Patents

Literature

41results about How to "No longer be formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

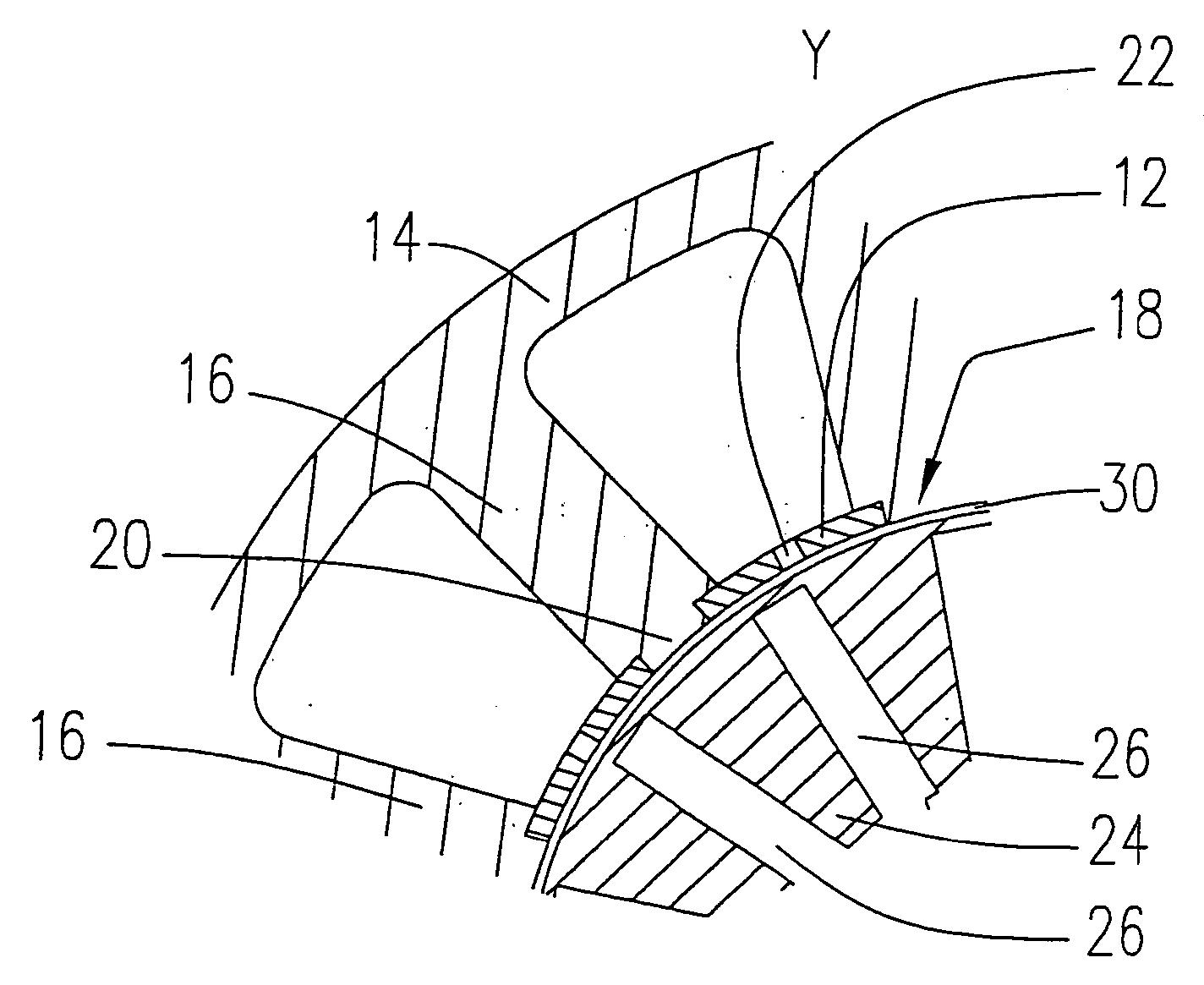

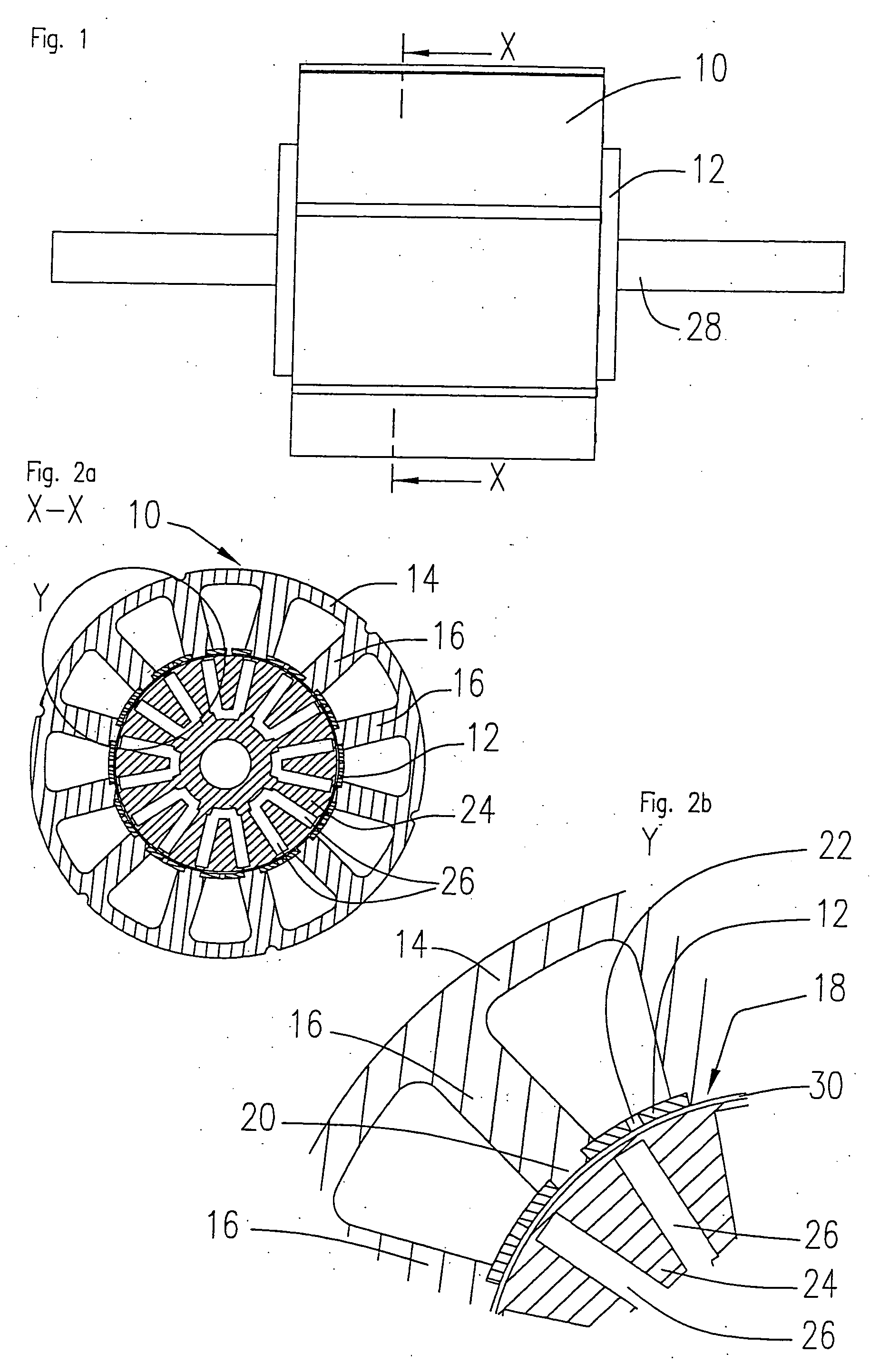

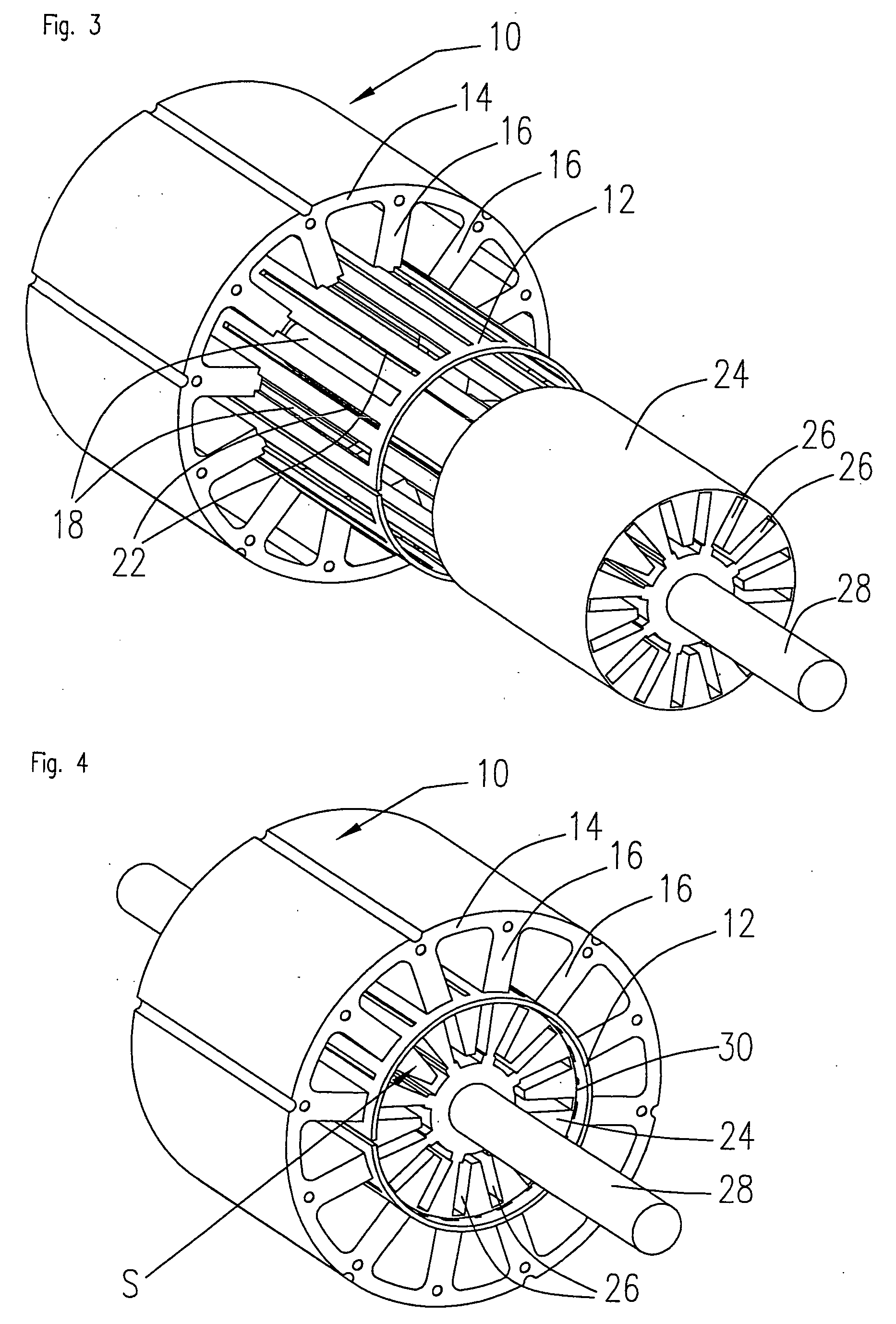

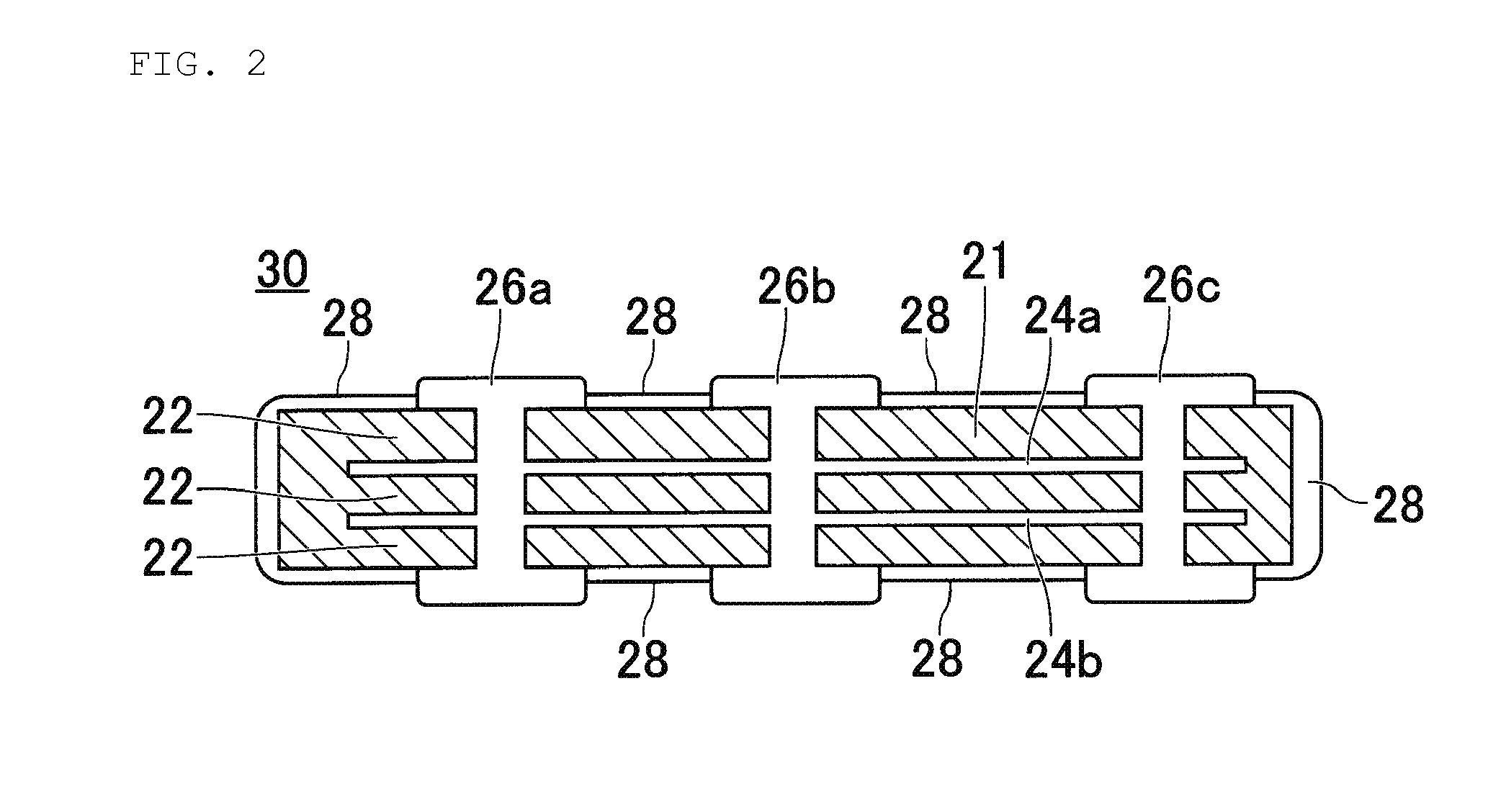

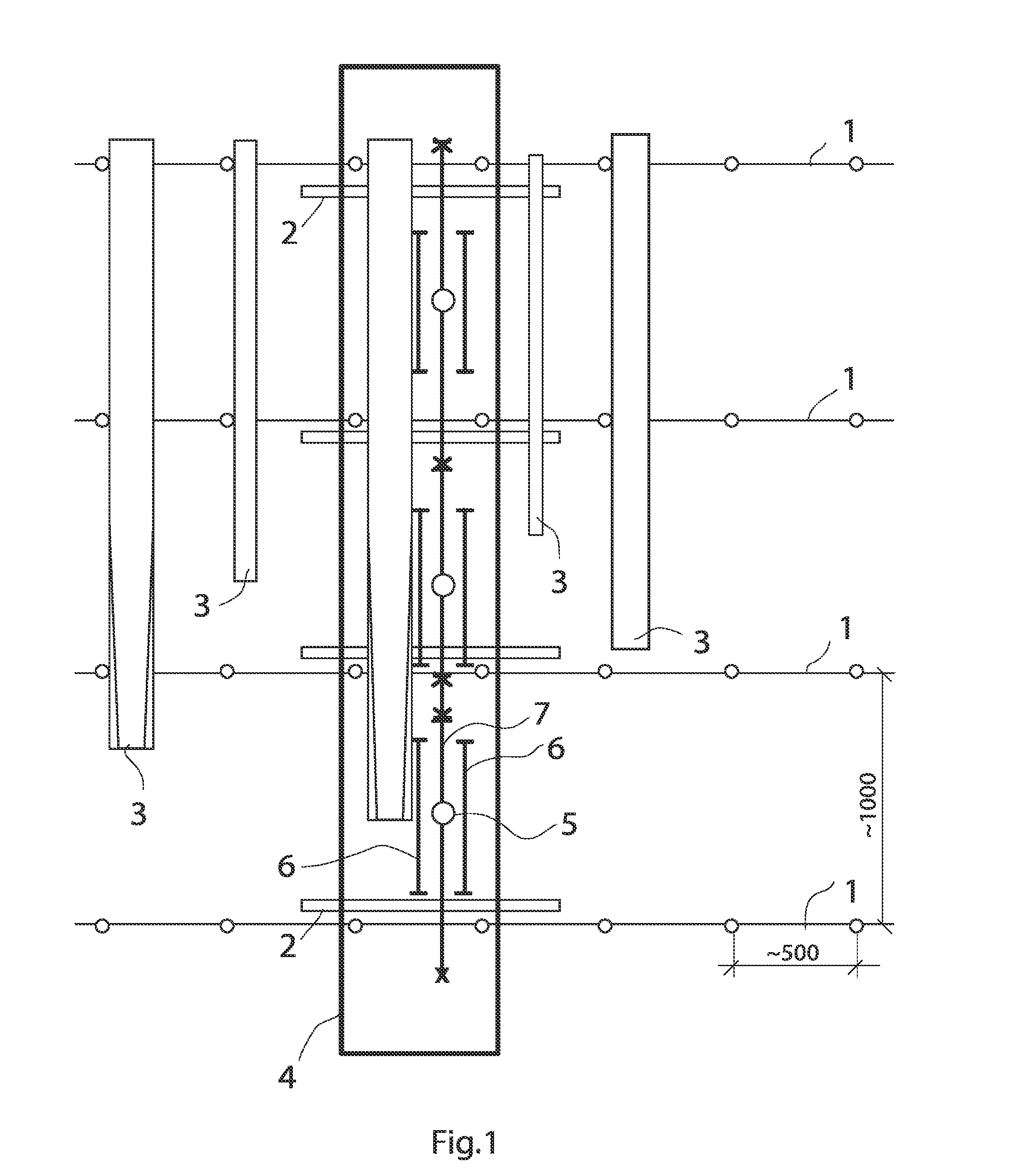

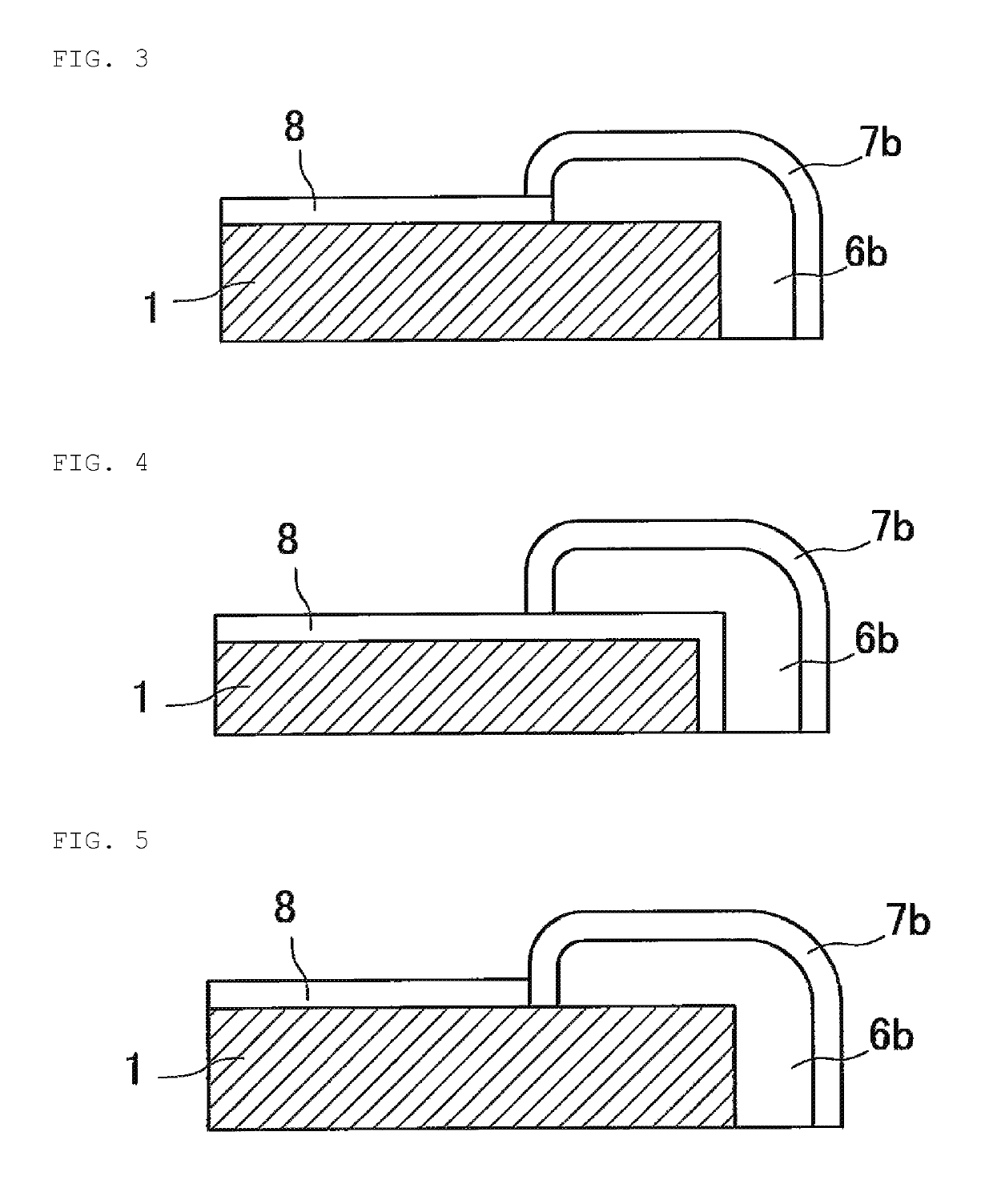

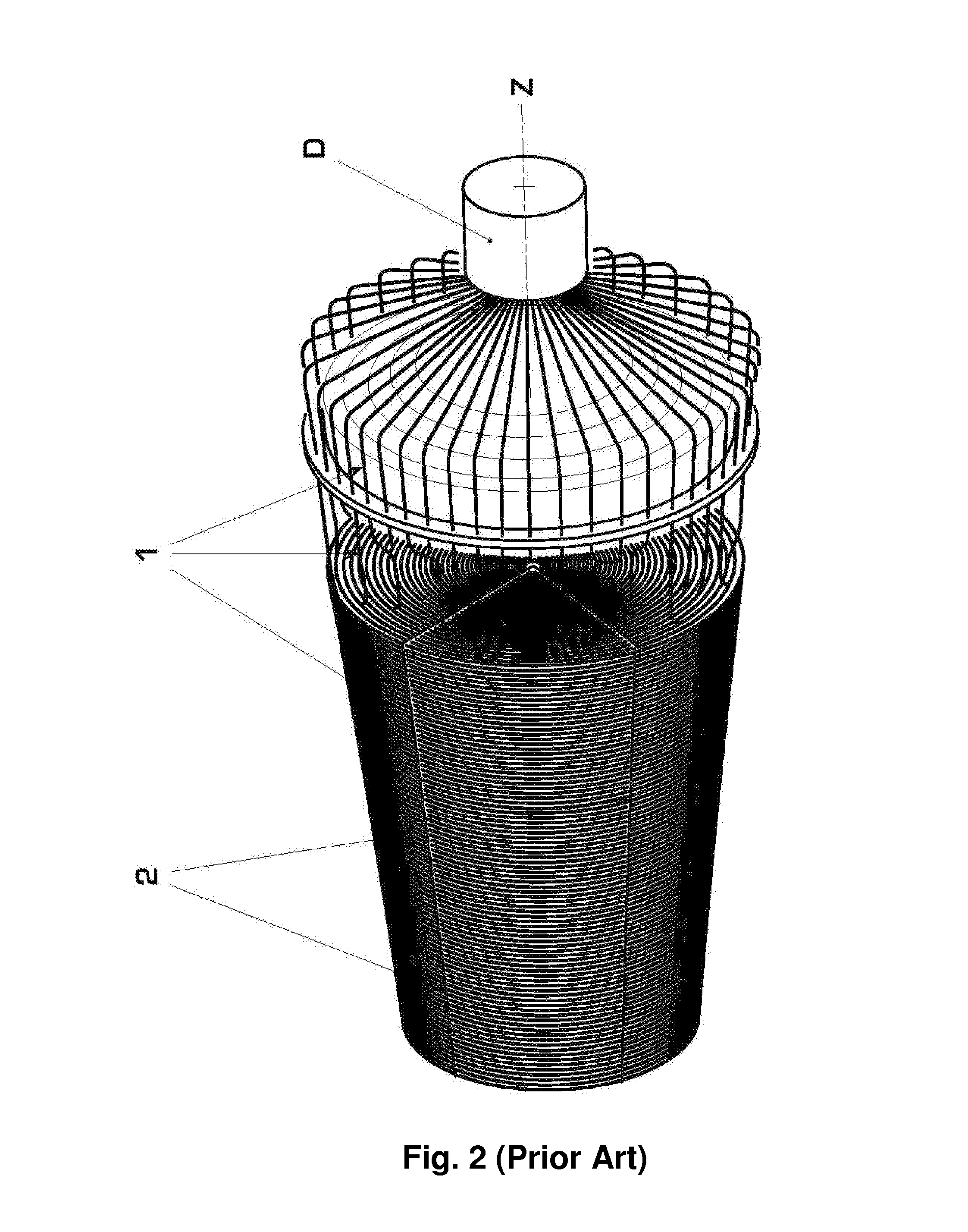

Stator arrangement for an electric machine, a method for the manufacture of a stator arrangement and a direct current motor

InactiveUS20060108890A1Minimizes problemPrevent materialWindingsMagnetic circuit stationary partsElectric machineConductor Coil

The invention relates to a stator arrangement for an electric machine, particularly a DC motor, comprising a stator body having a stator back yoke ring and a number of stator teeth between which stator slots to receive stator windings are formed, the stator teeth extending radially from the stator back yoke ring and stator poles being formed at the free ends of the stator teeth, the stator teeth being coupled to a sleeve, which extends coaxially to the stator body, at their free ends. The invention also relates to a method for the manufacture of a stator arrangement of this kind and a direct current motor that employs such a stator arrangement.

