Patents

Literature

36results about How to "Economic recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

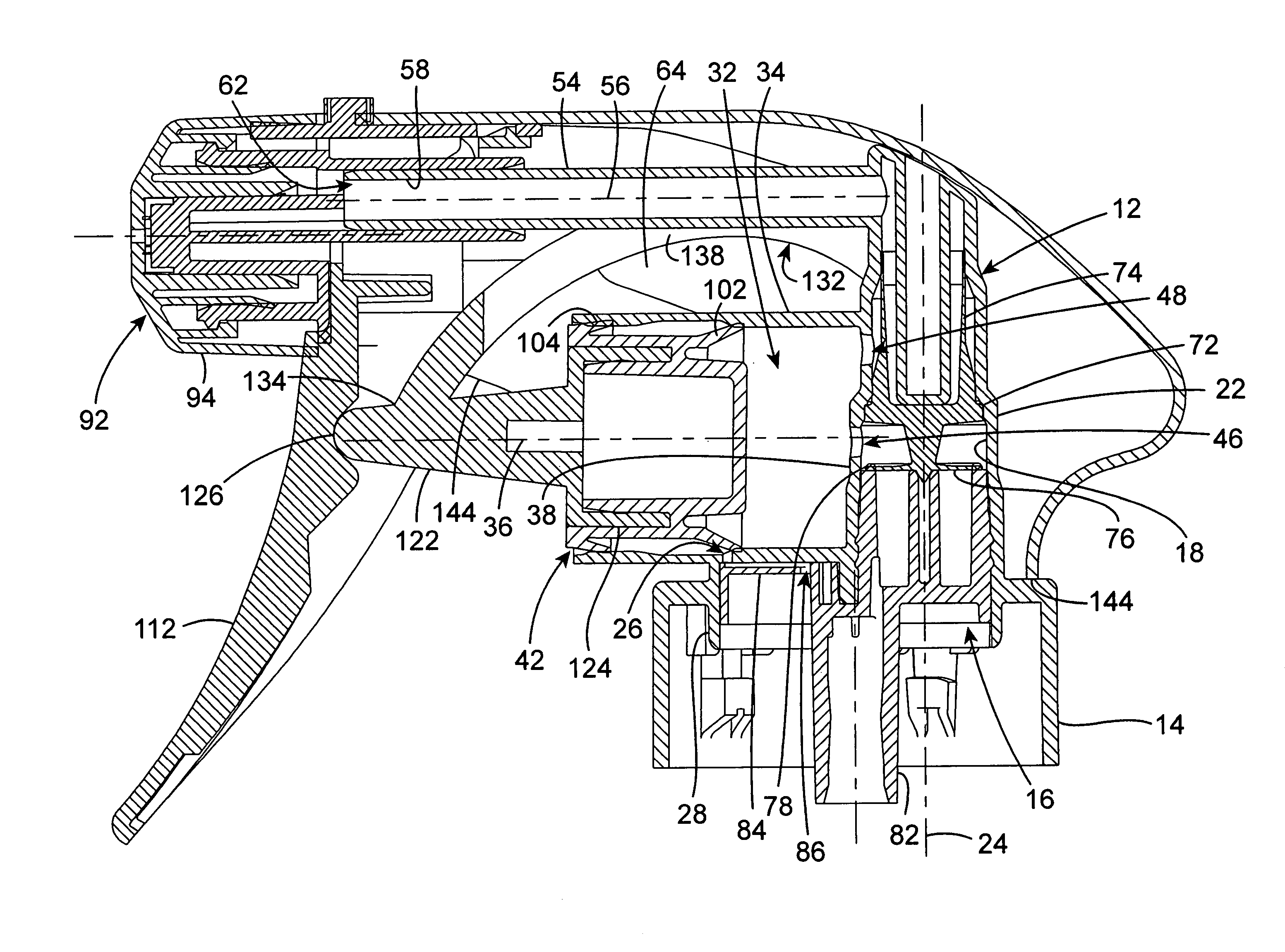

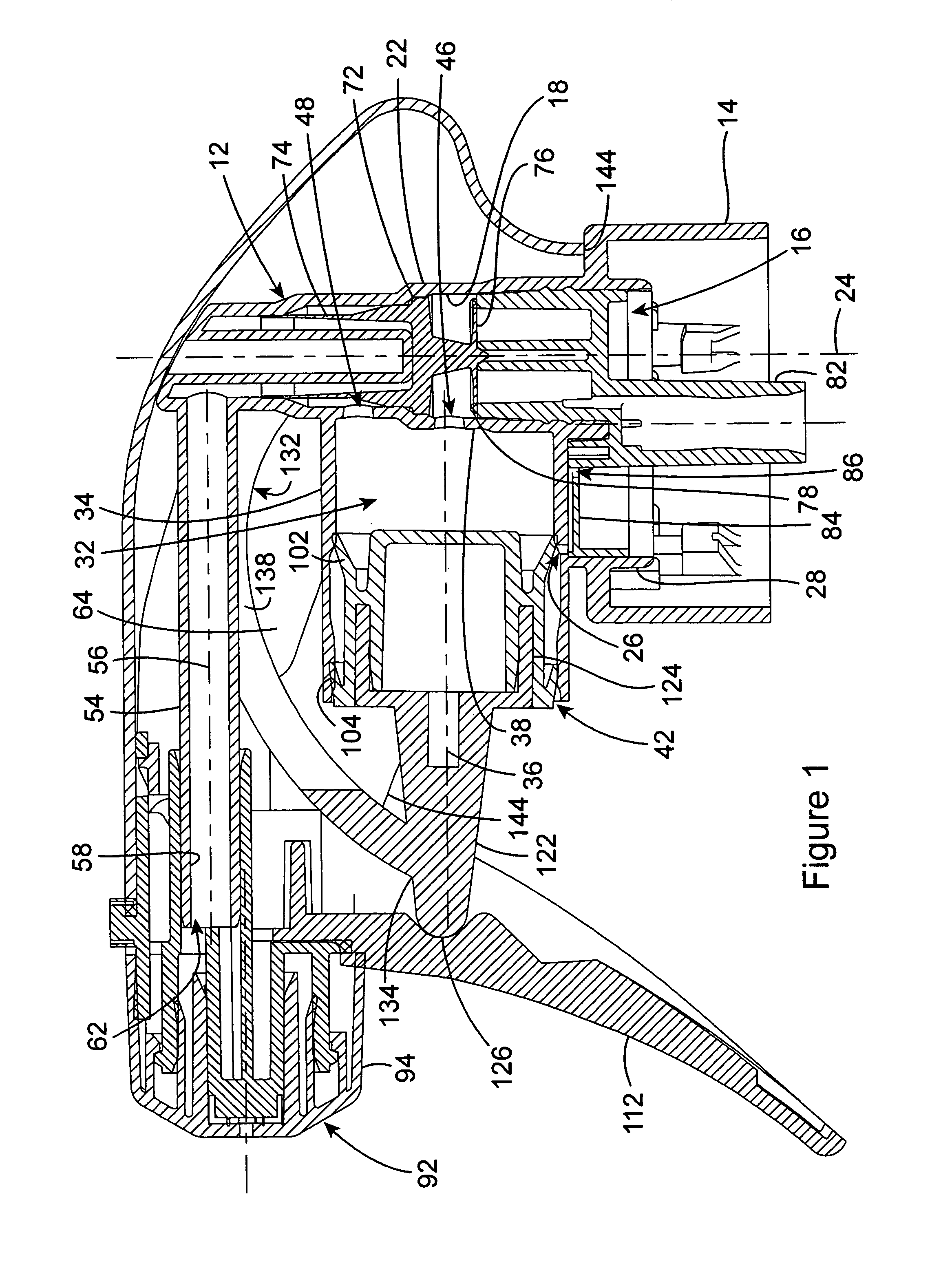

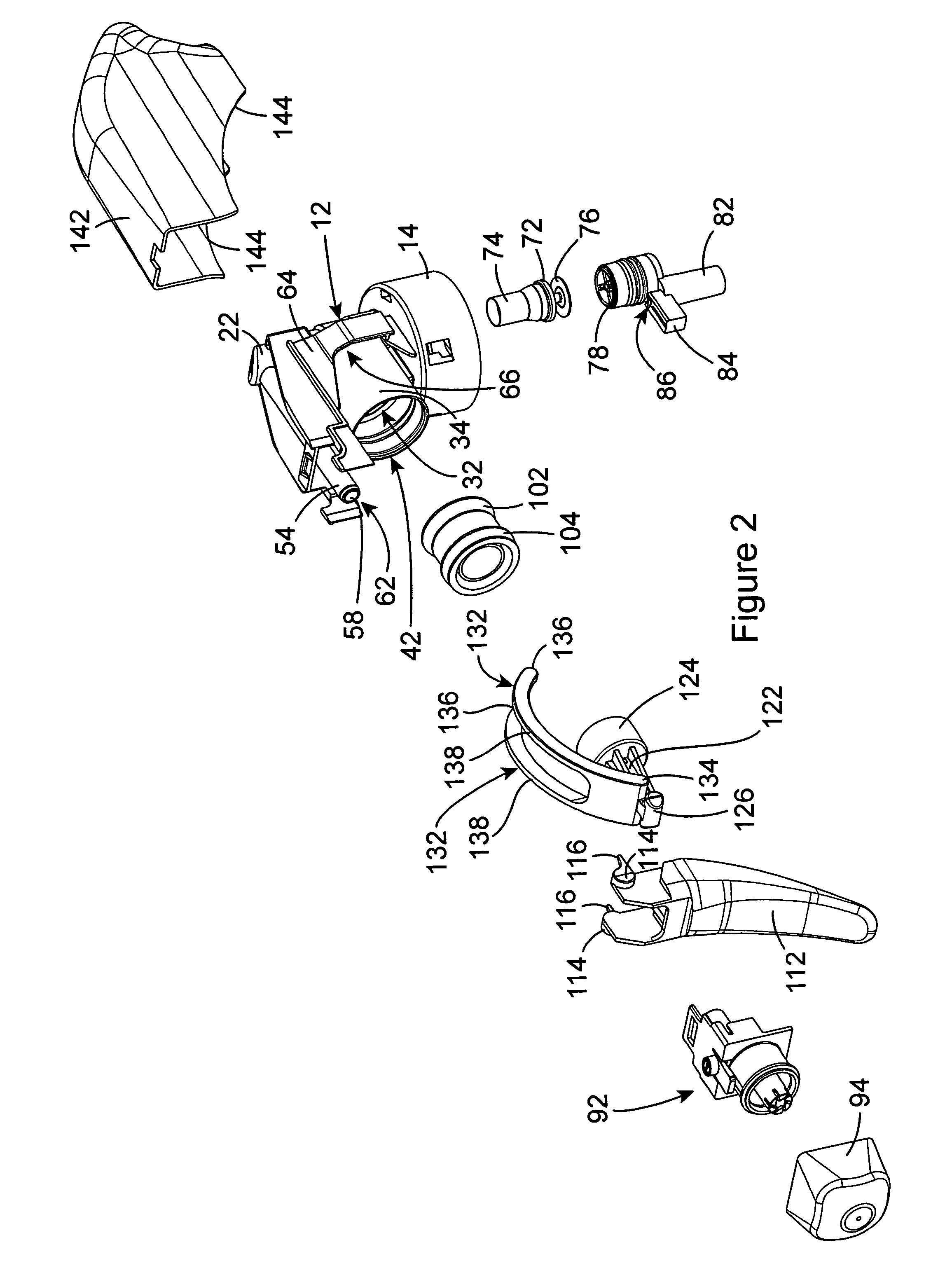

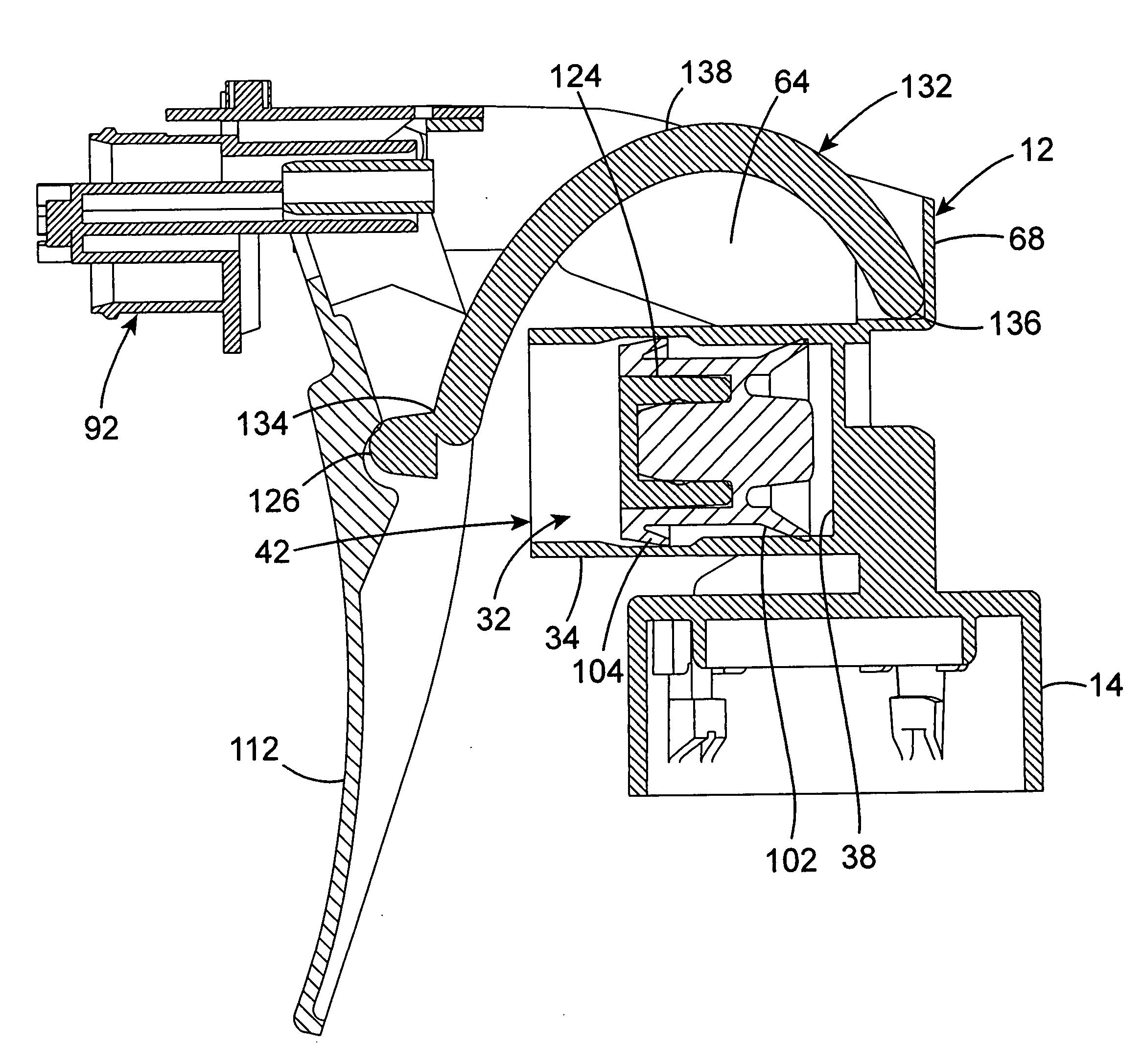

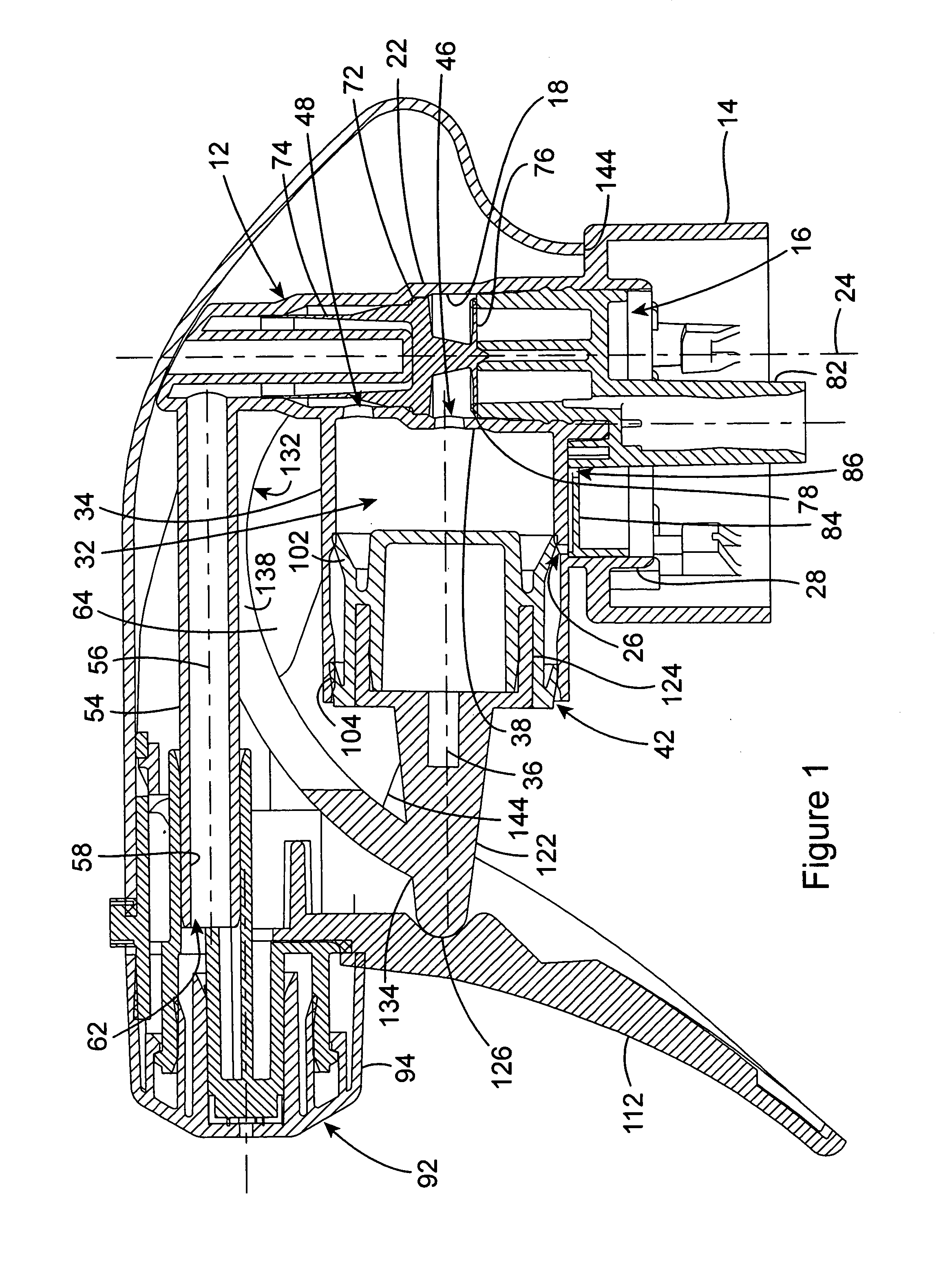

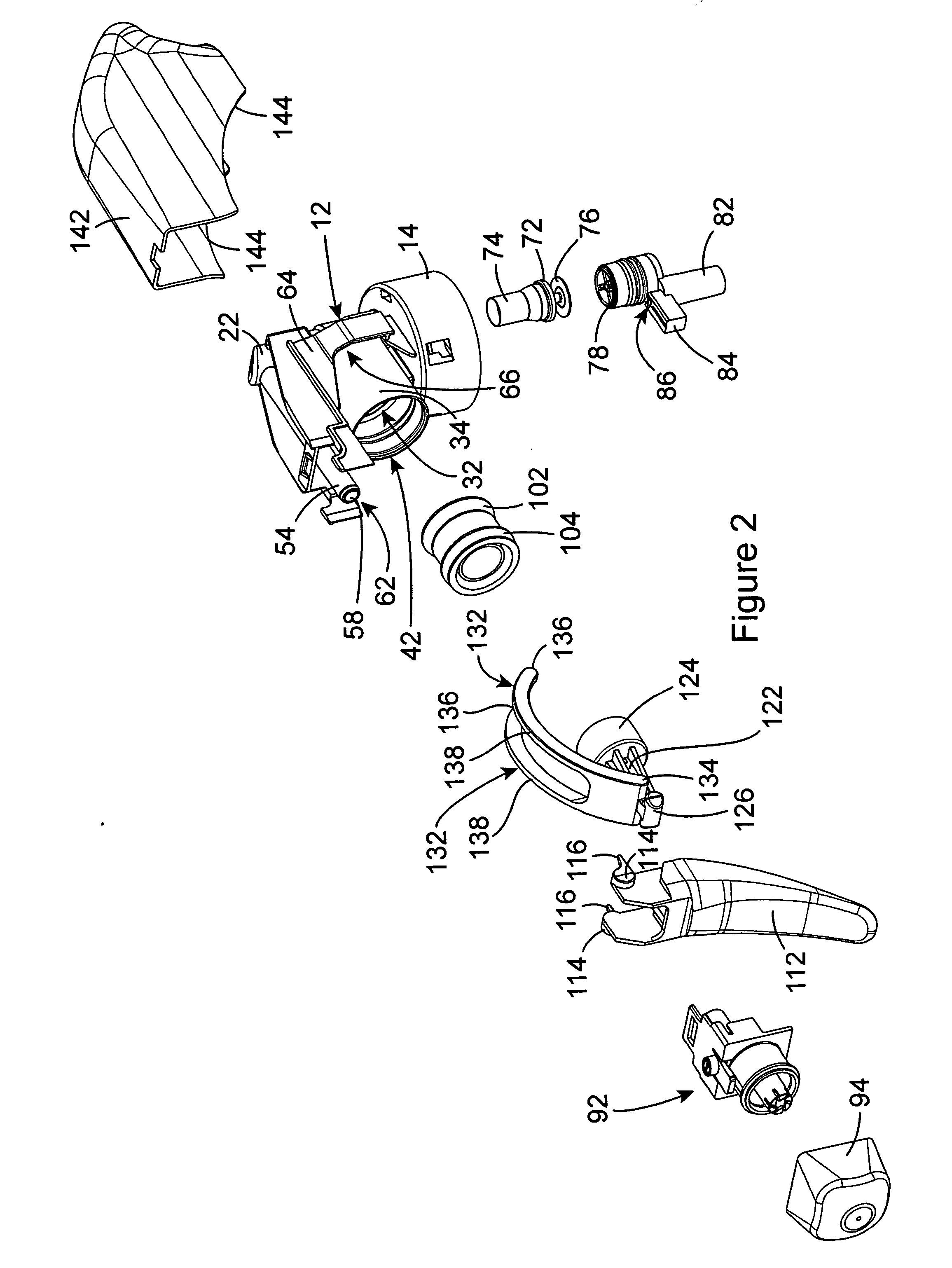

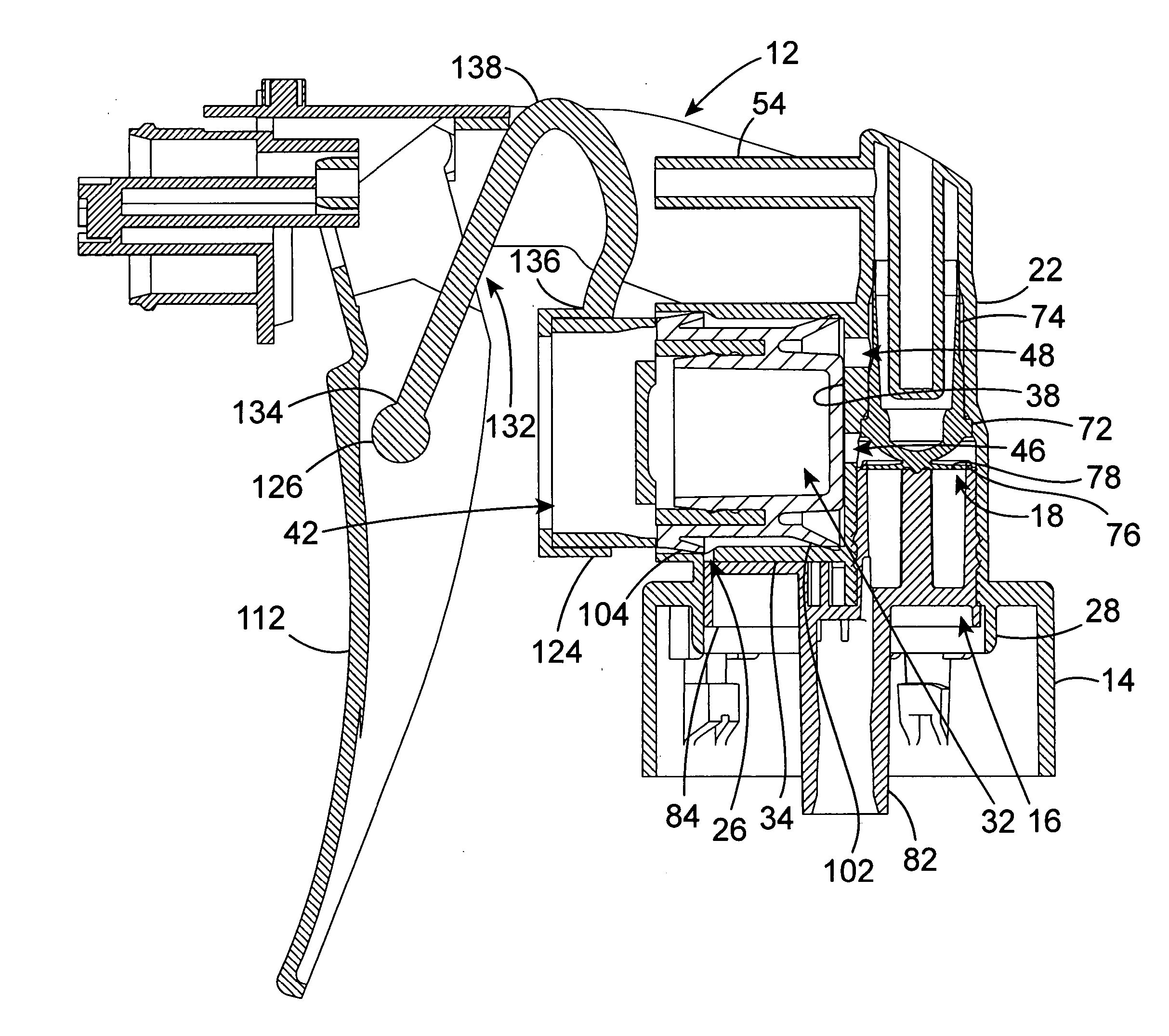

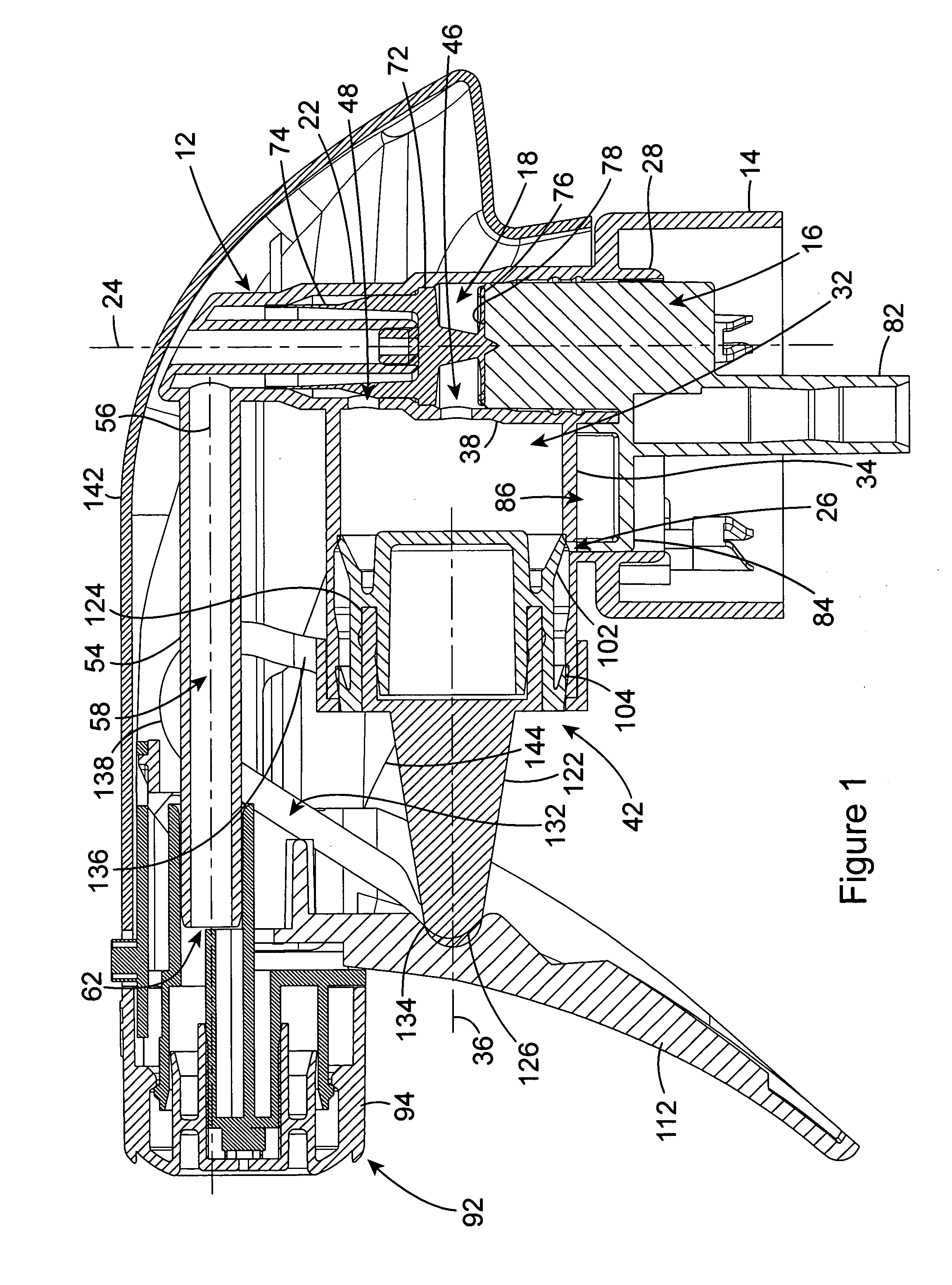

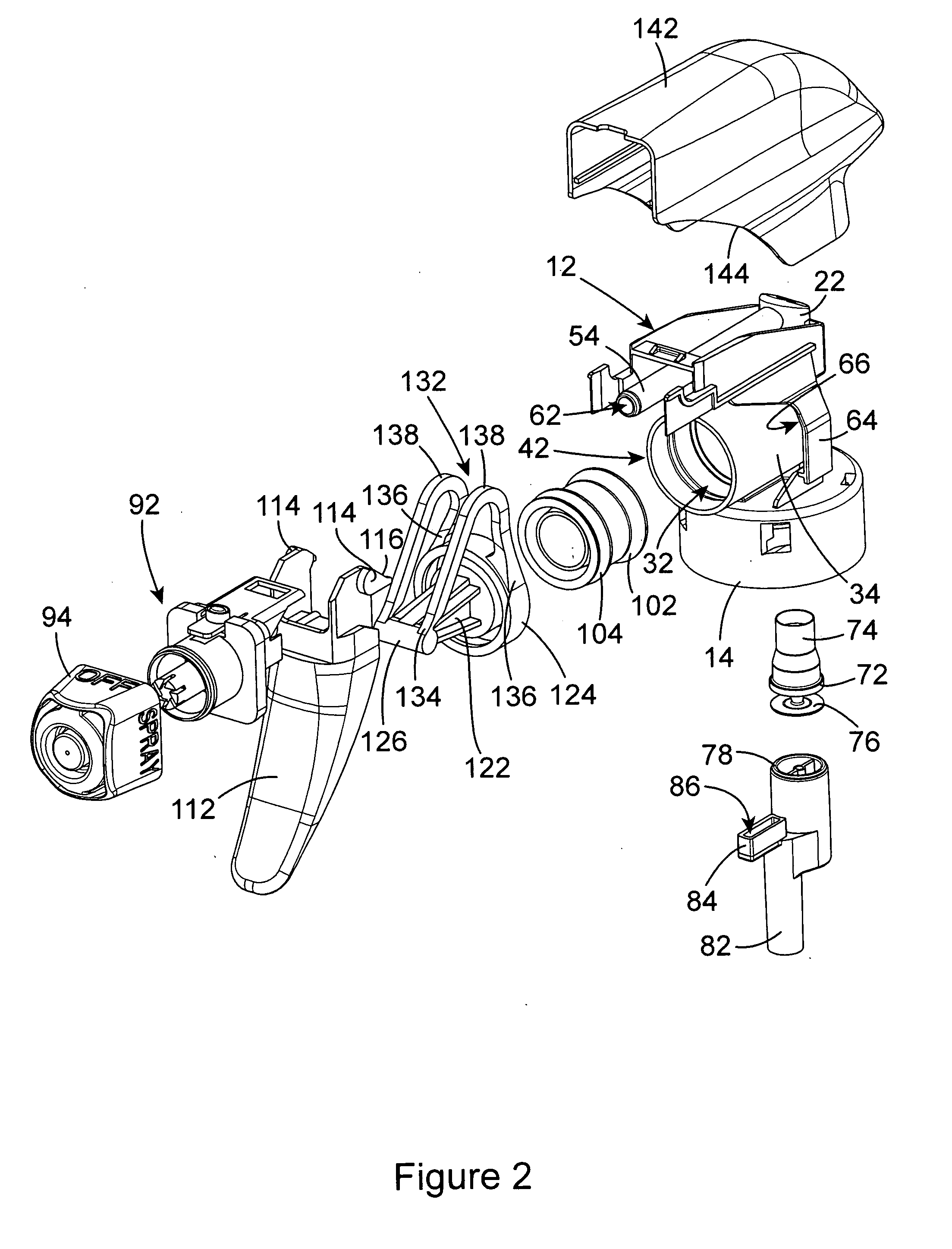

Trigger sprayer with integral piston rod and bowed spring

ActiveUS7497358B2Cost efficientRecycling of the trigger sprayer is more economicalLarge containersFire rescueSprayerPump chamber

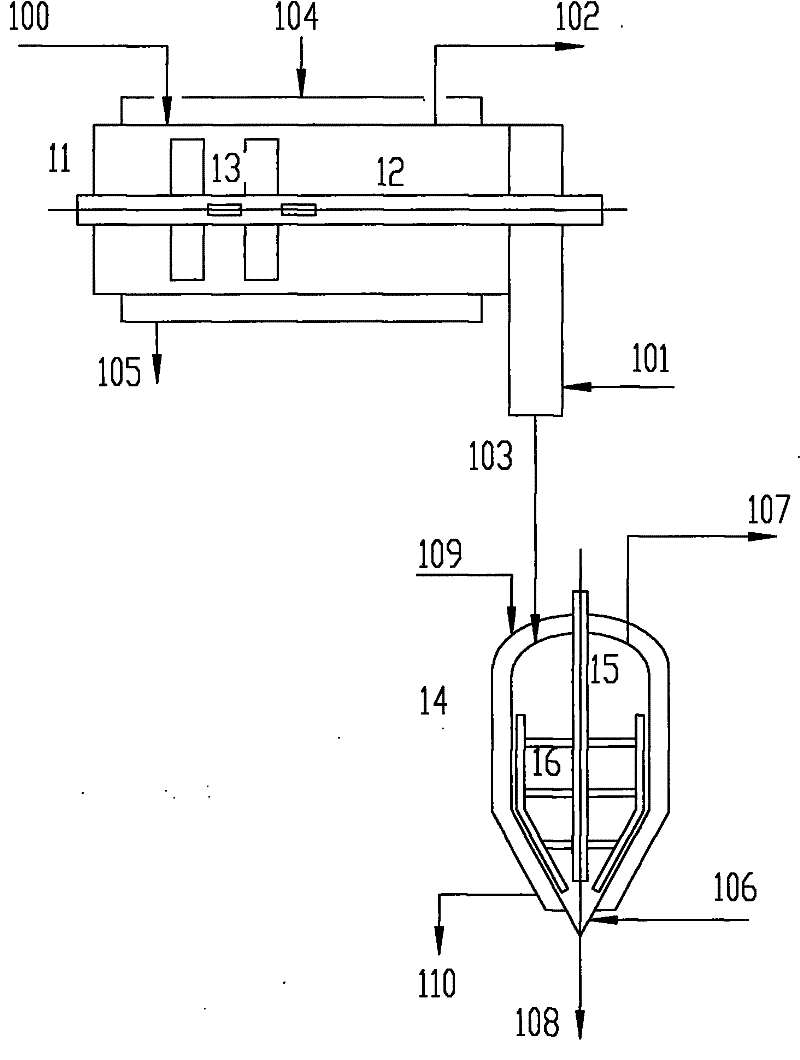

A manually operated trigger sprayer is constructed with a reduced number of parts and in a novel manner in which all of the component parts of the sprayer are constructed of a plastic material. The construction of the trigger sprayer replaces the conventional metal coil spring in the pump chamber with a pair of plastic bowed springs that are integral with the piston rod and are positioned outside the pump chamber. Constructing all of the sprayer parts of a plastic material enables a cost efficient recycling of the parts, which does not require disassembling the parts to remove a metal spring.

Owner:SILGAN DISPENSING SYST CORP

Trigger sprayer with integral piston rod and bowed spring

ActiveUS20070215645A1Reduce componentsReduce manufacturing costLarge containersFire rescuePump chamberSprayer

A manually operated trigger sprayer is constructed with a reduced number of parts and in a novel manner in which all of the component parts of the sprayer are constructed of a plastic material. The construction of the trigger sprayer replaces the conventional metal coil spring in the pump chamber with a pair of plastic bowed springs that are integral with the piston rod and are positioned outside the pump chamber. Constructing all of the sprayer parts of a plastic material enables a cost efficient recycling of the parts, which does not require disassembling the parts to remove a metal spring.

Owner:SILGAN DISPENSING SYST CORP

Trigger sprayer with integral piston rod and u-shaped spring

InactiveUS20070210116A1Cost efficientRecycling of the trigger sprayer is more economicalLarge containersLiquid transferring devicesSprayerPump chamber

