Patents

Literature

69results about How to "Full liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

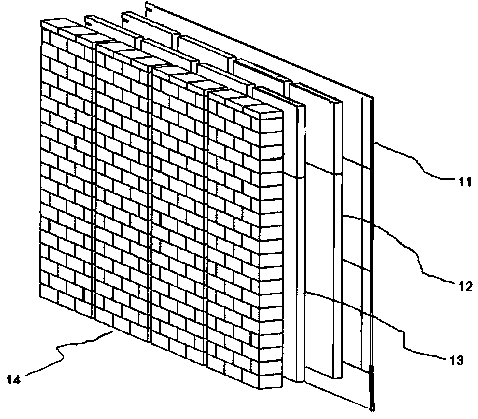

High-reflectivity photovoltaic module packaging film and application thereof

ActiveCN104497899AImproves UV resistanceIncrease usageNon-macromolecular adhesive additivesFilm/foil adhesivesHigh reflectivityReflective layer

The invention discloses a high-reflectivity photovoltaic module packaging film. The high-reflectivity photovoltaic module packaging film with a surface pre-crosslinked structure is prepared by the following steps: pre-mixing transparent resin with a high-reflectivity additive and other functional accessories, carrying out melting extrusion, film casting and surface pre-crosslinking treatment, and coiling. By adding the high-reflectivity additive, the ultraviolet-resistance performance of the film can be improved, and meanwhile, the utilization rate of a module on sunlight is enhanced, and therefore the effects of improving the service life and photoelectric conversion efficiency of the module are achieved; meanwhile, by virtue of the surface pre-crosslinked structure, the high-reflectivity layer film can be effectively prevented from overflowing during a photovoltaic module laminating process and the appearance of the module is effectively improved; the packaging film is universal for various laminating processes.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

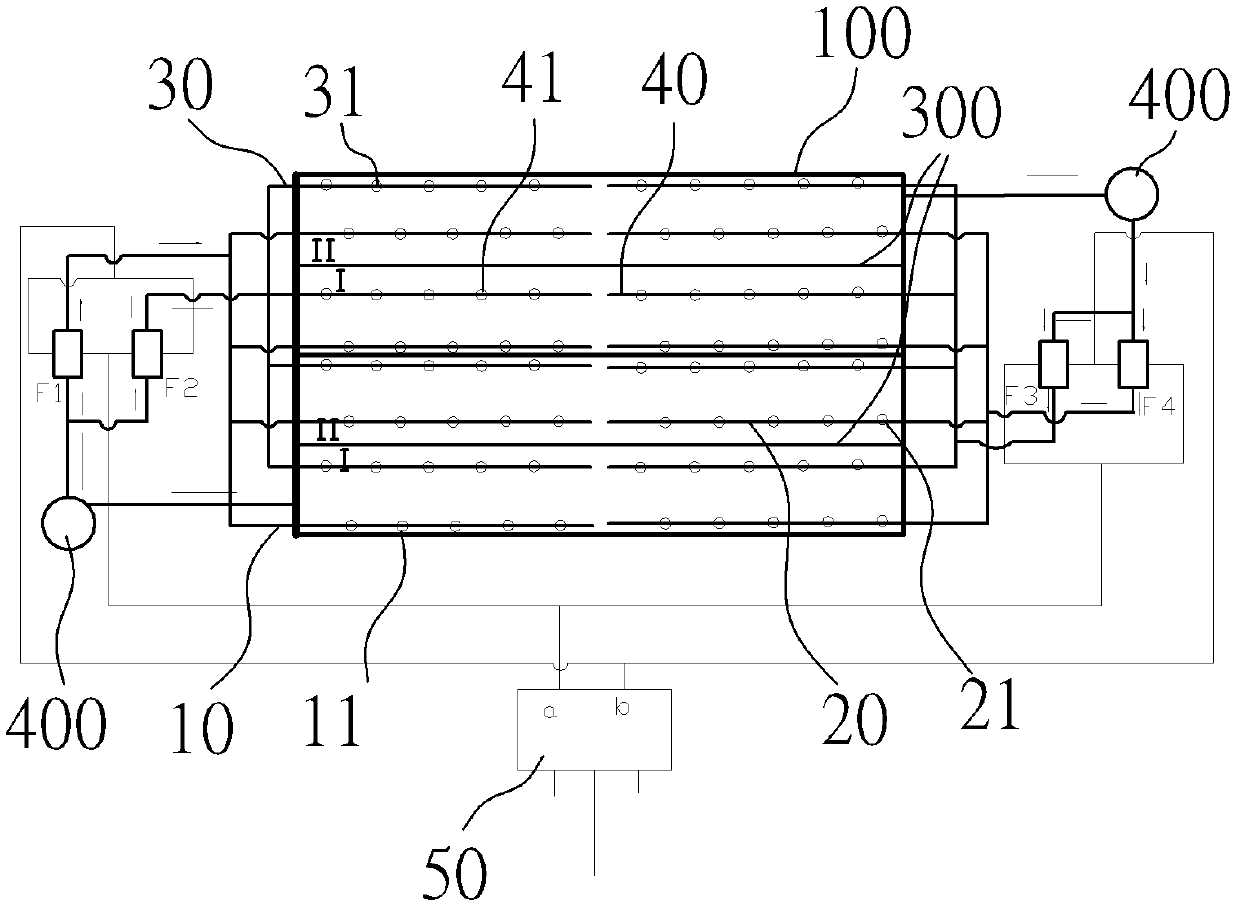

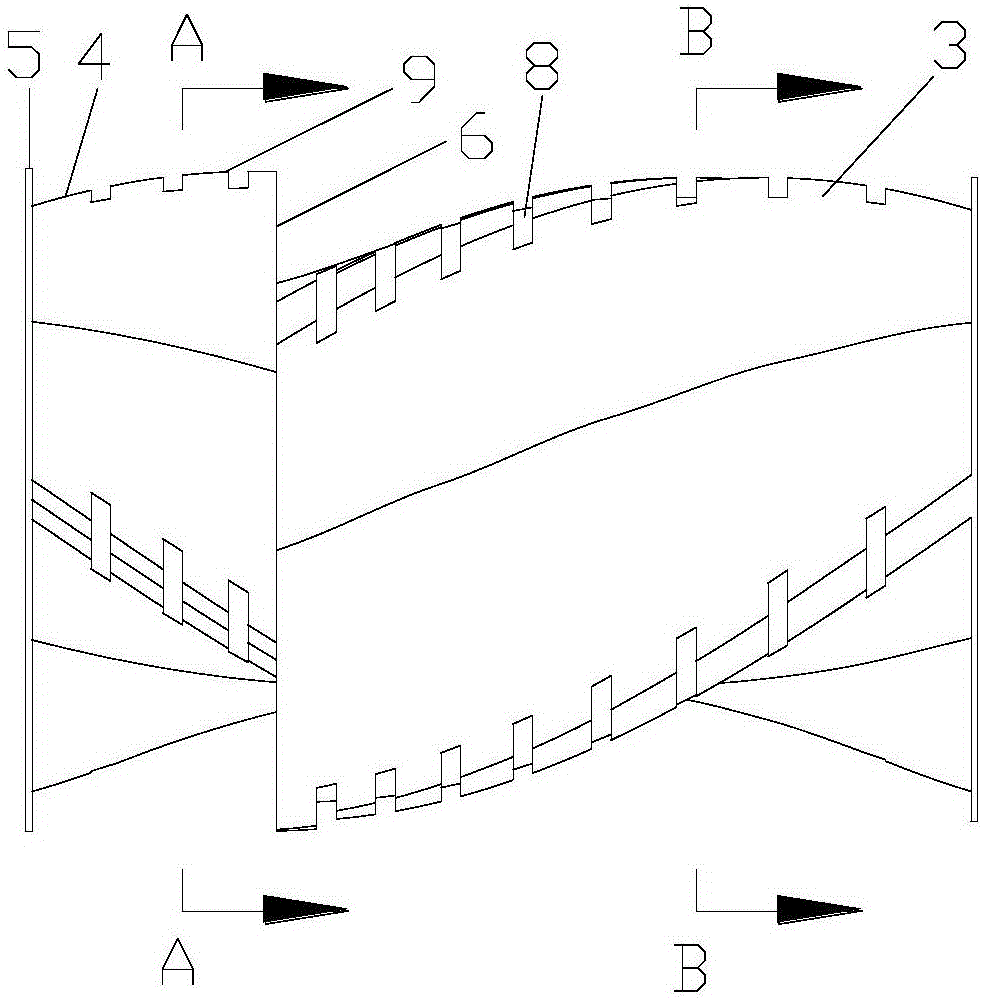

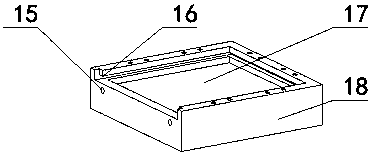

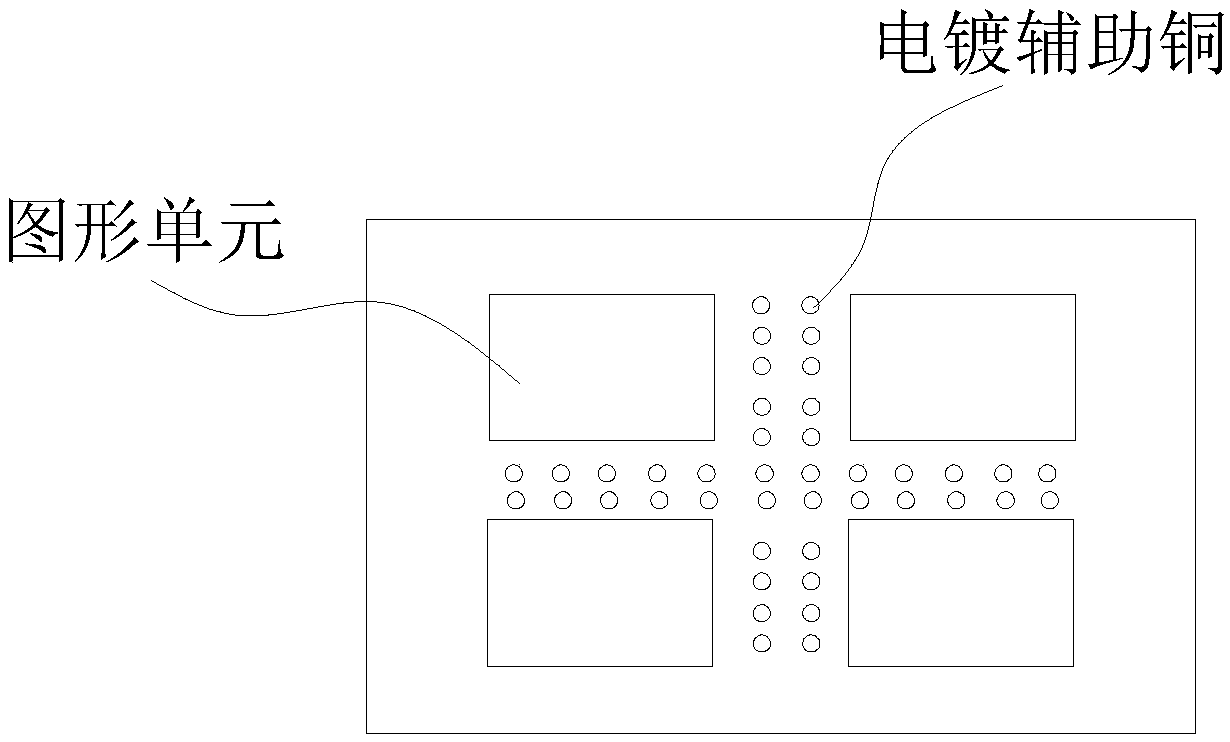

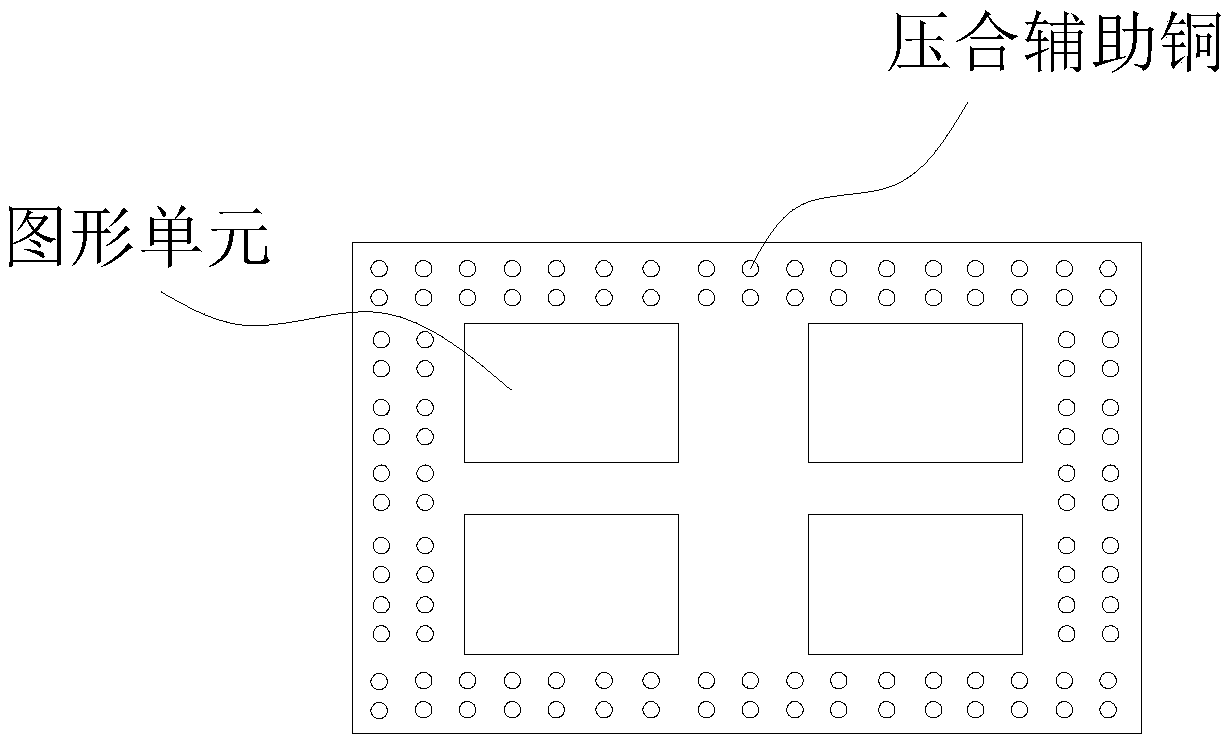

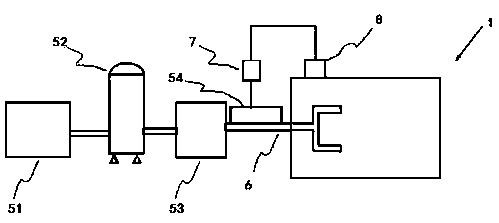

Electroplating method for PCB plate and apparatus

The invention discloses an electroplating method for a PCB plate and an apparatus. The method comprises: a preparation step comprising immersing the PCB plate in a plating solution of a plating bath in a way that a plate surface is perpendicular to a liquid surface, wherein a first side of the PCB plate has a first side nozzle set and a second bottom nozzle set, and a second side of the PCB plate has a second side nozzle set and a first bottom nozzle set; and a jet flow processing step, wherein a first nozzle group composed of the first side nozzle set and the first bottom nozzle set and a second nozzle group composed of the second side nozzle set and the second bottom nozzle set cyclically and alternately jet for predetermined times. The electroplating method for the PCB plate and the apparatus provided by the invention utilize a technical means that two nozzle groups cyclically and alternately jet. A relatively large negative pressure is generated at two sides of the holes of the PCB plate due to different flow rates of the plating solution. A flow effect of the plating solution is relatively full, an exchange capability is relatively strong, and a deposition speed of copper ions is increased, thereby improving a throwing power so that a thickness of electro-coppering is enough and uniform.

Owner:SHENNAN CIRCUITS

Method for manufacturing large-sized high-density chromium target

ActiveCN102677005AThe process is simpleOperation method standardizationVacuum evaporation coatingSputtering coatingChromiumPumping vacuum

The invention relates to a hot pressing method of a high-density chromium target. The method comprises the following seven sequential steps: vacuumizing, staged temperature and pressure increasing, pressure preserving furnace cooling, hot forging, annealing, hot rolling and machining. Through rationally designed process steps, stable technical parameters are selected so that the purpose of manufacturing the large-sized high-density chromium target at low cost is achieved.