Owner:MINEBEA CO LTD

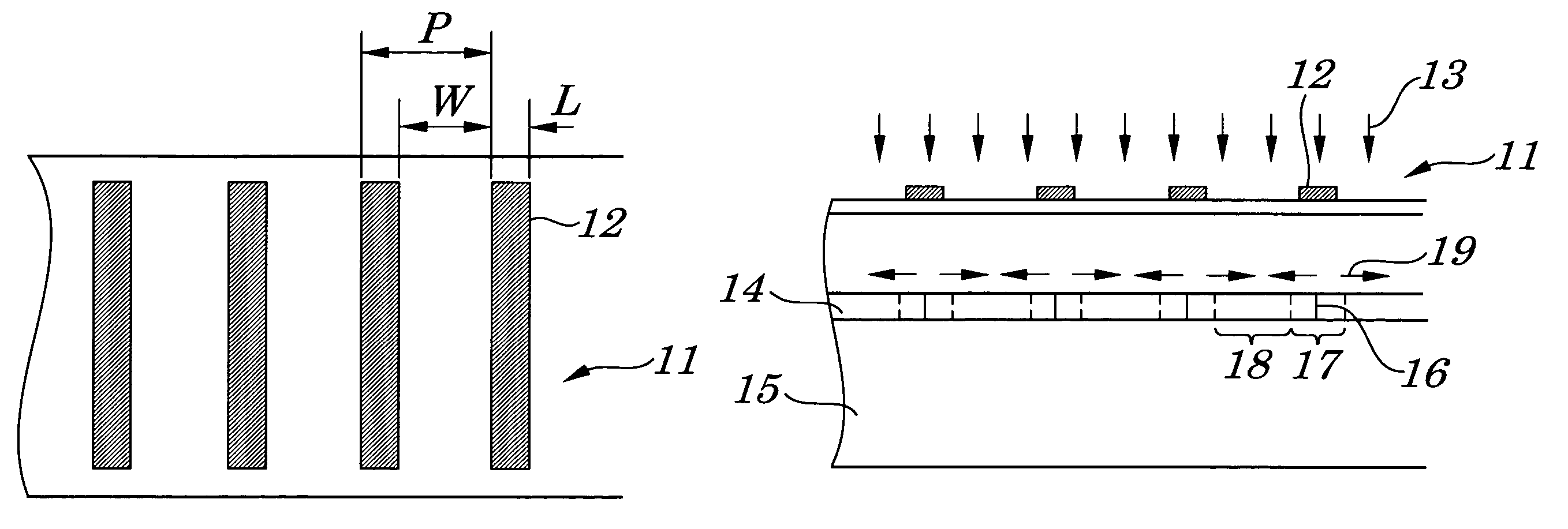

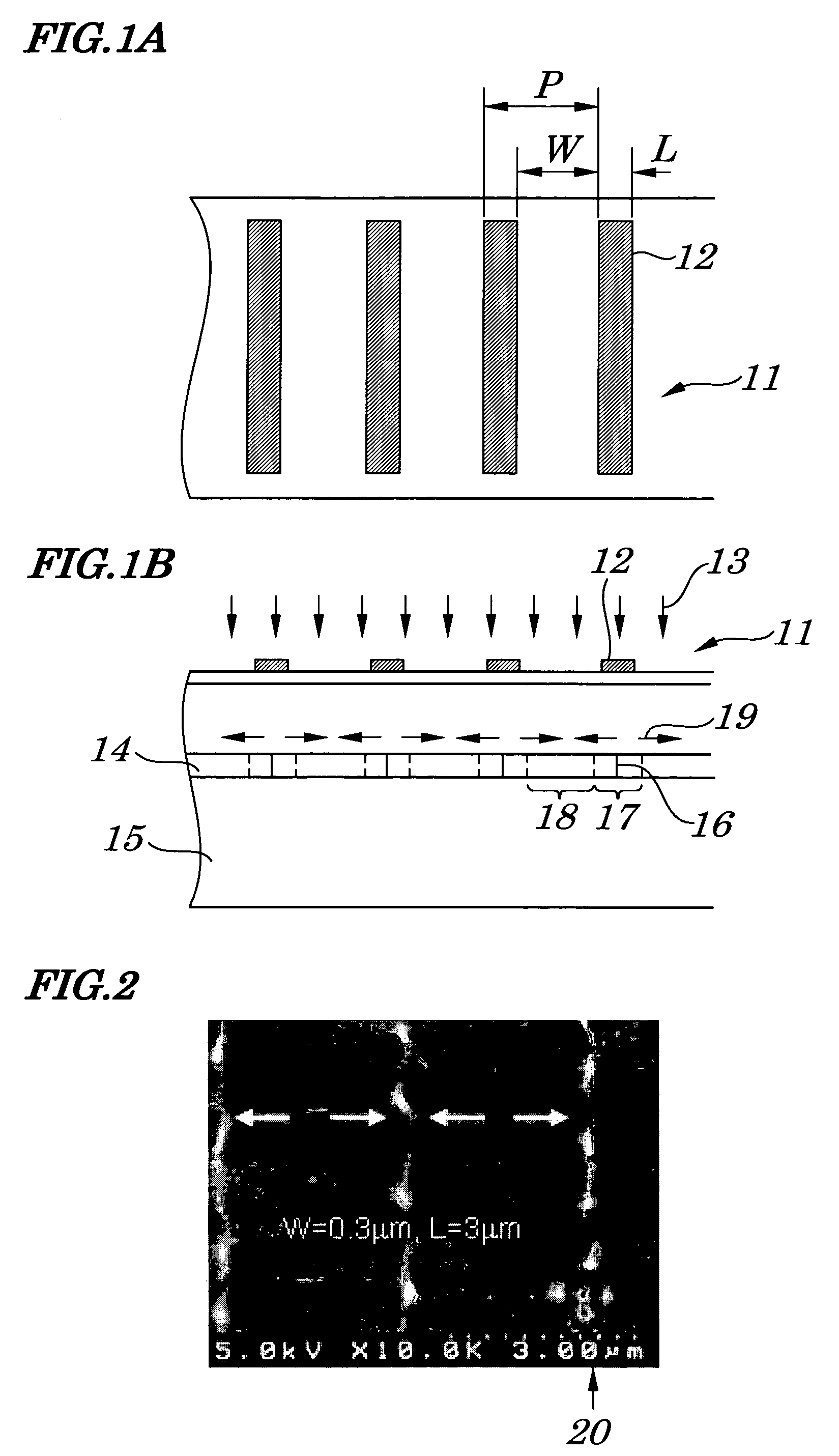

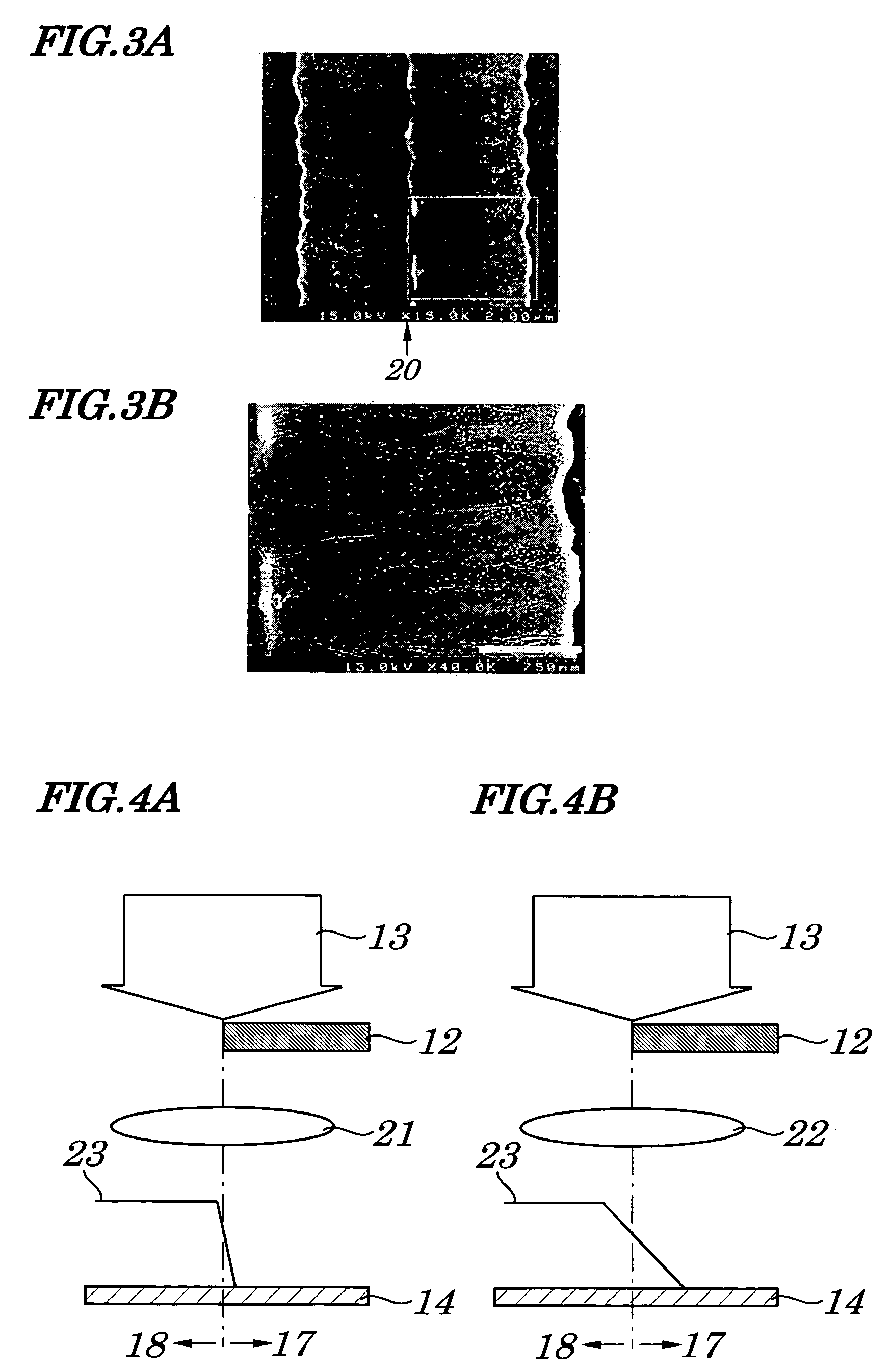

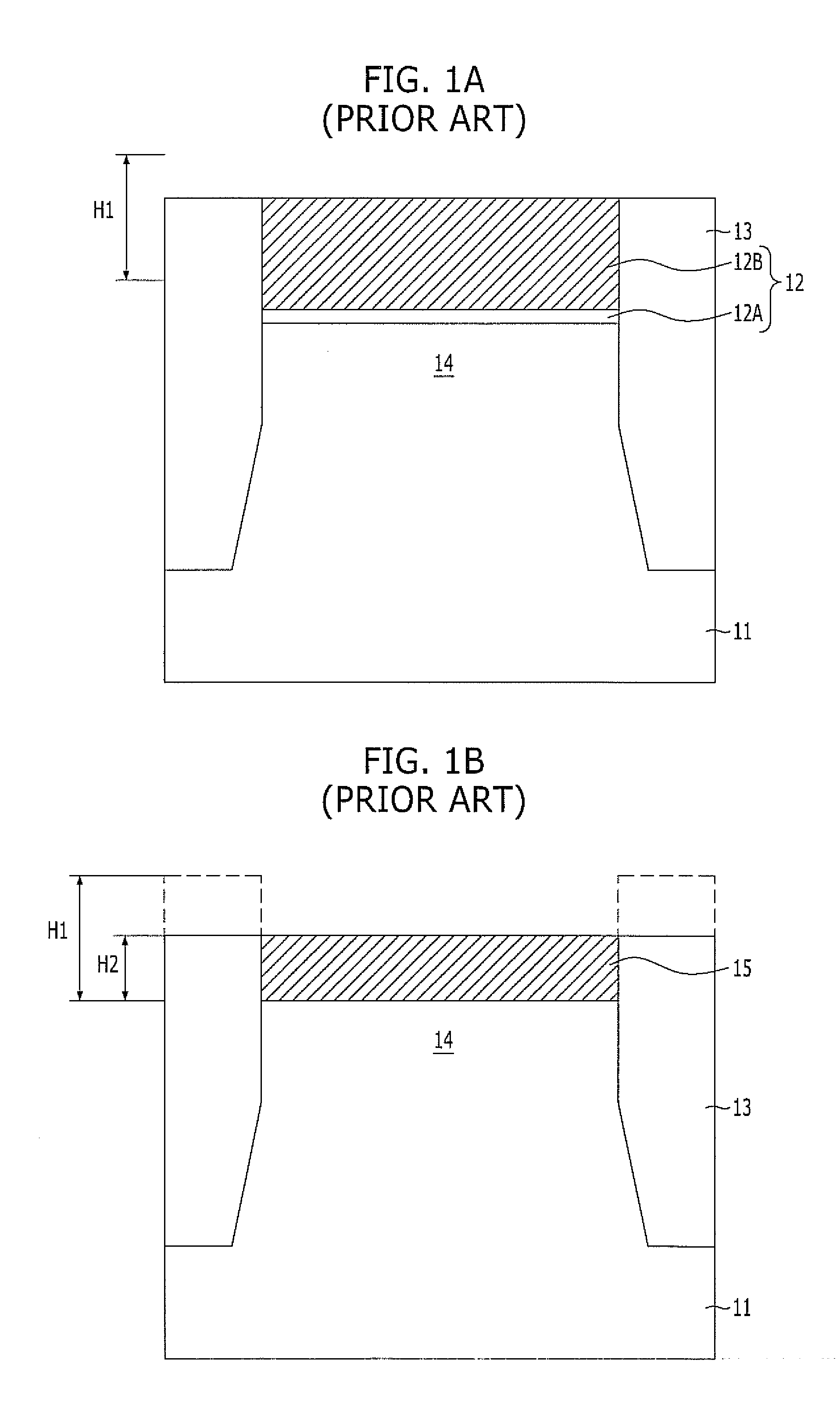

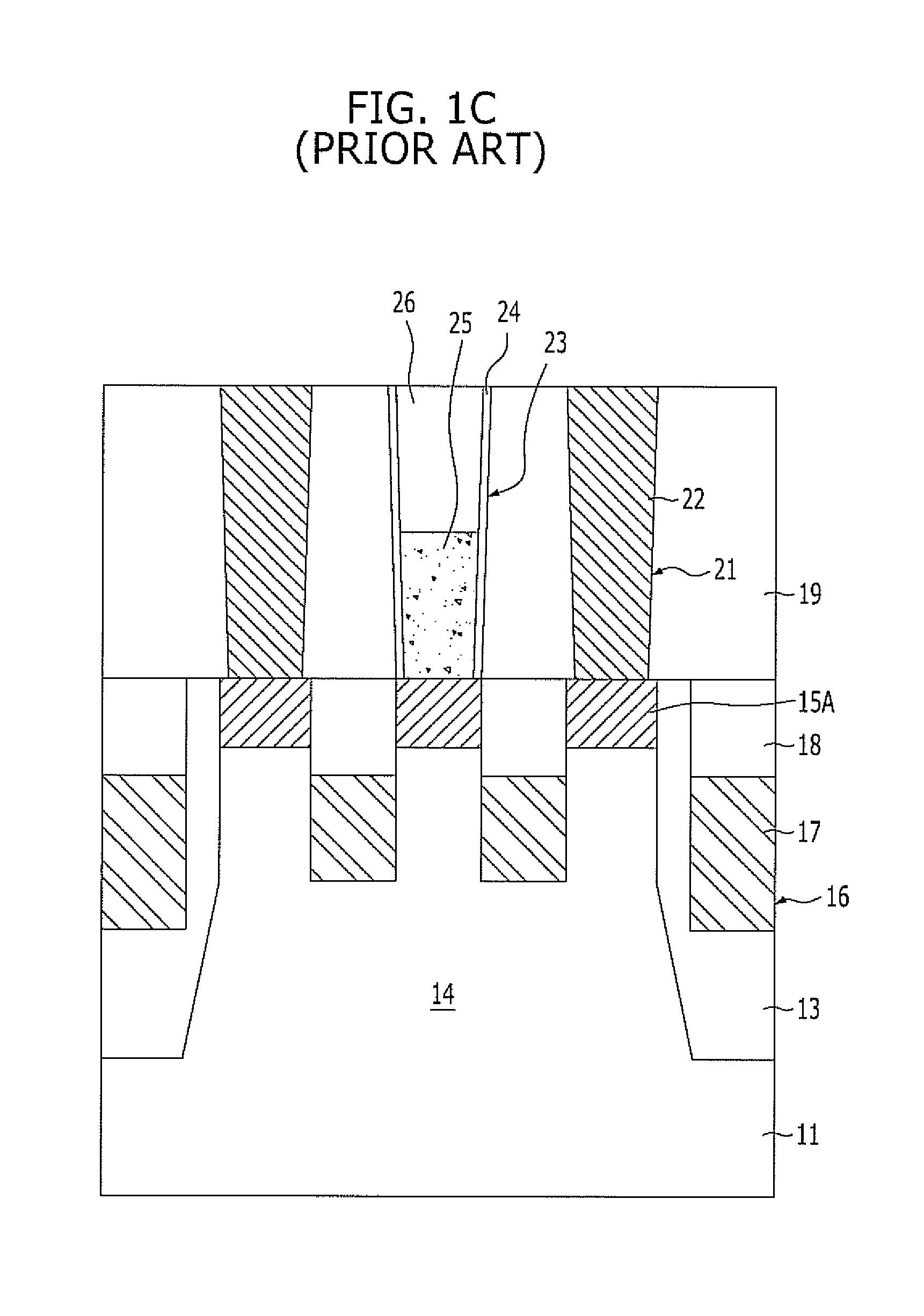

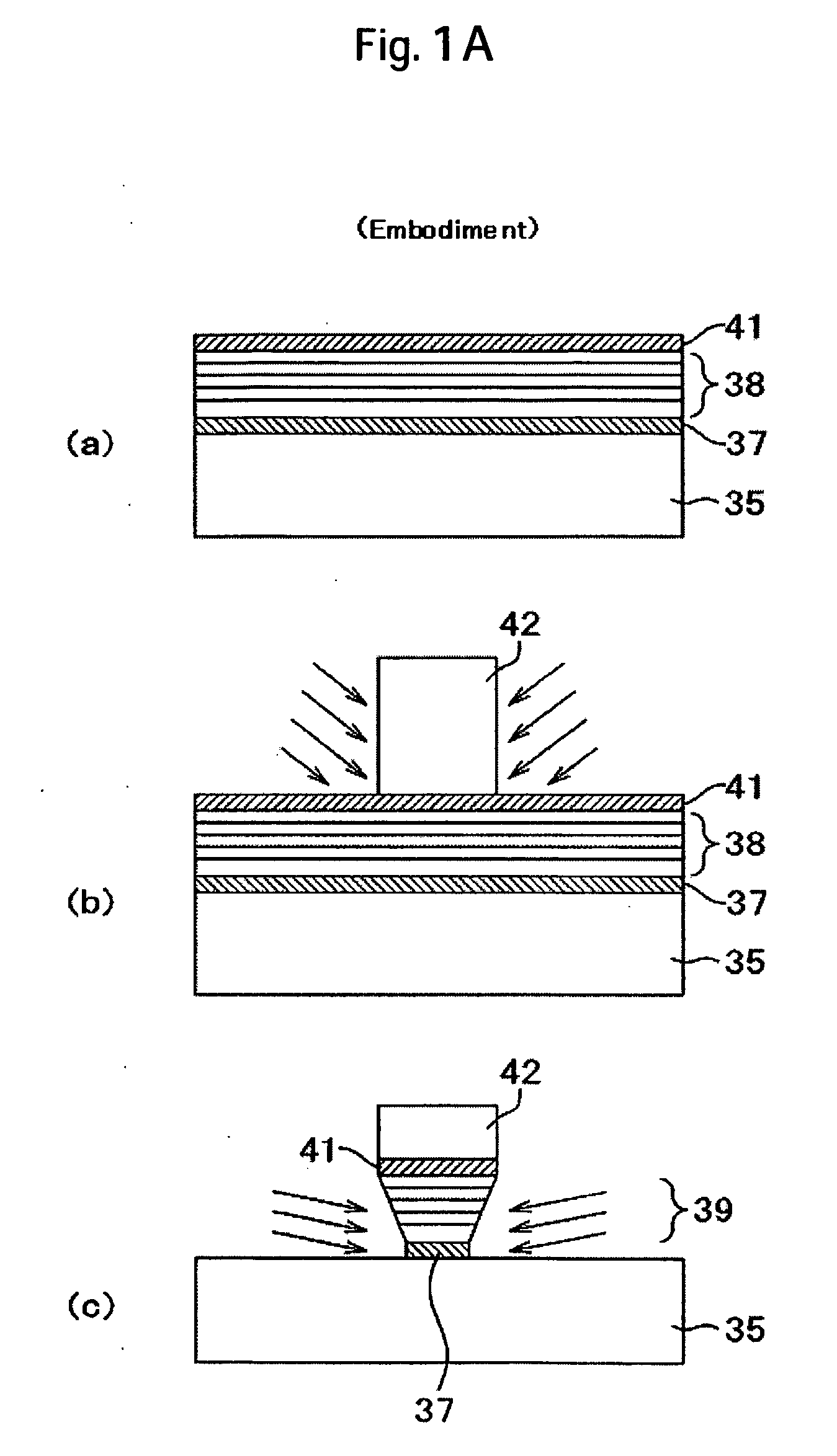

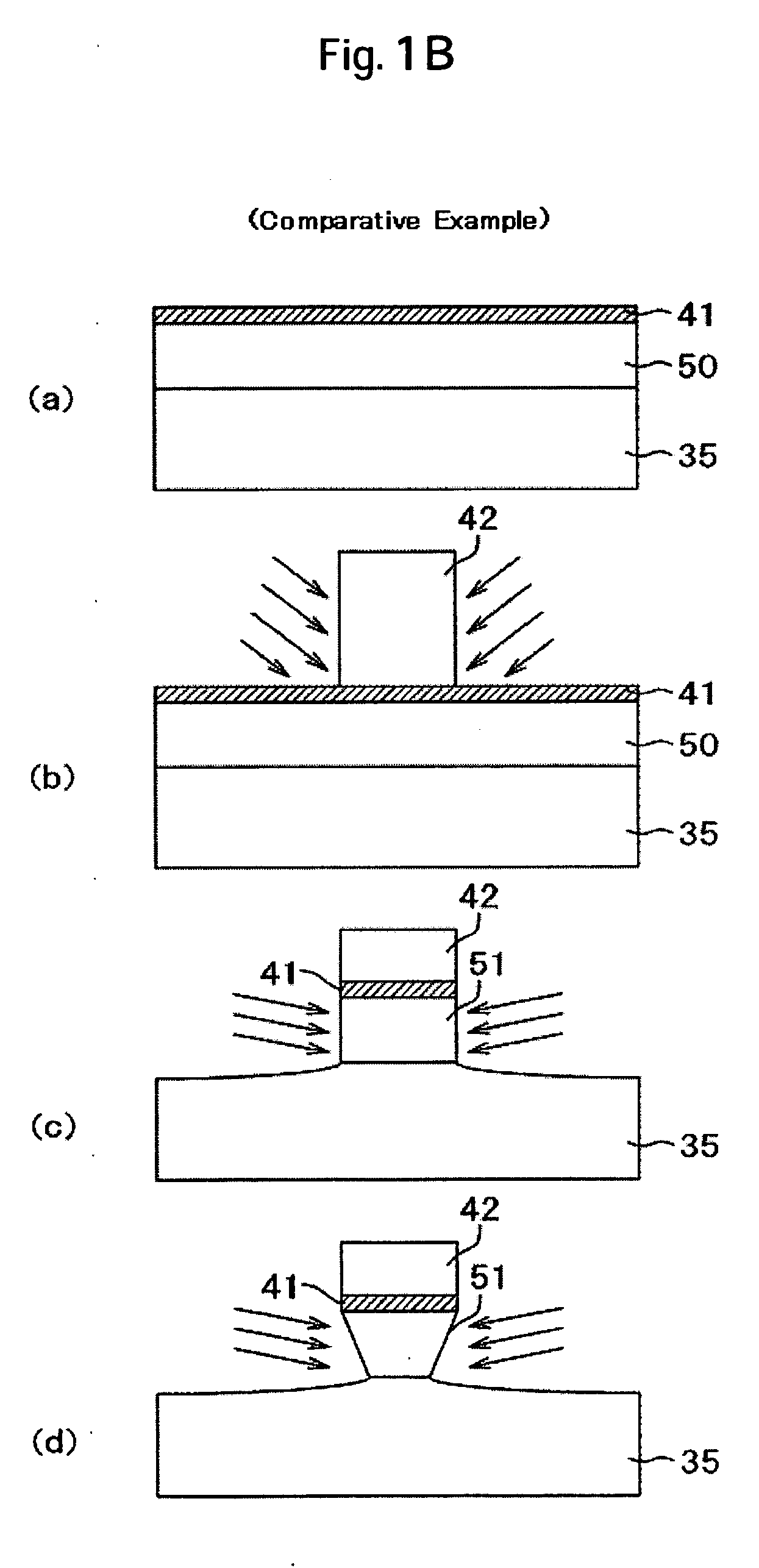

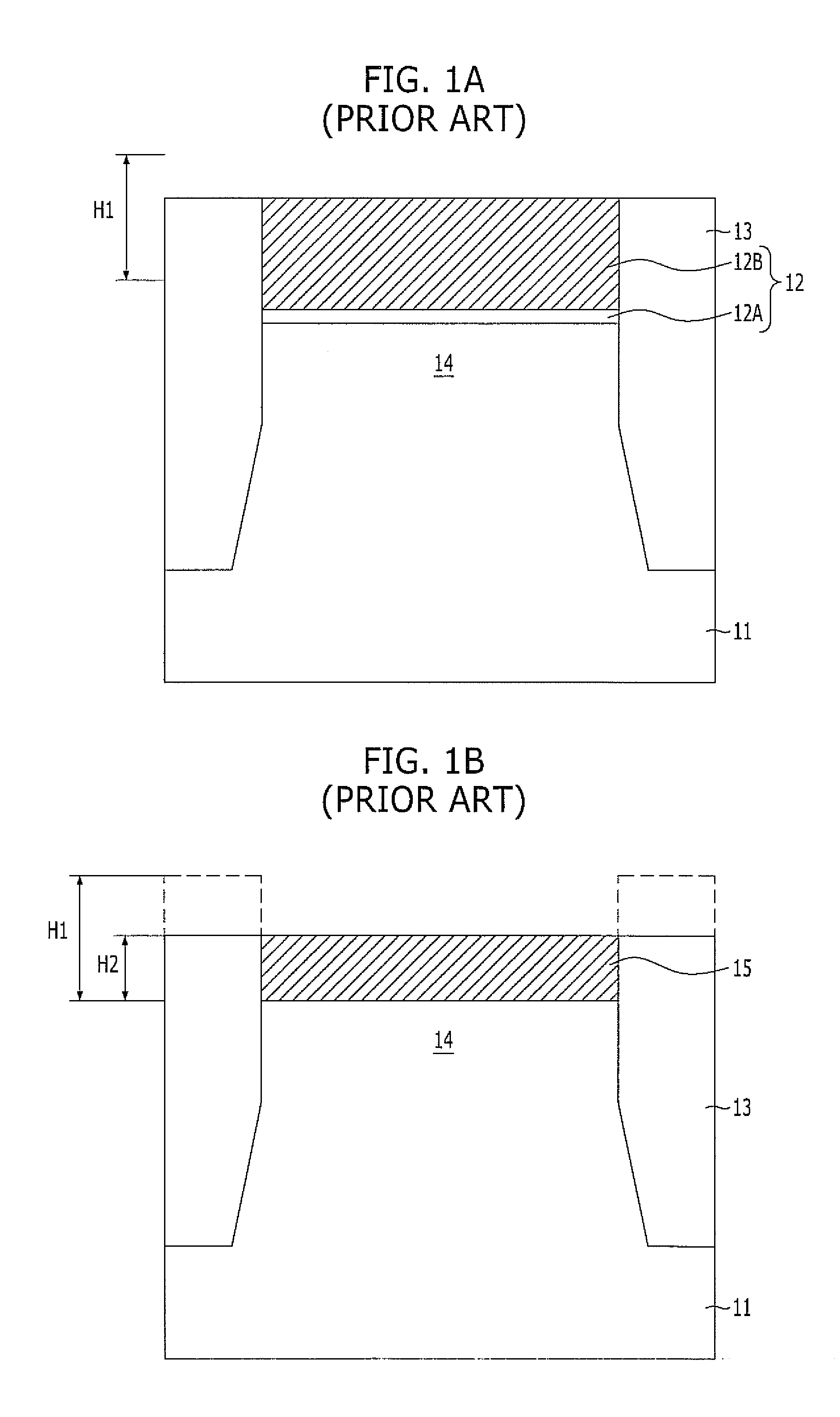

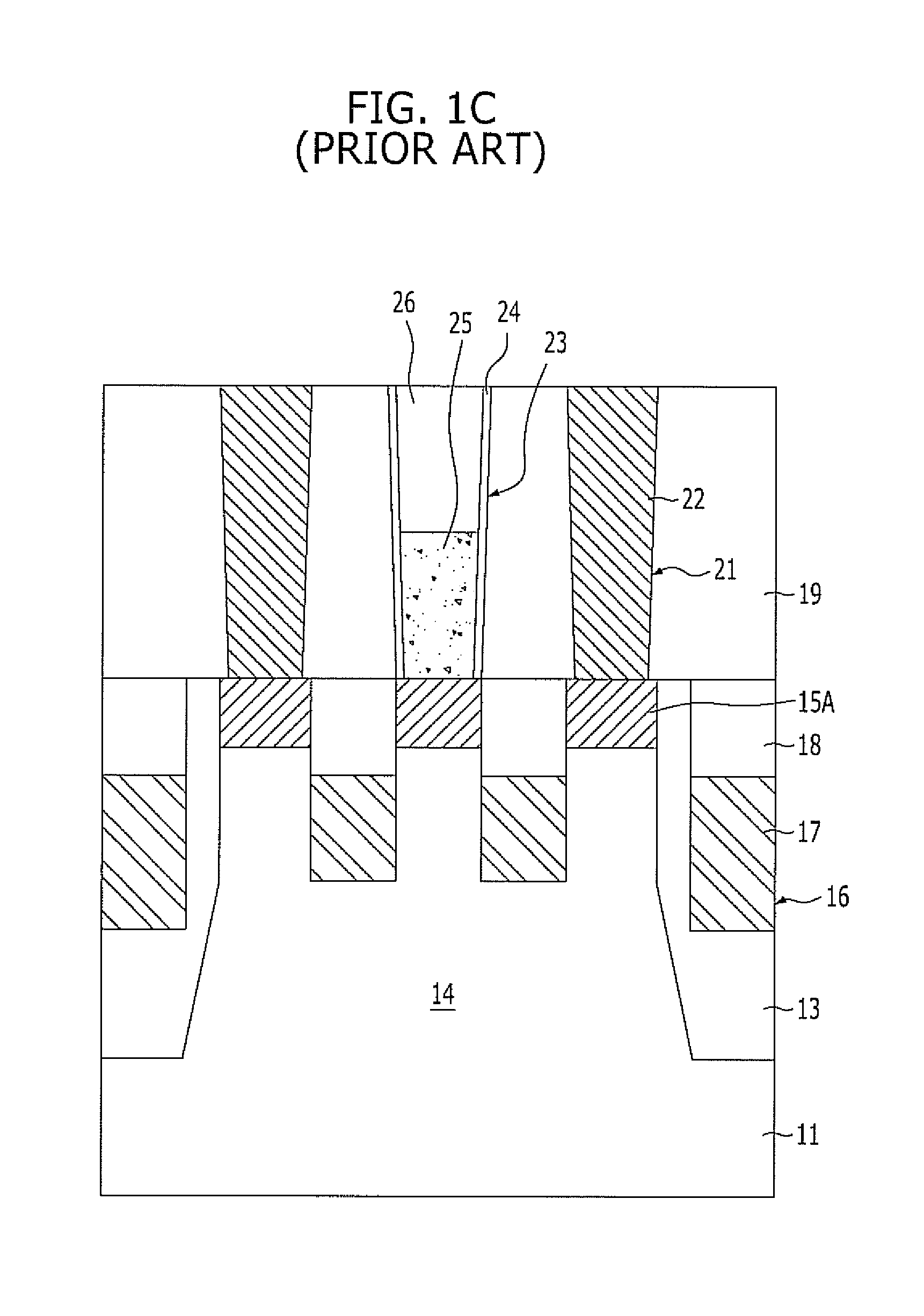

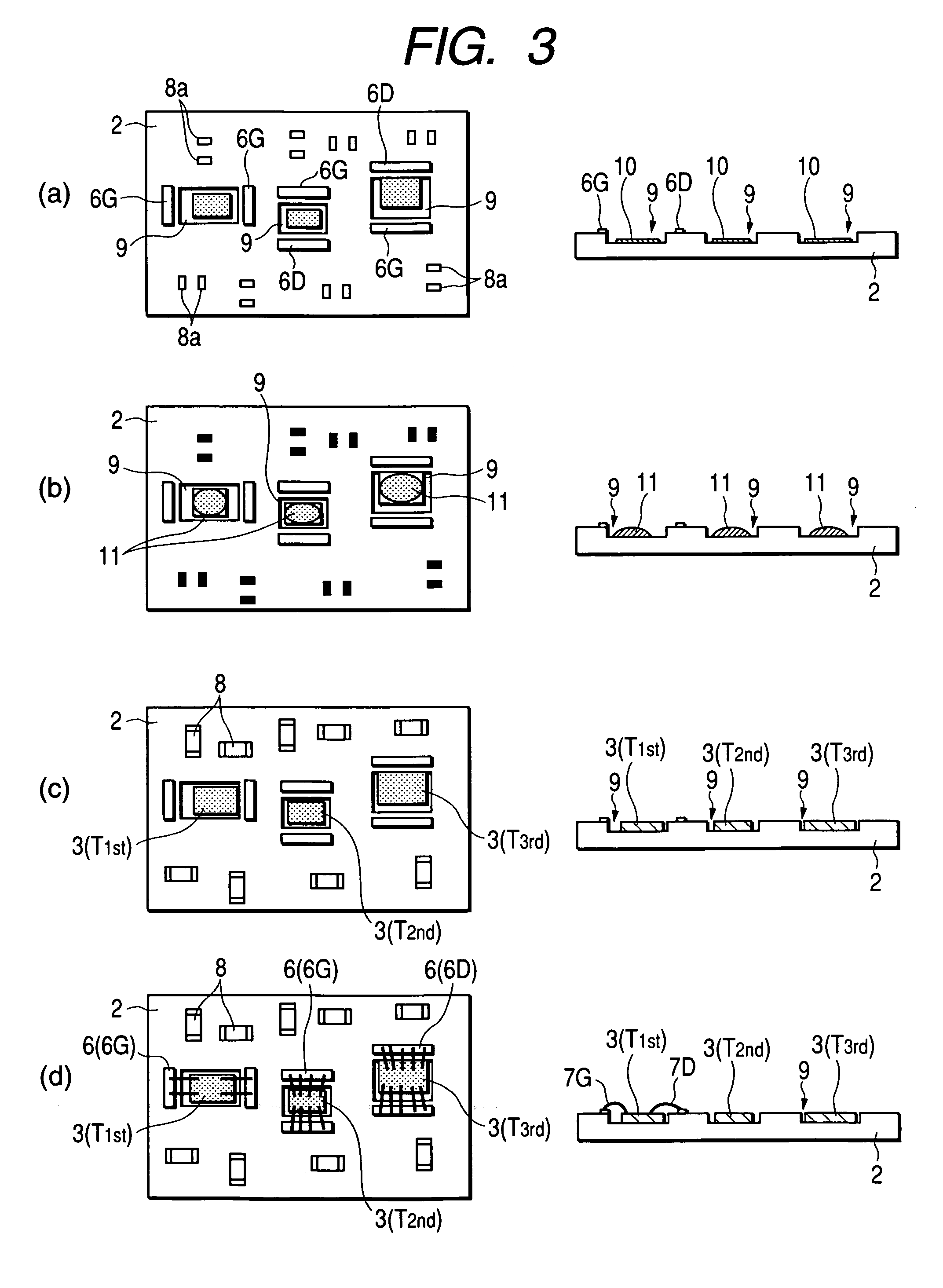

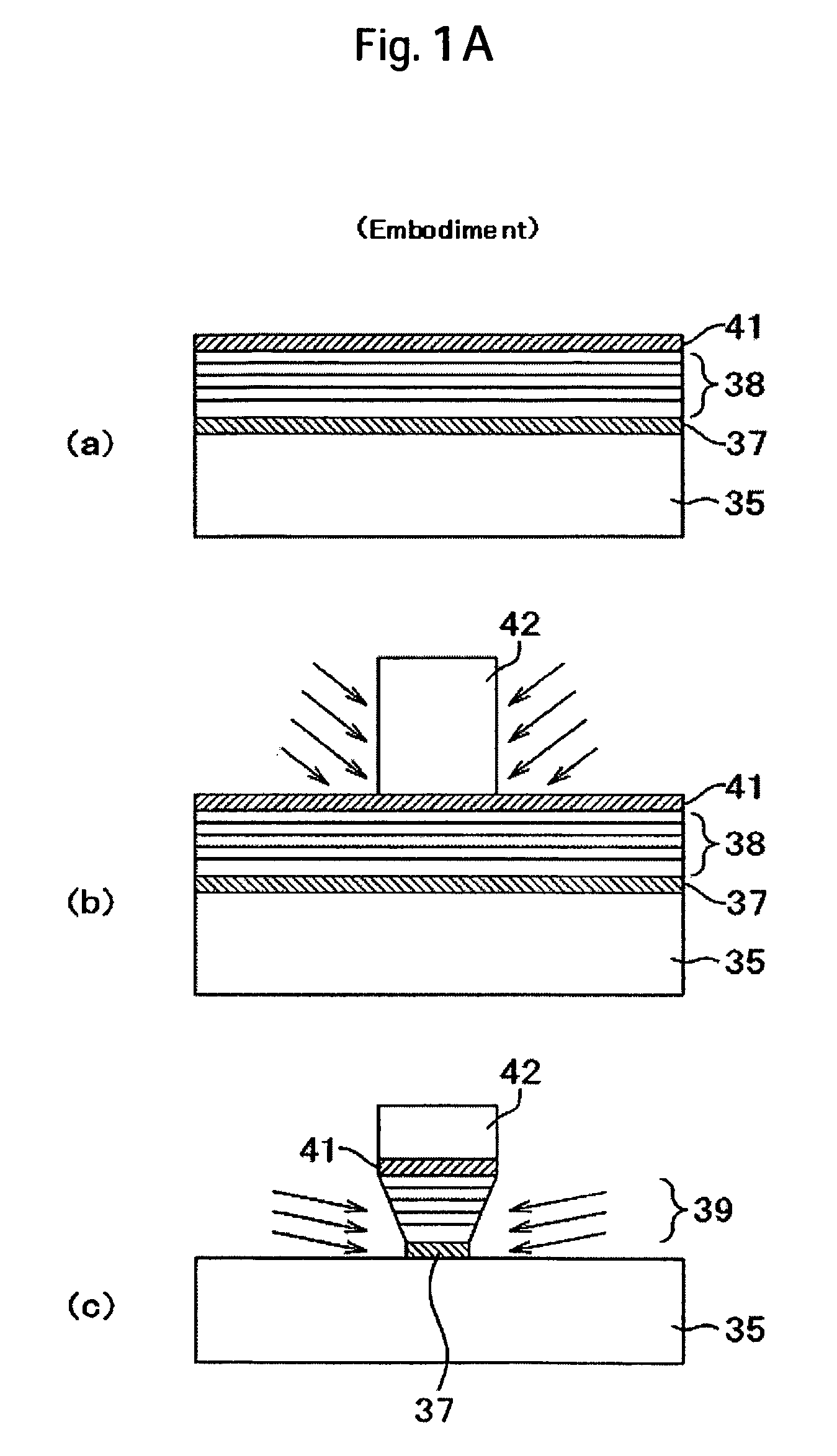

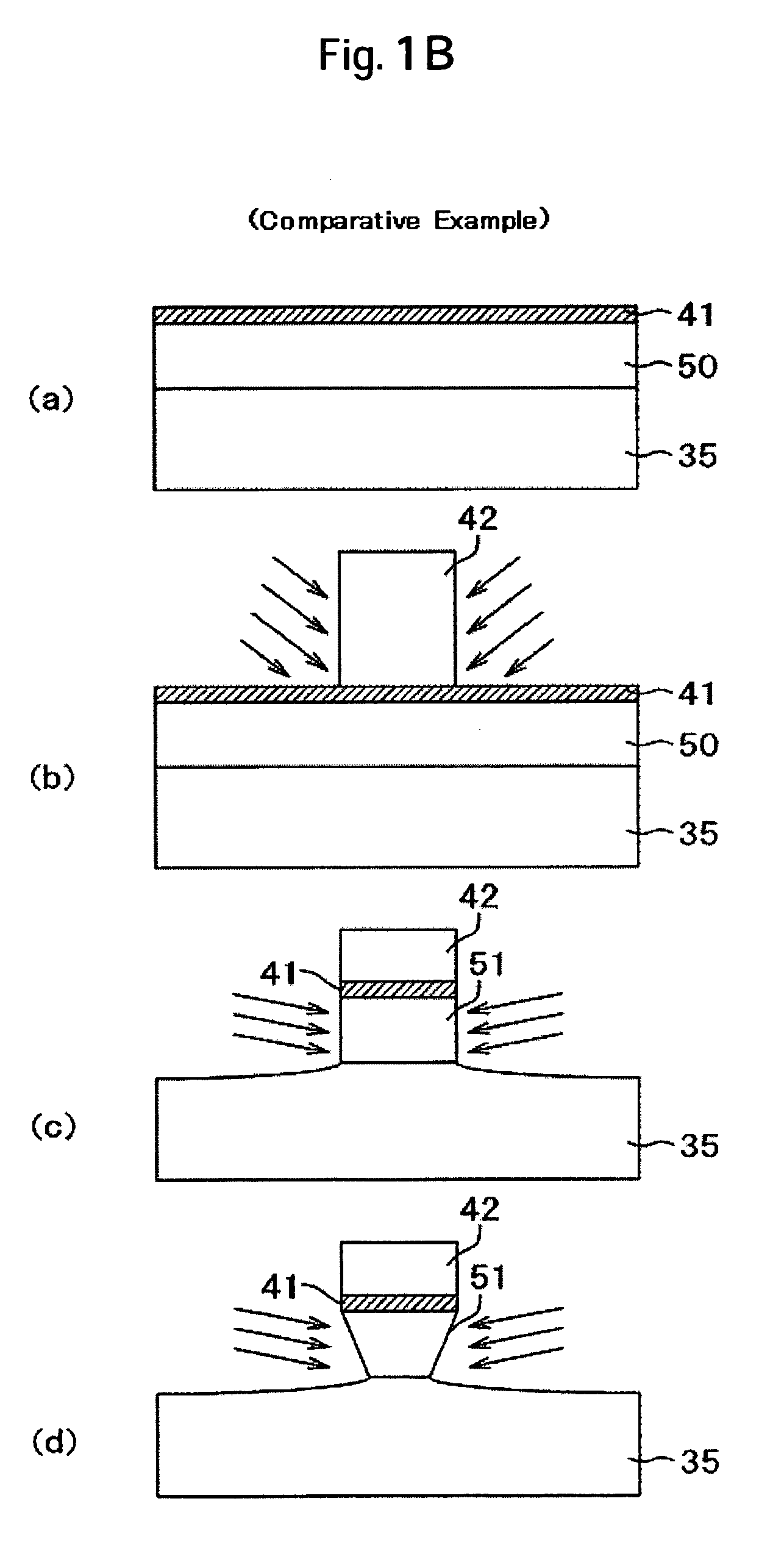

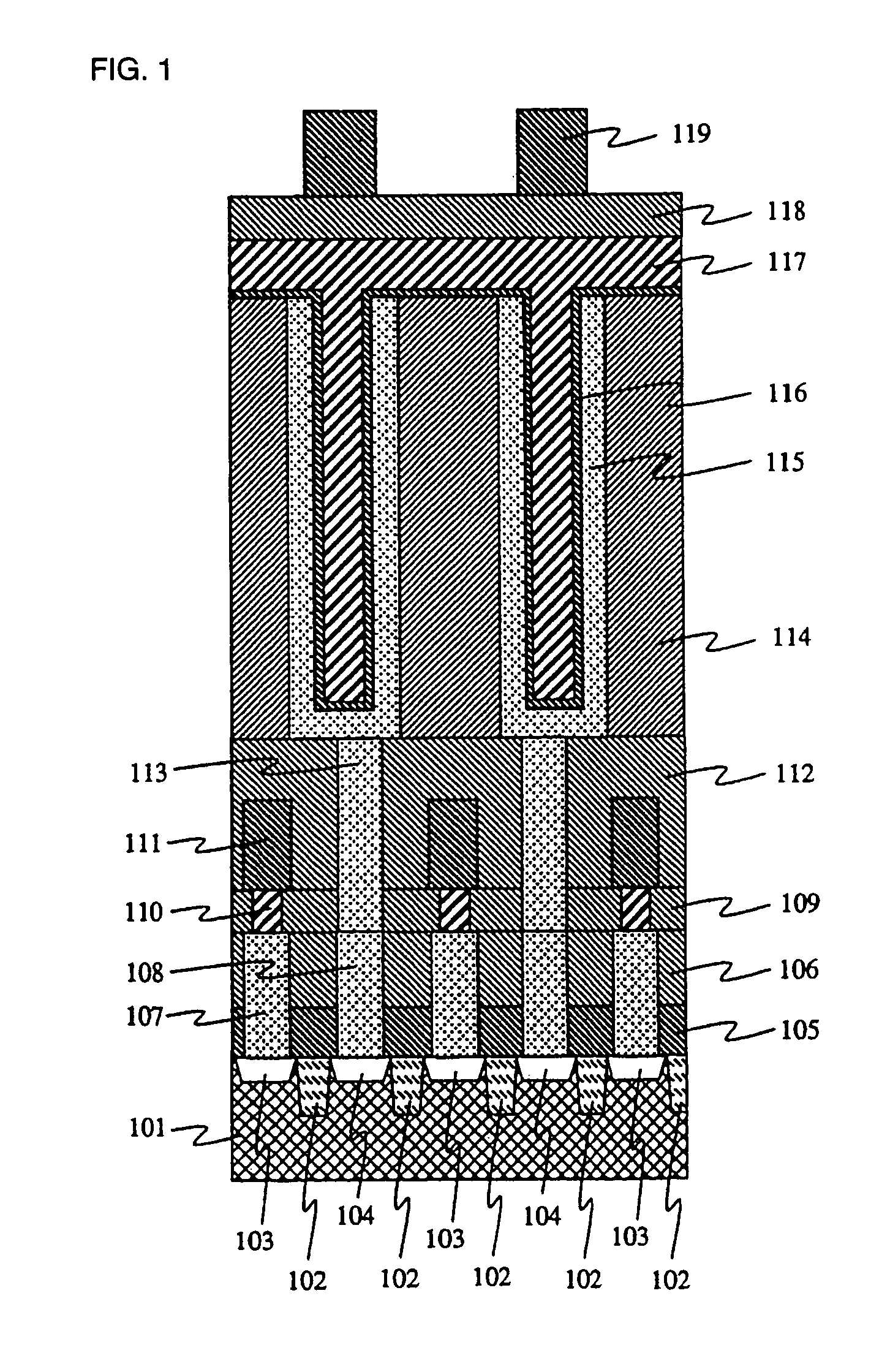

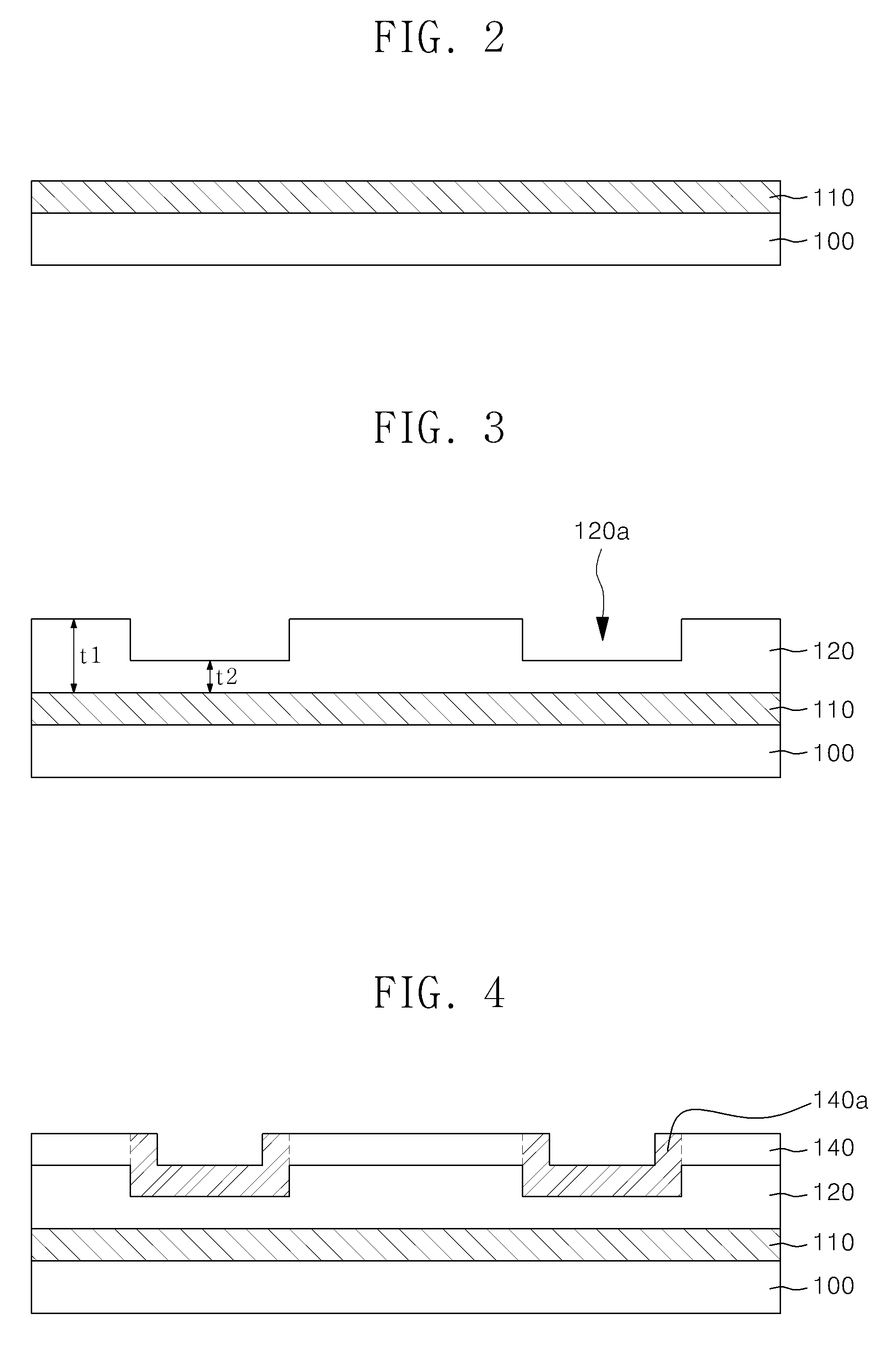

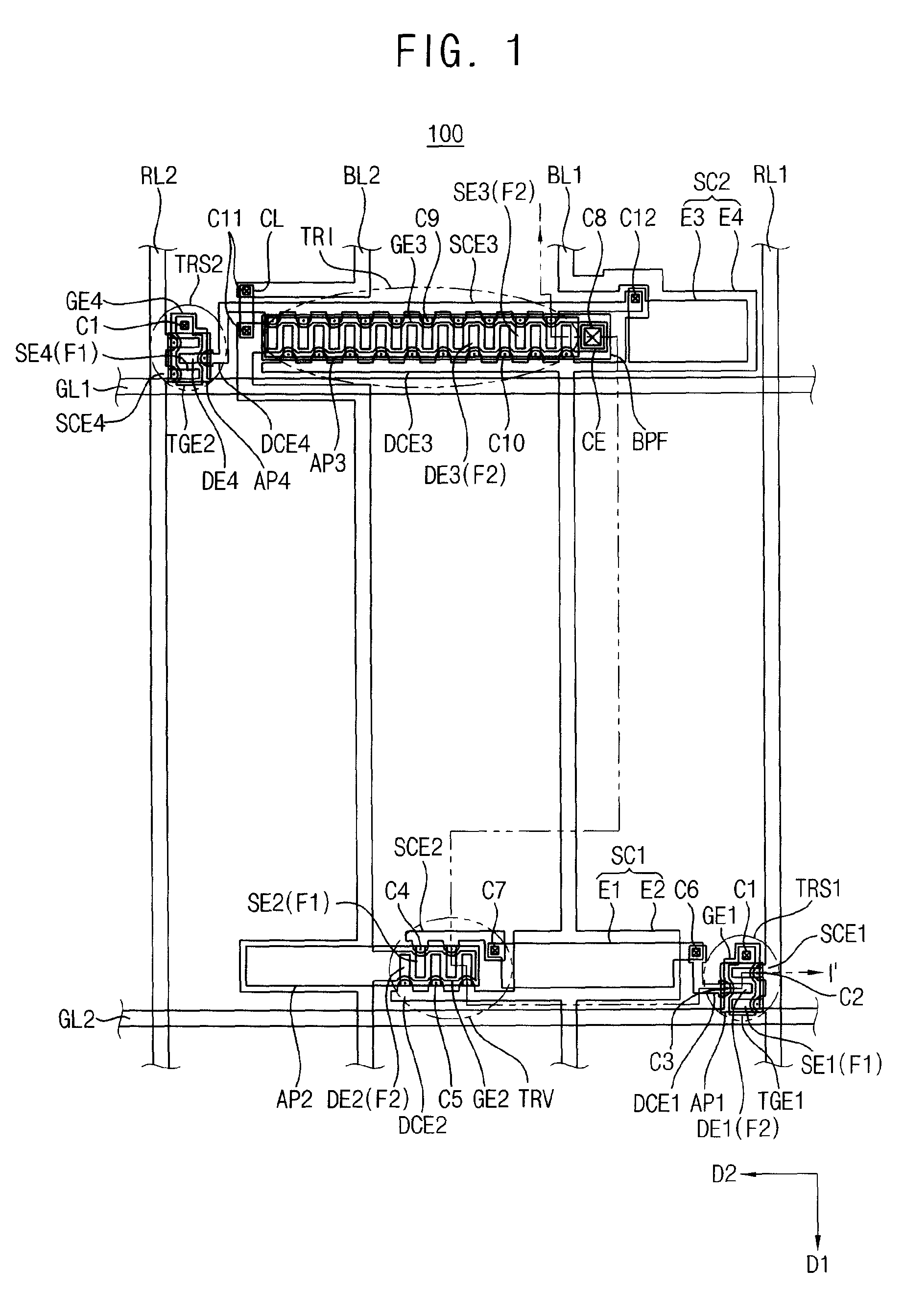

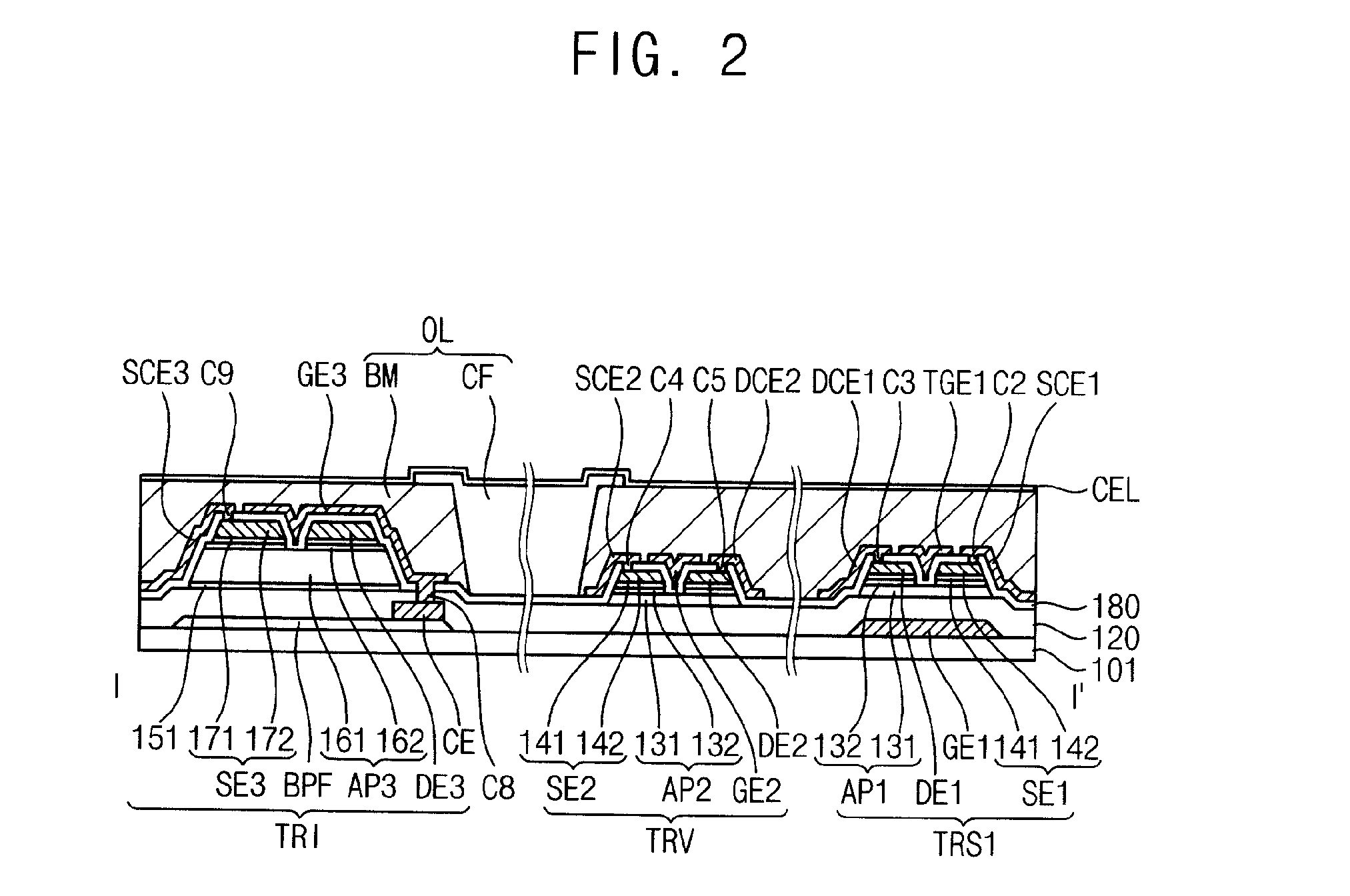

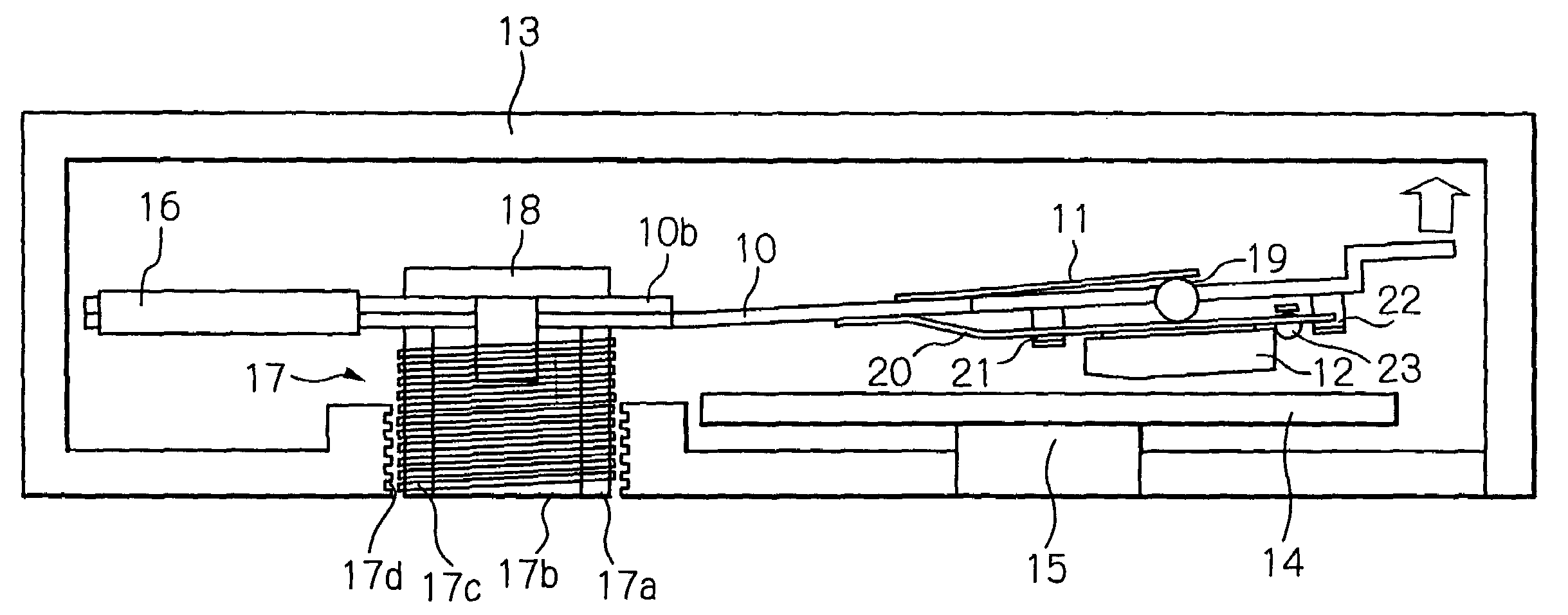

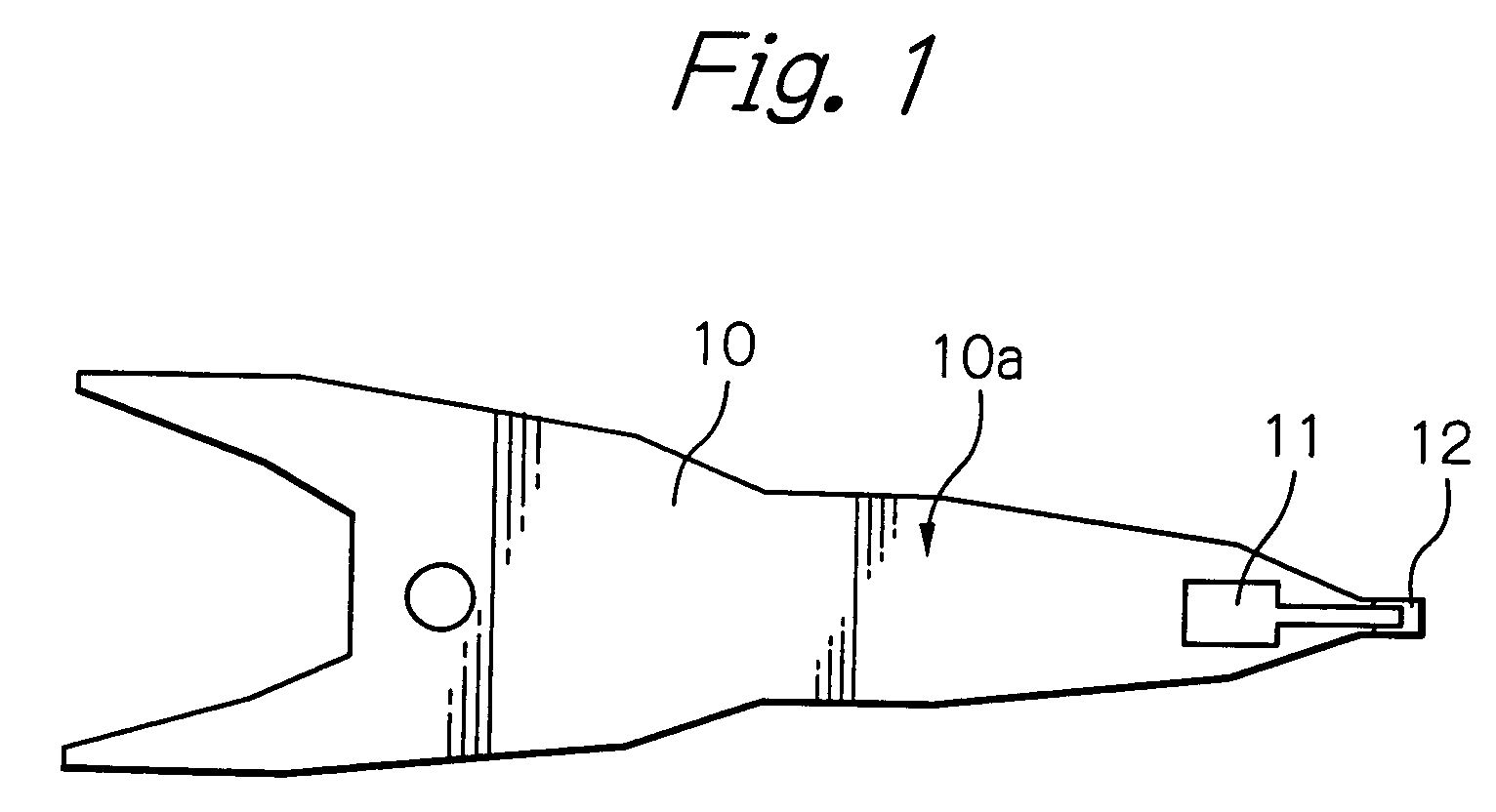

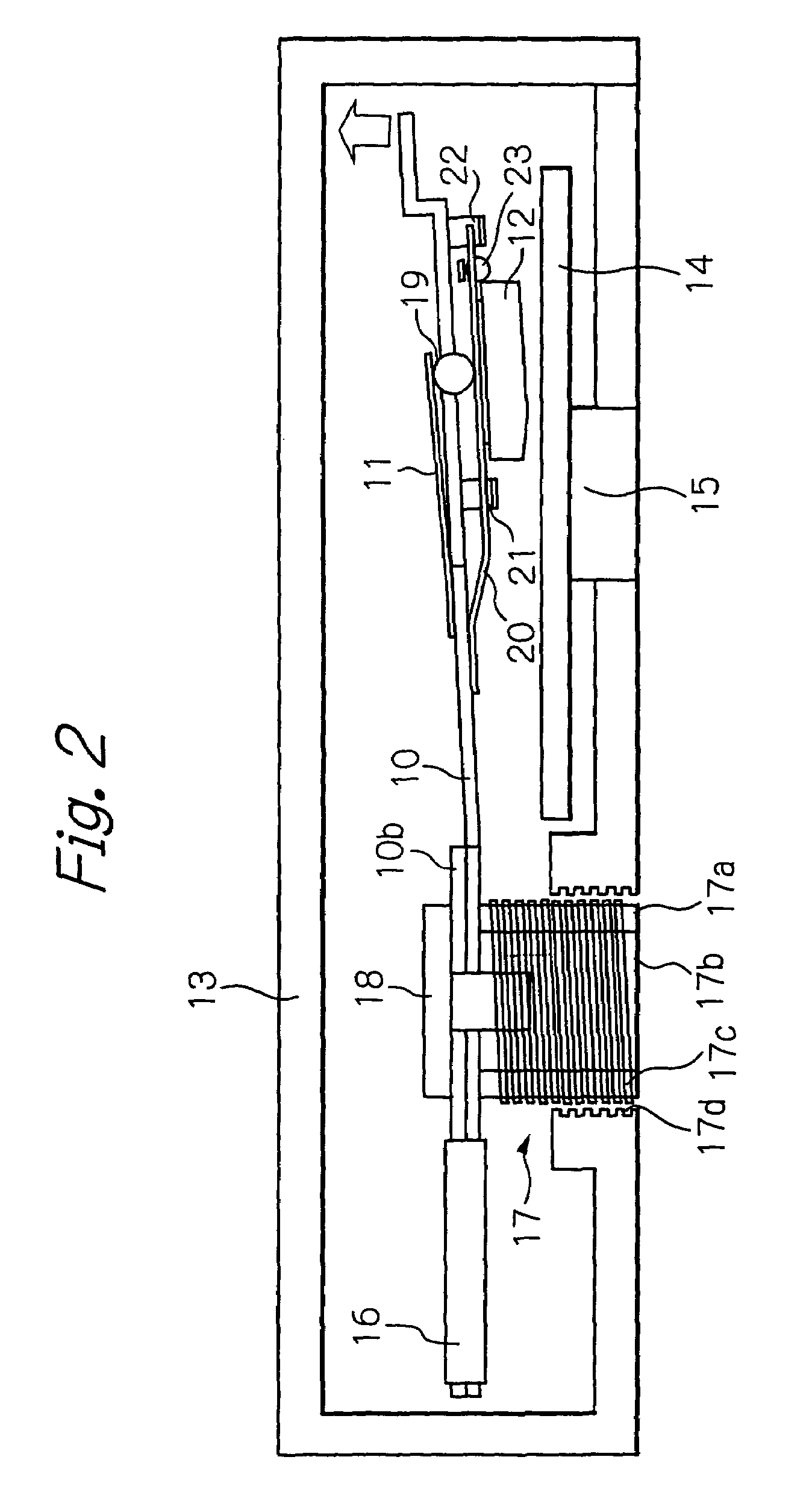

Semiconductor thin film, thin film transistor, method for manufacturing same, and manufacturing equipment of semiconductor thin film

ActiveUS7049184B2Small sizeNo longer be formedTransistorSemiconductor/solid-state device manufacturingImage resolutionLight beam

A method for manufacturing a semiconductor thin film is provided which can form its crystal grains having a uniform direction of crystal growth and being large in size and a manufacturing equipment using the above method, and a method for manufacturing a thin film transistor. In the above method, by applying an energy beam partially intercepted by a light-shielding element, melt and re-crystallization occur with a light-shielded region as a starting point. The irradiation of the beam gives energy to the light-shielded region of the silicon thin film so that melt and re-crystallization occur with the light-shielded region as the starting point and so that a local temperature gradient in the light-shielded region is made to be 1200° C. / μm or more. In the manufacturing method, a resolution of an optical system used to apply the energy beam is preferably 4 μm or less.

