Method for reducing axial conduction of cool storage material of heat regenerator of regenerative cryo refrigerator

A low-temperature refrigerator and cold storage material technology, applied in refrigerators, superheaters, refrigeration components, etc., can solve the problems of large heat conduction loss, large thermal conductivity, and low thermal conductivity of regenerators, and achieve sufficient heat exchange and flow. Low cost, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. The inner diameter of the regenerator of the regenerative cryogenic refrigerator is Φ5mm and the length is 50mm. According to the total thickness of the thermal barrier is 3% of the total length of the regenerator cylinder, the total thickness of the thermal barrier is 1.5mm , a total of 3 thermal barriers with a thickness of 0.5 mm need to be added, and the cold storage material of the regenerator is divided into 3 parts evenly. The outer diameter is closely matched with the inner hole of the regenerator, and the holes are evenly drilled on the thermal barrier. %,

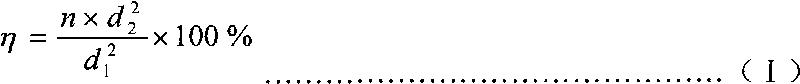

[0028] Calculation formula (I) for the ratio of the hollow area to the cross-sectional area of the thermal barrier:

[0029] η = n × d 2 2 d 1 2 × 100 % - - - ...

Embodiment 2

[0045] Step 1. The inner diameter of the regenerator of the regenerative cryogenic refrigerator is Φ7mm and the length is 55mm. According to the total thickness of the thermal barrier is 3% of the total length of the regenerator cylinder, the total thickness of the thermal barrier is 1.65mm , it is necessary to add 3 pieces of 0.5mm thick thermal barriers, divide the heat storage material of the regenerator into 3 uniform parts, and determine the outer diameter of the thermal barrier as Φ7mm according to the inner diameter of the regenerator as Φ7mm, so that the thermal barrier The outer diameter and the inner hole of the regenerator are closely matched, and the holes are evenly drilled on the thermal barrier. %,

[0046] Calculation formula (I) for the ratio of the hollow area to the cross-sectional area of the thermal barrier:

[0047] η = n × d 2 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com