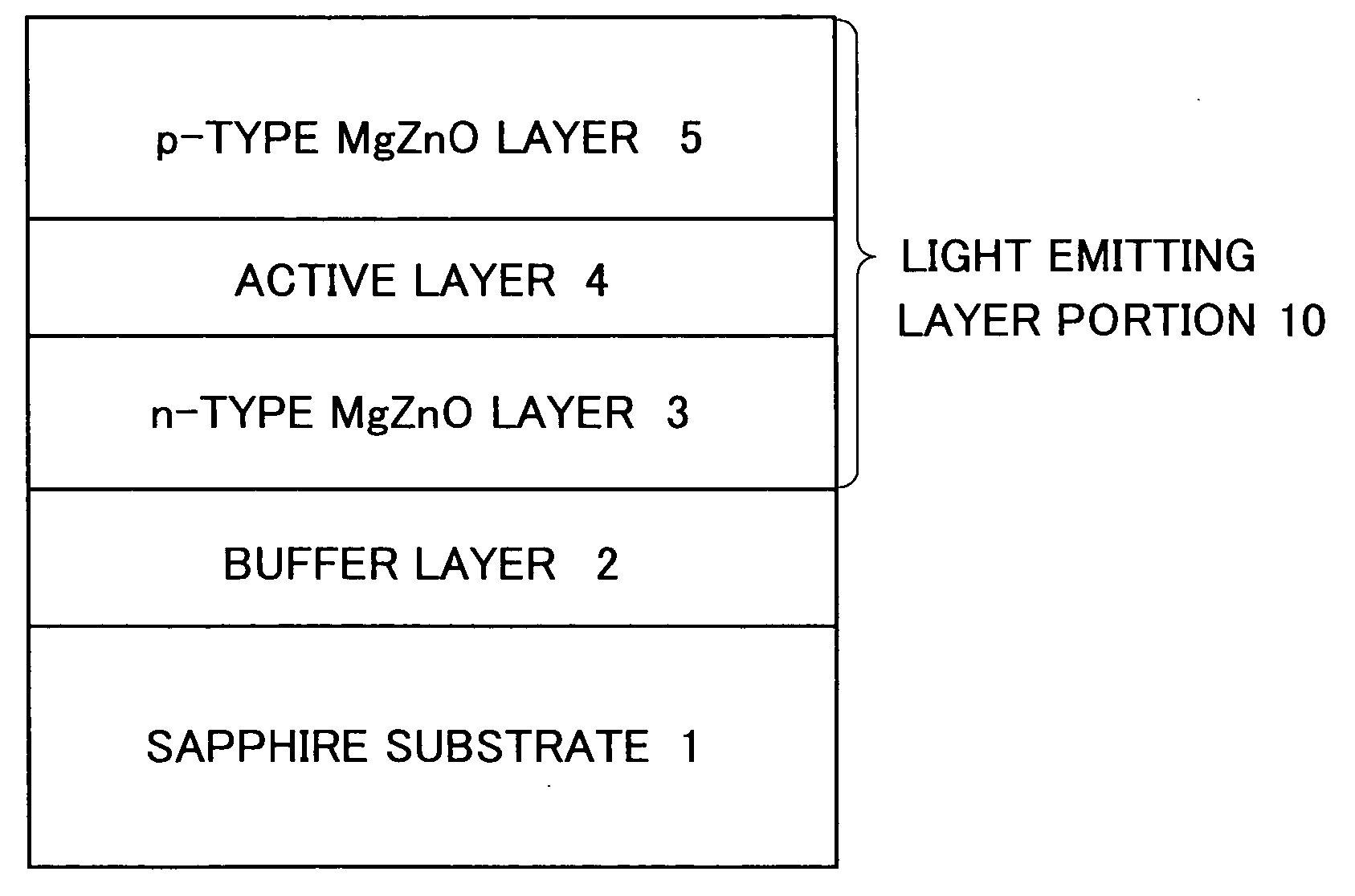

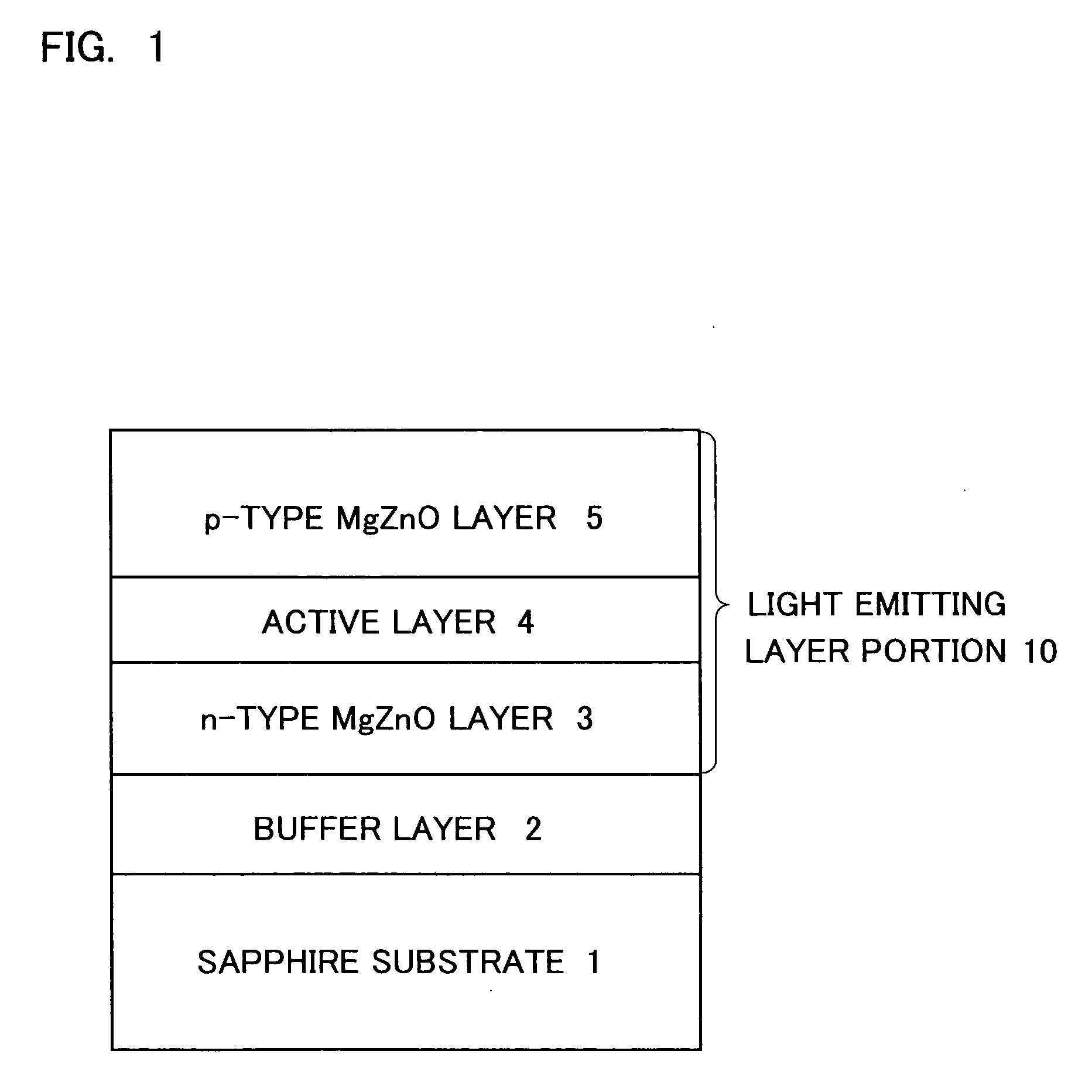

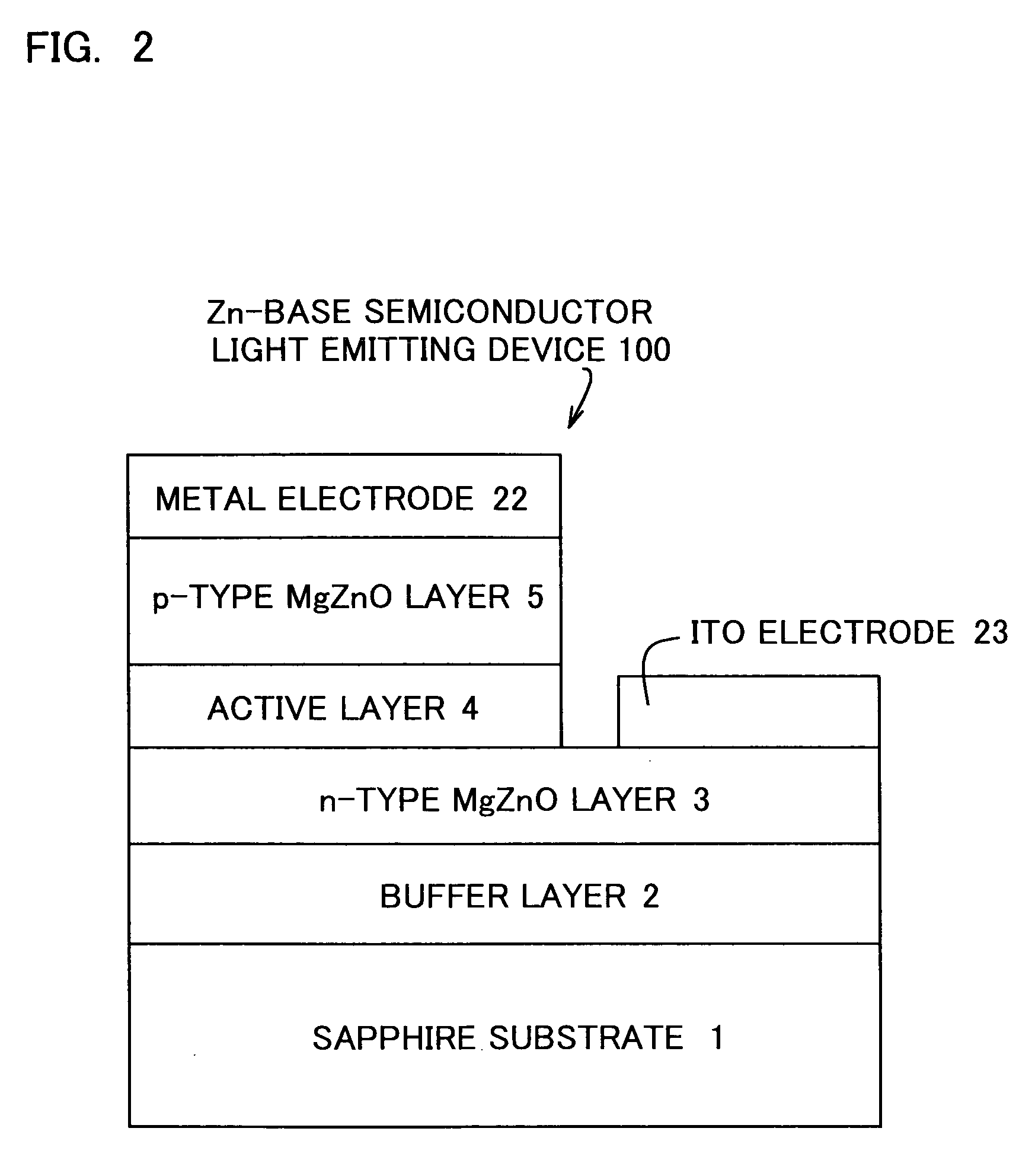

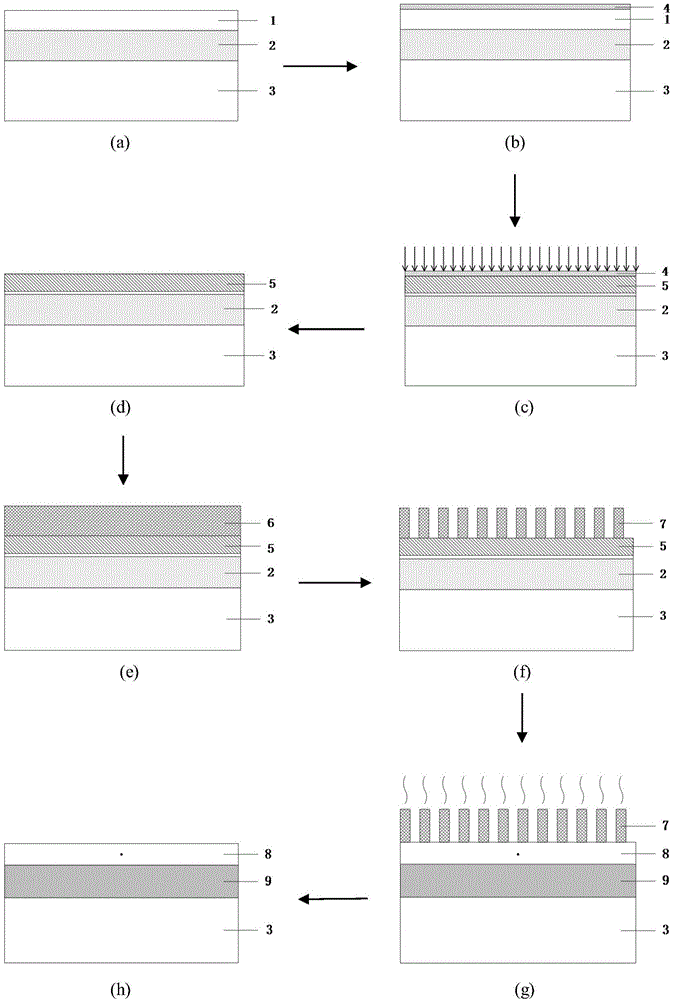

Semiconductor light-emitting device and method for manufacturing same

InactiveUS20050017261A1Quality improvementConvenient lightingSemiconductor/solid-state device manufacturingSemiconductor devicesLight emitting deviceSemiconductor

On the surface of a substrate 1, a precursory buffer layer 2′ composed of an In-base compound or a Zn-base compound, not contained in the substrate 1, is formed so as to be stacked thereon as a polycrystal layer or an amorphous layer. Before a light emitting region is formed, the precursory buffer layer 2′ is annealed for re-crystallization to thereby convert it into a buffer layer 2. This successfully provides a Zn-base semiconductor light emitting device which can readily be fabricated and capable of improving quality of the light emitting region, and a method of fabricating the same.

Owner:SHIN-ETSU HANDOTAI CO LTD

Polymorphs of abiraterone acetate and preparation method thereof

The invention discloses polymorphs A, B, C and D of abiraterone acetate. A preparation method of the polymorphs comprises the step of re-crystallizing the abiraterone acetate subjected to the separation and the purification of a chromatographic column in different solvents. Through stable investigation, four polymorphs have favorable stability and flowability, can be used as raw materials for storage and transportation and are suitably applied to antitumor medicinal preparations.