Owner:VISTA PEAK VENTURES LLC

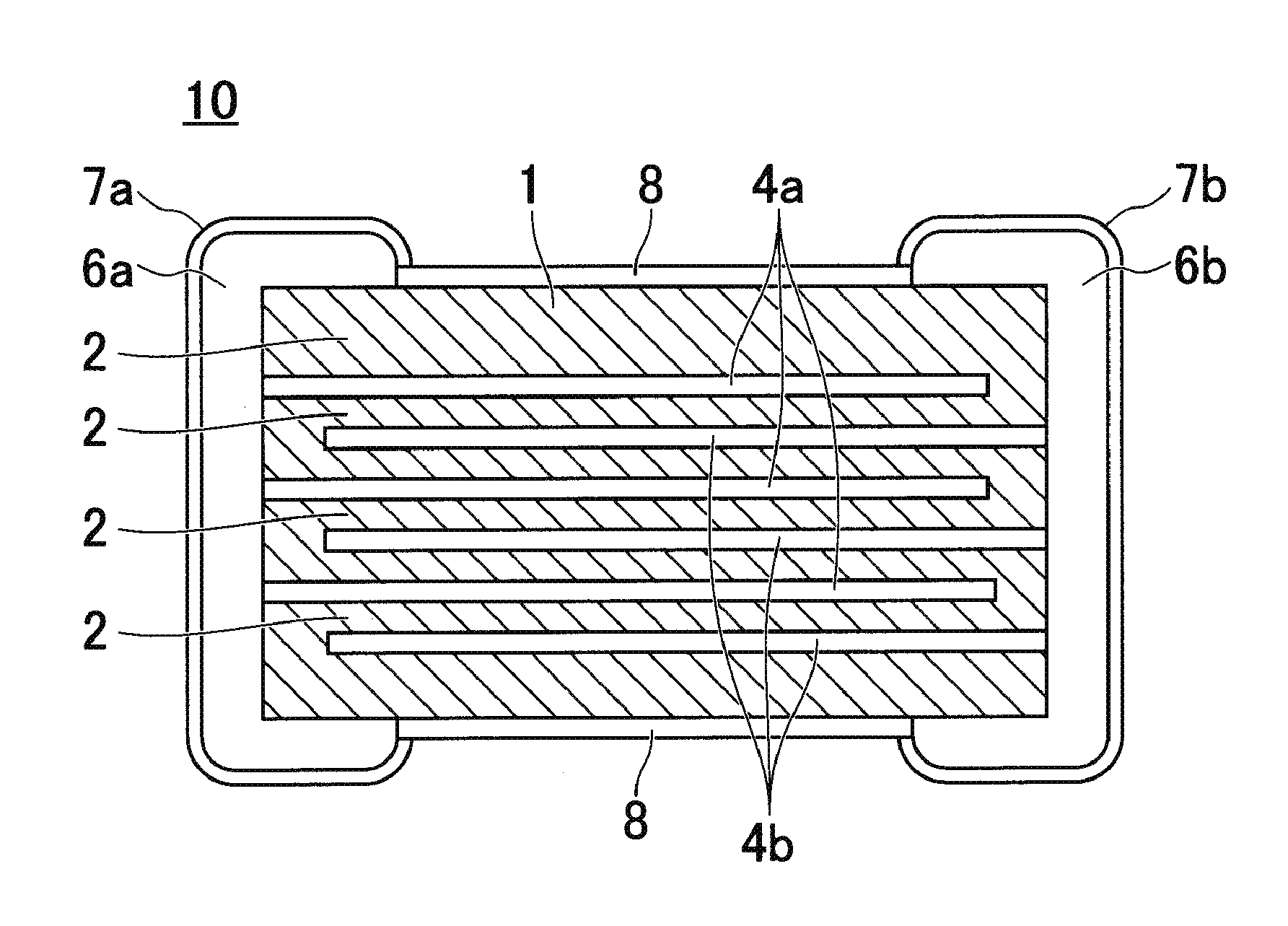

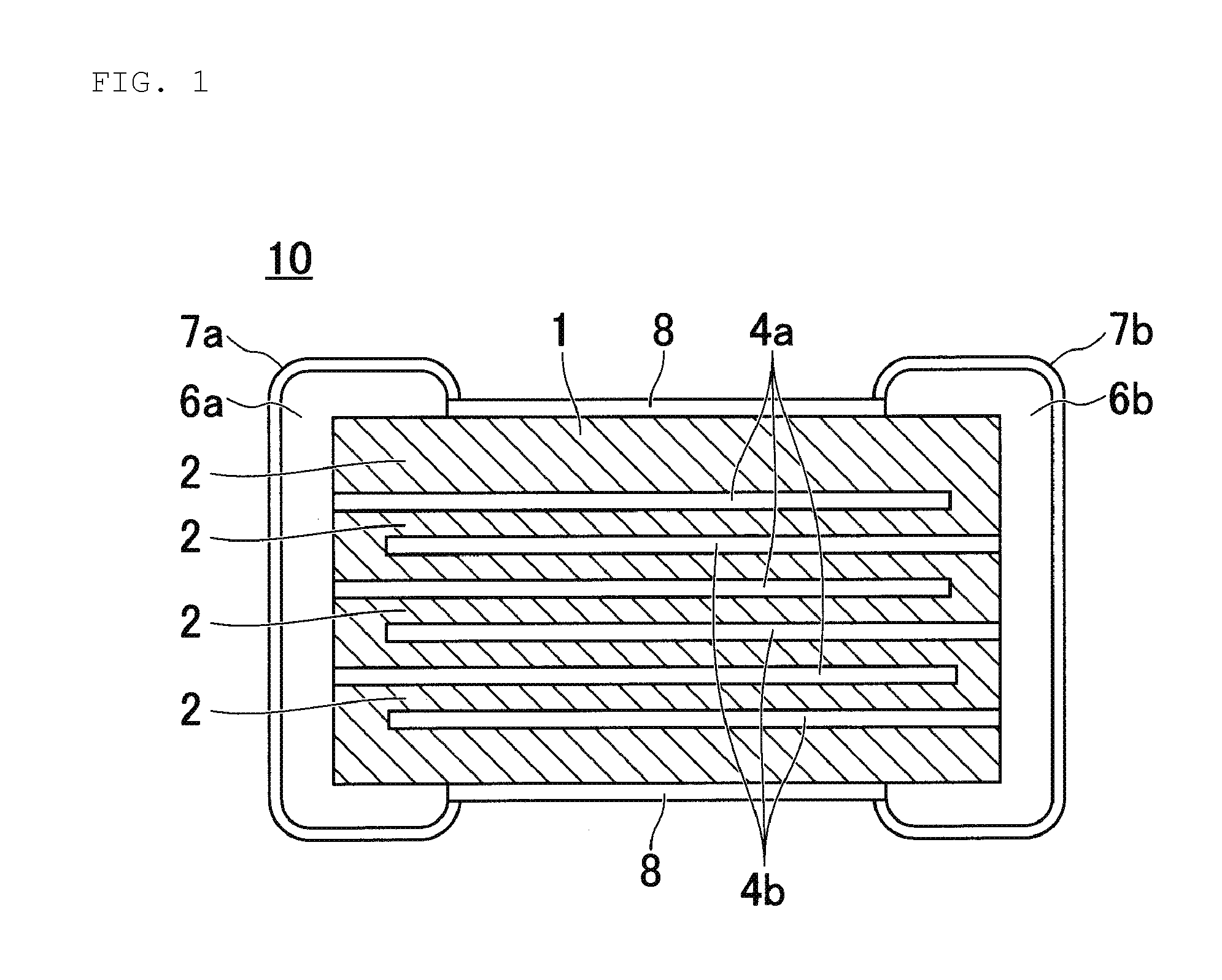

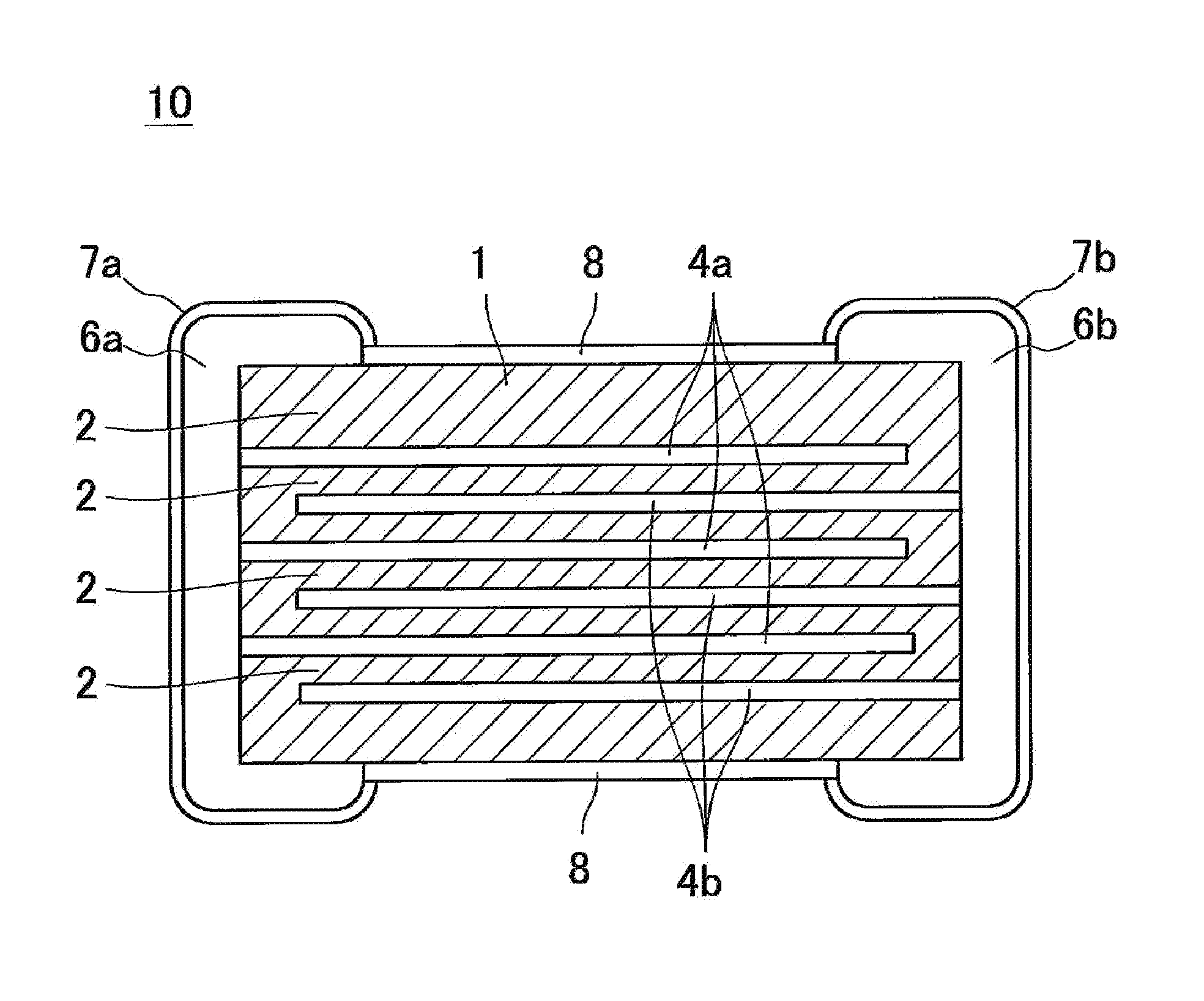

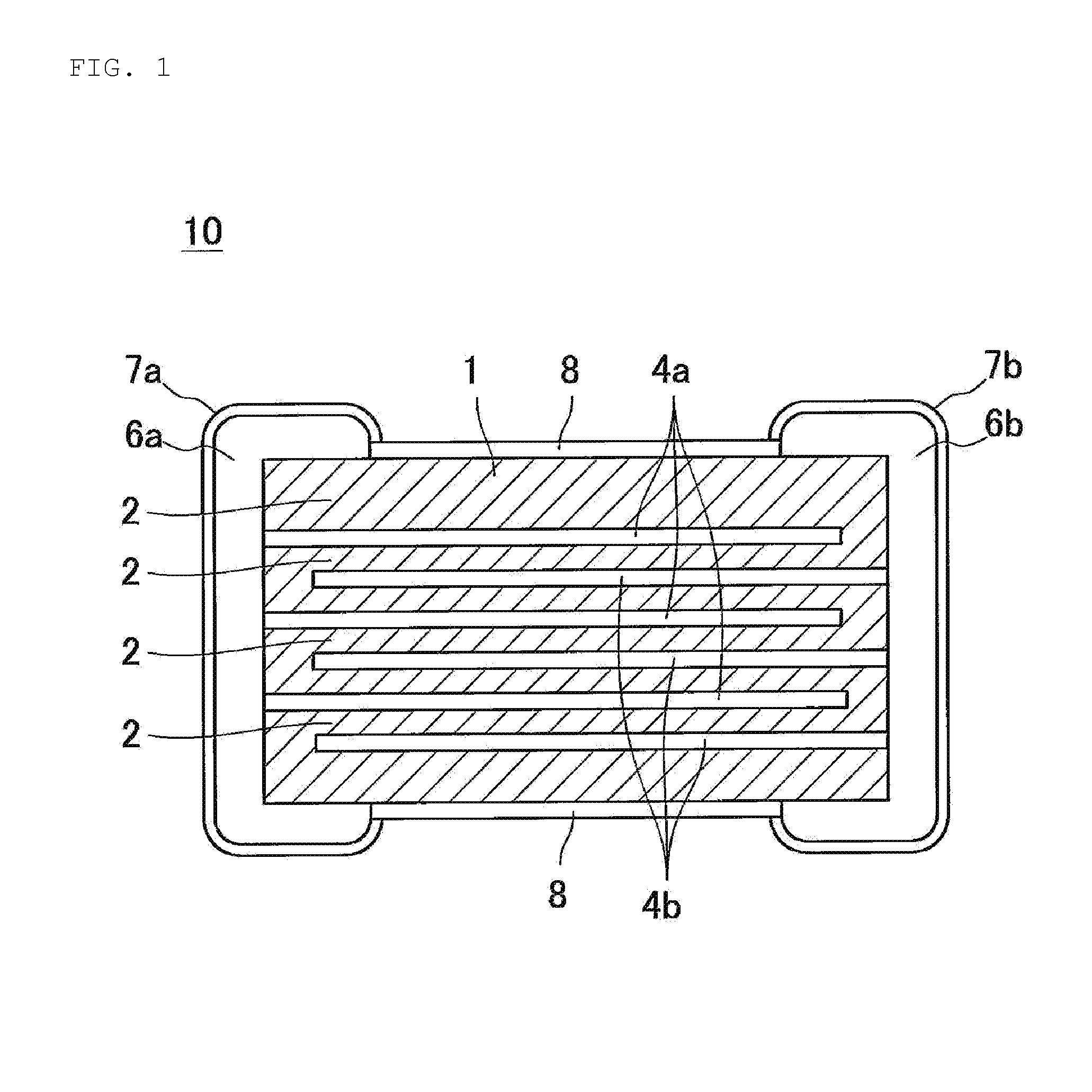

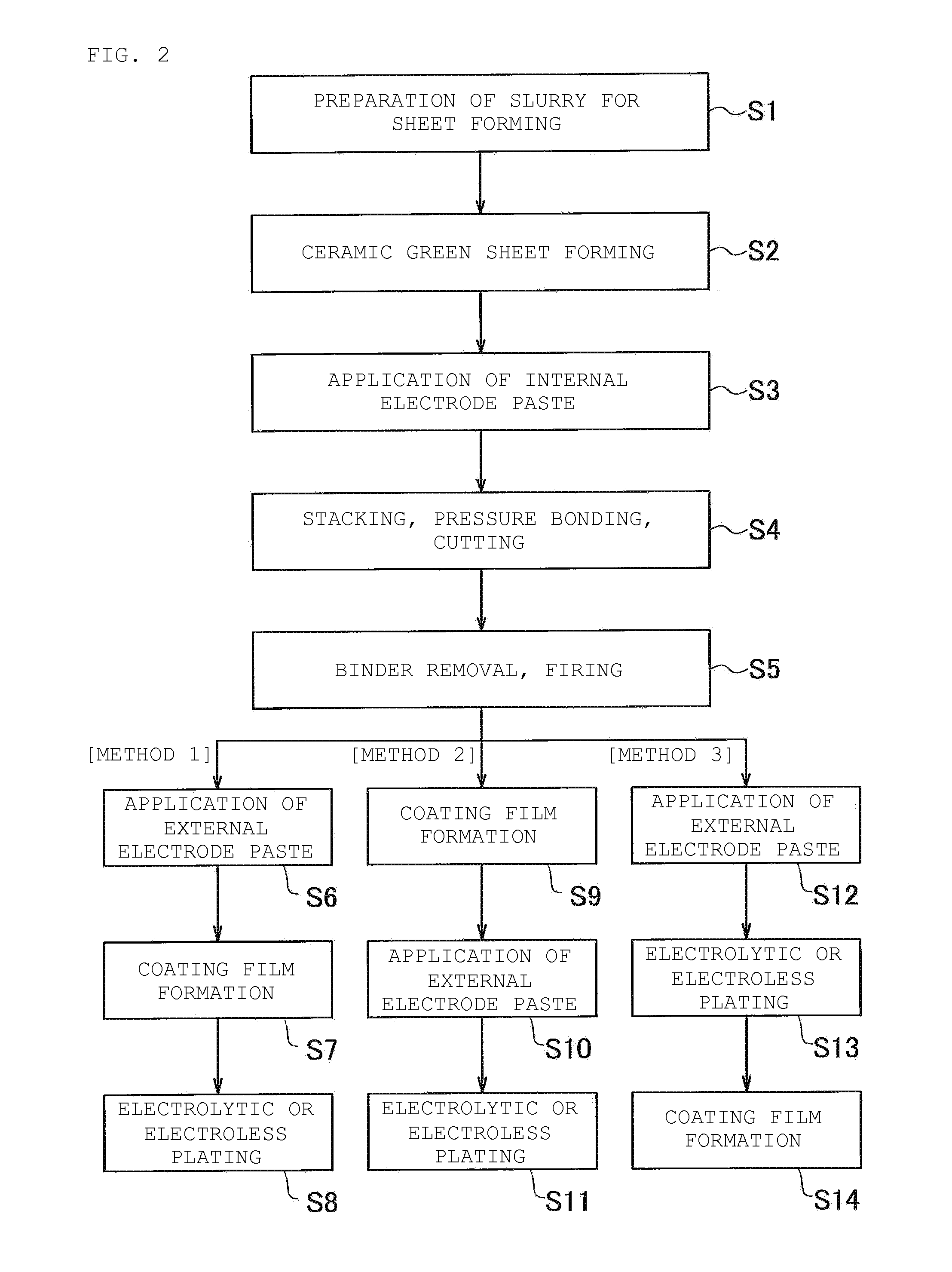

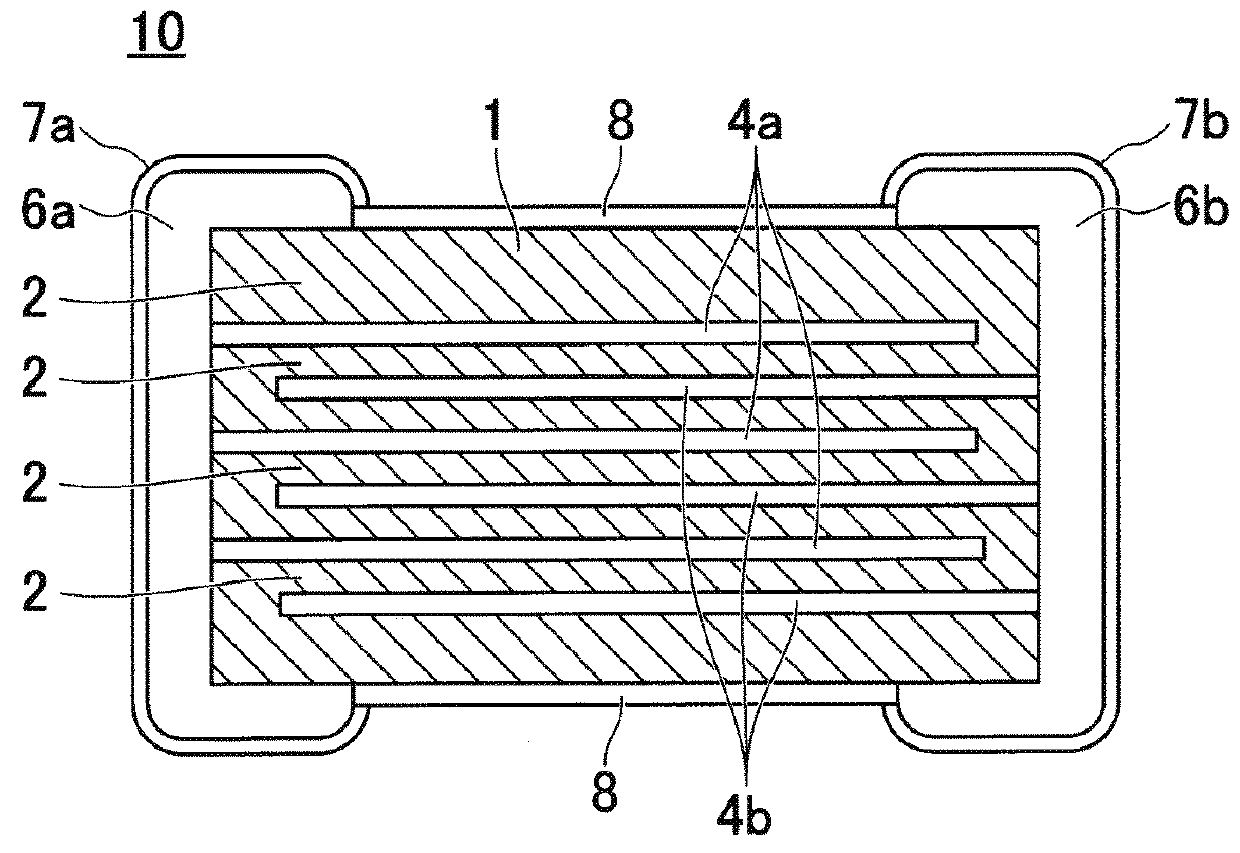

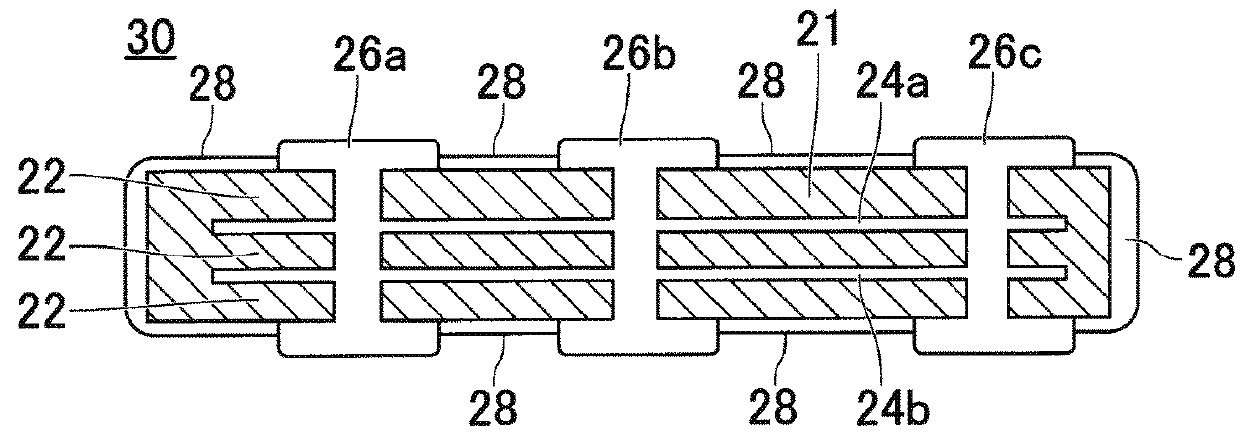

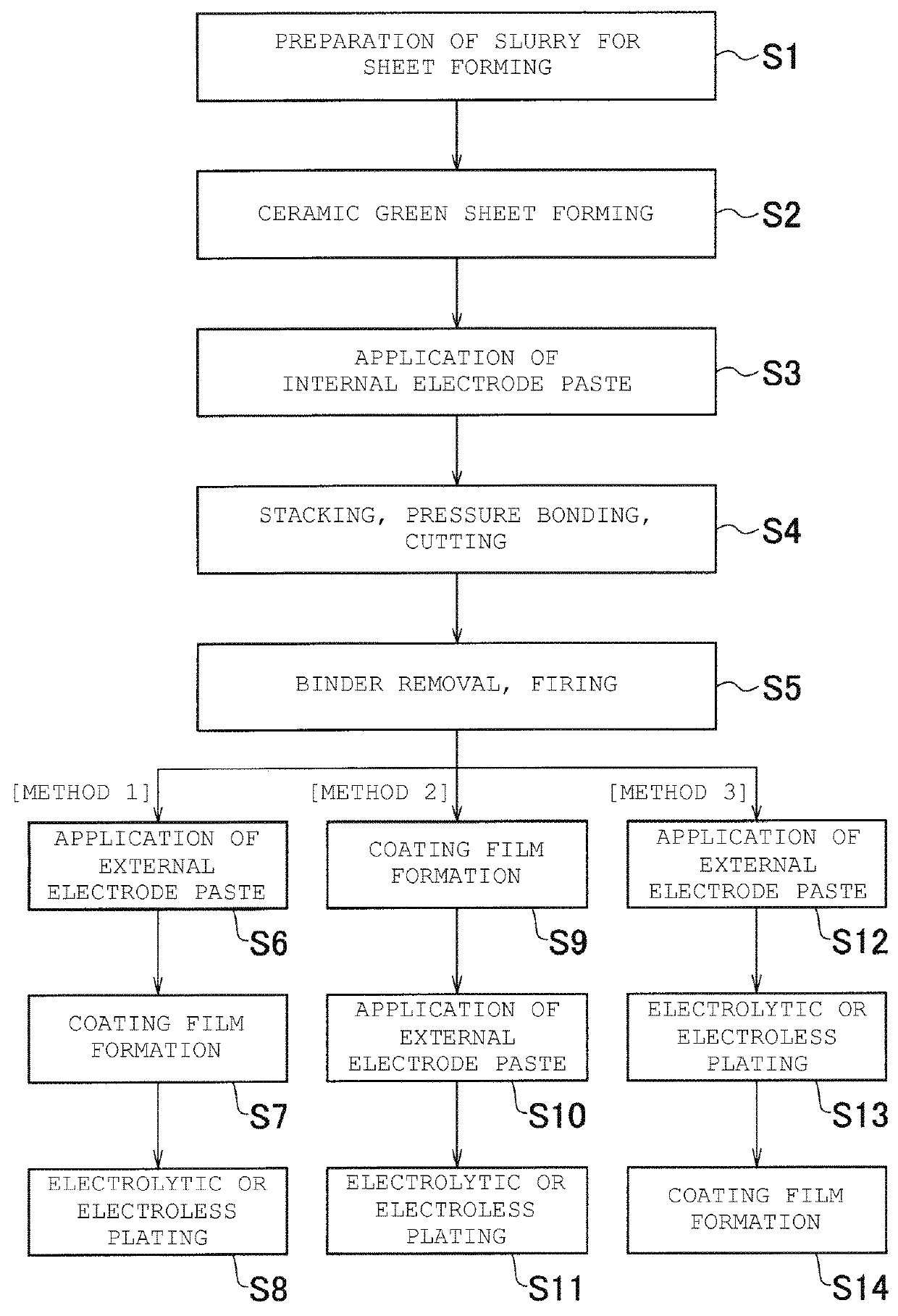

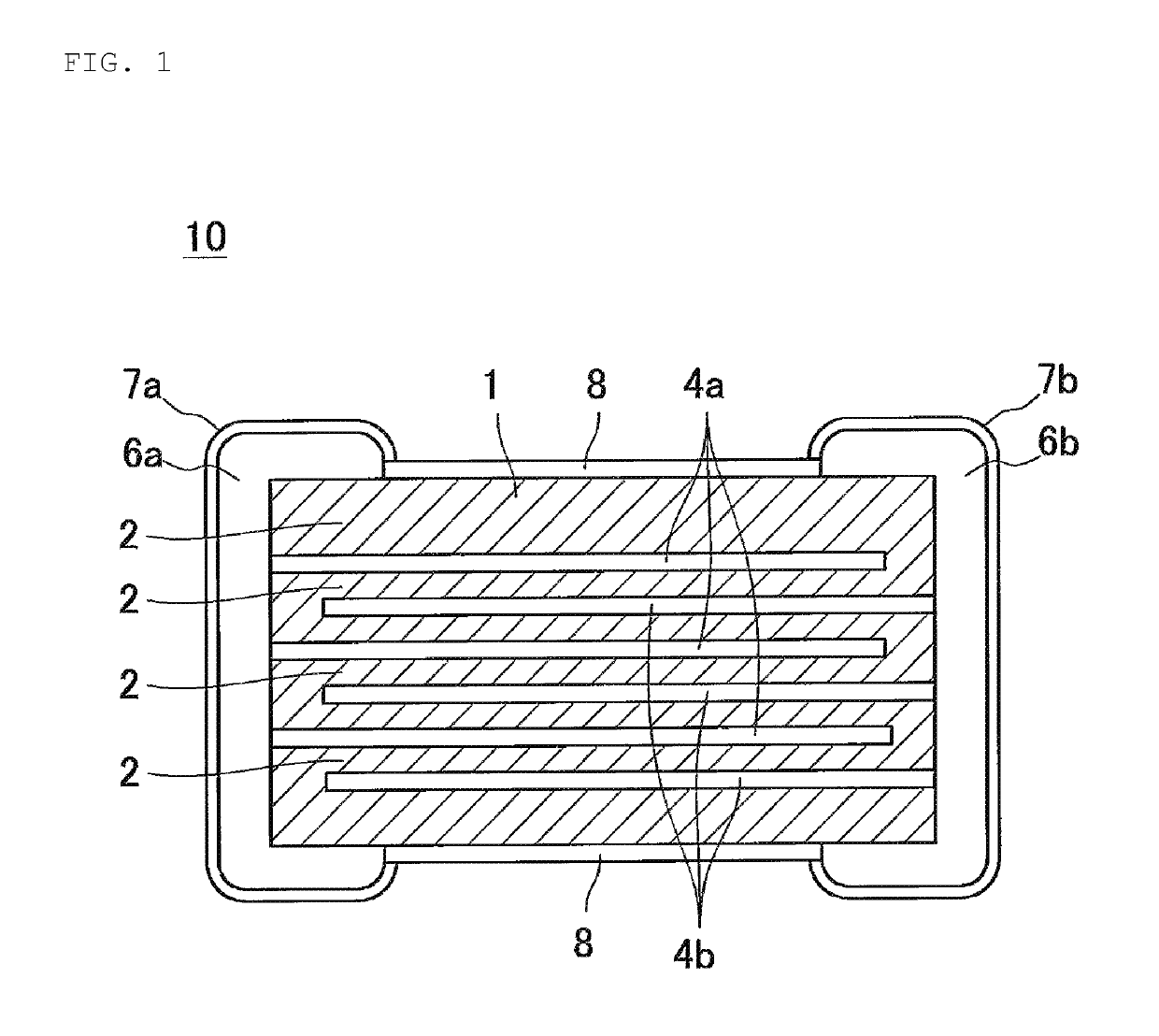

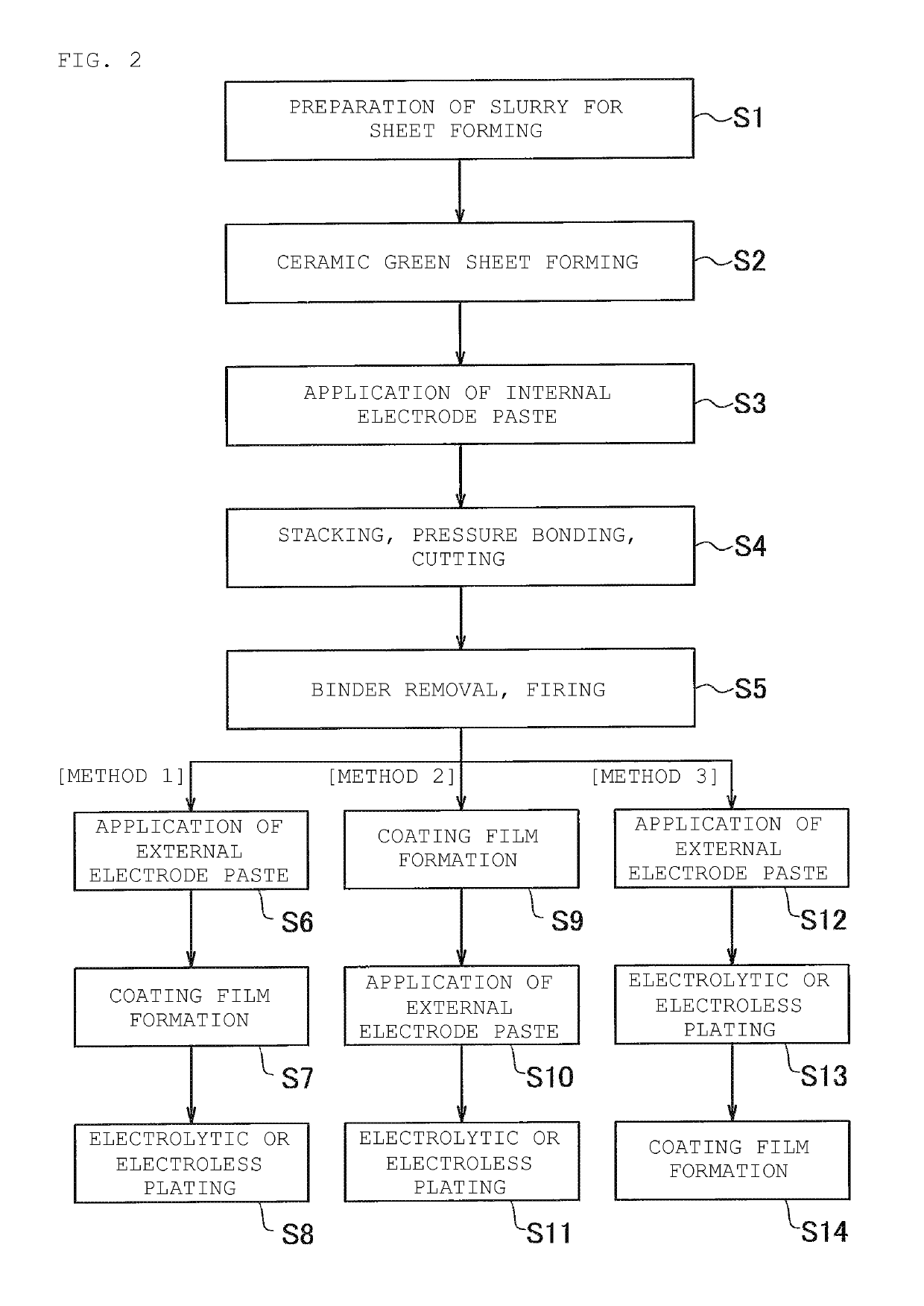

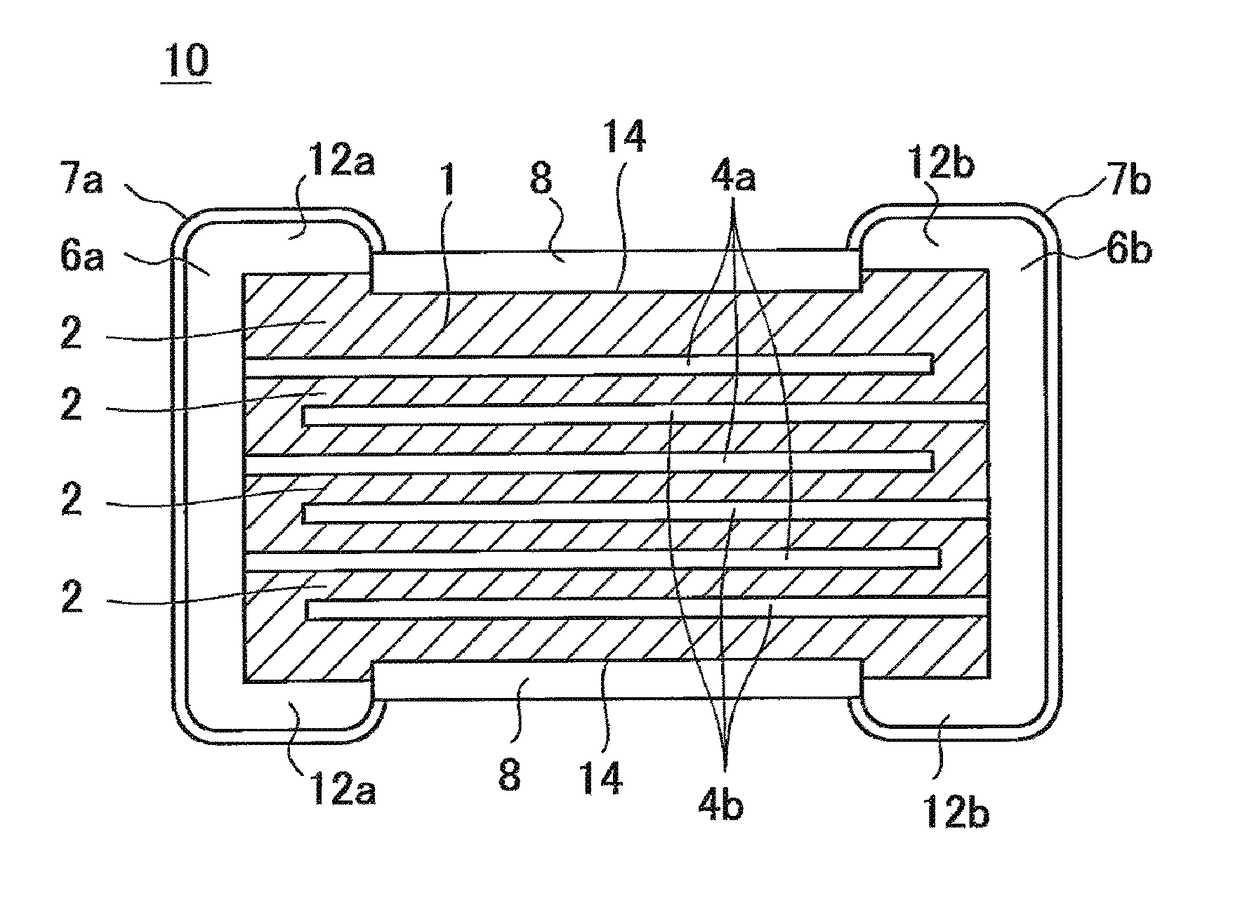

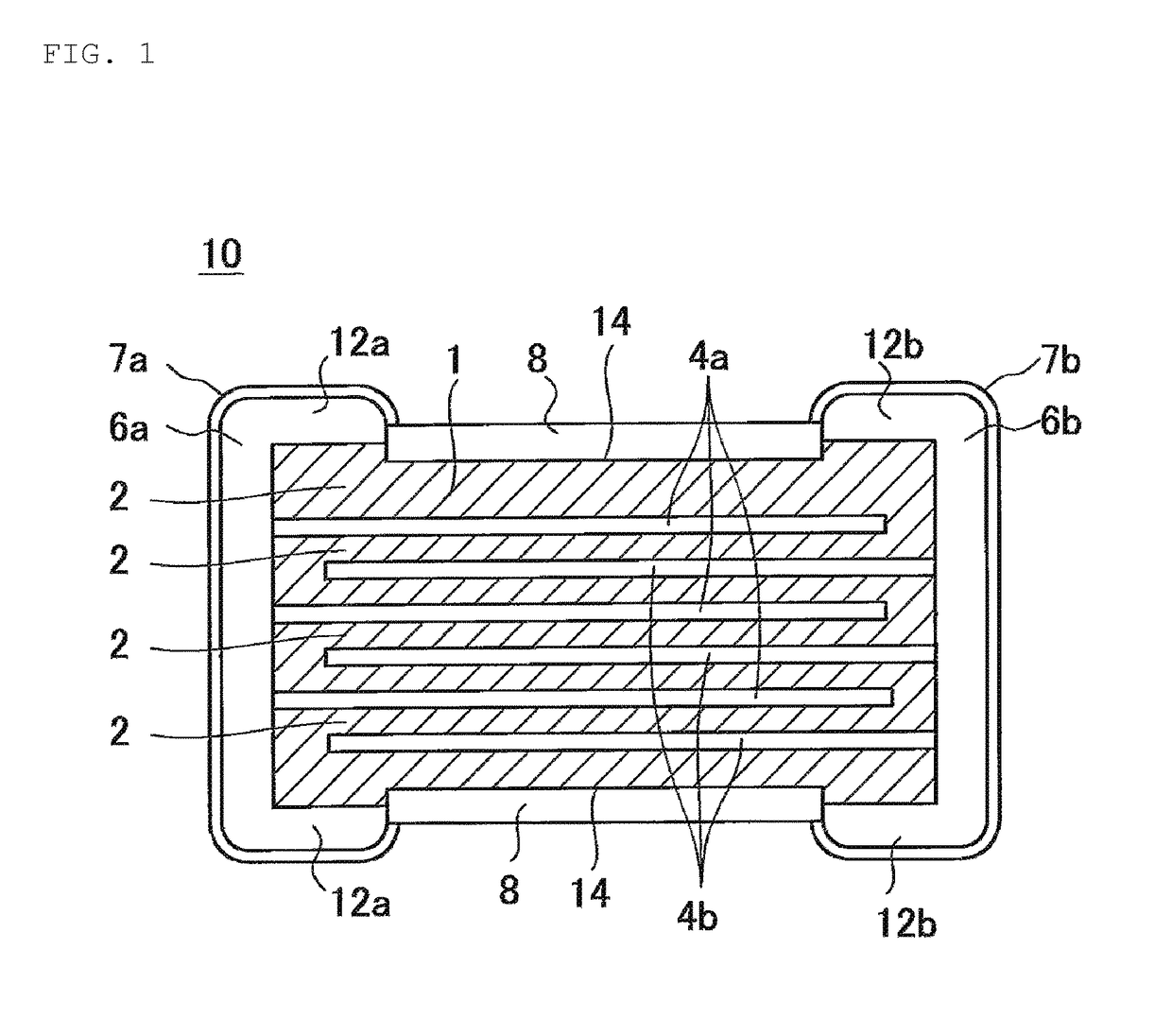

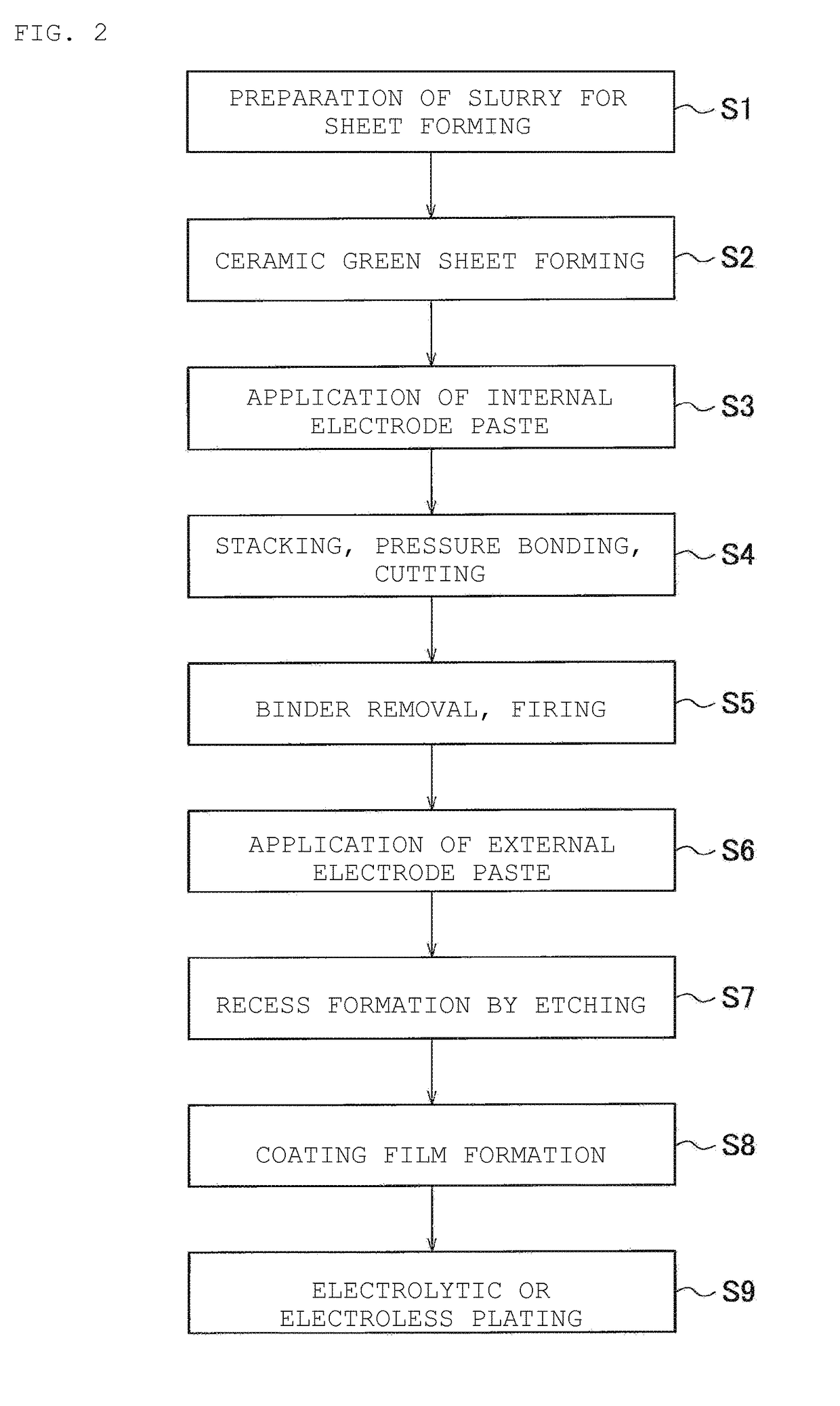

Ceramic electronic component and manufacturing method therefor

ActiveUS20150325369A1Reduce manufacturing costImprove heat resistanceEnvelope/housing resistor manufactureTransformers/inductances coils/windings/connectionsMetallurgyCoating

A ceramic electronic component that includes a ceramic main body, a coating film and external electrodes on the surface of the ceramic main body. The coating film is selectively formed on the surface of the ceramic main body by applying, to the surface of the ceramic main body, a resin-containing solution that etches the surface of the ceramic main body so as to ionize constituent elements of the ceramic main body. The coating film includes a resin and the constituent elements of the ceramic main body, which were ionized and deposited from the ceramic main body.

Owner:MURATA MFG CO LTD

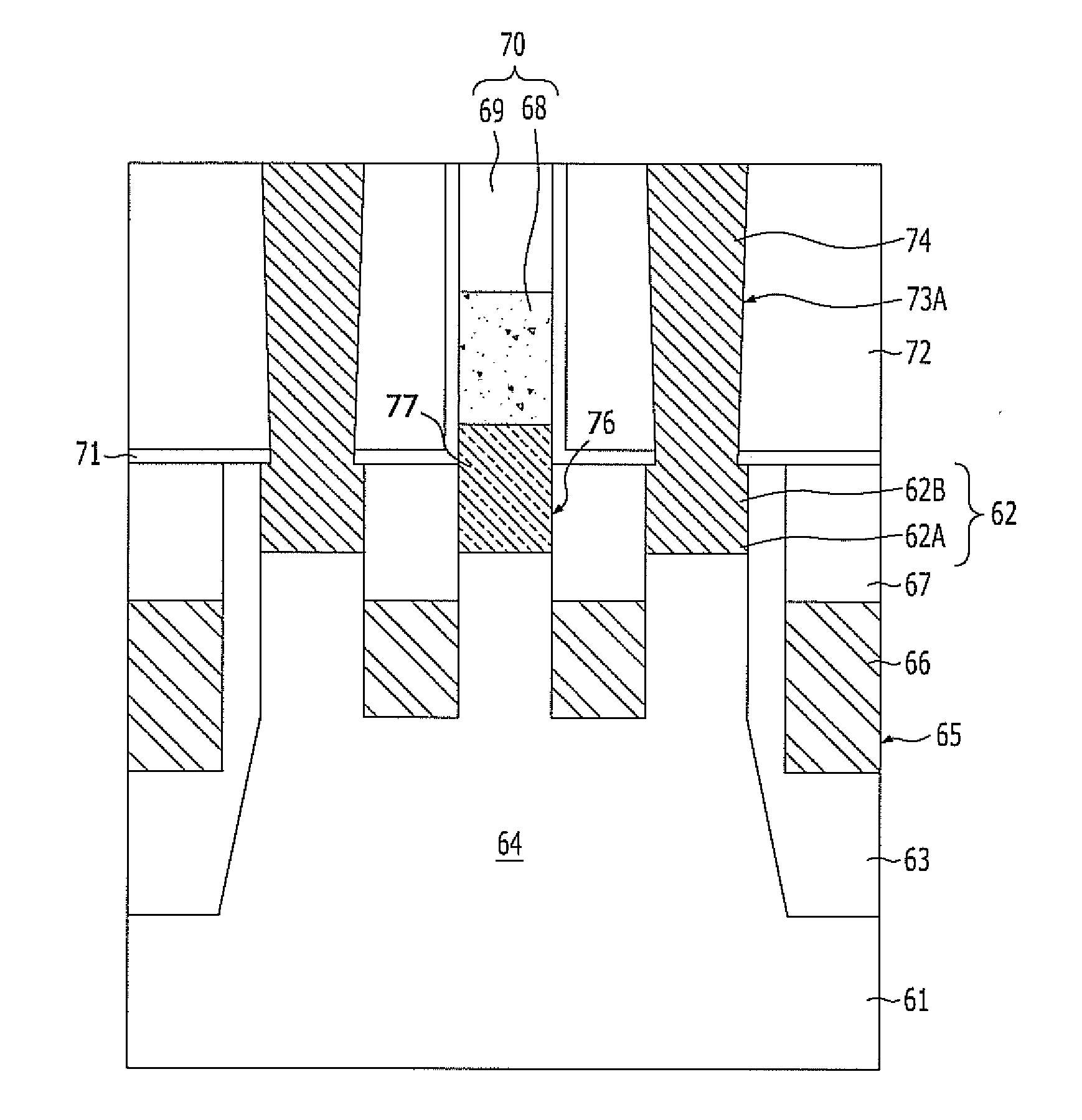

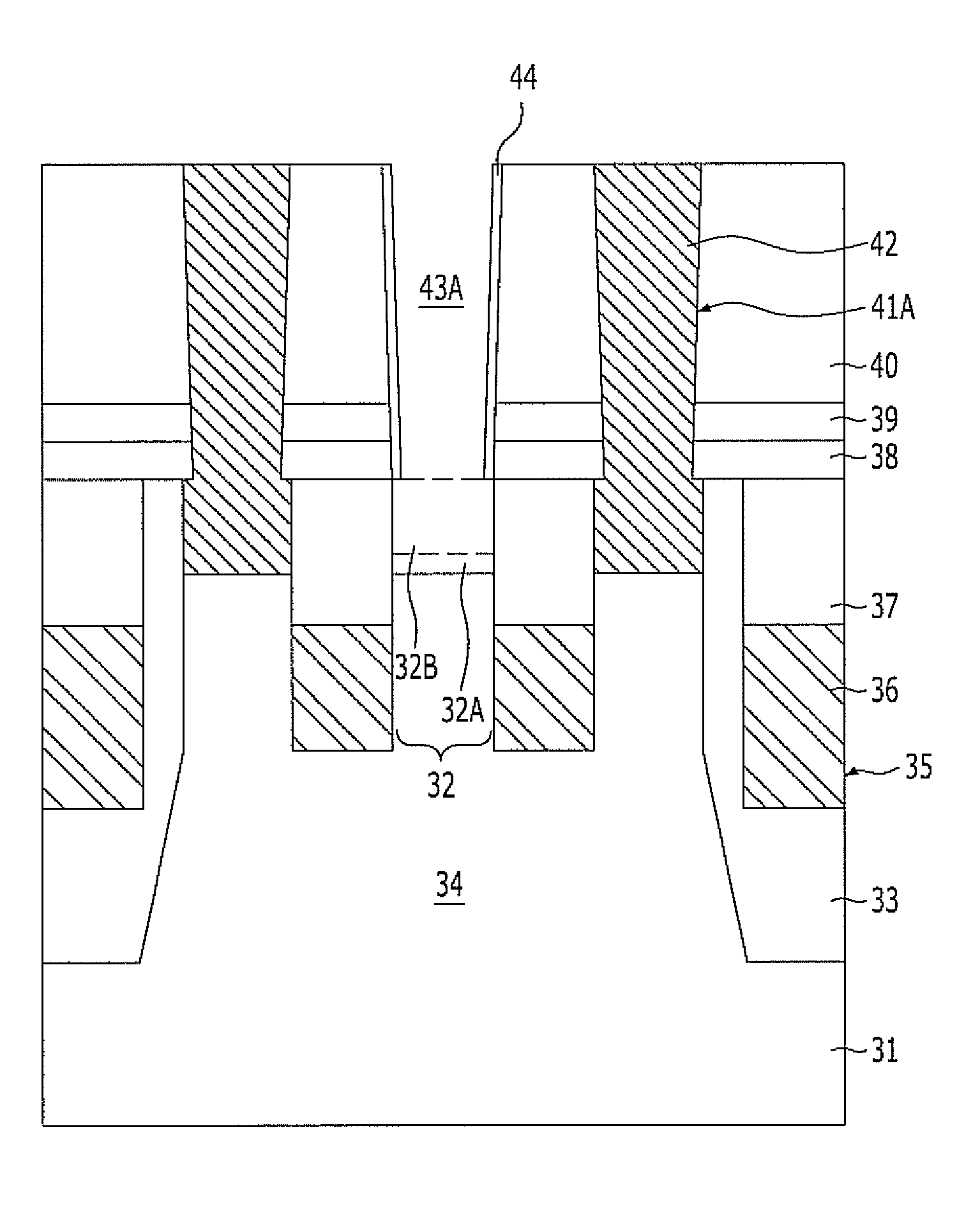

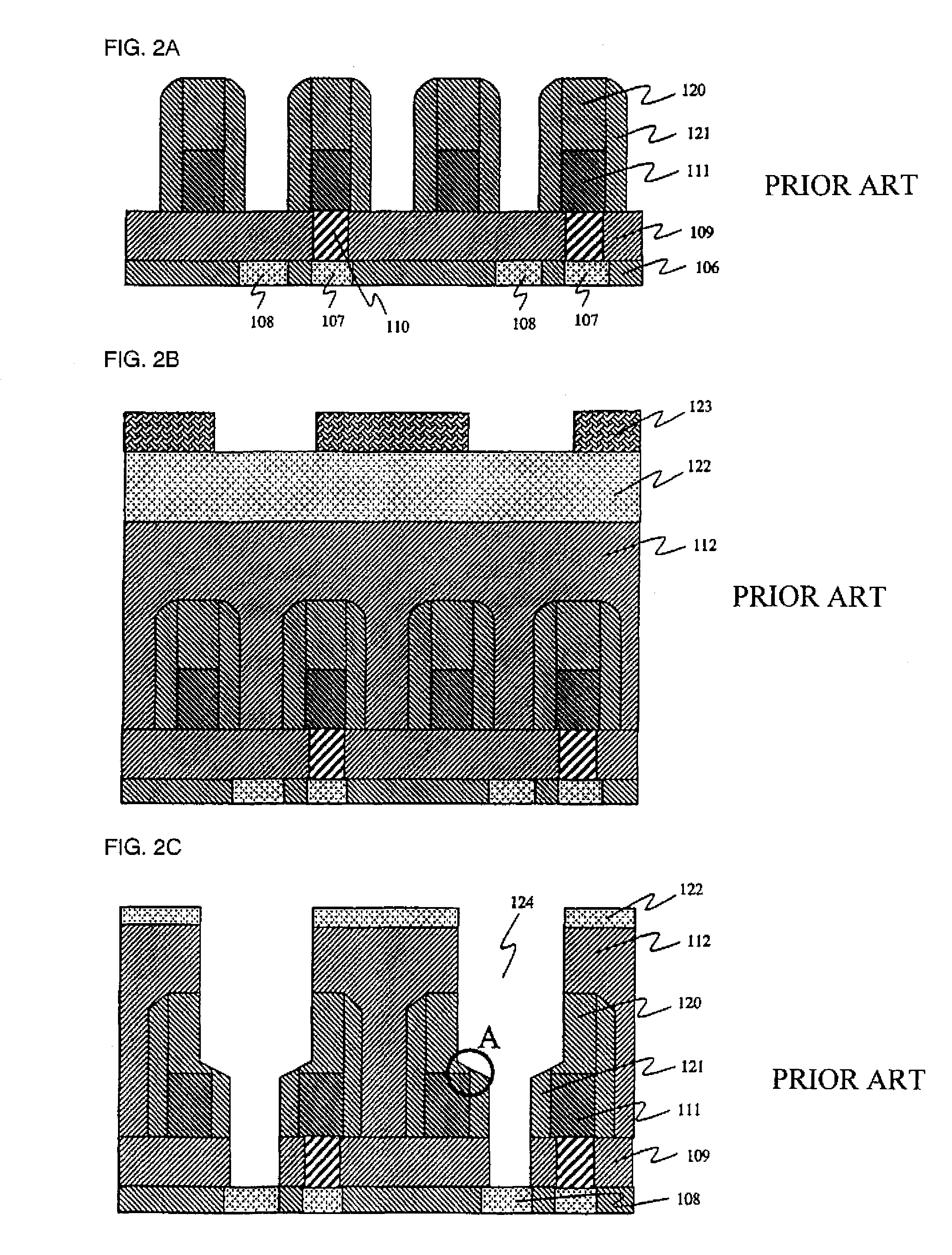

Method for fabricating semiconductor device with buried gate

InactiveUS20120156869A1Reduce contact resistanceIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesInter layerIsolation layer

A method for fabricating a semiconductor device includes forming a hard mask pattern over a substrate, forming an isolation layer for defining an active region by using the hard mask pattern, forming a buried gate in and across the active region and the isolation layer over the substrate, forming an inter-layer dielectric layer over the substrate, forming a storage node contact hole that exposes the hard mask pattern by selectively etching the inter-layer dielectric layer, extending the storage node contact hole to expose the active region by removing the hard mask pattern exposed under the storage node contact hole, and forming a storage node contact plug that fills the extended storage node contact hole.

Owner:SK HYNIX INC

Ceramic electronic component and manufacturing method therefor

ActiveUS20160024346A1Improve heat resistanceNo longer be formedTransformers/inductances coils/windings/connectionsResistor manufactureHydrofluoric acidPhosphoric acid

A ceramic electronic component that includes a ceramic element, and a coating film and external electrodes that are provided on the surface of the ceramic element. The coating film is selectively formed on the surface of the ceramic element by applying, to the ceramic electronic component, a resin-containing solution containing at least one anion of a sulfuric acid, a sulfonic acid, a carboxylic acid, a phosphoric acid, a phosphoric acid, and a hydrofluoric acid.