A manually operated trigger sprayer is constructed with a reduced number of parts and in a novel manner in which all of the component parts of the sprayer are constructed of a plastic material. The construction of the trigger sprayer replaces the conventional metal coil spring in the pump chamber with a pair of plastic springs having inverted U-shaped configurations that are integral with the piston rod and are positioned outside the pump chamber. Constructing all of the sprayer parts of a plastic material enables a cost efficient recycling of the parts, which does not require disassembling the parts to remove a metal spring.

Owner:CONTINENTALAFA DISPENSING CO

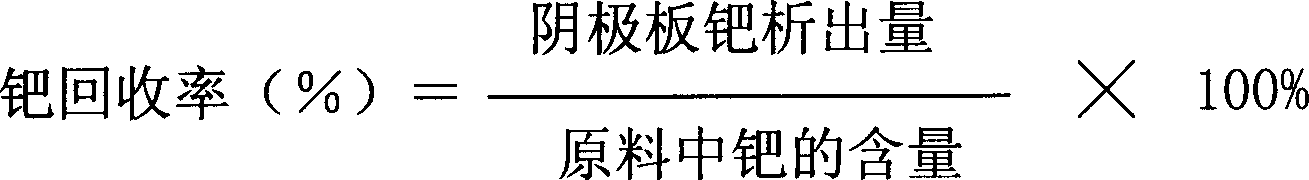

Process for reclaiming Pd from waste Pd-C catalyst

InactiveCN1690234AEconomic recyclingEfficient recyclingPhotography auxillary processesProcess efficiency improvementRecovery methodAlkaline earth metal

The invention provides a recovery method for palladium from lapsed Pd-C catalyst. With alkali or alkaline earth carbonate as an additive, in 700 to 800 Deg. C, oxygenizing and burning the lapsed Pd-C, refined residue reacting with alkali bisulfate and generating soluble palladium salt, then separating palladium by electrolysis, the single-pass recovery ratio can achieve more than 94 percent, and the purity is 99.95 percent.

Owner:PETROCHINA CO LTD

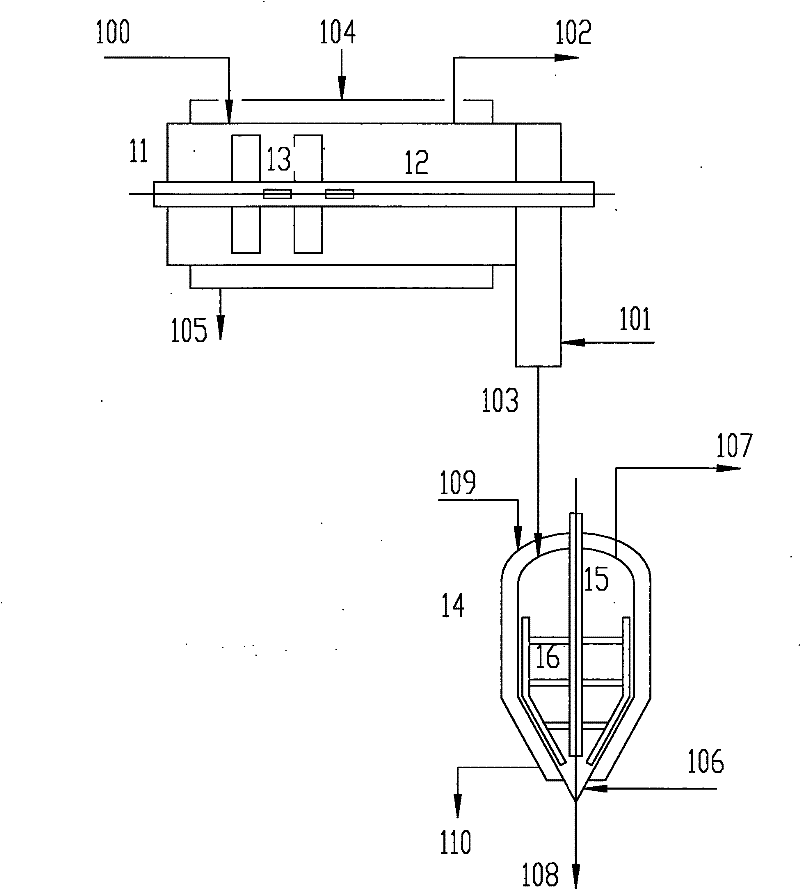

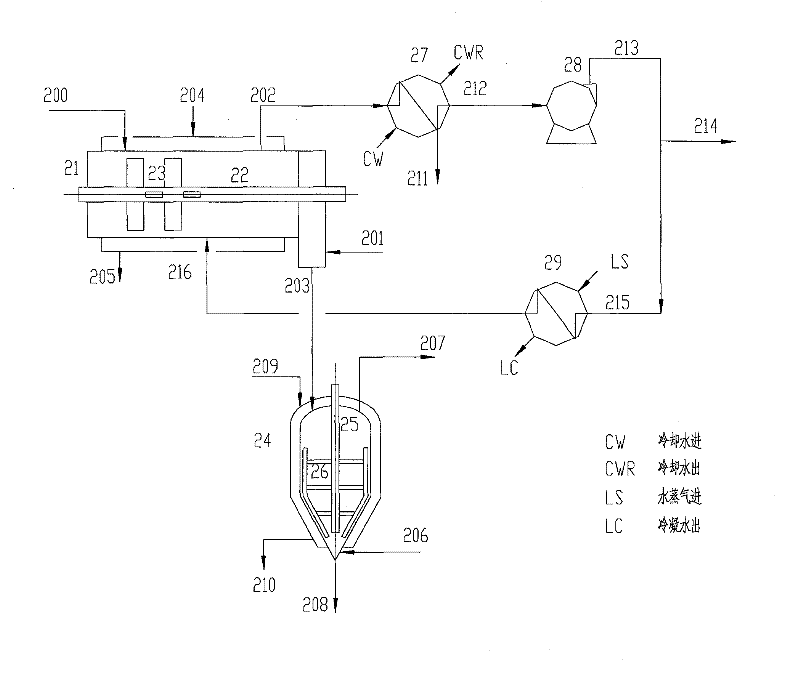

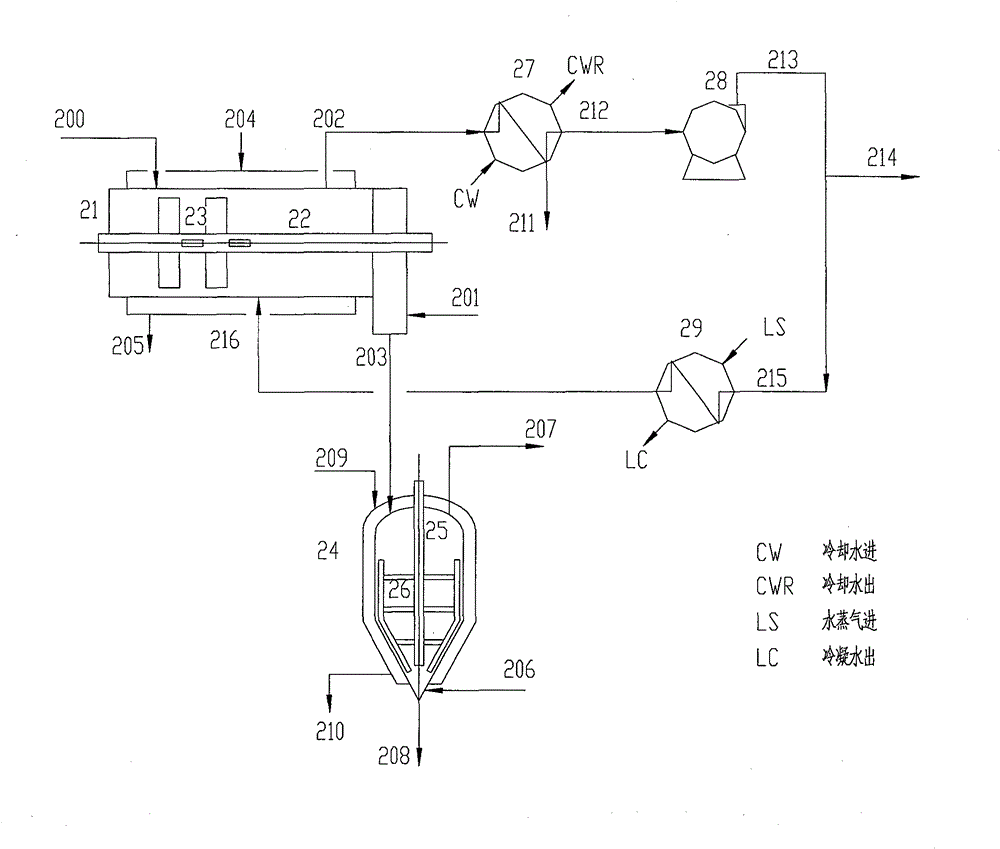

Post-processing method for polypropylene powder

The invention provides a post-processing method for polypropylene powder, which belongs to the petroleum chemical field. In the polypropylene post-processing method of the prior art, the method comprises the following steps: polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a drier, indirectly heated through steam and nitrogen is introduced, hydrocarbons can be removed in powder and then enters in a steamer, nitrogen and water vapor are introduced for inactivation of a catalyst; or the polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a degassing chamber, water vapor-containing nitrogen is introduced in the degassing chamber; the present invention modifies the prior art. The post-processing method of the invention comprises the following steps: introducing water vapor, modifying the drier to a steam drier used for recovering hydrocarbons and inactivating the catalyst, introducing a hydrocarbons-removed polymer in the steam drier (or a degassing chamber), adding nitrogen without water vapor in the steam drier, modifying the steam drier to a moisture eliminator used for removing water vapor in powder. The method of the invention is capable of thoroughly recovering hydrocarbons which depart from the polymerization system by an economic method, reducing the unit consumption and energy consumption, and thoroughly solving the problem on environmental protection.