Owner:深圳万乐药业有限公司

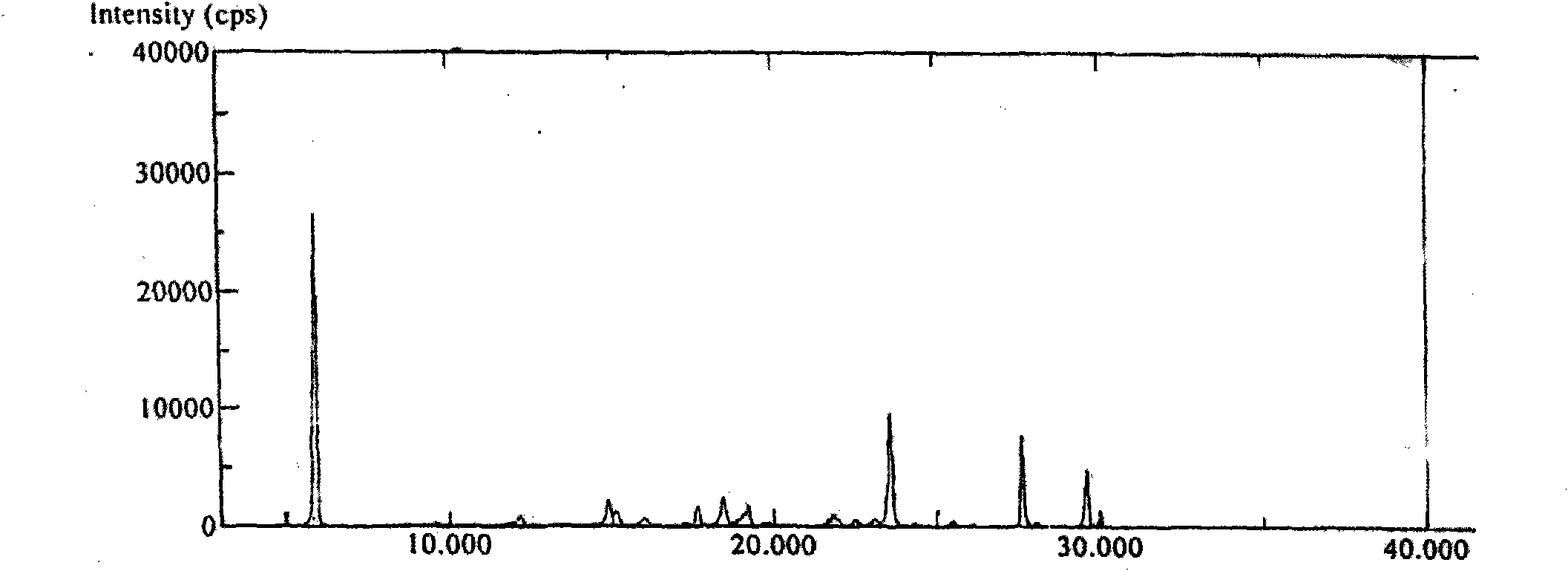

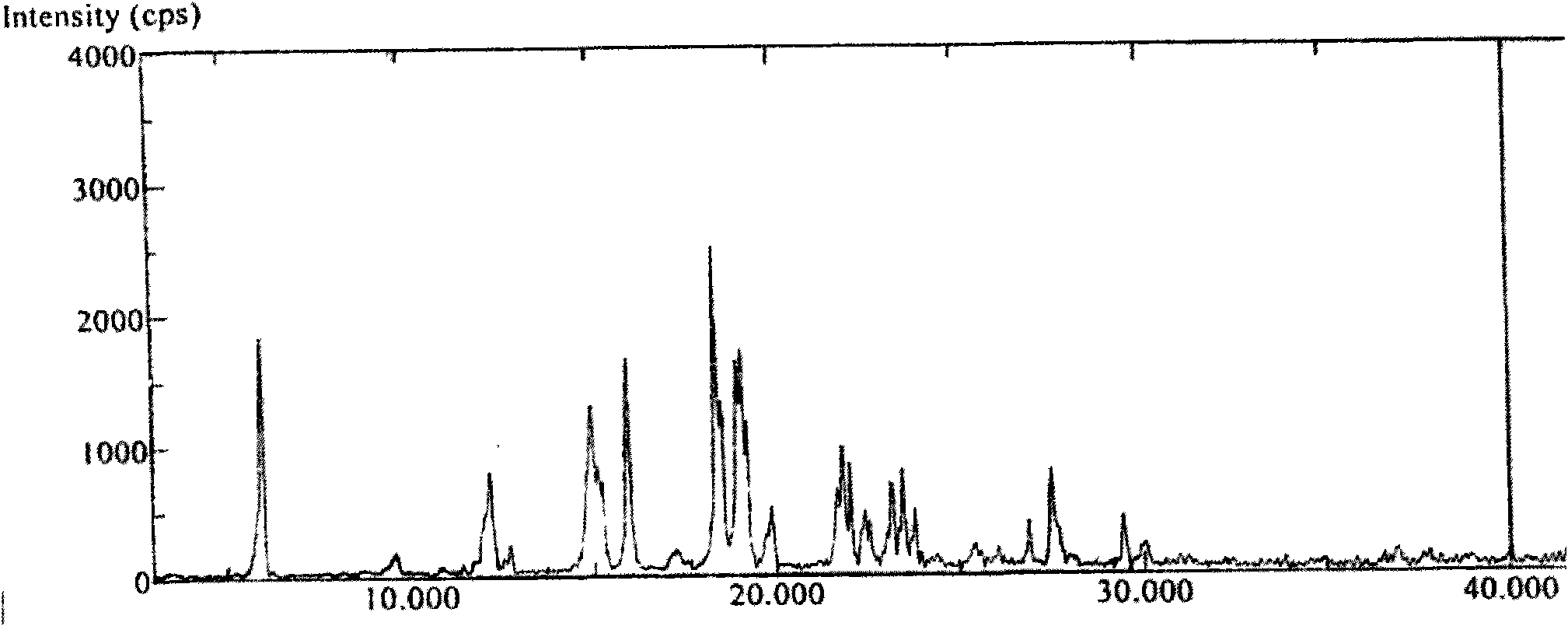

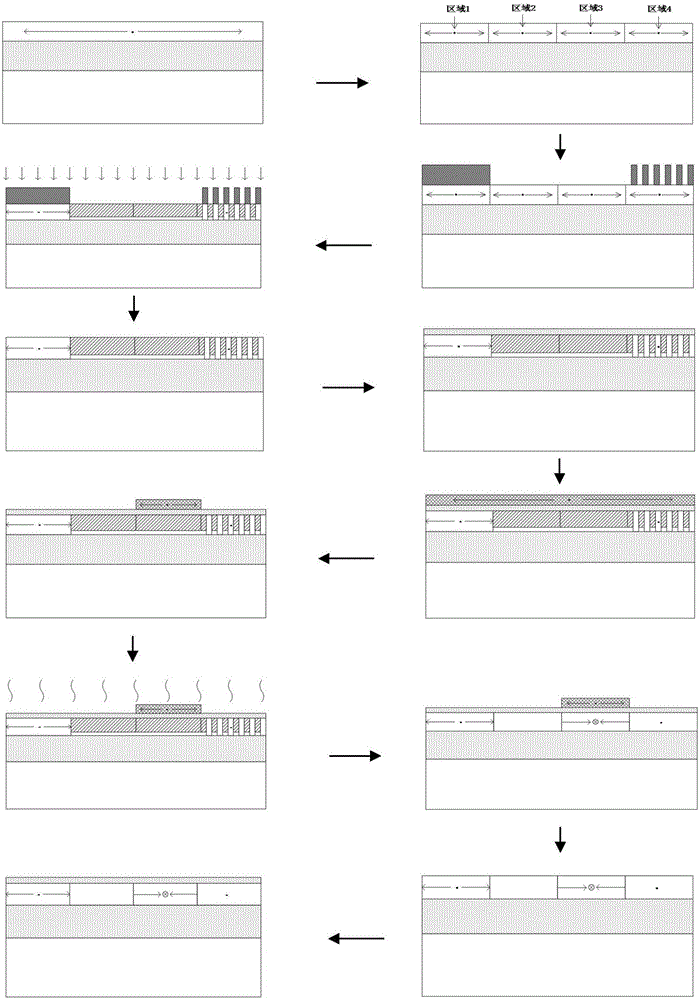

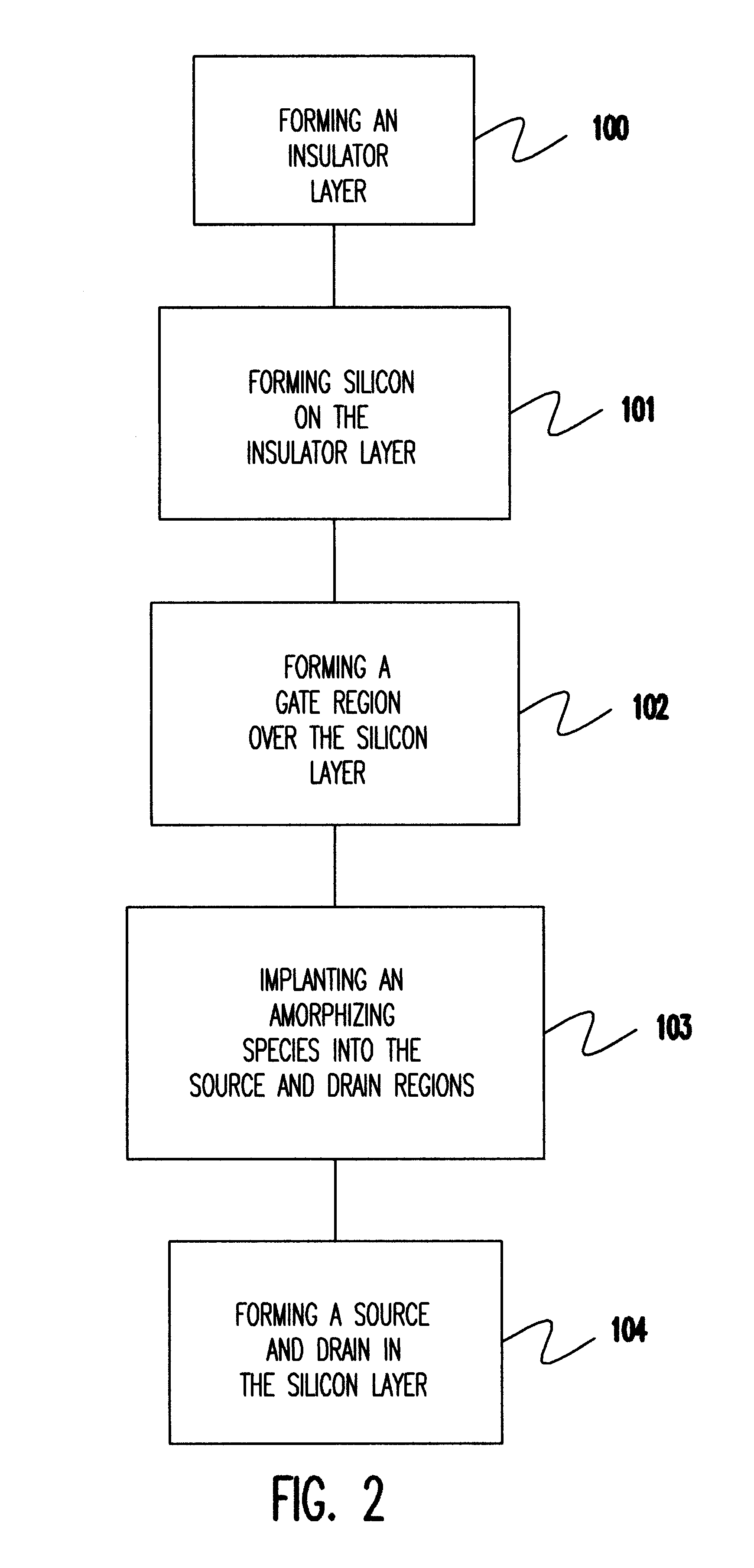

Fabrication method for wafer-level mono-axial strain Si on AlN-buried insulation layer based on non-crystallization and scale effect

ActiveCN106098609AImprove cooling effectImprove insulation performanceSemiconductor/solid-state device manufacturingInsulation layerScale effects

The invention discloses a fabrication method for wafer-level mono-axial strain Si on a AlN-buried insulation layer based on non-crystallization and a scale effect. The fabrication method is implemented according to the following steps of depositing a SiO2 layer at a Si layer at a top layer of a Si wafer on the cleaned AlN-buried insulation layer; performing ion injection on the Si layer at the top layer to form a non-crystallization layer, and removing the SiO2 layer on the non-crystallization layer; depositing a tensile stress SiN thin film or a press stress SiN thin film on the Si layer at the top layer, etching the SiN thin film to a mono-axial tensile stress SiN strip-shaped array or a mono-axial press stress SiN strip-shaped array, annealing the wafer to make the non-crystallization layer re-crystallized, and enabling the AlN-buried insulation layer to generate plastic deformation; and etching the SiN strip-shaped array to obtain the wafer-level mono-axial strain Si on the AlN-buried insulation layer. The wafer-level mono-axial strain Si has the advantages of high heat dissipation and large strain, and the fabrication method can be used for fabricating a wafer-level mono-axial strain Si material on the AlN-buried insulation layer.

Owner:XIDIAN UNIV

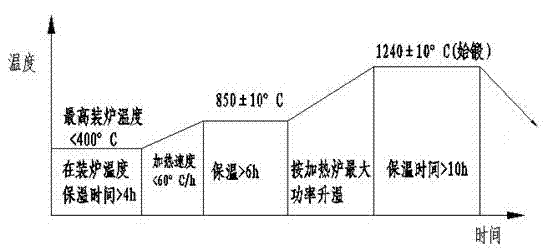

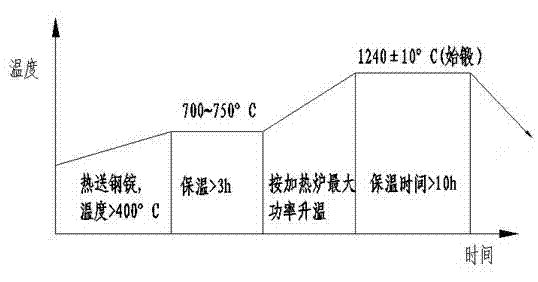

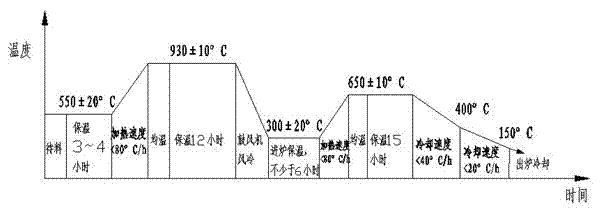

Wind-powered main shaft forging method

ActiveCN102806291AEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

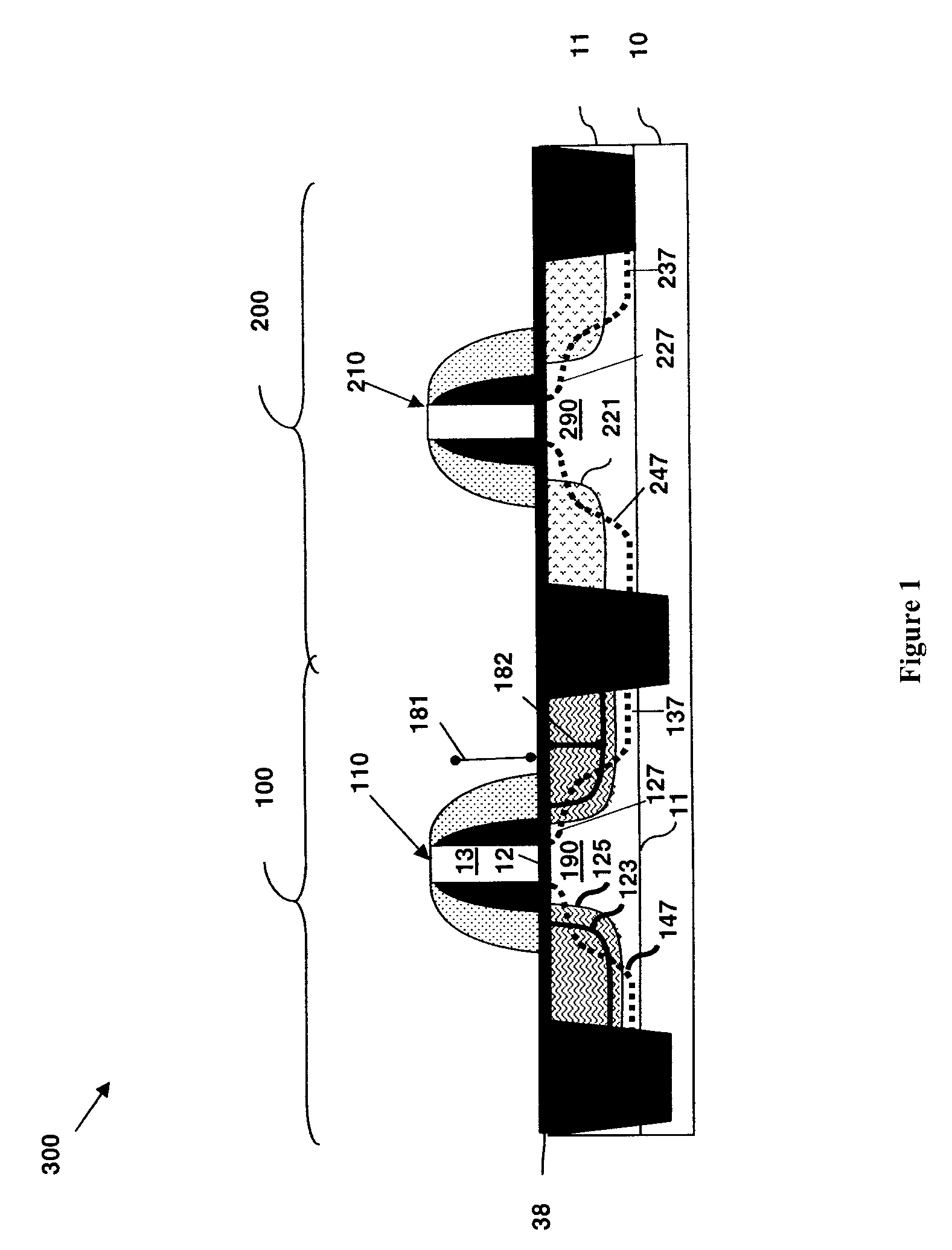

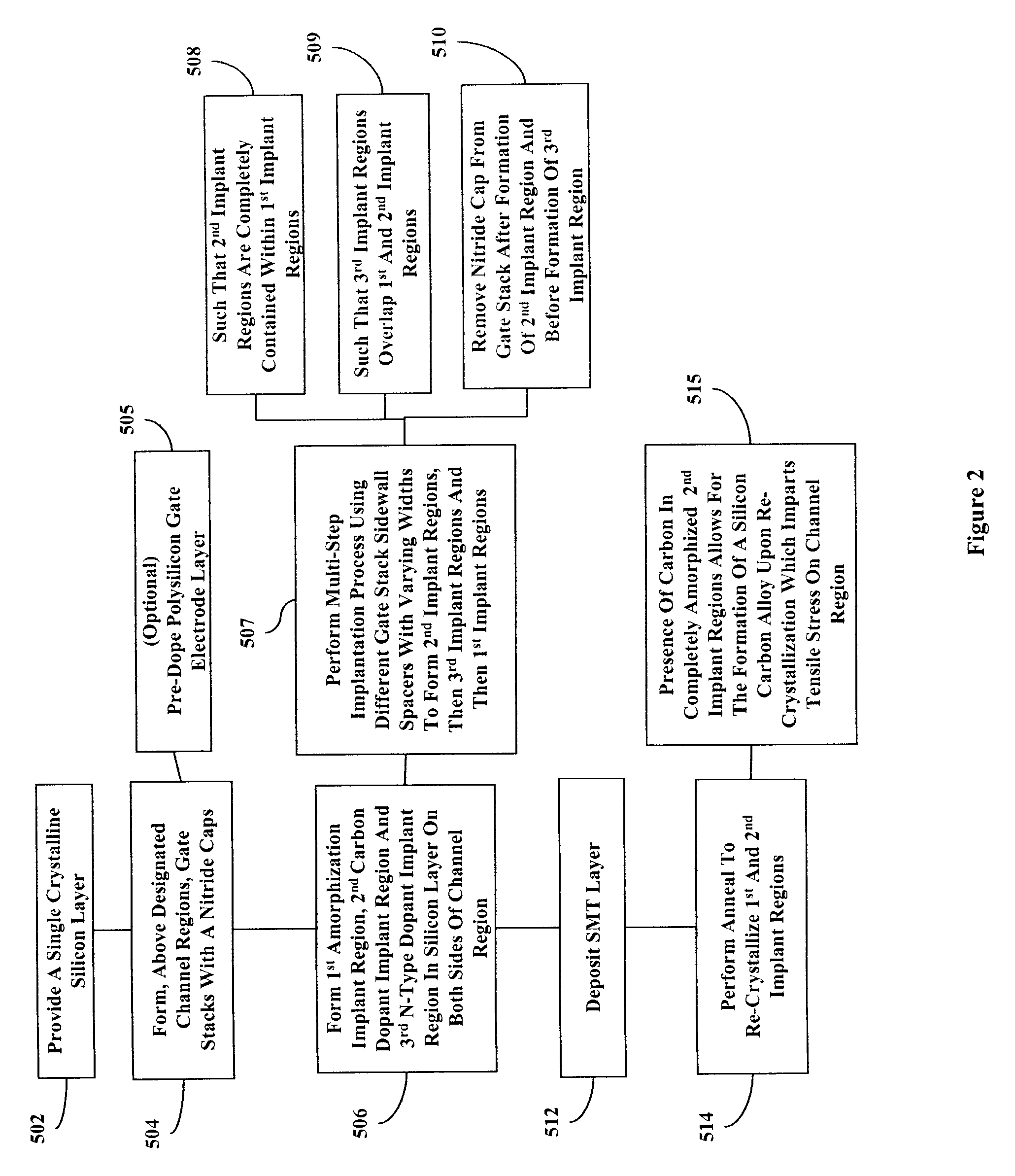

Semiconductor structure and method of forming the structure

InactiveUS20080191243A1Avoid less flexibilityImprove stress conditionTransistorSolid-state devicesSemiconductor structureGate stack

Disclosed are embodiments of an n-FET structure with silicon carbon S / D regions completely contained inside amorphization regions and with a carbon-free gate electrode. Containing carbon within the amorphization regions, ensures that all of the carbon is substitutional following re-crystallization to maximize the tensile stress imparted on channel region. The gate stack is capped during carbon implantation so the risk of carbon entering the gate stack and degrading the conductivity of the gate polysilicon and / or damaging the gate oxide is essentially eliminated. Thus, the carbon implant regions can be formed deeper. Deeper S / D carbon implants which are completely amorphized and then re-crystallized provide greater tensile stress on the n-FET channel region to further optimize electron mobility. Additionally, the gate electrode is uncapped during the n-type dopant process, so the n-type dopant dose in the gate electrode can be at least great as the dose in the S / D regions.