Owner:MURATA MFG CO LTD

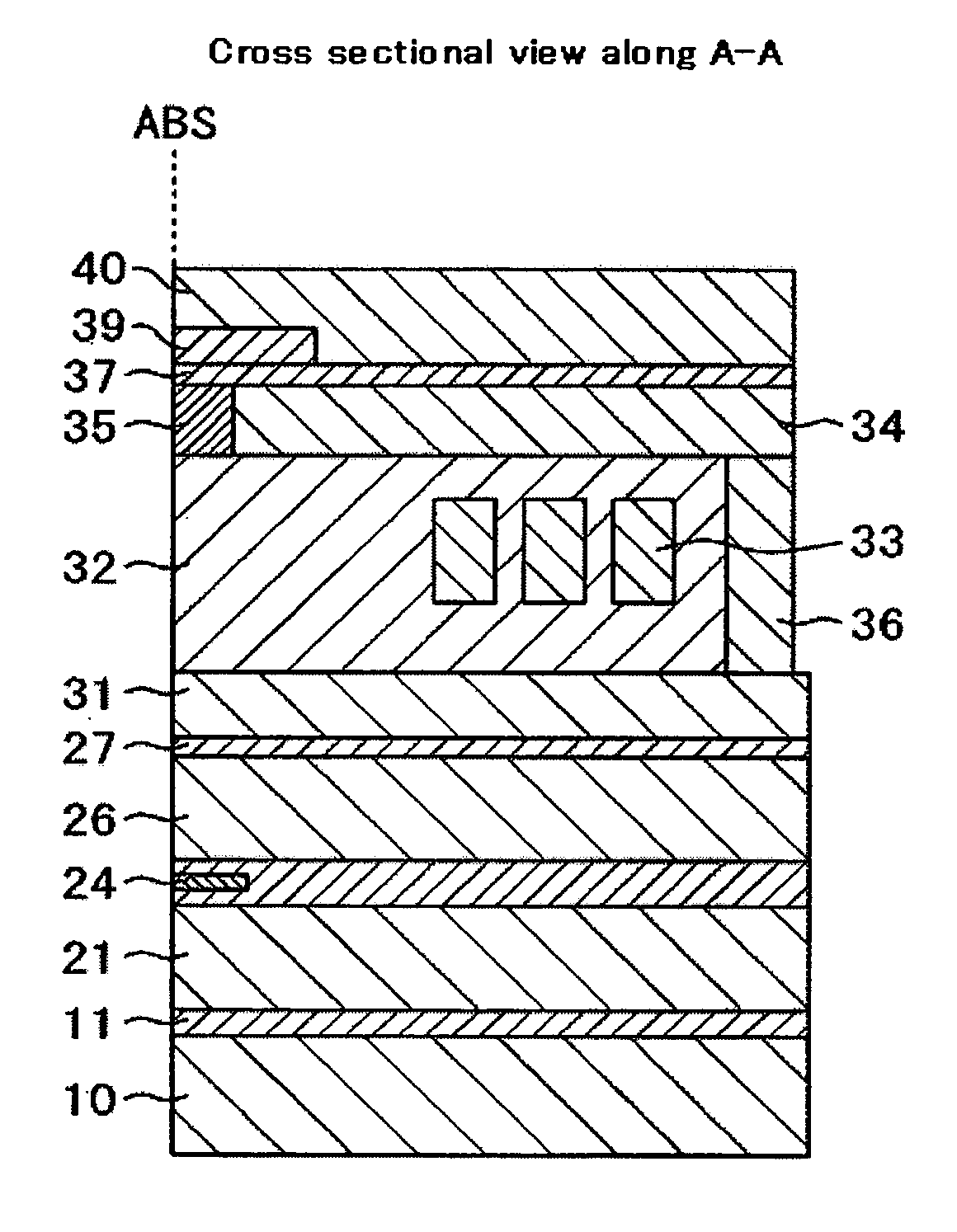

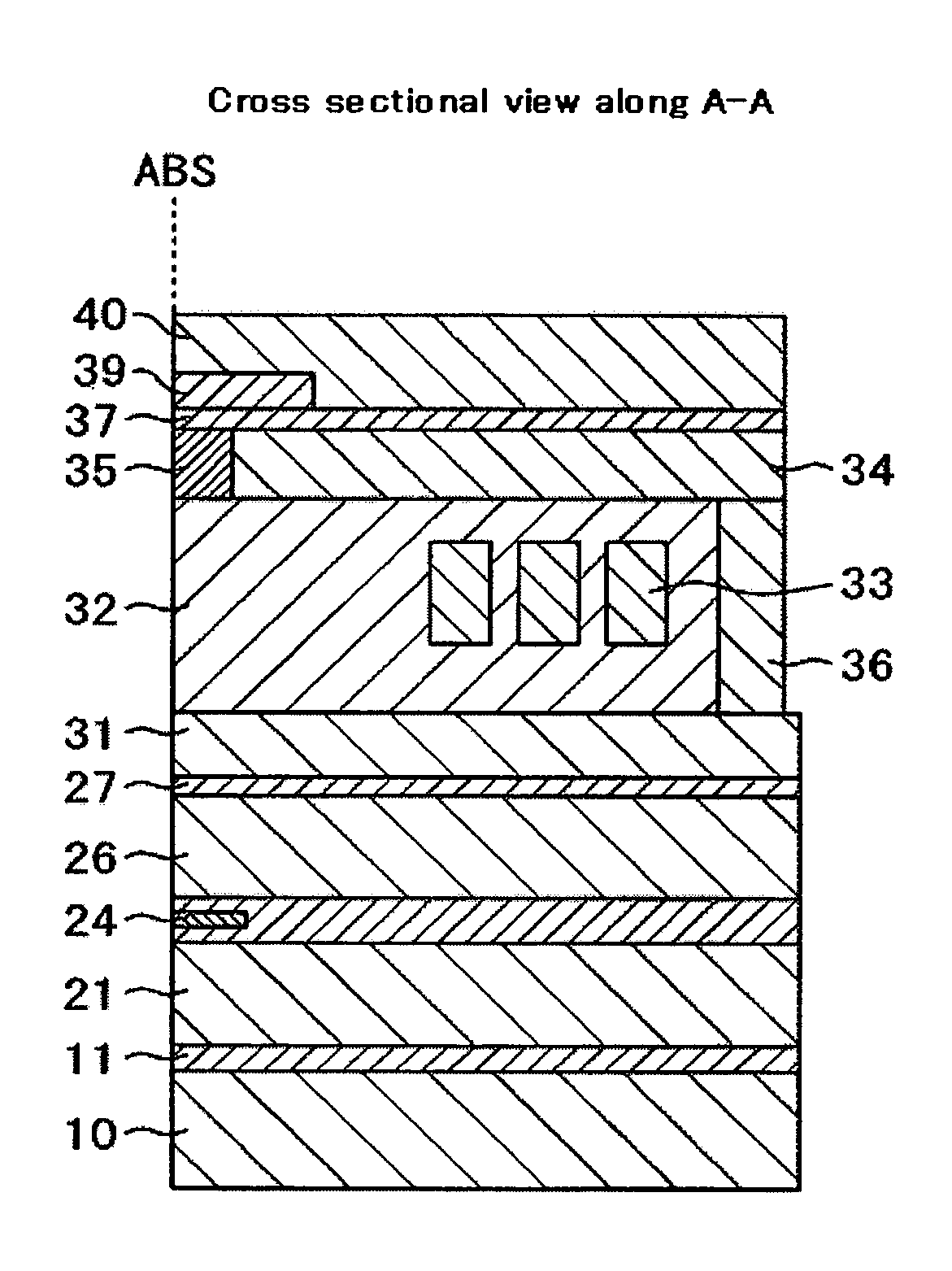

Method of manufacturing a magnetic head and a magnetic head

InactiveUS20060238918A1Less dimensional variationStay in shapeConstruction of head windingsElectrical transducersMagnetic layerEngineering

A main magnetic pole of a recording head is formed in an inverted trapezoidal shape by ion milling but, the long milling time poses a problem of variations in the inverted trapezoidal shape and the dimensional variations in track width. In one embodiment of the invention, a recording head is formed by first forming a lower magnetic pole, a gap layer, and conductor coils, forming an upper magnetic yoke over the gap layer at a position recessed from the air bearing surface, and forming an inorganic insulative layer in the recessed portion. A back magnetic pole connected with the upper magnetic yoke is formed on the back of the lower electrode. Successively, the upper surfaces of the inorganic insulative layer and the upper magnetic yoke are planarized, on which an underlayer film such as of Rh is formed. A magnetic layer is formed by stacking a plurality of thin magnetic films by sputtering over the underlayer film from the air bearing surface as far as the position overlapping the upper magnetic yoke. Successively, ion milling is applied to form a main magnetic pole of an inverted trapezoidal shape having a taper on the lateral surface as viewed from the air bearing surface.

Owner:WESTERN DIGITAL TECH INC

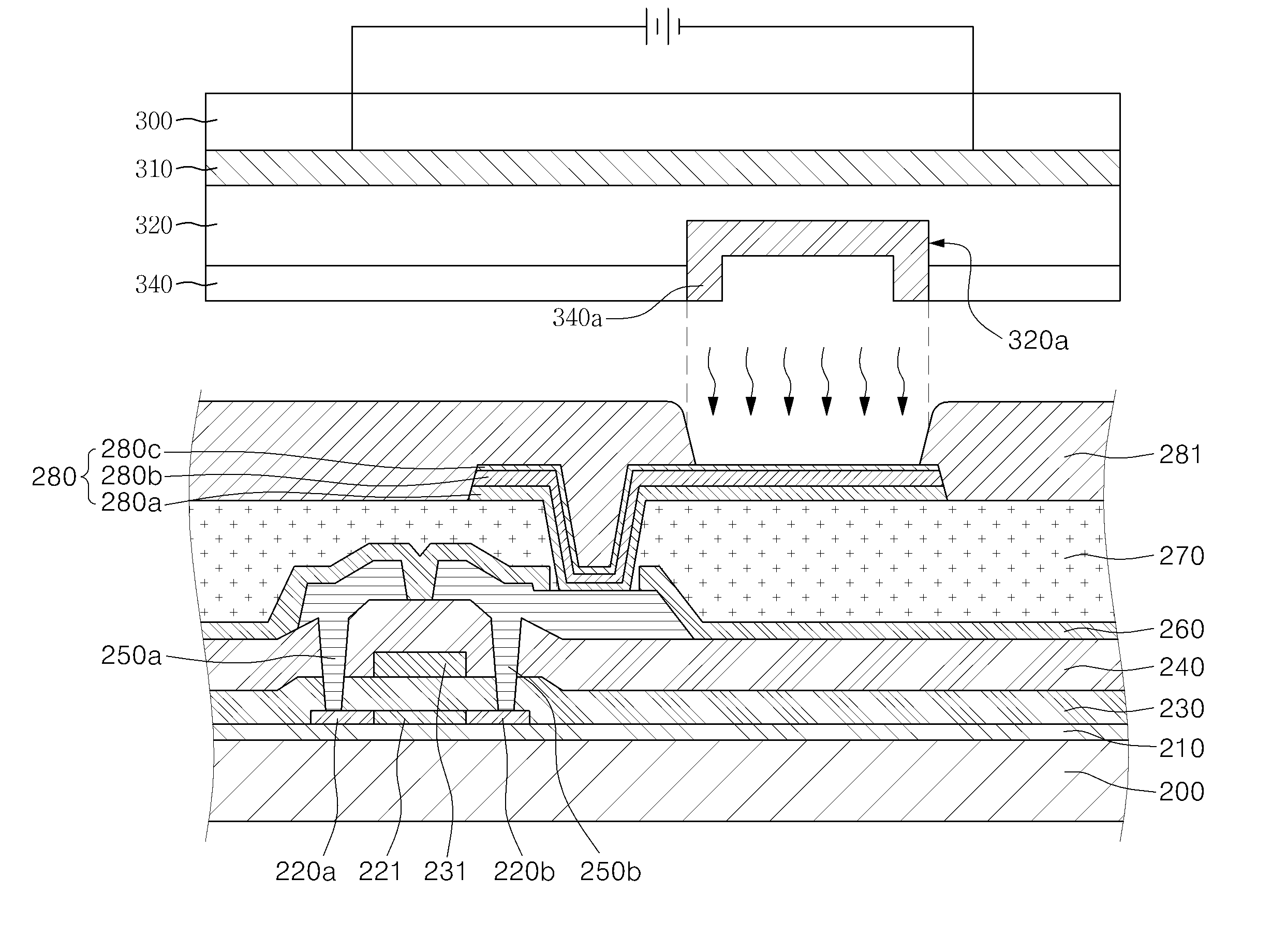

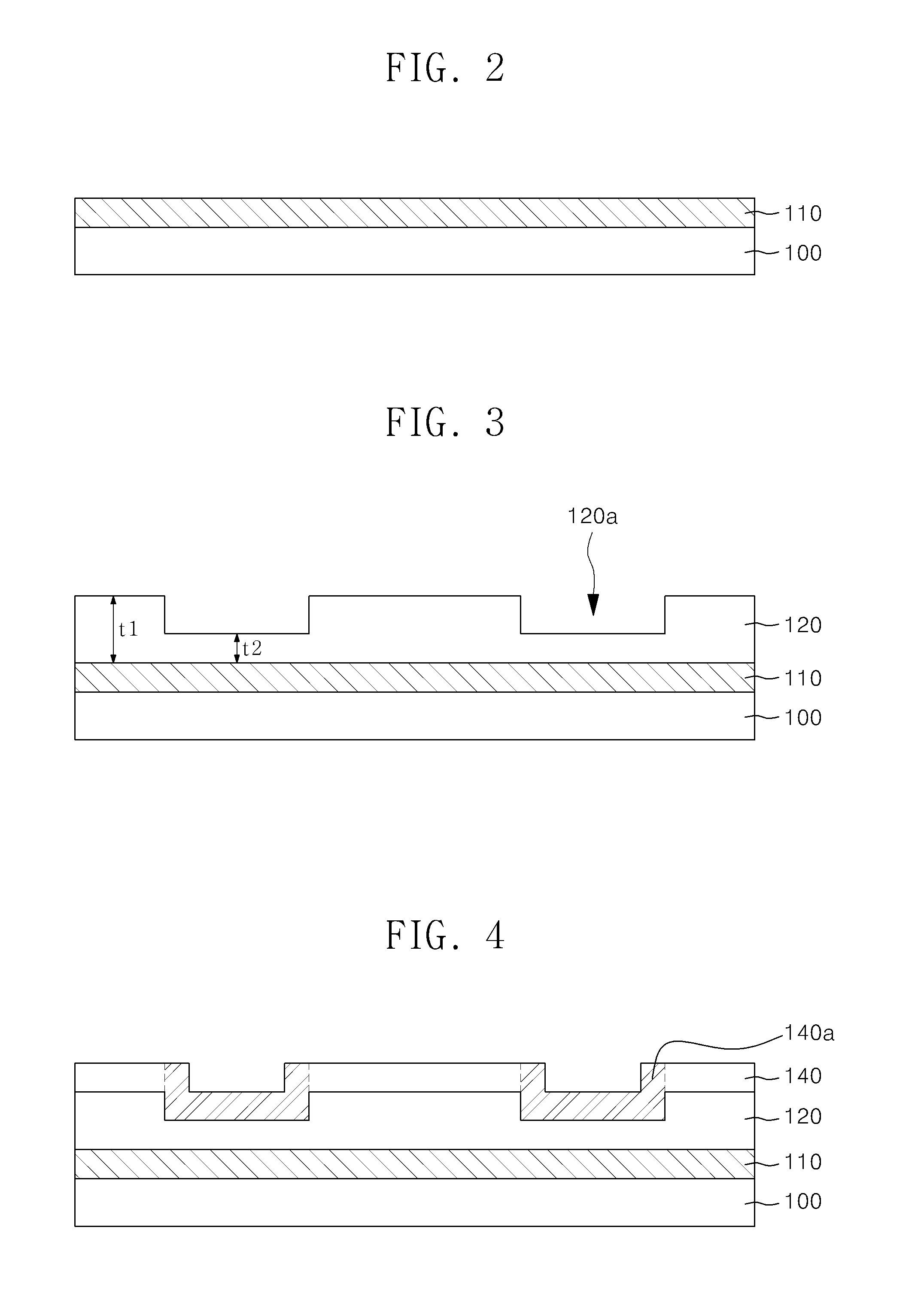

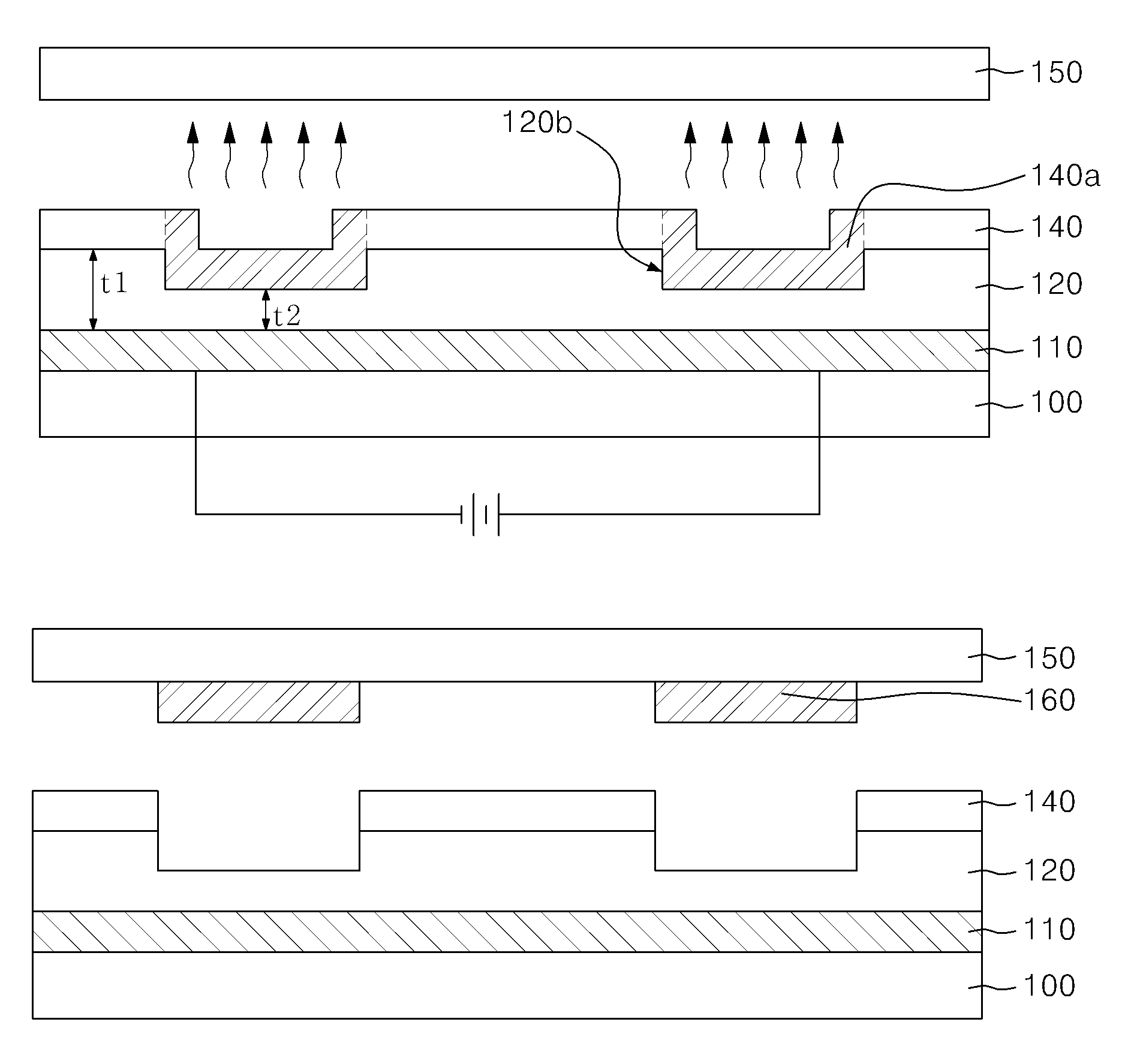

Deposition substrate of deposition apparatus, method of forming layer using the same, and method of manufacturing organic light emitting diode display device

InactiveUS20130267055A1Short timeSuitable for manufactureElectroluminescent light sourcesSolid-state devicesElectric fieldJoule heating

Provided are a deposition substrate of a deposition apparatus, a method of forming a layer using the same, and a method of manufacturing an organic light emitting diode (OLED) display device. The method of forming a layer using the deposition substrate includes preparing a substrate, forming a heating conductive layer for Joule heating on the substrate, forming a first insulating layer on the heating conductive layer for Joule heating and including a groove or hole, forming a deposition material layer on a top surface of the first insulating layer having the groove or hole, and applying an electric field to the heating conductive layer for Joule heating to perform Joule-heating on the deposition material layer. Thus, the method is suitable for manufacturing a large-sized device.