Owner:高煦

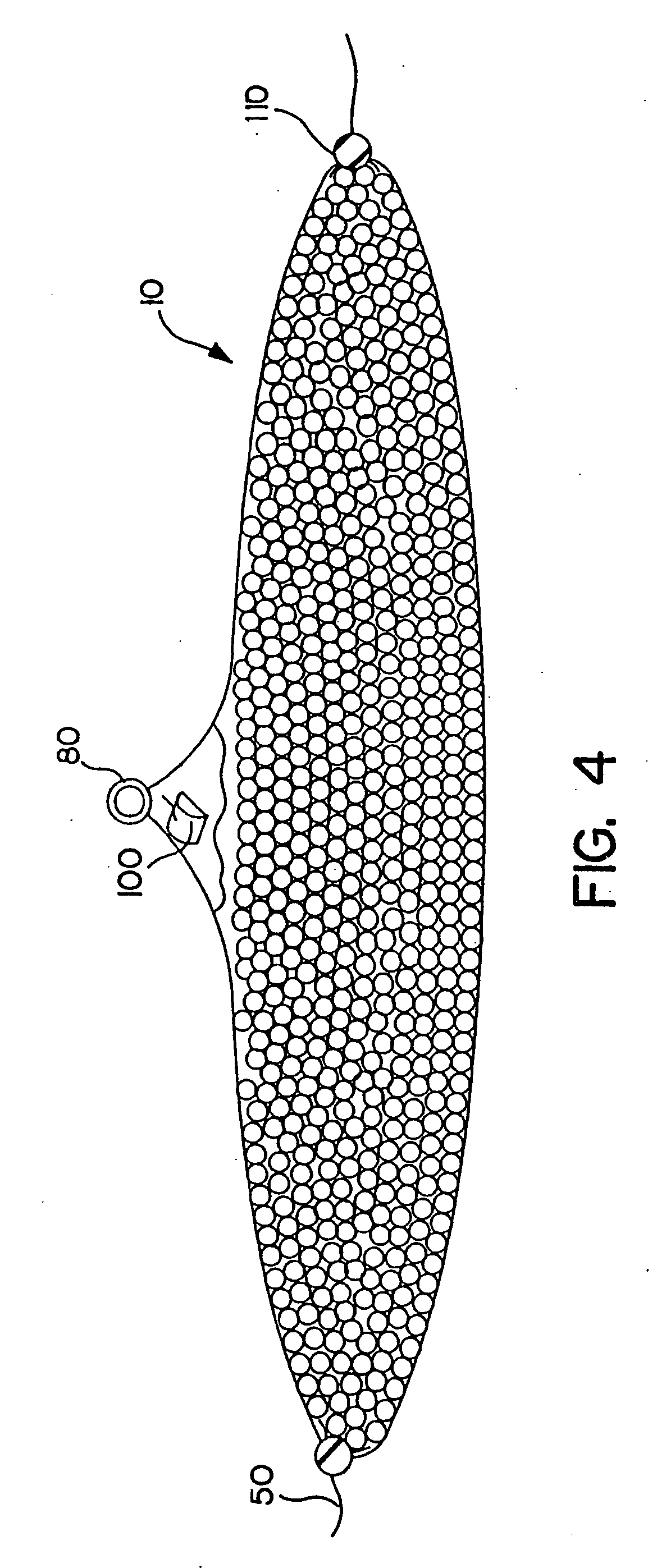

Process of forming oil-absorbent bodies

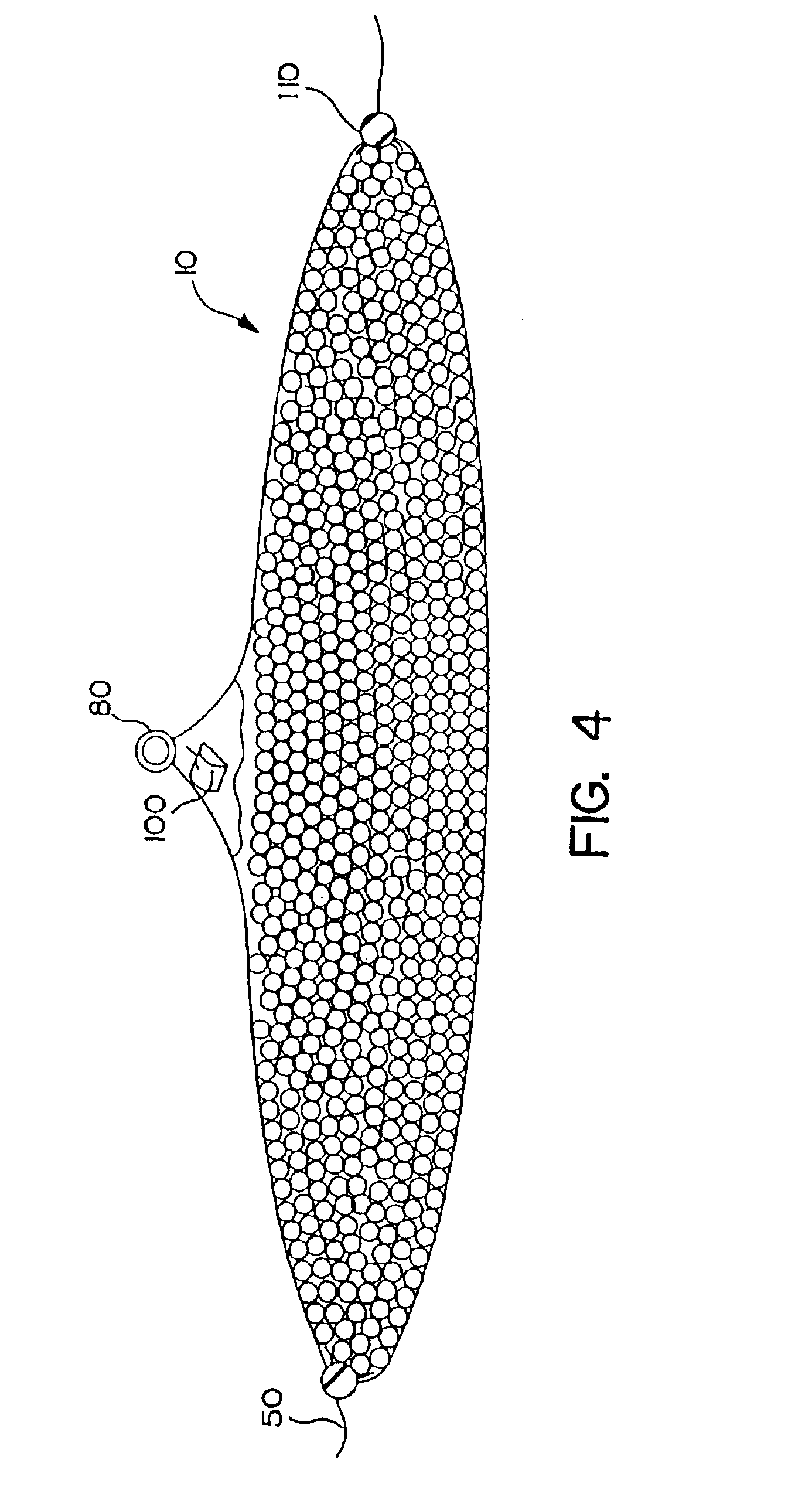

InactiveUS7048878B2Efficiently containedEasy to collectWater cleaningFatty/oily/floating substances removal devicesEthylene-propylene-diene-monomerSorbent

A process for forming an oil-sorbent composition of matter with bound combinations of styrene-butadiene-styrene (SBS) and ethylene propylene diene monomer (EPDM) utilizes a low-temperature extrusion process. The SBS, or both materials, may be in the form of multitudes of granules. In certain preferred embodiments, the combination is 10-30% by weight and the SBS is about 30% styrene and manufactured without talc. The composition of matter can be extruded into a solid, compliant body for use in a product for absorbing oil. The material can be extruded, in one preferred embodiment, into an extended cylinder body having an axial hole.

Owner:LIGHTAIR HLDG +1

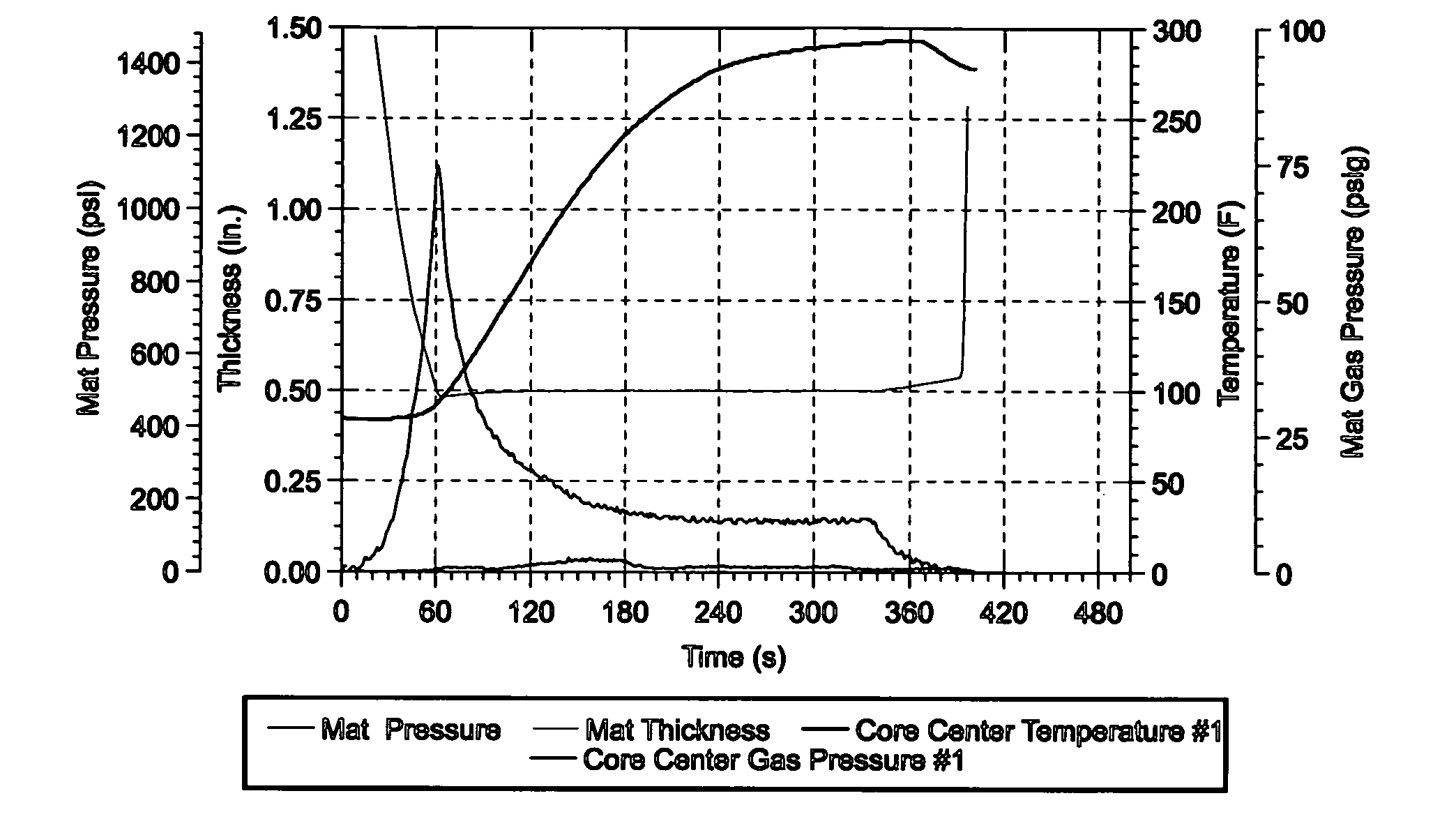

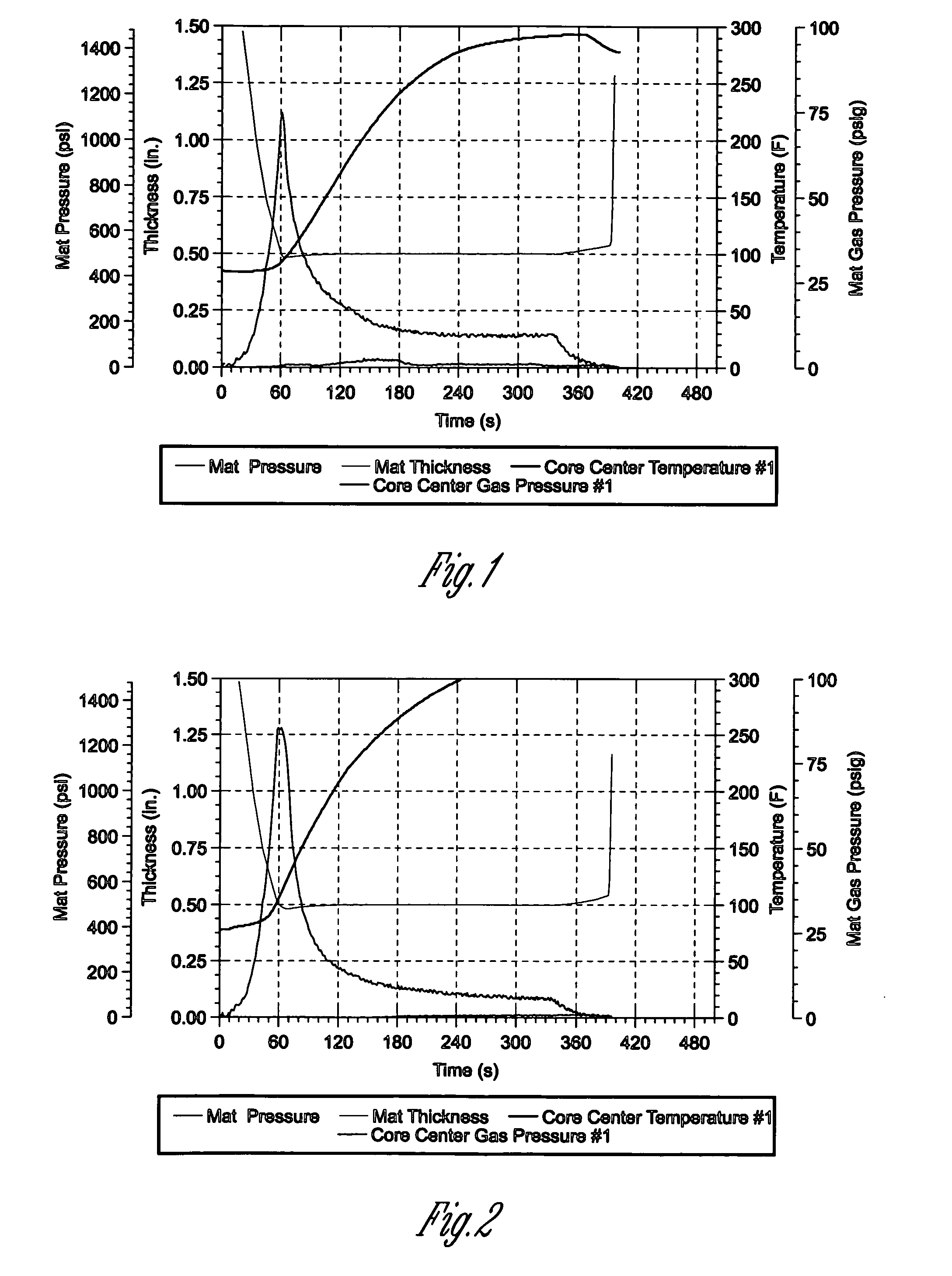

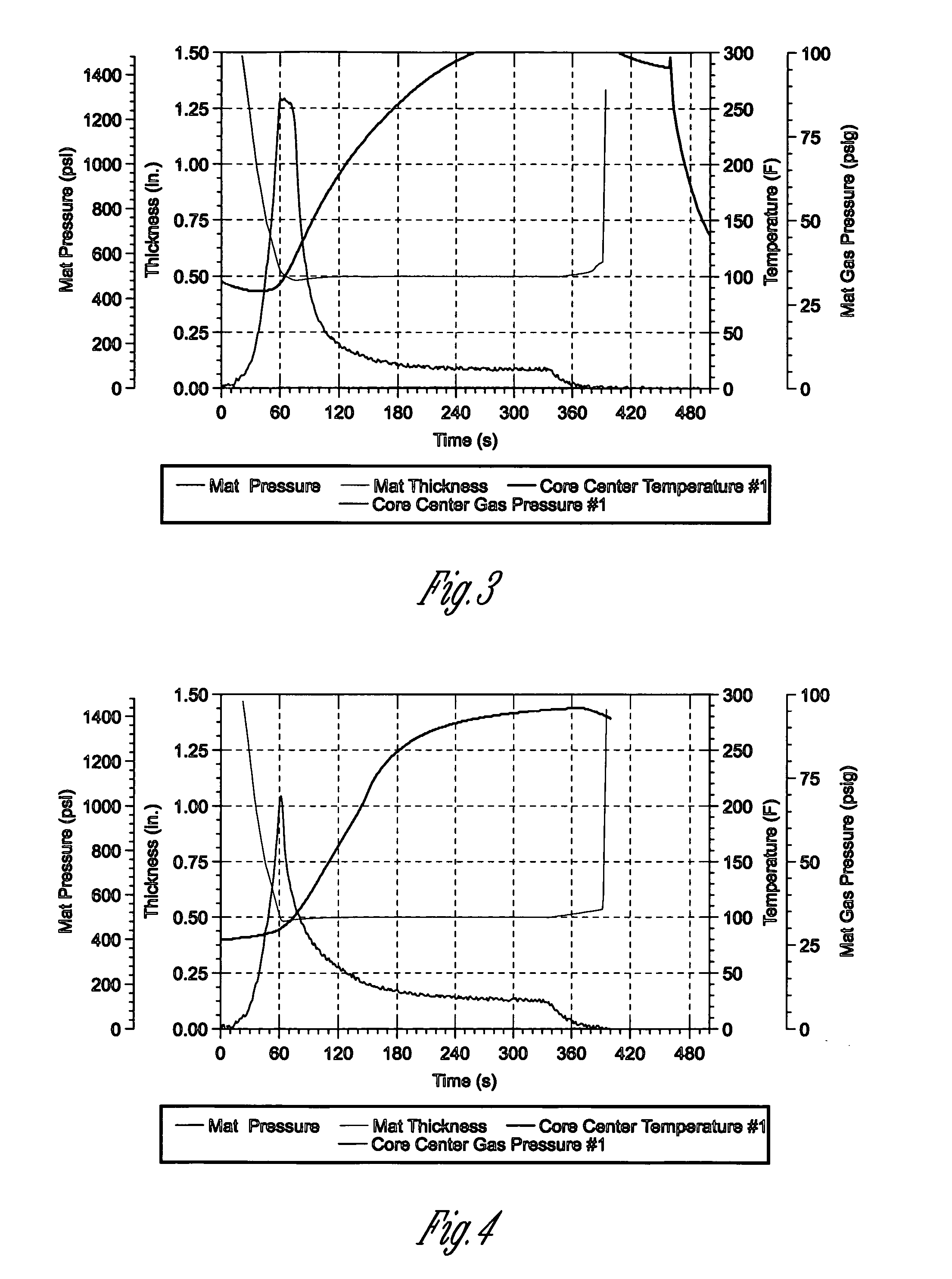

Agricultural stalk strandboard

InactiveUS20070049661A1Less expensiveToxic reductionCosmetic preparationsToilet preparationsWaxState of art

The process described herein presents a unique method and means of manufacturing strandboard using agricultural plant stalks. The plant stalks are first depithed and excess moisture is removed. The stalks are then combined with a resin component and a wax component, and the resulting mixture is cured. The strandboard is economical to manufacture than prior art strandboard in that it does not require the use of expensive MDI resin. Further, the strandboard is environmentally friendly in that it provides a beneficial use for agricultural waste.