Owner:GLOBALFOUNDRIES INC

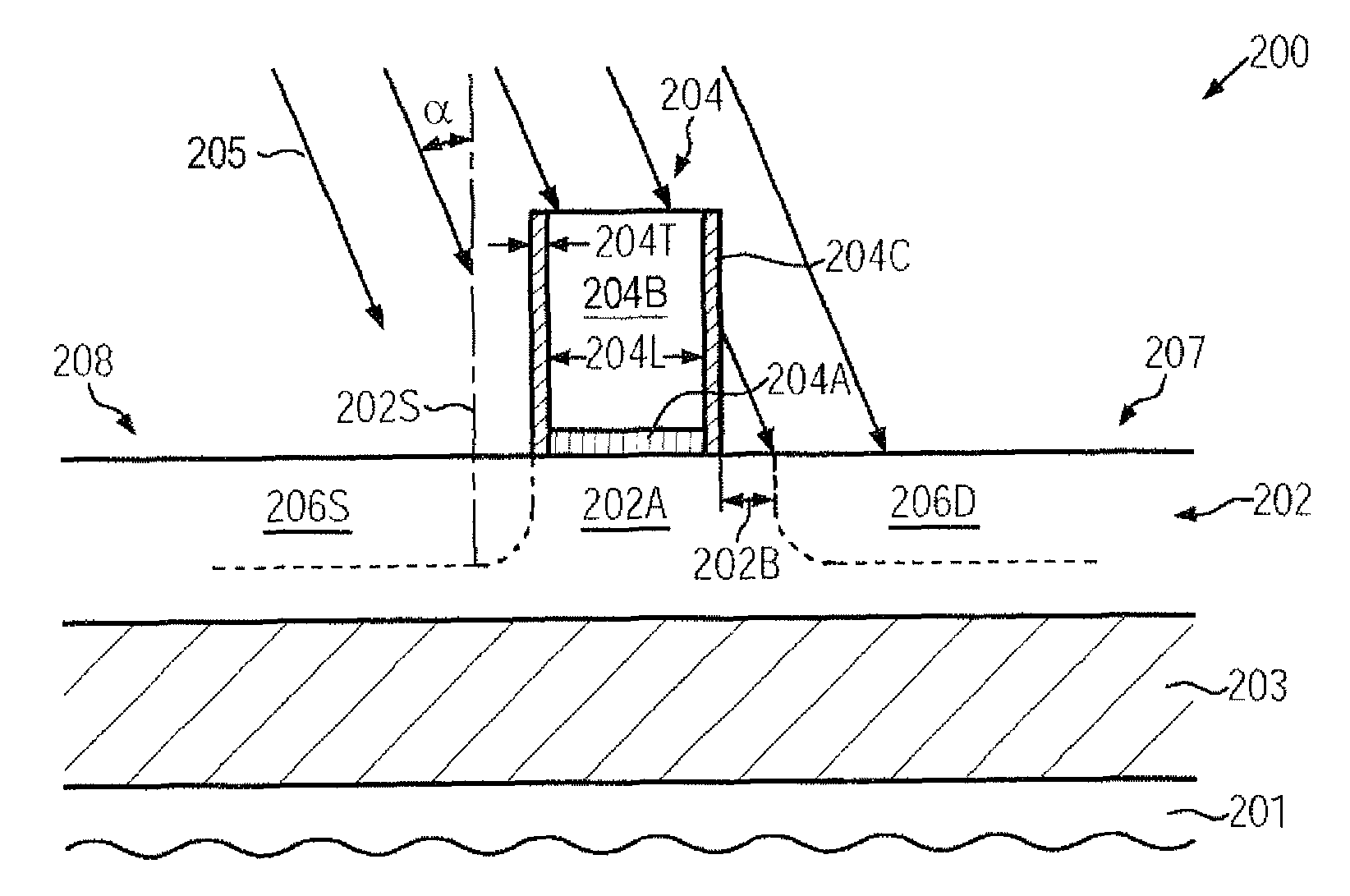

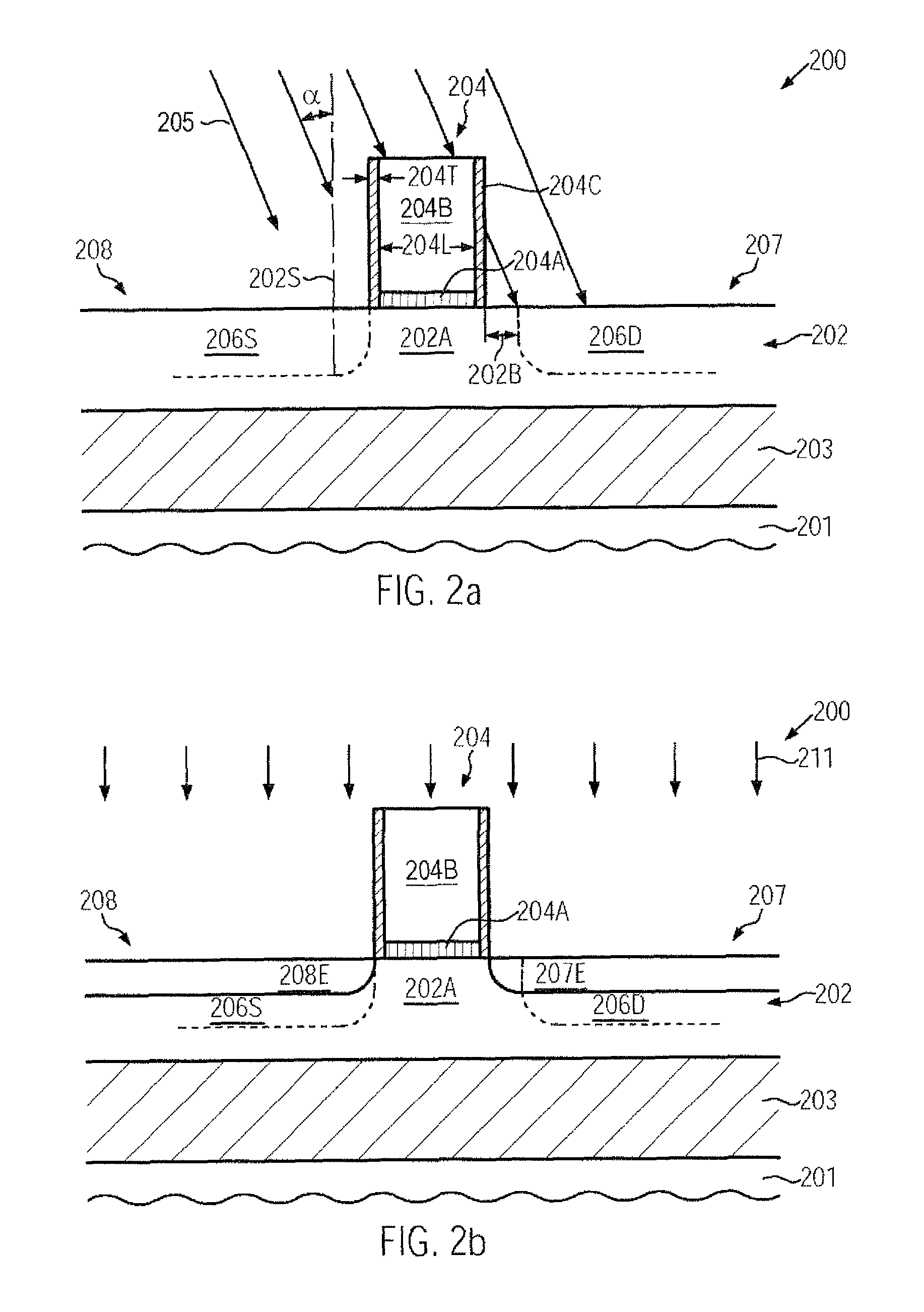

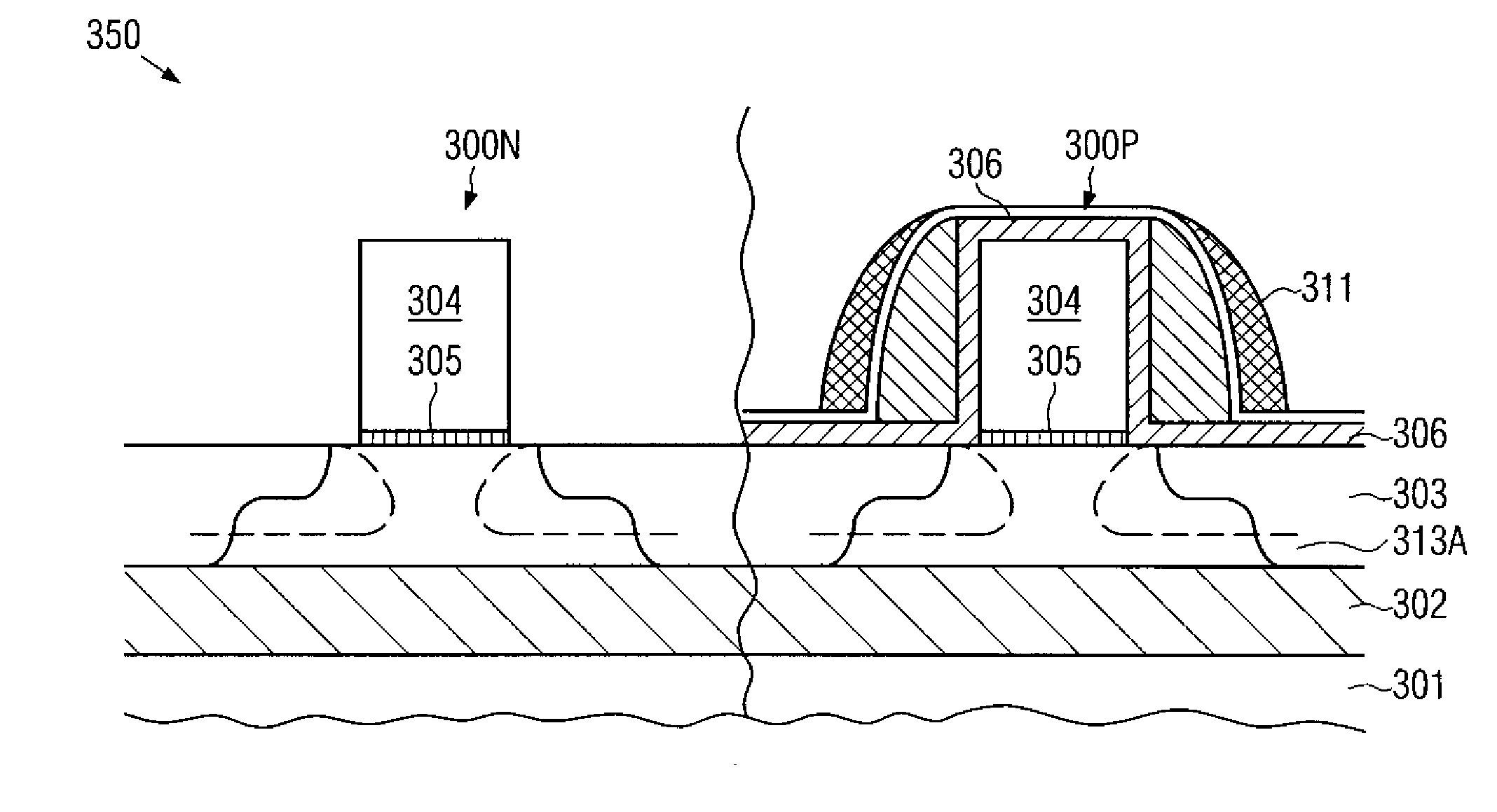

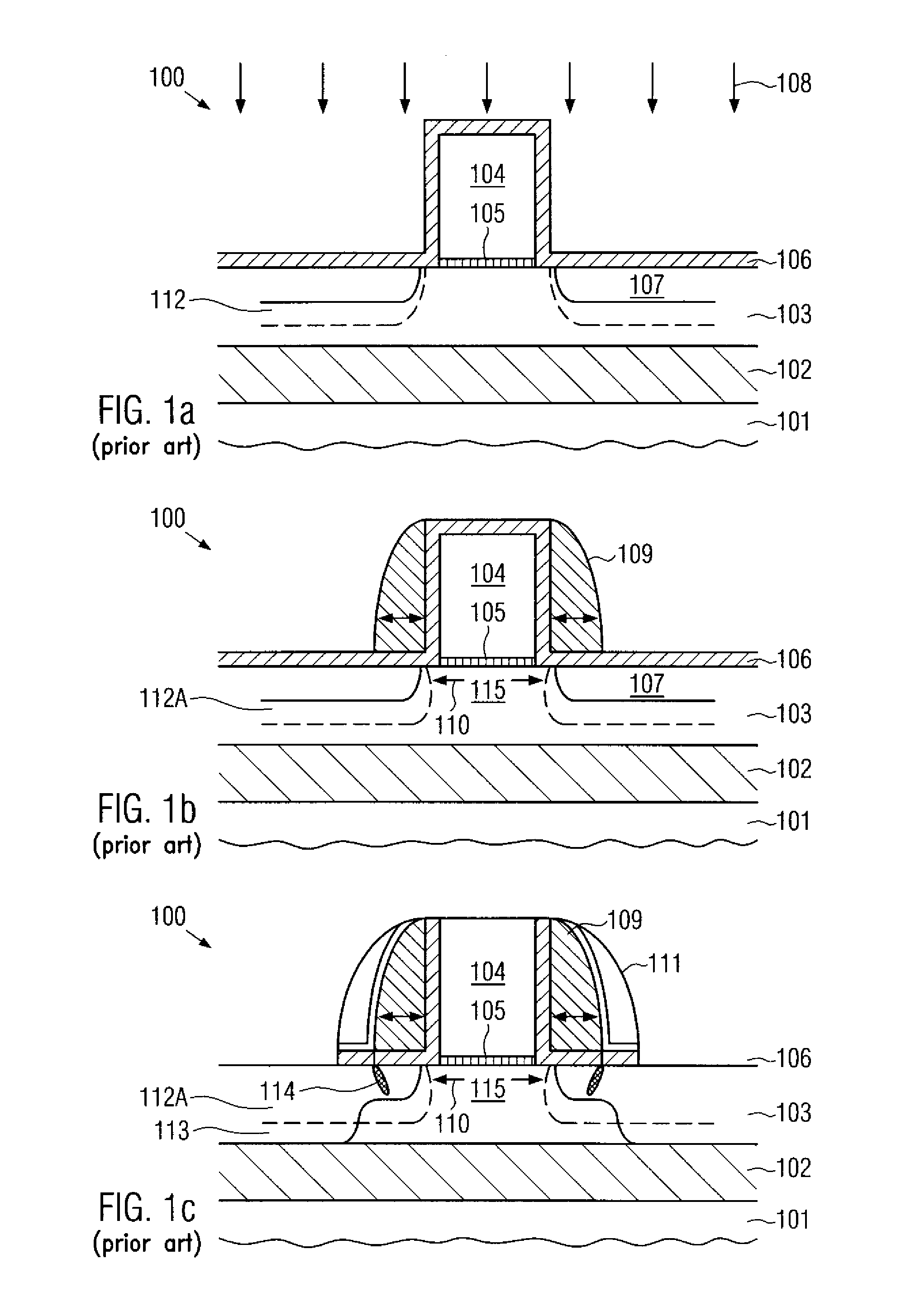

Technique for reducing crystal defects in strained transistors by tilted preamorphization

InactiveUS20070123010A1Improve performanceReduce creationTransistorSolid-state devicesEngineeringRe crystallization

By performing a tilted amorphization implantation and a subsequent re-crystallization on the basis of a stressed overlying material, a highly efficient strain-inducing mechanism is provided. The tilted amorphization implantation may result in a significantly reduced defect rate during the re-crystallization process, thereby substantially reducing leakage currents in sophisticated transistor elements.

Owner:GLOBALFOUNDRIES INC

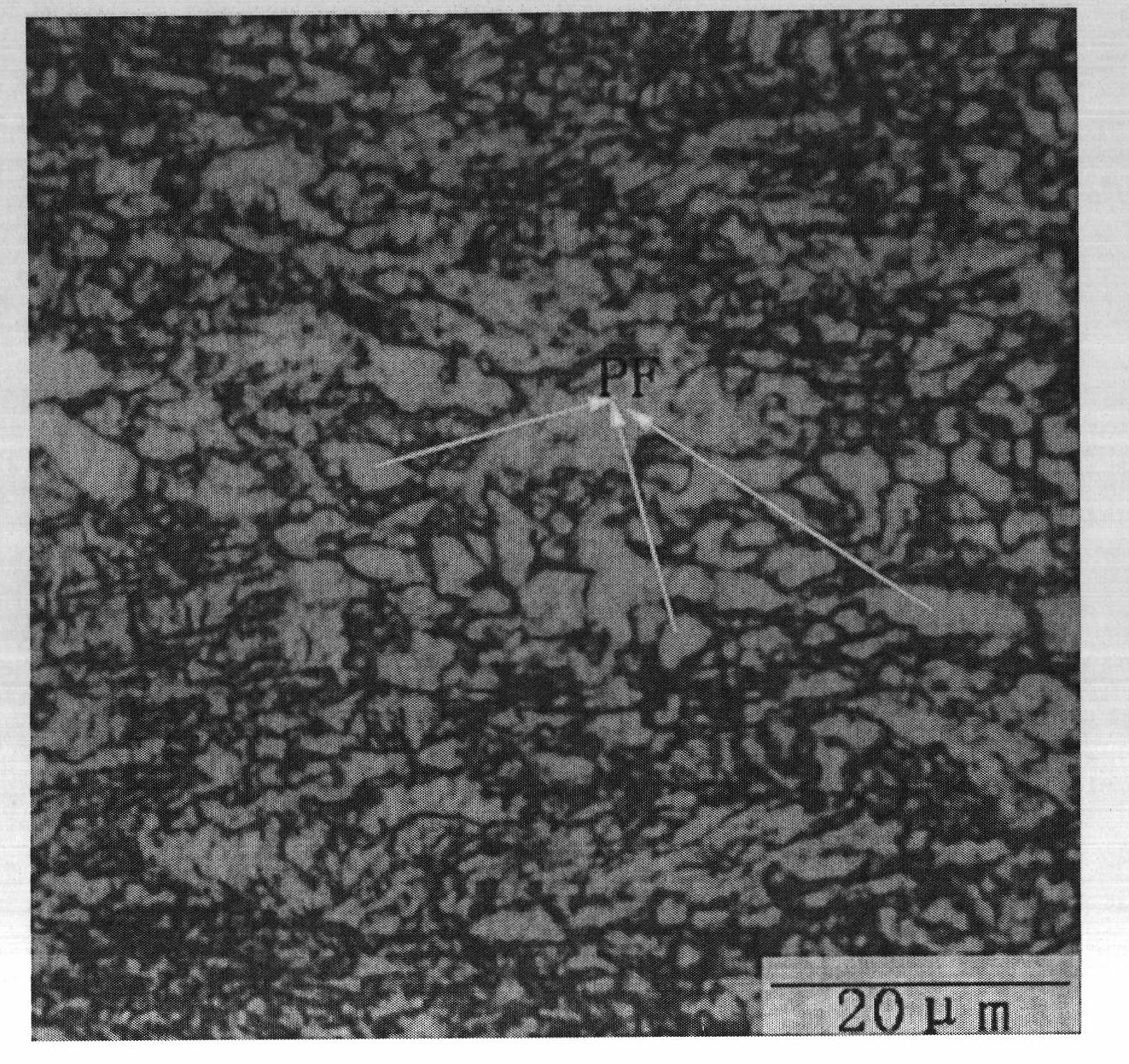

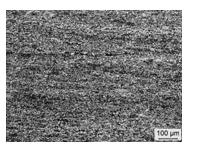

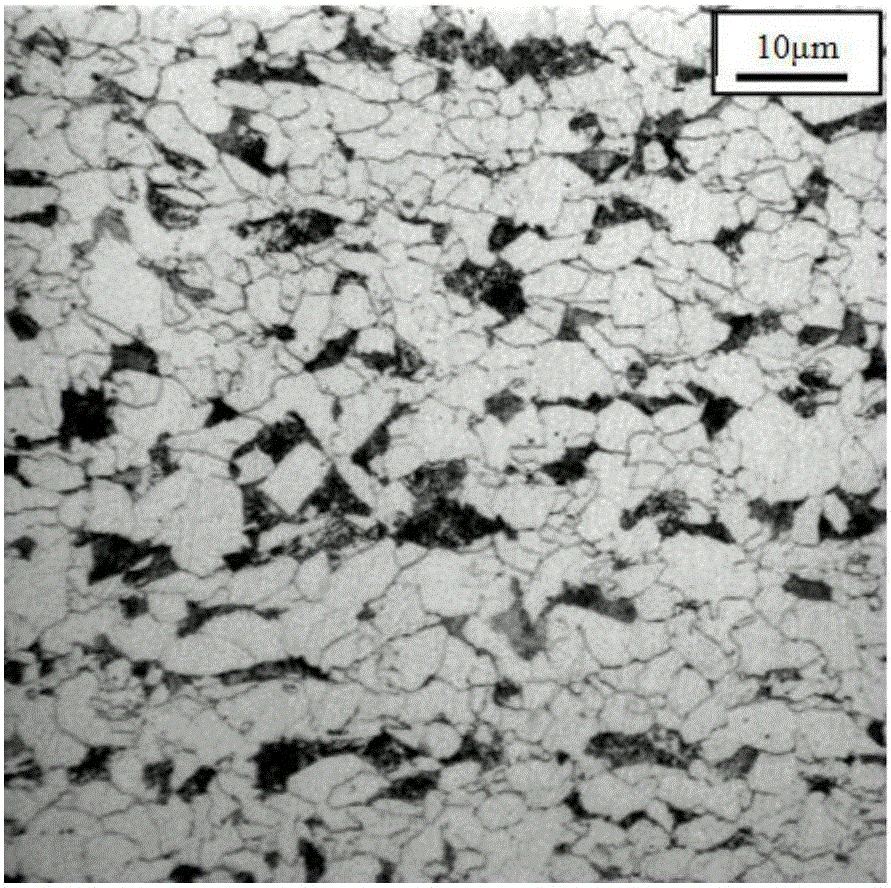

Low-cost and high-toughness X80 pipe steel with high deformation resistance and manufacture method thereof