Owner:YANTAI SHUODE NEW MATERIAL

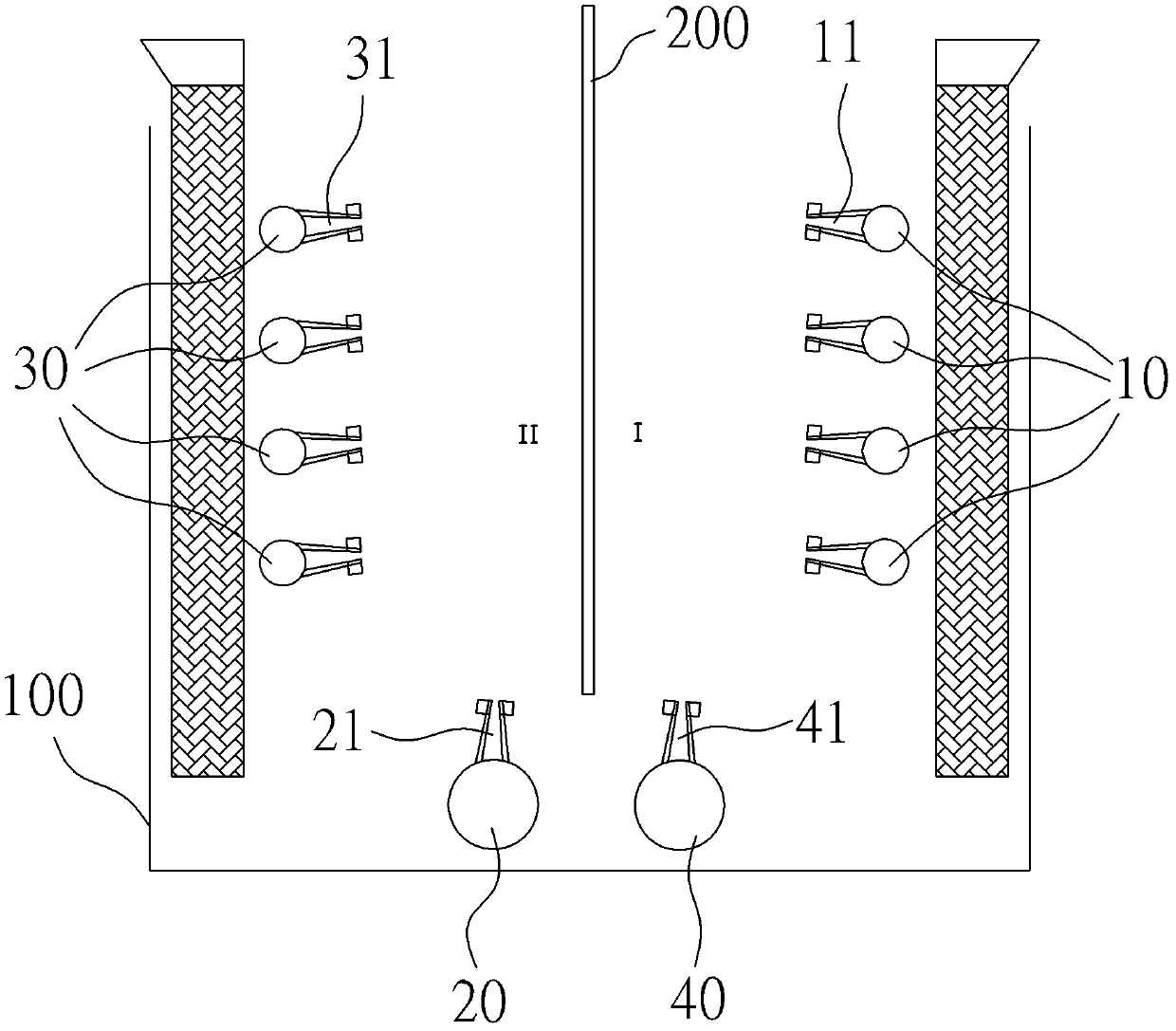

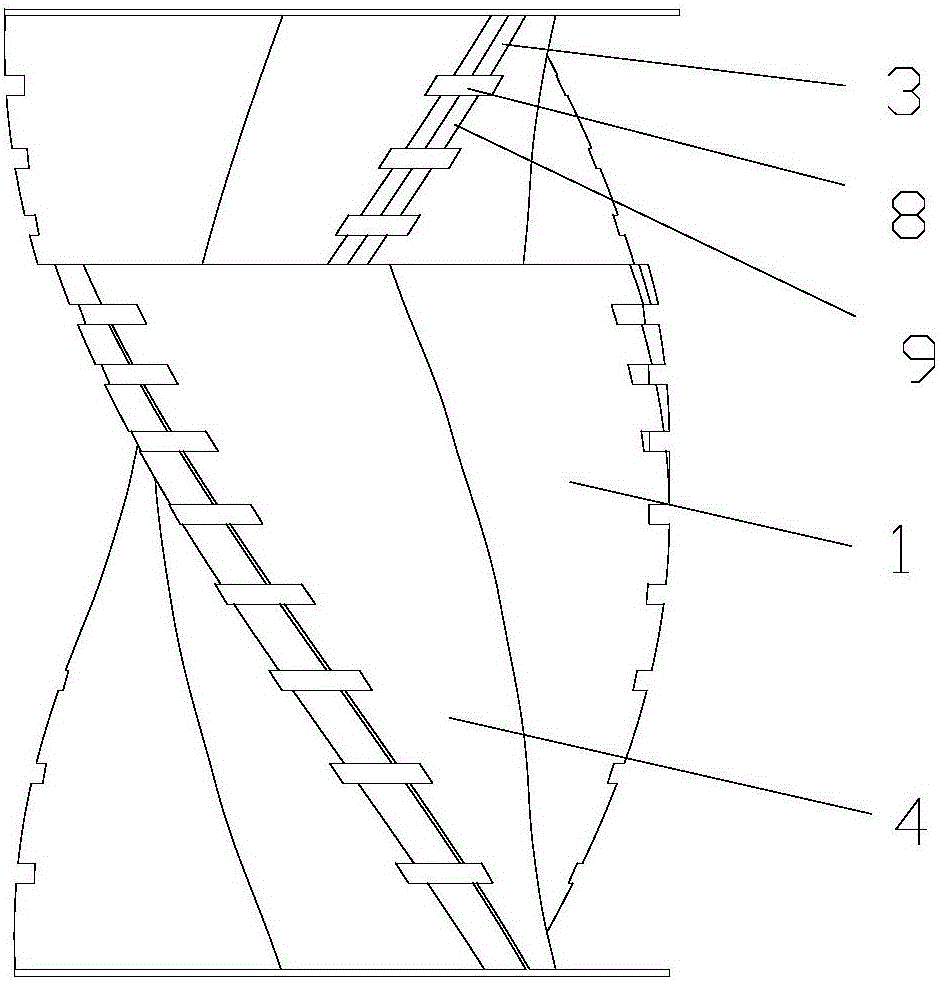

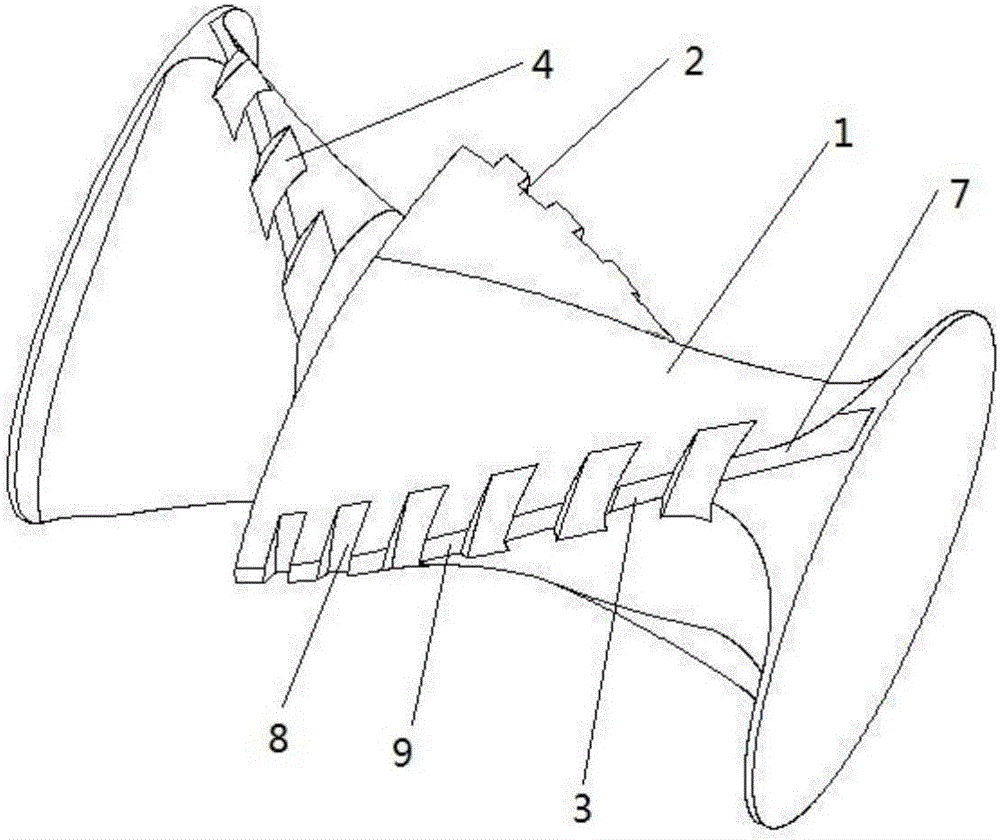

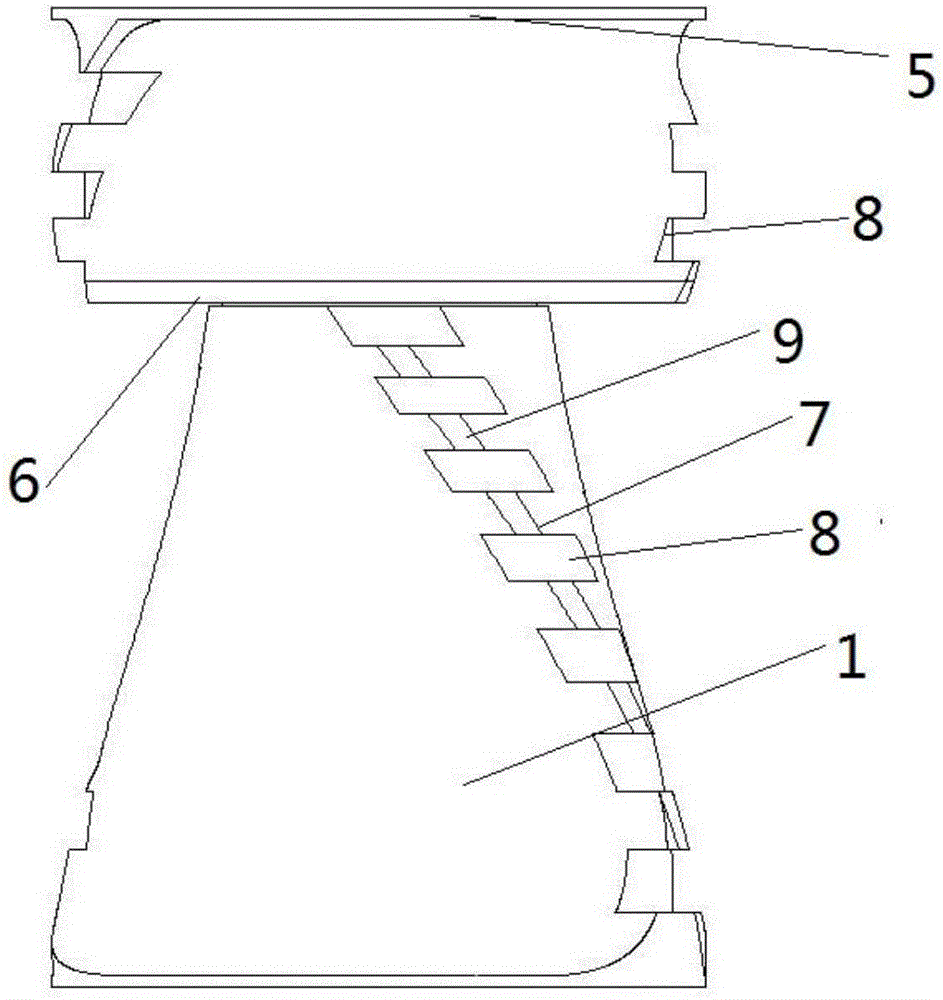

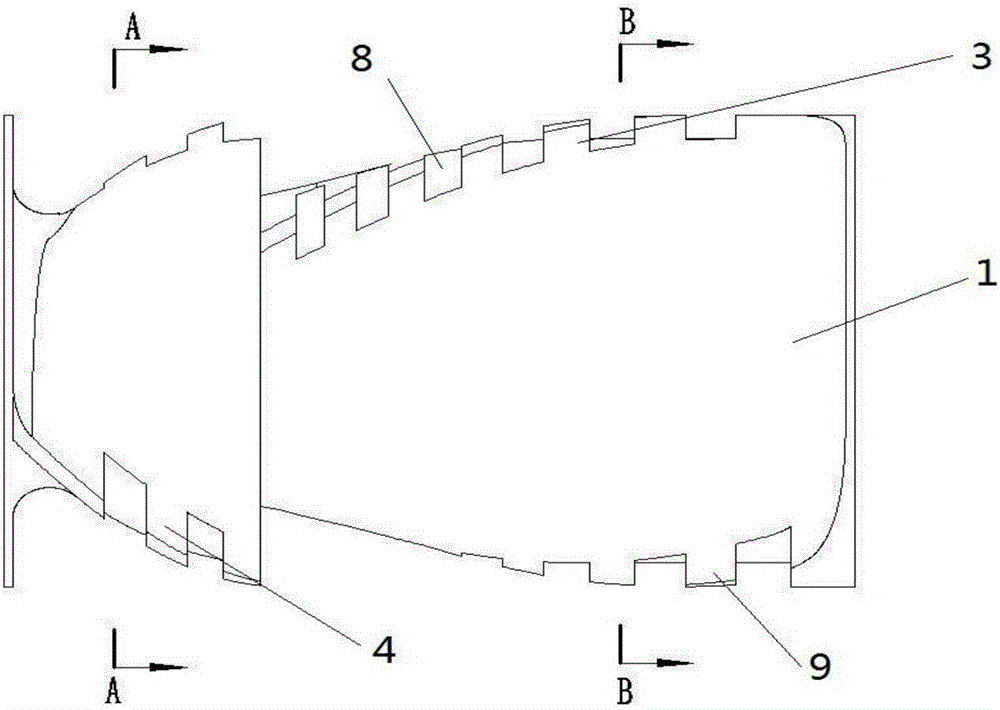

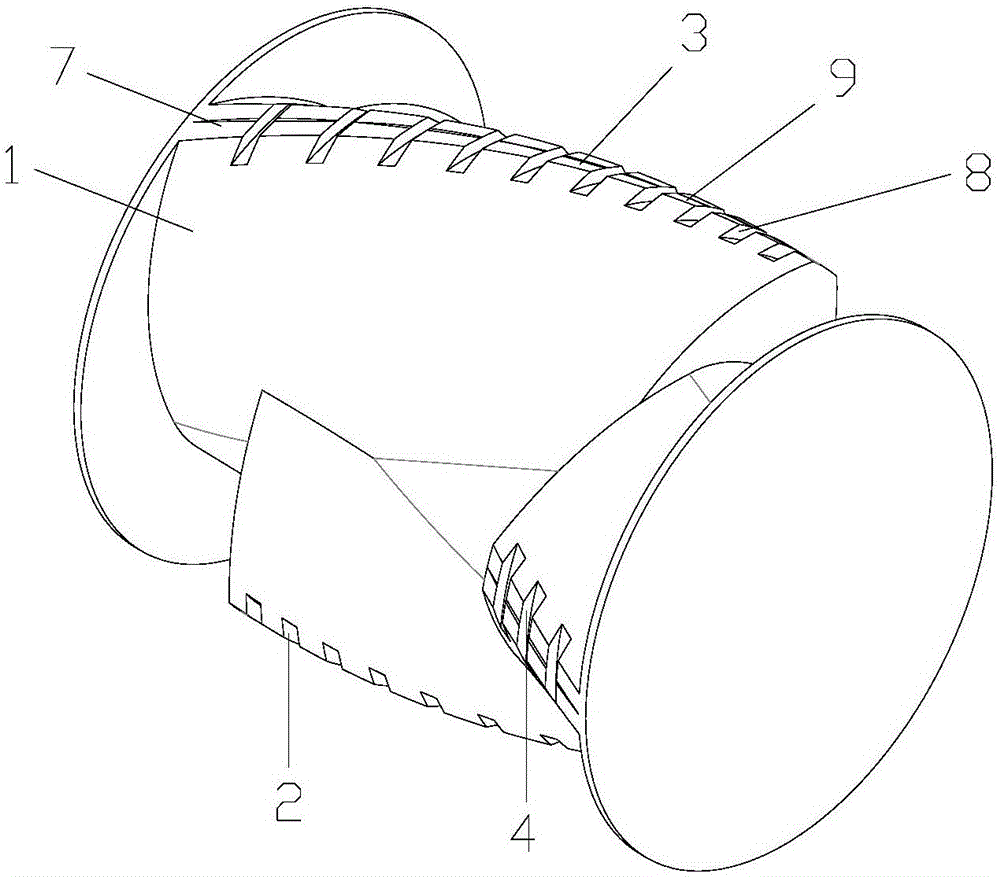

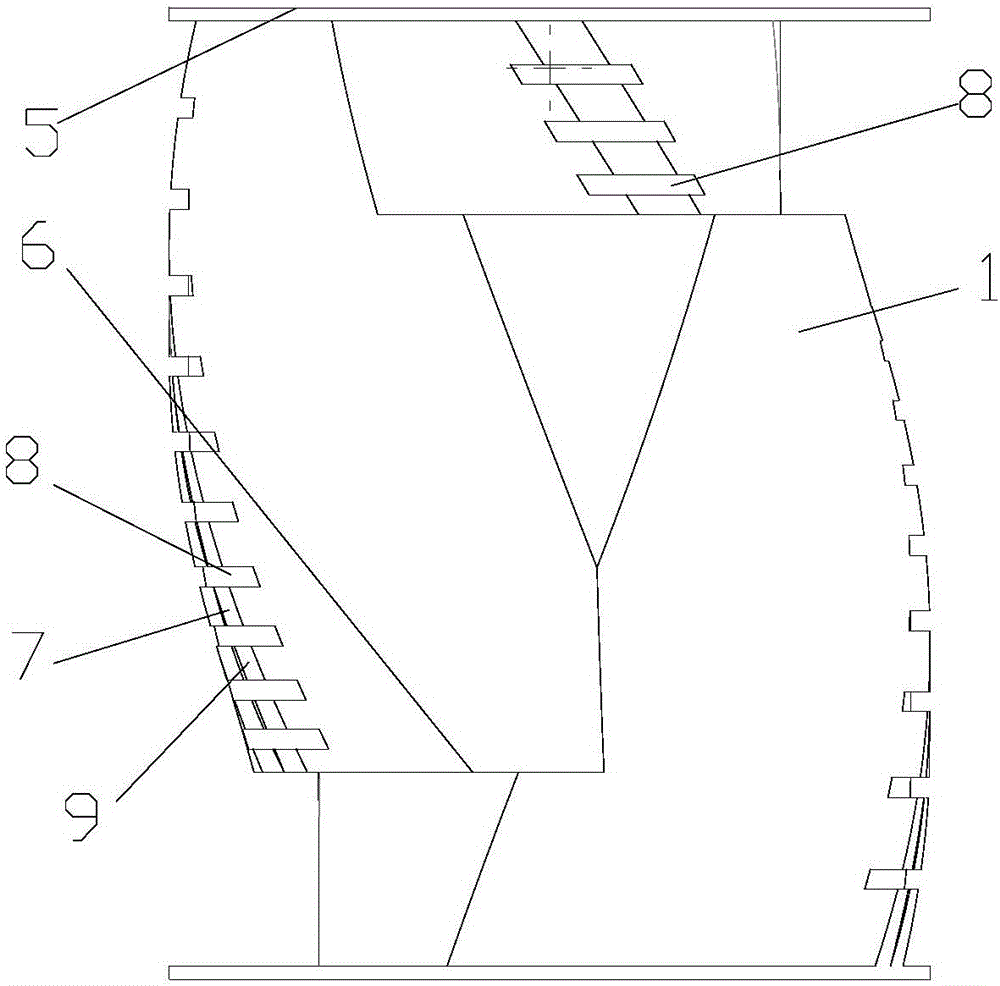

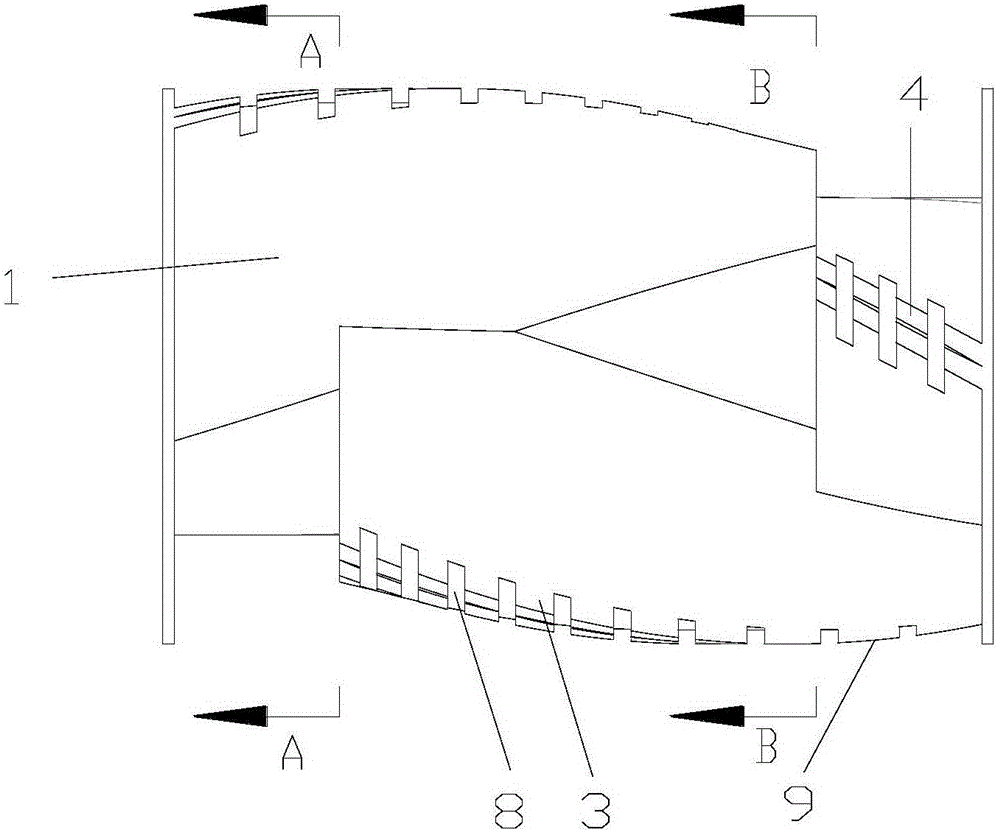

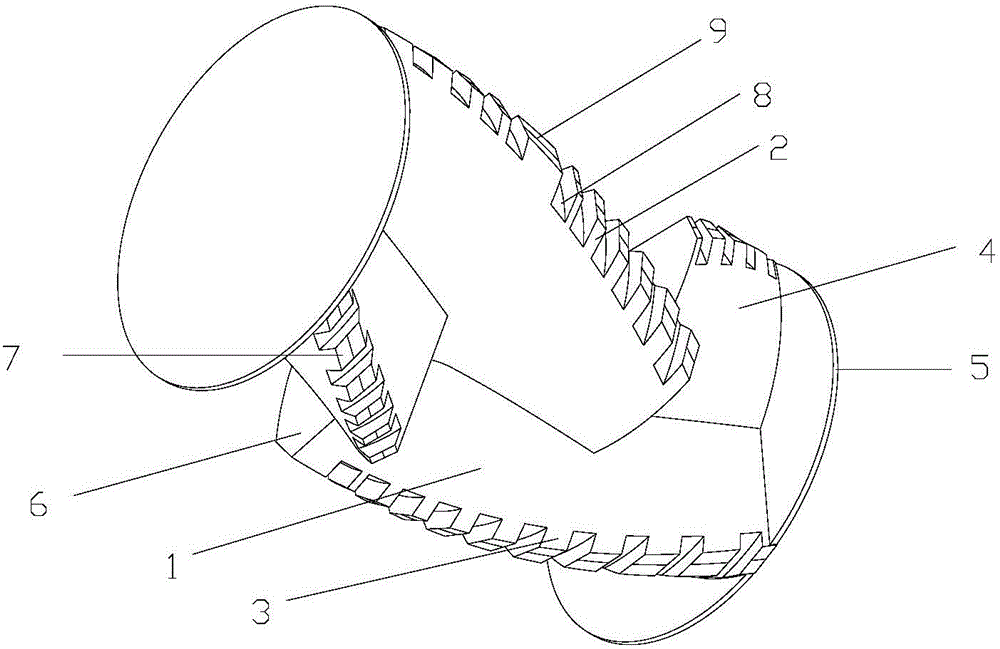

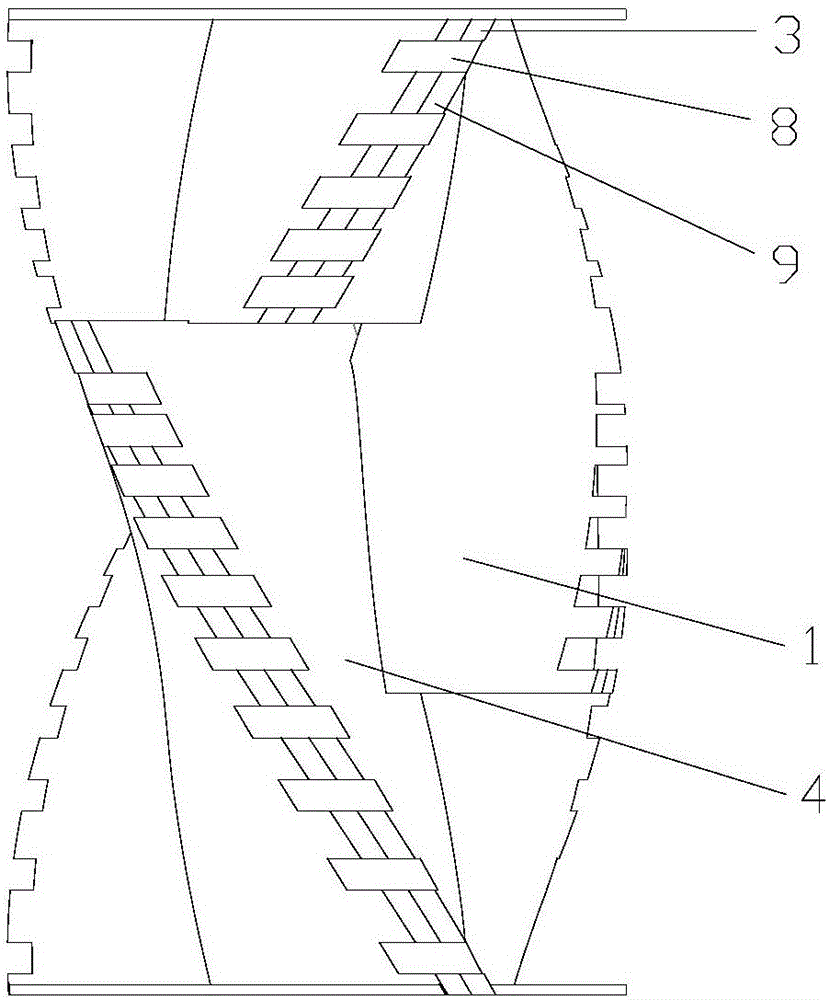

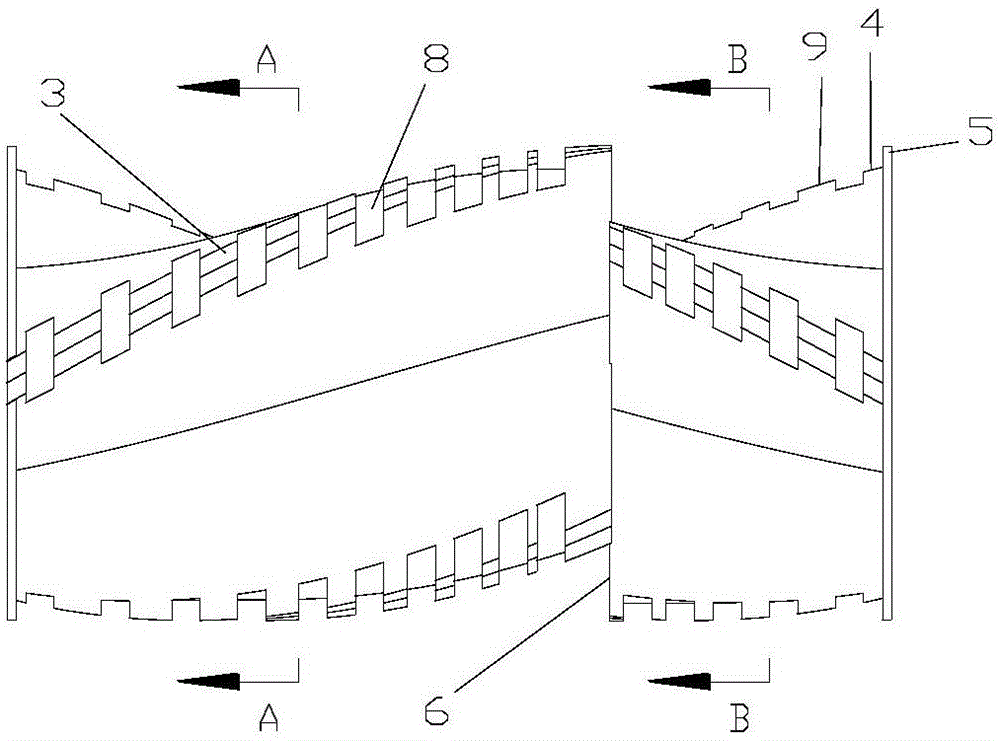

Synchronous six-edge saw tooth type dynamic variable-gap internal mixer rotor

The invention discloses a synchronous six-edge saw tooth type dynamic variable-gap internal mixer rotor. The internal mixer rotor comprises a rotor body; six convex edges are arranged on the rotor body, and include three long edges and three short edges; the convex edges spirally extend from two ends to middle of the rotor body, and include starting ends and ending ends; multiple tooth grooves are respectively formed in the edge tops of the convex edges; the distances between the tooth grooves are gradually decreased; and the depths of the tooth grooves are respectively changed on three edges of the same peripheral direction of the rotor by deep and shallow two gaps. The synchronous six-edge saw tooth type dynamic variable-gap internal mixer rotor has the following beneficial effects: the tooth grooves are added in the convex edges of the internal mixer rotor to change the peripheral flowing of glue, so that the distribution and the dispersion of various fillers and matching agents are facilitated; and the number and the distribution density of the tooth grooves are increased along with increment of the peripheral flowing speed of the glue, so that the kneading effect of the lump-shaped glue between the edges is reinforced, the flowing of the glue in a mixing chamber is more disordered, and the glue mixing quality and the glue mixing efficiency are improved.

Owner:QINGDAO UNIV OF SCI & TECH

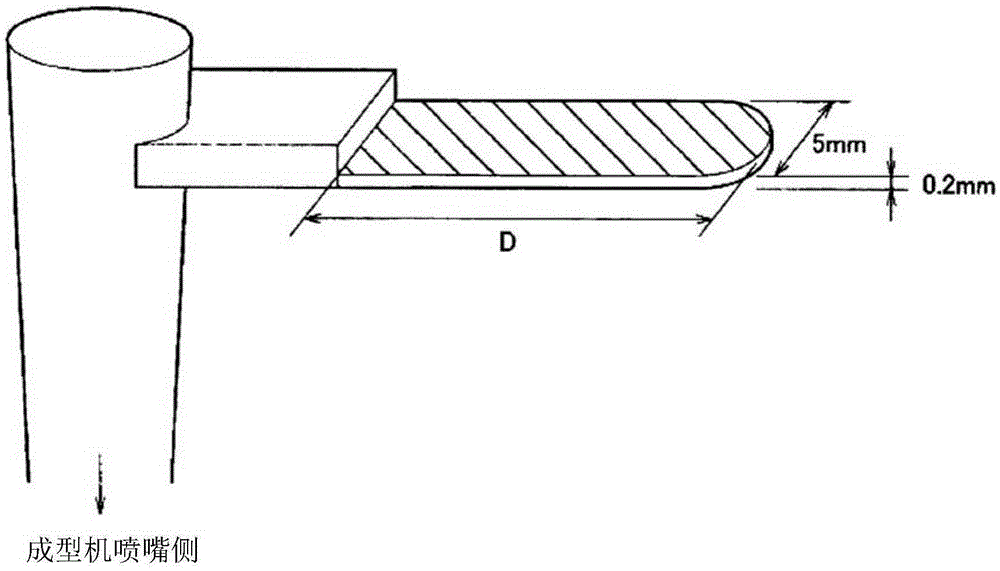

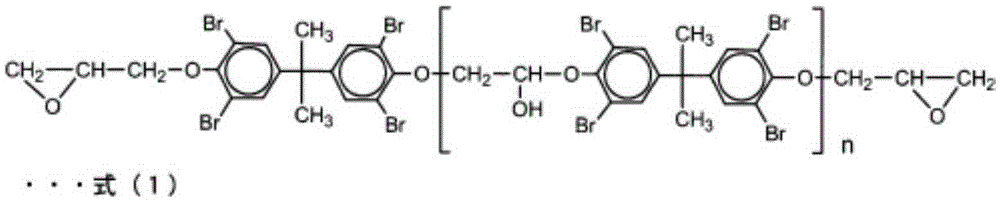

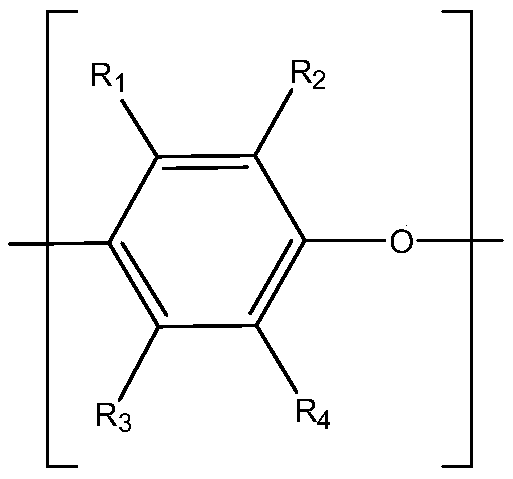

Polybutylene terephthalate resin composition and injection-molded article

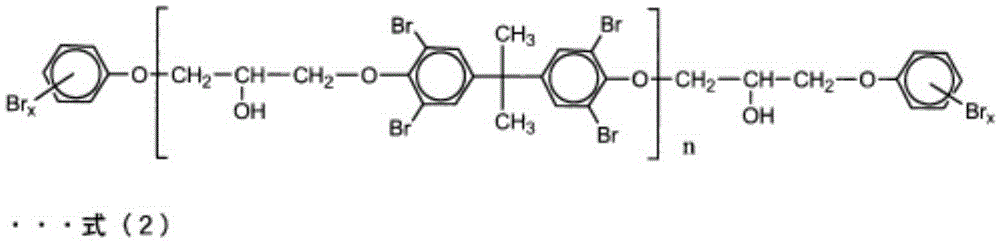

ActiveCN105377983AFull liquidityImprove flame retardant performanceCoatingsEpoxyPolytetramethylene terephthalate

Provided are a polybutylene terephthalate resin composition having sufficient fluidity to be molded as thin-walled during molding and having excellent flame retardancy even when molded as thin-walled, and an injection-molded article obtained using this resin composition. A polybutylene terephthalate resin composition containing 20 to 65 total parts by mass of (B) brominated epoxy flame retardant and / or brominated acrylate flame retardant, 10 to 30 parts by mass of (C) antimony flame retardant auxiliary, 3 to 15 parts by mass of (D) talc, and 1 to 10 parts by mass of (E) polyvalent hydroxyl group-containing compound having a hydroxyl value of 100 or higher per 100 parts by mass of (A) polybutylene terephthalate resin having an intrinsic viscosity of 0.70 to 1.00 g / dL; and an injection-molded article having a 0.2 to 0.5-mm-thick thin-walled portion in at least one portion obtained by injection-molding this resin composition.