Owner:PREMOMCNE

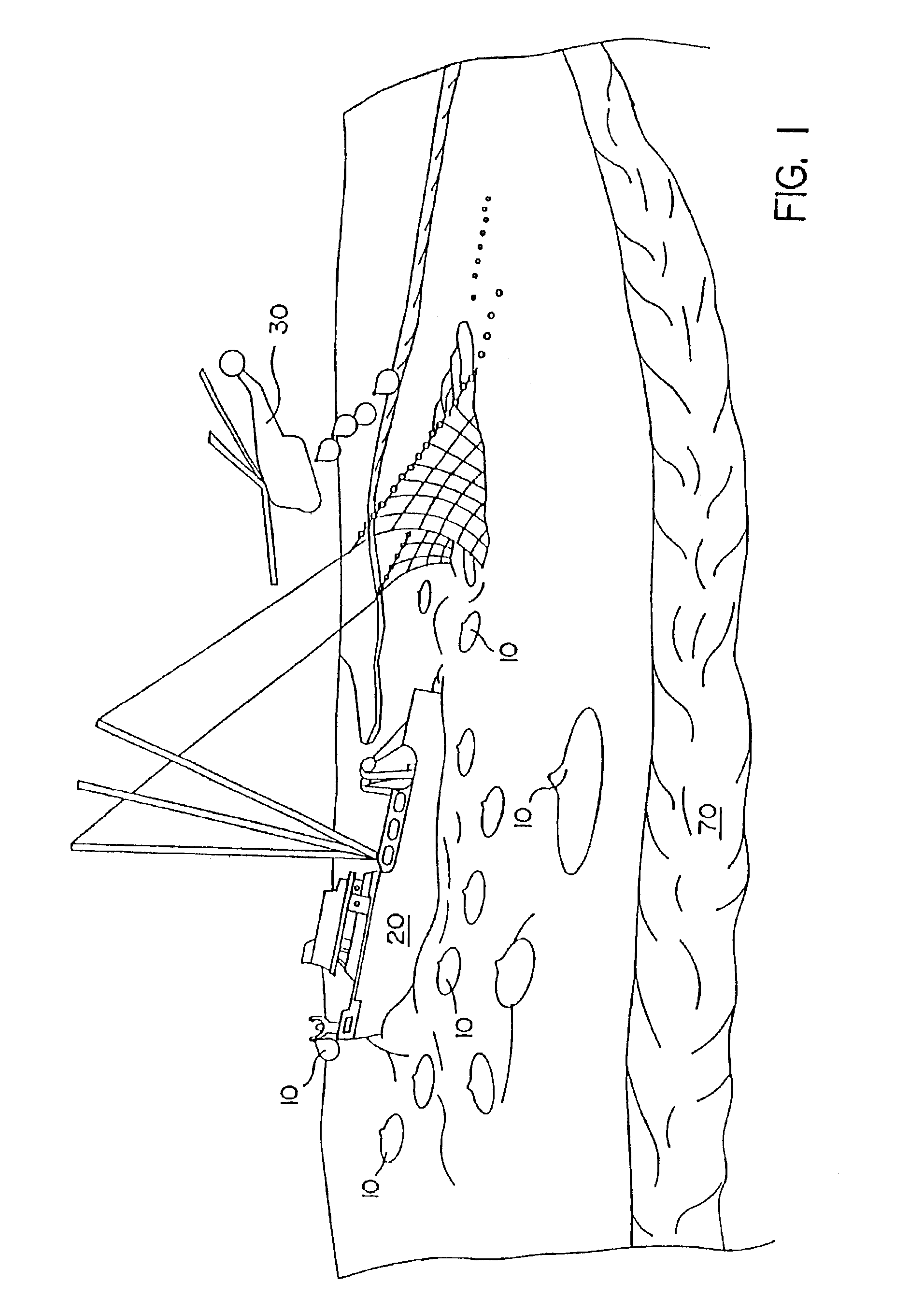

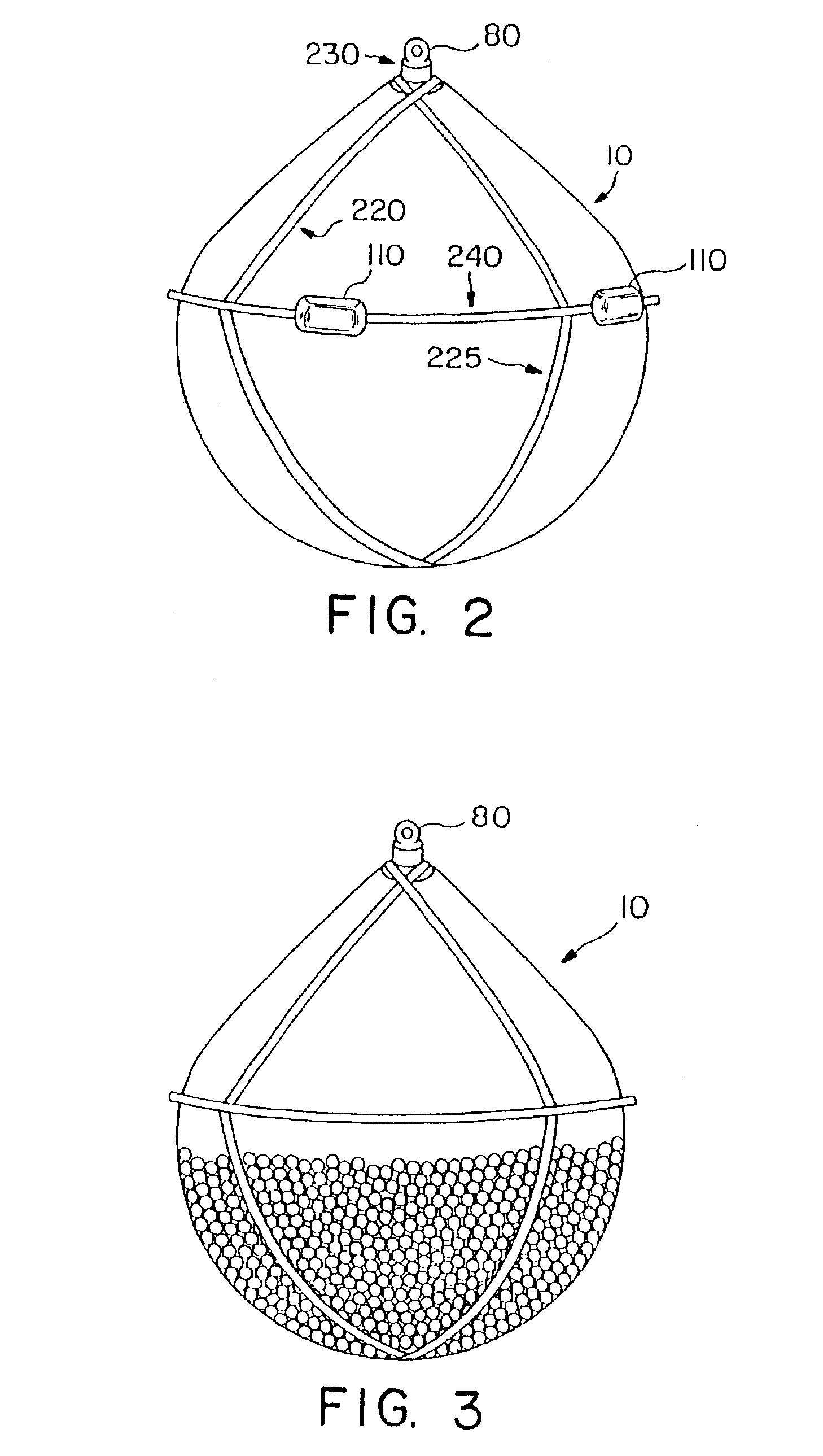

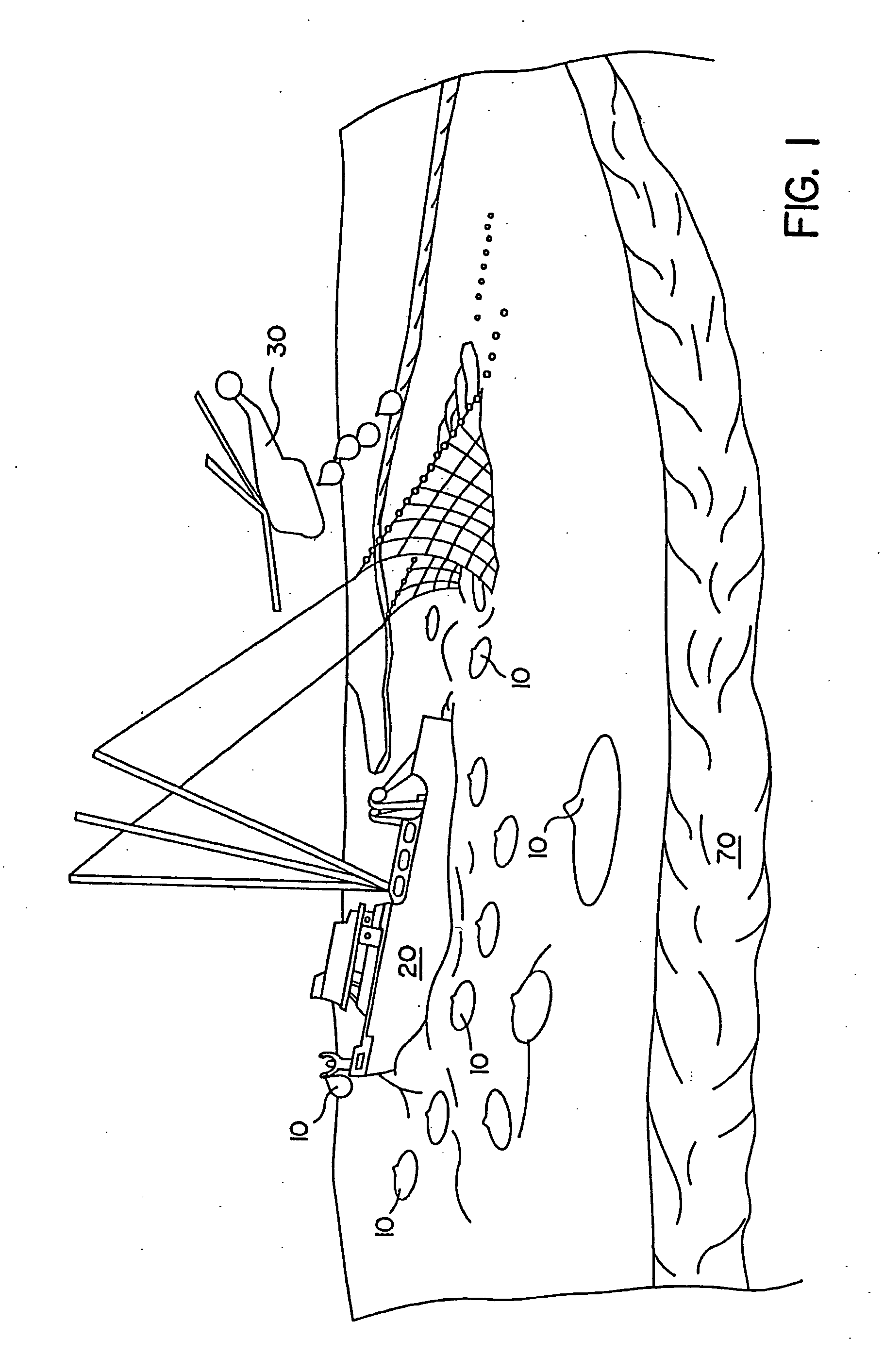

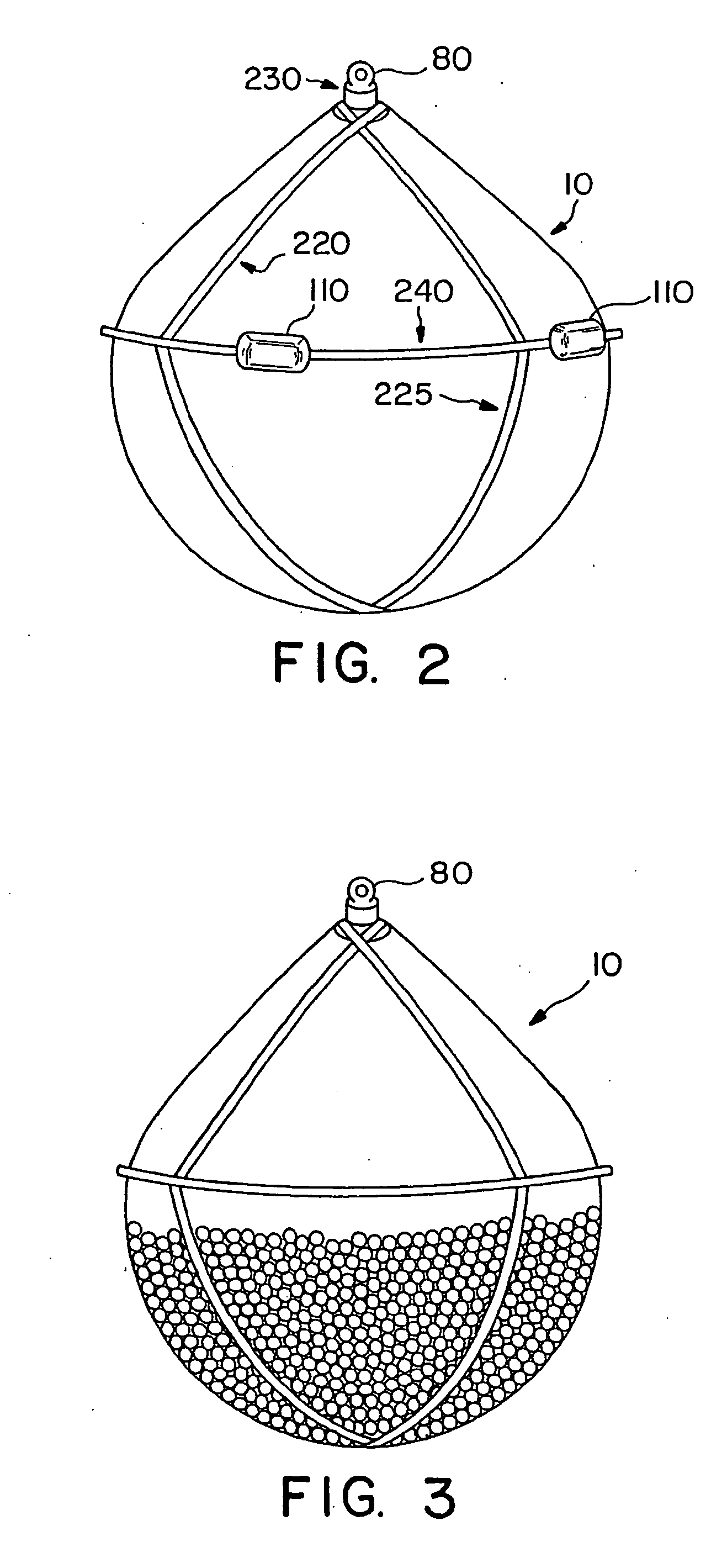

Sack-based systems and processes for recovering oil floating on water

InactiveUS20050151289A1Efficiently containedEasy to collectFatty/oily/floating substances removal devicesWater cleaningMarine engineeringDead body

One or more water- and oil-porous containers or sacks are made of a pair of mesh sheets affixed together and stiffened around their perimeter. The sacks can be partially filled with a multitude of tubular bodies made of an oil-entrapping polymer, which have their longest dimension parallel to an axial hole. A preferred material is composed of a combination of SBS and EPDM, formed by an extrusion technique, to create highly fissured generally cylindrical bodies. The sacks may be deployed in areas where oil is floating on water, such as where oil has spilled from tankers on oceans, seas, lakes, or rivers. When the bodies are afloat, oily water can pass through the axial holes of and around the bodies, maximizing the surface area contacted by the oil and minimizing gel blocking. After a time sufficient for the bodies in the sacks to adsorb oil, the sacks can be collected. Various deployment and collection methods are disclosed. After collection, the oil may be recycled; alternatively the sacks may be incinerated, to recover the energy content for use as power while disposing of the oil.

Owner:GILA RIVER RANCHES L L C

Reduction of the cooling time of the beer in processing tanks by injecting carbon dioxide gas

InactiveUS20110094387A1Prevent subsidenceWell mixedIce productionBeer fermentationCooling timeCarbon dioxide

A method and apparatus for cooling liquids, specifically beer, is disclosed. The method and apparatus utilize fluid carbon dioxide injected into a cooling apparatus. The cooling apparatus is submerged vertically in the beer when it is contained in a tank with the aim of cooling it.

Owner:SOTO PORRUA ANGEL JOSE ENRIQUE +1

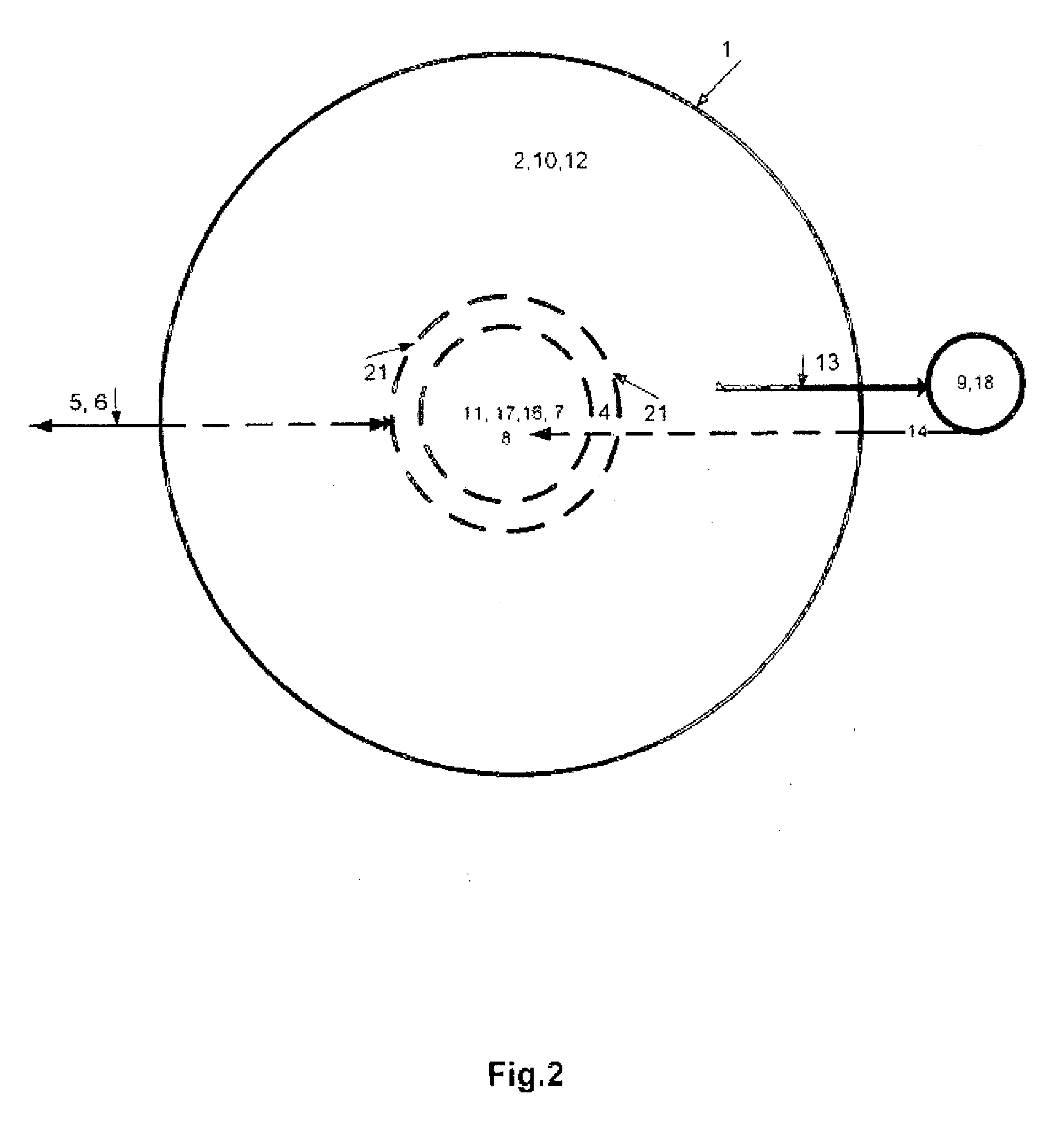

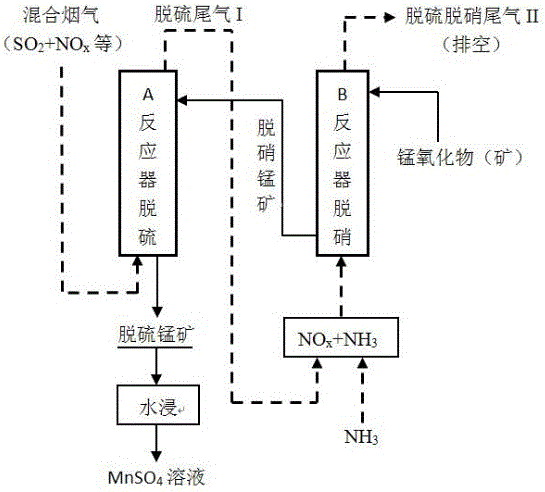

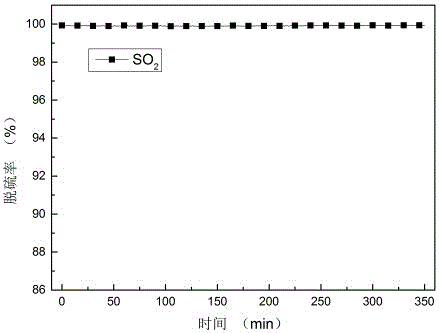

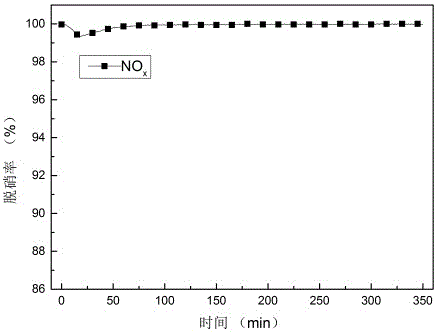

Desulphurization and denitrogenation integrated method

ActiveCN105771581AImprove removal efficiencyMeet emission requirementsGas treatmentDispersed particle separationFlue gasEconomic benefits

The invention relates to a desulphurization and denitrogenation integrated method. The method includes the following steps: putting manganese oxide in two reactors A and B respectively; respectively heating the reactors A and B; feeding flue gas containing SO2 and NOx into the reactor A, and performing reaction at the temperature of 100-700 DEG C to obtain desulphurized tail gas I and desulphurized manganese ore; mixing the desulphurized tail gas I with NH3 prior to feeding the mixture into the reactor B, and performing reaction in the temperature range of 50-400 DEG C to obtain desulphurized and denitrated tail gas II and denitrated manganese ore; discharging the desulphurized manganese ore; adding the denitrated manganese ore into the reactor A, and adding fresh manganese oxide into the reactor B; cycling and repeating in sequence to complete series connection of the desulphurization process in the reactor A and the denitrogenation in the reactor B so as to enable the desulphurization and denitrogenation integrated process to be continuous. The method is high in desulphurization and denitrogenation efficiency, low in cost and good in economic benefit and environmental protection benefit.