The invention belongs to the field of metal material rolling, relating to a low-cost and high toughness X80 pipe steel with high deformation resistance and a manufacture method thereof. The X80 pipe steel comprises the following components: C: 0.02 to 0.08%, Si: <=0.40%, Mn: 0.2 to 2.0%, P: <=0.015%, S: <=0.004%, Nb: 0.03to 0.08%, Ti: 0.005 to 0.03%, Mo: 0.10 to 0.30%, Cu: <=0.40%, Ni: <=0.30% and the balance Fe. The manufacture method of the X80 pipe steel comprises the steps of controlling the rolling of the reheating area as well as the re-crystallization area and the no-re-crystallization area for a plate slab in two stages, and controlling the cooling process of air cooling and water cooling in two stage after the rolling to obtain the high-toughness X80 pipe steel with high deformation resistance. Due to the component design of low Mo and Nb contents, in the manufacture method, the cost is effectively reduced, the comprehensive mechanical property is improved, the control applicability of the manufacture technology is significantly enhanced, and the difficulty of the manufacture is greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

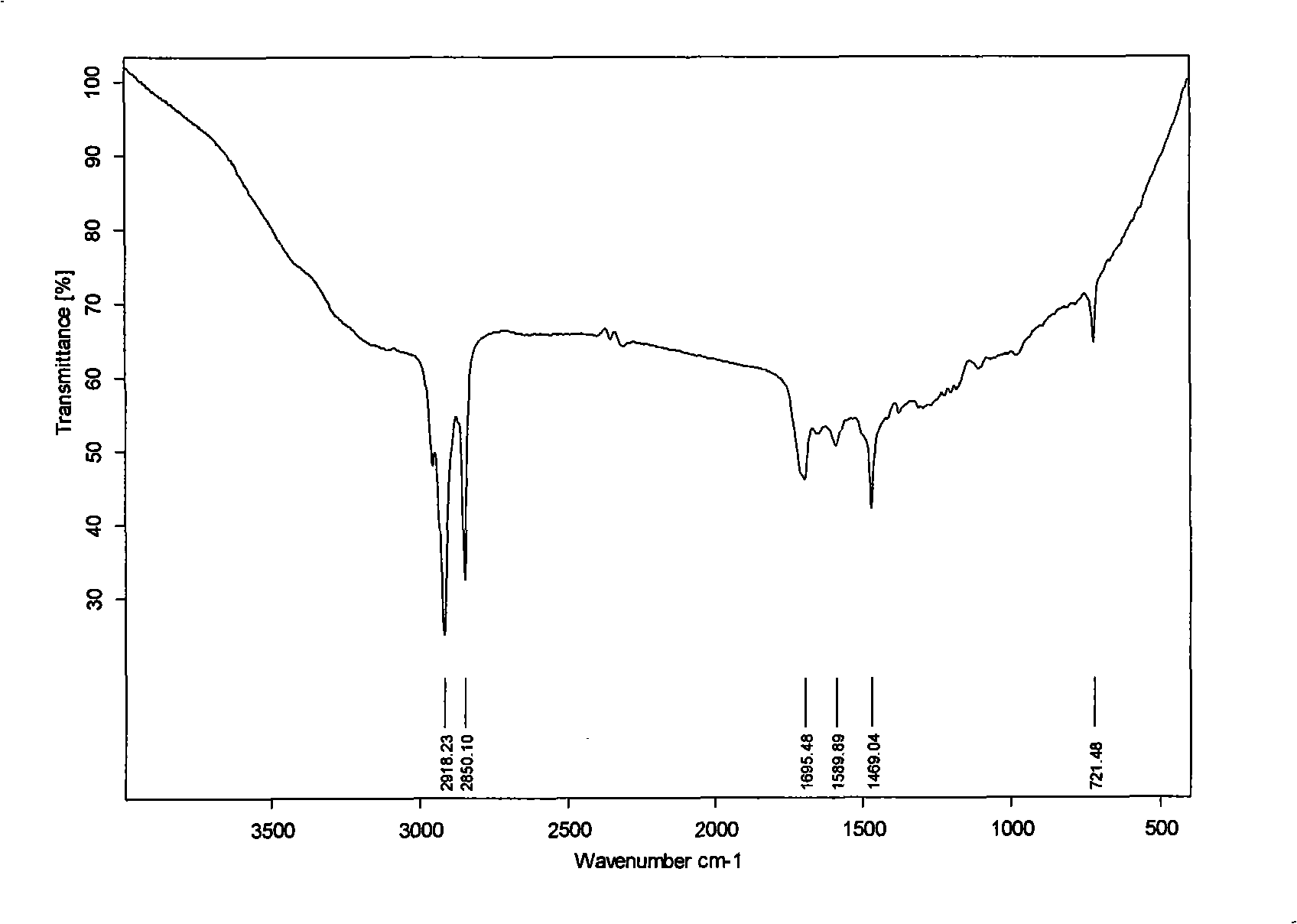

Gas pipeline drag reduction agent and preparing method thereof

The invention relates to a gas line drag reduction agent and a preparation method thereof, relating to the technical field of the composite of high-molecular compound and piping systems. The drag reduction agent consists of carbon bisulfide, hydrazine hydrate and long chain acid, the mol ratio of which is 1.8:1:1 to 2.2:1:1. The preparation method comprises the following steps: step one, CS2 is taken according to proportional quantity, dripped into the mixed liquor of the hydrazine hydrate and water with proportional quantity under agitation, reflowed for certain time in the temperature range of 90 to 95 DEG C, then cooled for 30 to 60 minutes in ice water bath and pumped and filtered, the mother liquor continues to react for two times, products of the third time are merged, washed by using ethanol and ether sequentially, and recrystallized by using boiling water so as to obtain symmetrical diaminothiourea clear crystal; and step two, symmetrical diaminothiourea with proportional quantity and the long chain acid with proportional quantity are dissolved in a pyridine solvent with nitrogen protection, reflowed at the temperature of 140 to 220 DEG C by adopting a temperature programming method, and react for 3 to 4 hours, then the mixture is cooled to the room temperature and recrystallizated by using the ethanol of 95 percent to obtain the brown product.

Owner:PIPECHINA SOUTH CHINA CO

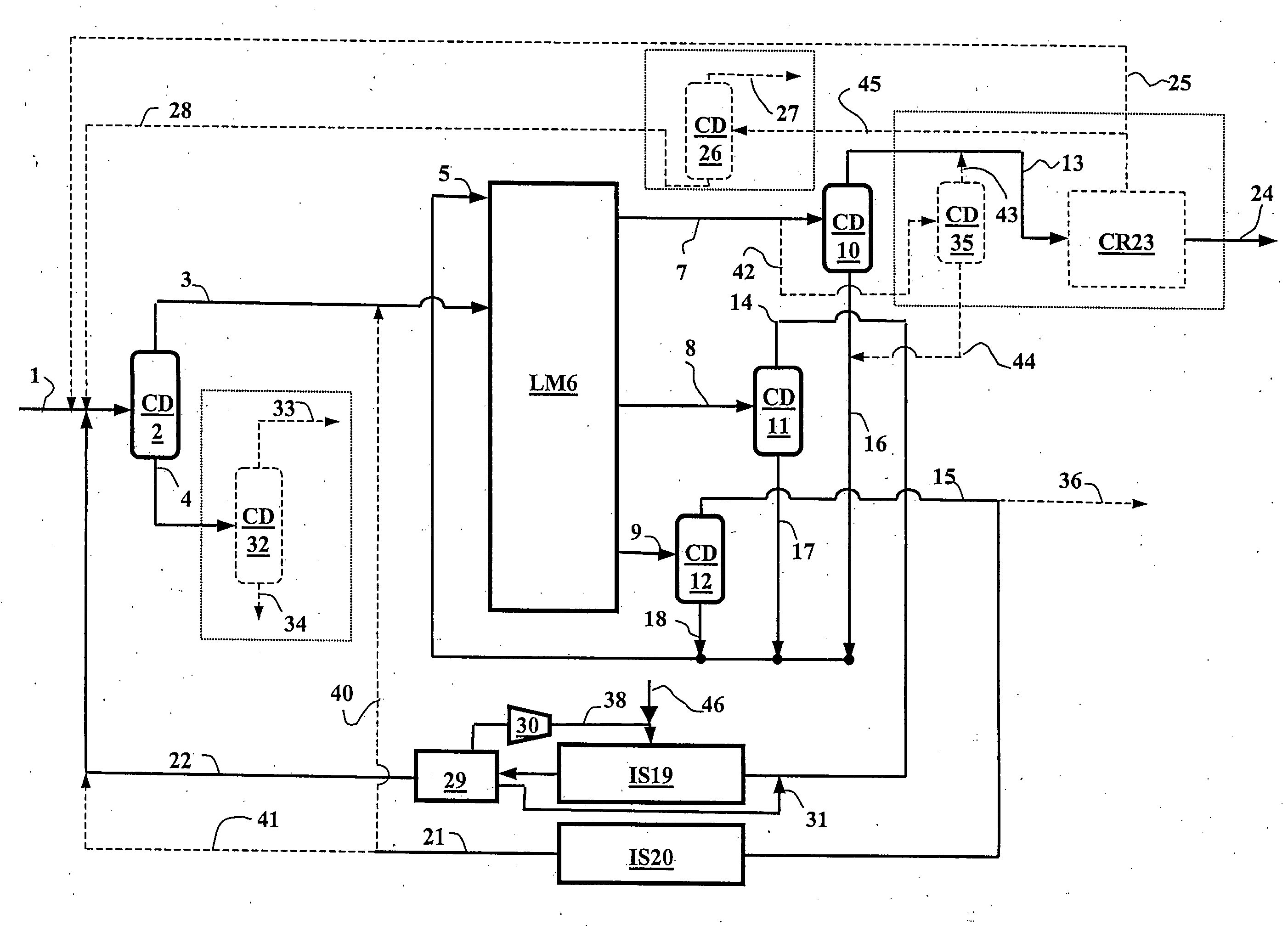

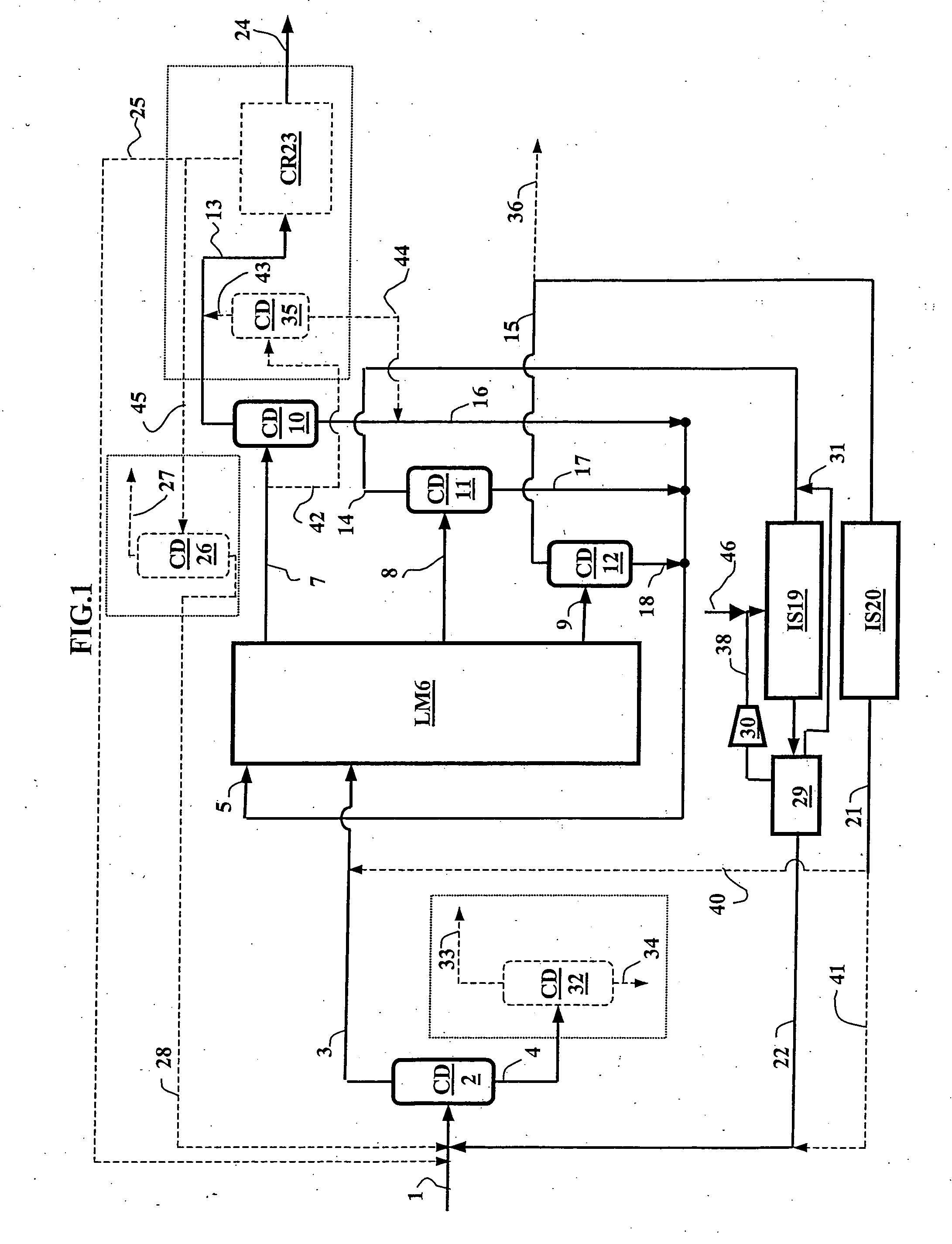

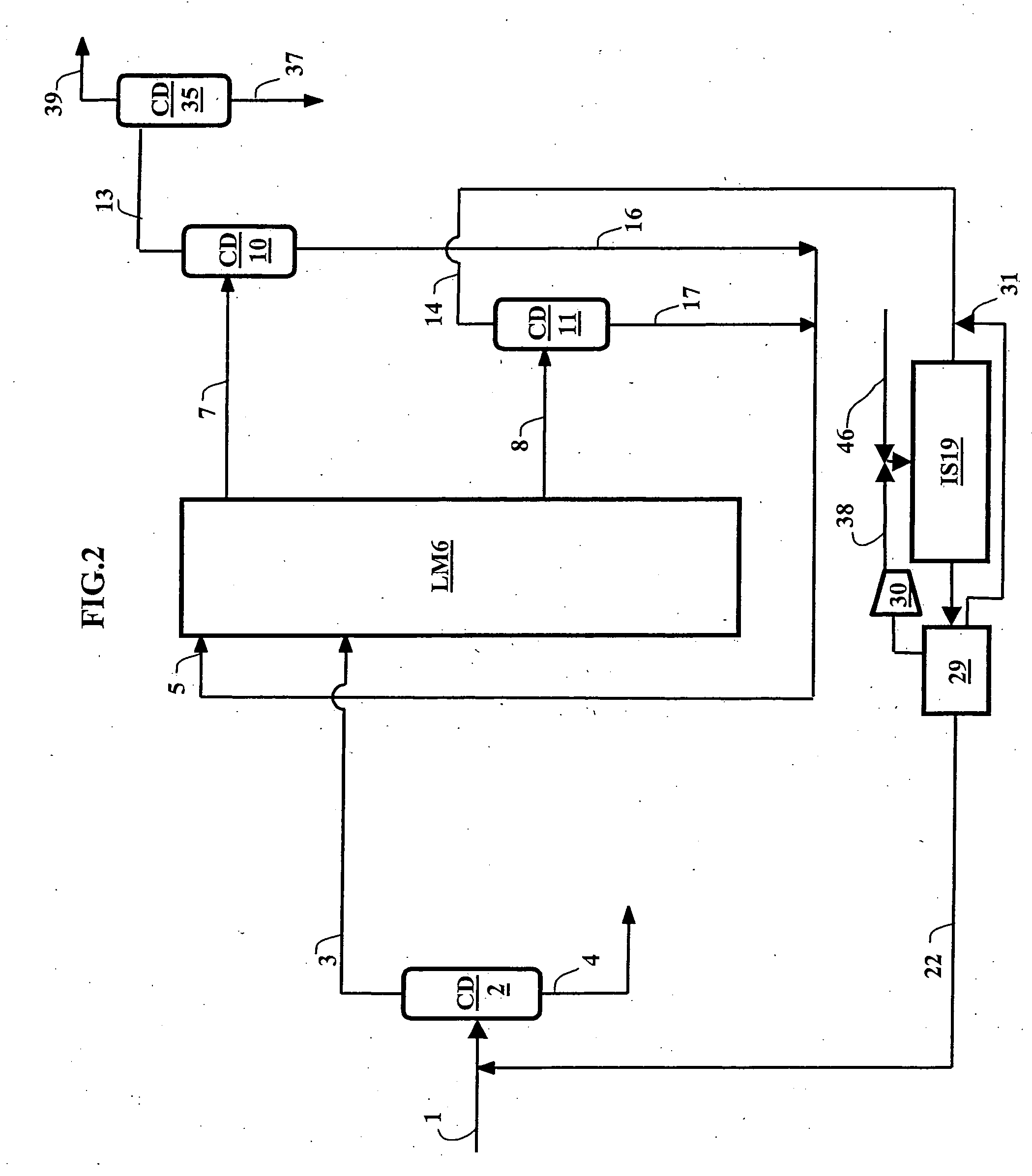

Method for Producing Paraxylene Comprising an Adsortion Step and Two Isomerization Steps

ActiveUS20080262282A1Overcome disadvantagesHydrocarbon by isomerisationHydrocarbon by hydrogenationXylyleneIsomerization

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffmate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

InactiveCN104371658AImprove thermal conductivitySimple structureHeat-exchange elementsMolten stateHydration reaction

The invention provides a packaging shape-stabilizing method of an inorganic hydrated salt phase-change heat storage material, which comprises the following steps: (1) adding a nucleator and deionized water into the inorganic hydrated salt phase-change material, and heating until the inorganic hydrated salt phase-change material achieves the molten state; (2) adding a porous propping material into the molten-state inorganic hydrated salt phase-change material, and stirring sufficiently and uniformly; (3) putting the molten-state mixture obtained in the step (2) in a vacuum environment to enhance the adsorptivity of the porous propping material for the inorganic hydrated salt phase-change material; and (4) moving the molten-state mixture out of the vacuum environment, and immediately putting the molten-state mixture into a low-temperature environment suitable for crystallization to perform recrystallization. The composite shape-stabilized phase-change material obtained by the method has the advantages of stable structure, high latent heat, no toxicity, simple preparation process, short time consumption and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

Linear friction welding process between aluminium part and steel part

InactiveCN101020275AAchieve weldingImprove plastic deformationWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingTemperature control