Owner:DAWONSYS

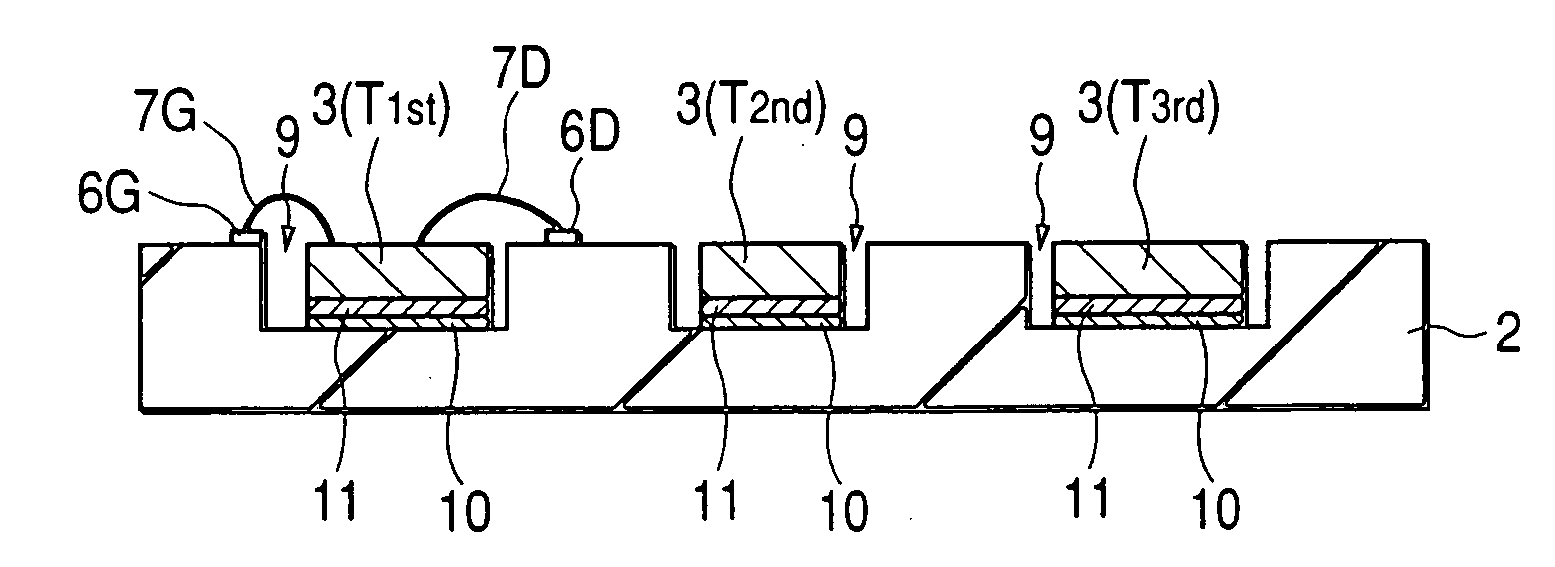

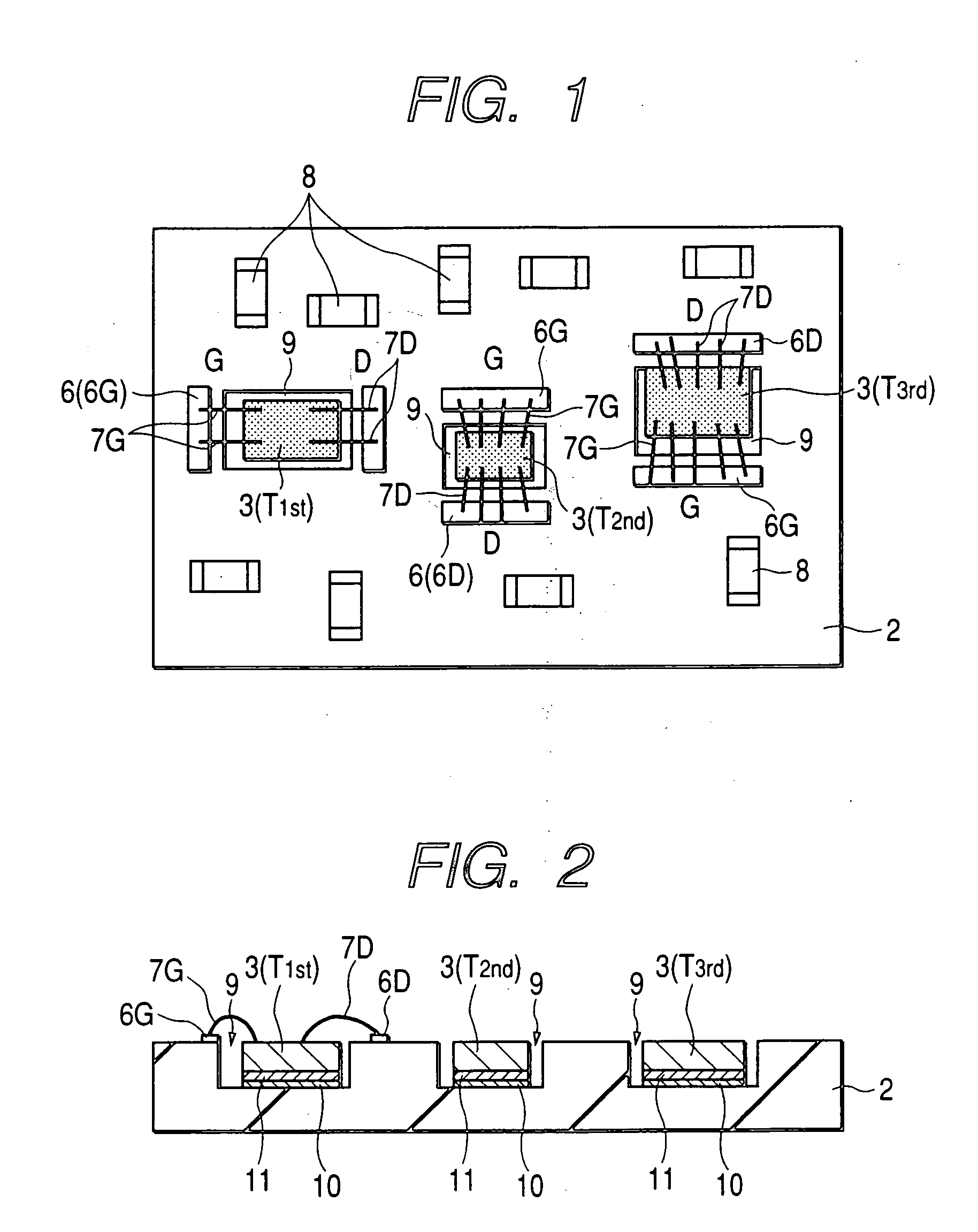

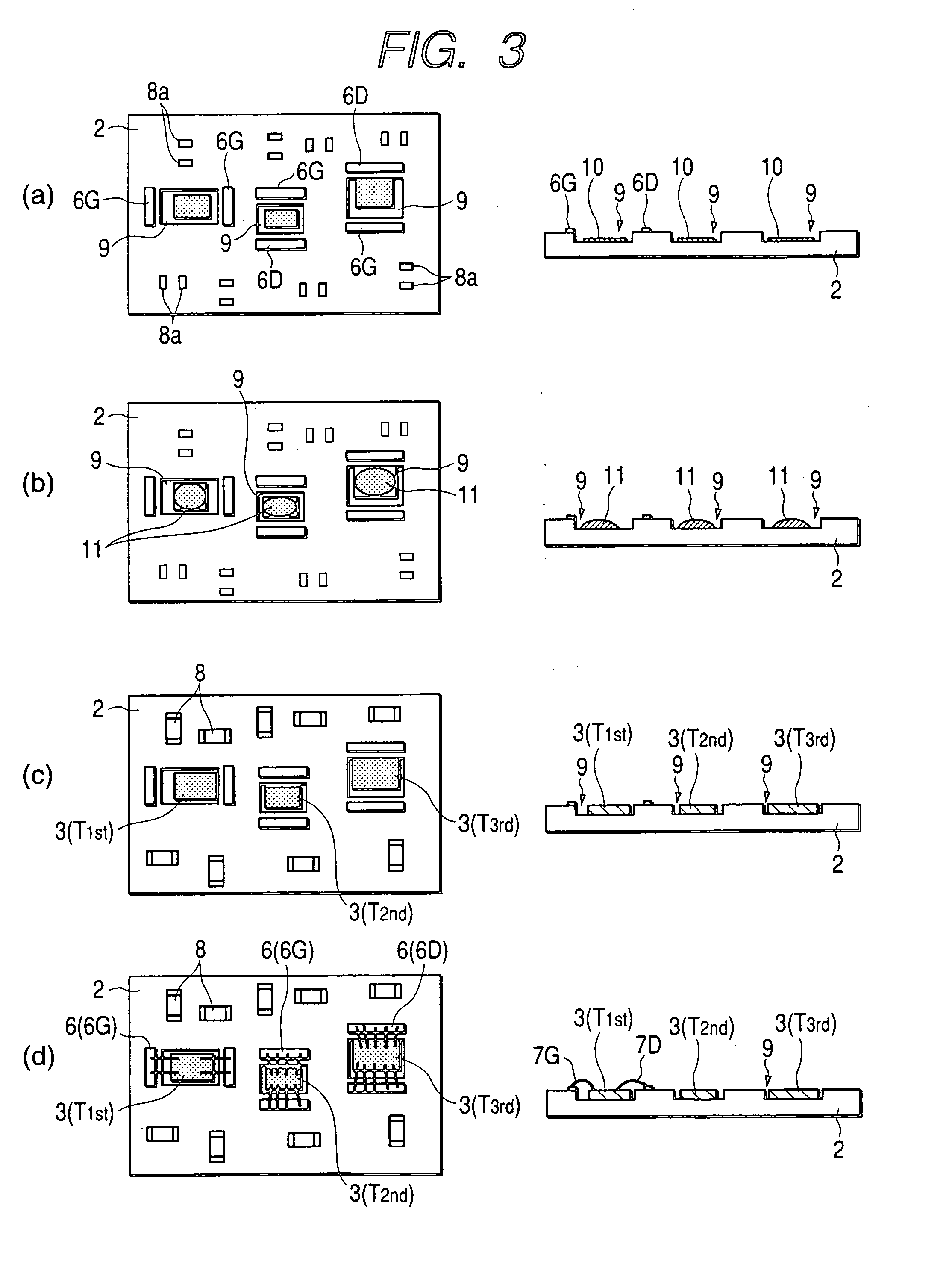

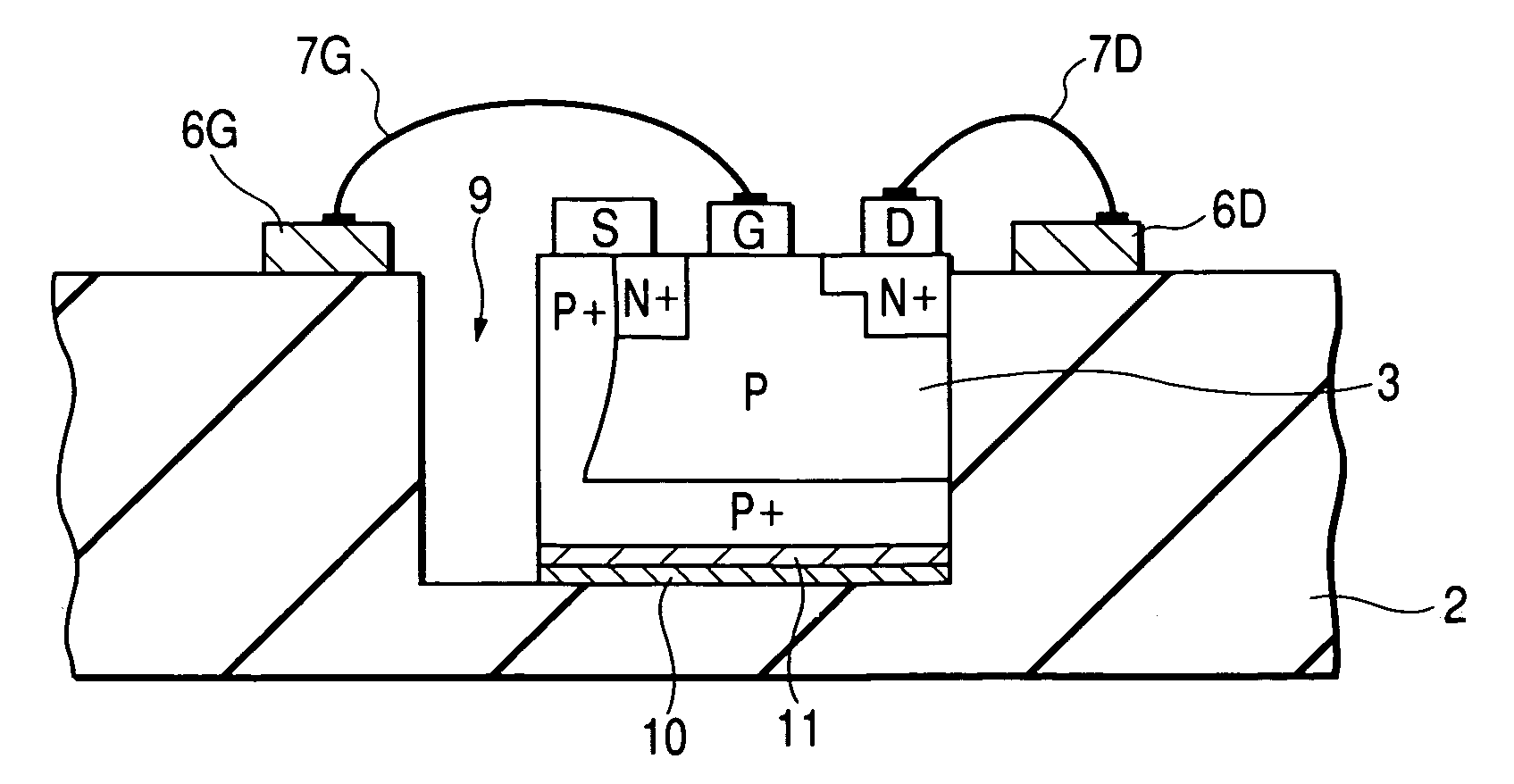

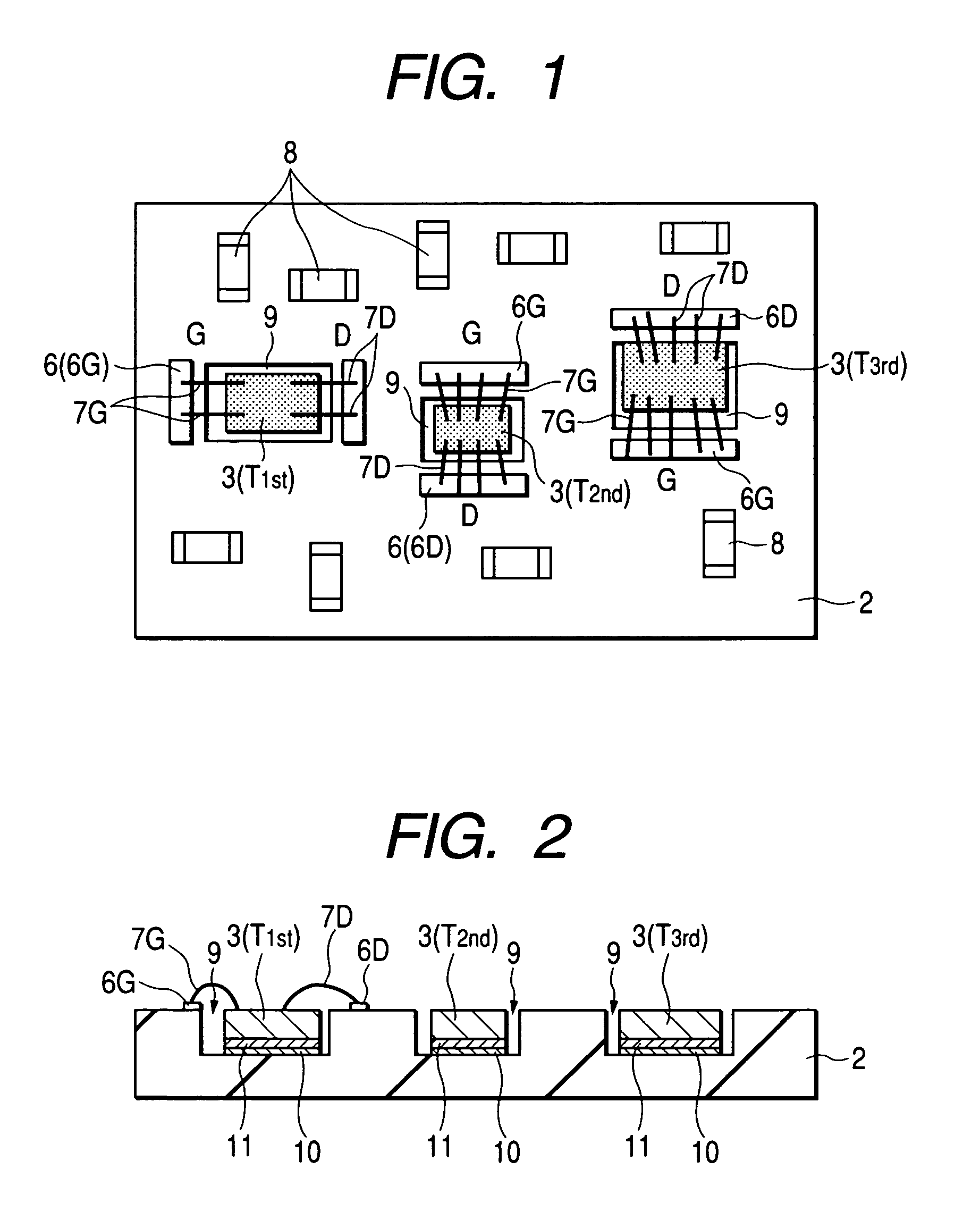

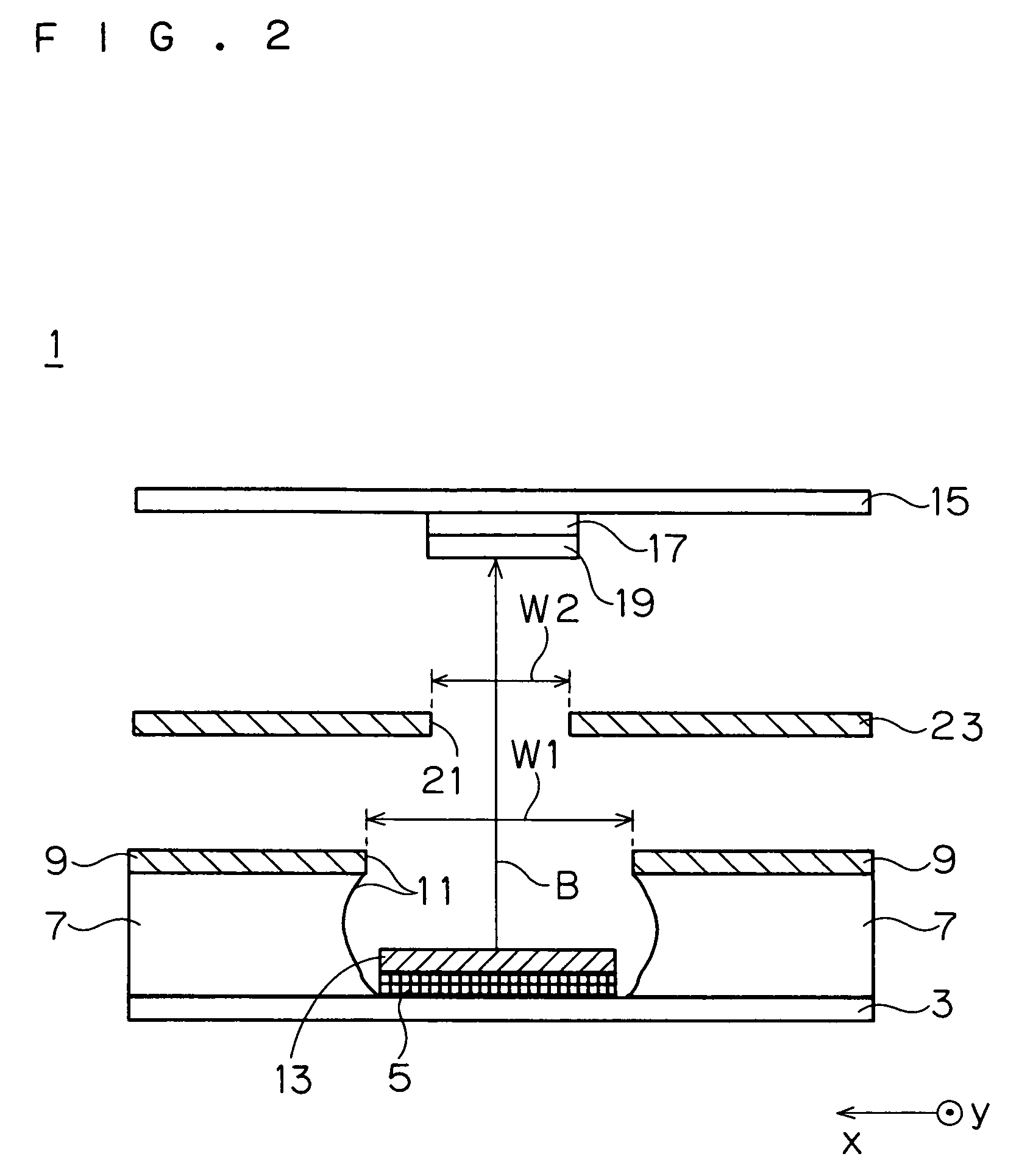

Semiconductor device, its manufacturing method, and radio communication device

ActiveUS20060118970A1No longer be formedReduce variationGated amplifiersGain controlAudio power amplifierChip size

The variation of the parasitic inductance generated at the output terminal of a transistor in the final stage of a multistage amplifier unit is reduced. One side of the semiconductor chip that includes the final stage transistor is put in contact with the inner wall of a square recess formed in a wiring substrate. The semiconductor chip is positioned and fixed accurately at the bottom of the recess, whereby the drain wire of the transistor is fixed. Then, a chip edge at which the drain electrode is disposed on top of the chip is put in contact with the inner wall of the recess, which is closer to the drain bonding pad. A metallized layer is formed of the same size as that of the chip at the bottom of the recess and a fusion bonding material is supplied on the metallized layer.

Owner:MURATA MFG CO LTD

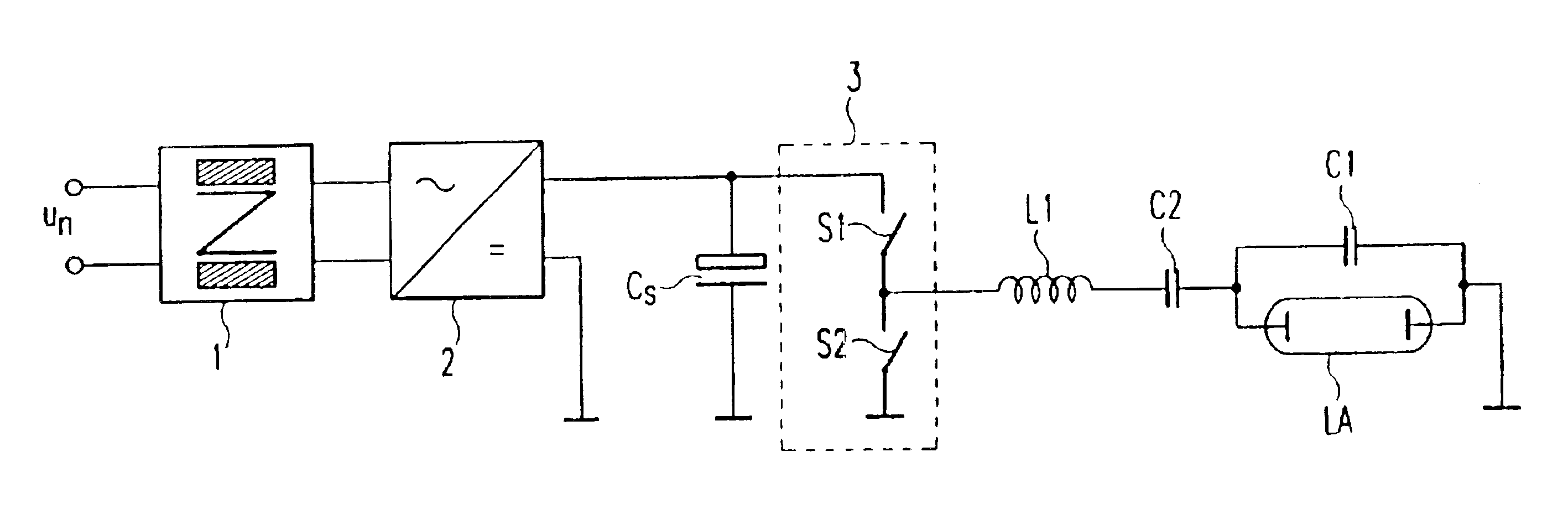

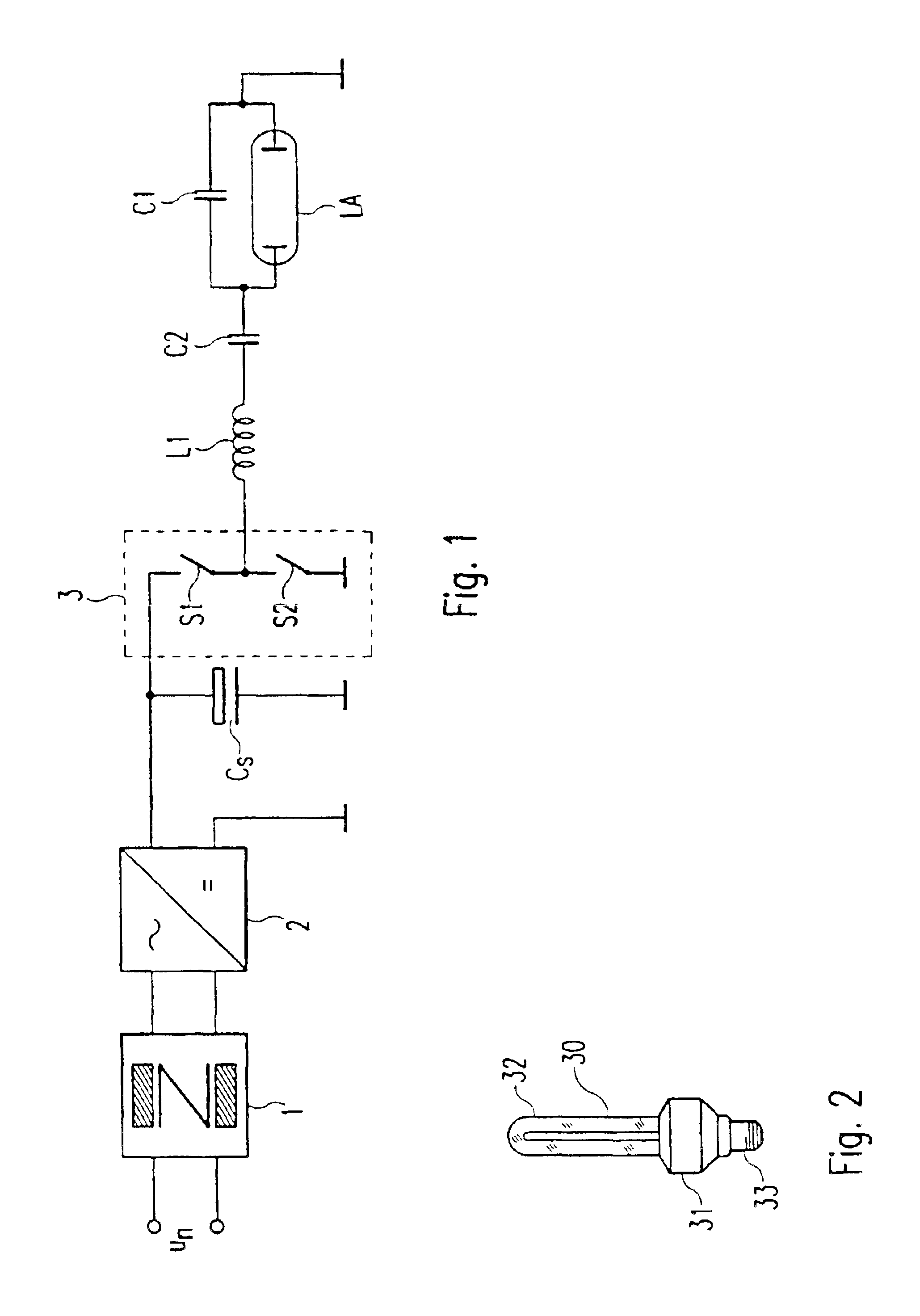

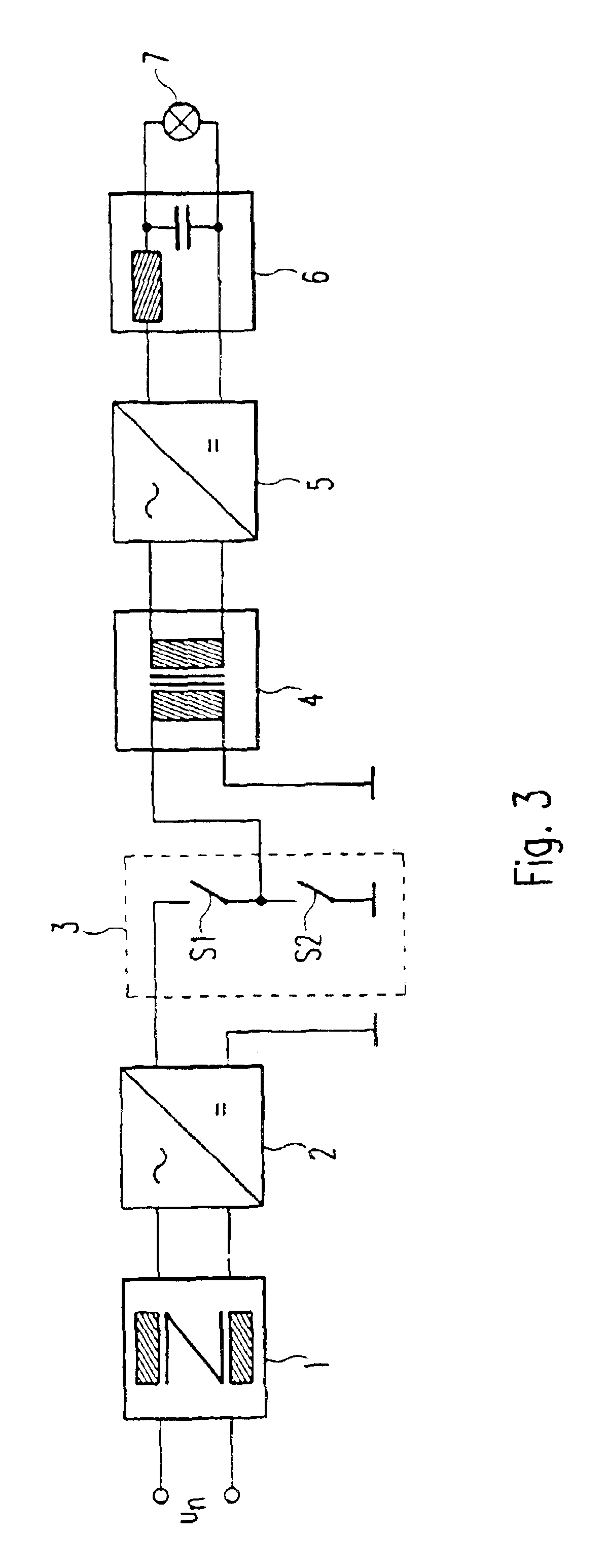

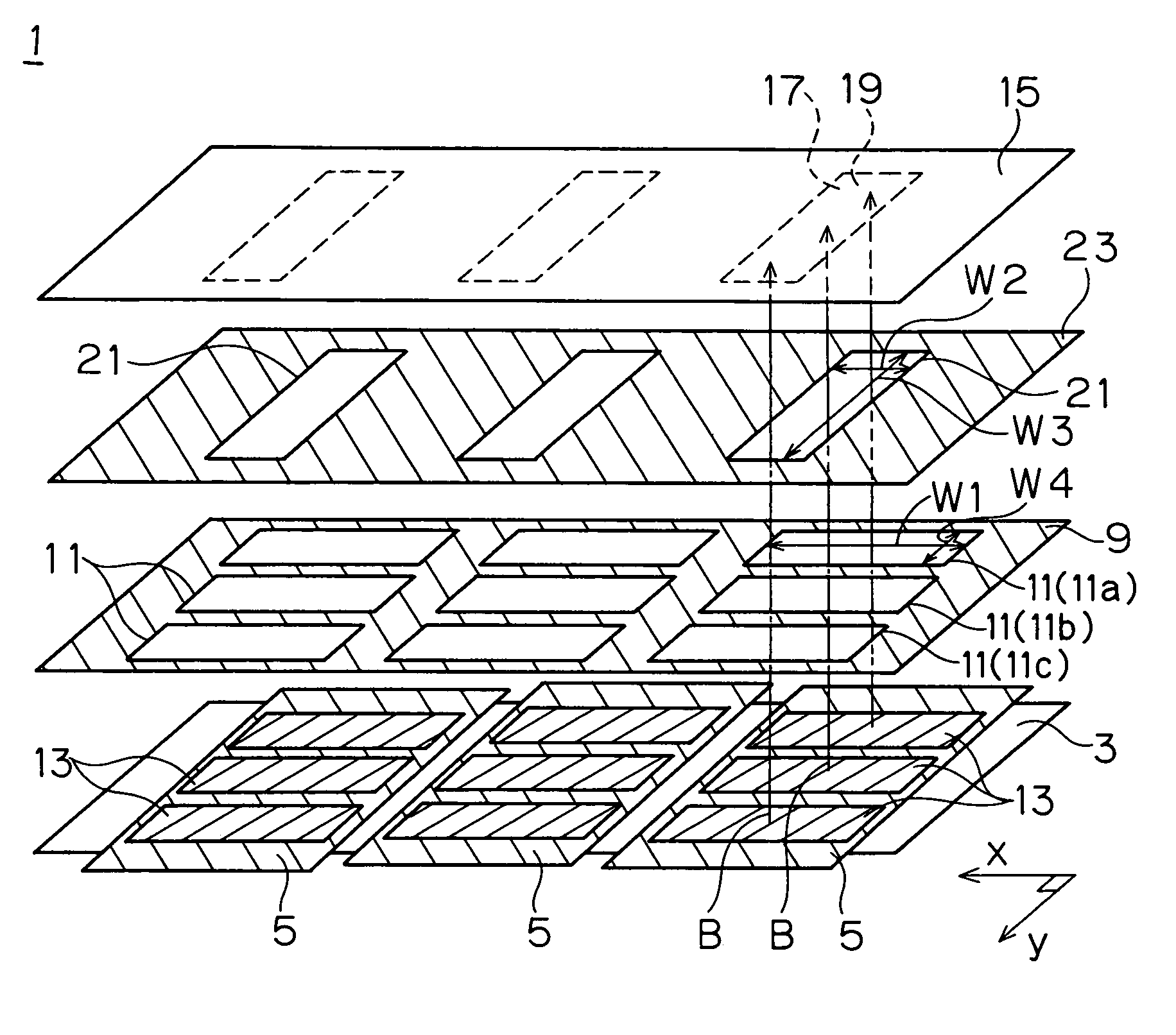

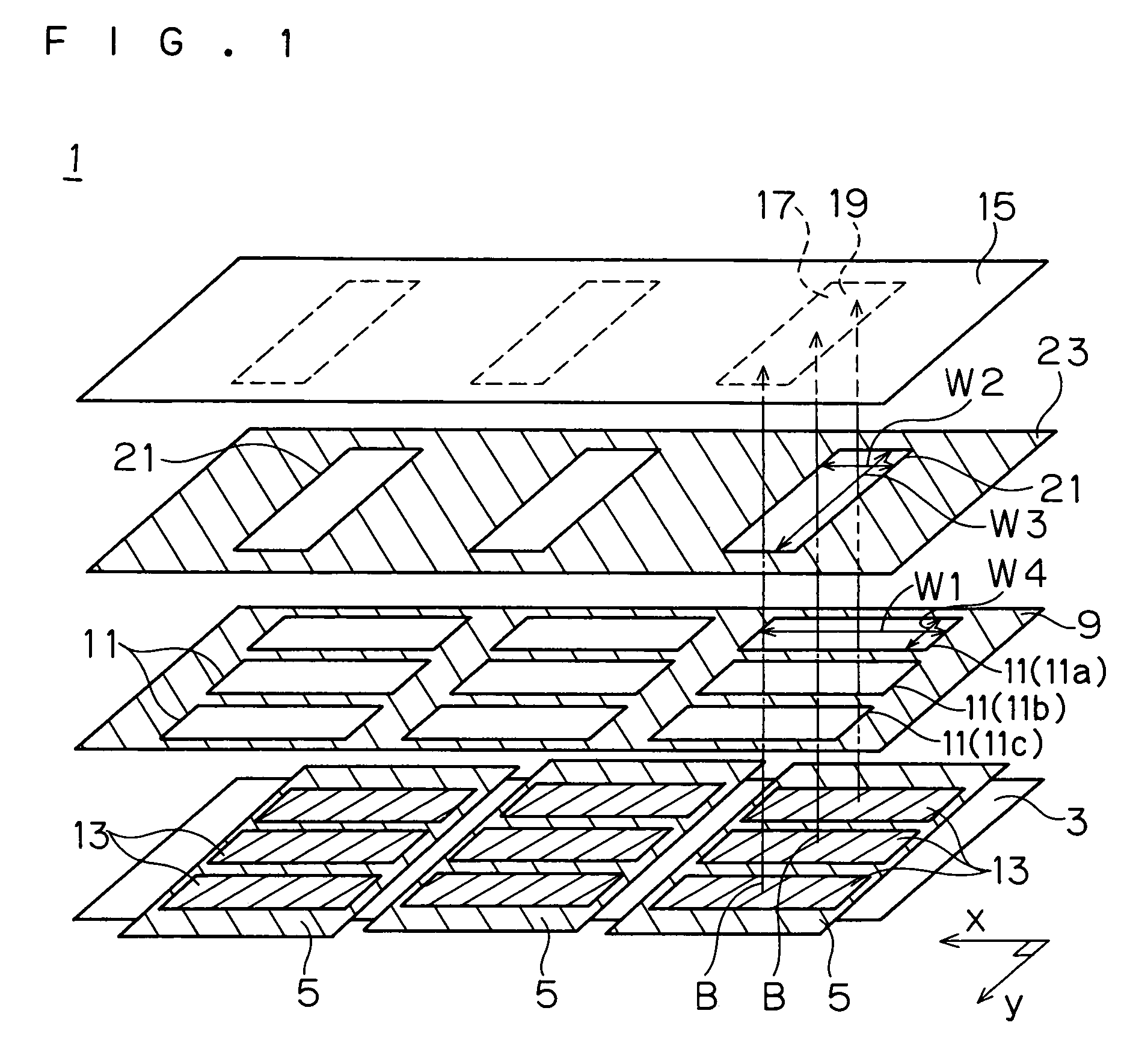

Electronic ballast and electronic transformer

InactiveUS6909246B2High outputImprove cooling effectElectric light circuit arrangementGas discharge lamp usageGas-discharge lampLoad circuit

An electronic ballast which includes a resonant load circuit (L1, C1) in series with a discharge lamp (LA), the resonant load circuit being supplied by an inverter (S1, S2) which outputs variable alternating voltages at frequencies above 200 KHZ. Alternatively, an electronic transformer incorporates a load circuit and a variable output frequency inverter for operating a low volt halogen lamp (7) at variable alternating frequencies above 200 KHZ. Passive components of the ballast and transformer are integrated into a multilayer circuit (13).