Owner:CENT SOUTH UNIV

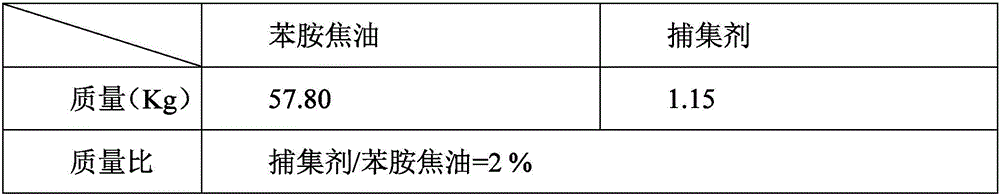

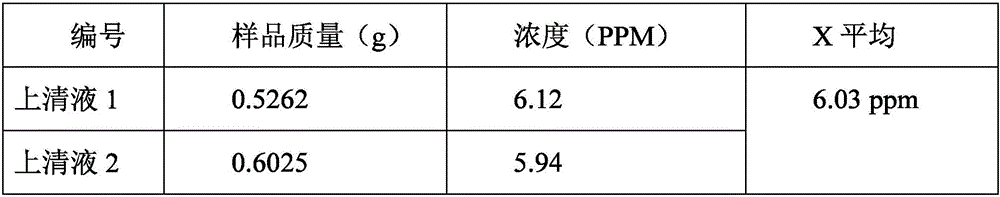

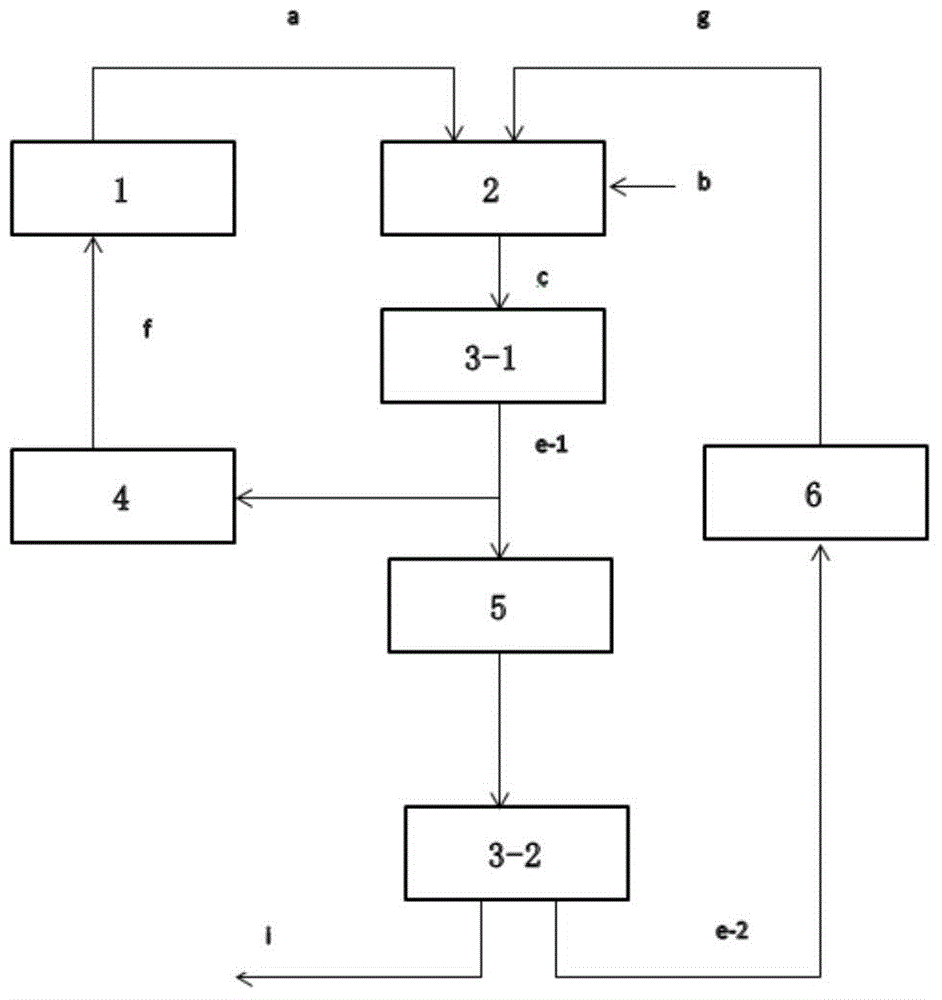

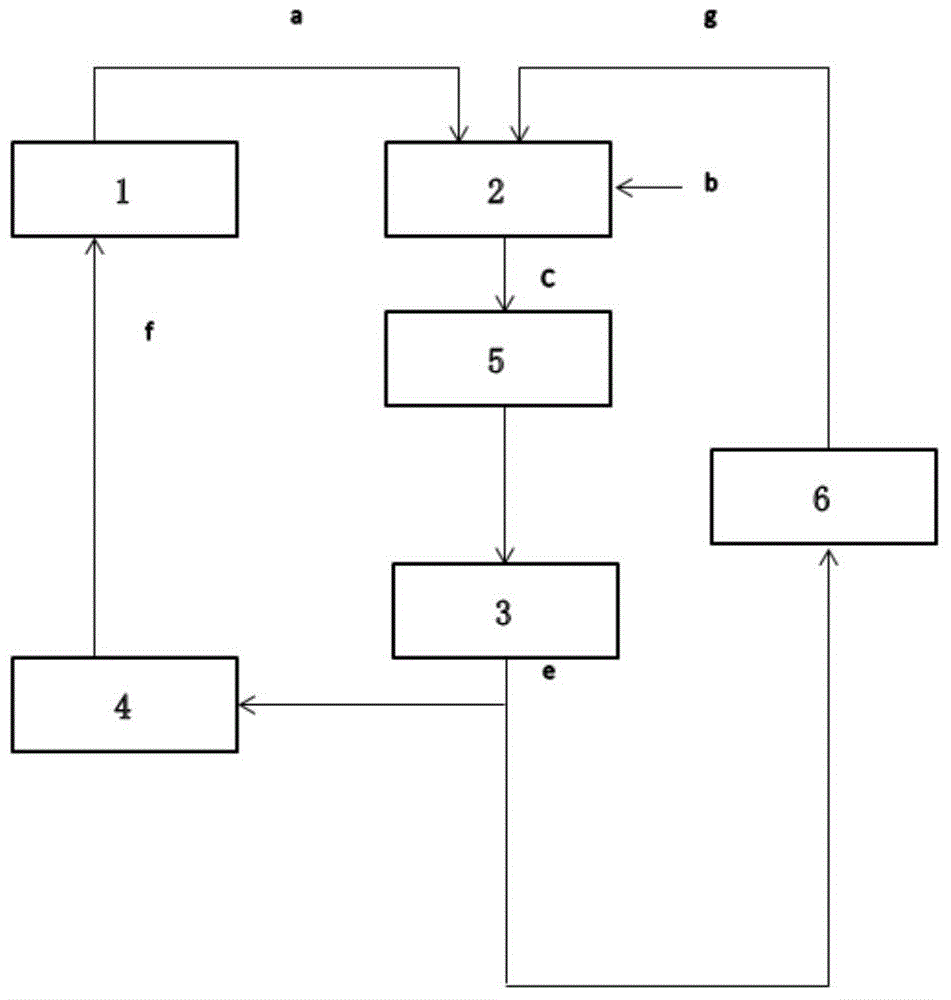

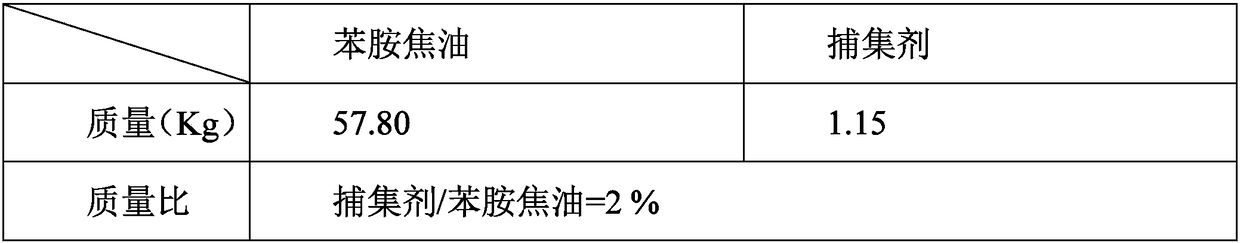

Method for recovering precious metal palladium from aniline tar

ActiveCN106480316AScientific recyclingEasy to recycleProcess efficiency improvementIron replacementTar

The invention relates to a method for recovering precious metal palladium from aniline tar. The method includes the following steps that aniline tar raw materials are heated to 80 DEG C, the PH is adjusted, a precious metal collector is added, constant temperature heating is carried out, stirring is carried out, standing depositing is carried out, cooling and filtering are carried out, filter residues are reserved and burned in a muffle furnace, ash is collected and reserved after burning is complete, mixed acid is added, boiling is carried out after stirring, complete dissolving is carried out, cooling and filtering are carried out, filter residues are collected and treated, filter liquor is reserved and is subject to concentration and nitre expelling, then iron replacement is carried out, cooling and filtering are carried out, filter liquor is subject to secondary recovering, filter residues are reserved and washed until water obtained after washing is neutral, filter residues are dried, coarse palladium is obtained, and the coarse palladium is refined to obtain sponge palladium. The method has the beneficial effects that the problem of losses of the palladium in the burning process is solved, the problem that palladium oxide is generated in the burning process is solved, the metal palladium recovering rate is improved, the recovering cost is reduced, and the recovering period is shortened.

Owner:NINGBO DADI CHEM ENG & ENVIRONMENTAL PROTECTION

Physical-sensible-heat recovery method and device of converter flue gas

InactiveCN103388048AThe cooling rate is smallEconomic recyclingIncreasing energy efficiencyManufacturing convertersEvaporative coolerFlue gas

The invention discloses a physical-sensible-heat recovery method and device of a converter flue gas, belongs to the technical fields of recovery and utilization of physical sensible heat in the converter flue gas, and mainly solves the problems comprising: intercepting some of the physical sensible heat from a high-temperature flue gas discharged by a converter flue cooling and heat-exchanging device, to make effective use; reducing water waste; and intercepting some of the physical sensible heat from high-temperature steam produced by an evaporative cooling process, to make effective use. The physical-sensible-heat recovery method of the converter flue gas is characterized in that: in an evaporative cooler, the temperature of the high-temperature flue gas is reduced to 350-700 DEG C, a waste-heat boiler is adopted for heat exchange, and the temperature of the high-temperature flue gas is further reduced to 120-250 DEG C. The physical-sensible-heat recovery device of the converter flue gas comprises a flue heat exchanger, the evaporative cooler, a coarse dust removal device, the waste heat boiler, a fine dust removal device, a draught fan and a switching station which are arranged in sequence. The invention is applicable to the technical fields of the recovery and utilization of the physical sensible heat in the converter flue gas.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

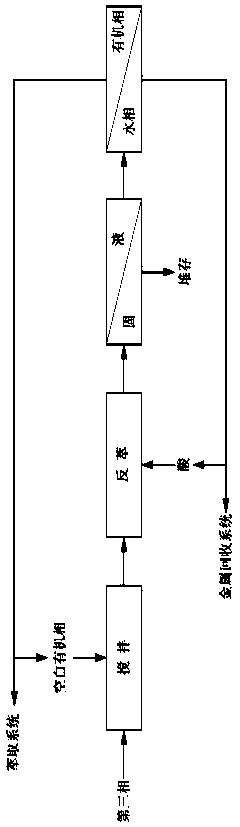

Treatment method of third phases in wet metallurgy extraction system

InactiveCN109112308AReduce lossesEconomic recyclingProcess efficiency improvementPhase splittingThird phase

The invention discloses a treatment method of third phases in a wet metallurgy extraction system. The method is characterized by comprising the following steps that a, extraction agents are added intothe third phases in the wet metallurgy extraction system; stirring is performed; b, acid is added into a mixture obtained in the step a for performing back extraction; c, a mixture obtained after back extraction in the step b is subjected to phase splitting. The treatment method has the advantages that material liquid and organic phases carried by the third phases can be economically, simply andconveniently recovered in an environment-friendly way; the loss caused by a third phase extraction system is reduced.

Owner:广西银亿新材料有限公司

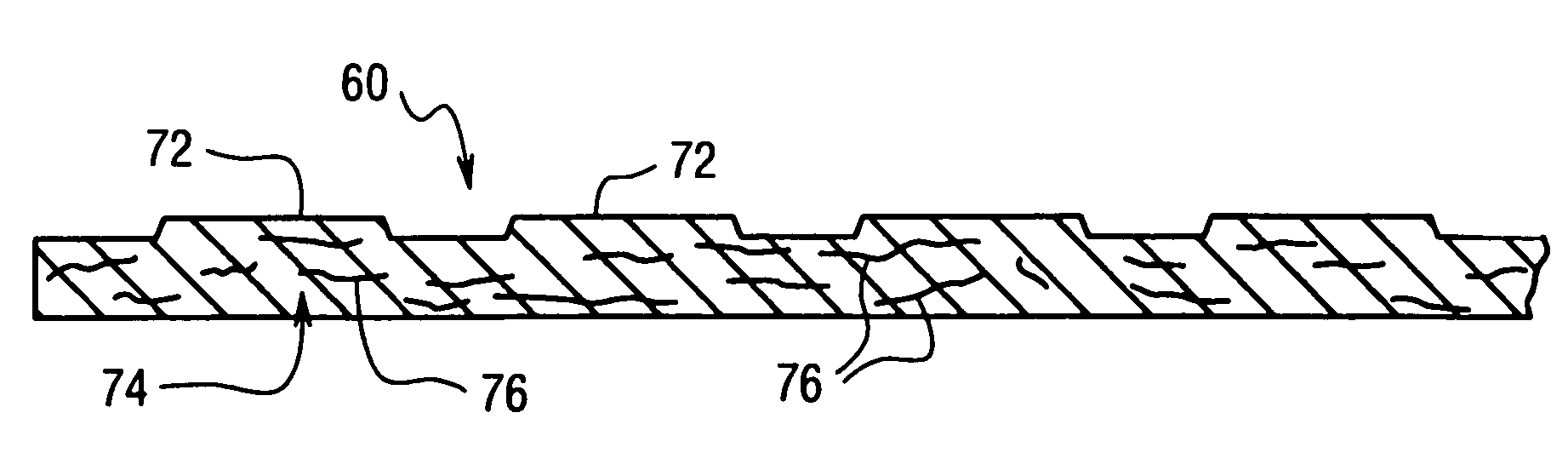

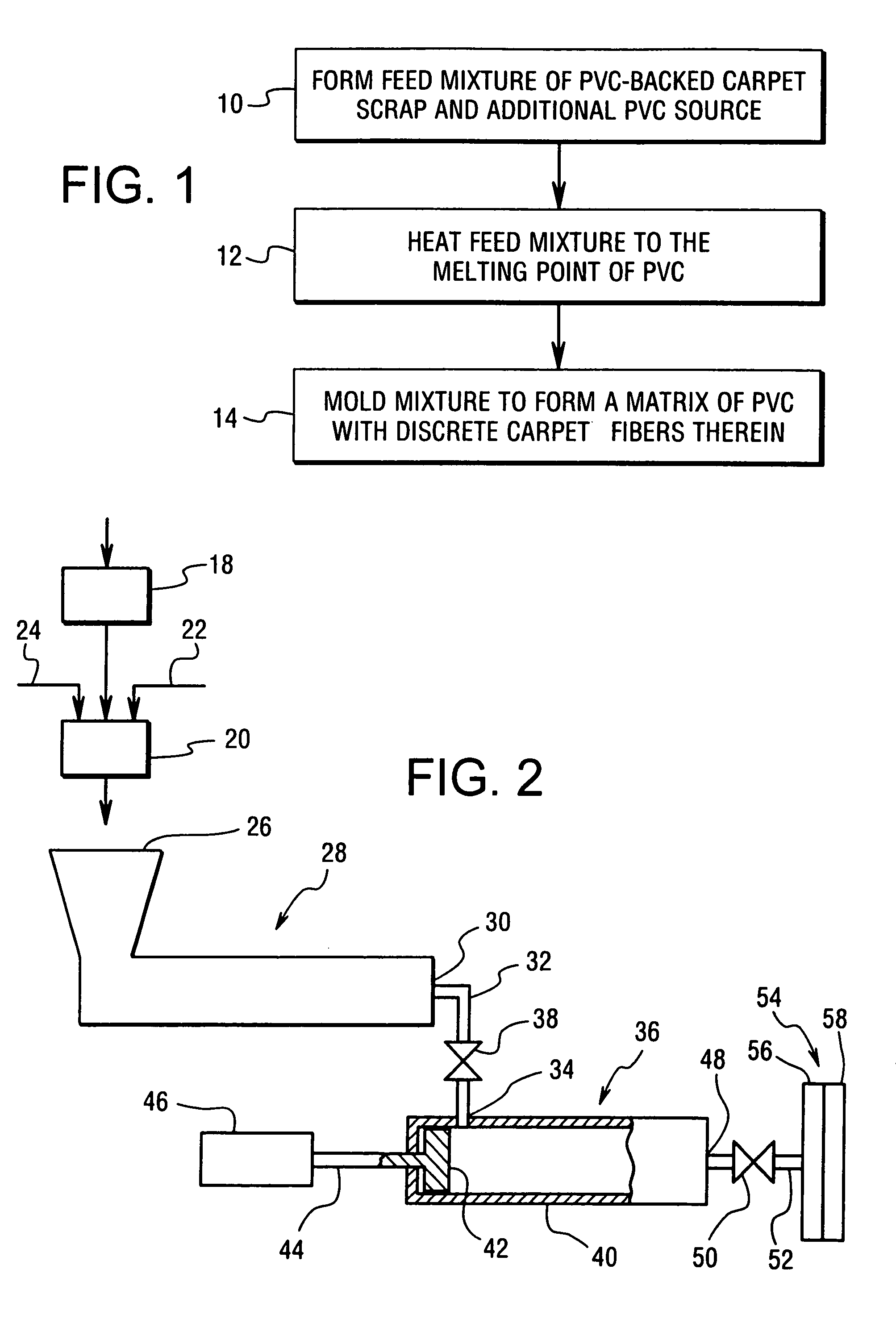

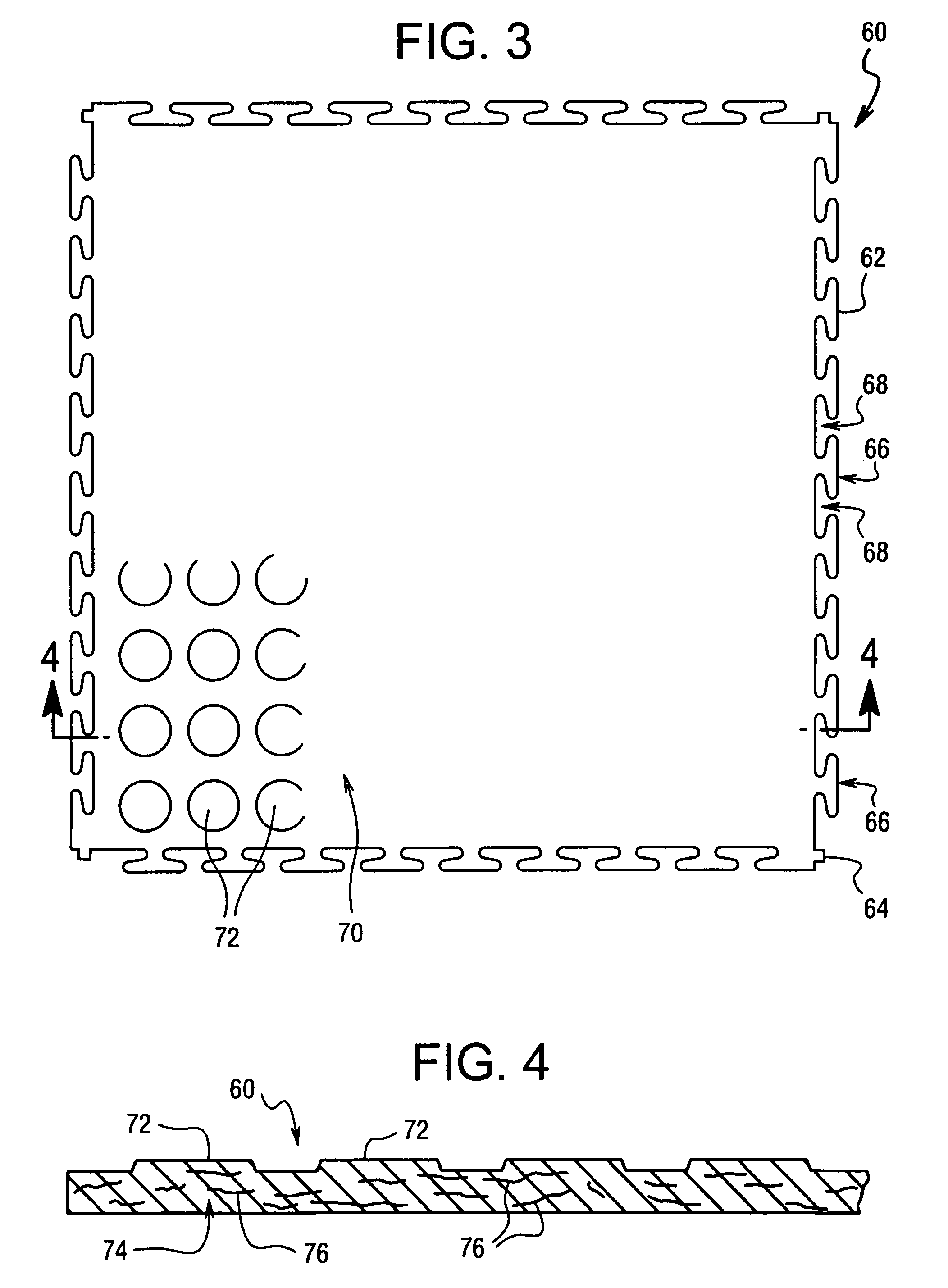

Product and process for producing a molded product from recycled carpet waste

ActiveUS8075987B2Economic recyclingShorten the lengthOther chemical processesSingle unit pavingsFiberPolymer science

Owner:SELECTECH

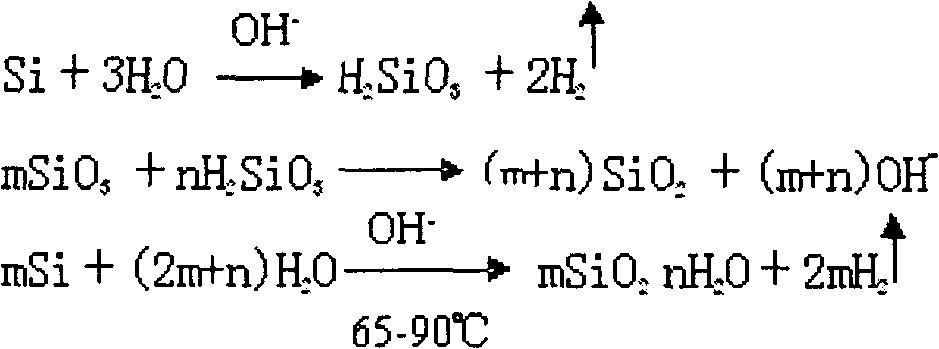

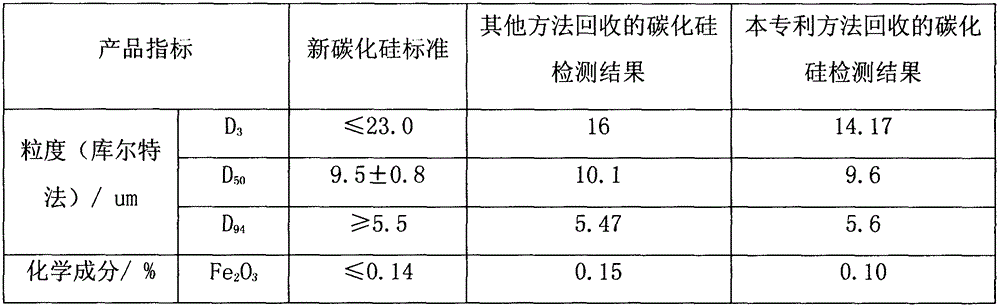

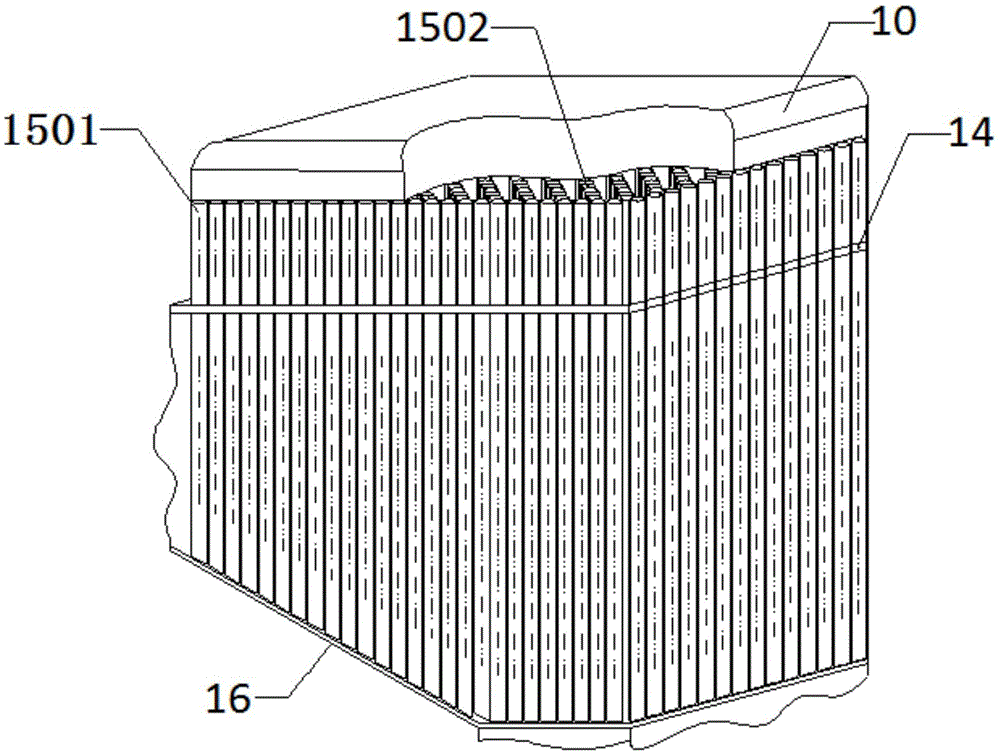

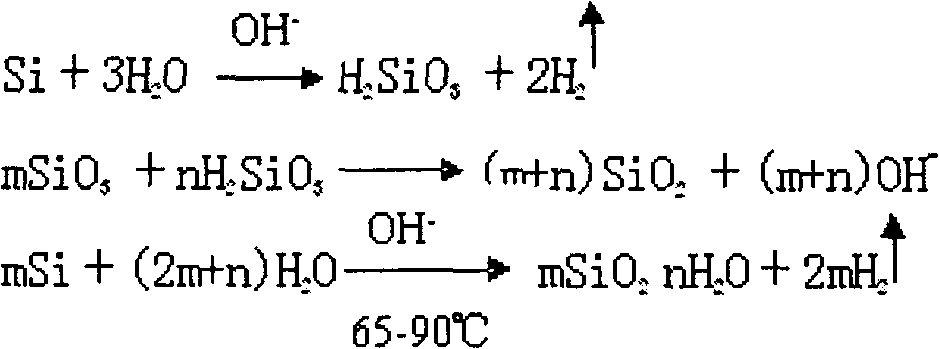

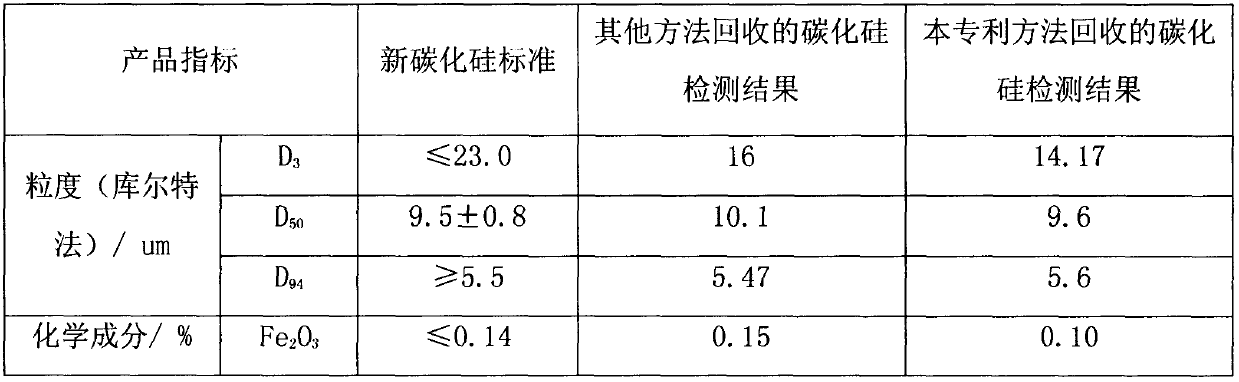

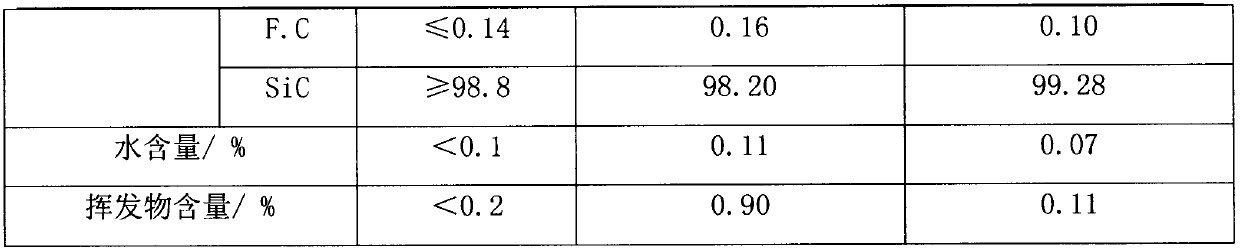

Method for recycling silicon cutting waste mortar

ActiveCN102746935AReduce dosageReduce cost investmentSilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