The linear friction welding process between aluminum part and steel part includes the following steps: fixing the steel part in a vibrating fixture; vibrating the steel part vertically by means of a vibrating source and a link rod and at 24-30 Hz frequency and 2.0-2.8 mm amplitude; fixing the aluminum part in a movable fixture; contacting the steel part and the aluminum part mutually with a pushing oil cylinder in the friction pressure of 3.5-5.5 Kg / sq mm for 1.5-2.0 sec; stopping vibration and applying forging pressure of 6.5-12.0 Kg / sq mm for 0.5-1 sec; and cooling naturally to form firm joint between the aluminum part and the steel part. The present invention controls the temperature in friction area at 0.8 time the smelting point of aluminum and applying forging pressure to produce plastic deformation so as to weld by means of re-crystallization and the atomic combination between aluminum and steel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

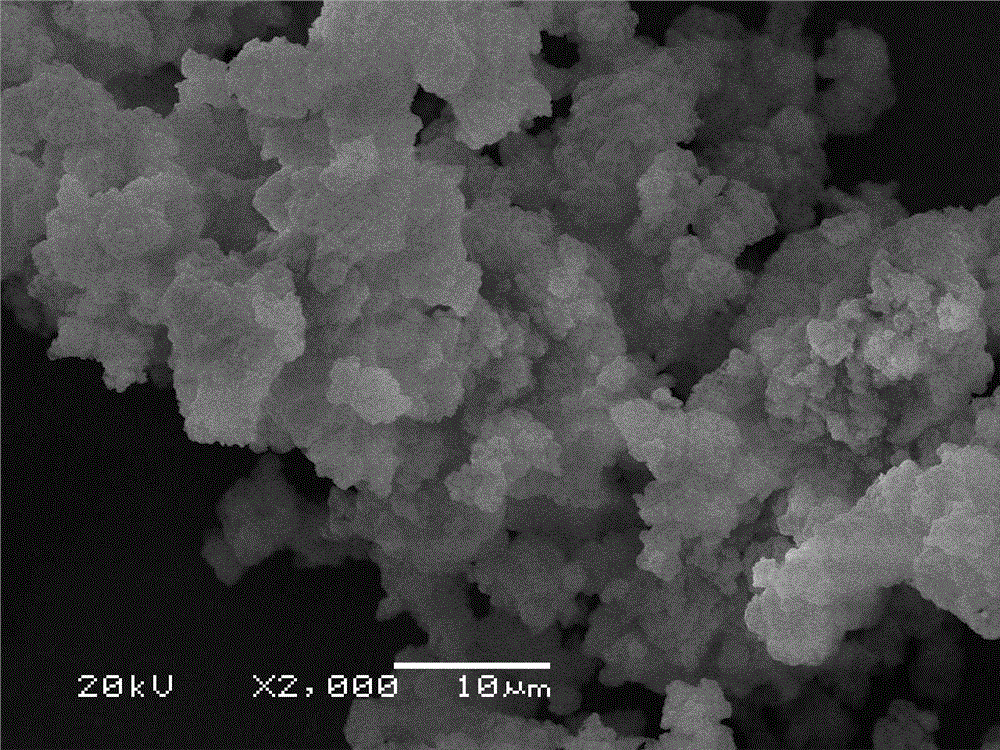

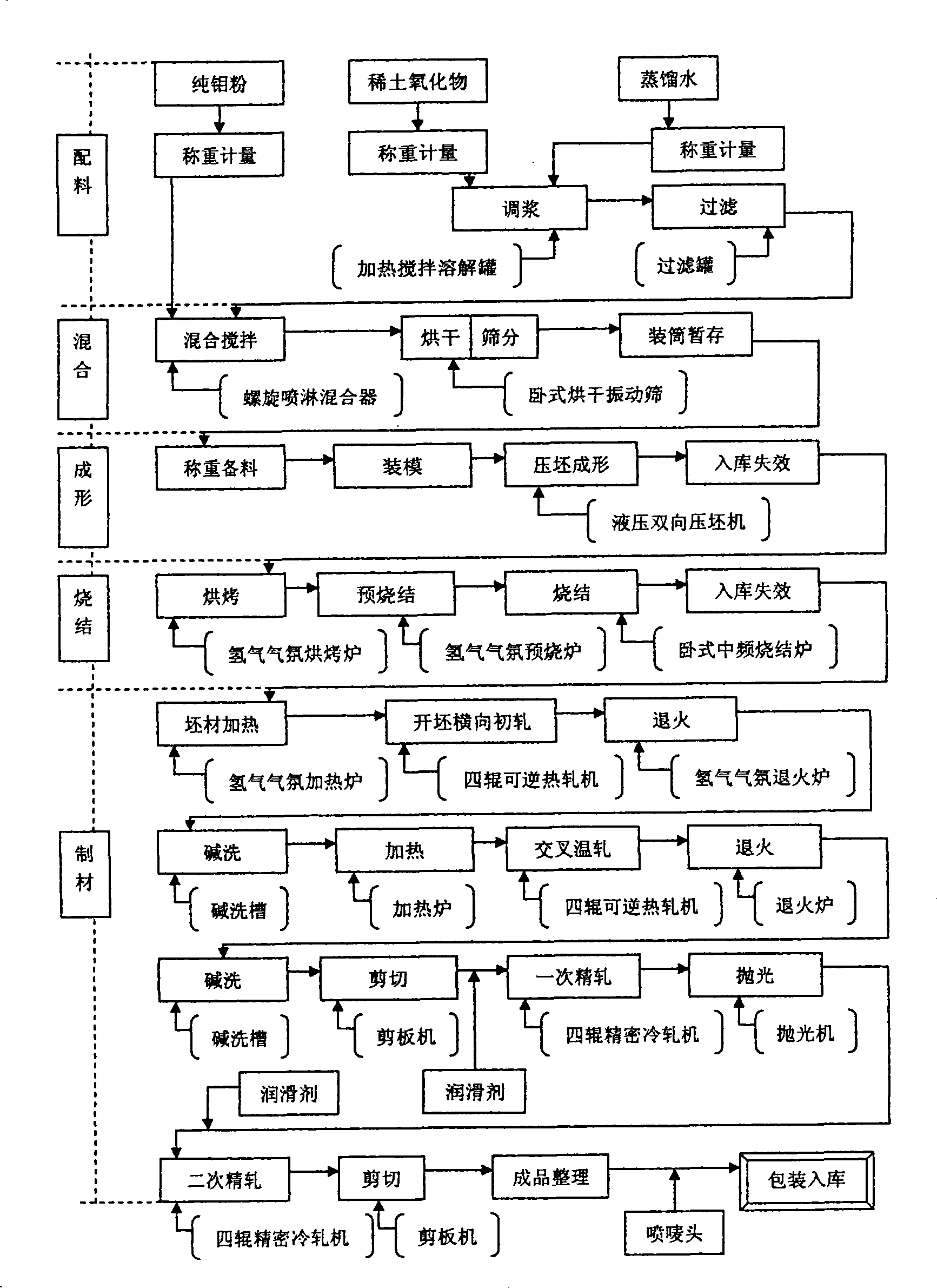

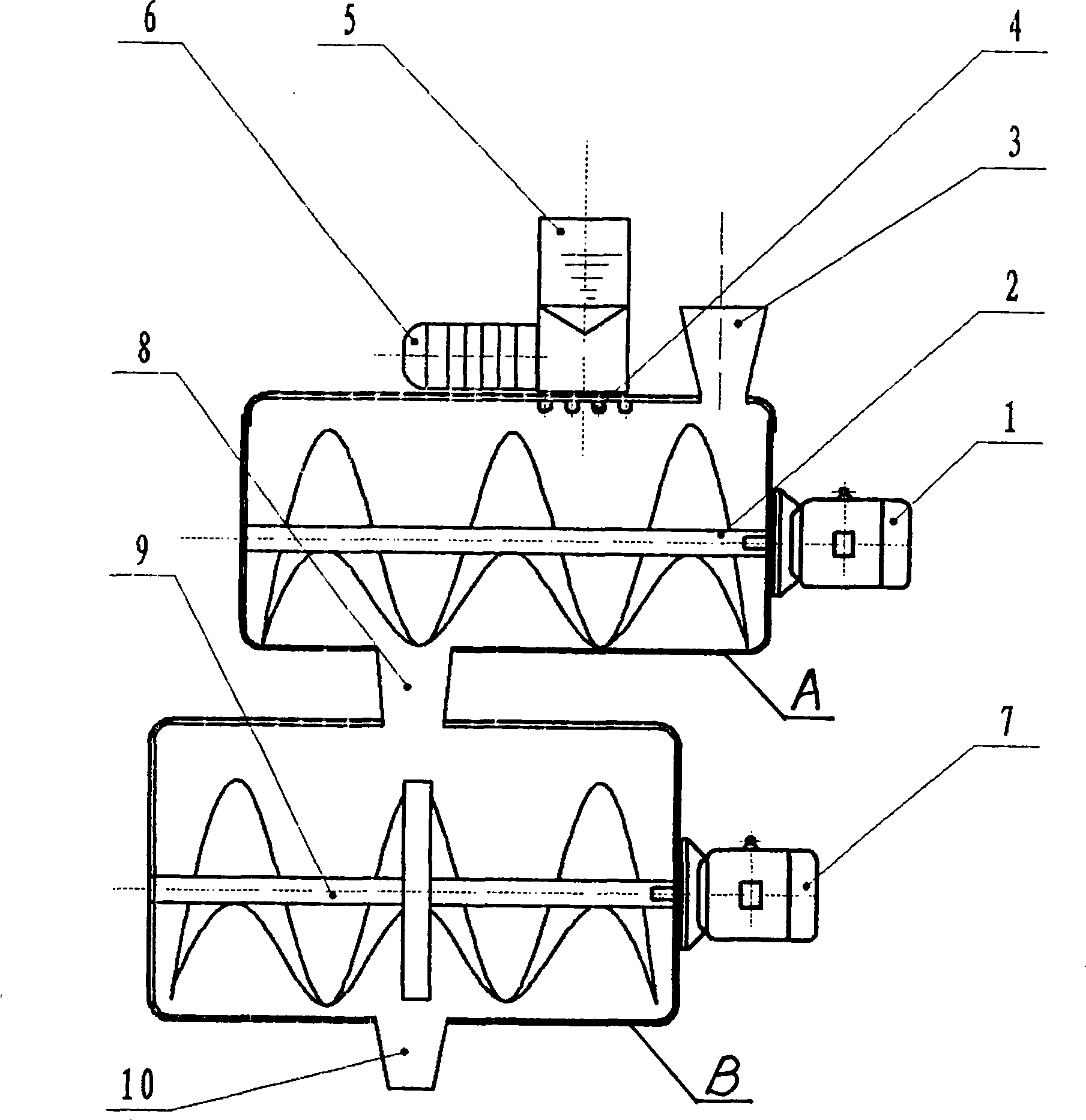

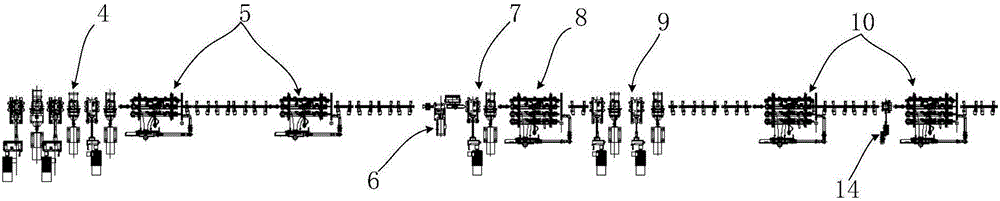

Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

ActiveCN101423911AFull atomic diffusionFull liquidityRoll mill control devicesMetal rolling arrangementsExtensibilityManufacturing technology

The invention relates to a process for manufacturing the molybdenum based rare earth alloy plate and equipment for manufacturing the same, wherein pure molybdenum powder is simultaneously added with four rare earth oxides of ZrO2, Y2O3, La2O3 and Nd2O3 according to certain ratio, by utilizing the chrematistics of long and large crystal grain and strong sag resistance and anti-creep property of rare earth alloy elements and the dispersion strengthening function, the re-crystallization temperature of the metal molybdenum is increased, the mechanical performances of the molybdenum based material such as tensile property, yielding behavior and extensibility are improved, and the application range of the molybdenum based material is widened; and the manufacturing process comprises production procedures of material preparation treatment, mixing treatment, forming treatment, sintering treatment, material making treatment and the like and the setting of various technical parameters of special technical equipment and process. With the preparation process, the molybdenum based rare earth alloy plate which has the advantages of good electric conductivity and heat conductivity, excellent high-temperature resistance and corrosion resistance and better mechanical performances such as tensile property, yielding behavior and extensibility, and fills in domestic blank and can replace the imported material can be manufactured.

Owner:四平市北威钼业有限公司

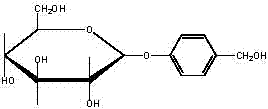

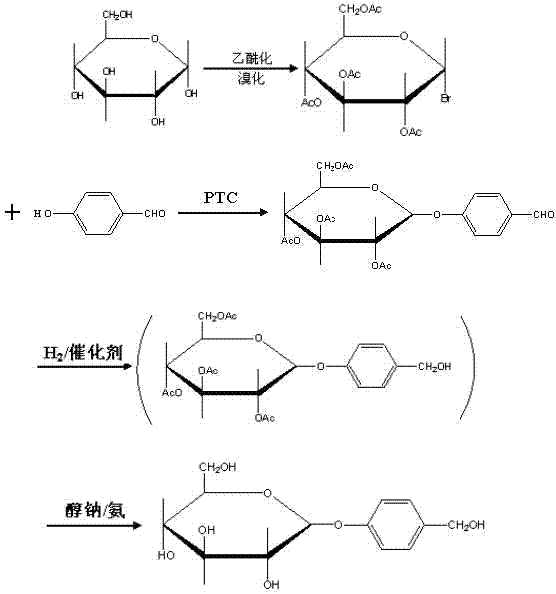

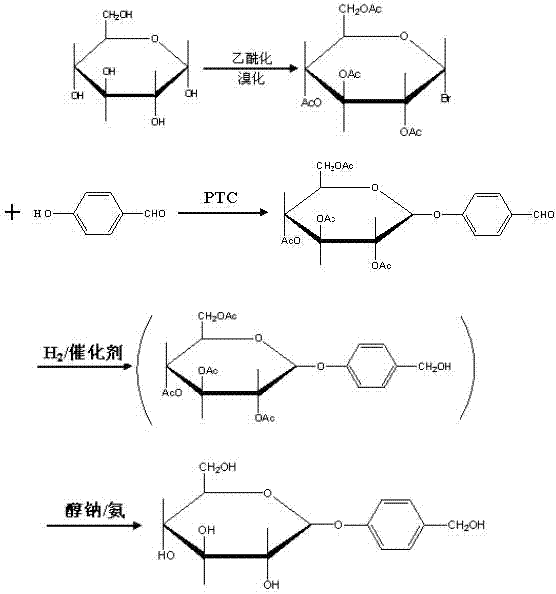

Gastrodin synthesizing method

InactiveCN102516329AReduce pollutionSuitable for industrial productionSugar derivativesSugar derivatives preparationKetone solventsPressure reduction

The invention relates to a gastrodin synthesizing method, which can effectively solve the preparation problem of gastrodin to meet the requirements of the gastrodin in pharmaceuticals. The method comprises the steps of adding catalyst perchloric acid, acetylating anhydrous dextrose by using acetic anhydride to produce per-acetyl dextrose, feeding hydrogen bromide to bromizing hemiacetal hydroxyl of the per-acetyl dextrose to produce bromo-tetraacethyl glucose, further and dropwise adding a bromo-tetraacethyl glucose solution into chloroform and tetrabutyl ammonium bromide, carbonate and para hydroxybenzene in water to obtain 4-formyl benzene-2', 3', 4', 6'- tetraacetyl-beta-D-glucopyranose, performing re-crystallization with ethanol, adding raney nickel or palladium and carbon, feeding hydrogen and pressurizing to hydrogenate, performing filtering, adding sodium alcoholate or ammonia in to filtrate to perform protecting group removal until the reaction is finished completely, performing pressure reduction and concentration to obtain crude gastrodin, and re-crystallizing the crude gastrodin by using alcohol or an alcohol and ester solvent or an alcohol and ketone solvent to obtain the gastrodin. The gastrodin synthesizing method is abundant and cheap in raw materials, simple in process, recycled in solvent, small in pollution and high in quality.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

Fully amorphized source/drain for leaky junctions

InactiveUS6395587B1TransistorSemiconductor/solid-state device manufacturingSingle crystalField-effect transistor

A semiconductor device having a silicon-on-insulator (SOI) structure includes a field-effect transistor having amorphized source and drain regions formed by implanting silicon or germanium ions into a silicon layer formed over a buried insulator. The fully amorphized source and drain regions ultimately result in permanent crystalline defects that cause p-n junction leakage which allows charge in the body of the device to dissipate, thereby improving the overall efficiency and performance of the device. The source and drain regions are amorphized throughout their entire thickness to prevent single crystal re-crystallization from occurring during annealing and other subsequent processing steps that can degrade the quality of the p-n leakage junctions.