Owner:POLYPLASTICS CO LTD

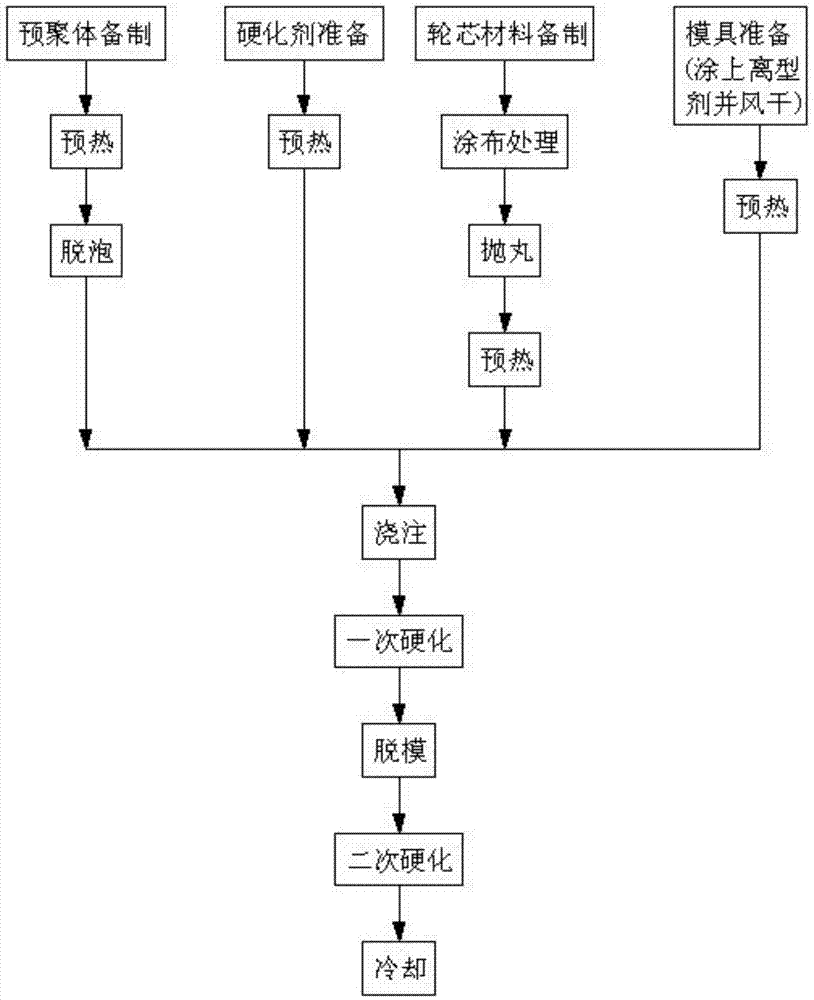

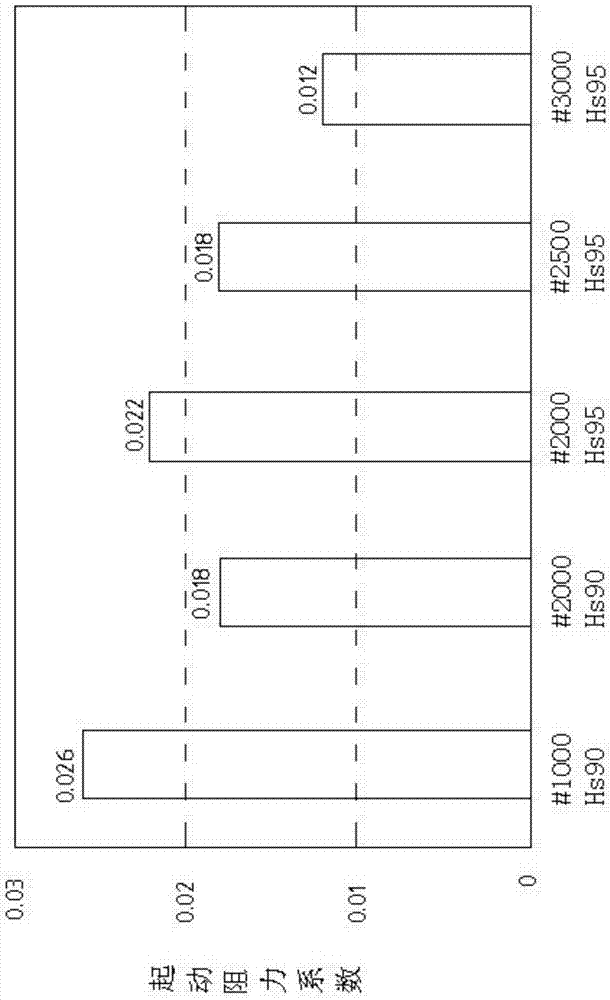

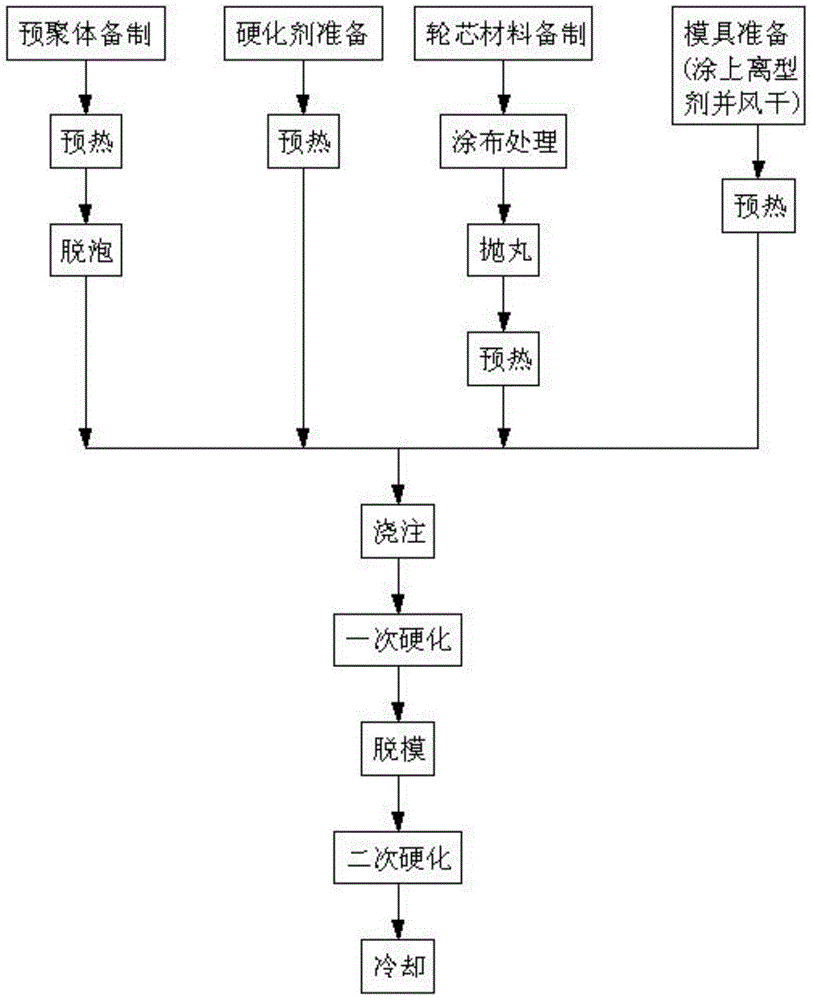

Method for fabricating casting-type polyurethane elastomer tire

The invention relates to a method for fabricating a polyurethane tire, and discloses a method for fabricating a casting-type polyurethane elastomer tire. The method comprises the following steps: preparing materials, coating, pre-treating a mold, preheating, assembling, casting, primarily hardening and secondarily hardening. By adopting the technology disclosed by the invention, polyurethane can be tightly bonded with a wheel core surface by expanding the molecular polarity; the wheel core surface is coated; the wheel core surface is coated with a material comprising per 1kg of an adhesion agent and 1.2-1.8kg of methyl ethyl ketone (MEK) coating; the relatively great matching is generated between the polyurethane and a wheel core; the bonding strength is improved; the polyurethane and a hardening agent are cast into the mold according to the ratio of 100:(10-100):15 by weight percent in the casting process; the cast mold is hardened twice, so that the polyurethane is full in liquidity in the casting process, and air bubbles are prevented from being formed on the wheel core surface, the adhesion reduction is reduced, and the degumming is avoided.

Owner:安徽台创智能科技有限公司

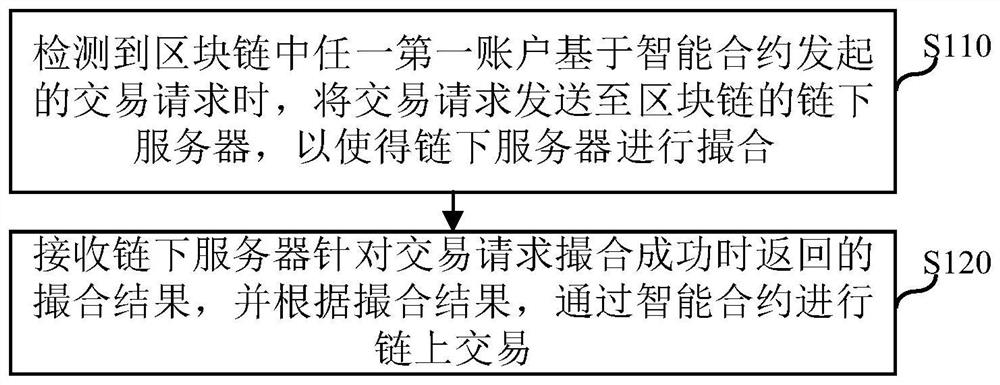

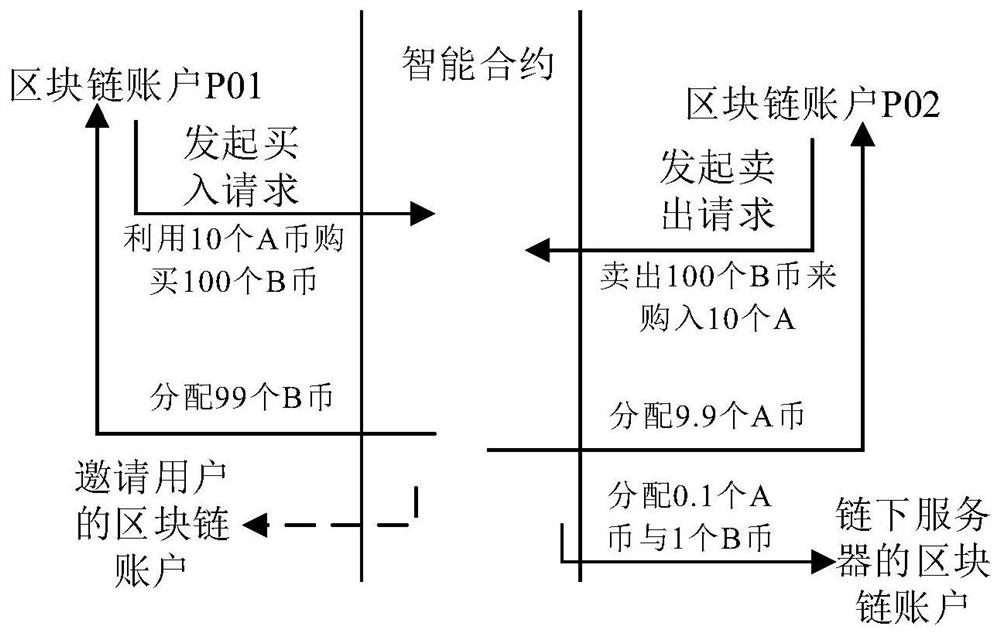

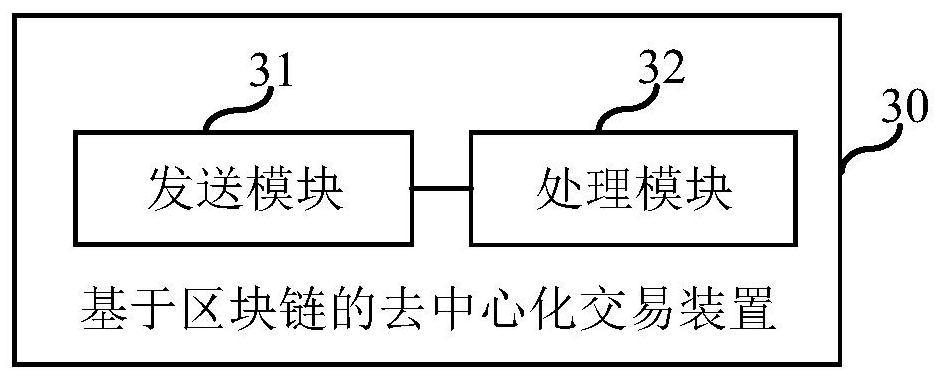

Decentralized transaction method and device based on block chain and electronic device

PendingCN111612453AImprove service experienceEnsure safetyPayment protocolsEngineeringFinancial transaction

The invention relates to the technical field of block chains, and discloses a decentralized transaction method and device based on a block chain and an electronic device. The decentralized transactionmethod based on the block chain is applied to a block chain server, and comprises the following steps: when a transaction request initiated by any first account in the block chain based on an intelligent contract is detected, sending the transaction request to an off-chain server of the block chain, so that the off-chain server performs matching; and receiving a matching result returned by the off-chain server for the transaction request, and performing on-chain transaction through the smart contract according to the matching result. According to the method, asset trusteeship, asset clearingand the like are executed on the block chain, not only is the security of the digital assets of the user ensured, but also each transaction is recorded on the block chain and displayed to all the users, so that the whole transaction process is public and transparent, the privacy of the users is not leaked excessively, and the transaction is carried out on the premise of ensuring the user information.