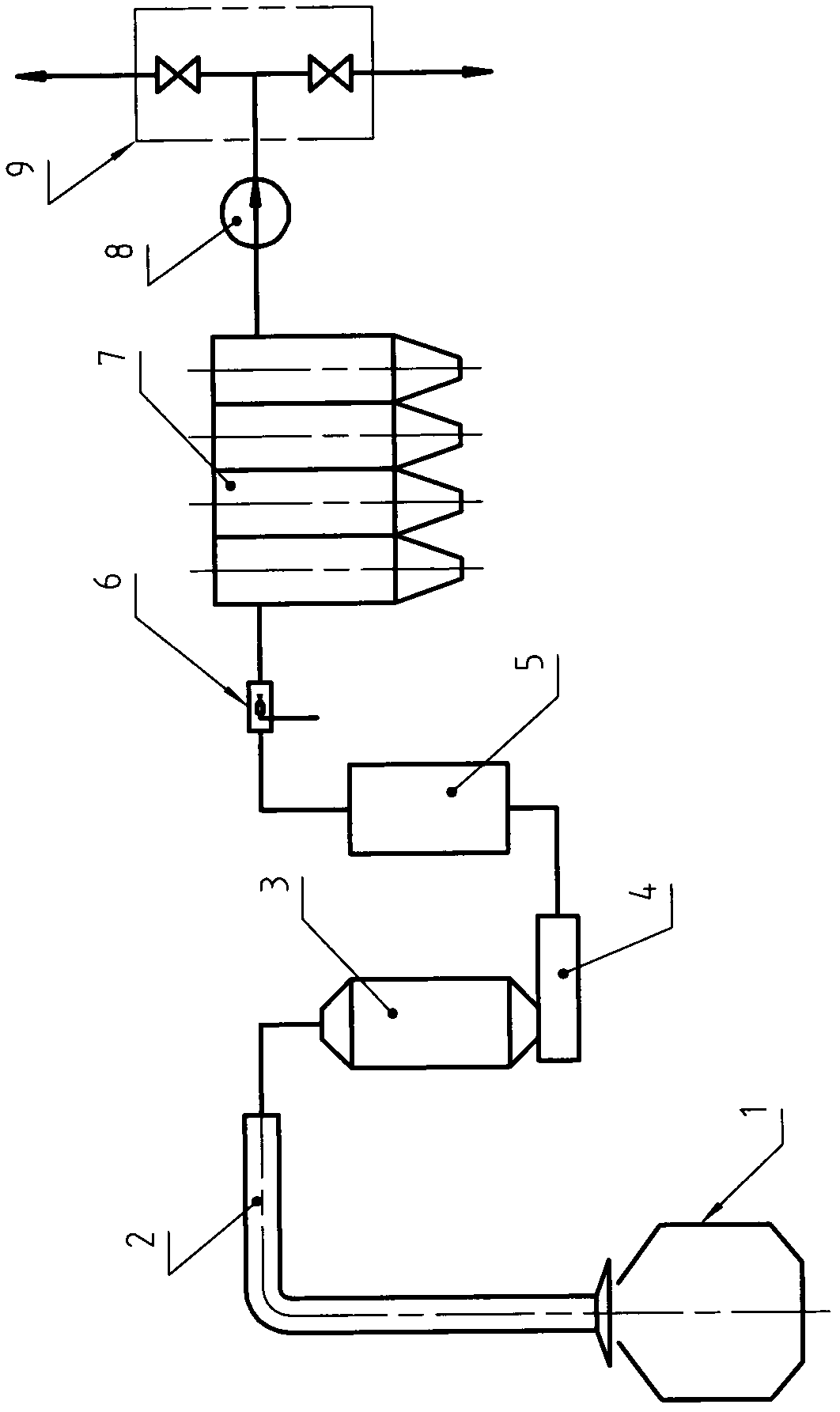

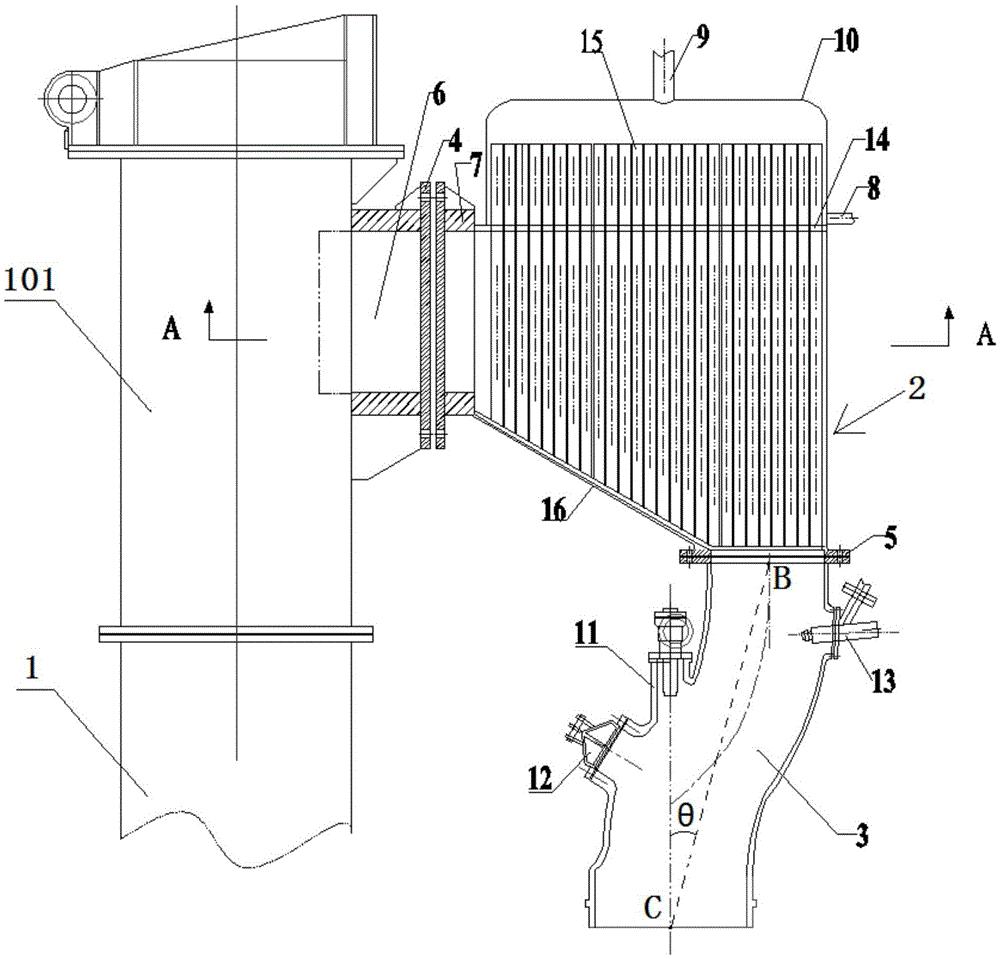

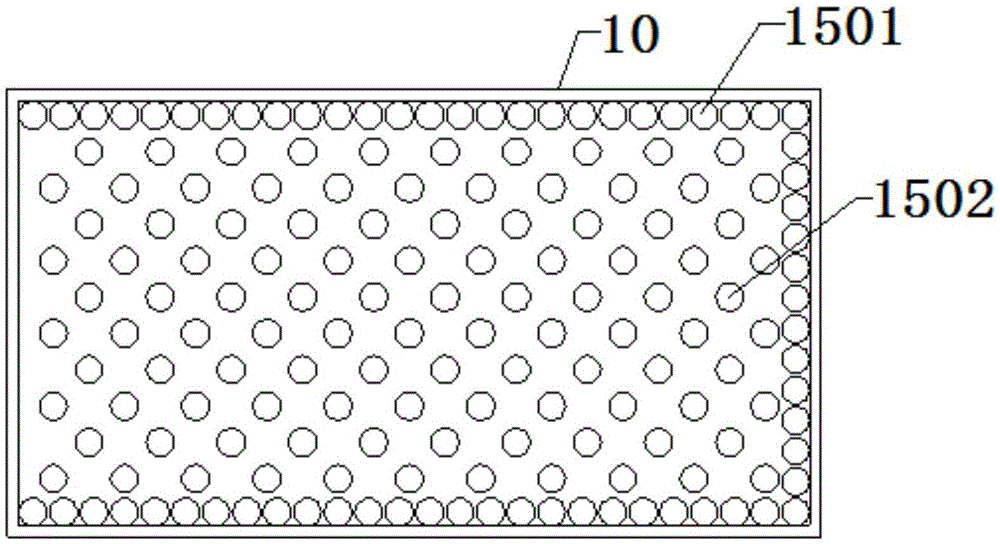

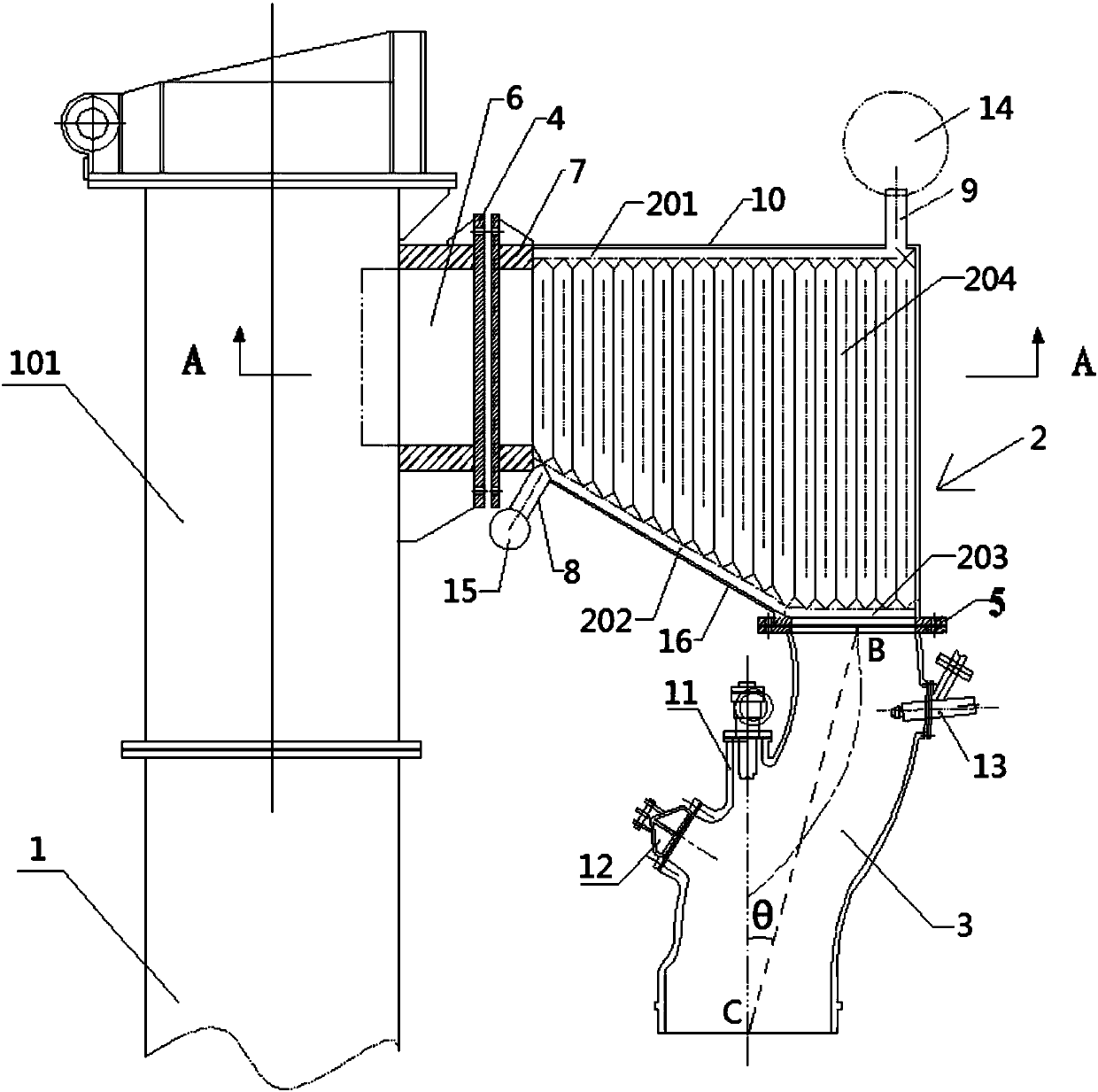

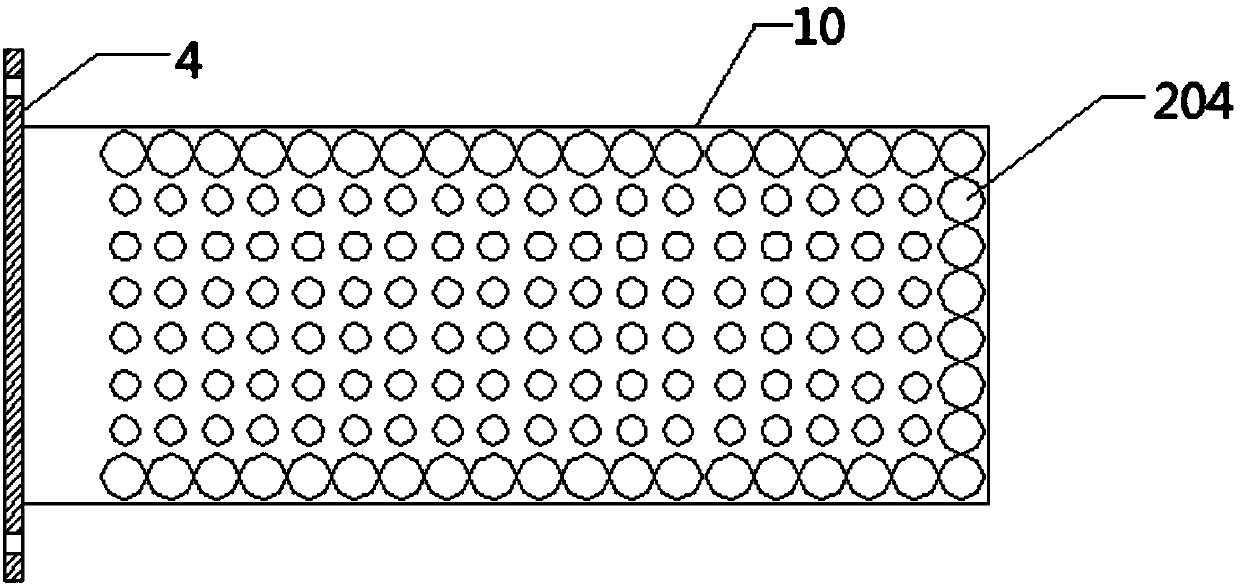

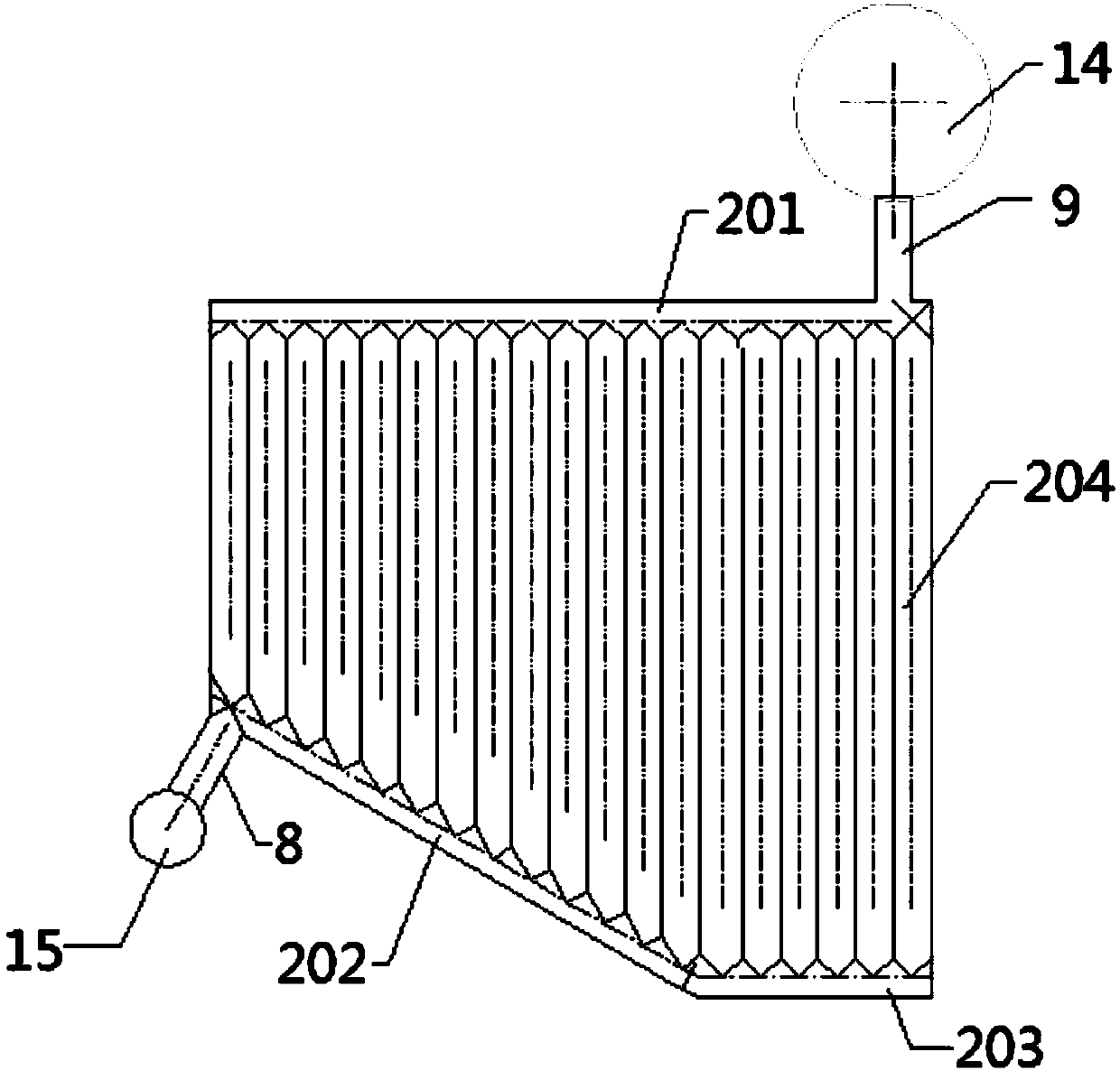

Heat pipe type anti-adhesion crude gas waste heat recycling system

ActiveCN105605954ASafe recyclingEconomic recyclingCorrosion preventionIndirect heat exchangersHeat pipeWaste management

The invention discloses a heat pipe type anti-adhesion crude gas waste heat recycling system, and belongs to the field of technologies for recycling crude gas waste heat in coking technological procedures. The heat pipe type anti-adhesion crude gas waste heat recycling system comprises a riser, a heat pipe heat exchange device and a special-shaped connecting pipe. A riser extension section is arranged on the top of the riser in the vertical direction and is communicated with the special-shaped connecting pipe via the heat pipe heat exchange device; optional heat exchange devices in the riser are omitted. The heat pipe heat exchange device comprises a heat-insulation tank, inlets of the heat-insulation tank are formed in the side surfaces of the heat-insulation tank, outlets of the heat-insulation tank are formed in the bottom surface of the heat-insulation tank, the inlets of the heat-insulation tank are connected with the outlets of the heat-insulation tank by a bottom heat-insulation plate which is obliquely arranged, and the bottom heat-insulation plate is detachably fixed to the bottom surface of the heat-insulation tank. The heat pipe type anti-adhesion crude gas waste heat recycling system has the advantage that crude gas waste heat resources can be safely, economically and efficiently recycled by the aid of the heat pipe type anti-adhesion crude gas waste heat recycling system.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for recycling silicon cutting waste mortar

ActiveCN102746935BGood dispersionImprove stabilitySilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