Owner:TRIDONIKATKO GMBKH & KO KG

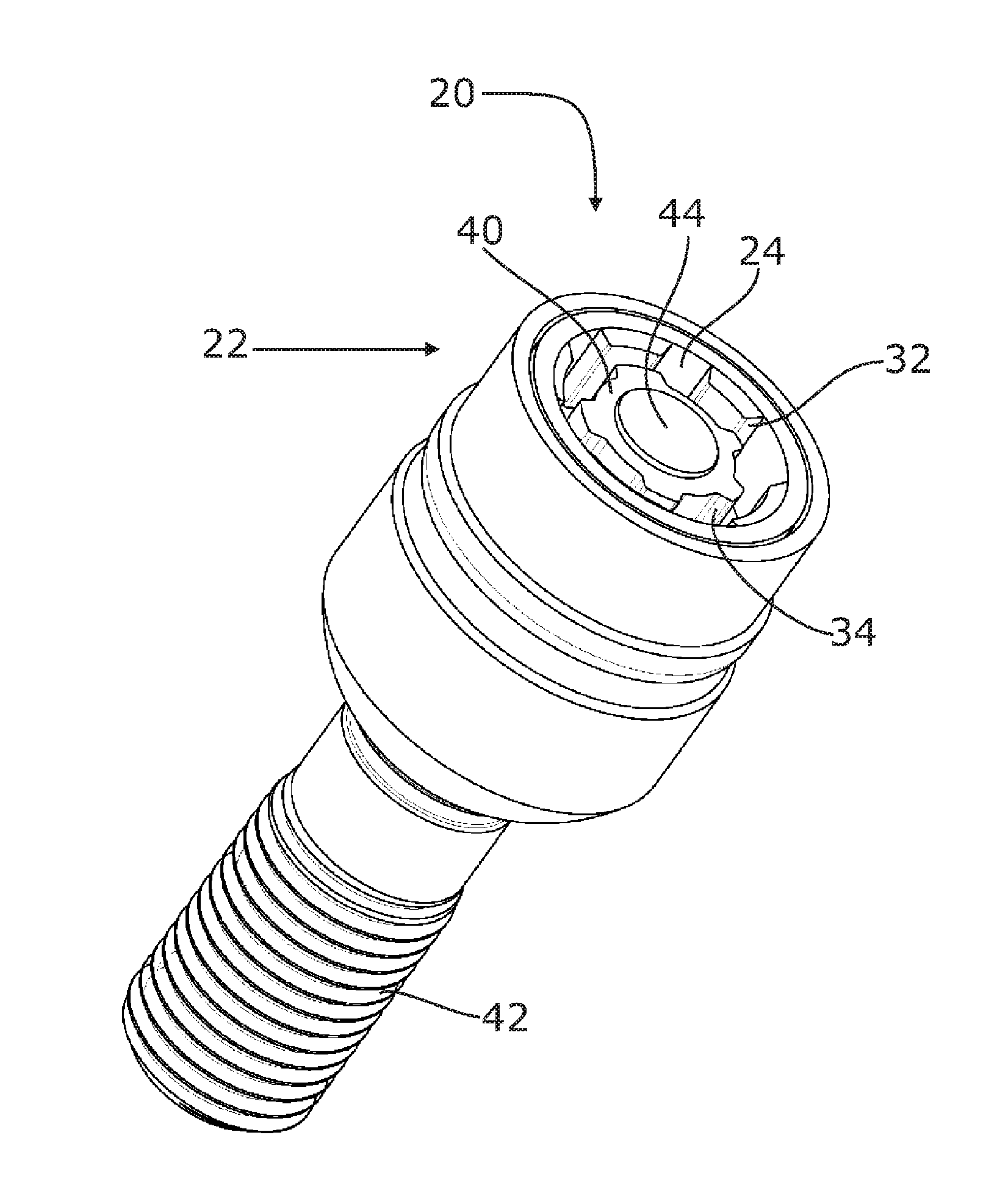

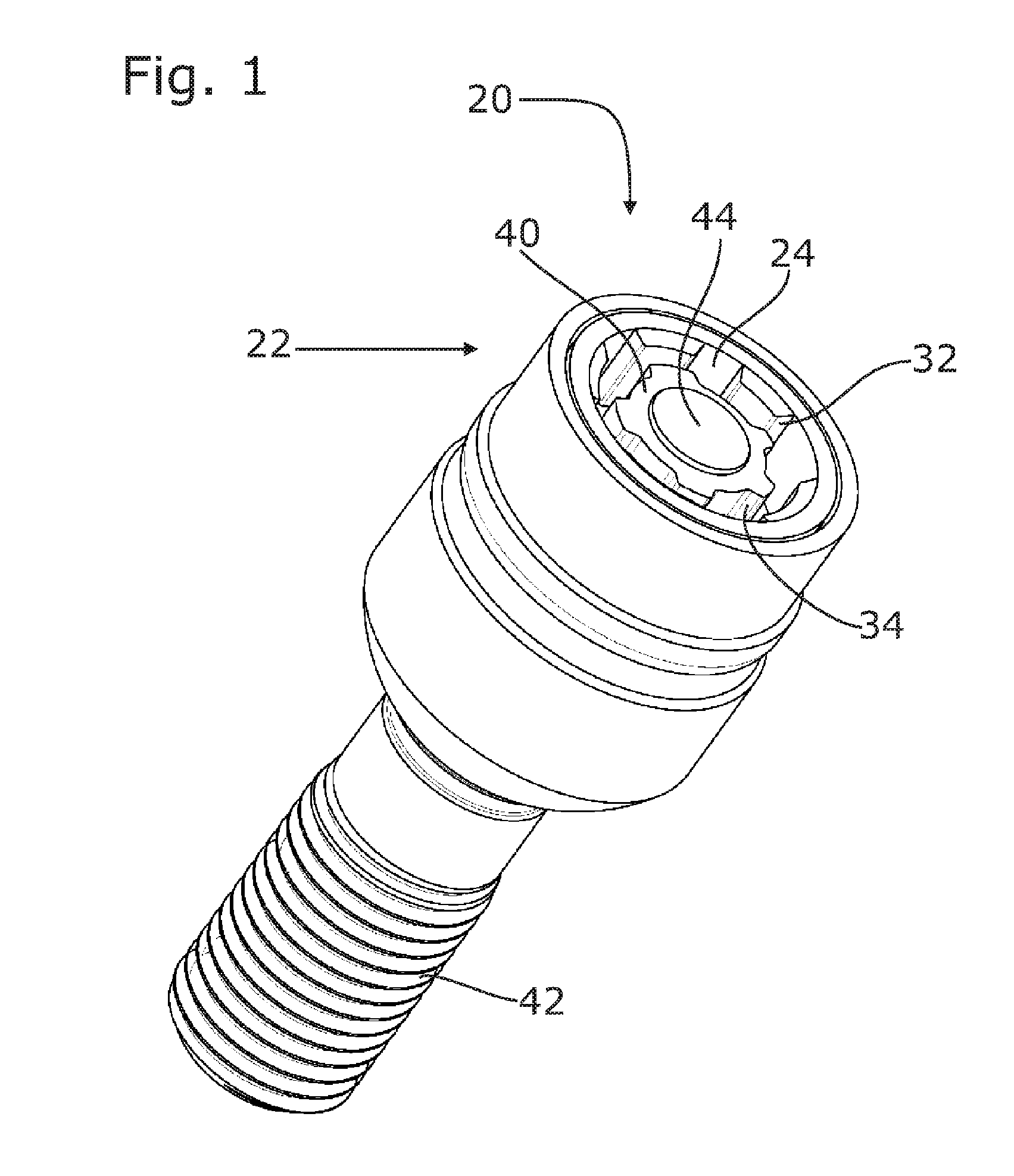

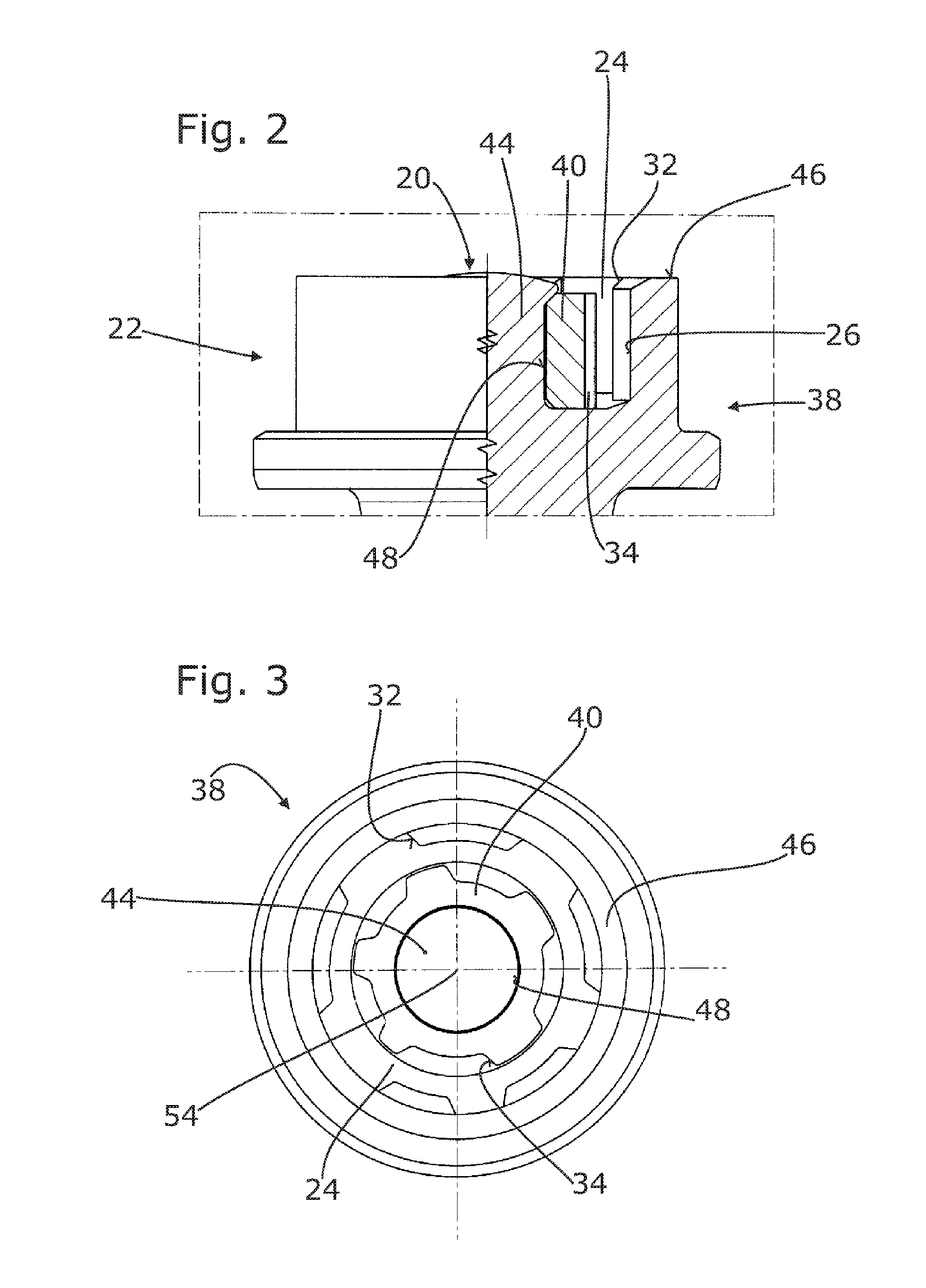

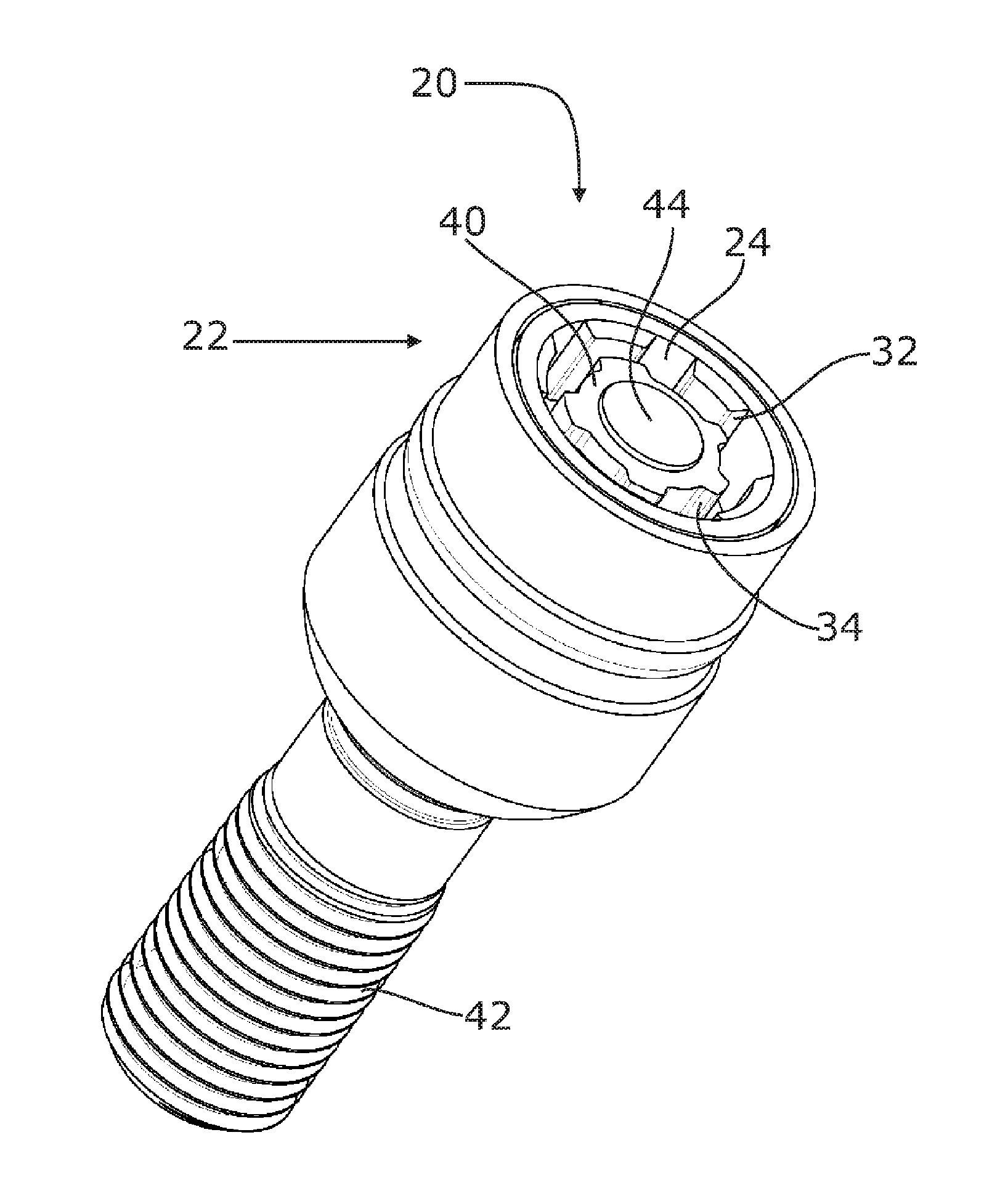

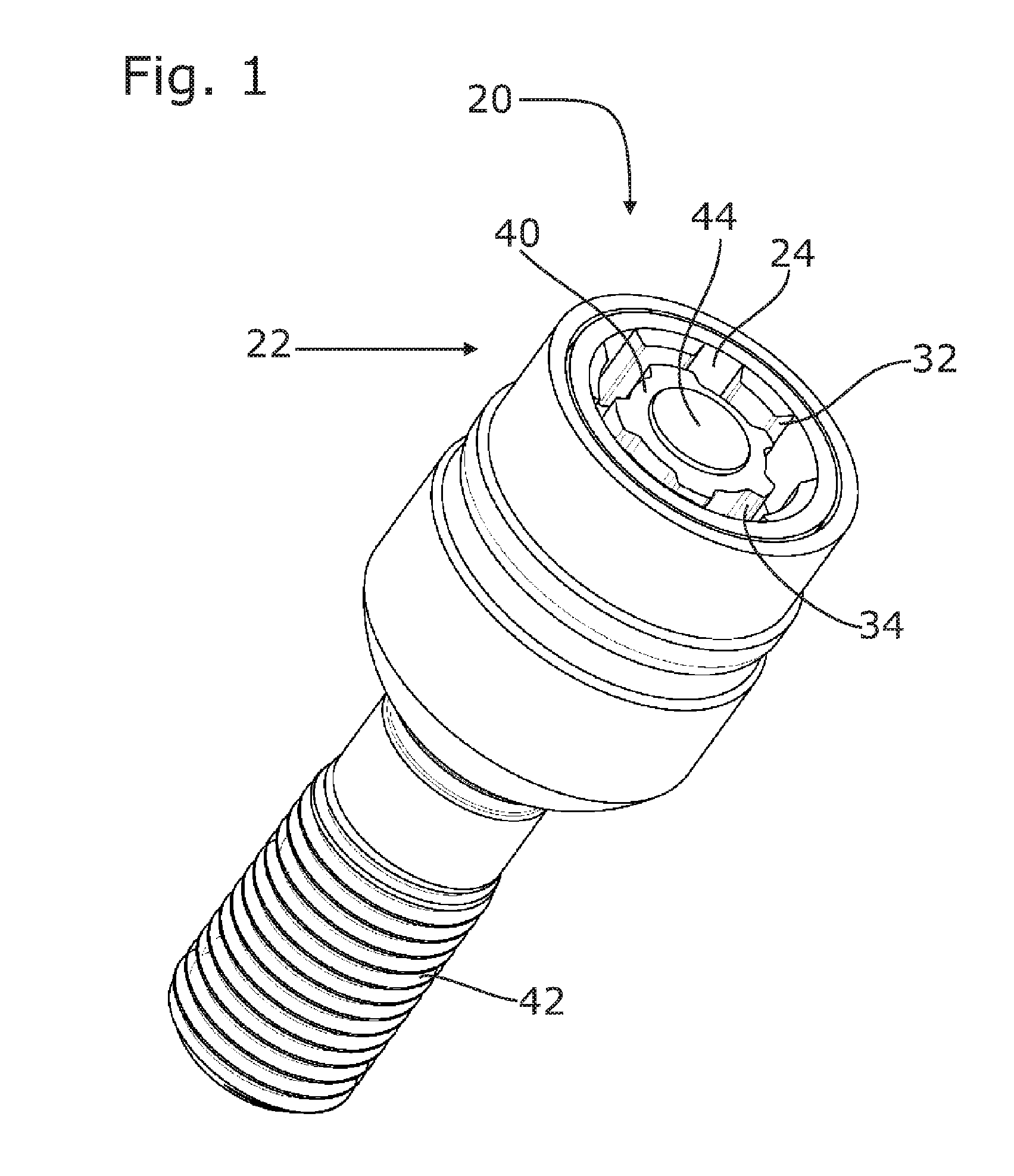

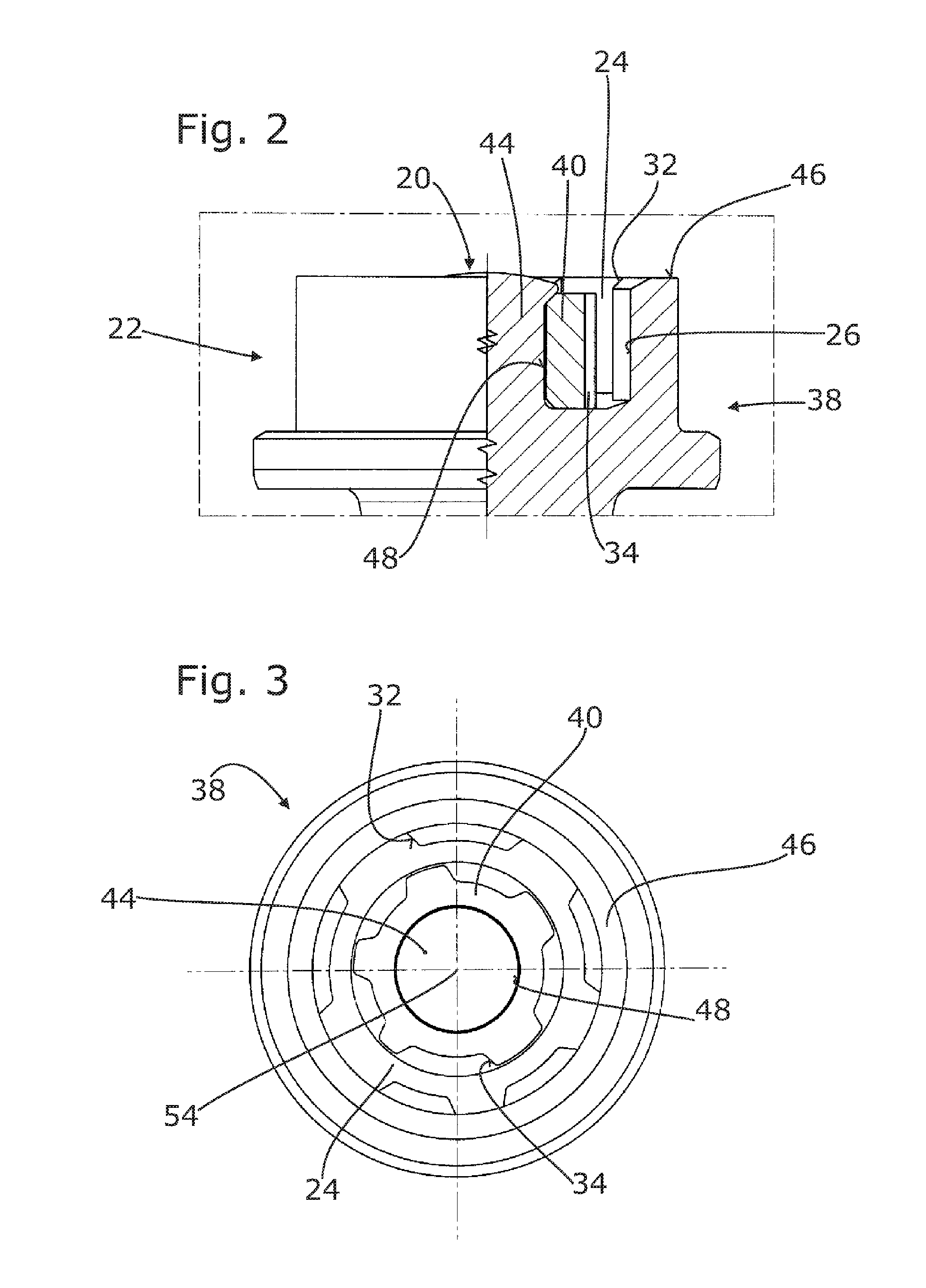

Theft-protected screw part

The theft-protected screw part in the form of a nut or a screw has a free end region and a ring-shaped depression formed at the end region for the engagement of a wrench for rotation the screw part. Viewed from radially outside to radially inside, the depression is delimited by an outer edge, a bottom and an inner edge. The outer edge forms outer abutment surfaces and the inner edge forms inner abutment surfaces for the wrench. The screw part is composed of a main part and an insert. The main part has a protrusion, which is located within the inner edge. The insert is designed in a ring shape, has a hole for accommodating the protrusion and forms the inner abutment surfaces.

Owner:ABC UMFORMTECHN

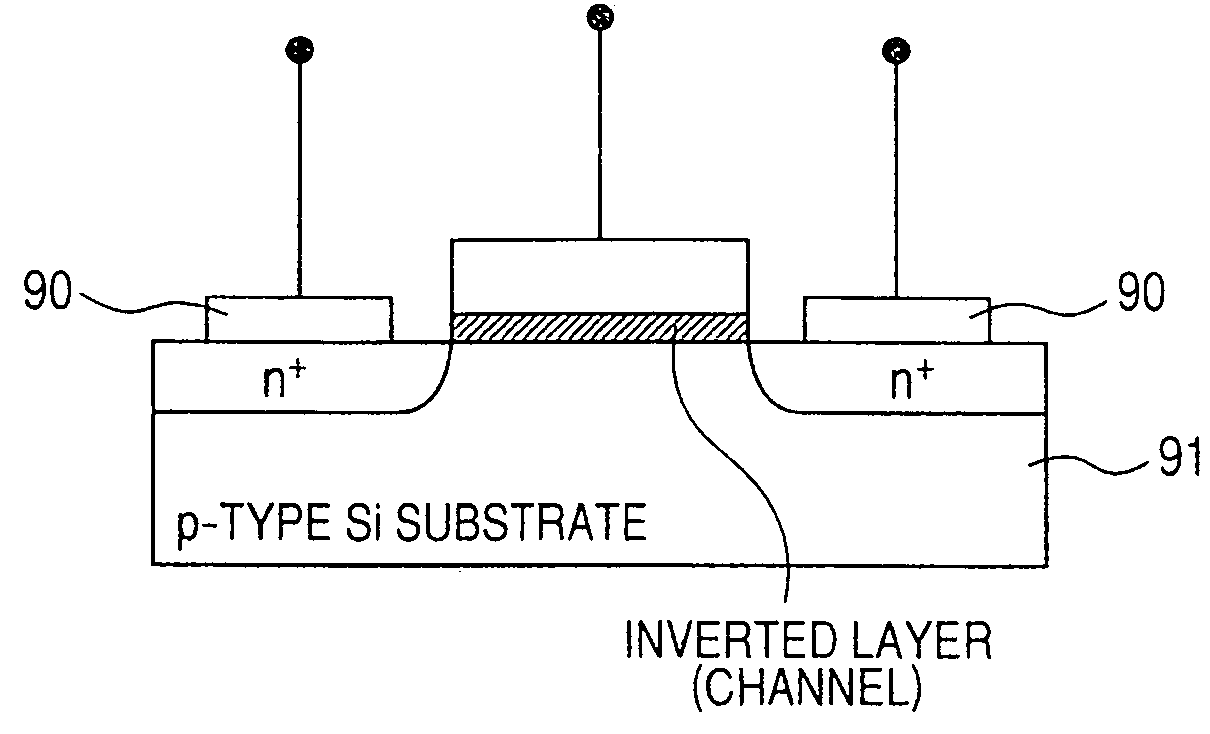

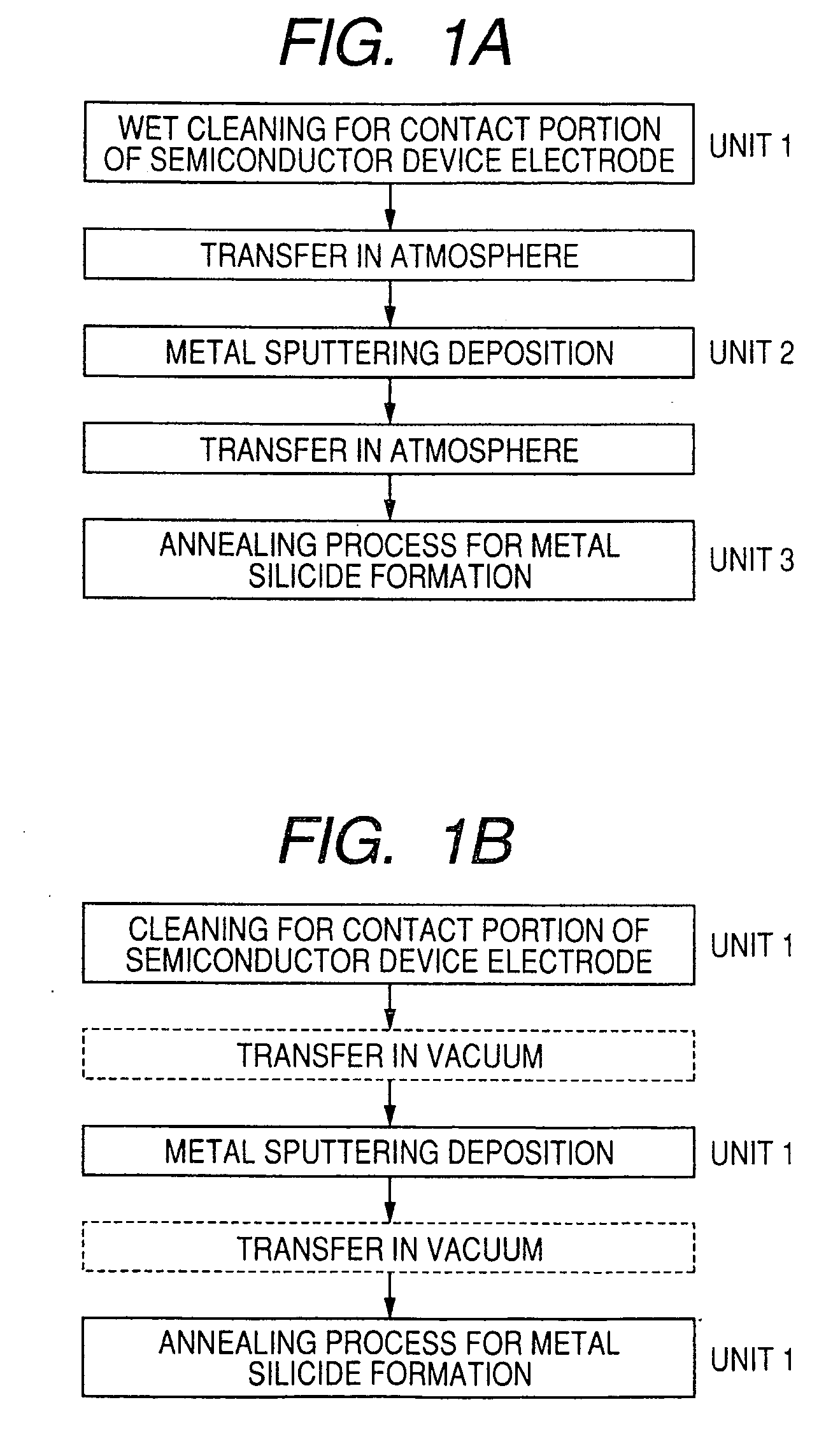

Silicide forming method and system thereof

InactiveUS20090298288A1Reduce impurityCost reductionLiquid surface applicatorsElectric discharge tubesAutoxidationSurface finishing

Radical in a plasma generation chamber is supplied to a process chamber through an introducing aperture, and HF gas is supplied as a process gas from the vicinity of the radical introducing aperture. A native oxide film of the substrate surface of a IV group semiconductor doped an impurity is removed, with a good surface roughness equal to the wet cleaning. The substrate after the surface treatment is deposited with a metal material and metal silicide formation by thermal treatment is performed, and during these processes, the substrate is not exposed to the atmosphere, and a good contact resistance equal to or better than the wet process is obtained.

Owner:CANON ANELVA CORP

Method for fabricating semiconductor device with buried gate

InactiveUS8623727B2Increase resistanceNo longer be formedSemiconductor/solid-state device detailsSolid-state devicesInter layerIsolation layer

A method for fabricating a semiconductor device includes forming a hard mask pattern over a substrate, forming an isolation layer for defining an active region by using the hard mask pattern, forming a buried gate in and across the active region and the isolation layer over the substrate, forming an inter-layer dielectric layer over the substrate, forming a storage node contact hole that exposes the hard mask pattern by selectively etching the inter-layer dielectric layer, extending the storage node contact hole to expose the active region by removing the hard mask pattern exposed under the storage node contact hole, and forming a storage node contact plug that fills the extended storage node contact hole.

Owner:SK HYNIX INC

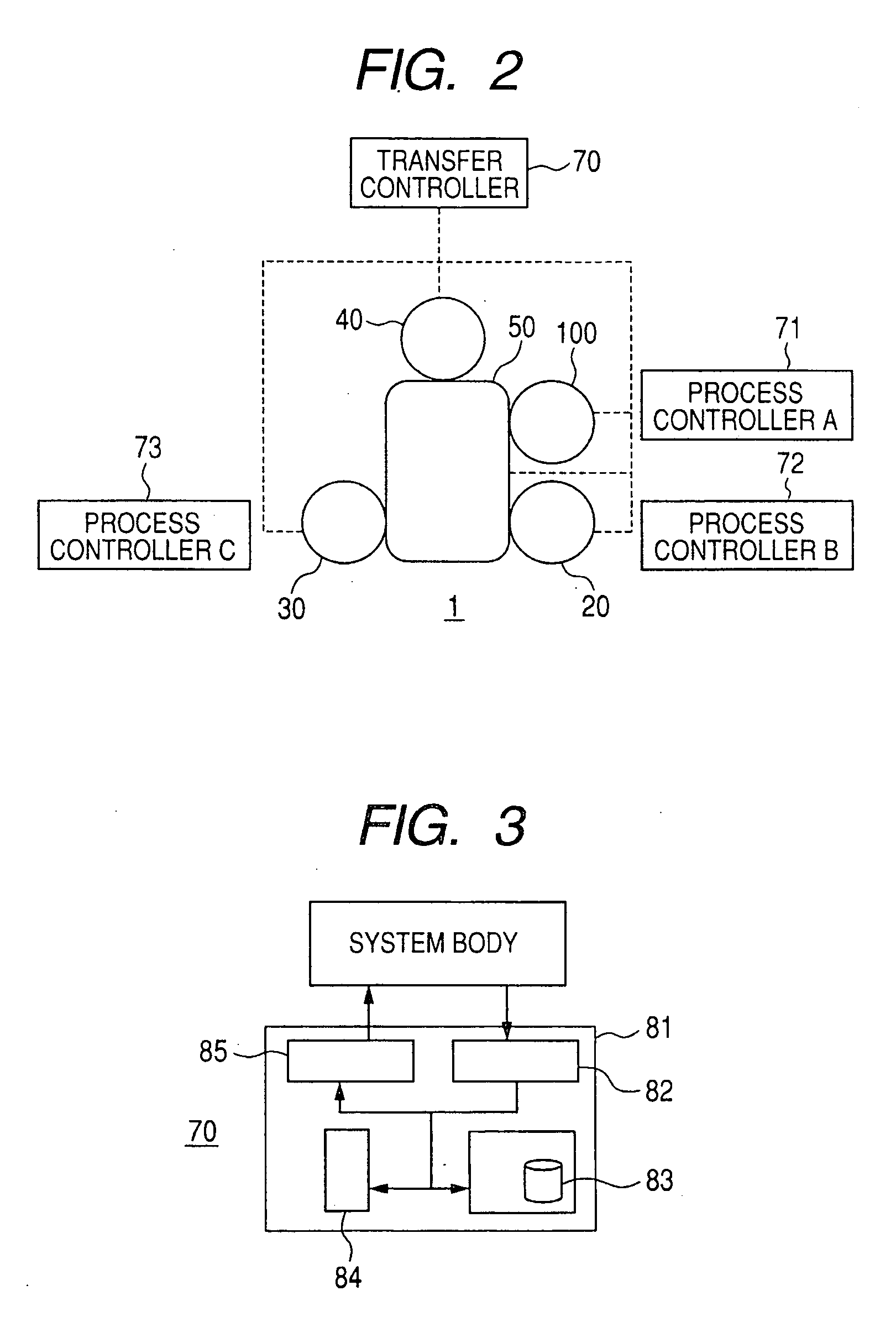

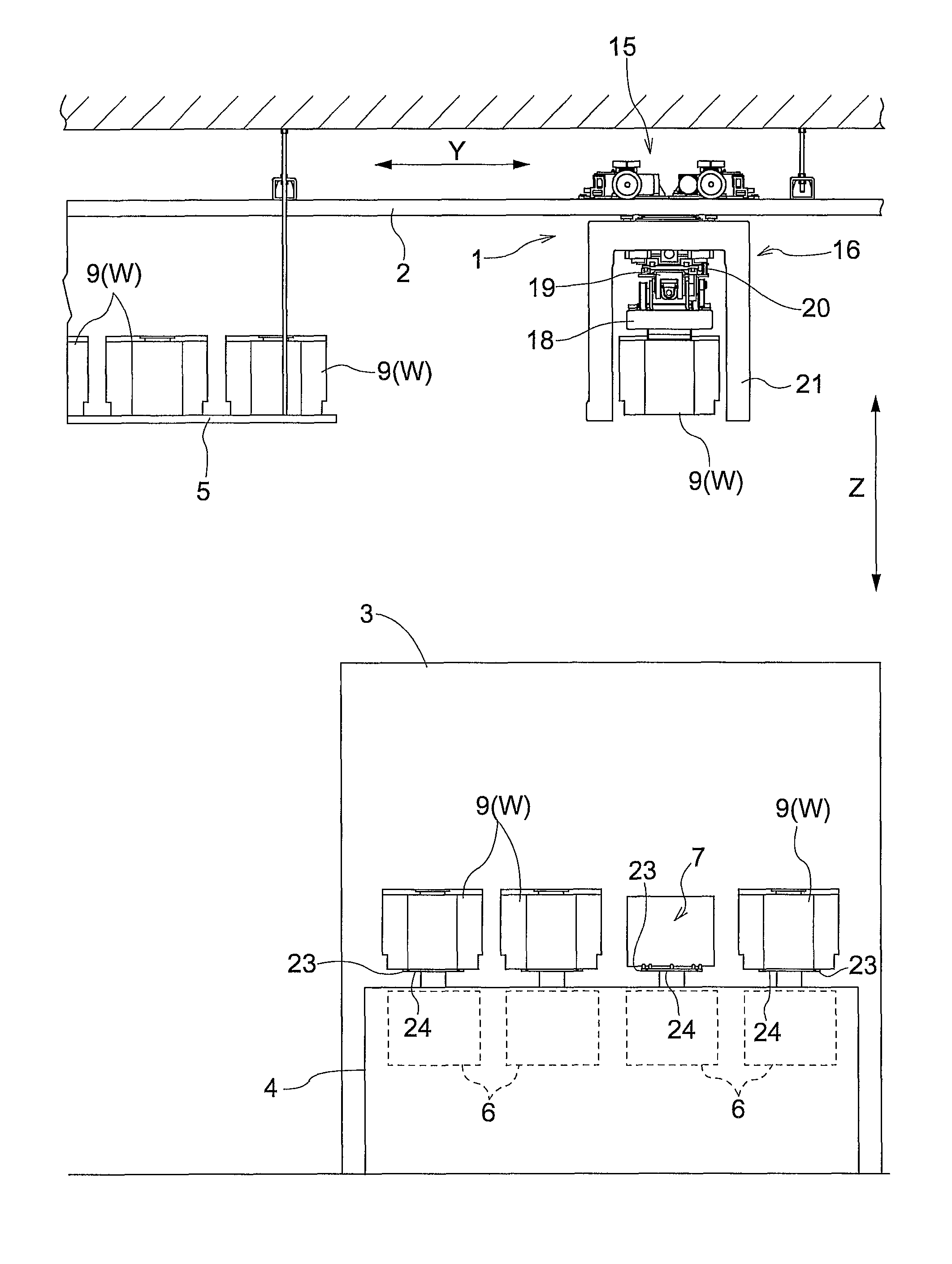

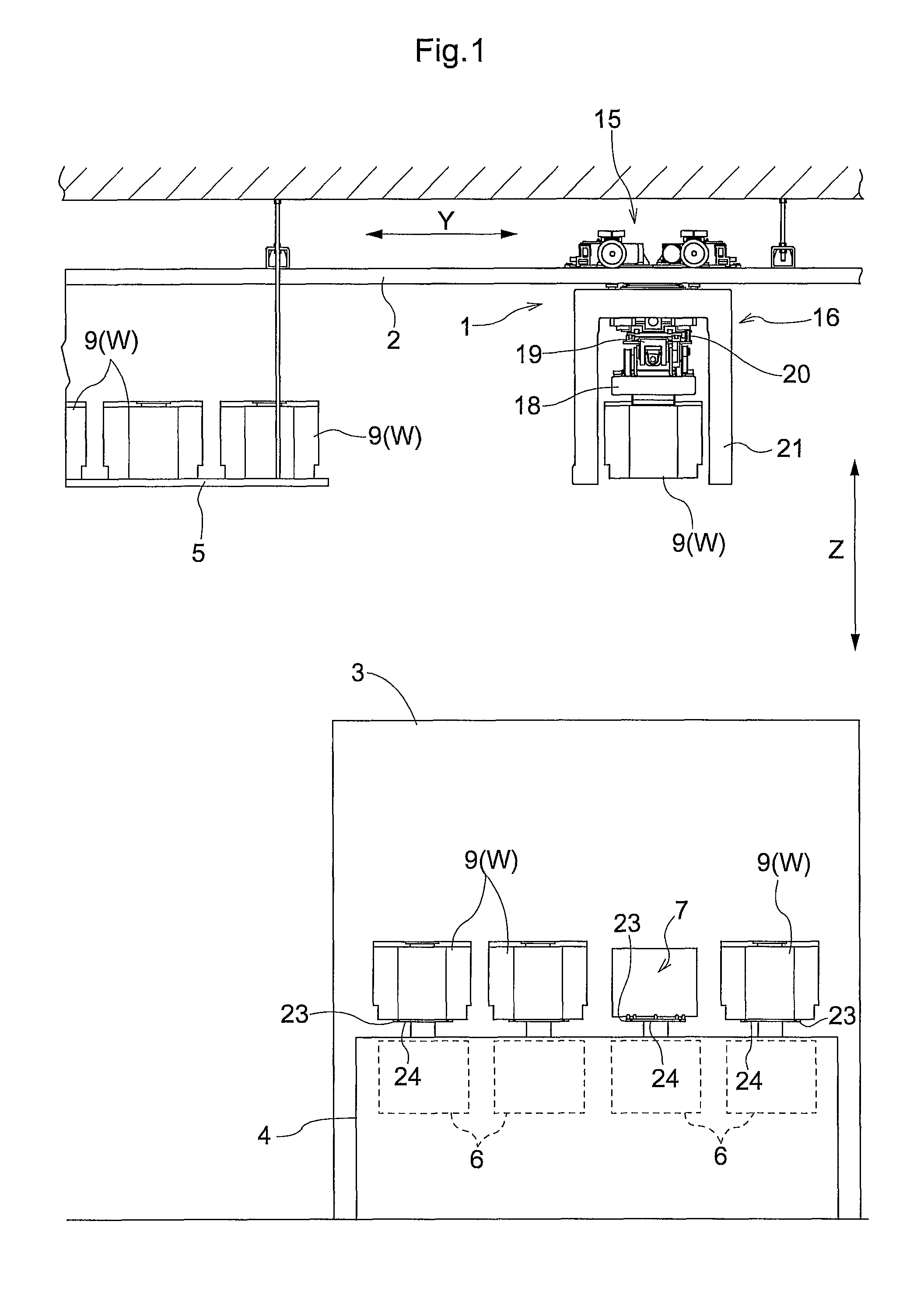

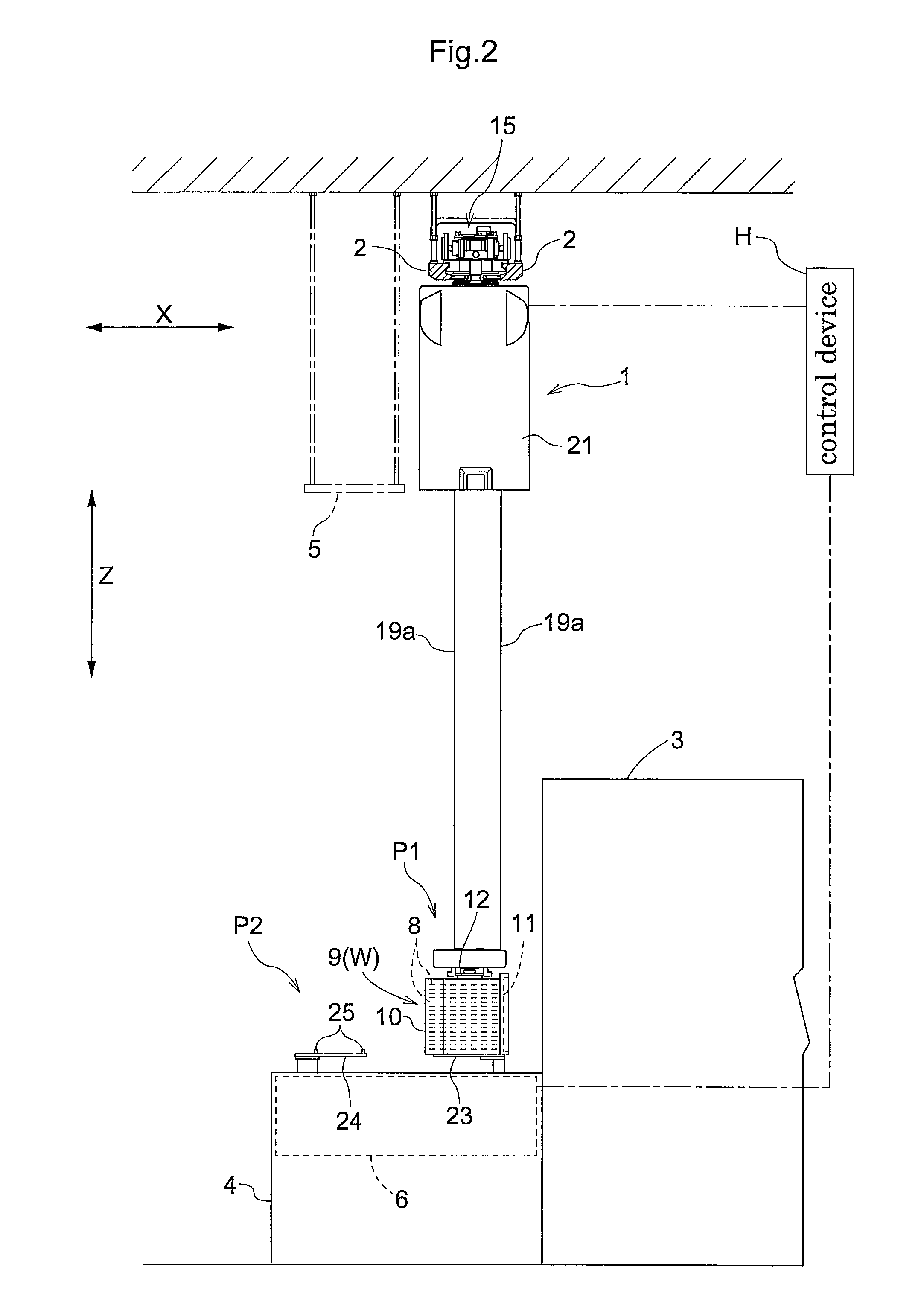

Article transport facility

ActiveUS8875866B2Shorten the lengthEasy to fixSemiconductor/solid-state device manufacturingControl devices for conveyorsEngineeringTransport facility

A ceiling transport carriage transfers an article at a first supporting position and receives the article from second supporting position in an article transfer section, in association with hoisting operations of a support unit. A ground transport device transports the article between the above two positions and a processing position where an article processing device effects a processing or operation on the article. The respective positions above are set in tandem in the article transfer section along a tandem direction along which the article processing device and the article transfer section are disposed in tandem. The ceiling transport carriage includes a movement operating mechanism for operating and moving a support unit along the tandem direction, to a position immediately above the first supporting position and to a position immediately above second supporting position.