Owner:海南趣块飞扬科技有限公司

Four-ledge zigzag dynamic variable-gap internal mixer rotor

The invention discloses a four-ledge zigzag dynamic variable-gap internal mixer rotor. The internal mixer rotor comprises a rotor body, wherein four ledges are arranged on the rotor body and comprise two long ledges and two short ledges; the ledges spirally extend from two ends of the rotor body to the middle of the rotor body; each ledge comprises an initial end and a tail end; a plurality of tooth grooves are formed in the top of each ledge; widths of the tooth grooves of each ledge are not changed in the direction from the initial end to the tail end; and distances among the tooth grooves are gradually reduced. The four-ledge zigzag dynamic variable-gap internal mixer rotor has the beneficial effects that the tooth grooves are formed in the ledges of the internal mixer rotor, circumferential flowing of rubber is changed, and distributing and dispersing of various packing and ingredients are facilitated; and the number and the distribution density of the tooth grooves are increased along with increasing of circumferential flowing speed of the rubber, the effect of mutual kneading of the lump-shaped rubber among the ledges is improved, so that flowing of the rubber in a mixing chamber is disordered, and rubber mixing quality and rubber mixing efficiency are improved.

Owner:QINGDAO UNIV OF SCI & TECH

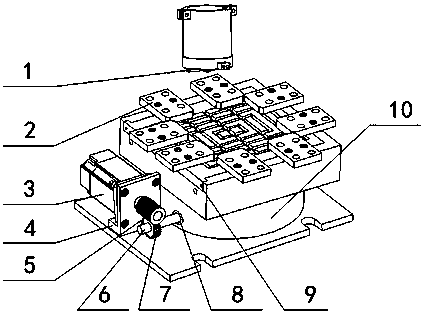

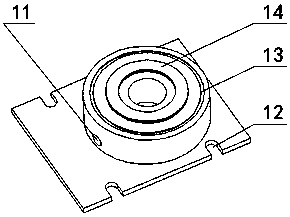

Friction-stir welding device applied to numerically-controlled machine tool

PendingCN108555434AFull liquidityNovel structureNon-electric welding apparatusNumerical controlLinear motion

The invention belongs to the technical field of metal welding and relates to a friction-stir welding device applied to a numerically-controlled machine tool. Positioning modules are mounted on a clamping module to jointly realize positioning and clamping functions along with the clamping module. A welding operating module is mounted on a spindle of the numerically-controlled machine tool to realize rotating and linear motion, and a driving module drives the clamping module to move. A direct-current loading module is positioned on the welding operating module. Magnetic field loading modules aremounted in the welding operating module and the clamping module, and welding of parts is finally realized. The friction-stir welding device has advantages that novel structure, simplicity, high universality and quickness in reaction are realized, and sheets different in size and thickness can be welded; weld joints in different shapes can be welded by the friction-stir welding device used with the numerically-controlled machine tool, and a welding direction and the horizontal plane always form a 2-degree inclination angle in a welding process to realize complete fluidity of weld joint materials; short-distance high current loading and magnetic field loading can be realized so as to achieve excellent weld joint performances.

Owner:JILIN UNIV

Synchronous four-ridge sawtooth type dynamic clearance changing internal mixer rotor

The invention discloses a synchronous four-ridge sawtooth type dynamic clearance changing internal mixer rotor. The internal mixer rotor comprises a rotor body. The rotor body is provided with four protruding ridges including the two long ridges and the two short ridges. The protruding ridges spirally extend to the middle from the two ends of the rotor body, and a starting end and an ending end are included. A plurality of tooth grooves are formed in the ridge tops of the protruding ridges, the width difference of the tooth grooves in each protruding ridge is not changed in the direction from the starting end to the ending end, the distances between the tooth grooves are gradually reduced, and two different degrees of changes in the aspect of depth and shallowness exist on the tooth grooves in the axial direction of the rotor. The synchronous four-ridge sawtooth type dynamic clearance changing internal mixer rotor has the beneficial effects that the tooth grooves are additionally formed in the positions of the protruding ridges of the internal mixer rotor, circumferential flowing of a sizing material is changed, and distributing and scattering of various kinds of filler and compounding agents are facilitated; the number and the distributing density of the tooth grooves are increased along with increasing of the circumferential flowing speed of the sizing material, the mutual kneading function of the lump sizing material is enhanced, flowing of the sizing material in a mixer chamber is more disordered, and the milling quality and efficiency are improved.

Owner:QINGDAO UNIV OF SCI & TECH

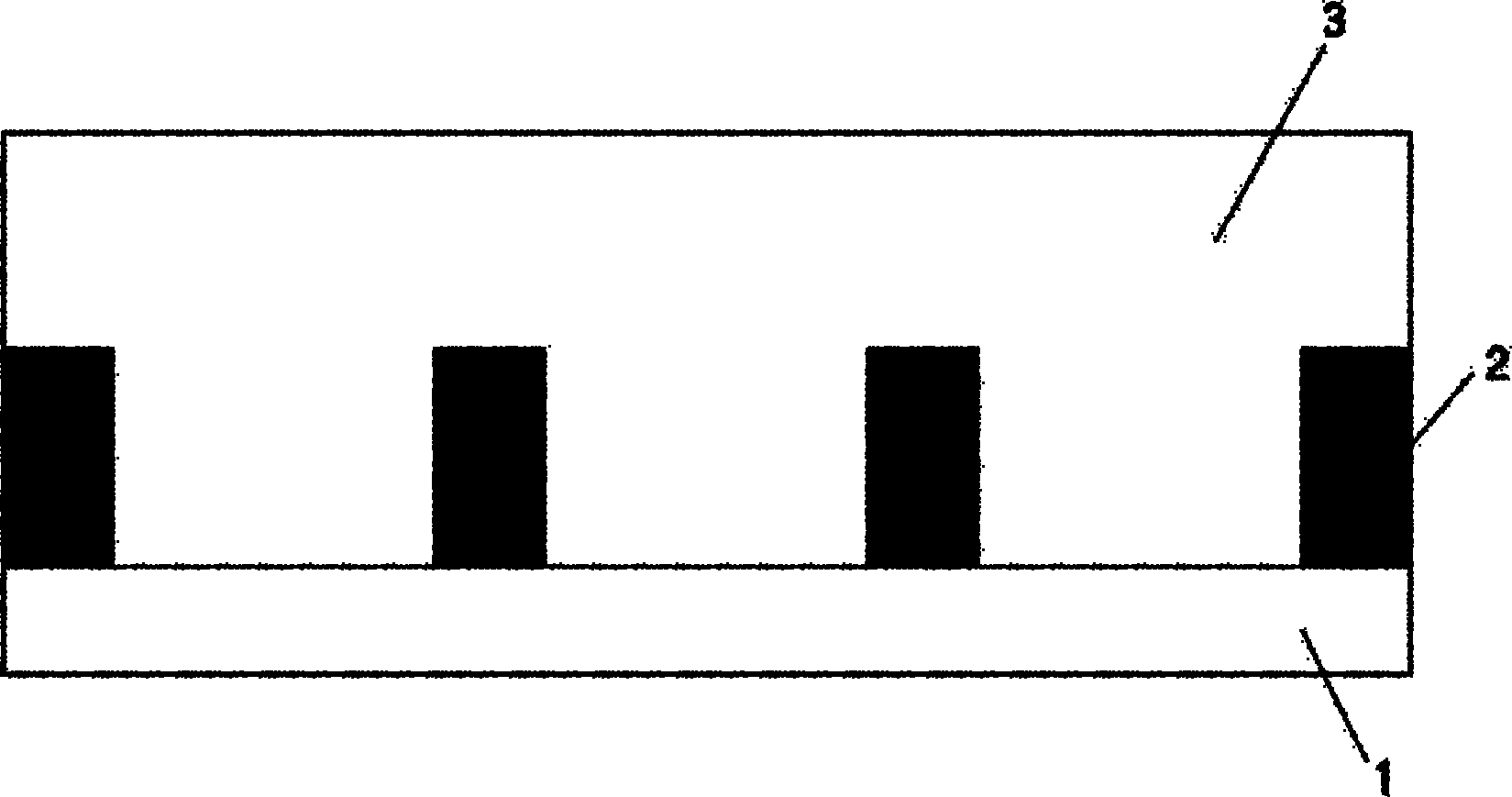

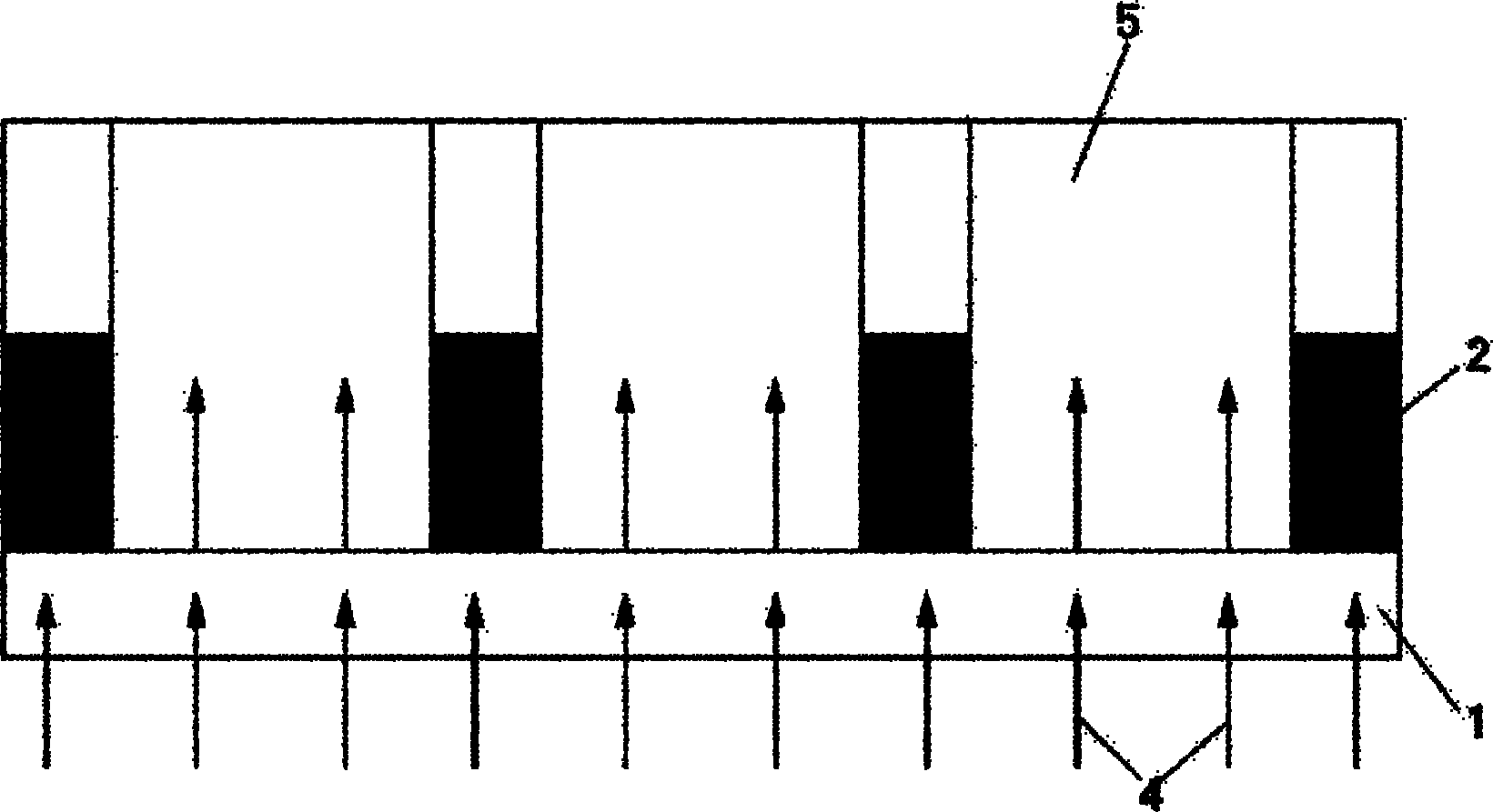

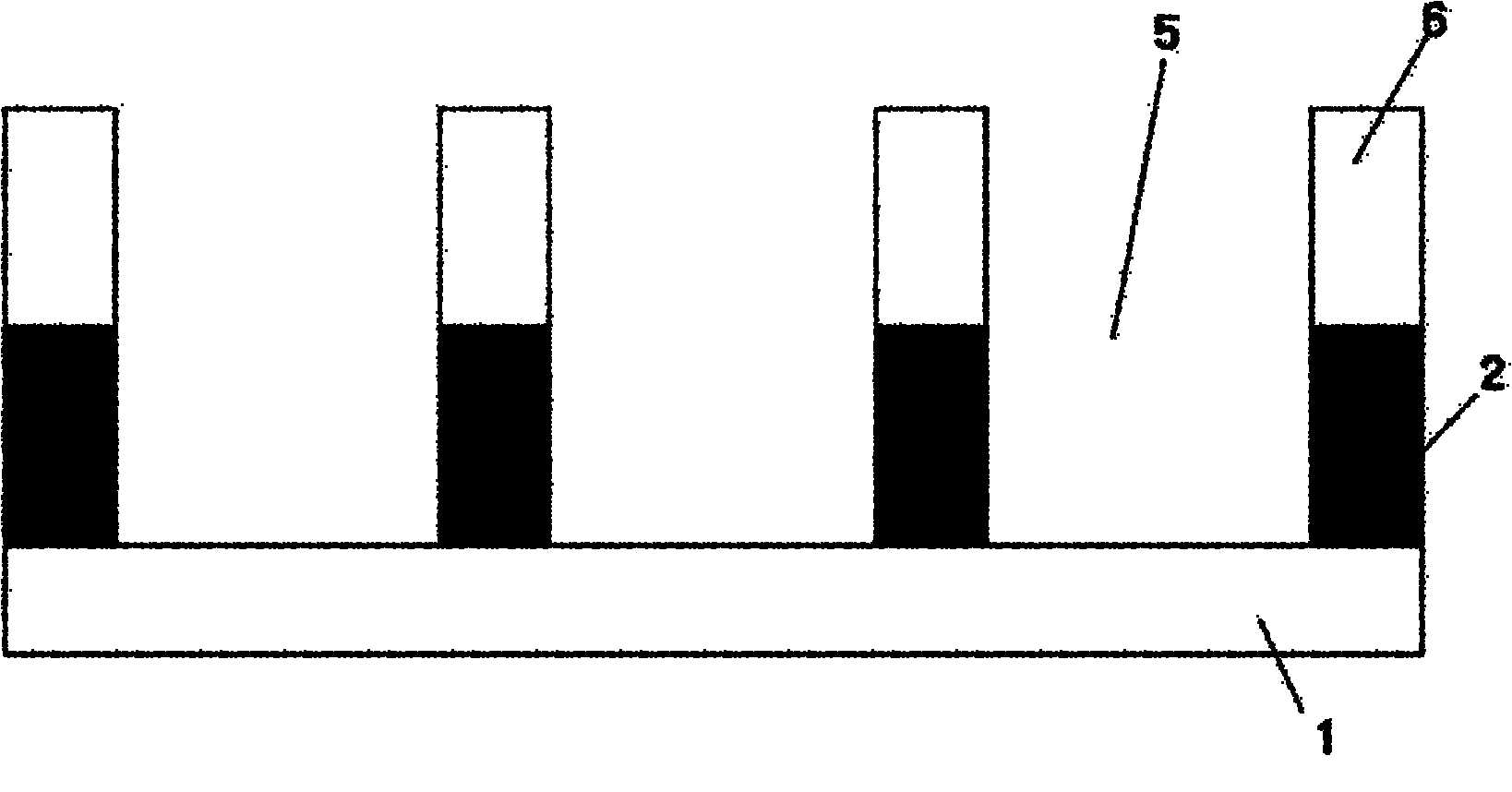

Method for manufacturing color filter, color filter substrate and color filter

InactiveCN102119347AFull liquidityUniform film thicknessOptical filtersPhotomechanical apparatusResistLiquid-crystal display

Disclosed is a method for manufacturing a CF, comprising a step for coating a photo-degradation type positive resist to cover at least black matrices formed on a surface of a color filter substrate, thereby forming a resist layer; a step for exposing the resist layer from the rear surface of the CF substrate; a step for washing and removing the resist layer melted by the exposure to form hole spaces or groove spaces (empty holes) separated by holed walls (groove walls, separation walls) made of the resist layer remaining on the BM; a step for providing the hole spaces with colored inks corresponding to pixels of the CF to form colored films; and a step for exposing from the BM side to melt and remove the separate walls made of the resist layer. The method can solve problems with respect to complicated processes, shortening of operation time, and so on in manufacturing of a CF having excellent performances in image properties, such as fine resolution of pixels and sharpness, thereby easily and economically providing a method for manufacturing a CF that can cope with either a large-size or miniaturized liquid crystal display.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Six-ridge serrated dynamic variable-gap internal mixer rotor

The invention discloses a six-ridge serrated dynamic variable-gap internal mixer rotor which comprises a rotor body. Six protruded ridges are arranged on the rotor body, include three long ridges and three short ridges, spirally extend from two ends of the rotor body to the middle of the rotor body and comprise starting ends and finish ends; a plurality of tooth spaces are respectively arranged on ridge tops of the protruded ridges, the difference of the widths of the tooth spaces on each protruded ridge keeps unchanged in the direction from the starting end to the finish end of the protruded ridge, and the distances among the tooth spaces on each protruded ridge are gradually shortened in the direction from the starting end to the finish end of the protruded ridge. The six-ridge serrated dynamic variable-gap internal mixer rotor has the advantages that the tooth spaces are additionally arranged at the protruded ridges of the six-ridge serrated dynamic variable-gap internal mixer rotor, accordingly, peripheral flowing of rubber materials can be changed, and the six-ridge serrated dynamic variable-gap internal mixer rotor is favorable for distributing and dispersing various fillers and compounding ingredients; the quantities and the distribution density of the tooth spaces are increased along with increase of the peripheral flowing speeds of the rubber materials, accordingly, effects of masticating the lump-shaped rubber materials among the ridges can be enhanced, the rubber materials can flow in internal mixing chambers chaotically, and the rubber mastication quality and the rubber mastication efficiency can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

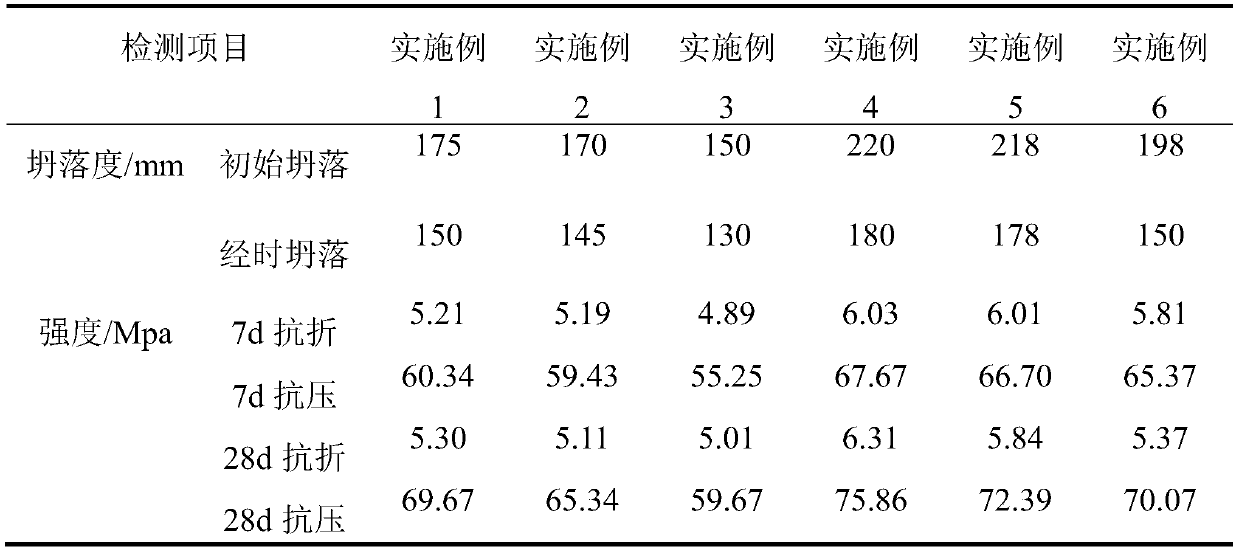

Anti-mud additive suitable for machine-made sand concrete and compounding method thereof

The invention relates to an anti-mud additive suitable for machine-made sand concrete and a compounding method thereof. The anti-mud additive comprises the following components in parts by weight: 30-50 parts of a lignosulfonate water reducing agent, 20-35 parts of a viscosity reduction type polycarboxylic acid water reducing agent, 0.2-0.25 part of a defoaming agent and 20-45 parts of water. Thecompounding method specifically comprises the following steps: mixing and compounding the mud-resistant admixture and the machine-made sand concrete, wherein the performance of the machine-made sand concrete can be changed by changing the adding sequence of the lignosulfonate water reducing agent. Compared with the prior art, the anti-mud additive can be used for improving the mud resistance of the machine-made sand concrete, and the cohesiveness and compressive strength of the machine-made sand concrete can be remarkably improved.