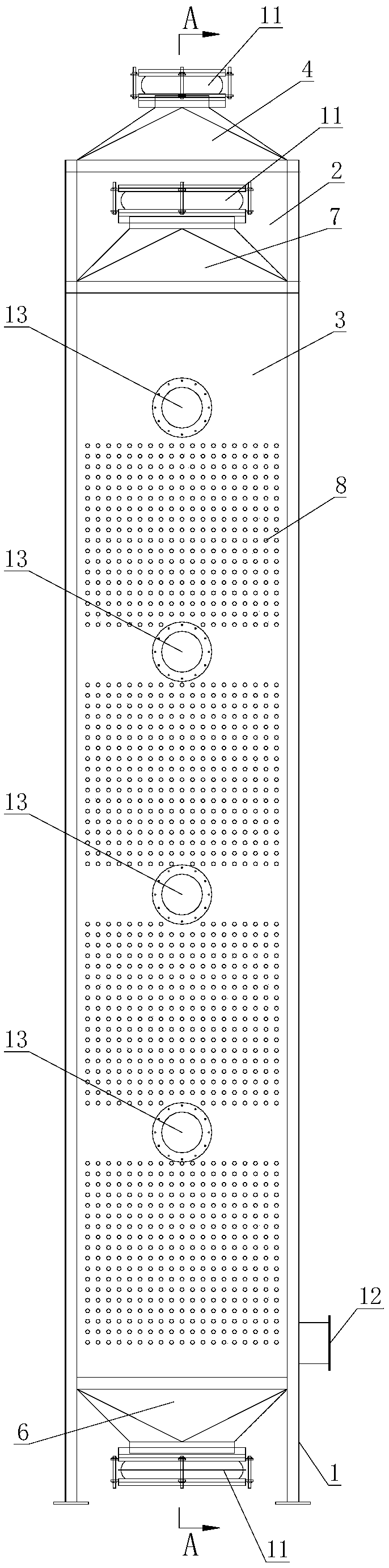

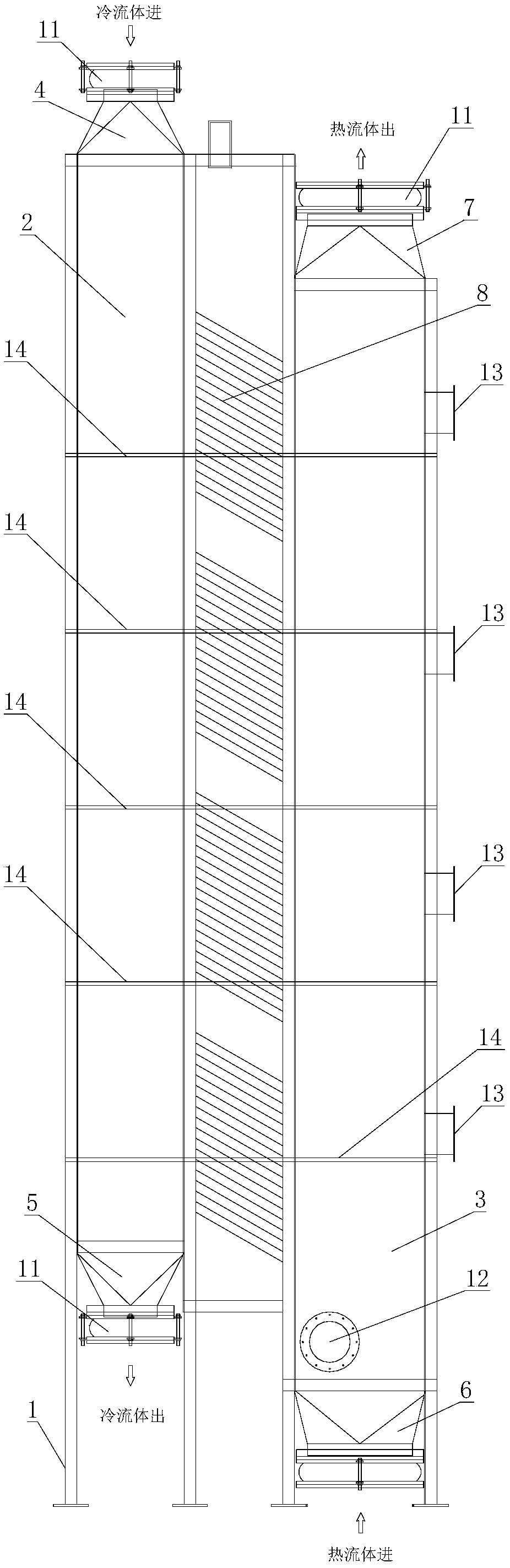

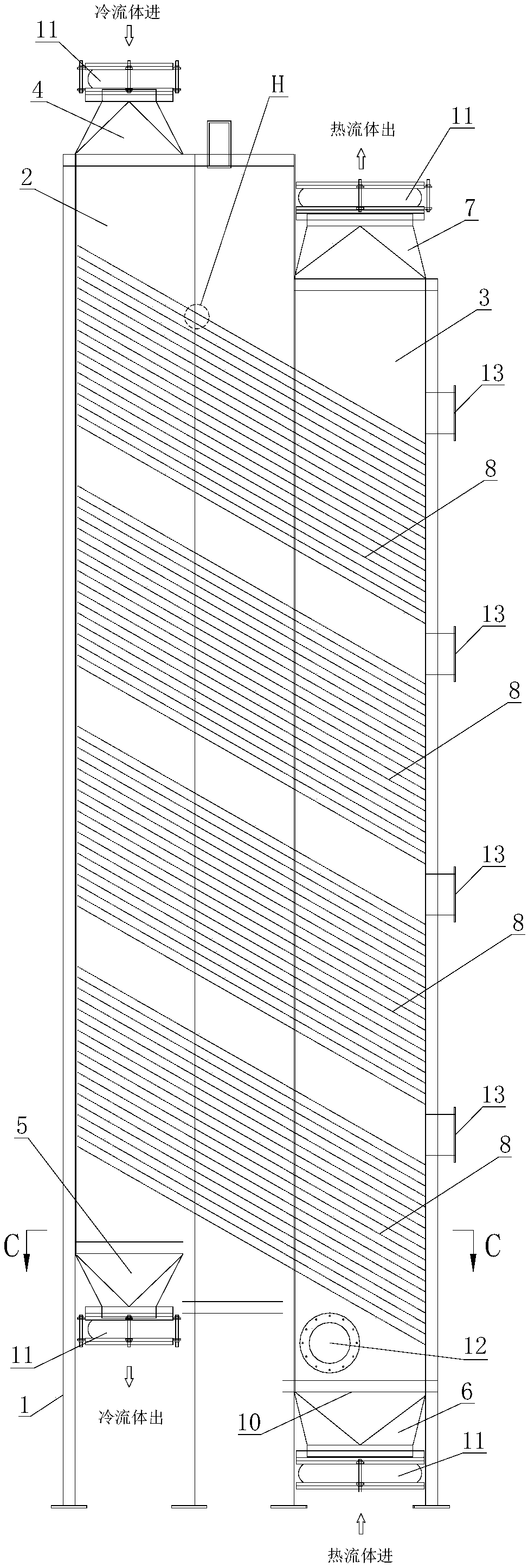

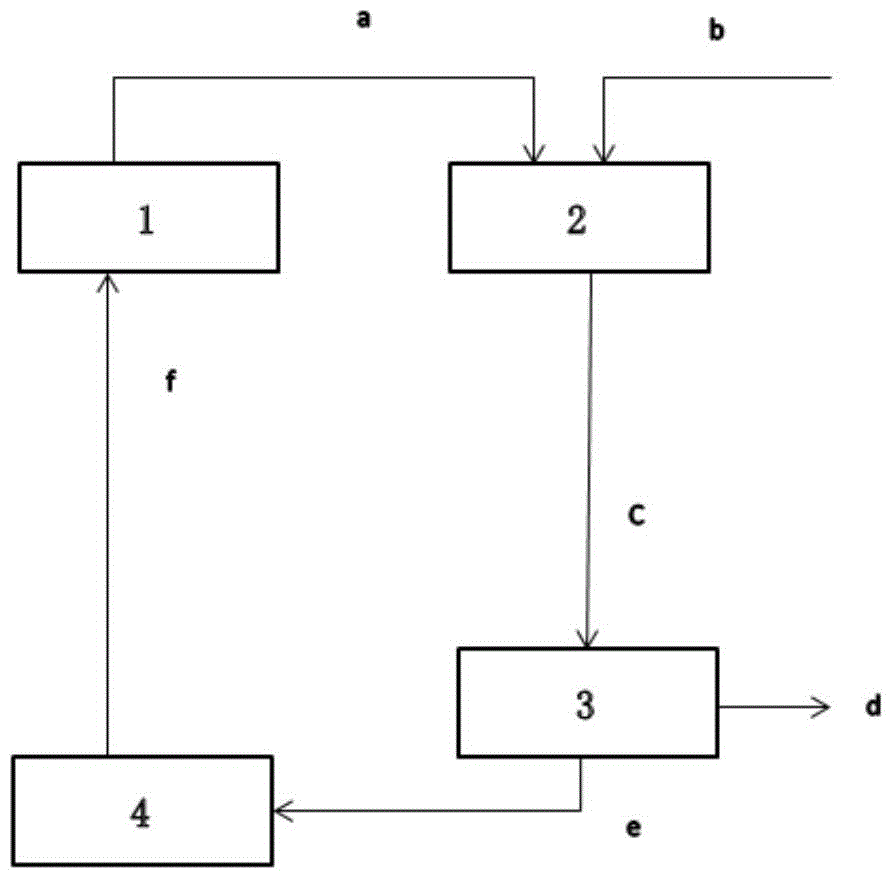

Three-section heat pipe cyclone heat exchanger

PendingCN109269330ADoping will not occurImprove safety and reliabilityIndirect heat exchangersCycloneEvaporation

The invention discloses a three-section heat pipe cyclone heat exchanger which comprises a frame. A cold fluid tank and a hot fluid tank are not contacted and arranged on the frame, and a space is reserved between the cold fluid tank and a hot fluid tank. An inlet of the cold fluid tank is provided with a cold fluid inlet flared opening while an outlet is provided with a cold fluid outlet flared opening, and an inlet of the hot fluid tank is provided with a hot fluid inlet flared opening while an outlet is provided with a hot fluid outlet flared opening. A plurality of heat exchange units formed by a plurality of heat pipes are arranged between the hot fluid tank and the cold fluid tank along a fluid flow direction. One end of each heat pipe extends into the hot fluid tank while the otherend extends into the cold fluid tank. Each heat pipe is partitioned into a heat pipe evaporation section in the hot fluid tank, a heat pipe insulation section between the hot fluid tank and the cold fluid tank and a heat pipe condensation section in the cold fluid tank by the cold fluid tank and the hot fluid tank. The three-section heat pipe cyclone heat exchanger has advantages of high heat exchange efficiency and wide temperature adaptive range.

Owner:江苏龙净节能科技有限公司

Method and device for treating iron-containing waste sulfuric acid

InactiveCN104692338AEfficient regenerationEconomic recyclingSulfur-trioxide/sulfuric-acidSulfateRoom temperature

The invention discloses a method for treating iron-containing waste sulfuric acid. The method comprises the following steps: adding concentrated sulfuric acid into the iron-containing waste sulfuric acid until the sulfuric acid concentration in the mixed solution is higher than 45wt%; at room temperature, separating out dissolved iron in the mixed solution basically in the form of ferrous sulfate crystal; separating solid and liquid mixtures; discharging solid ferrous sulfate; diluting a part of the liquid or the entire liquid by using water to obtain regenerated diluted sulfuric acid; freezing the other part; subsequently performing solid and liquid separation; discharging water from the solid; taking the liquid as regenerated concentrated sulfuric acid; or directly freezing the solid and liquid mixtures and then performing solid and liquid separation; discharging the water of the solid and the ferrous sulfate crystal; diluting a part of the liquid by water to obtain regenerated diluted sulfuric acid, and taking the other part as regenerated concentrated sulfuric acid. The invention also discloses a device for treating the iron-containing waste sulfuric acid. The sulfuric acid treated by the method and the device disclosed by the invention is basically free of iron component, can be effectively reutilized, is high in concentration and can be used as mixed concentration sulfuric acid or reused for acid washing after being diluted, so that economical and high-efficiency treatment of the waste sulfuric acid is realized.

Owner:金大一

A kind of method that recovers precious metal palladium from aniline tar

ActiveCN106480316BScientific recyclingEasy to recycleProcess efficiency improvementIron replacementTar