Owner:TWITTER INC

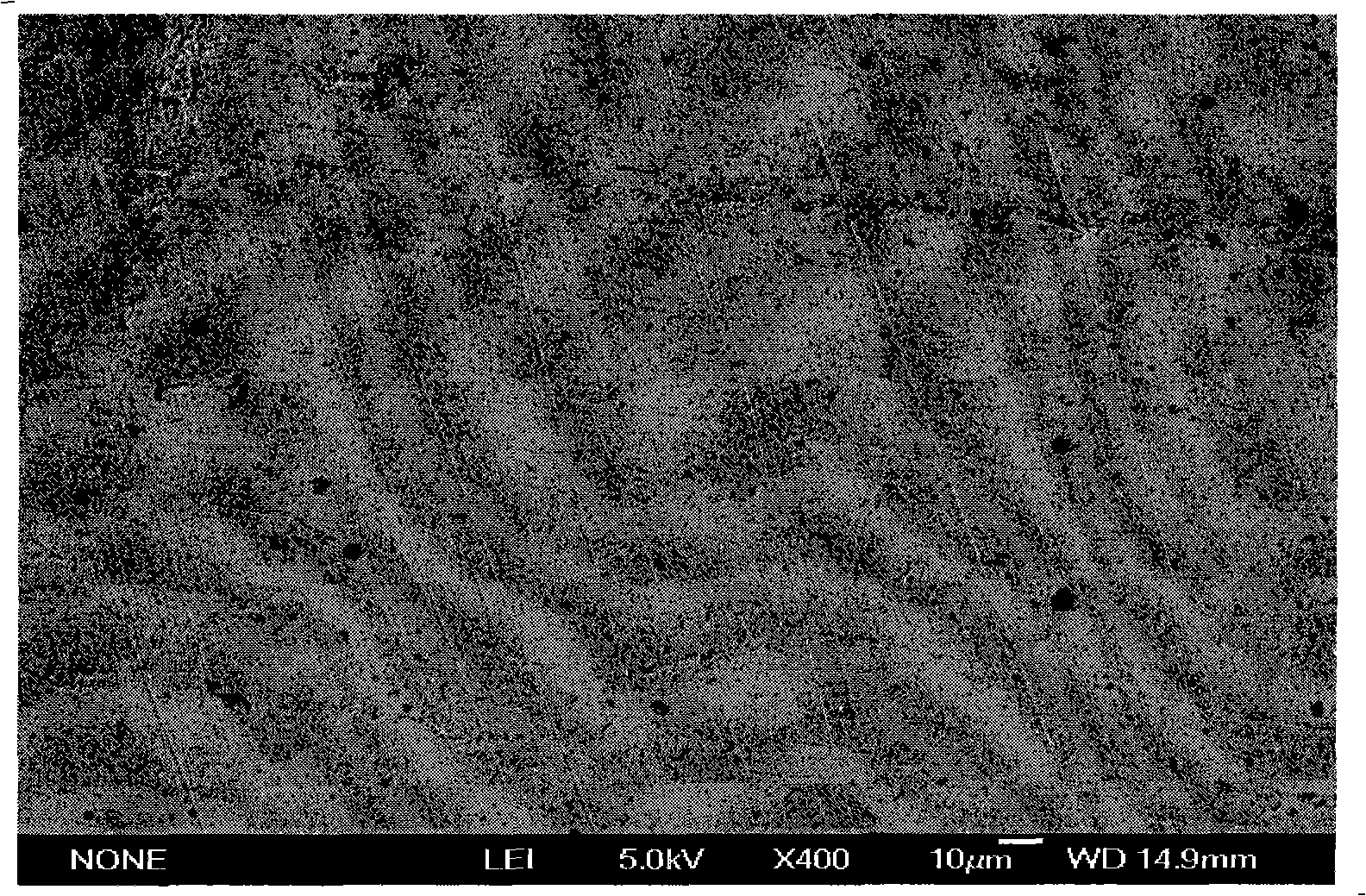

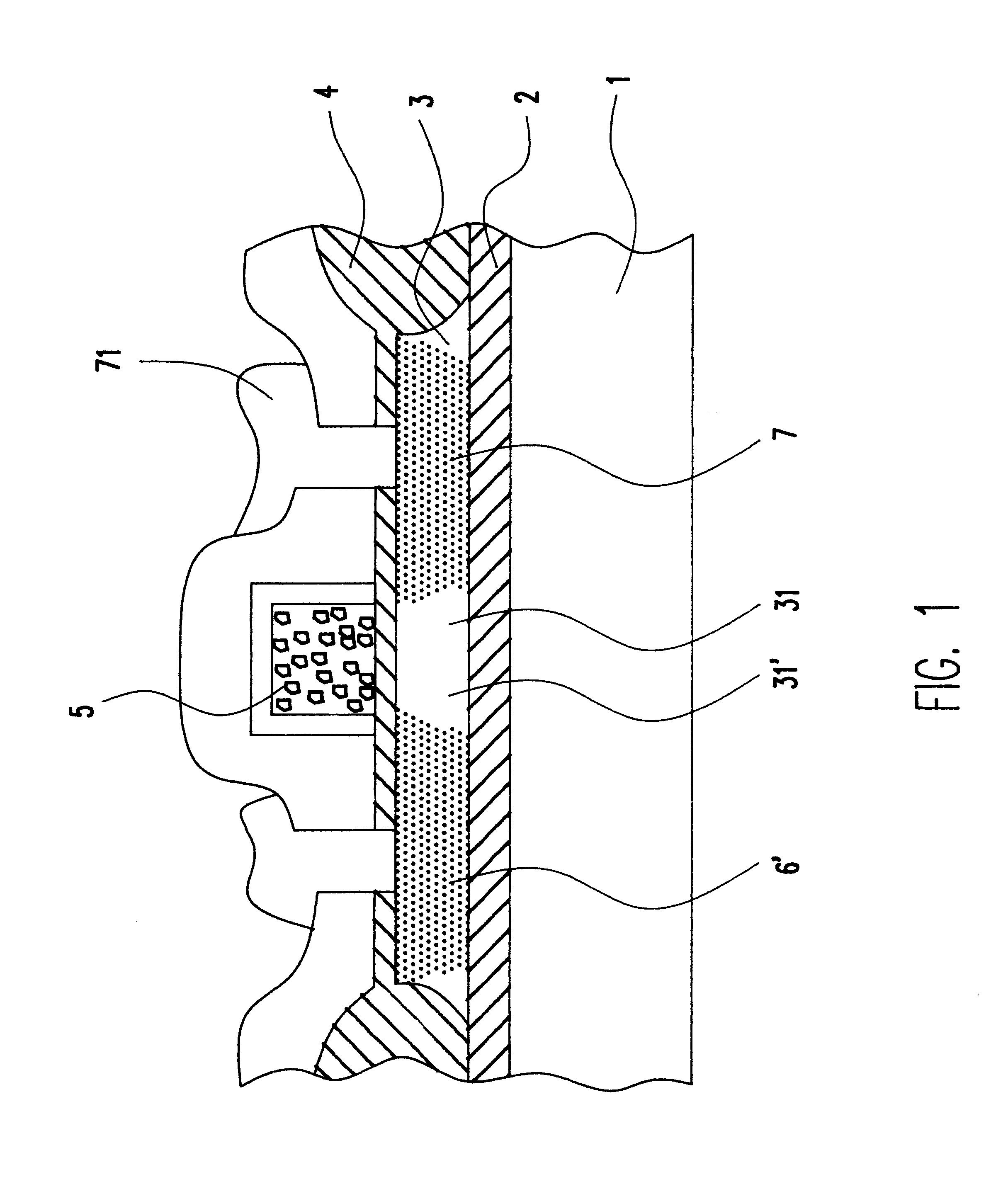

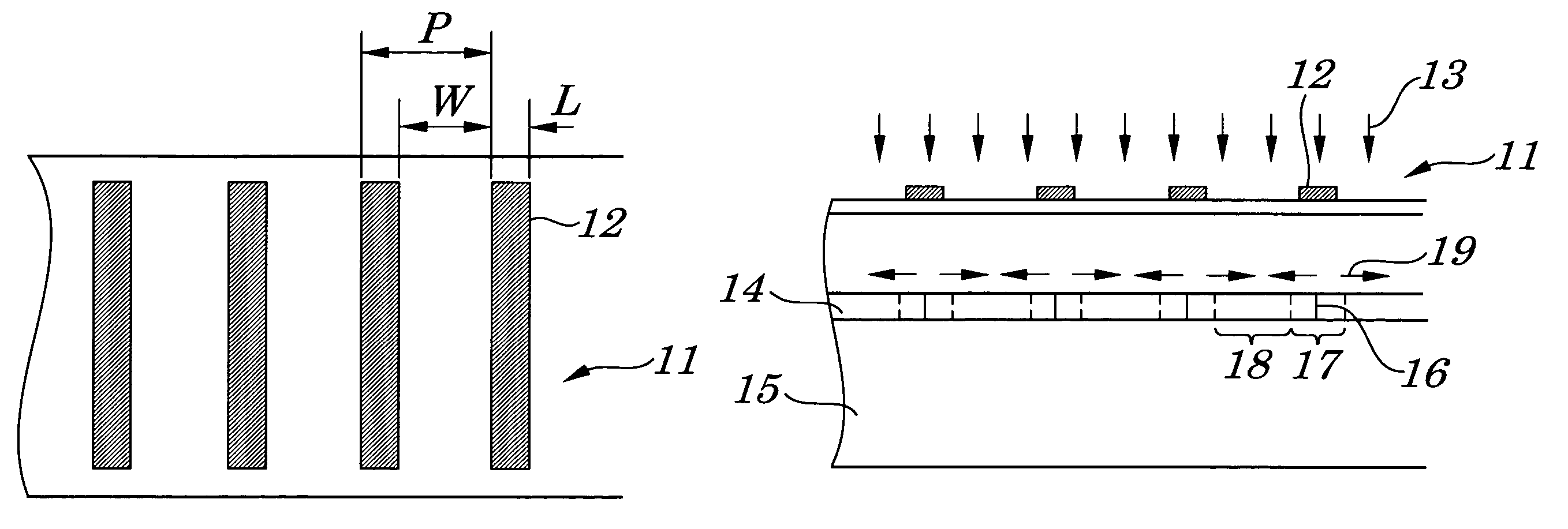

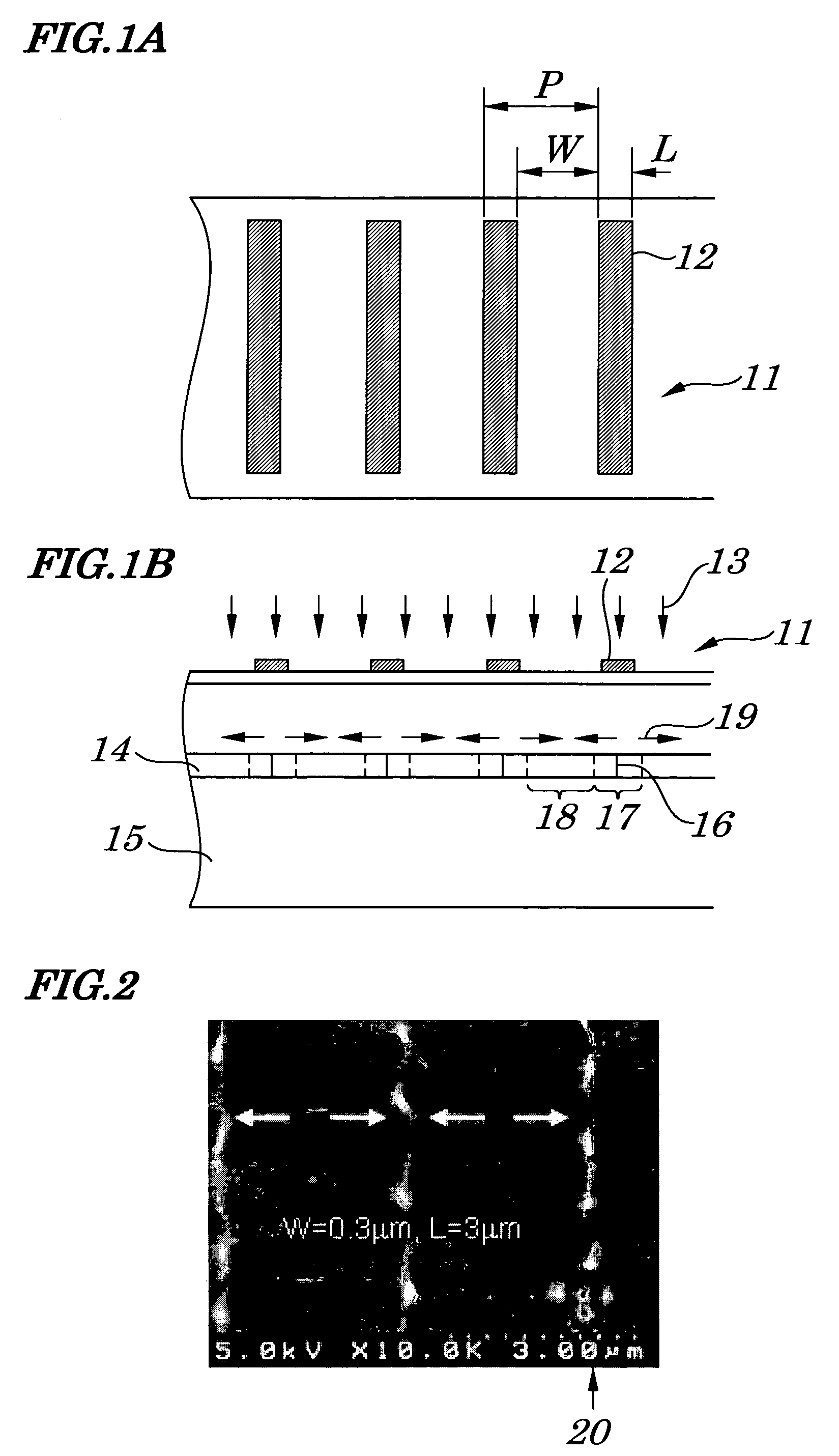

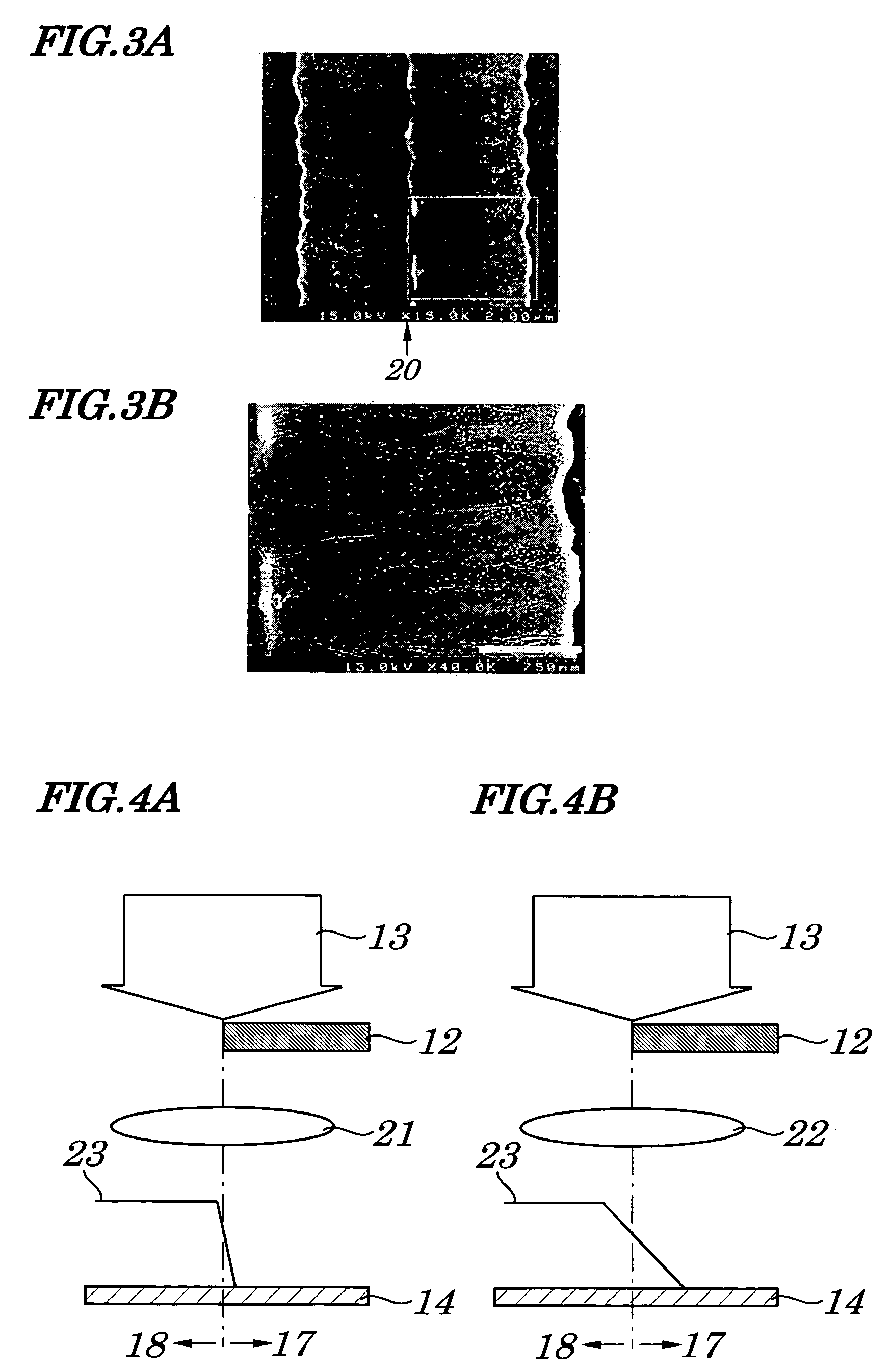

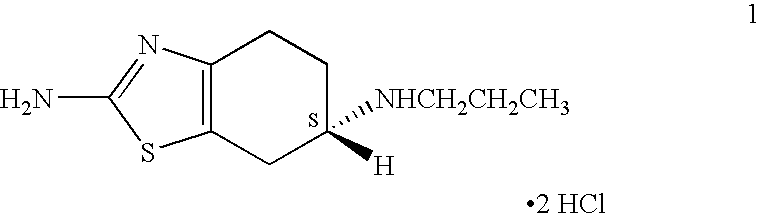

Semiconductor thin film, thin film transistor, method for manufacturing same, and manufacturing equipment of semiconductor thin film

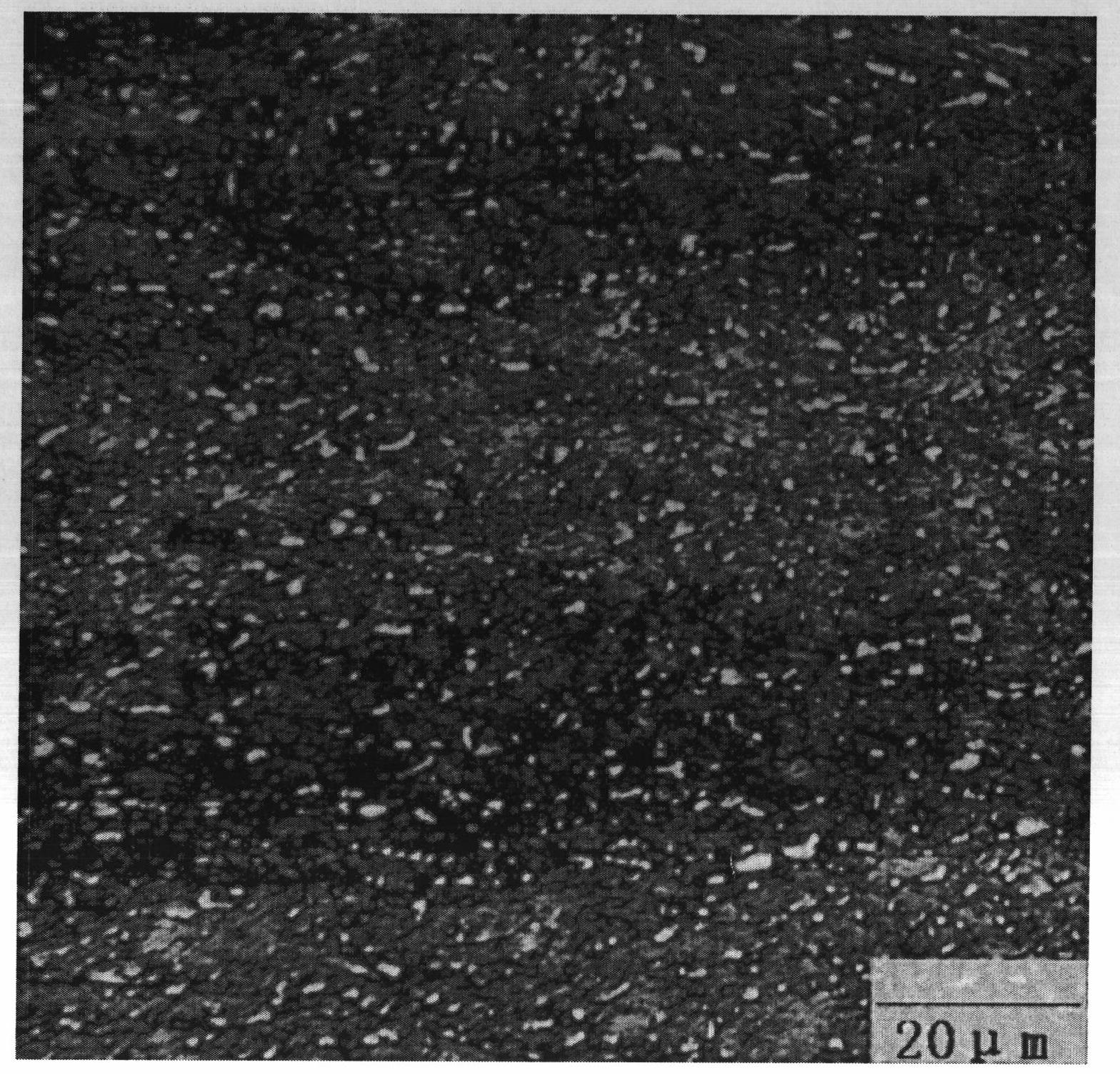

ActiveUS7049184B2Small sizeNo longer be formedTransistorSemiconductor/solid-state device manufacturingImage resolutionLight beam

A method for manufacturing a semiconductor thin film is provided which can form its crystal grains having a uniform direction of crystal growth and being large in size and a manufacturing equipment using the above method, and a method for manufacturing a thin film transistor. In the above method, by applying an energy beam partially intercepted by a light-shielding element, melt and re-crystallization occur with a light-shielded region as a starting point. The irradiation of the beam gives energy to the light-shielded region of the silicon thin film so that melt and re-crystallization occur with the light-shielded region as the starting point and so that a local temperature gradient in the light-shielded region is made to be 1200° C. / μm or more. In the manufacturing method, a resolution of an optical system used to apply the energy beam is preferably 4 μm or less.