Owner:DAIFUKU CO LTD

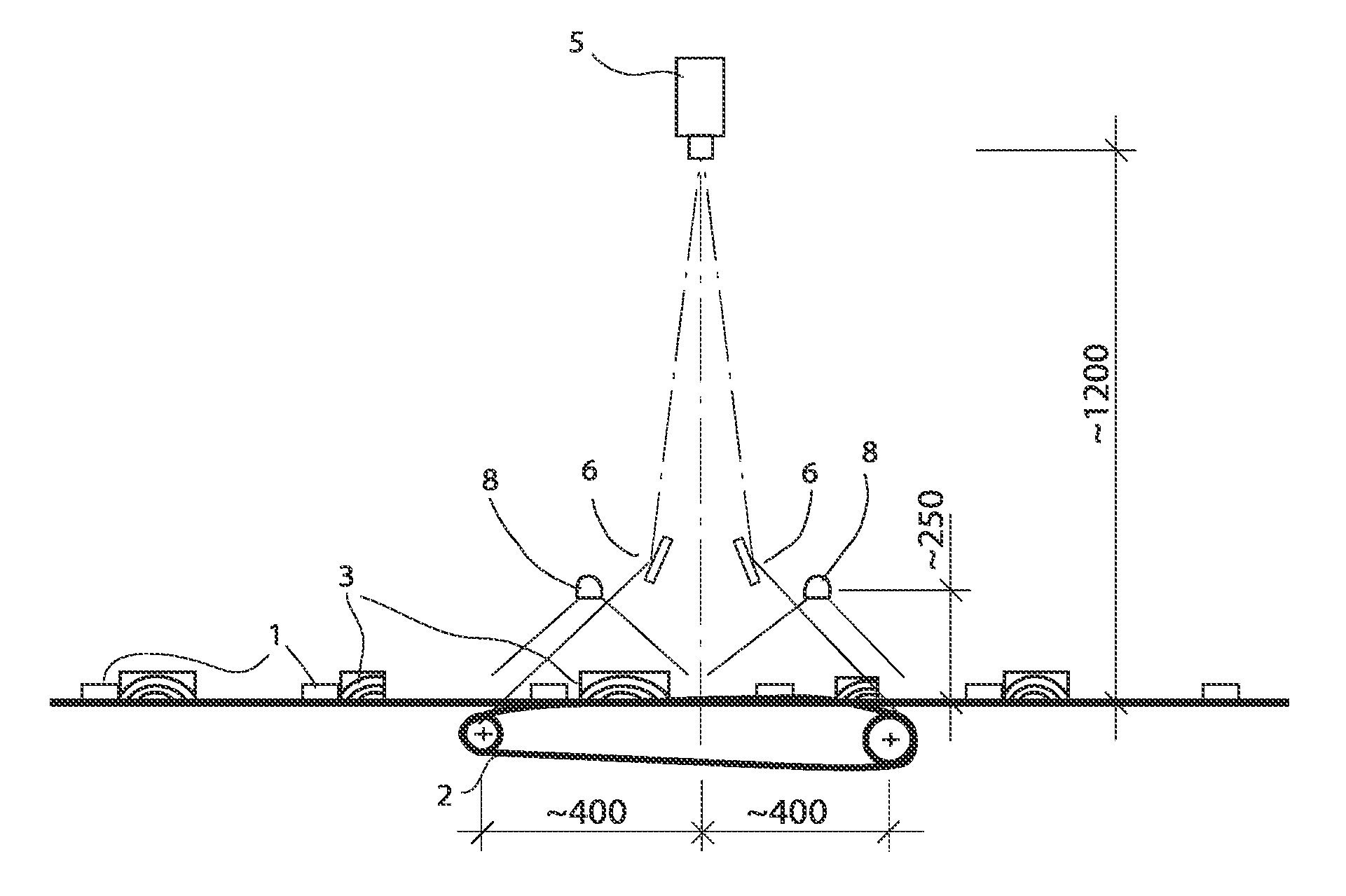

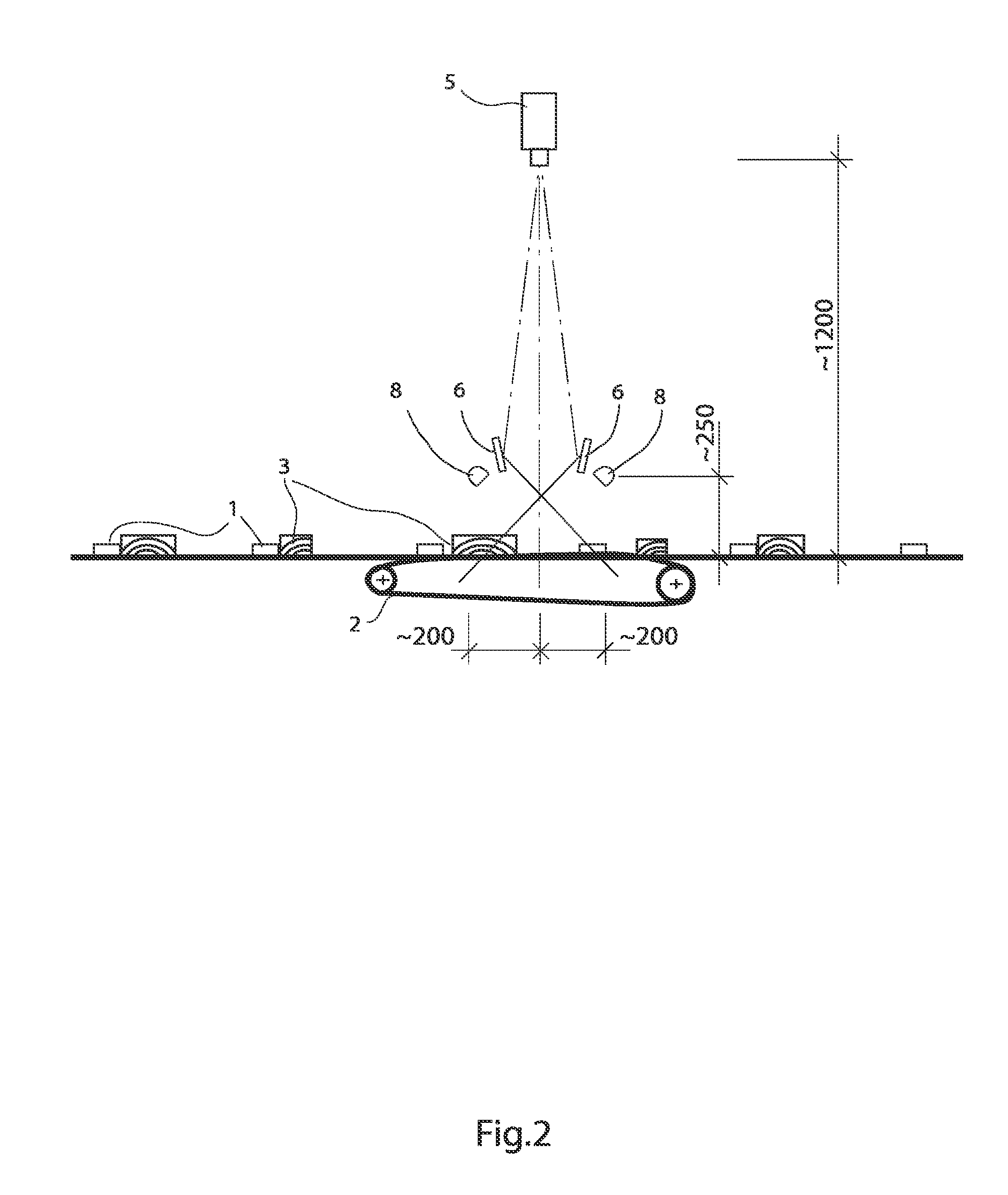

System for imaging sawn timber

InactiveUS20140002634A1Easy to implementNo longer be formedMaterial analysis by optical meansColor television detailsEngineeringMirror image

System for imaging pieces of sawn timber travelling transversely past the system. Each piece of sawn timber includes a top surface and a bottom surface, with sides connecting them. The system is arranged to image the top surface and at least one side when the sawn piece travels past the system's measuring area. At least one matrix camera is positioned in a first position relative to the path of the sawn pieces. At least one minor is positioned in a second position relative to the path of the sawn pieces and to the said first position. The first and second positions are selected in such a way that each sawn piece travelling past transversely can be imaged using the at least one matrix camera directly from a first direction and as a mirror image through the at least one mirror from at least one second direction.

Owner:FIN SCAN

Semiconductor device, its manufacturing method, and ratio communication device

InactiveUS7119004B2Parasitic inductance can be reducedReduce distanceGated amplifiersSemiconductor/solid-state device detailsAudio power amplifierChip size

The variation of the parasitic inductance generated at the output terminal of a transistor in the final stage of a multistage amplifier unit is reduced. One side of the semiconductor chip that includes the final stage transistor is put in contact with the inner wall of a square recess formed in a wiring substrate. The semiconductor chip is positioned and fixed accurately at the bottom of the recess, whereby the drain wire of the transistor is fixed. Then, a chip edge at which the drain electrode is disposed on top of the chip is put in contact with the inner wall of the recess, which is closer to the drain bonding pad. A metallized layer is formed of the same size as that of the chip at the bottom of the recess and a fusion bonding material is supplied on the metallized layer.

Owner:MURATA MFG CO LTD

Theft-Protected Screw Part

The theft-protected screw part in the form of a nut or a screw has a free end region and a ring-shaped depression formed at the end region for the engagement of a wrench for rotation the screw part. Viewed from radially outside to radially inside, the depression is delimited by an outer edge, a bottom and an inner edge. The outer edge forms outer abutment surfaces and the inner edge forms inner abutment surfaces for the wrench. The screw part is composed of a main part and an insert. The main part has a protrusion, which is located within the inner edge. The insert is designed in a ring shape, has a hole for accommodating the protrusion and forms the inner abutment surfaces.

Owner:ABC UMFORMTECHN

Ceramic electronic component and manufacturing method therefor

ActiveUS9997293B2Improve heat resistanceNo longer be formedEnvelope/housing resistor manufactureTransformers/inductances coils/windings/connectionsMetallurgyElectronic component

A ceramic electronic component that includes a ceramic main body, a coating film and external electrodes on the surface of the ceramic main body. The coating film is selectively formed on the surface of the ceramic main body by applying, to the surface of the ceramic main body, a resin-containing solution that etches the surface of the ceramic main body so as to ionize constituent elements of the ceramic main body. The coating film includes a resin and the constituent elements of the ceramic main body, which were ionized and deposited from the ceramic main body.

Owner:MURATA MFG CO LTD

Method of manufacturing a magnetic head

InactiveUS7716812B2No longer be formedLess dimensional variationManufacture head surfaceElectrical transducersSputteringElectrical conductor

A main magnetic pole of a recording head is formed in an inverted trapezoidal shape by ion milling but, the long milling time poses a problem of variations in the inverted trapezoidal shape and the dimensional variations in track width. In one embodiment of the invention, a recording head is formed by first forming a lower magnetic pole, a gap layer, and conductor coils, forming an upper magnetic yoke over the gap layer at a position recessed from the air bearing surface, and forming an inorganic insulative layer in the recessed portion. A back magnetic pole connected with the upper magnetic yoke is formed on the back of the lower electrode. Successively, the upper surfaces of the inorganic insulative layer and the upper magnetic yoke are planarized, on which an underlayer film such as of Rh is formed. A magnetic layer is formed by stacking a plurality of thin magnetic films by sputtering over the underlayer film from the air bearing surface as far as the position overlapping the upper magnetic yoke. Successively, ion milling is applied to form a main magnetic pole of an inverted trapezoidal shape having a taper on the lateral surface as viewed from the air bearing surface.

Owner:WESTERN DIGITAL TECH INC

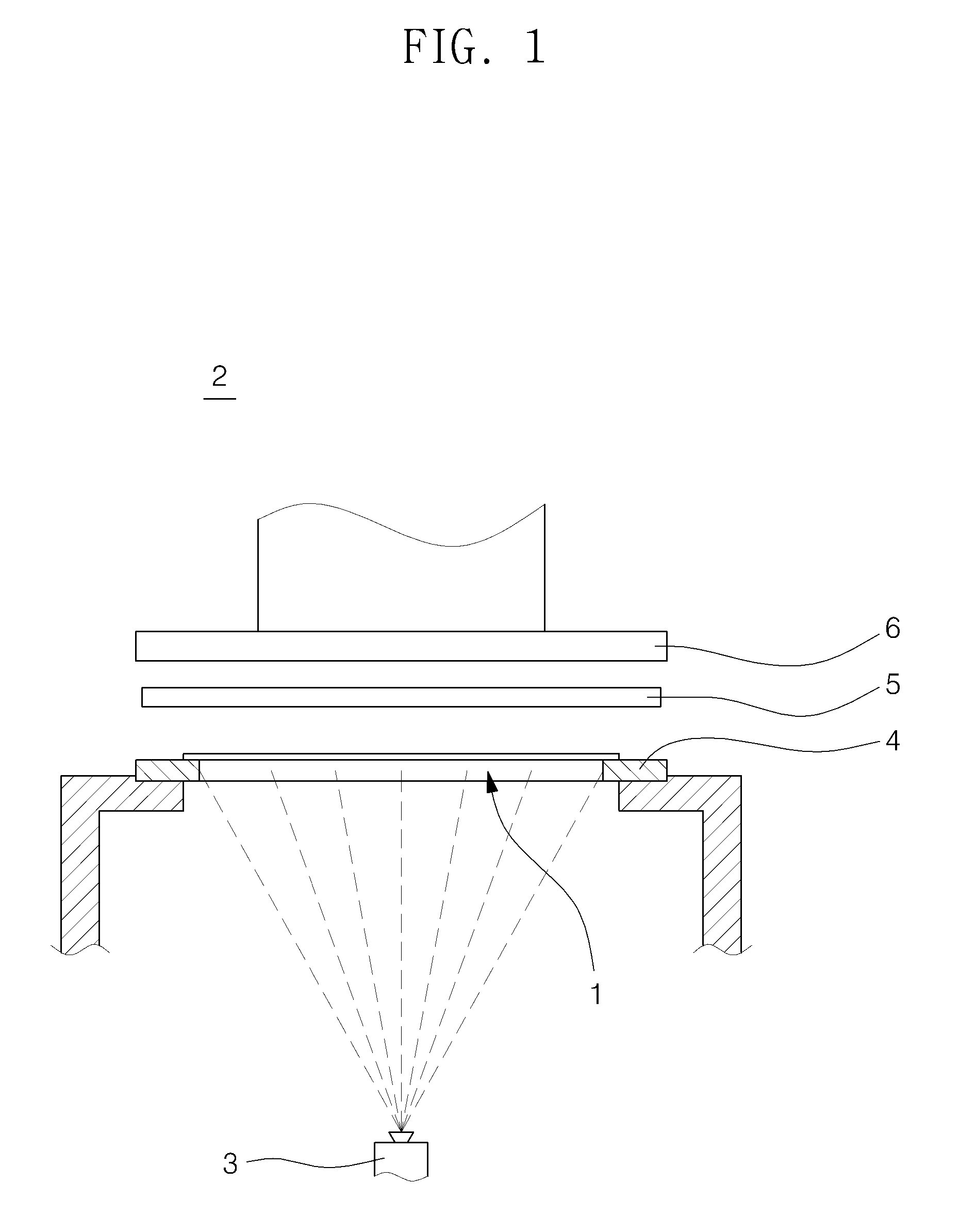

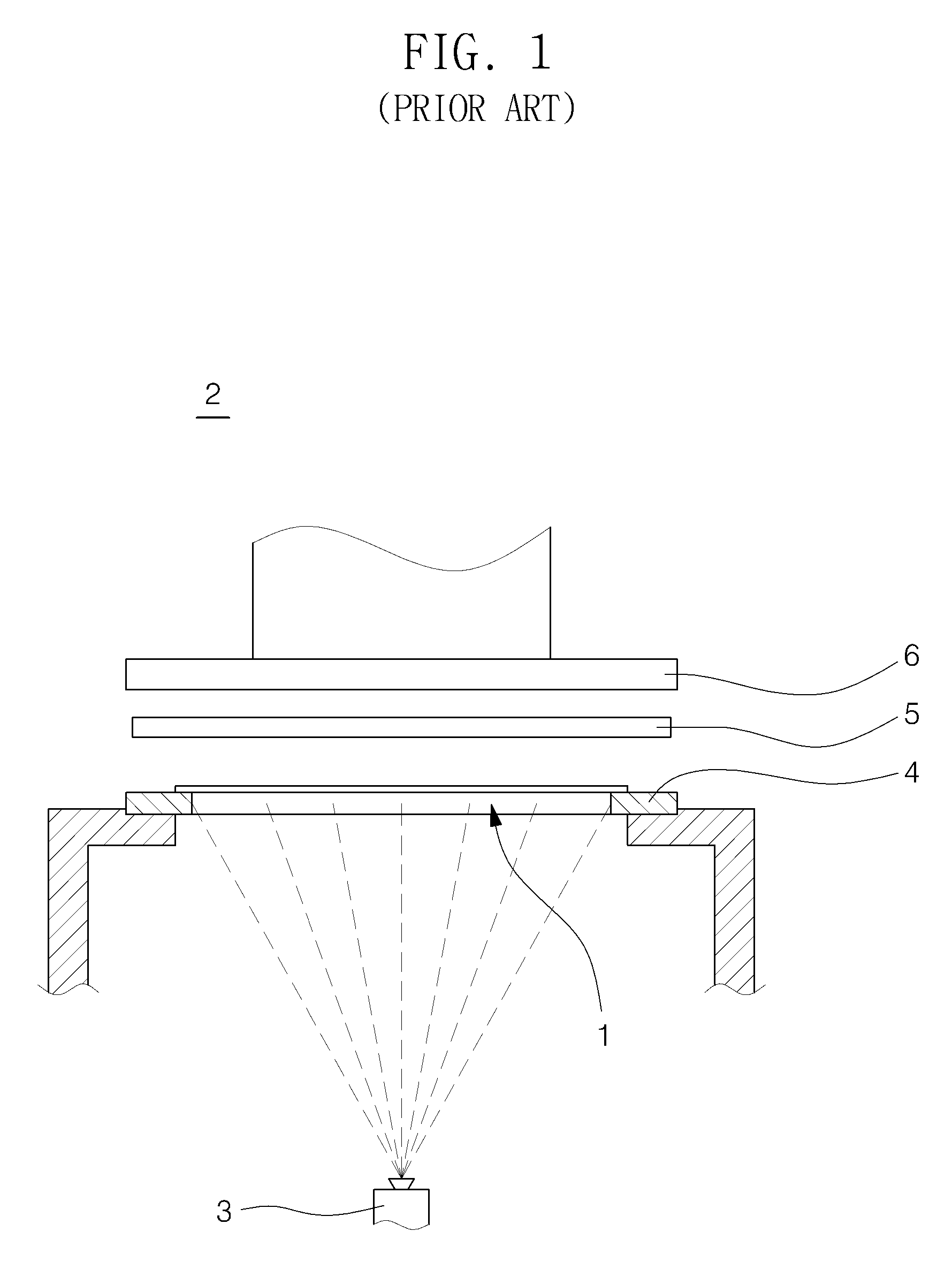

Field emission display device and method of manufacturing same

InactiveUS7180234B2Improve assembly accuracyLight evenlyDischarge tube luminescnet screensLamp detailsField emission displayPhysics

In a field emission display device, an opening dimension in a predetermined direction (or x direction) of an opening of a control electrode is greater than an opening dimension in the predetermined direction of an electron pass aperture of a shield electrode, and the shield electrode is located at the front of the control electrode so that the entire range of the opening dimension in the predetermined direction of the electron pass aperture is within the range of the opening dimension in the predetermined direction of the opening of the control electrode.

Owner:MITSUBISHI ELECTRIC CORP

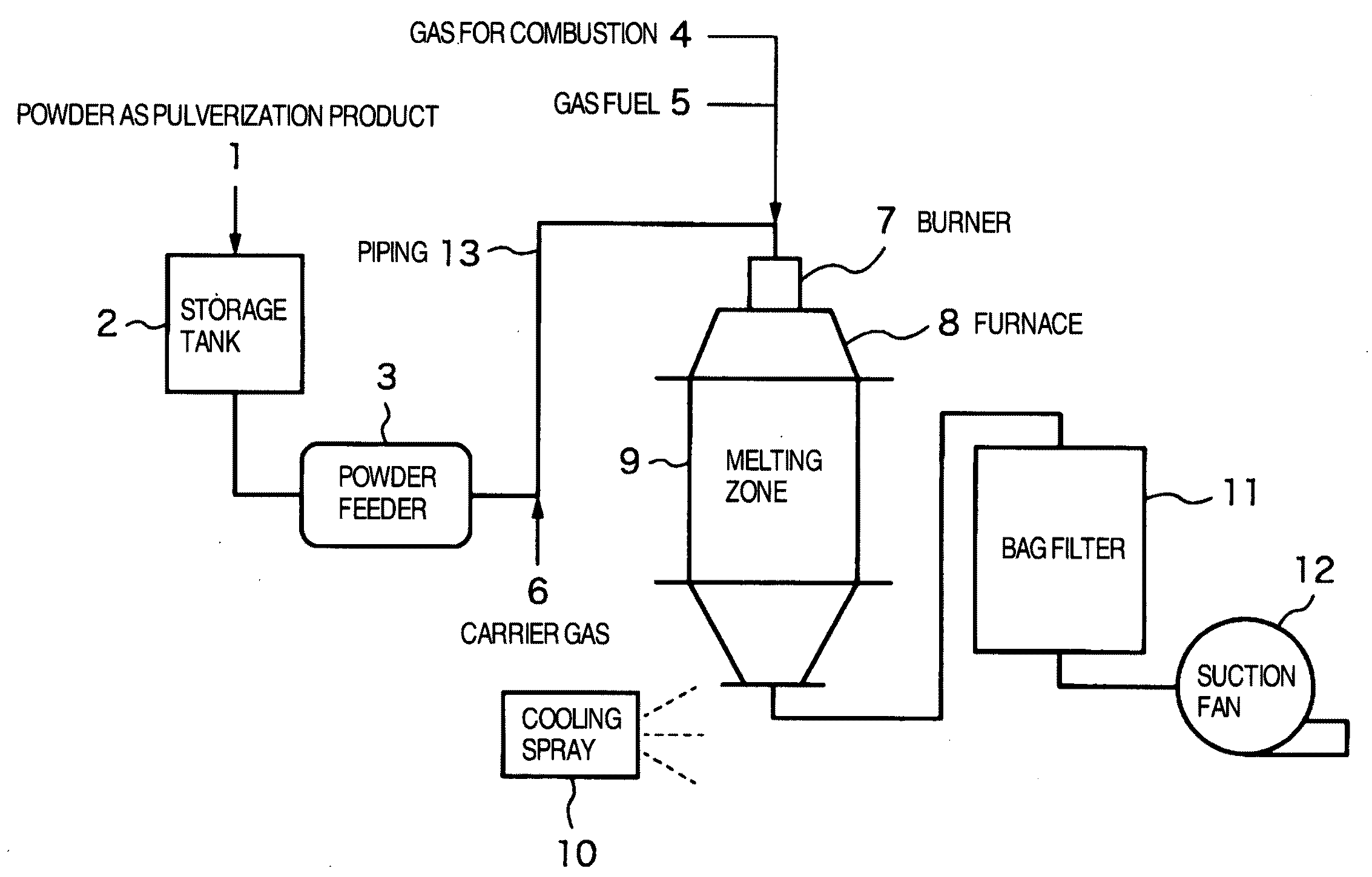

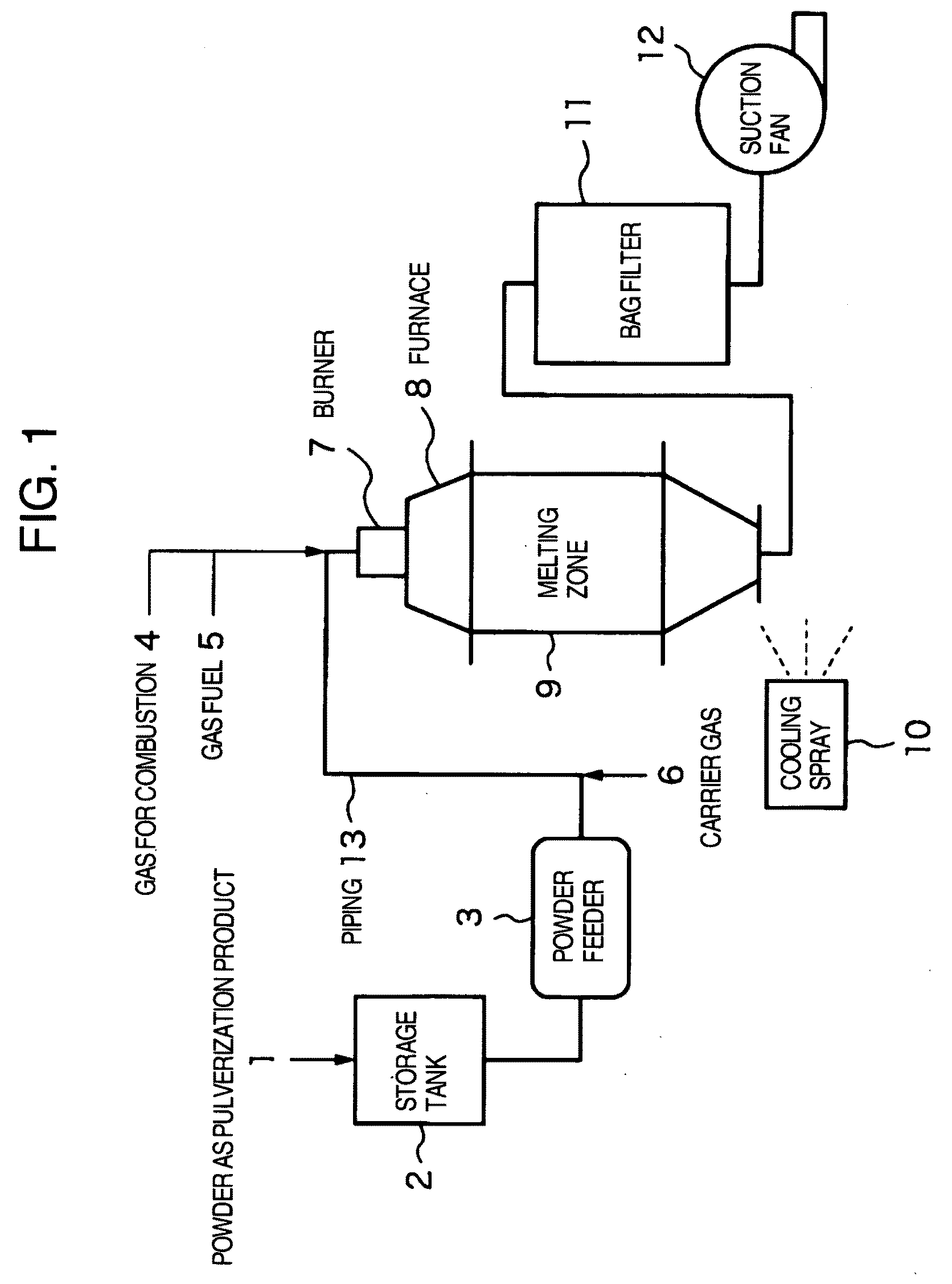

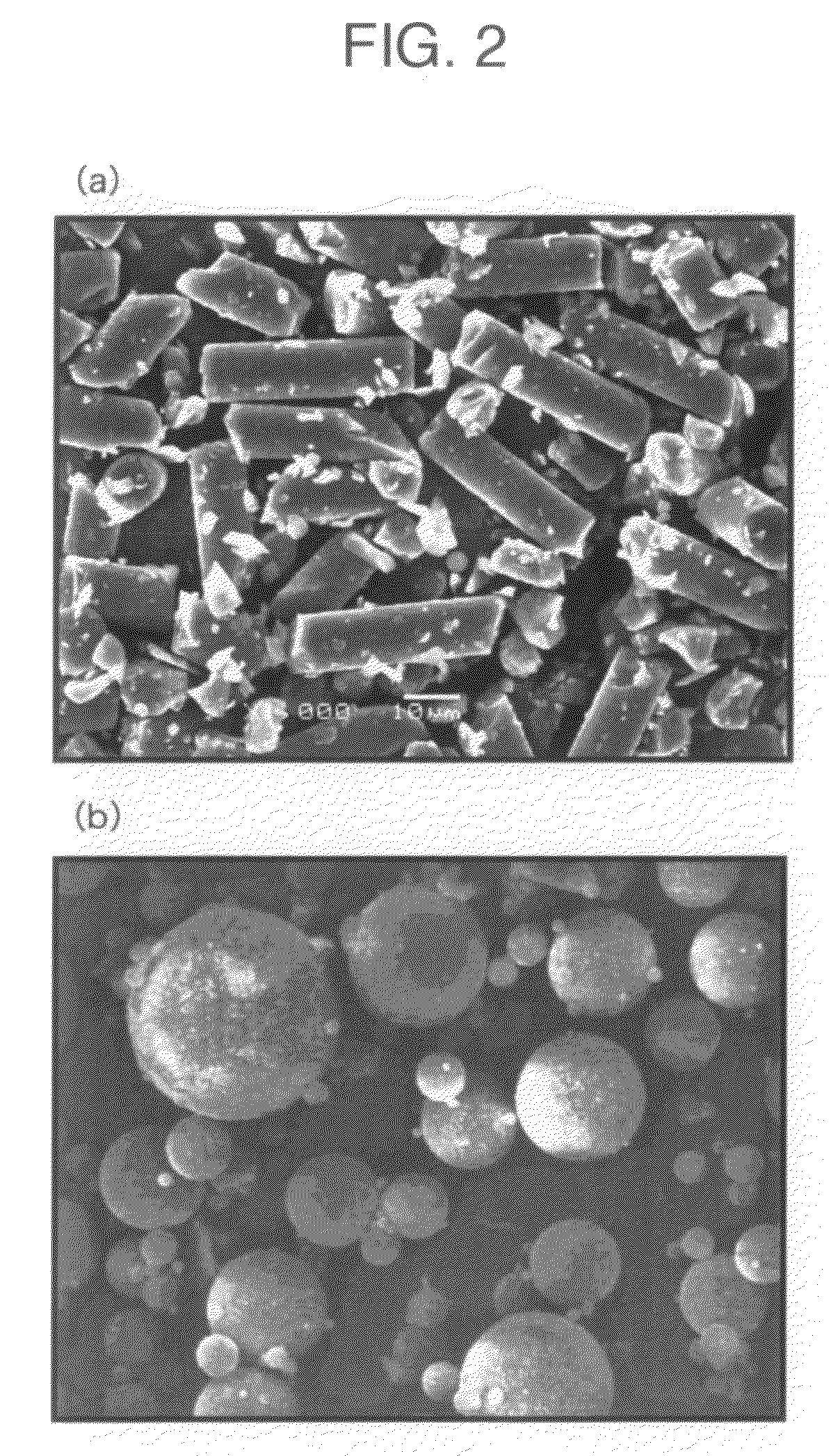

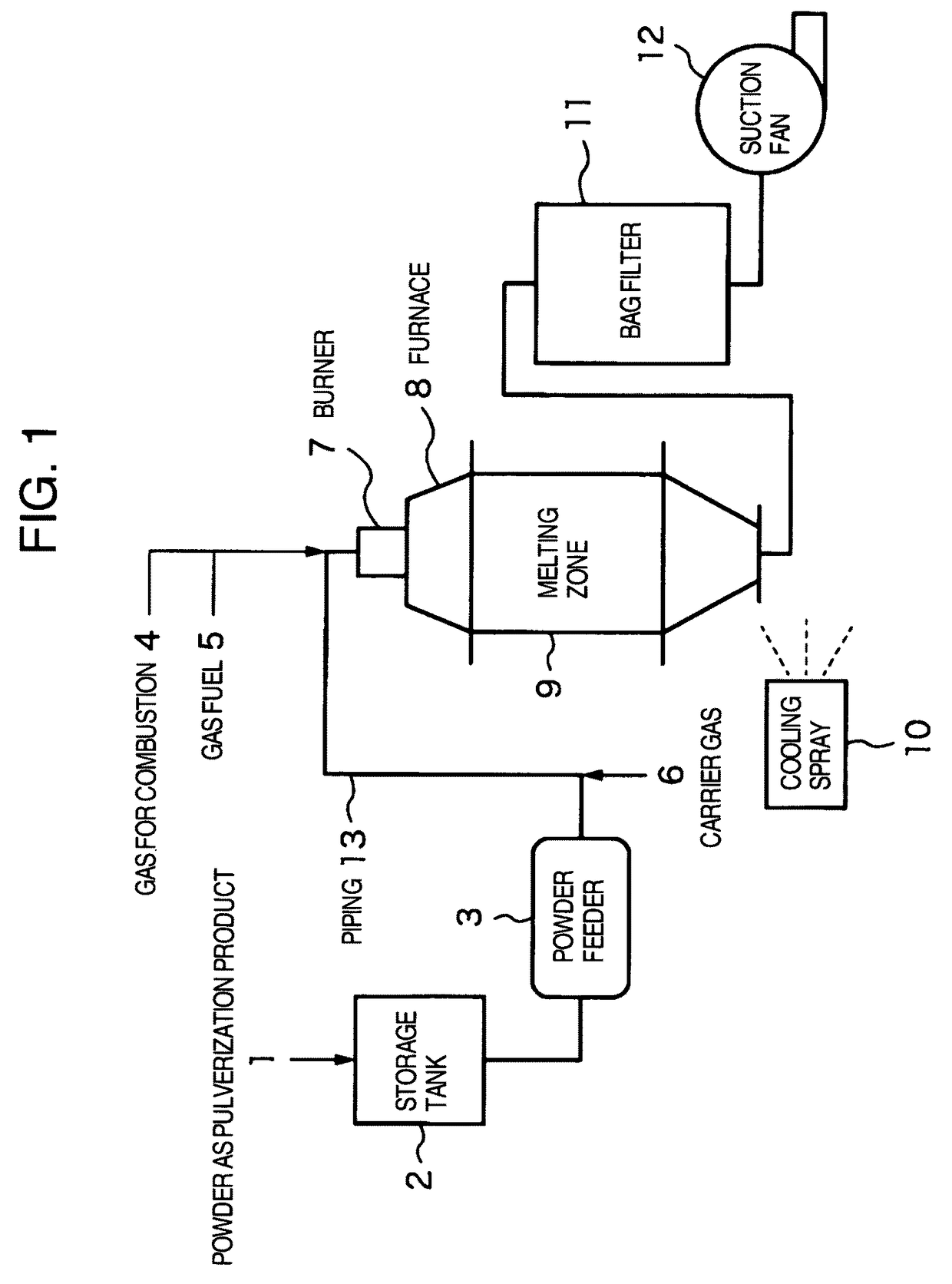

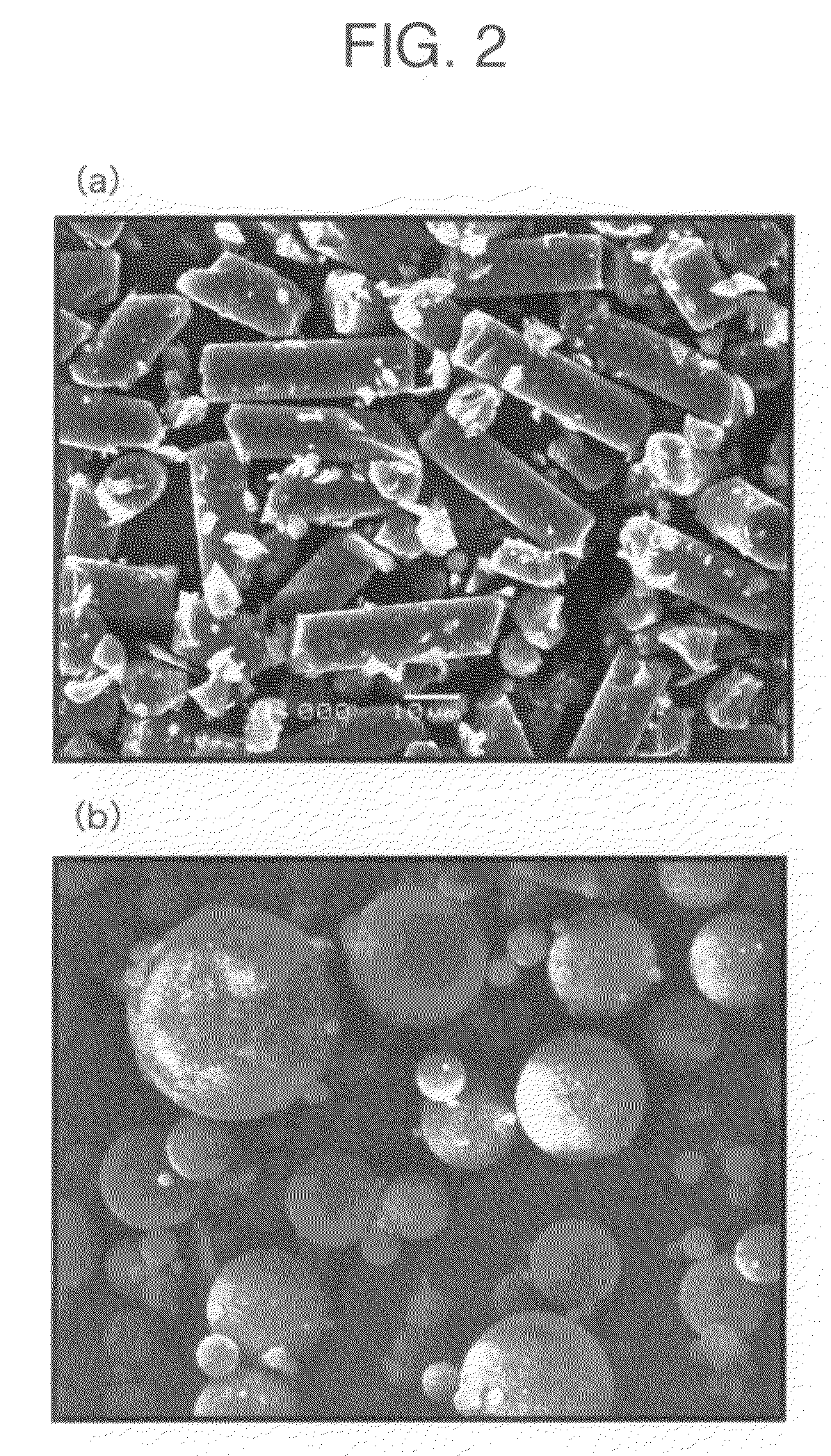

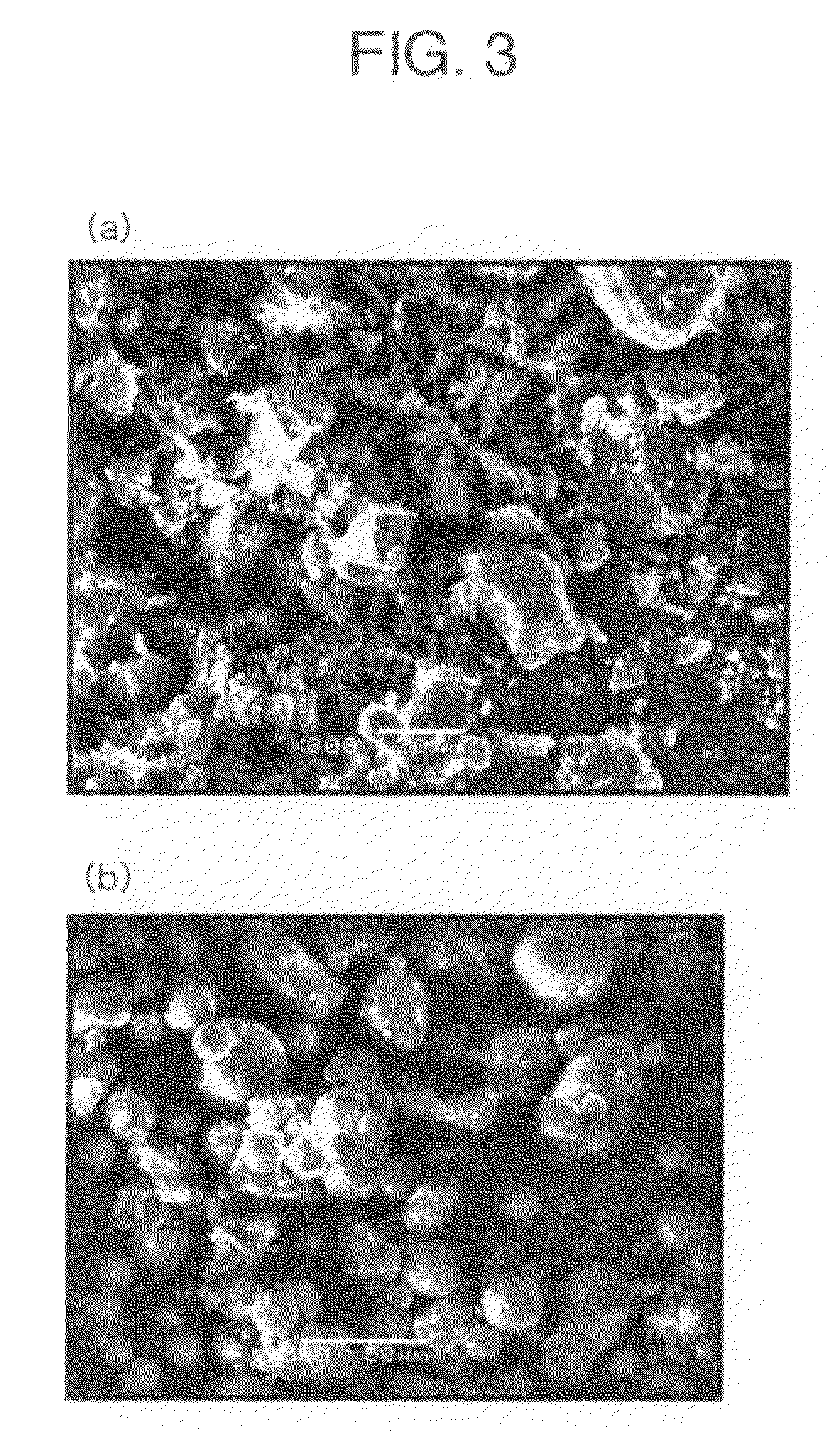

Process for producing spherical inorganic particle

InactiveUS20090249833A1Improve liquidityHigh proportionGlass blowing apparatusGlass reforming apparatusInorganic particleComposite substrate

A process for producing spherical inorganic particles which have high flowability, can be incorporated in a high proportion, and are useful as a filler for composite substrates such as printed wiring boards and encapsulating materials. Also provided is a process for producing spherical inorganic particles which have high flowability and can be incorporated in a high proportion and which are useful as a filler for encapsulating materials and give an encapsulating material having high electrical insulating properties. One of the processes for producing spherical inorganic particles comprises: (a1) pulverizing a silicate-containing inorganic material to form a pulverization product; (b1) heating the pulverization product in an atomized state to form the pulverization product into spherical particles; (c1) spraying water over the spherical particles to cool them while maintaining the atomized state of the spherical particles; and (d1) collecting the spherical particles. The other process, which is for producing spherical glass particles, comprises: a pulverization step in which a silicate-containing vitreous material is pulverized to form a pulverization product; an acid treatment step in which the pulverization product is contacted with an acid; and a sphering step in which the pulverization product is heated in a suspended state and formed into spherical particles.