Owner:TONGJI UNIV

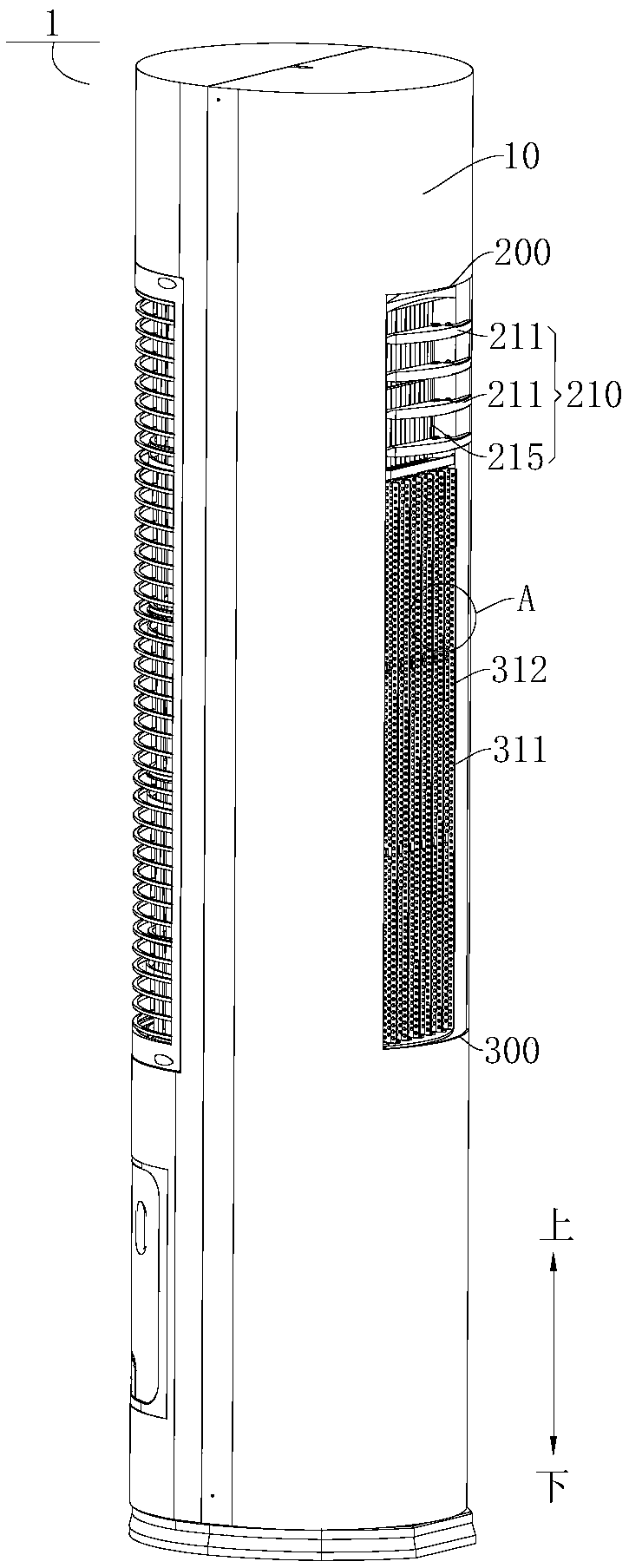

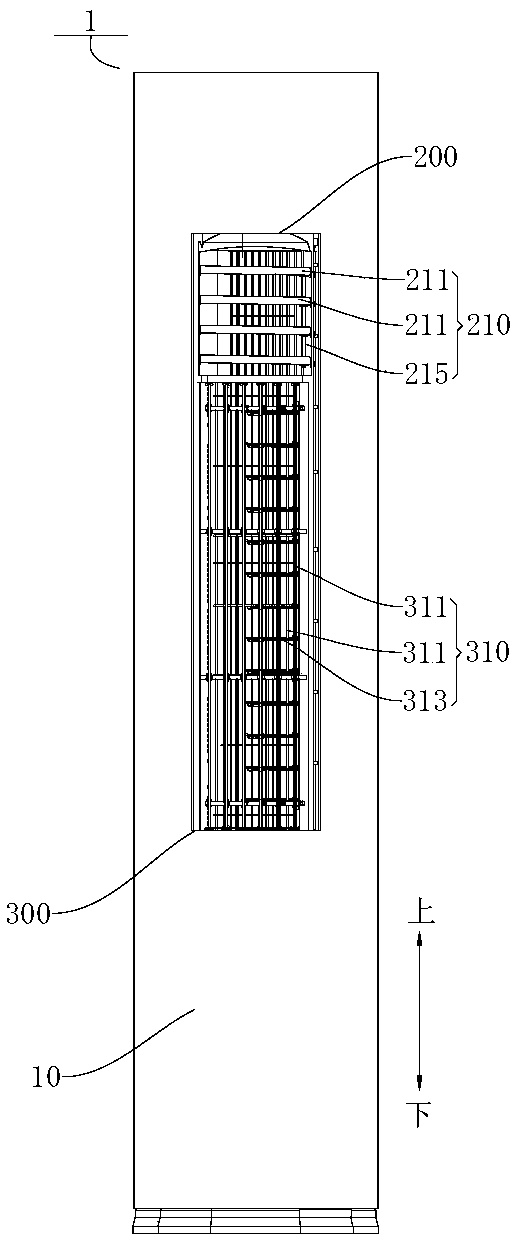

Air conditioner

PendingCN109405077AAdjustable temperatureFull liquidityLighting and heating apparatusAir conditioning systemsIndoor airComfort levels

The invention discloses an air conditioner. The air conditioner comprises a shell body, the shell body is provided with a first air supply assembly and a second air supply assembly, the farthest air supply distance of the first air supply assembly is larger than the farthest air supply distance of the second air supply assembly; the first air supply assembly comprises a first air outlet, and the second air supply assembly comprises a second air outlet. According to the air conditioner, the first air supply assembly and the second air supply assembly are arranged on the shell body of the air conditioner, the first air supply assembly and the second air supply assembly can achieve air supply flow with different air supply distances, the two air supply flows can form an air outlet effect of surrounding air in a room, so that indoor air flow can flow and transfer heat completely, the temperature of different areas in the room can be quickly adjusted, and then the comfort level of use of auser can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

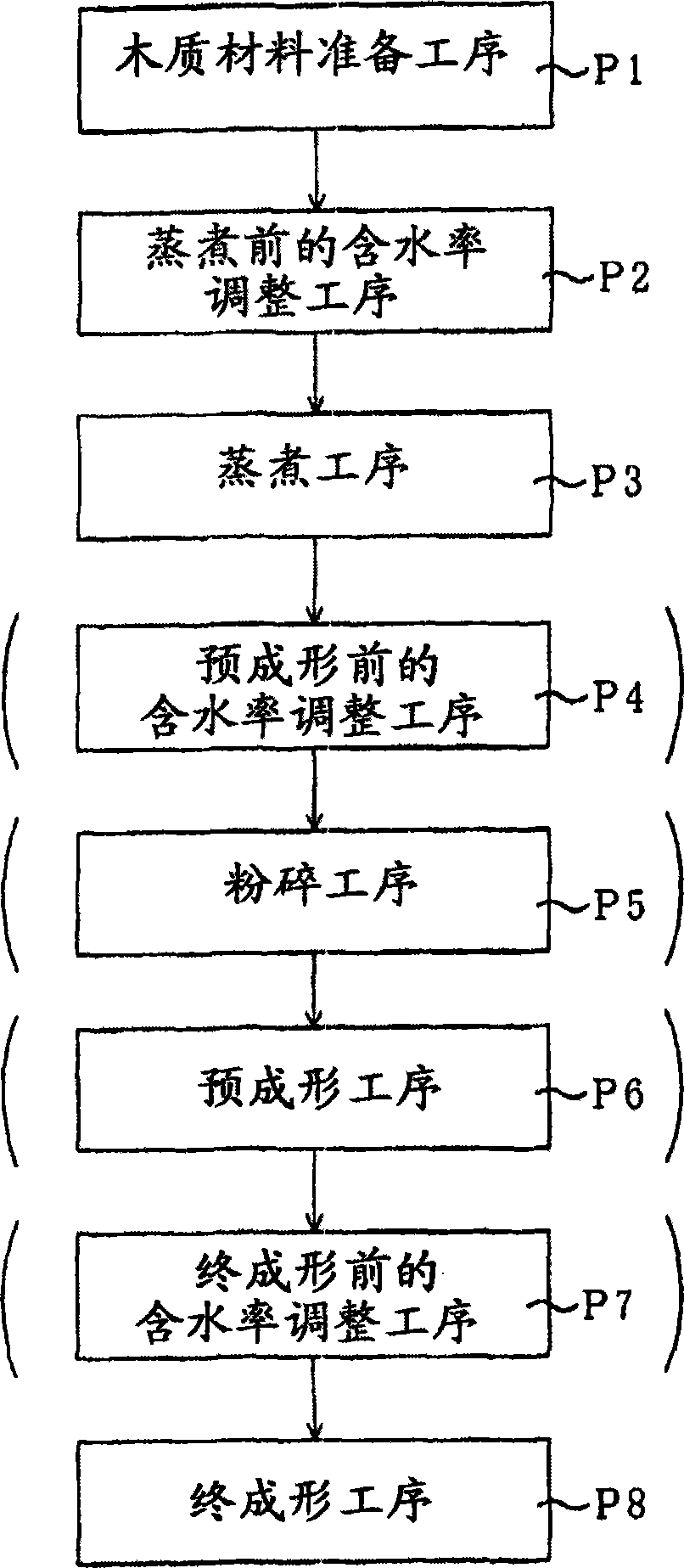

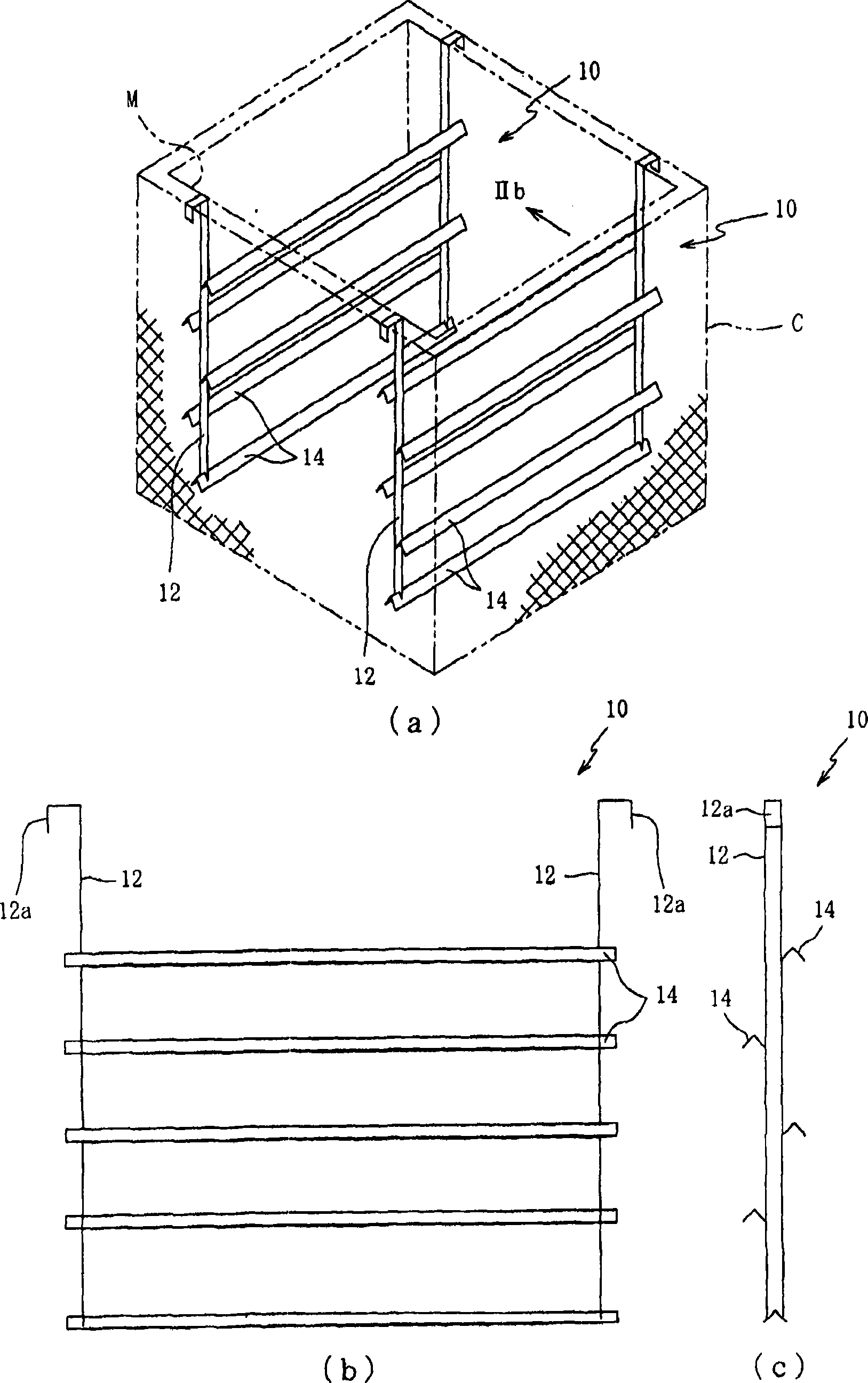

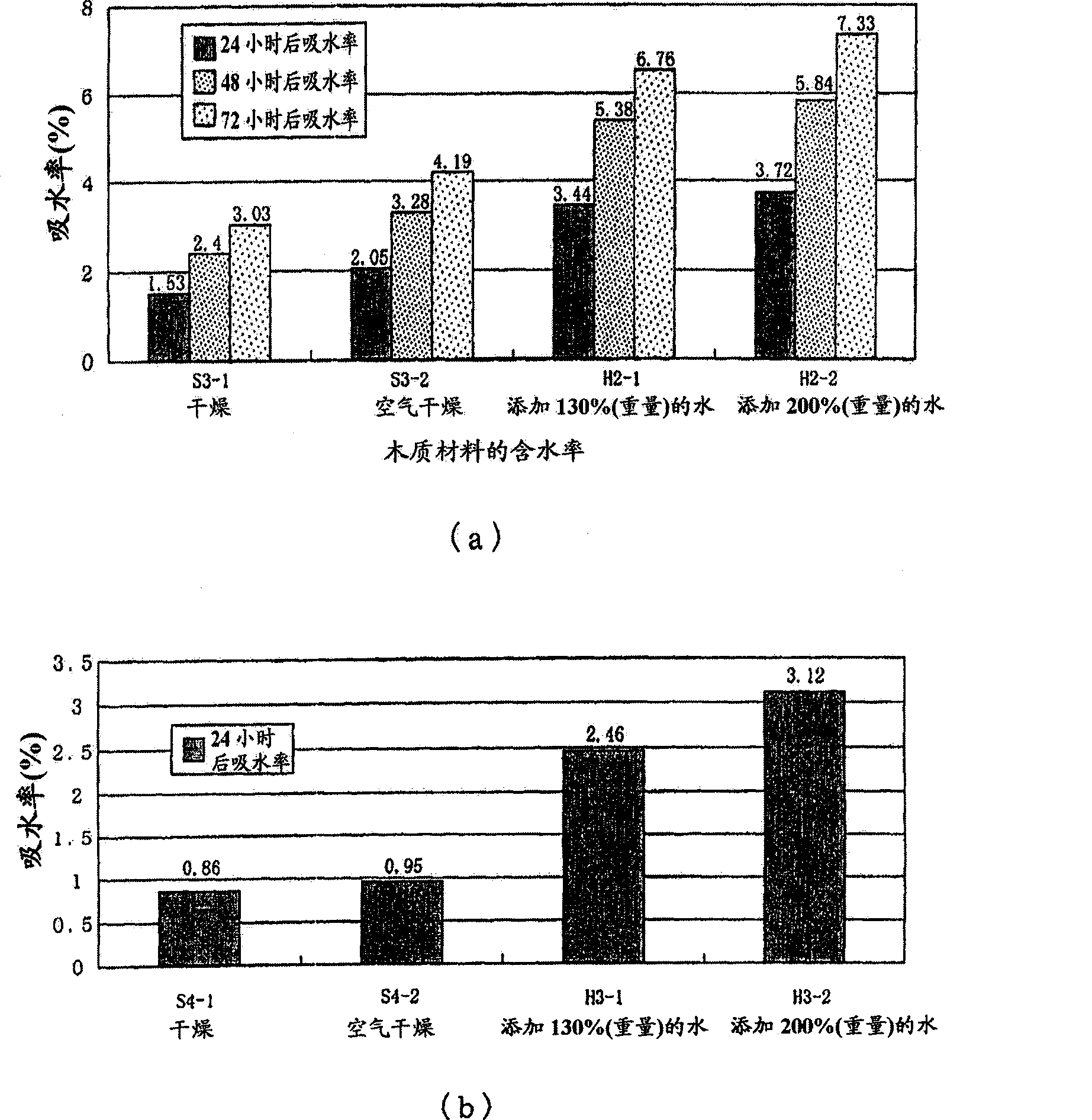

Method for producing xylon molded body and xylon molded body

InactiveCN101428431AShorten the timeLow thermal conductivityWood compressionWood dampingFormic acidMoisture

The invention relates to a woody material resinification, especially to a method for manufacturing a woody formed article and the woody formed article which is characterized by a reduced odor and a low water absorption ratio of a woody material resinification topic. The invention relates to the method for manufacturing the woody formed article which shows an adhesivity or a thermal flow property in the woody article and the woody formed article. After the moisture percentage of the woody material is regulated, the cooking treatment to a woody tissue by contacting a heated aqueous vapor can reduce the water absorption ratio and the odor from a formic acid or an acetic acid to minimum.