Owner:VISTA PEAK VENTURES LLC

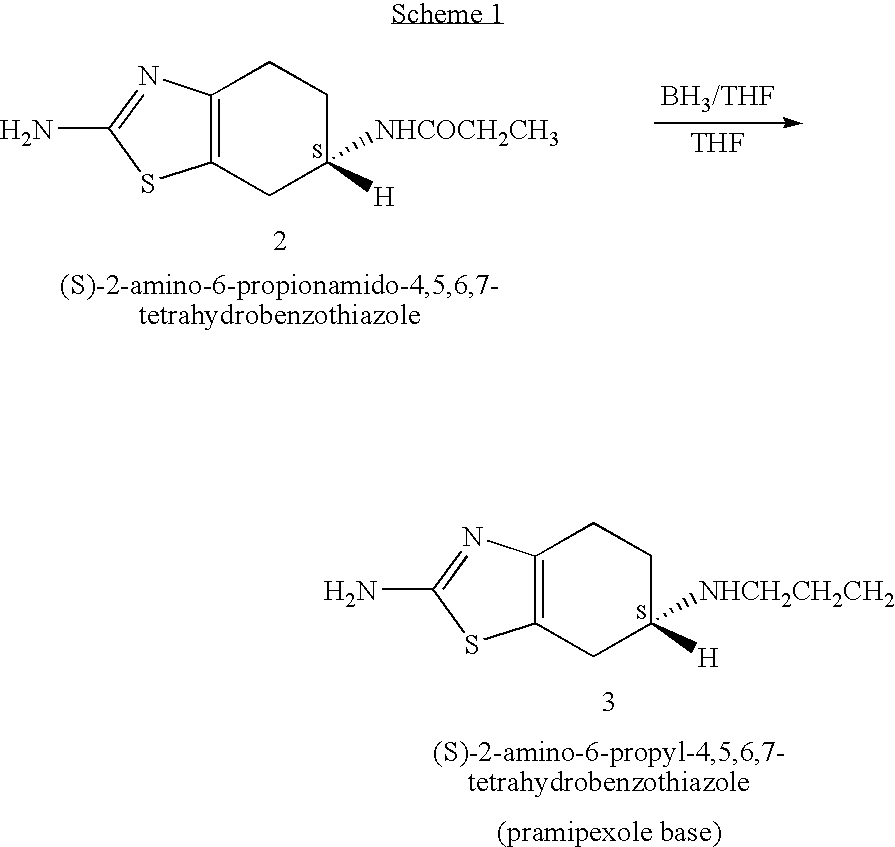

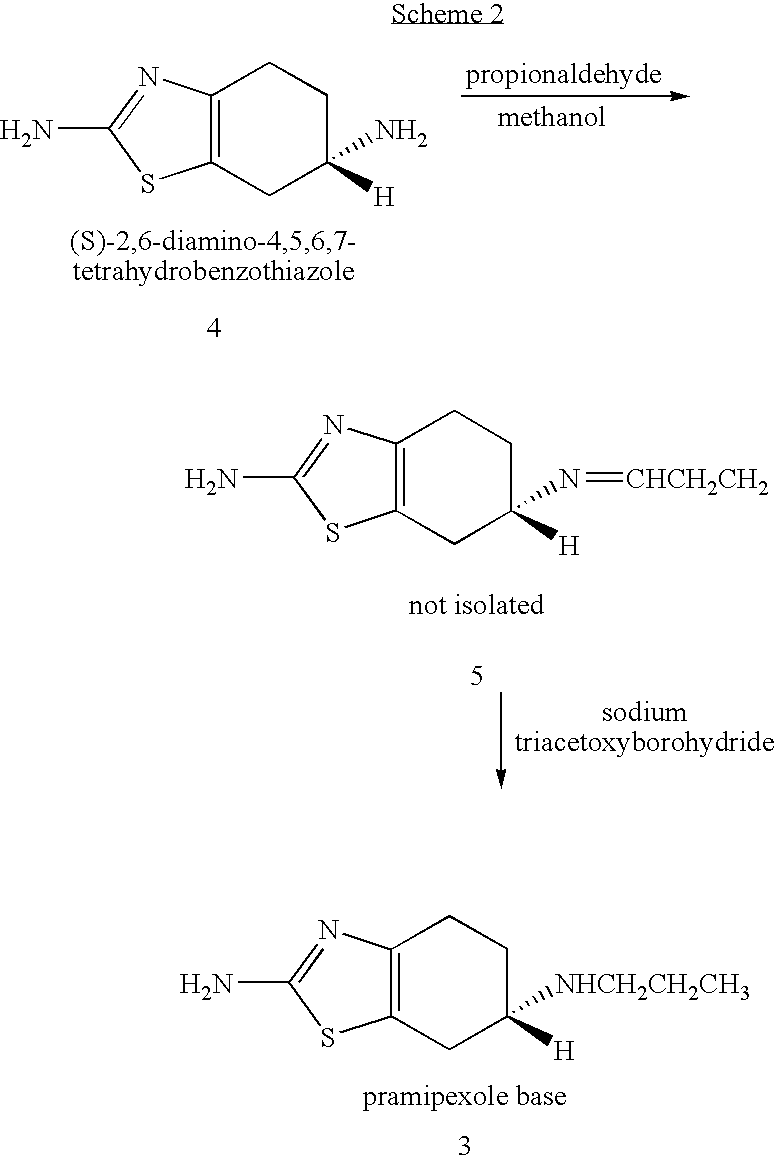

Novel process for preparing pramipexole and its optical isomeric mixture by reduction with sodium triacetoxyborohydride

InactiveUS20060148866A1Reduce usageBiocideOrganic active ingredientsOrganic solventSodium triacetoxyborohydride

A novel process is provided for producing pramipexole base or its optical isomeric mixture as defined hereinabove i.e. (R,S)-2-amino-6-propyl-4,5,6,7-tetrahydrobenzothiazole avoiding the use of borane tetrahydrofuran complex and using a more convenient reducing agent like sodium triacetoxyborohydride instead. The provided process comprises reacting the starting material (S)-2,6-diamino-4,5,6,7-tetrahydrobenzothiazole or its optical isomeric mixture as defined hereinabove i.e. (R,S)-2,6-diamino-4,5,6,7-tetrahydrobenzothiazole with propionaldehyde in an organic solvent to obtain the respective enamine, which is subsequently reduced in situ, optionally without isolation, to obtain pramipexole or its optical isomeric mixture as defined hereinabove i.e. (R,S)-2-amino-6-propyl-4,5,6,7-tetrahydrobenzothiazole, and the acid addition salts thereof. The present invention also provides a process for purifying pramipexole dihydrochloride or the dihydrochloride salt of its optical isomeric mixture as defined hereinabove i.e. (R,S)-2-amino-6-propyl-4,5,6,7-tetrahydrobenzothiazole dihydrochloride by re-crystallization from a suitable solvent.

Owner:CHEMAGIS

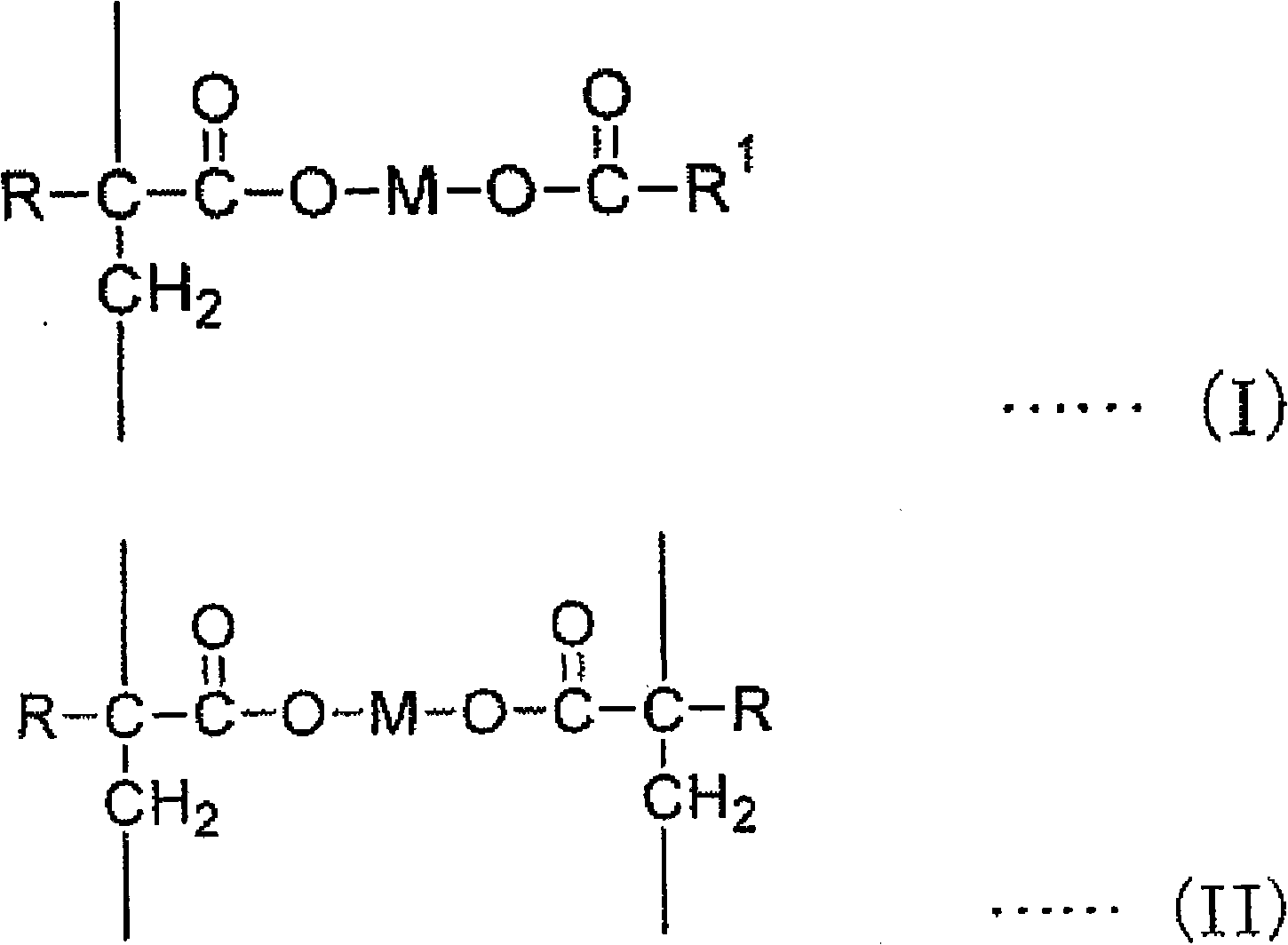

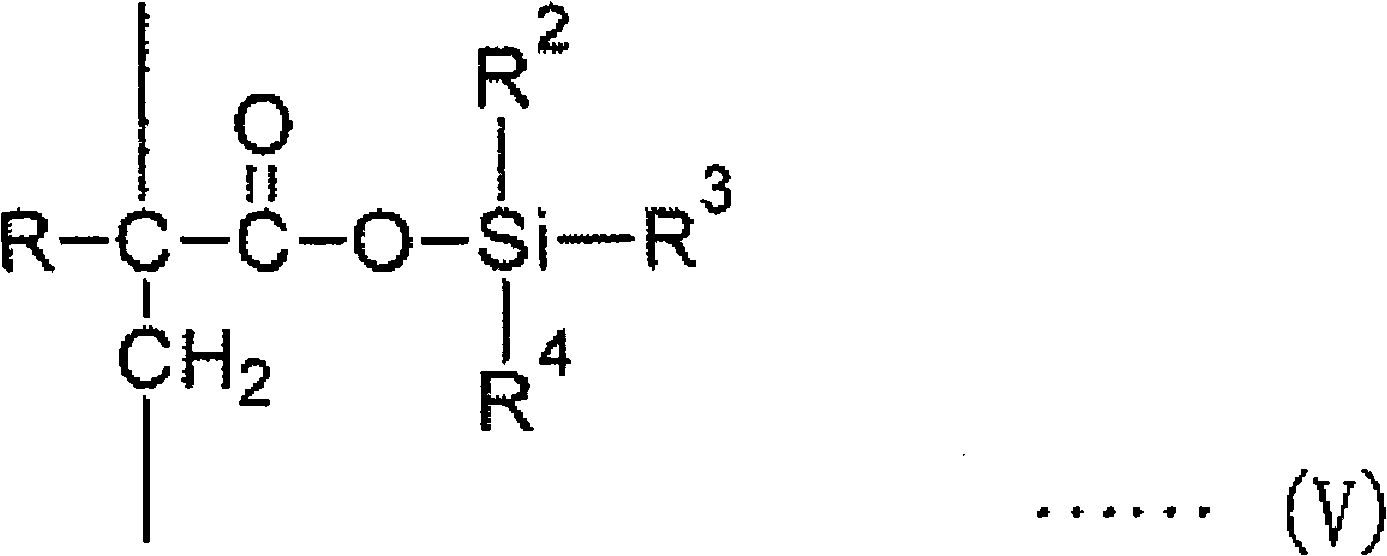

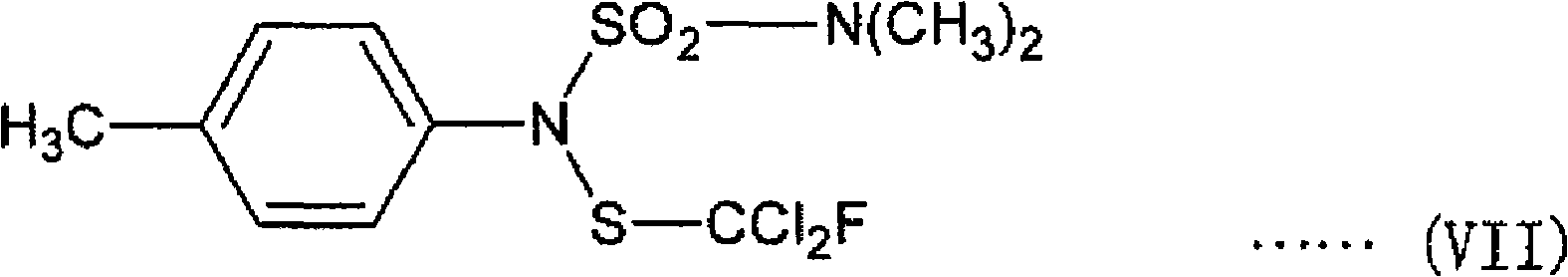

Anti-stain coating composition containing copper compound and having improved slime resistance and storage stability

InactiveCN101842453AAdequate mucus resistanceBiocideAntifouling/underwater paintsChemical compoundSulfamide

Disclosed is an anti-stain coating composition which enables to form a stain-proof coating film that can impart excellent slime resistance, and in which the re-crystallization of an anti-stain agent in the coating can be prevented. The anti-stain coating composition is characterized by comprising a coating film-forming resin (A) and the following anti-stain agents (B) and (C): (B) an inorganic copper-containing anti-stain agent (e.g., copper suboxide); and (C) N,N'-dimethyl-N'-tolyl-(N-fluorodichloromethylthio)- sulfamide. The anti-stain agent (B) is preferably contained at a ratio of 60 to 1000 parts by weight relative to 100 parts by weight of the coating film-forming resin (A). The anti-stain agent (C) is preferably contained at a ratio of 1.4 to 80 parts by weight relative to 100 parts by weight of the coating film-forming resin (A). The anti-stain agent (C) is preferably contained at a ratio of 0.1 to 100 parts by weight relative to 100 parts by weight of the anti-stain agent (B).

Owner:CHUGOKU MARINE PAINTS

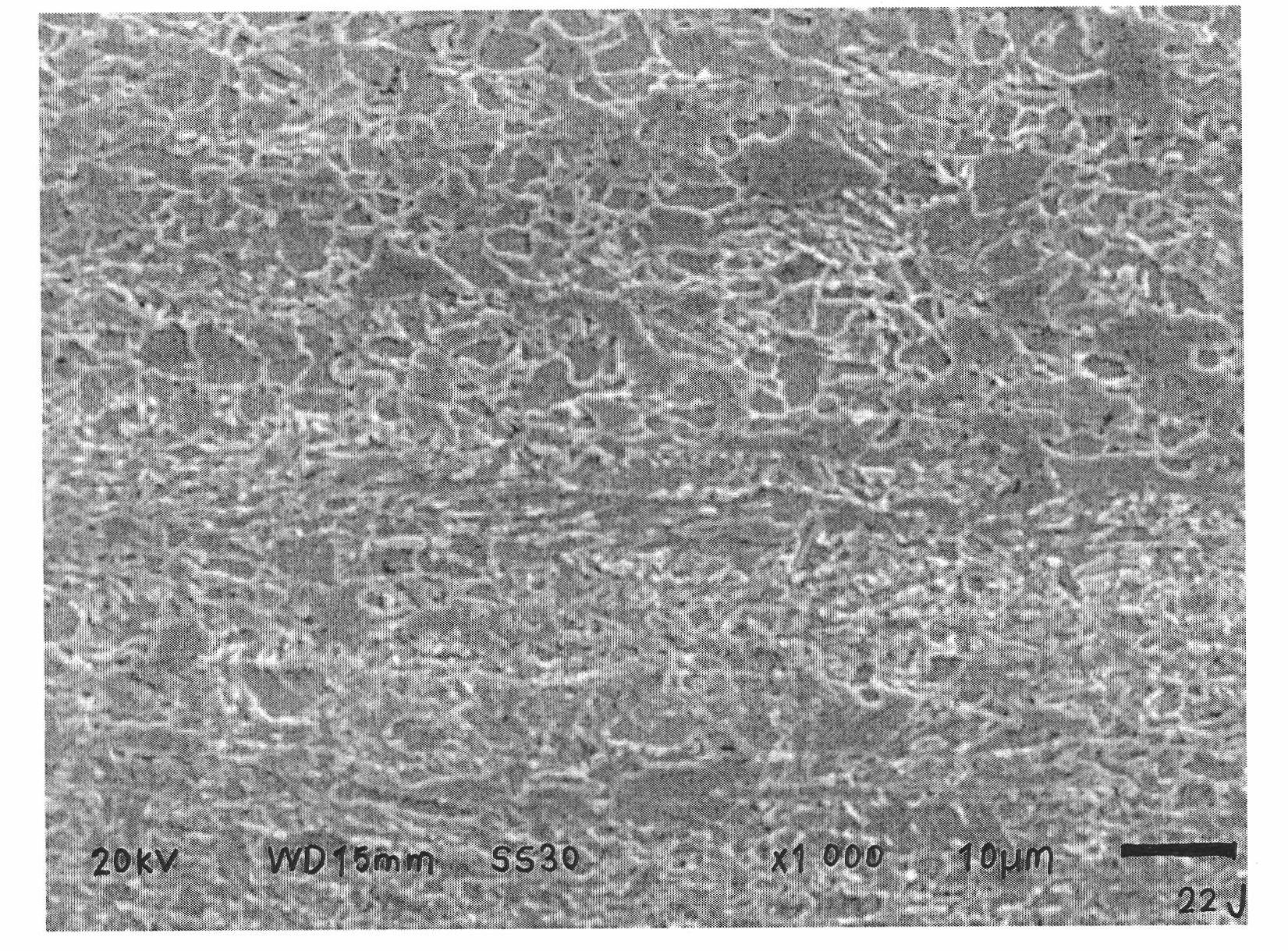

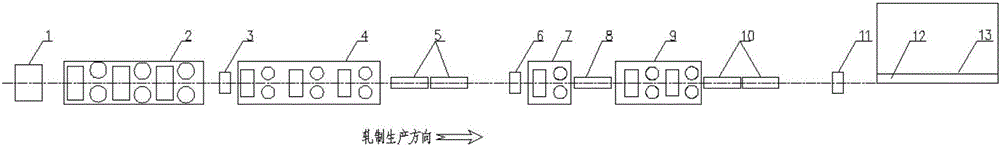

Production system and method of low-yield-ratio hot-rolled high-strength anti-seismic reinforcing steel bars

ActiveCN106077085ALow yield ratioHigh strengthTemperature control deviceWork treatment devicesRebarMaterials science

The invention provides a production system and method of low-yield-ratio hot-rolled high-strength anti-seismic reinforcing steel bars. The method includes the steps that a heating furnace, a rough rolling unit, a pair of truncate scissors, an intermediate rolling unit, a post-intermediate-rolling water cooling device, another pair of truncate scissors, a finish rolling unit front section, a finish rolling water cooling device, a finish rolling unit rear section, a post-finish-rolling water cooling device, multi-lengths flying shears and a cooling bed are sequentially arranged in the rolling direction; rolling of a re-crystallization area is achieved by precisely controlling rolling temperature, austenite grains are refined, the rolling temperature of a critical austenitic area and ferrite re-crystallization area is precisely controlled through water cooling and a recovery section, deformation induced ferrite phase change and two-phase district ferrite phase change are achieved, perlitic transformation and little bainite transformation are achieved through after-rolling water cooling, strength, plasticity and toughness of the ribbed bars can be remarkably improved, and the ribbed bars have a low yield ratio and good plasticity, toughness, anti-seismic performance and welding performance. Meanwhile, the rolling fault rate is reduced through high-temperature rolling of a rough rolling area and an intermediate rolling area and production efficiency is improved.