Owner:NITTO BOSEIKI CO LTD

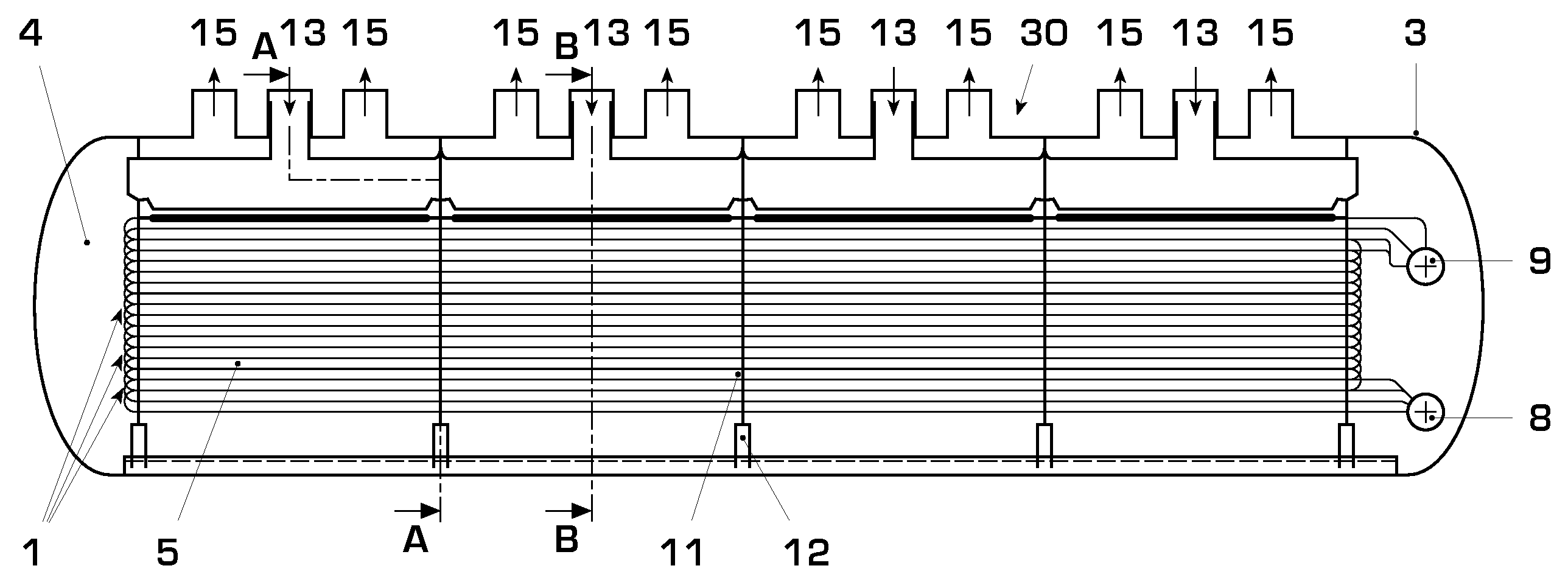

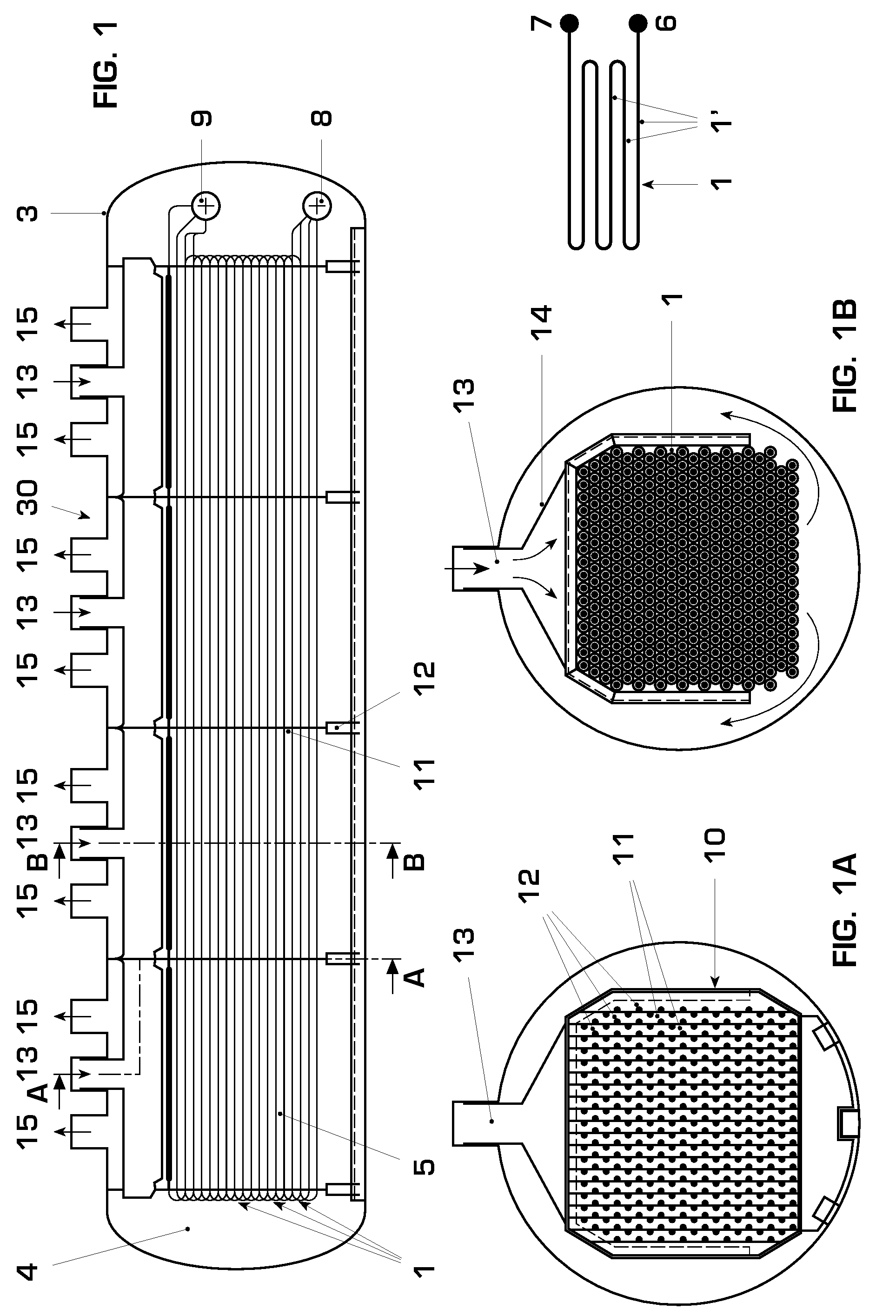

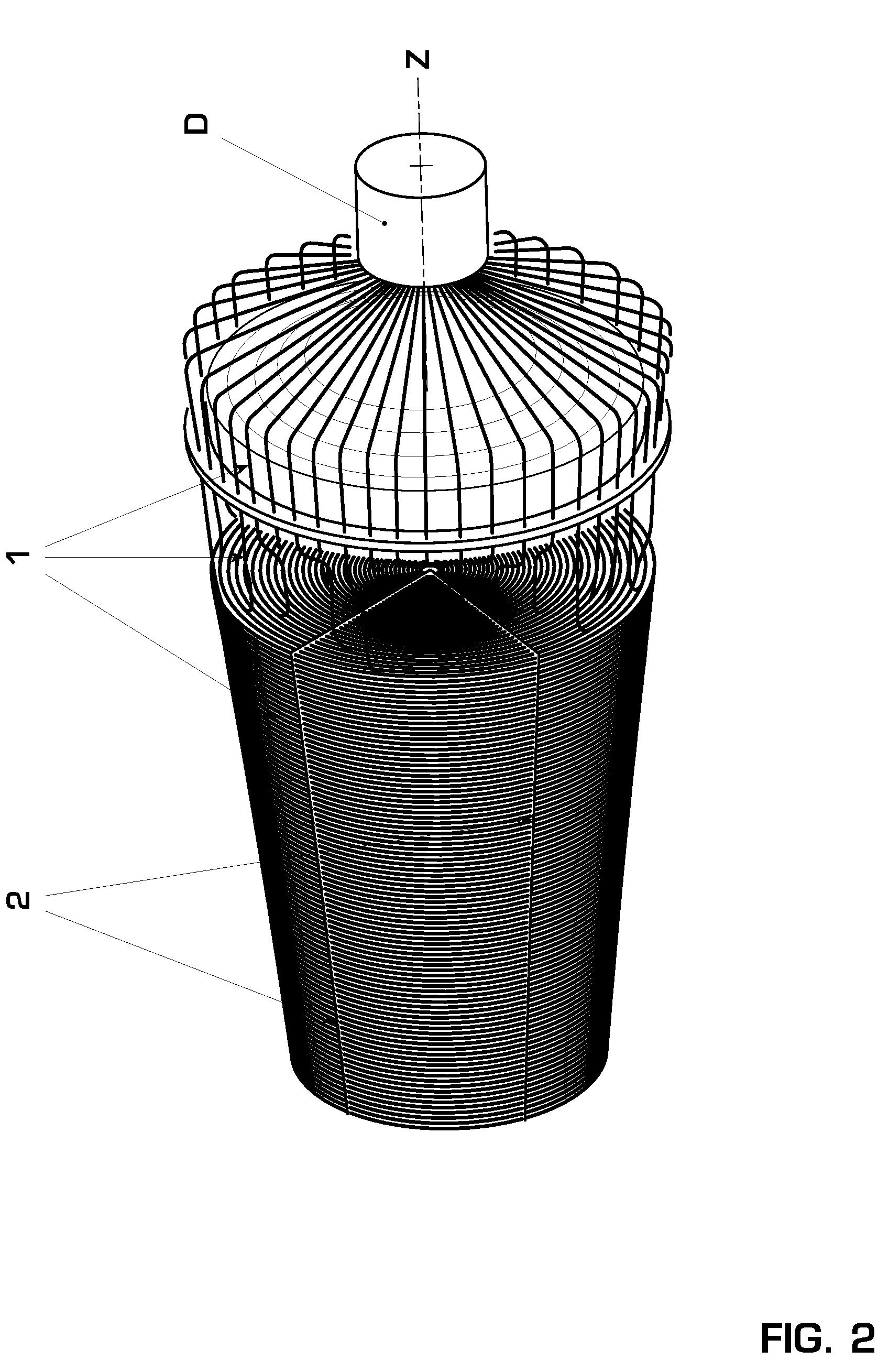

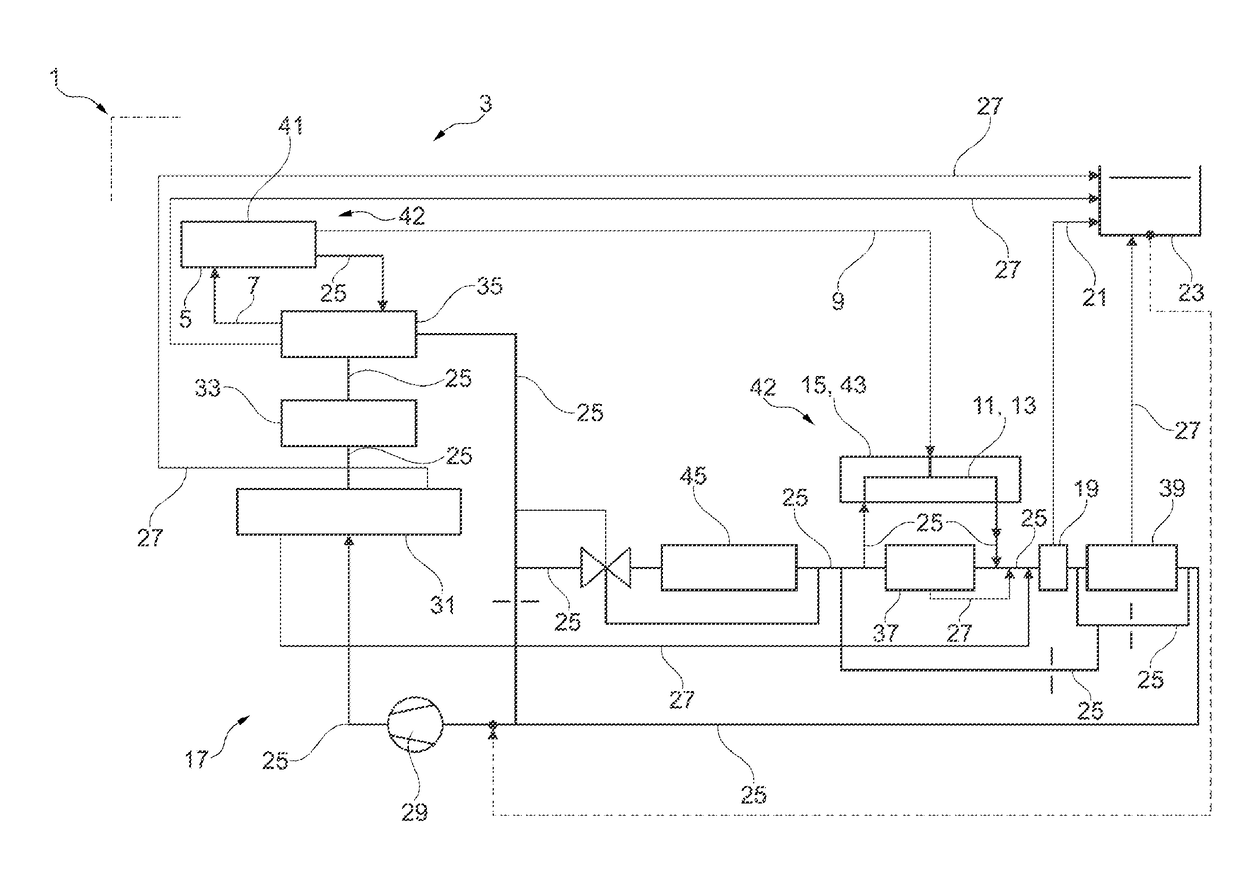

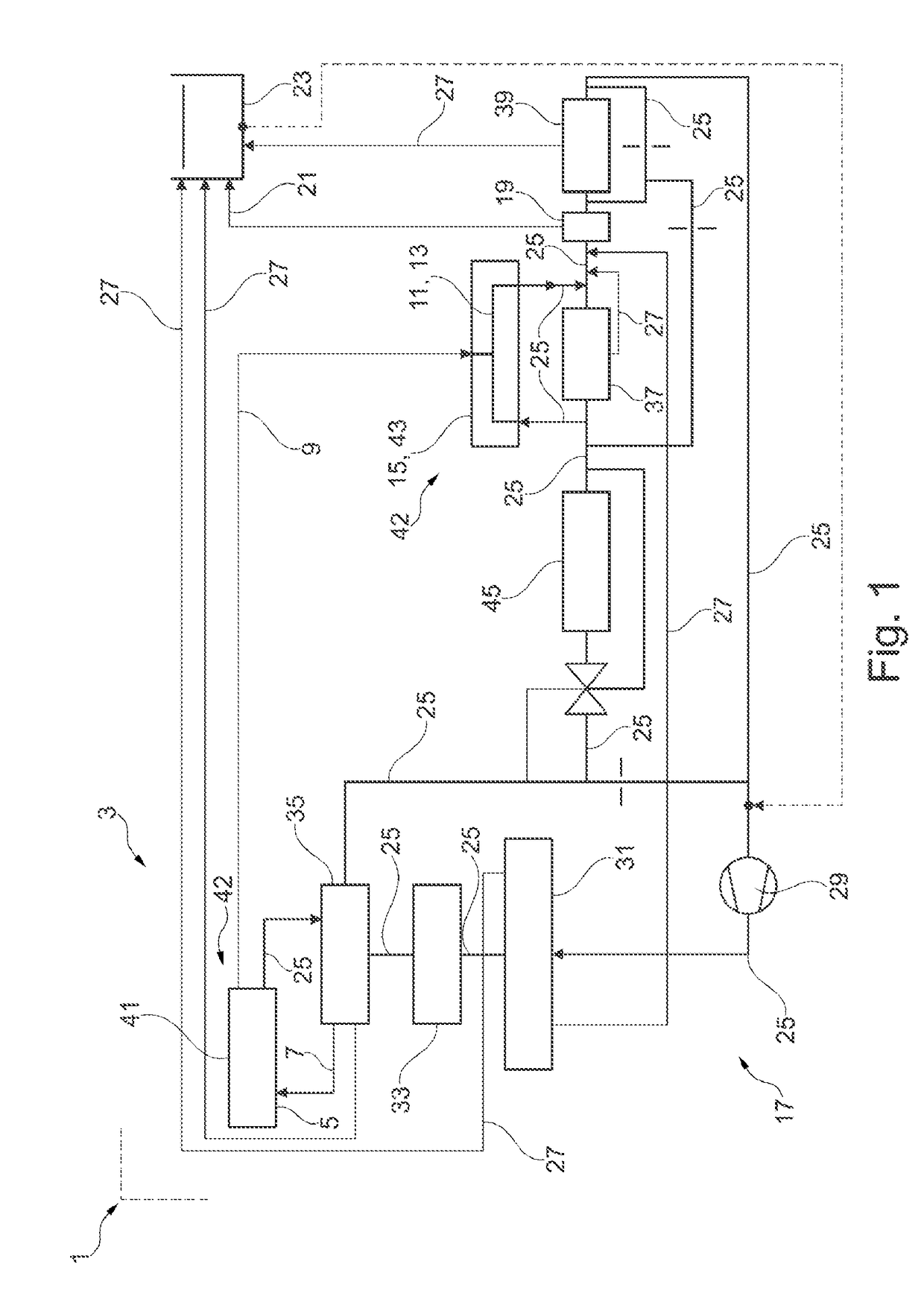

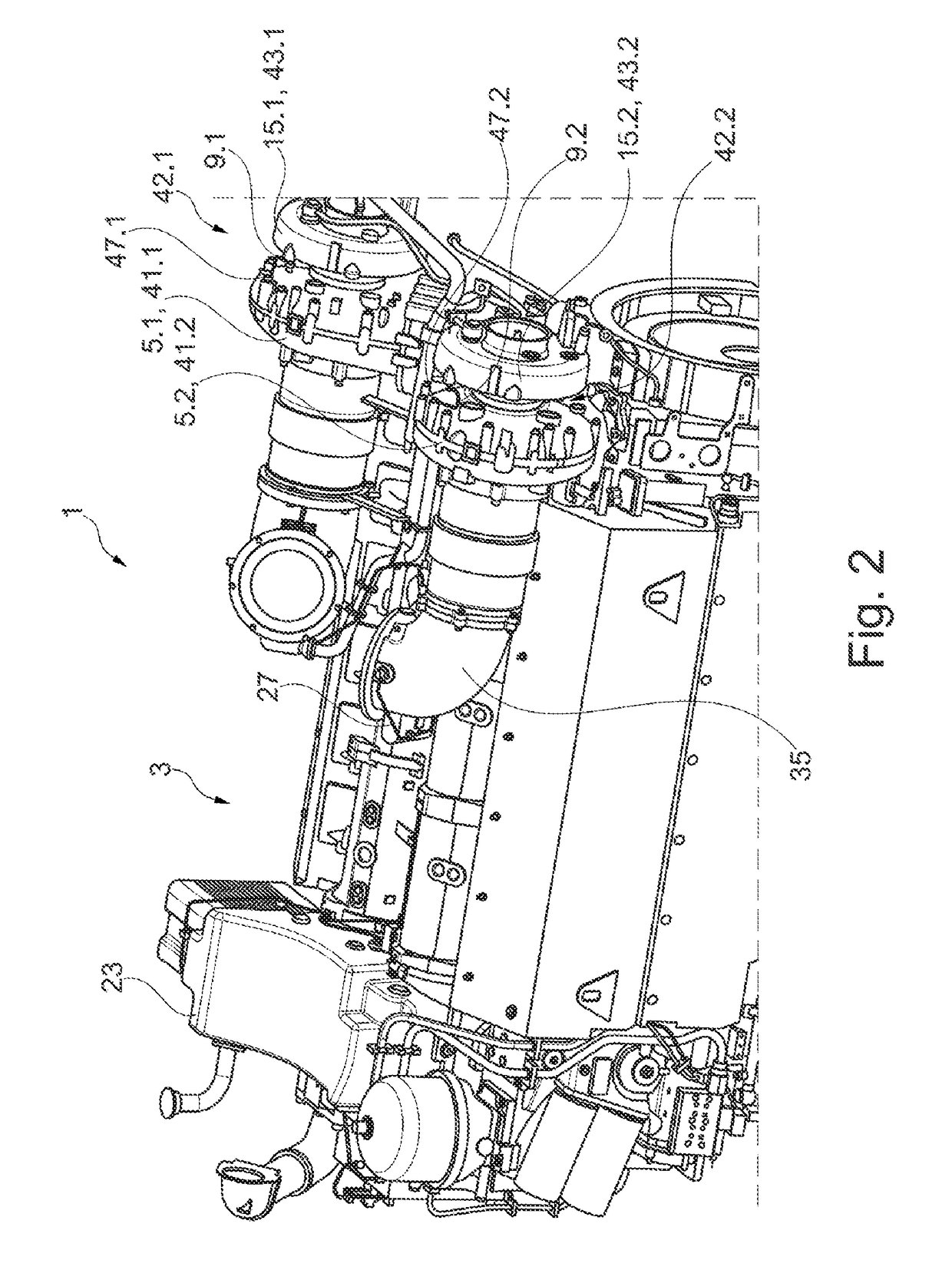

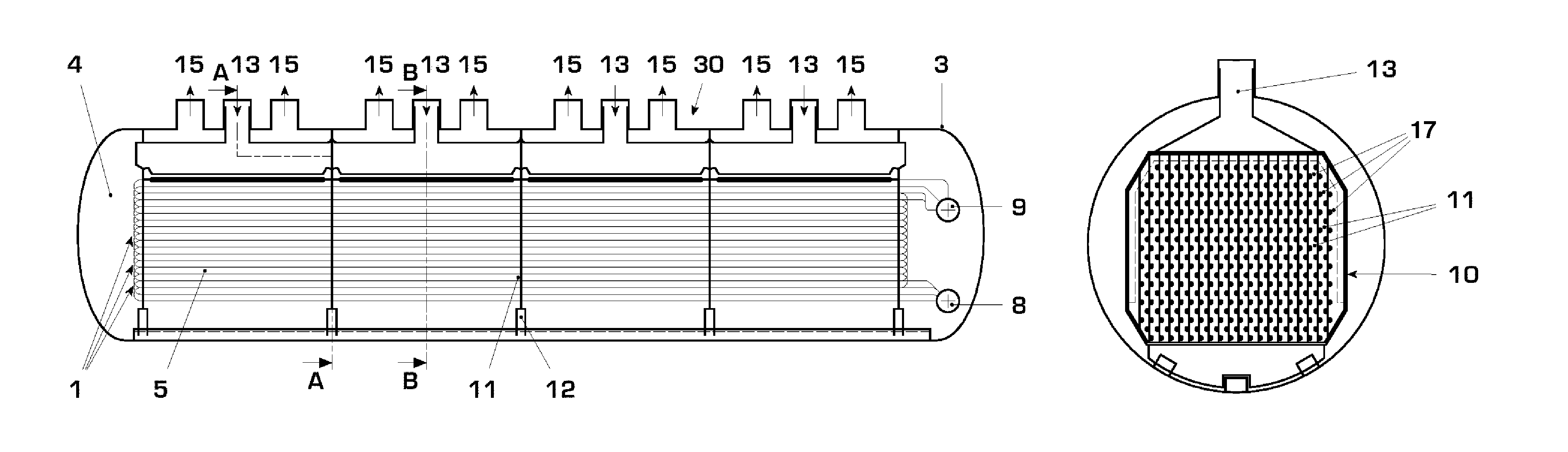

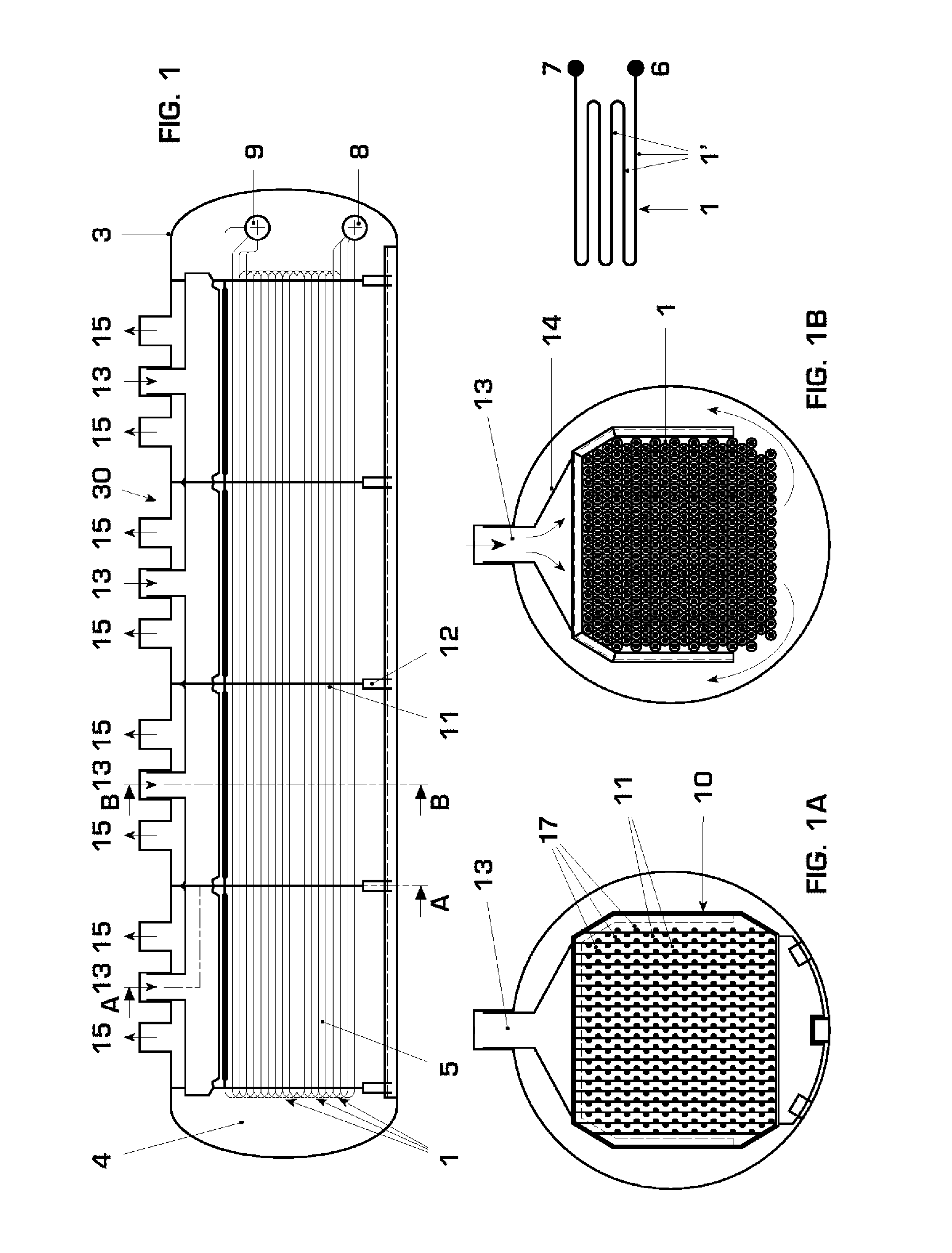

Steam Generator

InactiveUS20070227469A1Improve efficiencyLean structureWater circulationIgnition automatic controlEngineeringMechanical engineering

Owner:ALSTOM TECH LTD

Process for producing spherical inorganic particle

InactiveUS8117867B2Improve liquidityHigh proportionGlass blowing apparatusGlass reforming apparatusInorganic particleComposite substrate

A process for producing spherical inorganic particles which have high flowability, can be incorporated in a high proportion, and are useful as a filler for composite substrates such as printed wiring boards and encapsulating materials. Also provided is a process for producing spherical inorganic particles which have high flowability and can be incorporated in a high proportion and which are useful as a filler for encapsulating materials and give an encapsulating material having high electrical insulating properties. One of the processes for producing spherical inorganic particles comprises: (a1) pulverizing a silicate-containing inorganic material to form a pulverization product; (b1) heating the pulverization product in an atomized state to form the pulverization product into spherical particles; (c1) spraying water over the spherical particles to cool them while maintaining the atomized state of the spherical particles; and (d1) collecting the spherical particles. The other process, which is for producing spherical glass particles, comprises: a pulverization step in which a silicate-containing vitreous material is pulverized to form a pulverization product; an acid treatment step in which the pulverization product is contacted with an acid; and a sphering step in which the pulverization product is heated in a suspended state and formed into spherical particles.

Owner:NITTO BOSEIKI CO LTD

Ceramic electronic component and manufacturing method therefor

ActiveUS10304630B2Improve heat resistanceNo longer be formedFixed capacitor electrodesResistor terminals/electrodesHydrofluoric acidO-Phosphoric Acid

Owner:MURATA MFG CO LTD

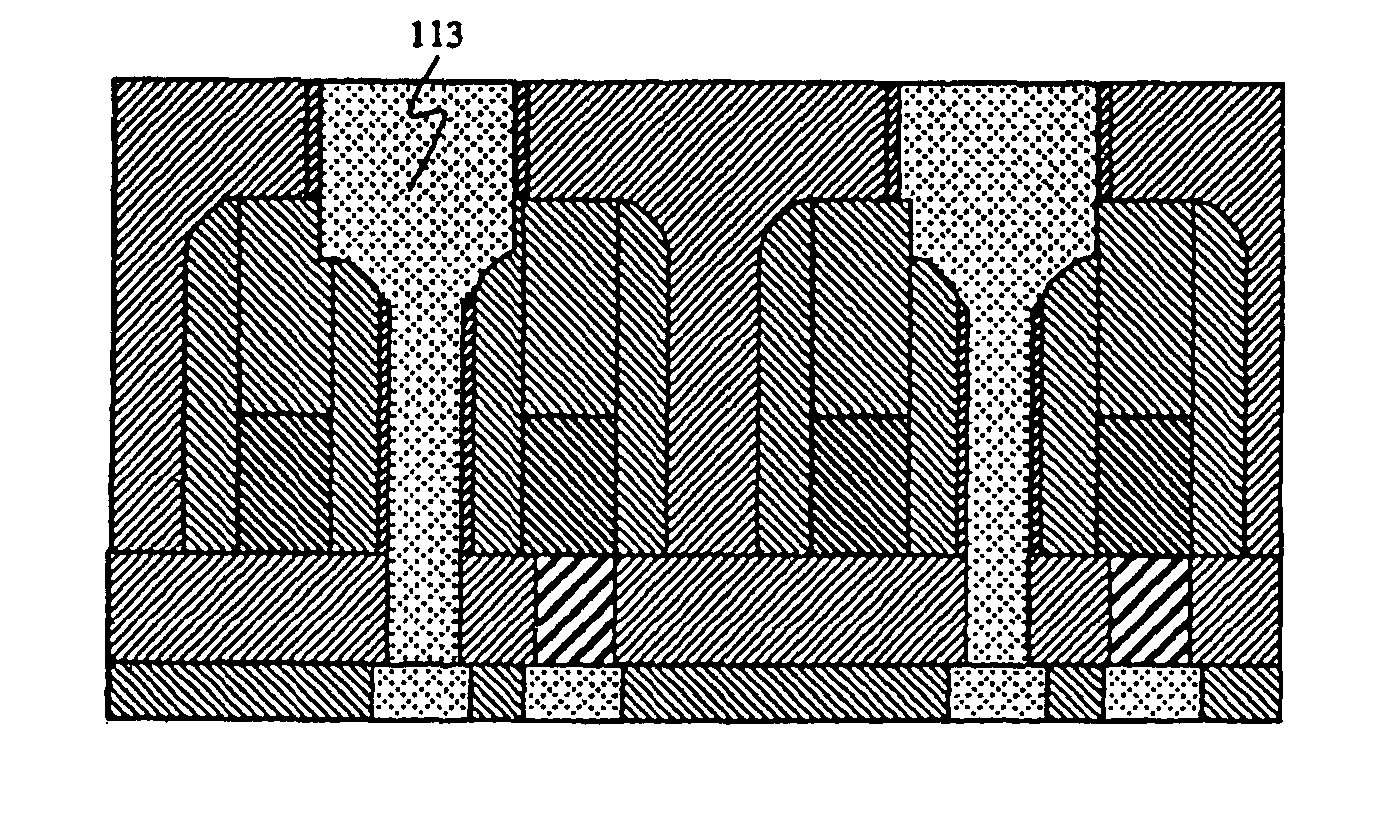

Method of manufacturing semiconductor device

ActiveUS7767569B2Avoid insufficient thicknessNo longer be formedSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceBit line

Method of forming a high-reliability contact plug which prevents a short circuit between the plug and a bit line by applying a material having an etching rate ratio of 100 or more with respect to a silicon nitride film which forms a self-aligned contact plug. After the formation of a bit line, whose top surface and side surfaces are covered with a silicon nitride film, a sacrificial interlayer film is formed which covers the whole surface of the bit line, and a contact hole is formed by etching the sacrificial interlayer film and then the lower-layer interlayer insulating film to form a capacitance contact plug. A column of a capacitance contact plug is then formed by removing the sacrificial interlayer film, a third interlayer insulating film is formed on the column, and part of this interlayer is removed to expose a surface of the contact plug.

Owner:HEFEI RELIANCE MEMORY LTD

Deposition substrate of deposition apparatus, method of forming layer using the same, and method of manufacturing organic light emitting diode display device

InactiveUS8951891B2Suitable for manufactureNo longer be formedLayered productsSemiconductor/solid-state device detailsDisplay deviceLight-emitting diode

Provided are a deposition substrate of a deposition apparatus, a method of forming a layer using the same, and a method of manufacturing an organic light emitting diode (OLED) display device. The method of forming a layer using the deposition substrate includes preparing a substrate, forming a heating conductive layer for Joule heating on the substrate, forming a first insulating layer on the heating conductive layer for Joule heating and including a groove or hole, forming a deposition material layer on a top surface of the first insulating layer having the groove or hole, and applying an electric field to the heating conductive layer for Joule heating to perform Joule-heating on the deposition material layer. Thus, the method is suitable for manufacturing a large-sized device.

Owner:DAWONSYS

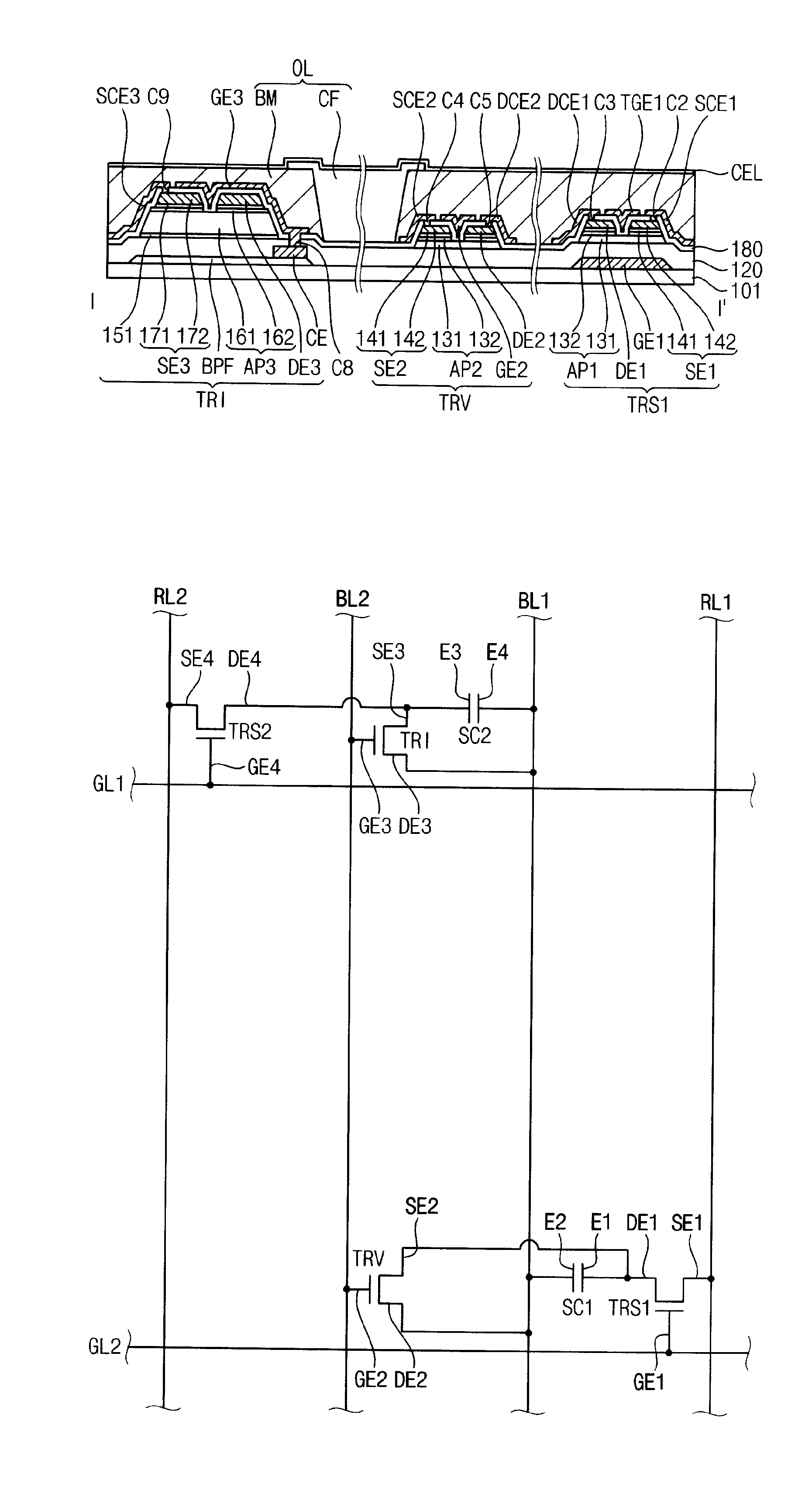

Touch sensing substrate and method of manufacturing the same

InactiveUS8901691B2Improve reliabilitySimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLight sensingTouch Senses

A touch sensing substrate includes a substrate, a first light sensing element, a second light sensing element and a first bias line. The first light sensing element includes a first gate electrode, a first active pattern overlapping with the first gate electrode, a first source electrode partially overlapping with the first active pattern and a first drain electrode partially overlapping with the first active pattern. The second light sensing element includes a second gate electrode, a second active pattern overlapping with the second gate electrode, a second source electrode partially overlapping with the second active pattern and a second drain electrode partially overlapping with the second active pattern. The first bias line is connected to the first and second gate electrodes.

Owner:SAMSUNG DISPLAY CO LTD

Cooling system, and internal combustion engine comprising a cooling system of said type

ActiveUS20170204776A1Susceptibility to oscillations-canReduce riskLiquid coolingMachines/enginesLine tubingNuclear engineering

A cooling system including a first coolant line and a second coolant line, at least one first component to be cooled, into which the first coolant line opens, and a first ventilation line. The first ventilation line is fluidically connected to the at least one first component and is configured for ventilating the at least one first component. The first ventilation line opens into the second coolant line.

Owner:ROLLS ROYCE SOLUTIONS GMBH

Head arm assembly and disk drive apparatus with the head arm assembly

ActiveUS7079356B2Raise the resonance frequencyImprove performanceRecord information storageStructure of arm assemblyHigh stiffnessEngineering

An HAA includes a head slider having at least one head element, a high-stiffness arm member for supporting the head slider at one end section, an actuator, mounted to the other end section of the arm member, for rotationally moving the arm member in a direction substantially parallel with a recording medium surface around a horizontal rotation axis of the arm member, and a resilient plate spring for generating a load, the plate spring having one end section fixed to the arm member and the other end section provided with a load point for energizing the head slider in a direction to the recording medium surface.

Owner:SAE MAGNETICS (HK) LTD

Steam generator

InactiveUS7958853B2Improve efficiencyLean structureWater circulationIgnition automatic controlEngineeringMechanical engineering

Owner:ALSTOM TECH LTD

Ceramic electronic component

ActiveUS9959975B2Increase in sizeImprove corrosion resistanceFixed capacitor dielectricStacked capacitorsMetallurgyElectronic component

A ceramic electronic component that includes a ceramic element, and a coating film and external electrodes on a surface of the ceramic element. The coating film includes cationic elements from a constituent element of the ceramic element, which are ionized and deposited from the ceramic element, and a resin. The surface of the coating film is recessed relative to a surface of wrapping parts of the external electrodes on the surface of the ceramic element.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com