Owner:中日精工株式会社

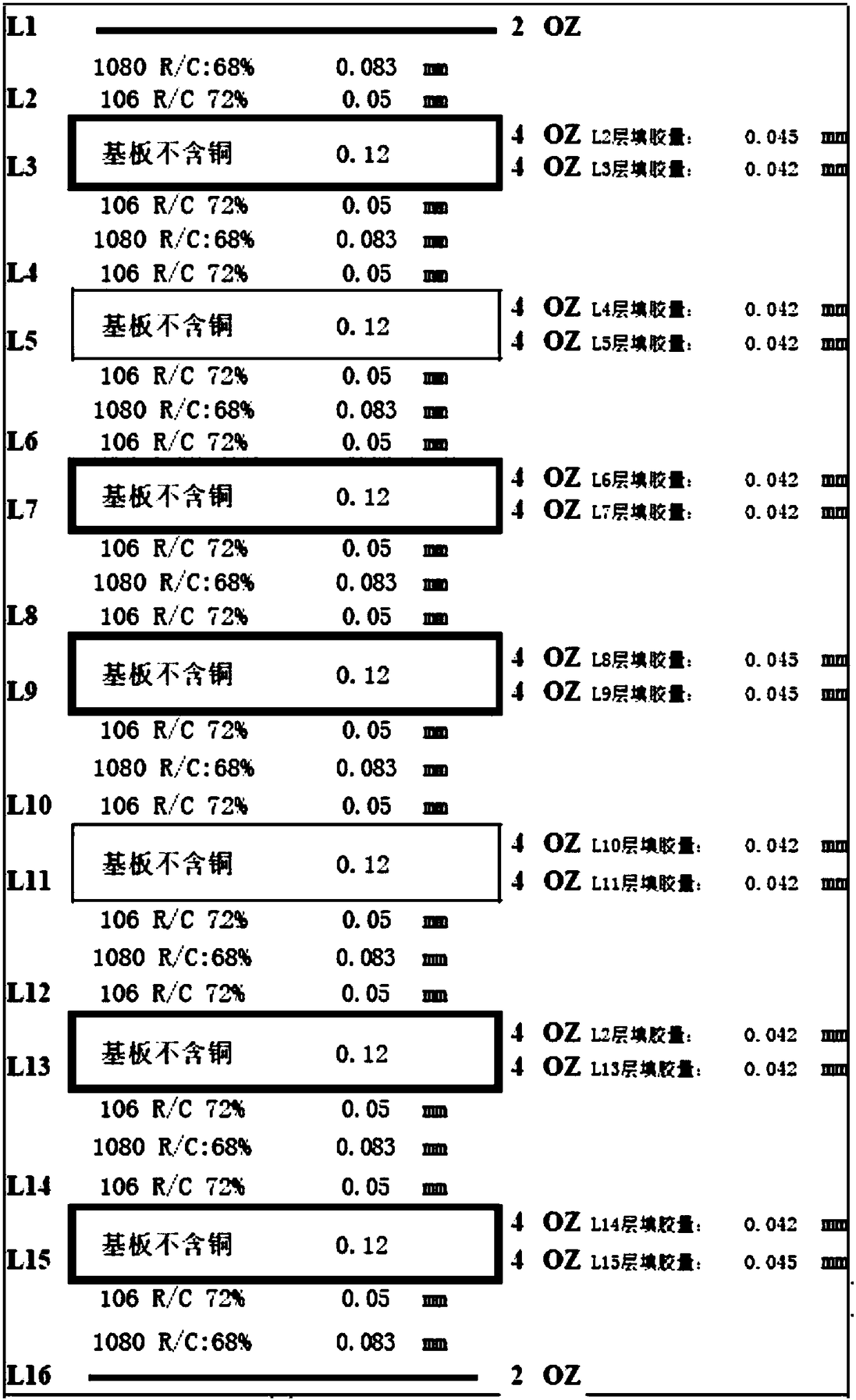

High-multilayer circuit board and manufacturing method thereof

ActiveCN108323000AImprove the amount of glueImprove insulation and heat resistancePrinted circuit aspectsCircuit susbtrate materialsComposite structureEngineering

The invention provides a high-multilayer circuit board and a manufacturing method thereof, and belongs to the technical field of a circuit board. In the scheme, 106 prepregs and 1080 prepregs are utilized to realize interlayer prepreg combined design, and the high-multilayer circuit board formed like such has a special laminated composite structure with high resin content, thereby improving interlayer glue filling amount, enabling the resin to be able to fully flow and cured, improving heat resistance and insulation of the high-multilayer circuit board and effectively solving the problems of interlayer mismatch (board slip), delamination, resin cavity and bubble residual and the like in the laminating process.

Owner:江西景旺精密电路有限公司

A high reflectivity photovoltaic module encapsulation adhesive film and its application

ActiveCN104497899BImproves UV resistanceIncrease usageNon-macromolecular adhesive additivesFilm/foil adhesivesPhysical chemistryHigh reflectivity

The invention discloses a high-reflectivity photovoltaic component encapsulating adhesive film. A high-reflectivity photovoltaic module with a surface pre-crosslinked structure is obtained by pre-mixing transparent resin, high-reflection additives and other functional additives, melt-extruding, casting into a film, and performing surface pre-crosslinking treatment. Packaging film. By adding high-reflective additives, the UV resistance of the adhesive film can be improved, and at the same time, the utilization rate of sunlight by the module can be increased, so as to improve the service life of the module and the photoelectric conversion efficiency; at the same time, the surface pre-crosslinked structure can effectively prevent photovoltaic The overflow of the high-reflection layer adhesive film during the lamination process of the module effectively improves the appearance of the module and is universal to different lamination processes.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

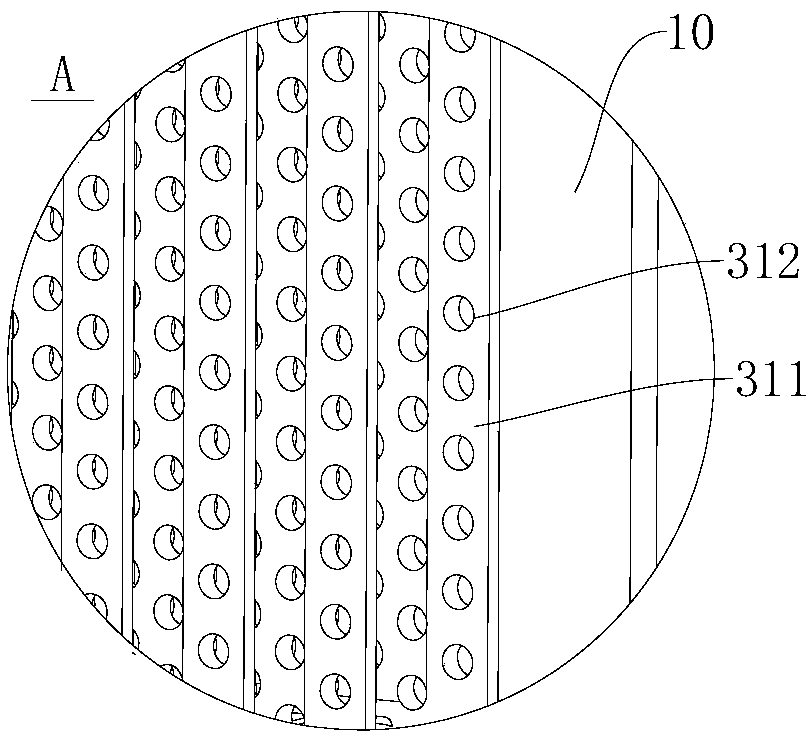

Method for reducing axial conduction of cool storage material of heat regenerator of regenerative cryo refrigerator

InactiveCN101762119AThe heat exchange effect is sufficientFull liquiditySuperheatersHeat resistanceCool storage

The invention relates to a method for reducing axial conduction of a cool storage material of a heat regenerator of a regenerative cryo refrigerator. When filling the cool storage material of the heat regenerator of the refrigerator, heat barriers made of the heat-insulating material are placed in a barrel of the heat regenerator at certain distance intervals, the cool storage material of the heat regenerator is separated into several thermally-unconnected sections, the middle part of each heat barrier is provided with small holes distributed evenly and densely, which has no influence on the reciprocal flow of the working medium in the heat regenerator, and the local part of each heat barrier is provided with small holes arranged regularly, which facilitates the heat exchange of the working medium and the cool storage material. The heat resistance of the heat barrier is more than 40 times of the heat resistance of the cool storage material of the heat regenerator having the same thickness, which has little influence on the heat efficiency of the heat regenerator. The invention reduces the axial conduction of the heat regenerator of the refrigerator effectively, ensures a directional and unblocked flow path of the working medium gas without any gas hold-up, and increases the effective refrigerating output and efficiency of the refrigerator. The method can be applied to a variety of regenerative cryo refrigerators.

Owner:WUXI HONGRUI AEROSPACE MECHANICAL & ELECTRICAL EQUIP CO LTD

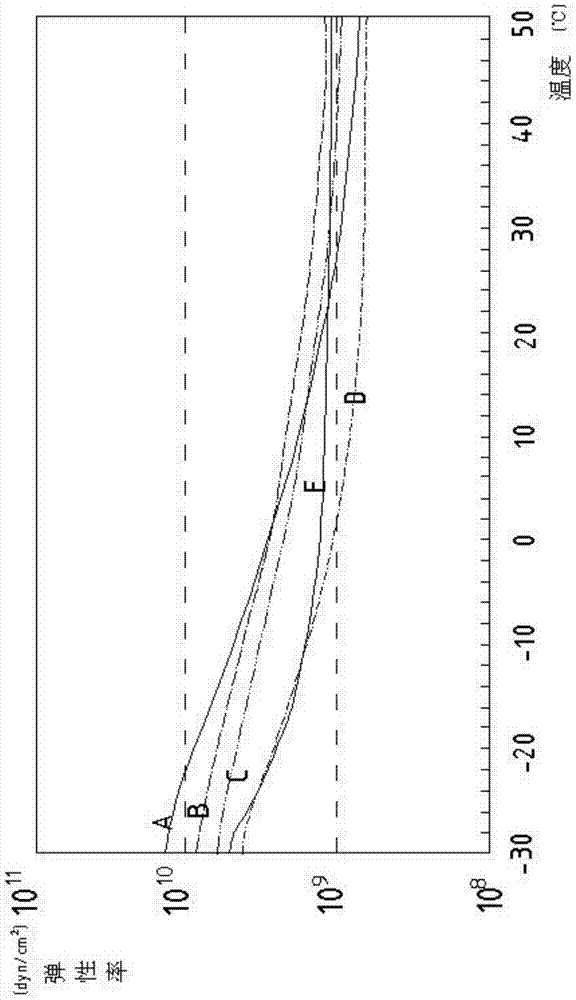

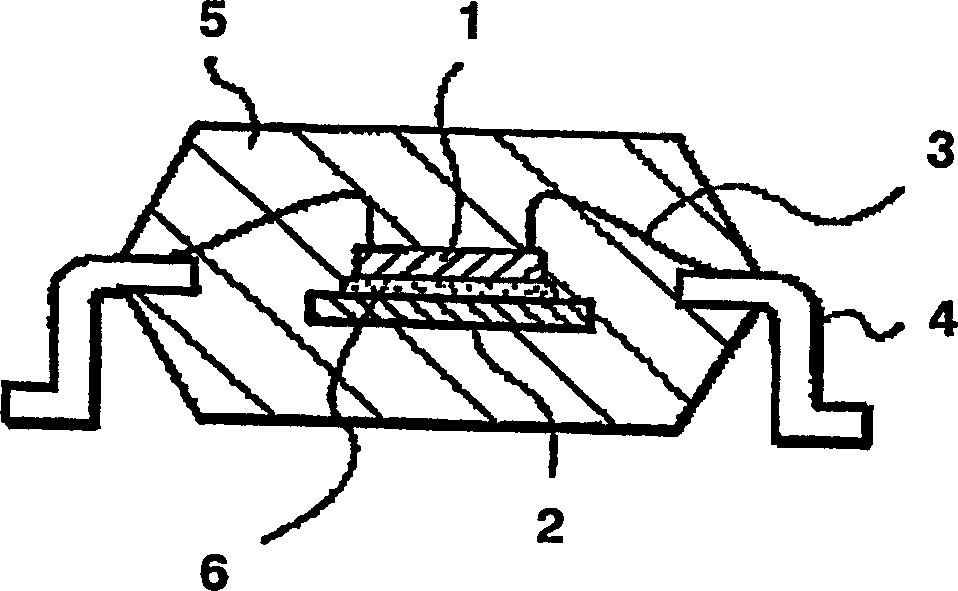

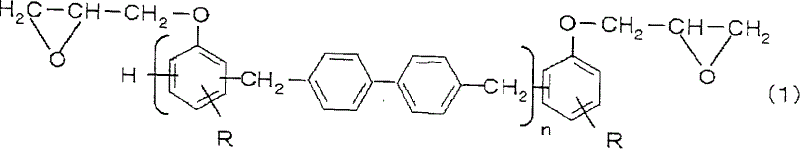

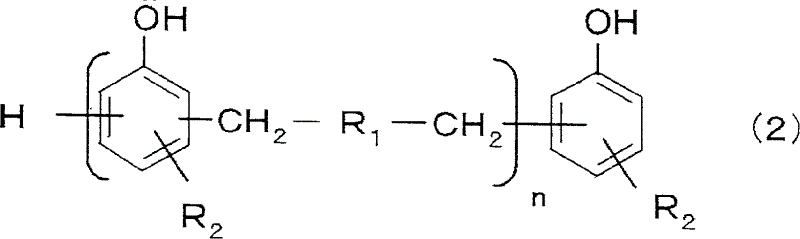

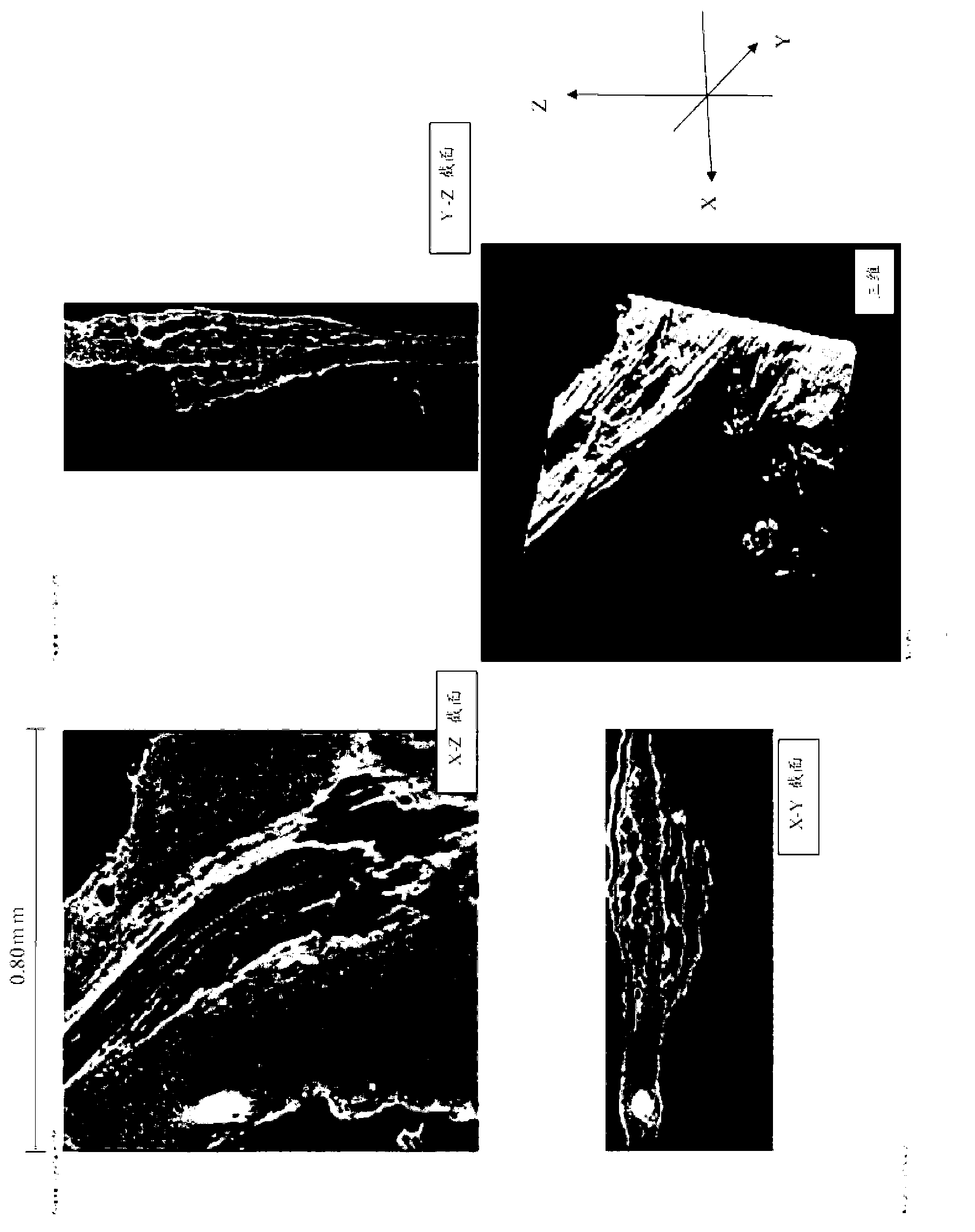

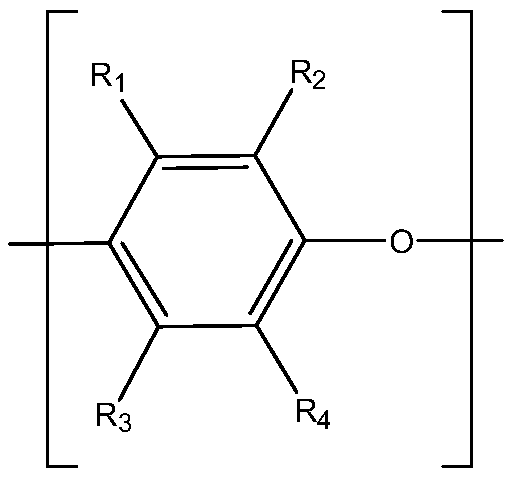

Resin composition for encapsulating semiconductor chip and semiconductor device therewith

ActiveCN1761692AFully curableFull liquiditySemiconductor/solid-state device detailsSolid-state devicesEpoxySemiconductor chip

An epoxy resin composition for encapsulating a semiconductor chip, which has good flowability without deterioration in curability. Specifically, a resin composition is disclosed for encapsulating a semiconductor chip containing a phenol aralkyl type epoxy resin containing biphenylene structure(A), a phenol aralkyl type resin containing phenylene or biphenylene structure (B), an inorganic filler (C) and a curing accelerator (D) as main components, further containing a silane coupling agent (E) in 0.01 wt % to 1 wt % both inclusive of the total amount of the epoxy resin composition and a Compound (F) containing two hydroxyl groups combined with each of adjacent carbon atoms on a naphthalene ring in more than or equal to 0.01 wt % of the total amount of the epoxy resin composition.

Owner:SUMITOMO BAKELITE CO LTD

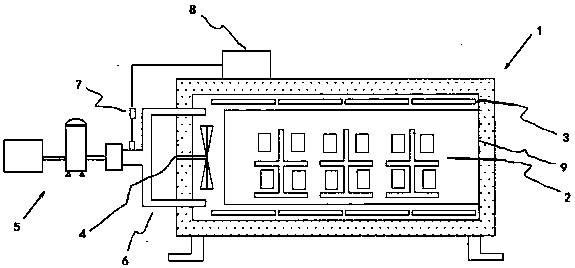

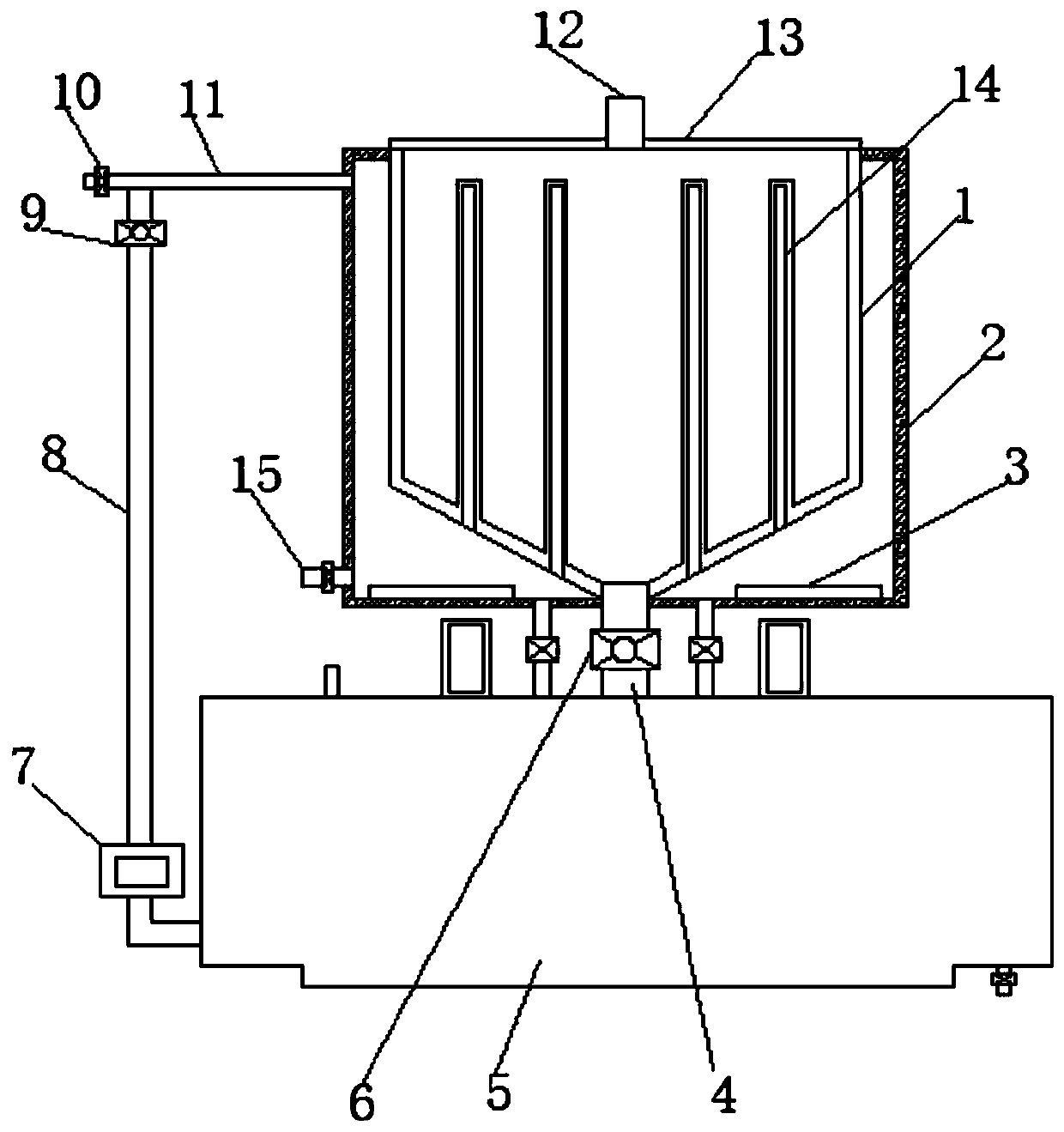

Box-type annealing furnace

The invention provides a box-type annealing furnace, which comprises a hollow heat insulation layer, a bracket and a heating wire which are installed in the hollow part of the heat insulation layer, and a circulation fan installed on one side of the heat insulation layer, wherein a gas transmission component is installed on one side of the heat insulation layer. The box-type annealing furnace hashigh annealing efficiency, good thermal insulation performance and strong air circulation performance, the temperature and humidity inside the annealing furnace can be monitored in real time and effectively controlled so as to solve the problems such as incomplete annealing and excessive moisture inside the furnace, can further reduce the corrosion and loss caused to workpieces and improve the quality of products, and saves the cost of use.

