Production system and method of low-yield-ratio hot-rolled high-strength anti-seismic reinforcing steel bars

A technology of anti-seismic steel bars and low yield ratio, which is applied in the field of iron and steel metallurgical hot rolling, can solve the problems of reducing the service life of rolling mills and shearing machines, large tendency of stress corrosion cracking, and low heating temperature of billets, so as to improve market competitiveness and improve Pass reduction and the effect of reducing the yield-strength ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

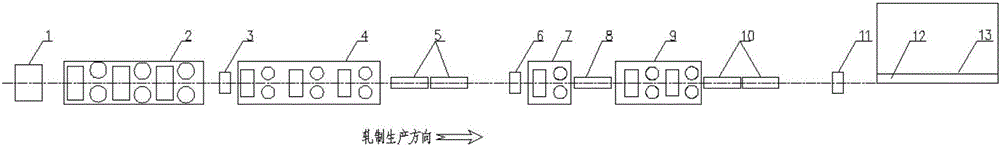

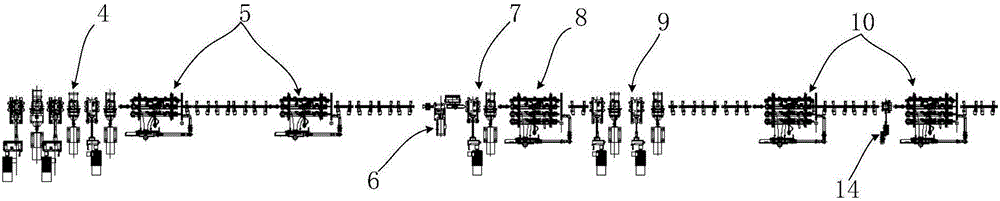

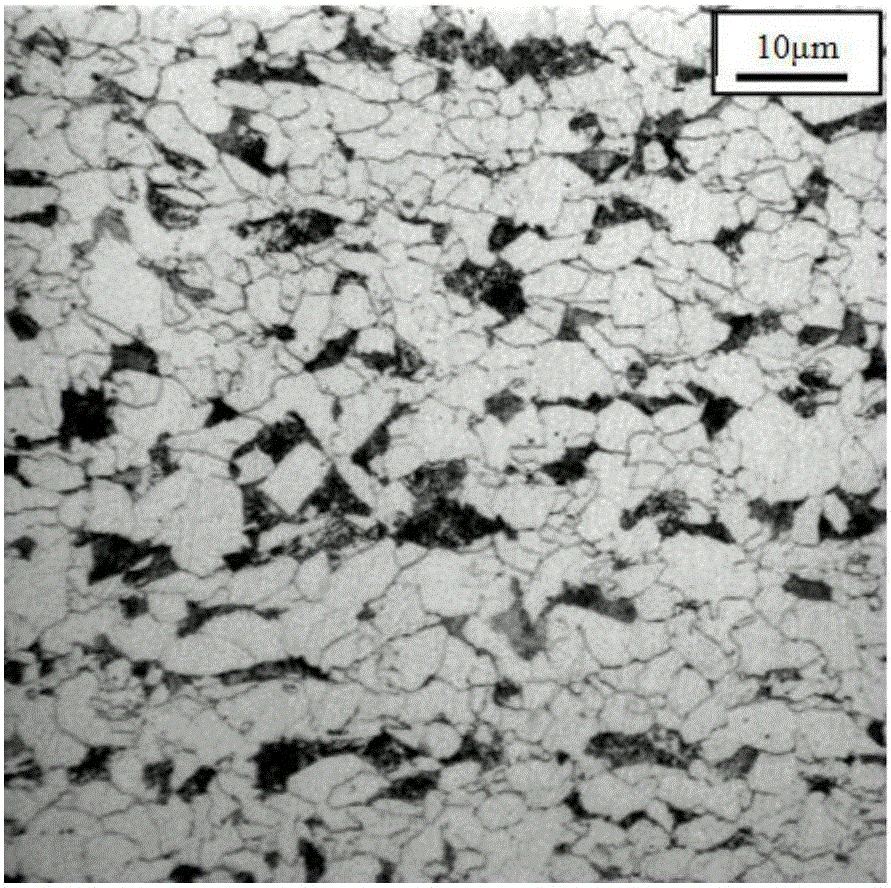

[0032] Such as figure 1 and figure 2 As shown, a production system for hot-rolled high-strength anti-seismic steel bars with low yield strength ratio, including heating furnace 1, rough rolling unit 2, cutting head flying shear 3, intermediate rolling unit 4, post-intermediate rolling Water cooling device 5, cutting head flying shear 6, front section of finishing rolling unit 7, water cooling device in finishing rolling room 8, rear section of finishing rolling unit 9, water cooling device after finishing rolling 10, double-scale flying shear 11 and cooling bed 13, of which water cooling device Water tanks are used, and the water tank is arranged between the front section 7 of the finishing mill and the rear section 9 of the finishing mill. By controlling the water cooling parameters and the recovery section, rolling in the ferrite recrystallization zone is realized, and the austenite grains are refined and the phase transformation is completed. Organization, improve the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com