Owner:CISDI ENG CO LTD

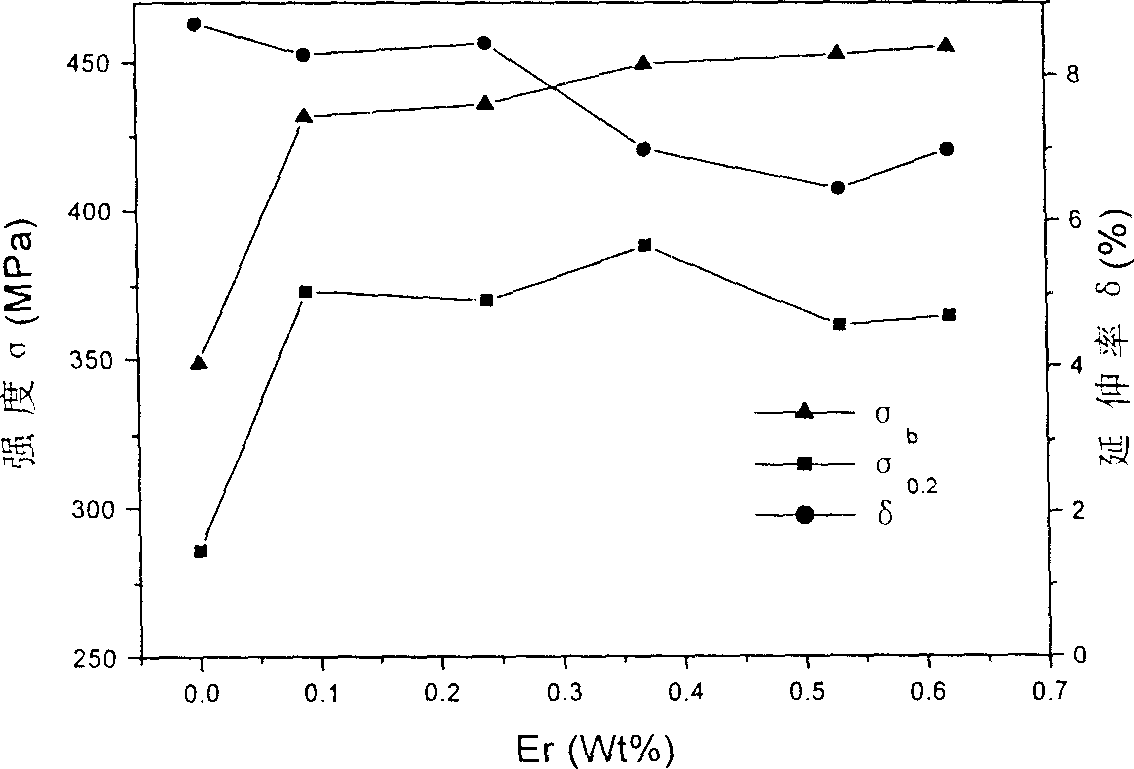

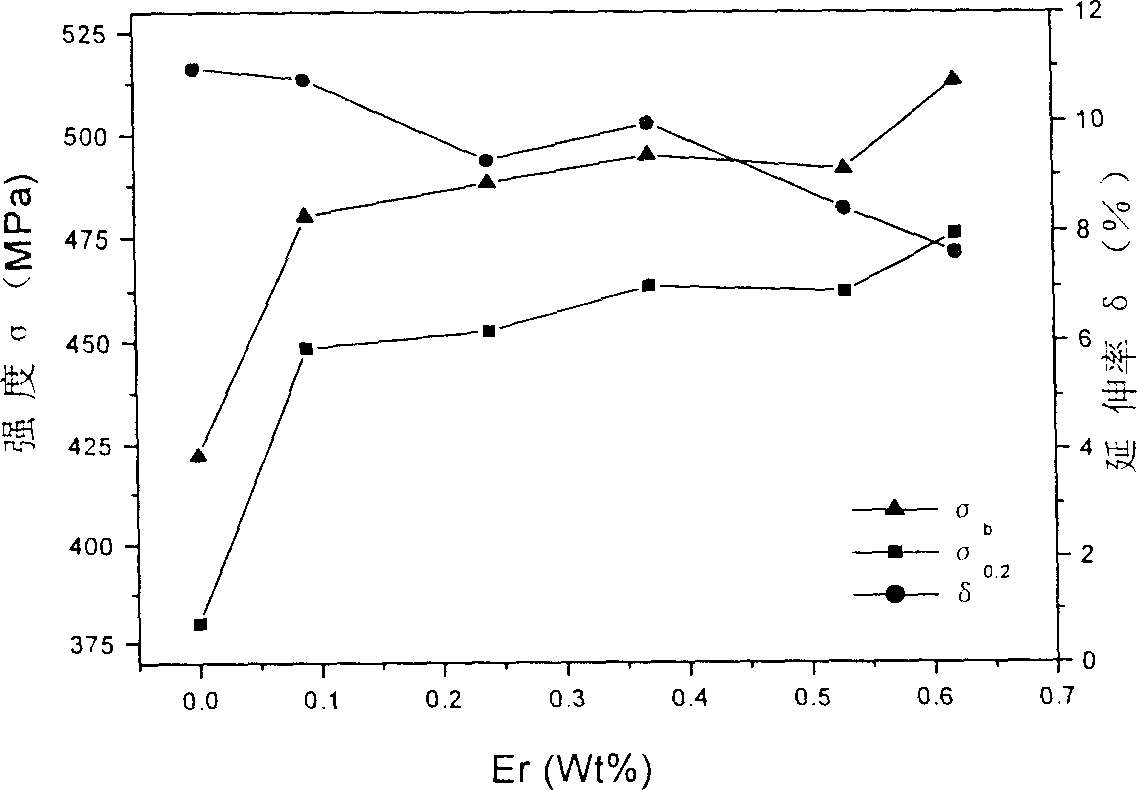

Al-Zn-Mg-Er rare earth aluminium alloy

The present invention relates to metal alloy technology. The key of the present invention is the addition of RE element Er in the experiment determined amount 0.1-0.7 wt% into the alloy. During the preparation process of the Al-Zn-Mg-Er alloy, Al-Er intermediate alloy through vacuum smelting is added into Al-Zn-Mg alloy. The addition of Er can fine obviously the alloy grains, raise alloy strength greatly and suppress re-crystallization. In addition, Er is relatively cheap and its addition has no significant increase in production cost. On the basis of Al-Zn-Mg alloy as one of the typical industrial Al alloy, one series of Er containing Al-RE alloy may be developed and used in astronautics, aeronautics, traffic and other fields.

Owner:BEIJING UNIV OF TECH

Method for refining long-carbon chain dicarboxylic acid

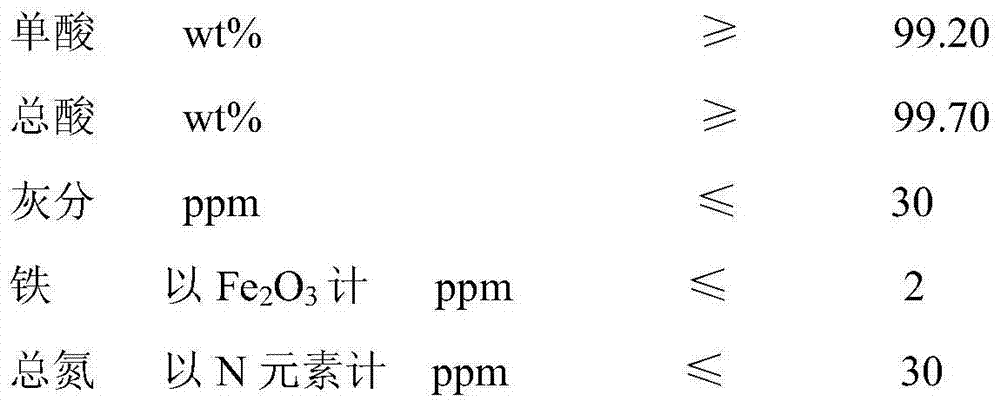

ActiveCN104496793AMeet the technical requirements of useLess investmentCarboxylic compound separation/purificationEngineeringCarboxylic acid

The invention relates to a method for refining long-carbon chain dicarboxylic acid. A long-chain dicarboxylic acid crude product prepared by a fermentation method is used as a raw material, acetic acid is used as a solvent, and the refining and purification are performed by recrystallization treatment. The method comprises the process steps of bleaching filtration, cooling crystallization, centrifugal separation, centrifugal material washing, secondary centrifugation and drying, and is characterized in that a. the long-chain dicarboxylic acid crude product to be refined does not need to be dried; b. the acetic acid solvent is recycled by an azeotropic distillation method, and isopropyl acetate is used as an azeotropic dehydrating agent; and c. the isopropyl acetate is used as a centrifugal material washing solvent for replacing the acetic acid. The purification method of the long-carbon chain dicarboxylic acid provided by the invention has the advantages of distillation equipment investment conservation, low operating power consumption, good product color, high purity, high refining yield and low production cost, the long-carbon chain dicarboxylic acid to be refined does not need to be dried and dehydrated, and the acetic acid solvent is completely recyclable. The quality of the refined product can meet the technical requirements of use of condensed monomer raw materials used by synthesis of high polymer materials.

Owner:山东广通新材料有限公司

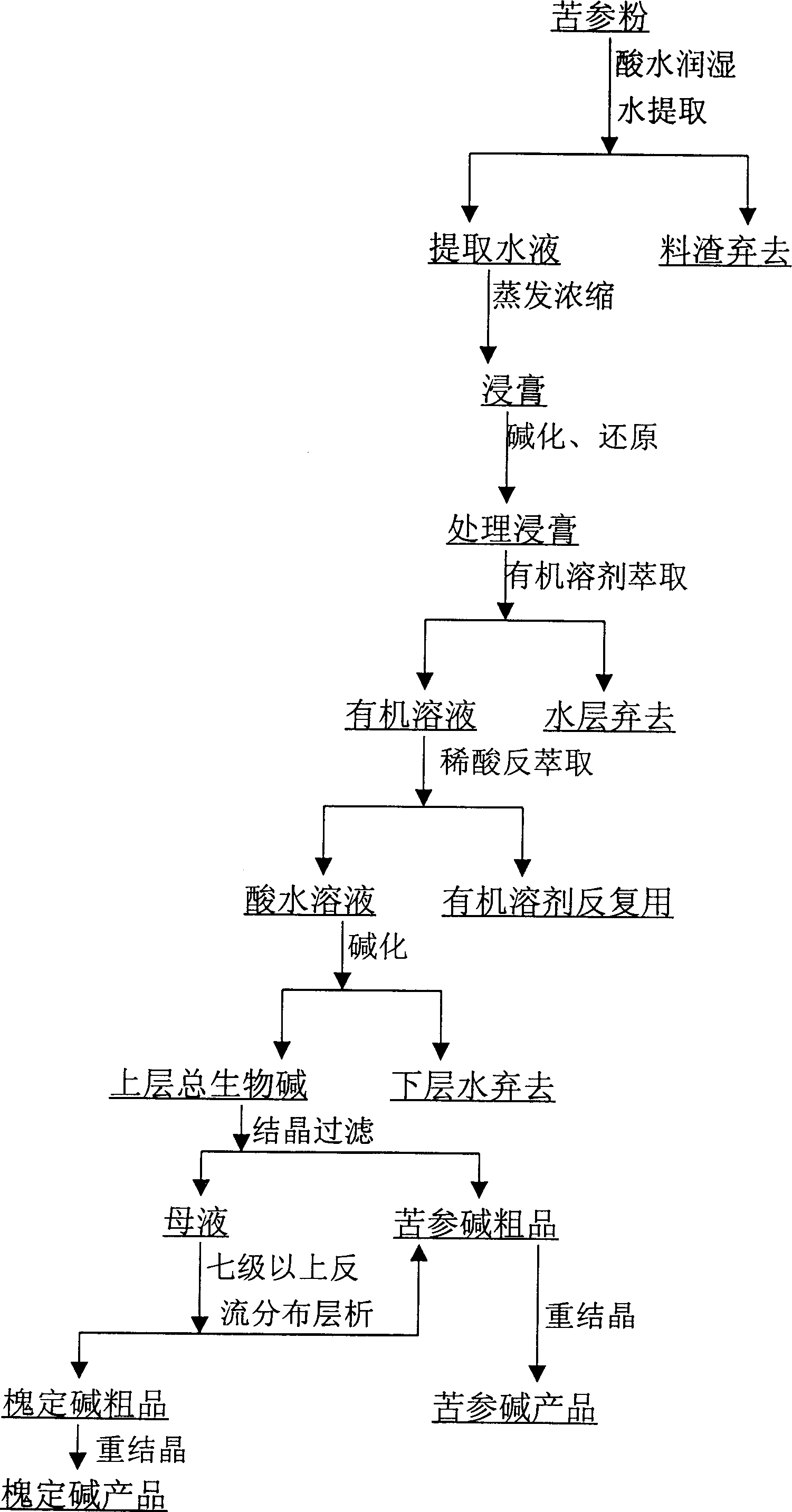

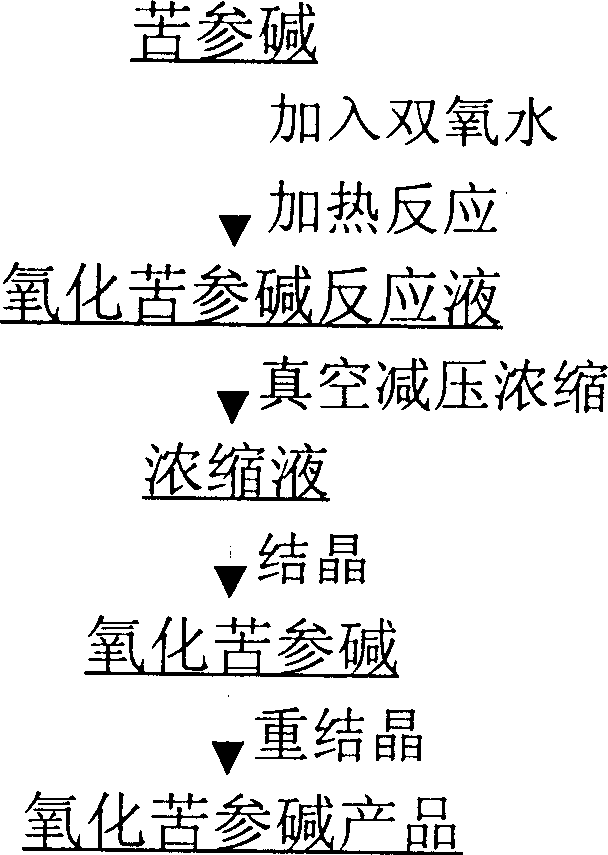

Prepn of matrine, oxymatrine and sophoxidine from flavescent sophora root

The production process features that dried and crushed flavescent sophora root is processed through extraction, concentration, alkalization, reduction, solvent extraction, acid reverse extraction, deposition and separation to produce coarse matrine product and coarse sophoridine product; coarse matrine product and coarse sophoridine product are recrystallized and dried to obtain matrine product and sophoridine product; and matrine is further processed through oxidation with hydrogen peroxide, decompression distillation, crystallization, filtering, re-crystallization and drying to obtain oxymatrine product. The said three products are material for producing medicine for treating hepatitis B, hepatitis C, leucopenia, arrhythmia, cancer and other diseases.The production process of the present invention is simple, low in cost, high in product purity and suitable for industrial production.

Owner:王答祺 +2

Preparation method of metformin hydrochloride

ActiveCN103435518AHigh recovery rateImprove securityOrganic chemistryOrganic compound preparationMetformin hclPharmacology

The invention discloses a preparation method of metformin hydrochloride. The preparation method is characterized by using dicyandiamide and dimethylamine hydrochloride as raw materials, feeding the materials in a mole ratio of (1:1)-(1:1.2), using N,N-dimethylacetamide or dimethyl sulfoxide 2-4 times dicyandiamide by weight as a solvent, and reacting for 4-8 hours at 140+ / -5 DEG C to prepare a crude metformin hydrochloride product; recrystallizing the crude product with ethanol, regulating the pH value to be 5-6, decoloring the crystal, cooling the crystal to minus 10-0 DEG C while stirring, precipitating the crystal, obtaining a refined metformin hydrochloride product through filtering and drying, and recovering the solvent from filtrate. The qualified product has yield of 80-85% and high purity. The preparation method has the advantages that as the selected reaction solvent has a relatively high boiling point, the recovery rate of the solvent is high; the phenomenon of material surging can be effectively avoided, so that the preparation method has the advantages of mild reaction conditions, simplicity in operation and high safety.

Owner:QINGDAO HUANGHAI PHARM CO LTD

Preparation method of ambroxol hydrochloride

InactiveCN103012167AAvoid processing powerAvoid the corresponding processOrganic compound preparationAmino-hyroxy compound preparationBiotechnologyBiochemical engineering

The invention discloses a preparation method of ambroxol hydrochloride. According to the preparation method, a 'one-pot reaction' is adopted in the reaction, so that the separation of an intermediate is avoided, the operation is simple, the production period is short, the production cost is reduced, and the method is suitable for industrial production and application; the operation in refining the ambroxol hydrochloride is easy to carry out; and the ambroxol hydrochloride with purity more than 99.9% can be simply obtained by one-time recrystallization, so that the demand on preparation production can be met.

Owner:石药集团中诺药业(石家庄)有限公司

Antioxidant EGCG aliphatic ester and prep. thereof

InactiveCN1448395AImprove securityHigh antioxidant factorOrganic chemistryChemical inhibitorsVegetable oilOrganic solvent

The EGCG fatty ester is prepared with natural catechin EGCG monomer and C12-C22 fatty acyl chloride in the molar ratio of 1-2 as material. In the presence of alkali catalyst or metal catalyst and in25-65 deg.c, fatty acyl chloride is dropped slowly into inert organic solvent containing catechin EGCG monomer; and through filtering, water washing, decompression concentration, re-crystallization and dewatering to dry, white solid EGCG fatty ester is prepared. The liposoluble EGCG fatty ester thus prepared has determined components, high antioxidant factor content, molecular structure capable of maintaining the structure features of catechin and even higher stability. The present invention may be used in medicine, edible vegetable oil, fried food, cosmetics, feed and other fields needing antioxidant additive.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com