Owner:本溪鹤腾科技发展有限公司

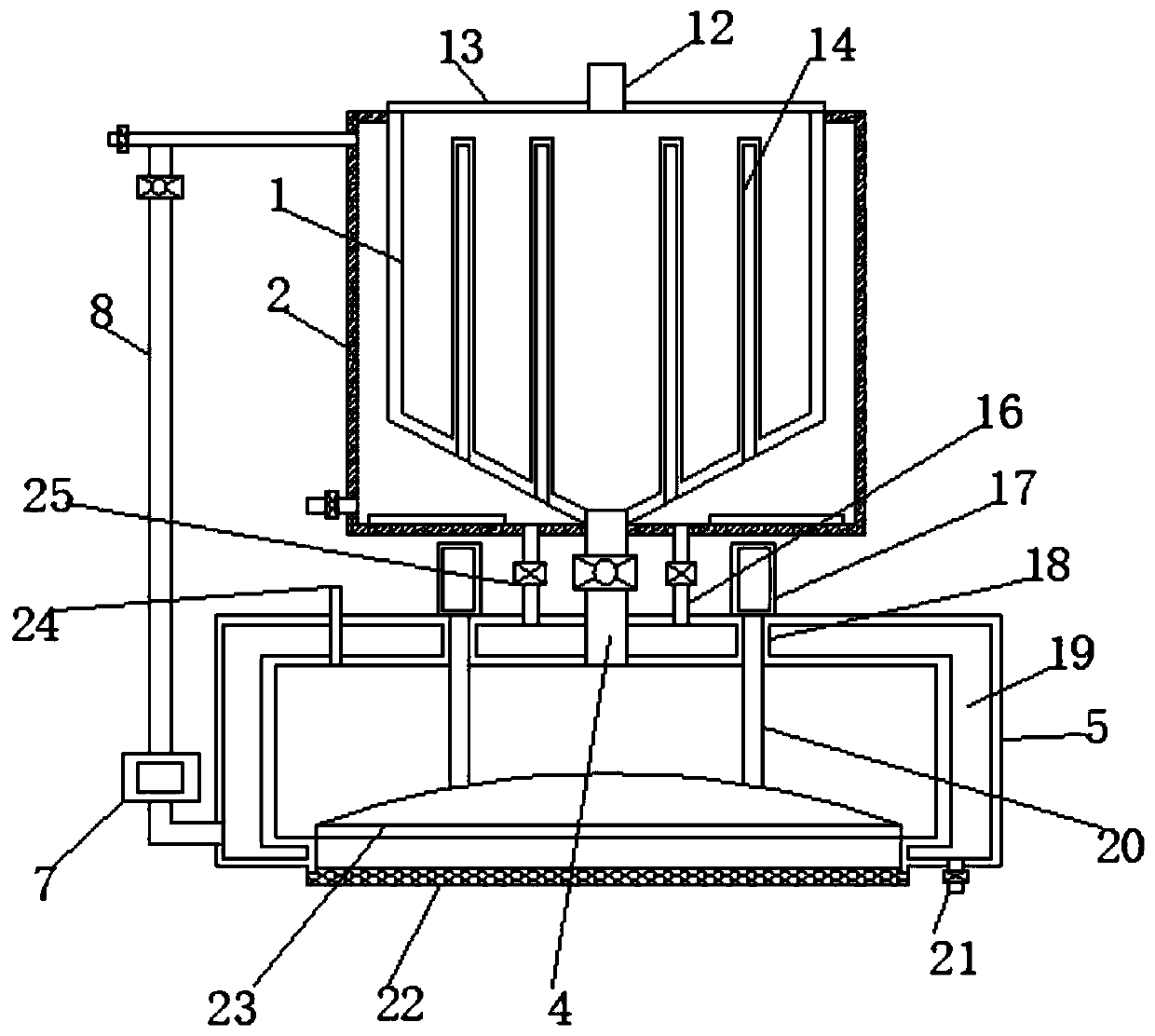

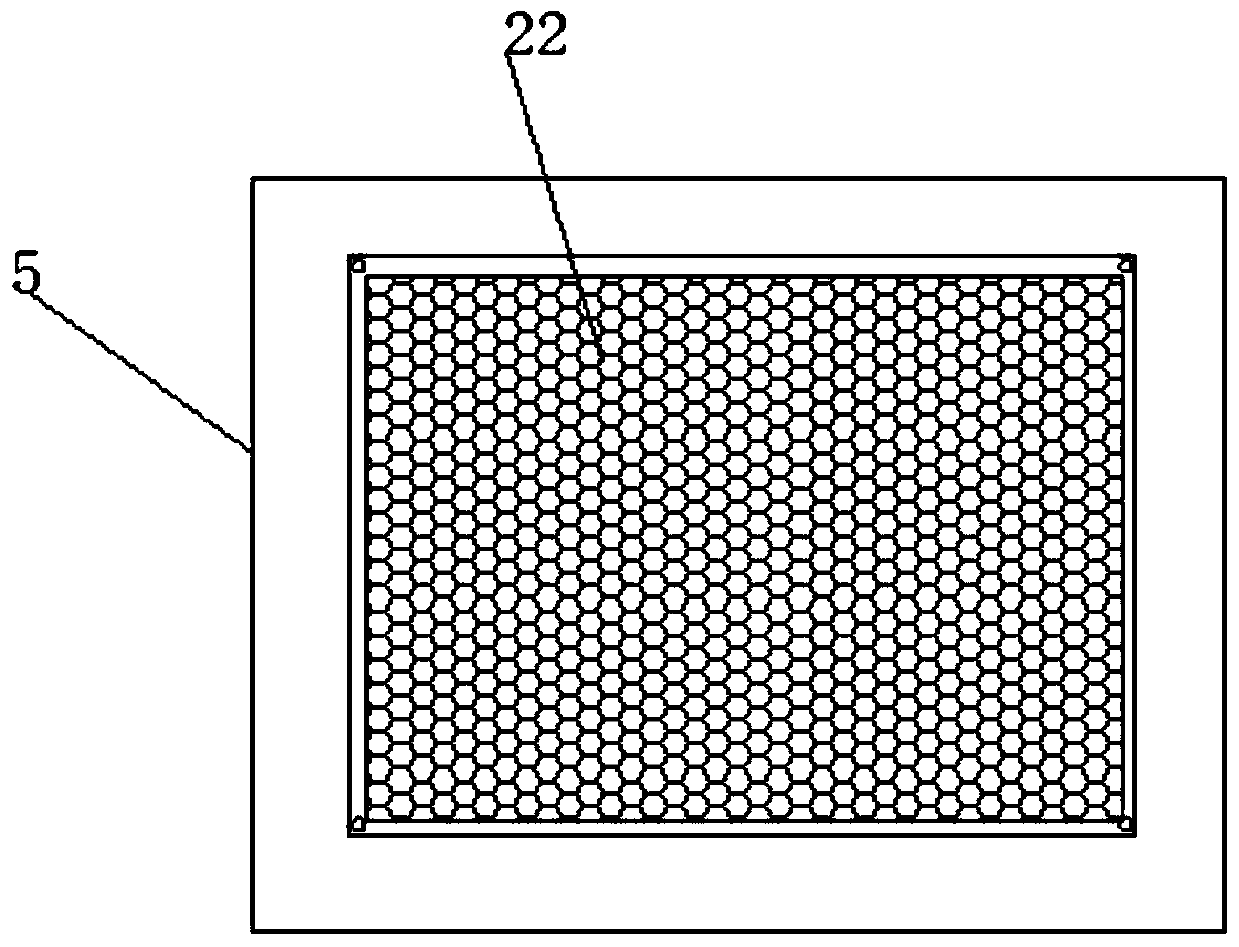

Corrugated carton gluing device

InactiveCN111001533AFully heatedIncrease the heating areaLiquid surface applicatorsSpraying apparatusCartonEngineering

The invention discloses a corrugated carton gluing device. The device comprises an inner charging barrel; the outer portion of the inner charging barrel is fixedly wrapped with an outer heat preservation cover; the middle position of the bottom of the inner charging barrel is fixedly communicated with a conveying pipe; hot water electric heating pipes are fixedly mounted at the left part and rightpart of the bottom of the outer heat preservation cover; a water incoming pipe and a first blow-off pipe are fixedly communicated with the upper part and lower part of the left side of the outer heatpreservation cover; and the bottom of the inner cavity of the inner charging barrel is vertically, fixedly and hermetically communicated with a plurality of stainless steel pipes which are distributed in an equal-pipe-diameter mode;. According to the device of the invention, the bottom of the inner cavity of the inner charging barrel is vertically, fixedly and hermetically communicated with the plurality of stainless steel pipes distributed in an equal-pipe-diameter mode; the outer heat preservation cover, the hot water electric heating pipes and the multiple stainless steel pipes are adopted, so that glue in the inner charging barrel is fully heated, and therefore, sufficient fluidity is guaranteed; water temperature is controlled to be about 60 DEG C; after the multiple stainless steelpipes are filled with the hot water, the heating area of the glue in the inner charging barrel is increased, and therefore, the heating effect of the glue is guaranteed, and the glue can better flow naturally.

Owner:津市中南新鲁包装印刷有限公司

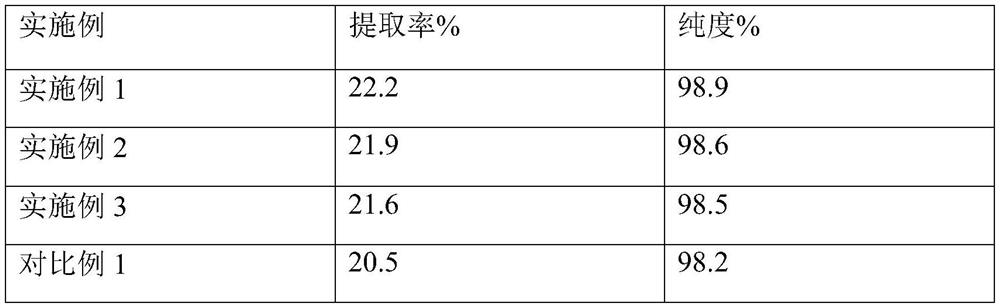

Extraction method and application of tremella polysaccharide

The invention relates to the technical field of traditional Chinese medicine, in particular to an extraction method and application of tremella polysaccharide. The method comprises the following steps: (1) soaking tremella with a solvent; adding water, pulping, centrifuging, and taking supernate 1; (2) adding inorganic salt into the supernate 1, stirring, centrifuging, and taking supernate 2; (3) adding the supernate 2 into an ethanol-acetone aqueous solution, standing, and sieving with a 200-300-mesh sieve to obtain a polysaccharide precipitate; and (4) redissolving the polysaccharide precipitate, heating to remove the organic solvent, and freeze-drying in vacuum to obtain the polysaccharide. The extraction method is high in tremella polysaccharide extraction rate, high in purity, short in extraction time and beneficial to industrial large-scale production.

Owner:金唐(福建)健康科技有限公司

Glass for tailless sealing of stainless steel vacuum insulation container and preparation method for glass

The invention discloses glass for tailless sealing of a stainless steel vacuum insulation container and a preparation method for the glass. The preparation method comprises the following steps: mixing raw materials including 75-85% of PbO, 5-15% of B2O3, 0-5% of ZnO, 1-5% of SiO2, 0.5-5% of Al2O3 and 0-5% of CuO in a mixer; melting in a platinum pot at 1,100 DEG C, rolling into sheets by a rolling machine, performing ball-milling by a corundum pot, and screening by a 200-mesh sieve; adding 0.1-1.0% of an organic granulating agent-polyoxyethylene for granulating, forming by a pressing machine, and sintering in a box-type high-temperature resistance furnace to form a glass blank. The glass is free of air bubbles, unlikely to fall off and good in acid resistance during sealing.

Owner:贵州省轻工业科学研究所

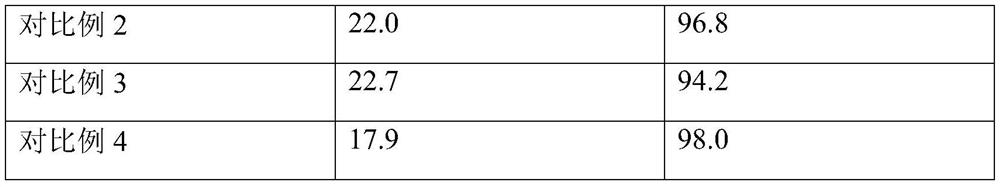

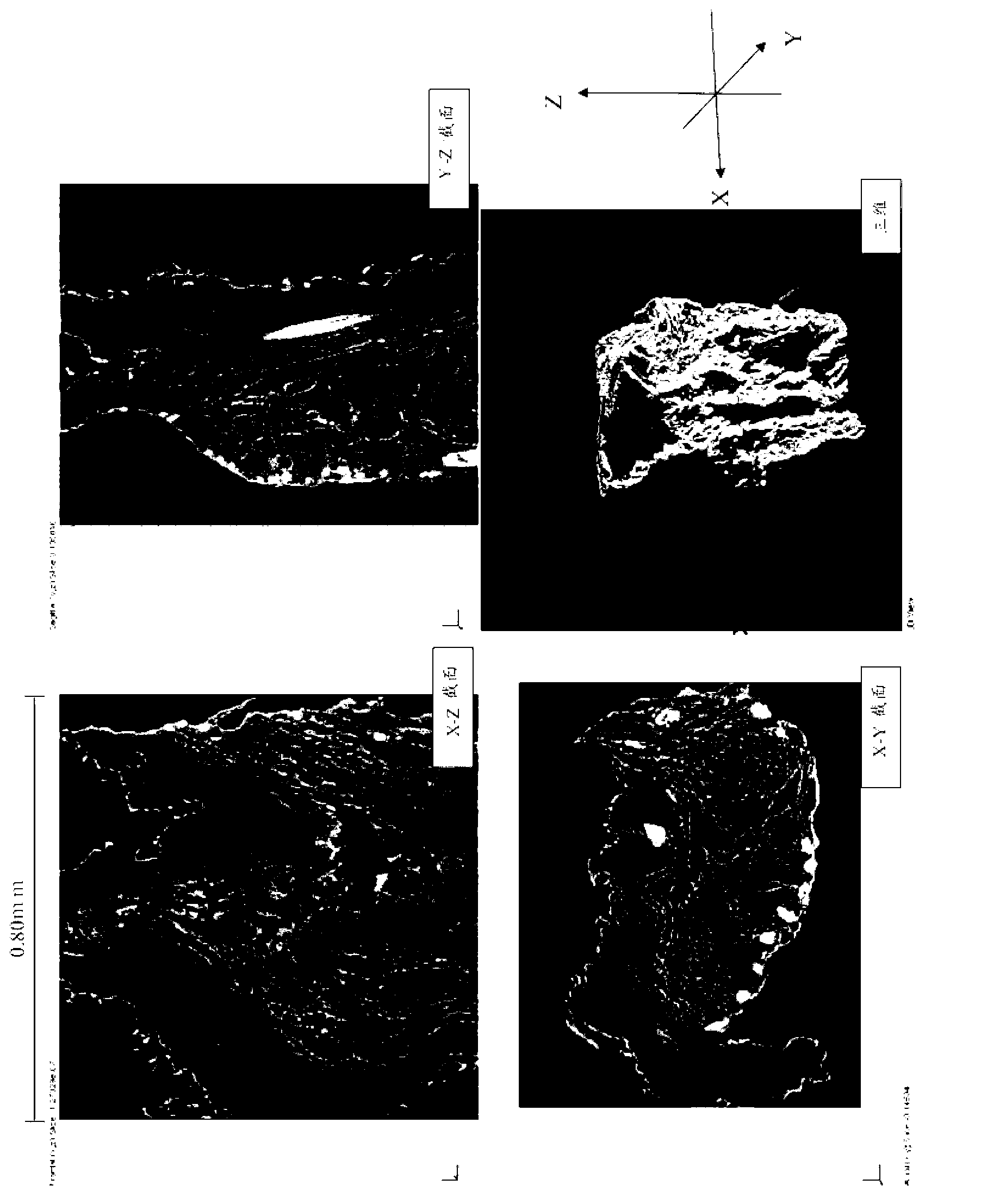

Method for manufacturing aloe powder

InactiveCN102711519AEfficient productionSmooth tasteCosmetic preparationsToilet preparationsEngineeringExtraction methods

Owner:MORINAGA MILK IND CO LTD

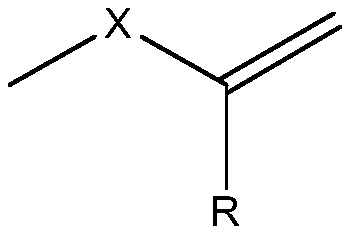

Adhesion sheet and preparation method thereof, and copper clad laminate using adhesion sheet

PendingCN110408332AHigh viscosityImprove liquidityNon-macromolecular adhesive additivesSynthetic resin layered productsDielectric lossHeat resistance

The present invention provides an adhesion sheet, which comprises, by mass, 25-65 parts of a matrix resin, 20-60 parts of a fiber reinforcement body, 10-40 parts of a filler, and 0-15 parts of a flameretardant, wherein the matrix resin comprises, by mass, 20-70 parts of modified polyphenylene ether, 30-70 parts of a polydiolefin type polymer, and 0-5 parts of an initiator. The present invention further provides a preparation method of the adhesion sheet, and a copper clad laminate using the adhesion sheet. According to the present invention, the heat resistance of the adhesion sheet and the copper clad laminate can reach more than 200 DEG C, such that the problems of defects, delamination and the like generated in the processing of the multilayer copper clad laminate due to insufficient heat resistance of the adhesion sheet can be solved; the fluidity of the adhesion sheet is maintained at 5-15%, such that the sufficient flowing and filling of the resin in the preparation process of the multi-layer copper clad laminate can be ensured, and the quality and the batch stability of the product can be ensured; and the cured adhesion sheet has low dielectric loss so as to meet the needsof the future high frequency field.

Owner:AAC TECH NANJING

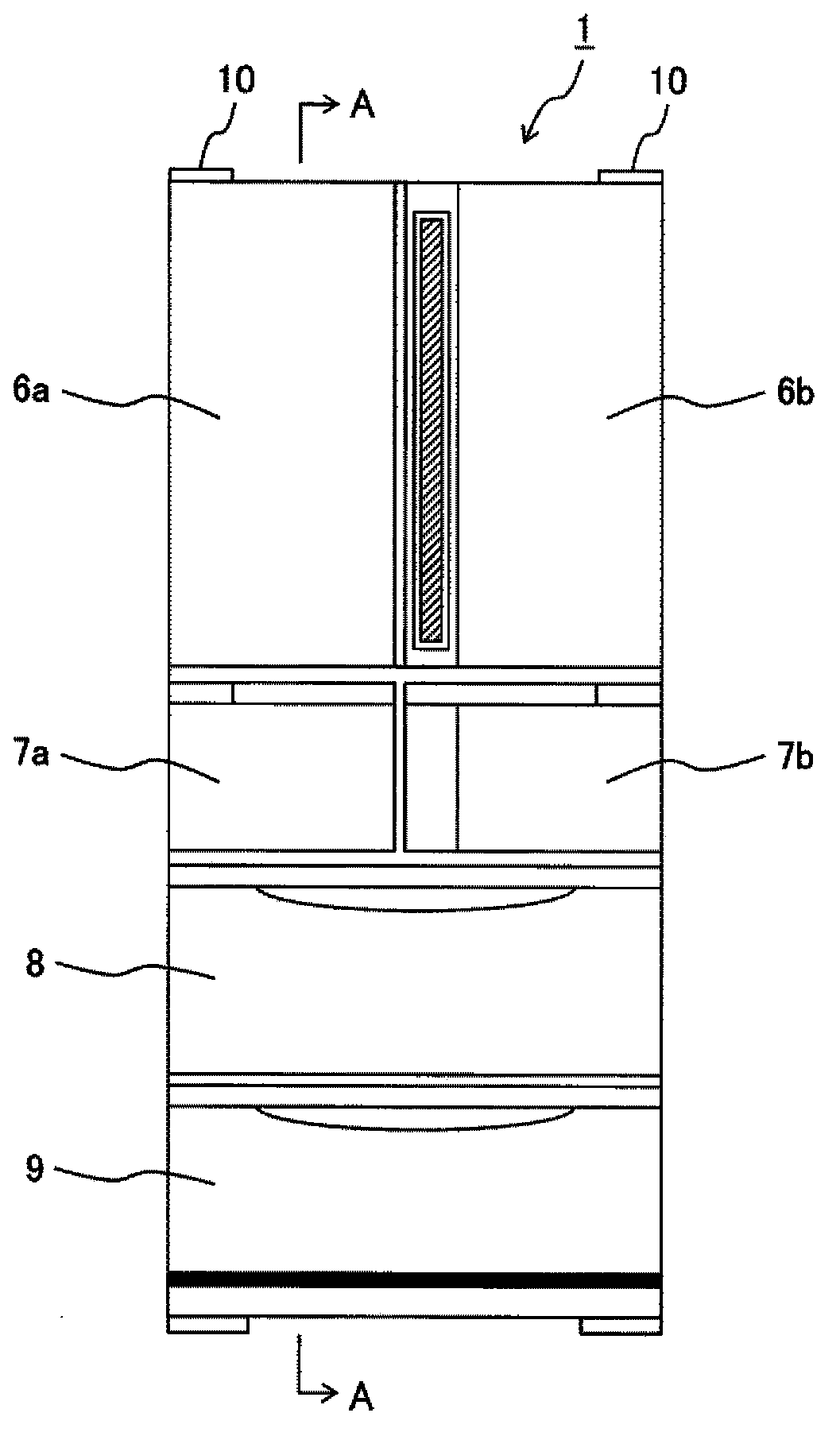

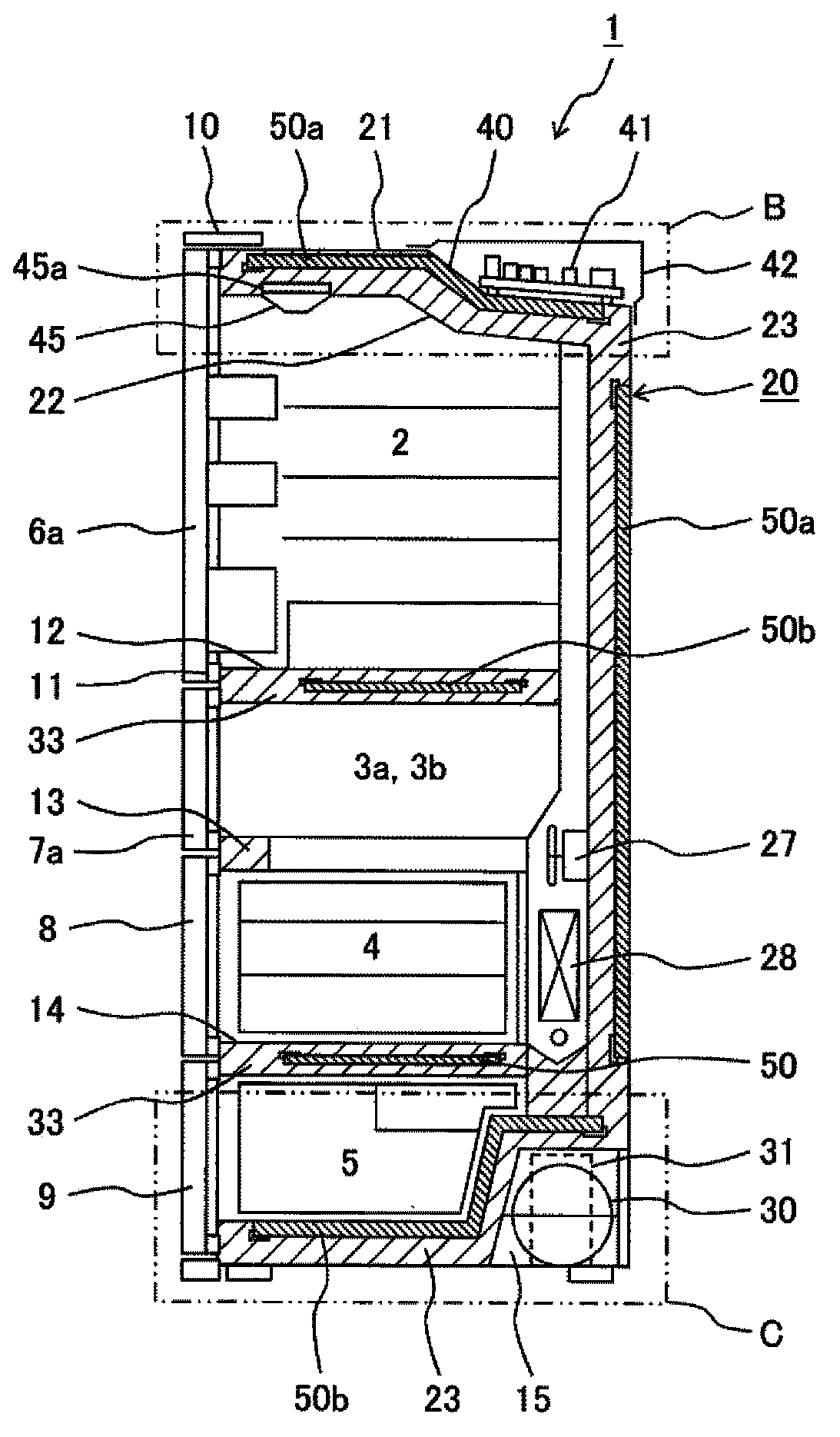

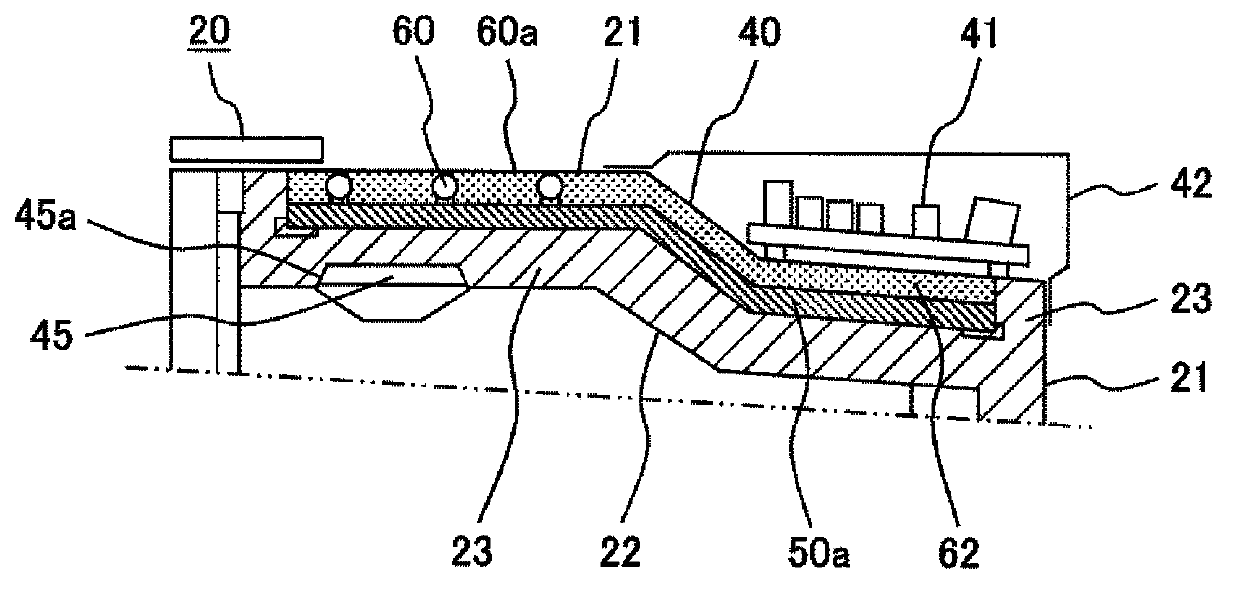

Hard polyurethane foam and premixed dolichol for manufacturing the same

The present invention provides a hard polyurethane foam and a premixed dolichol for manufacturing the same. The invention aims to improve mobility of carbamate raw material (premixed dolichol) and adjust the reactivity. The hard polyurethane foam is sufficiently filled into a heat insulation door of a refrigerator and narrow parts in a box, thereby improving heat insulation performance of the heat insulation door and the box of the refrigerator, and reducing shrinkage of the formed carbamate foam under low temperature. The method for settling the task of the invention is providing the hard polyurethane foam which utilizes the premixed dilichol and polymethylene diisocyanate, wherein the premixed dilichol comprises dilichol, catalyst, water, cyclopentane and foam stabilizer. 30-80% by weight of the dolichol is a behnyl alcohol with 4-8 active hydrogen groups and / or a polyol compound with added oxyalkylene on polyamine. When the absorption spectrum peak intensity of 1700-1720cm<-1> infrared ray of the hard polyurethane foam is represented by A1, and the absorption spectrum peak intensity of 1590-1610cm<-1> infrared ray is represented by A2, a ratio A1 / A2 is 1.7-2.0.

Owner:HITACHI APPLIANCES INC

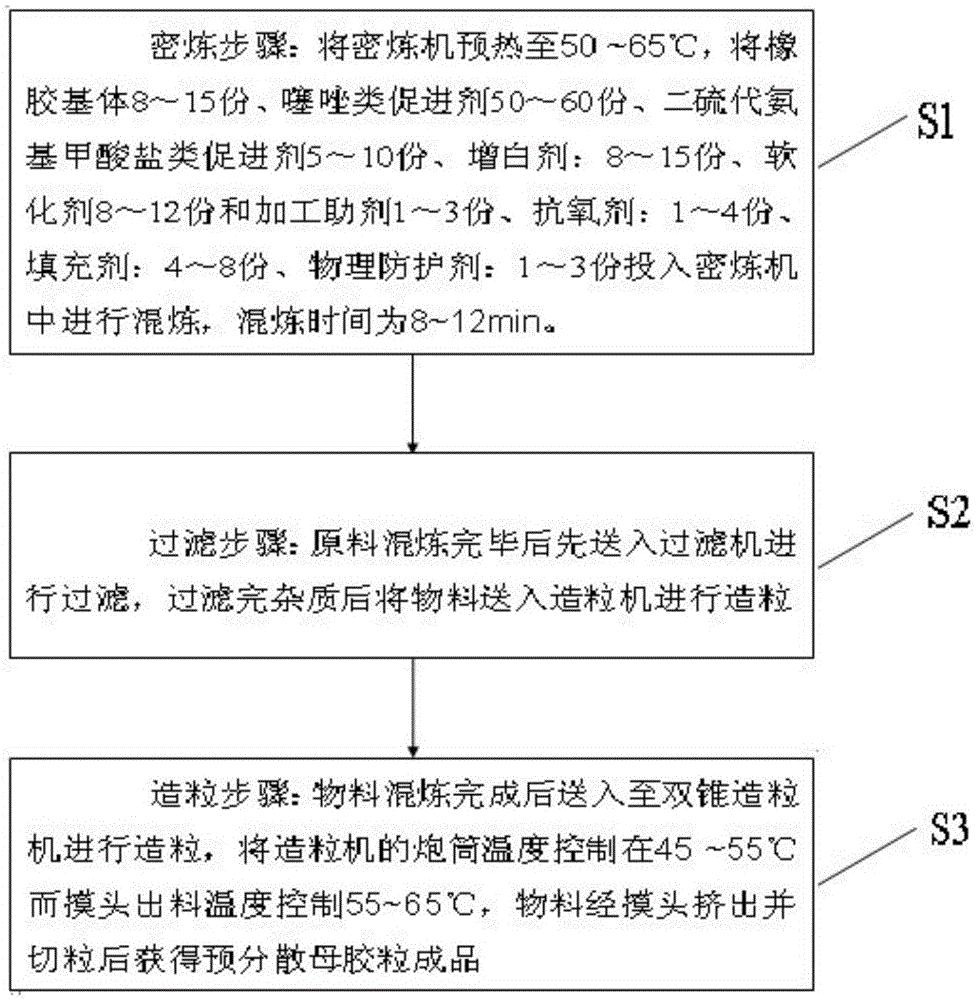

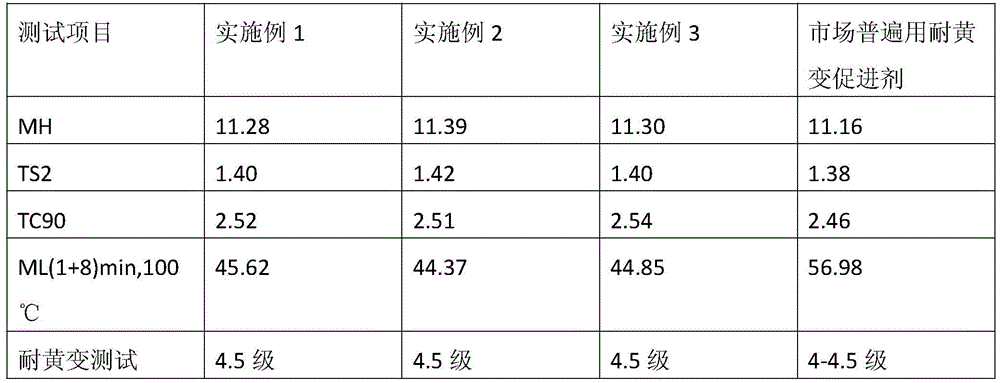

Anti-yellowing comprehensive accelerator pre-dispersion rubber masterbatch particles for rubber and preparation method of particles

The invention discloses anti-yellowing comprehensive accelerator pre-dispersion rubber masterbatch particles for rubber. The particles are prepared from, by weight, 8-15 parts of rubber matrix, 50-60 parts of thiazole accelerator, 5-10 parts of dithiocar-bamate accelerator, 8-15 parts of brightening agent, 8-12 parts of softener, 1-3 parts of processing agent, 1-4 parts of antioxidant, 4-8 parts of filler and 1-3 parts of physical protective agent. A preparation method includes the steps of firstly, conducting mixing, wherein certain ratios of thiazole accelerator, dithiocar-bamate accelerator, brightening agent, softener, processing agent, anti-ageing agent, filler and physical protective agent are put in an internal mixer to be mixed for about 30 seconds, rubber matrix is added, the temperature is 50-65 DEG C, and time is 8-12 minutes; secondly, conducting granulating, wherein the materials are sent into a granulator to be granulated after being mixed. The pre-dispersion rubber masterbatch particles have the advantages of being easy to disperse, free of pollution, high in machinability and the like when used for preparing rubber materials, and the anti-yellowing effect of rubber is quite good.

Owner:GUANGDONG DUBA NEW MATERIAL CO LTD

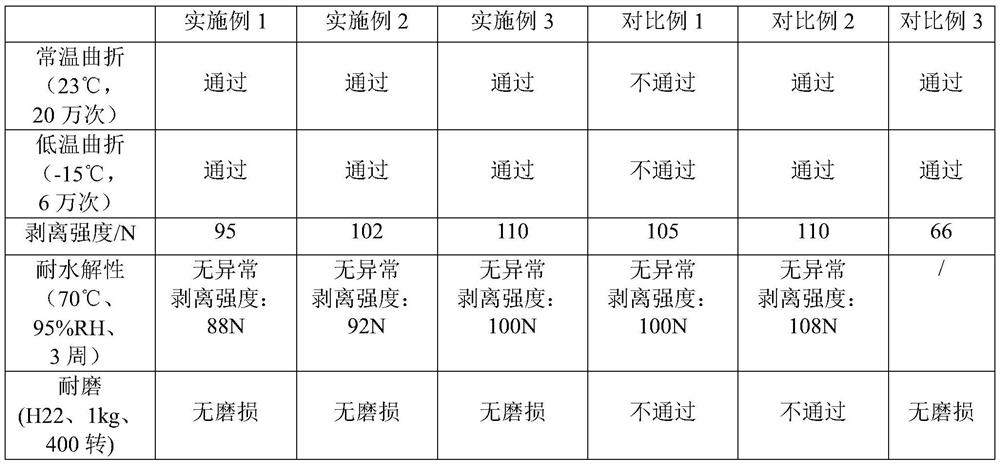

Water-based dry-bonded split leather transfer-film leather and preparation method thereof

PendingCN114108335AHigh peel strengthStable Peel StrengthTextiles and paperPolymer sciencePolyethylene terephthalate

The invention provides water-based dry-sticking split leather transfer-film leather and a preparation method thereof.The preparation method comprises the steps that auxiliaries such as a water-based wetting agent, a curing agent and a thickening agent are added into water-based polyurethane resin, a surface material, an intermediate material and a dry-sticking sticking material of the water-based polyurethane resin are prepared through stirring, a surface layer is firstly scraped on release paper through a dry-method transfer-film technology, then the surface layer is scraped on the release paper through a dry-method transfer-film technology, and the dry-sticking sticking material is scraped on the release paper through a dry-method transfer-film technology; the water-based dry-sticking split leather transfer-film leather is prepared by the following steps of: drying the release paper, scraping a middle layer after drying, scraping a dry-sticking sticking layer after drying, drying to be transparent at high temperature, sticking with split leather under the pressure of 3-5kg, attaching a PET (Polyethylene Terephthalate) film, rolling, curing in a greenhouse, and stripping the release paper and the PET film, thereby obtaining the water-based dry-sticking split leather transfer-film leather. The obtained water-based dry-sticking split leather transfer-film leather can be applied to the field of sneaker leather, is high in peel strength, resistant to bending at normal and low temperatures and resistant to jungle hydrolysis, can improve the additional value of split leather, is comparable to first-layer leather, can effectively and uniformly permeate a dry-sticking layer according to the compaction degrees of different leather blanks, guarantees stable peel strength, and has a good application prospect. The method is suitable for large-scale mass production.

Owner:WANHUA CHEM GRP CO LTD

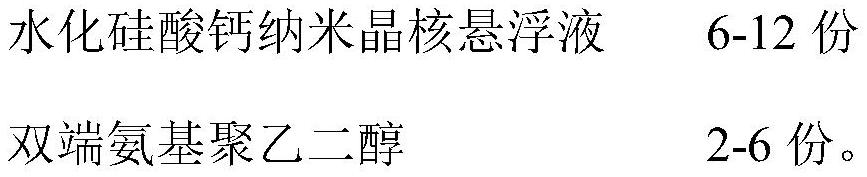

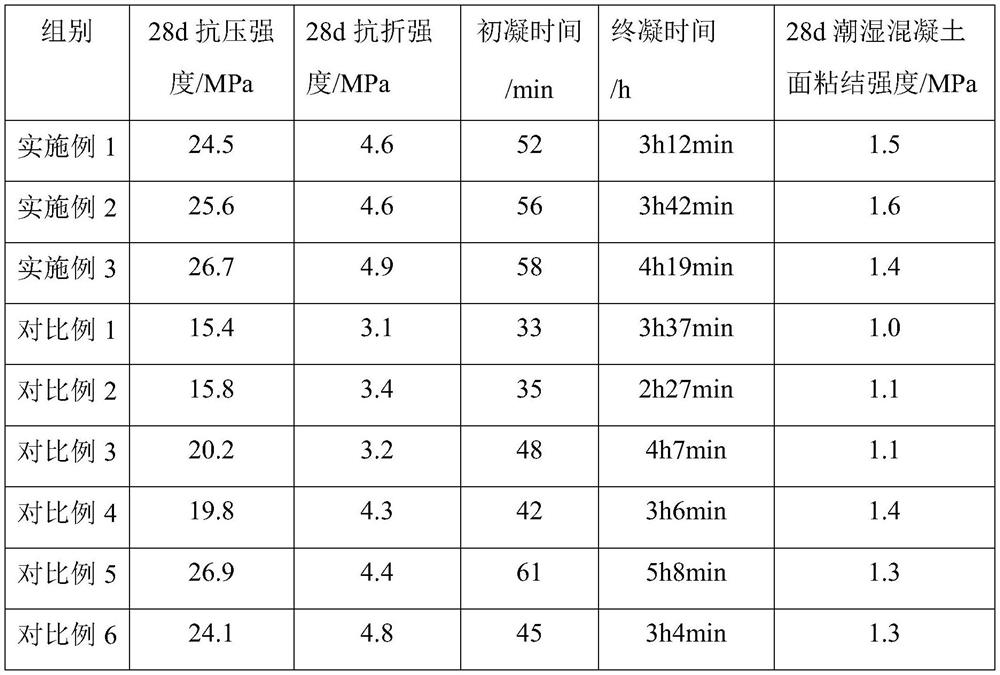

Cement-based capillary crystalline material and preparation method thereof

ActiveCN114507051AIncreased durabilityPromotes hydrationSolid waste managementCrystalline materialsSodium silicate

The invention discloses a cement-based capillary crystalline material and a preparation method thereof. The cement-based capillary crystalline material is prepared from the following raw materials in parts by weight: 40-55 parts of cement, 28-30 parts of quartz sand, 3-8 parts of calcium hydrophosphate, 1-3 parts of sodium silicate, 6-12 parts of hydrated calcium silicate nanocrystal nucleus suspension and 2-6 parts of amino-terminated polyethylene glycol. The waterproof and anti-seepage performance of the concrete structure is improved while the compression resistance and fracture resistance of the concrete are guaranteed.

Owner:GUANGDONG TAISHI IND CO LTD

Casting type elastomeric polyurethane tire manufacturing method

Owner:安徽台创智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com