Owner:NINGBO DADI CHEM ENG & ENVIRONMENTAL PROTECTION

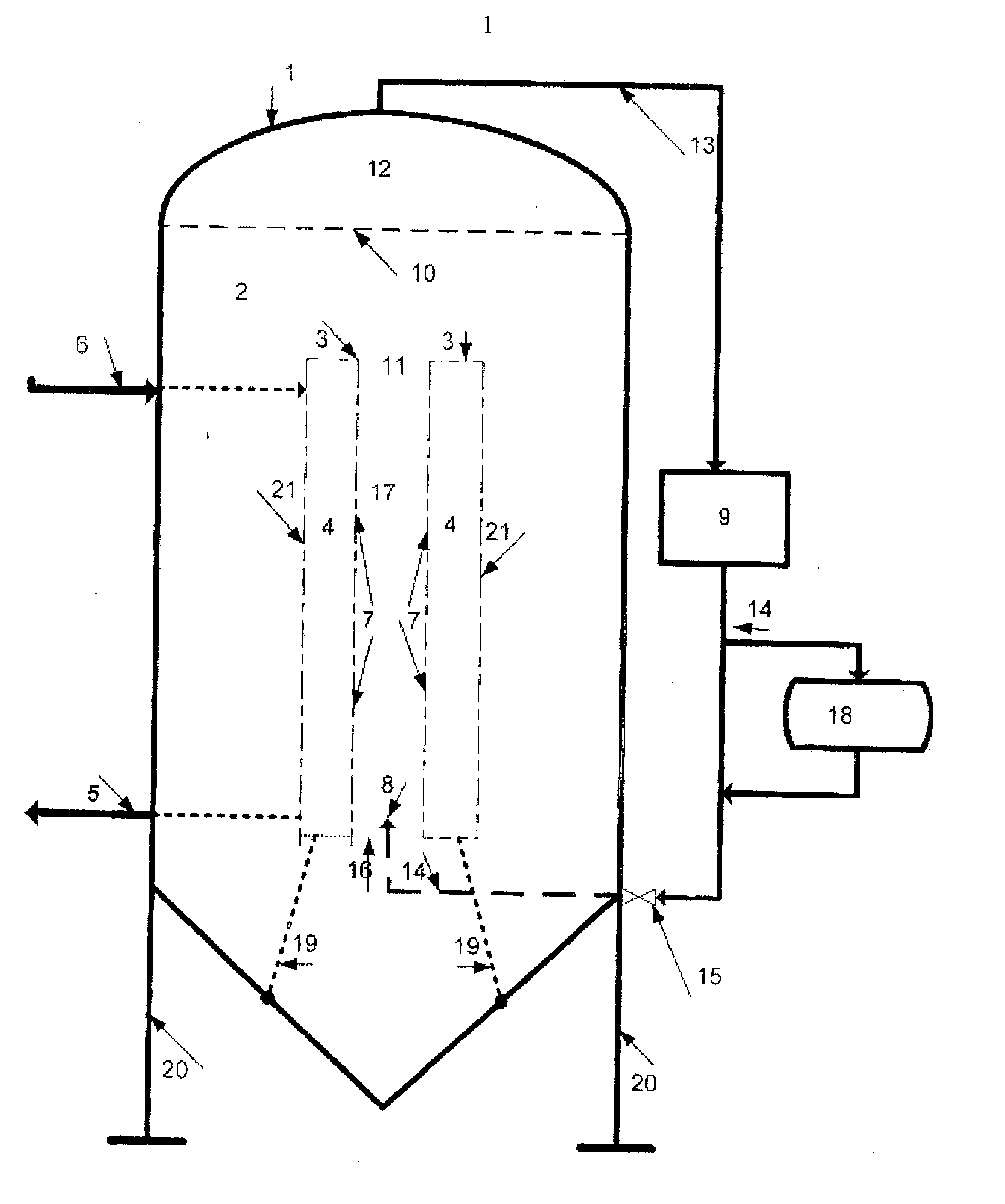

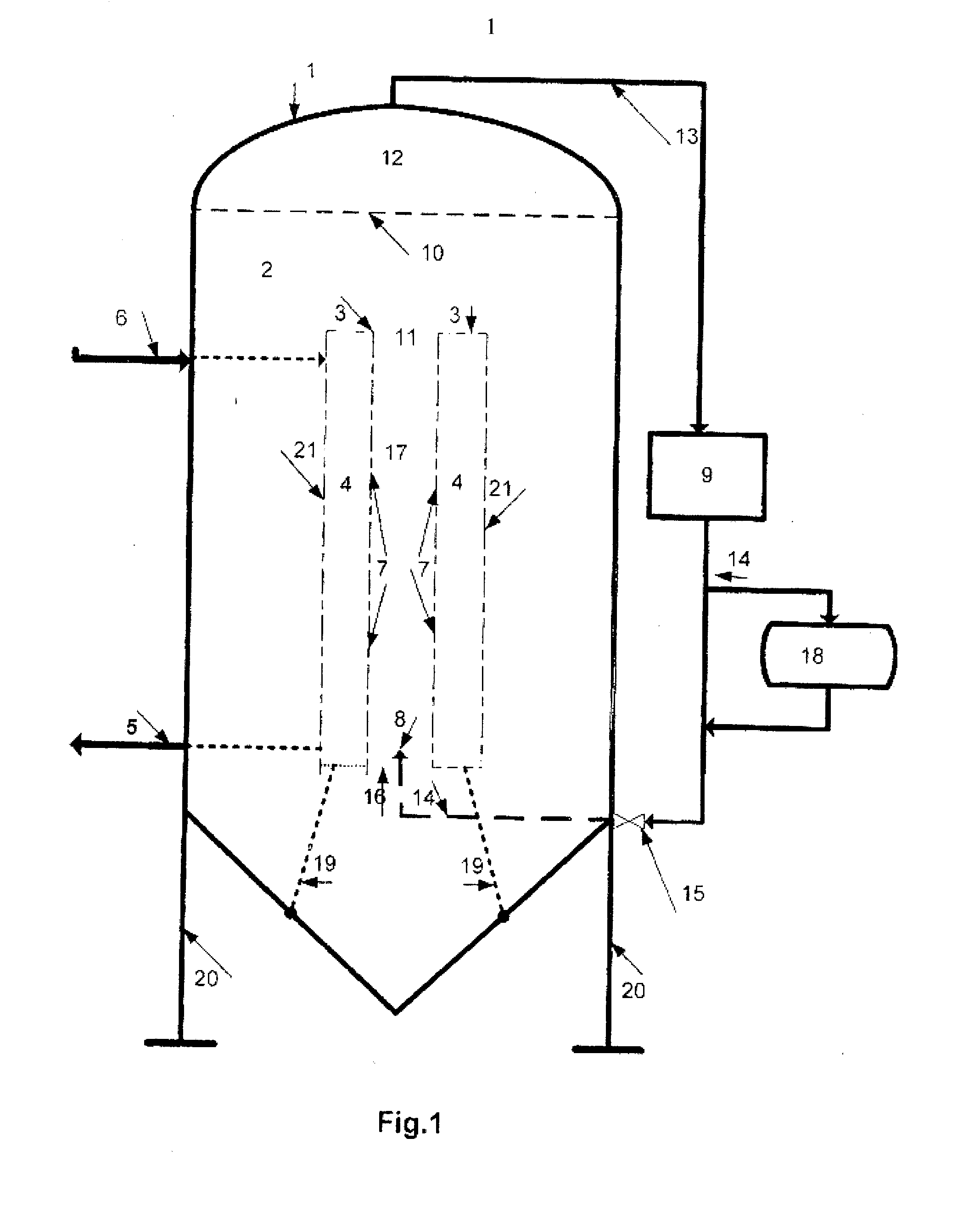

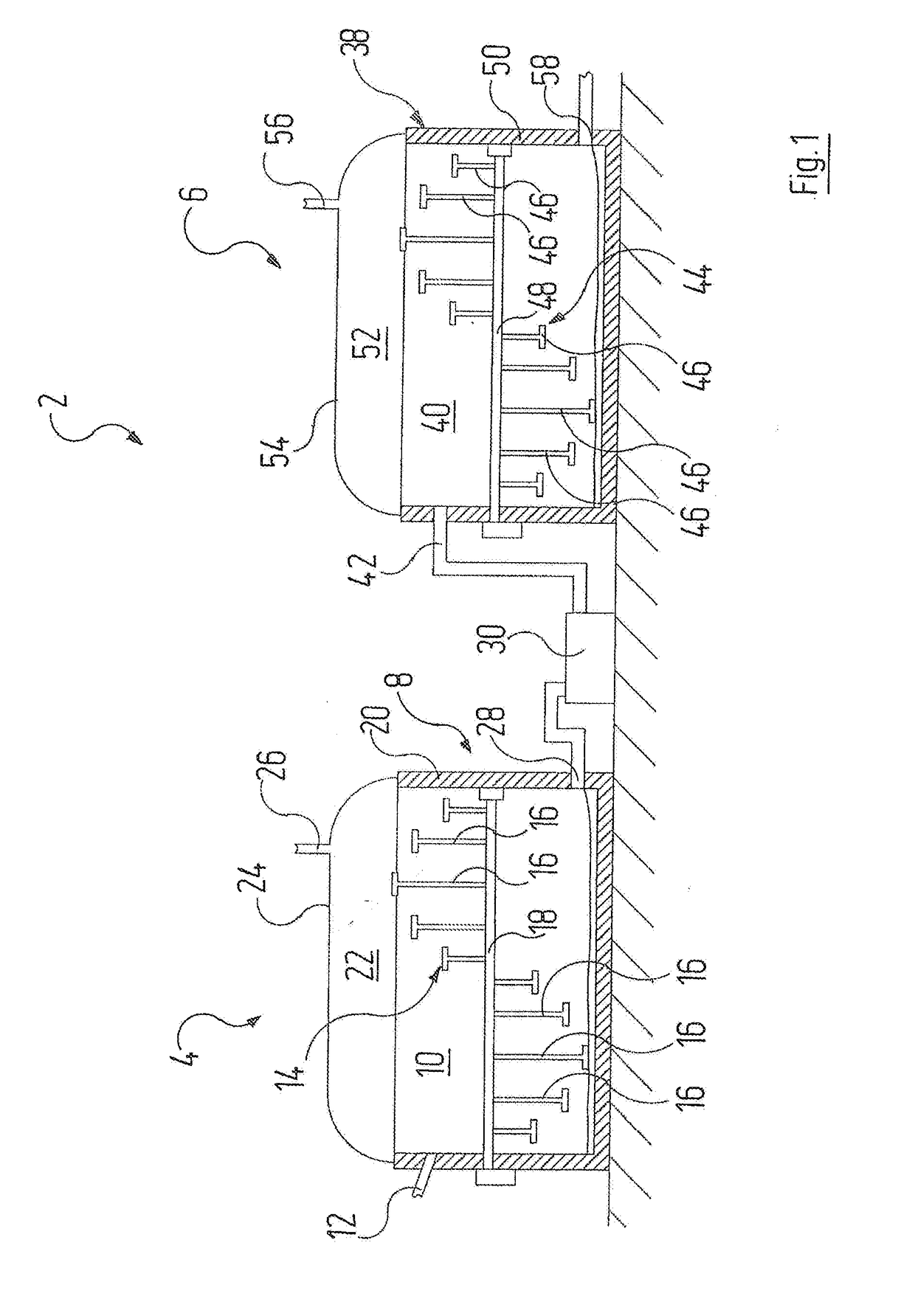

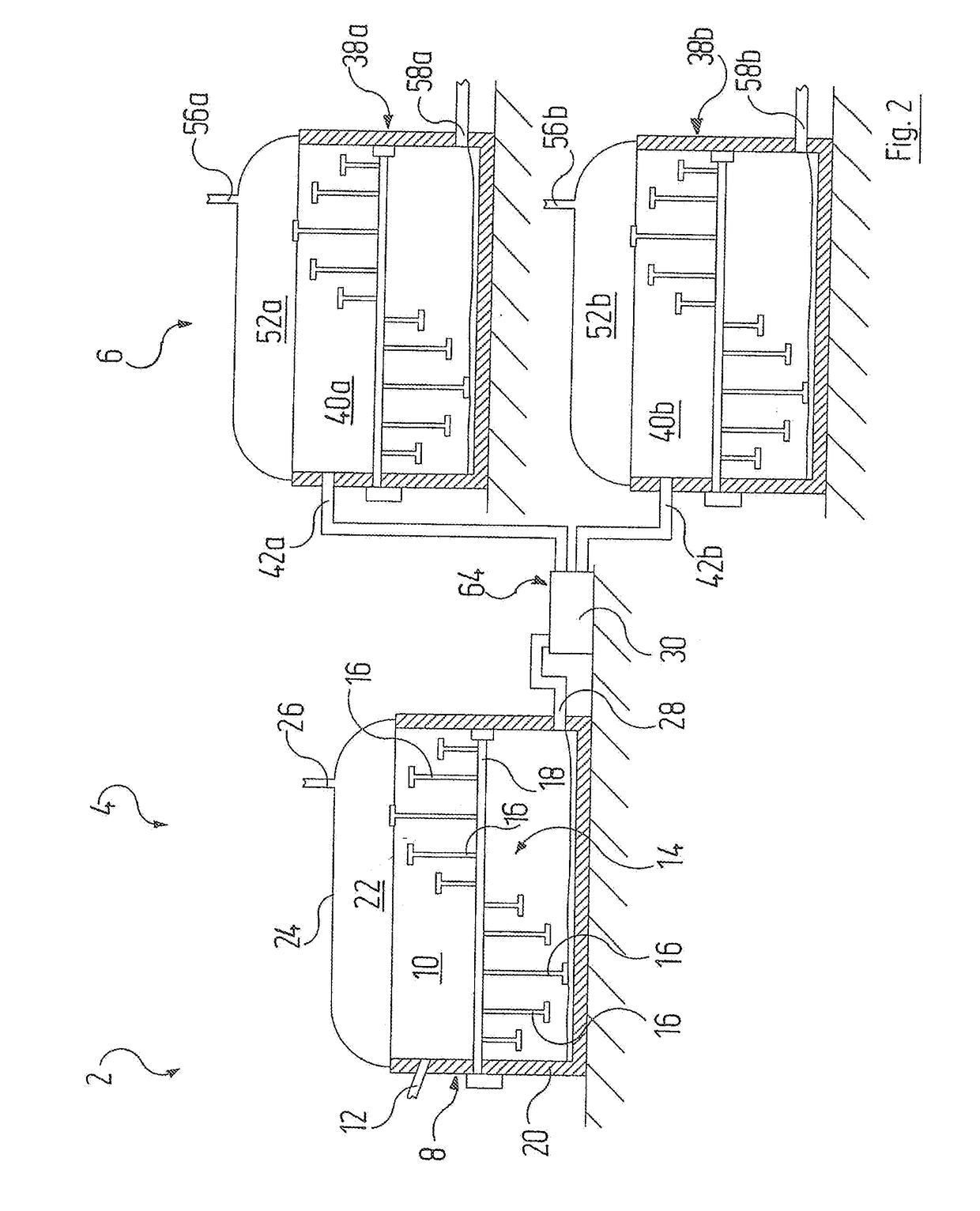

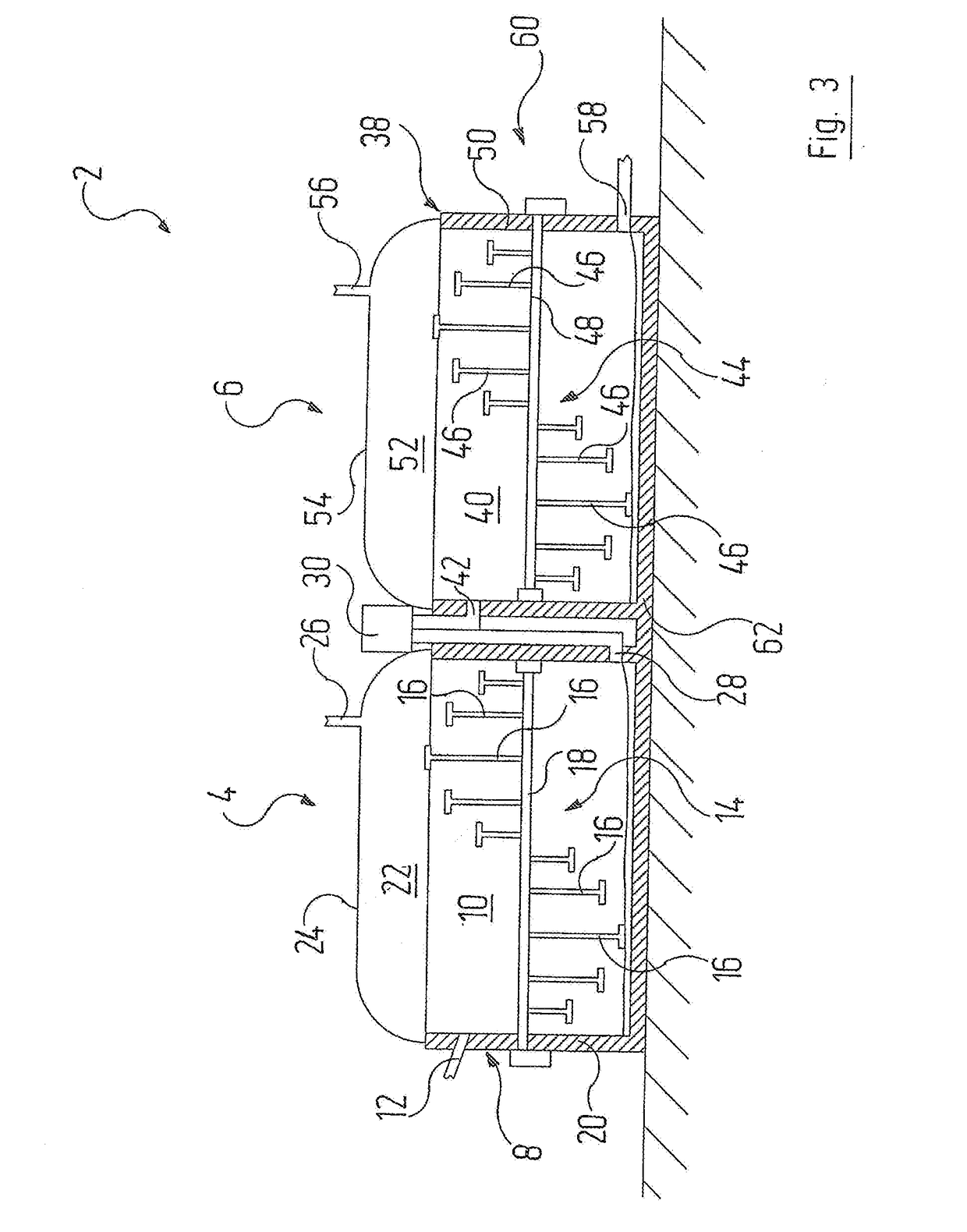

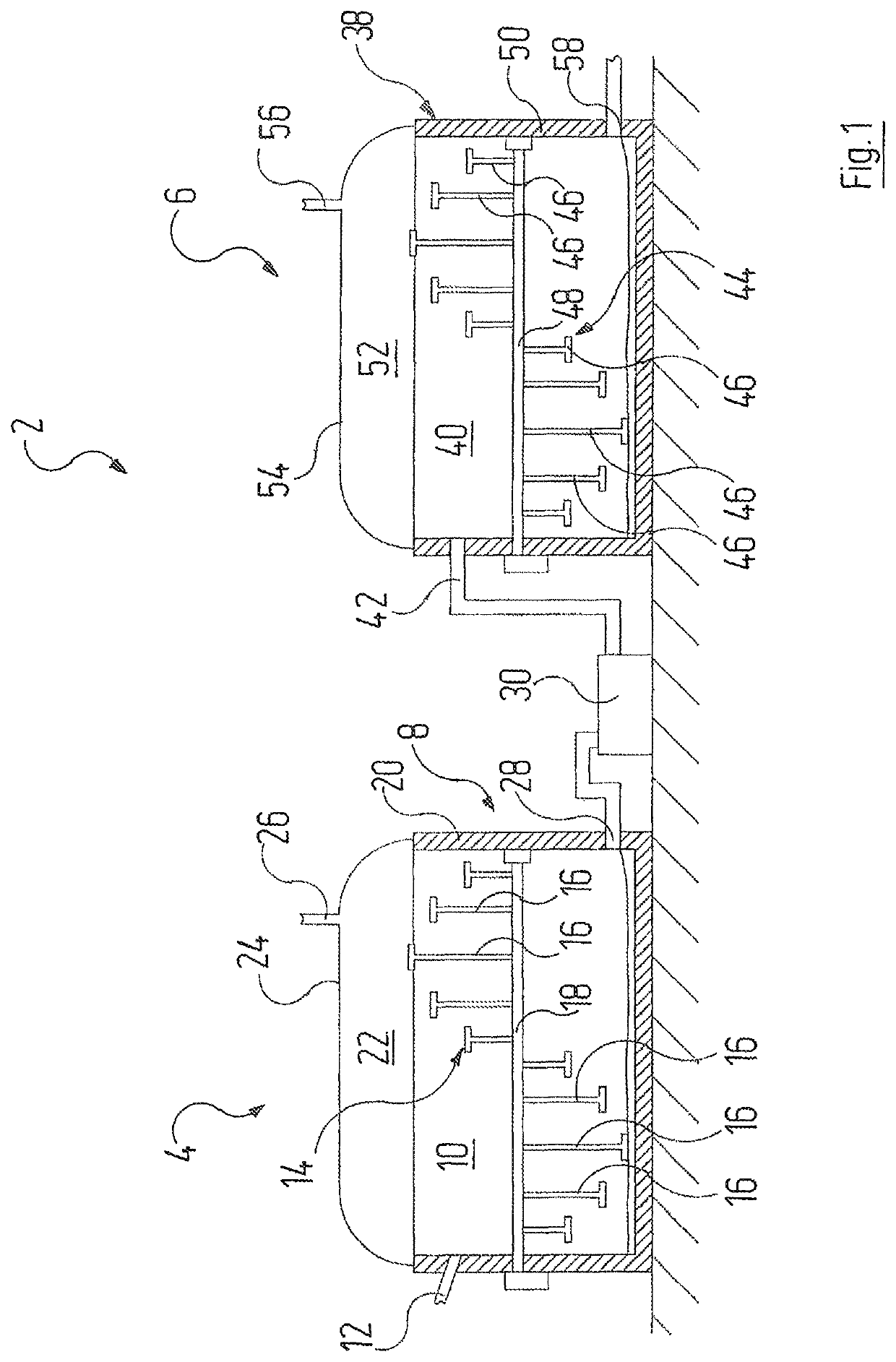

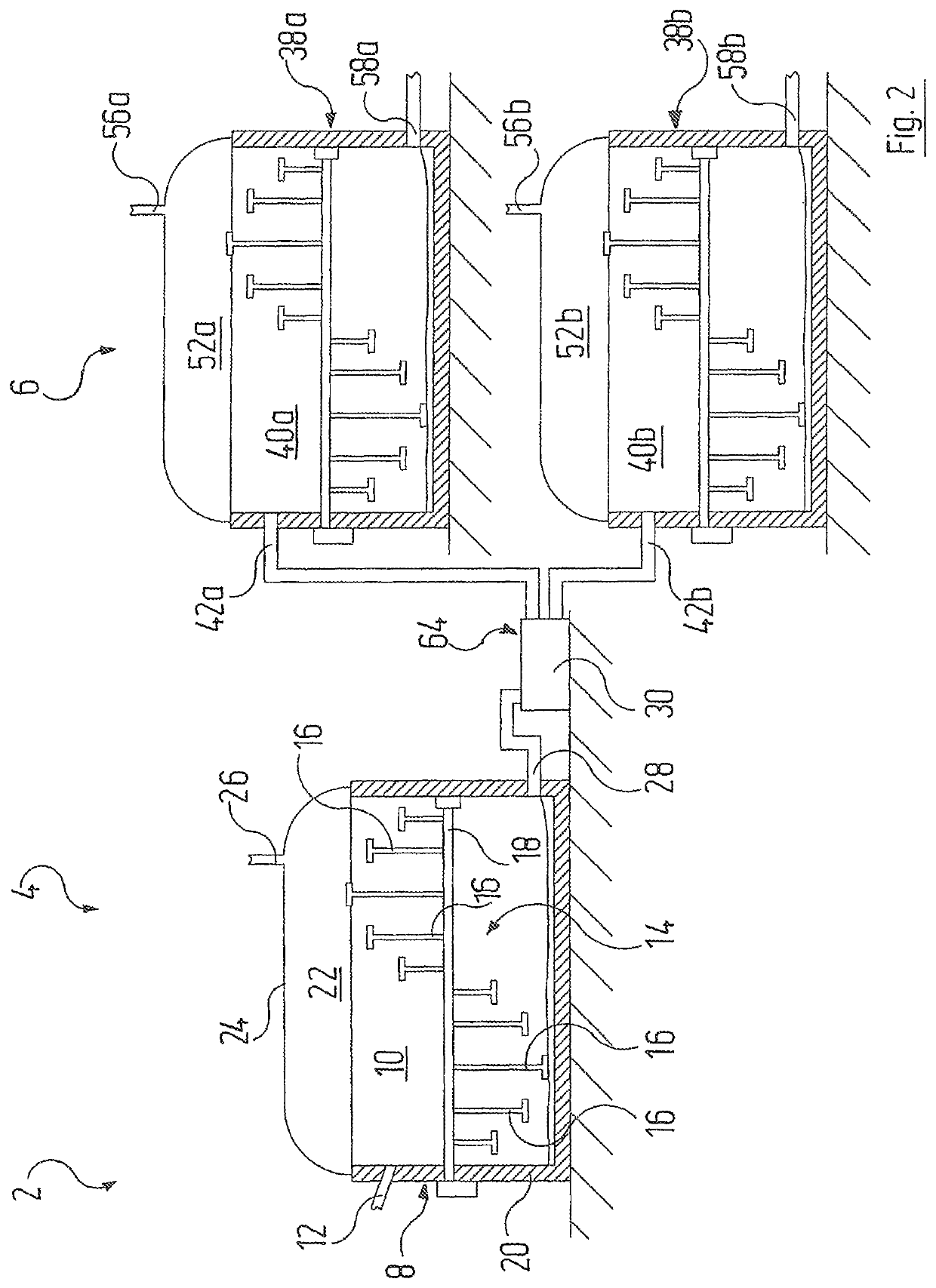

Facility and Process for the Recycling of Biomaterial

ActiveUS20170267598A1Economic recyclingEasy to controlBioreactor/fermenter combinationsBio-organic fraction processingBiotechnologyFermentation

A facility for the recycling of biomaterial with a fermentation stage, whereby the fermentation stage has a fermentation chamber for the production of biogas through anaerobic fermentation of the biomaterial, and with a hygiene stage that is positioned downstream from the fermentation stage, whereby the hygiene stage has a hygienization chamber for the reception and the thermal hygienization of biomaterial discharged from the fermentation stage. A process for the recycling of biomaterial by zymosis is also provided, whereby biogas is produced in a fermentation stage through anaerobic fermentation of the biomaterial, whereby the biomaterial is, after flowing through the fermentation stage, conveyed to a hygiene stage in which the biomaterial thermal is hygienized, and whereby the biomaterial is, after flowing through the hygiene stage, made available as recyclable agricultural, hygienized fermentation residue.

Owner:EISENMANN SE

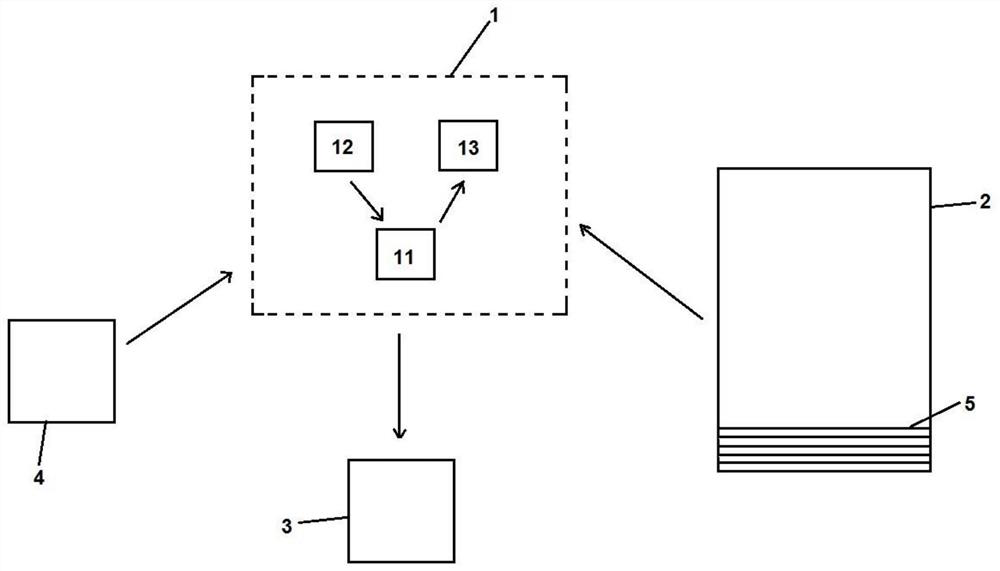

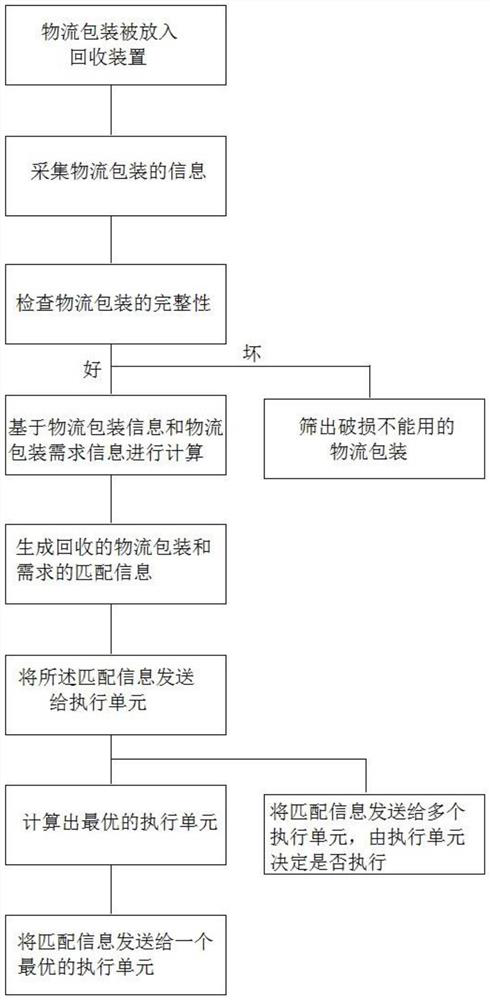

Logistics package recycling system and logistics package recycling method

InactiveCN111950741APromote recoveryEconomic recyclingSustainable waste treatmentBinding material applicationLogistics managementServer

The invention relates to a logistics package recycling system and a logistics package recycling method, the logistics package recycling system comprises a cloud server, and the cloud server is provided with an information receiving module, a processor module and an information sending module; the system also comprises a recycling device used for recycling a logistics package, collecting information of the logistics package and sending the collected logistics package information to the cloud server; wherein the information receiving module is used for receiving logistics package demand information and logistics package information from the recycling device, and the processor module is used for calculating based on the logistics package information and the logistics package demand information from the recycling device so as to generate matching information of recycled logistics packages and demands. The information sending module is configured to send the matching information to an execution unit. According to the logistics package recycling system, rapid, economical and manageable recycling of logistics packages is achieved.

Owner:惜袋(北京)科技有限公司

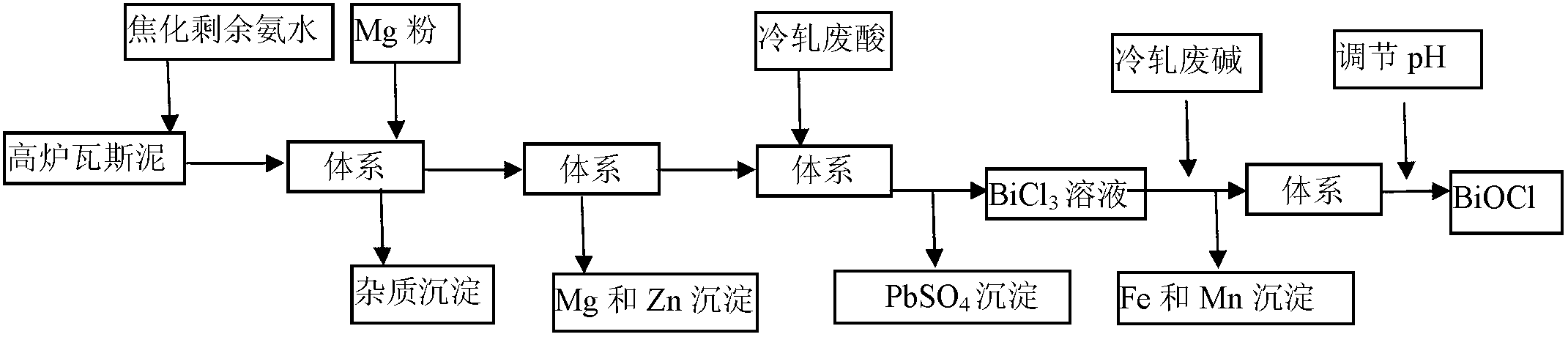

Process for recycling bismuth from gas sludge to prepare BiOCl (Bismuth Oxychloride)

The invention relates to a process for recycling bismuth from gas sludge to prepare BiOCl (Bismuth Oxychloride). The process comprises the following steps: taking the gas sludge, and soaking in coking residual ammonia wastewater; adding Mg powder into the soaking system, and replacing metal impurity elements having poorer activity than that of the MG powder into corresponding simple substances to be filtered and eliminated; heating so as to convert the magnesium element and the zinc element in the system into MgCO3 or ZnCO3 to be deposited, filtered and eliminated; adding cold rolling waste acid, eliminating the lead element through a PbSO4 deposit form, leaving metal impurity elements which are easy to be dissolved as acid in an ion manner, and leaving the bismuth element in a Bi3+ form; adding cold rolling alkali waste so as to correspondingly deposit and precipitate the metal impurity ions including Fe2+, Fe3+, Mn2+ and Mn4+; adjusting the system pH within 1.5-2.1, carrying out cohydrolysis of C1- and Bi3+ in the system so as to generate BiOCl deposit, and treating the BiOCl deposit so as to obtain the BiOCl. The process is low in cost, and bismuth can be economically recycled from gas sludge to prepare the BiOCl.

Owner:武汉钢铁有限公司

Facility and process for the recycling of biomaterial

ActiveUS10961164B2Economic recyclingEasy to controlBioreactor/fermenter combinationsBio-organic fraction processingBiochemical engineeringPulp and paper industry

A facility for the recycling of biomaterial with a fermentation stage, whereby the fermentation stage has a fermentation chamber for the production of biogas through anaerobic fermentation of the biomaterial, and with a hygiene stage that is positioned downstream from the fermentation stage, whereby the hygiene stage has a hygienization chamber for the reception and the thermal hygienization of biomaterial discharged from the fermentation stage. A process for the recycling of biomaterial by zymosis is also provided, whereby biogas is produced in a fermentation stage through anaerobic fermentation of the biomaterial, whereby the biomaterial is, after flowing through the fermentation stage, conveyed to a hygiene stage in which the biomaterial thermal is hygienized, and whereby the biomaterial is, after flowing through the hygiene stage, made available as recyclable agricultural, hygienized fermentation residue.

Owner:EISENMANN SE

A kind of floating nano zero-valent iron material and preparation method thereof

ActiveCN108249542BImprove purification effectEasy to recycleWater/sewage treatment by reductionParticulatesContaminated water

The invention relates to nanometer materials, and specifically discloses a floating nanometer zero-valent iron material and a preparation method thereof. The floatable nanometer zero-valent iron material of the present invention is prepared from biomass adsorption particles with suspending or buoyant properties through iron adsorption loading and in-situ rapid reduction process; wherein, the preparation method of the biomass adsorption particles is as follows: : Breaking the biomass material, passing through a 40‑100 mesh sieve to obtain powder particles, stirring in water, wetting, standing still, collecting the floating particles to obtain biomass adsorption particles. The floatable nanometer zero-valent iron material provided by the present invention can be thrown in the polluted water body in a suspended or floating state, without settling to the bottom of the water body, thereby maintaining a more sufficient contact with the water body and a more continuous reaction, which is expected Obtain unique application effects in some special water purification.

Owner:北京科大科技园有限公司

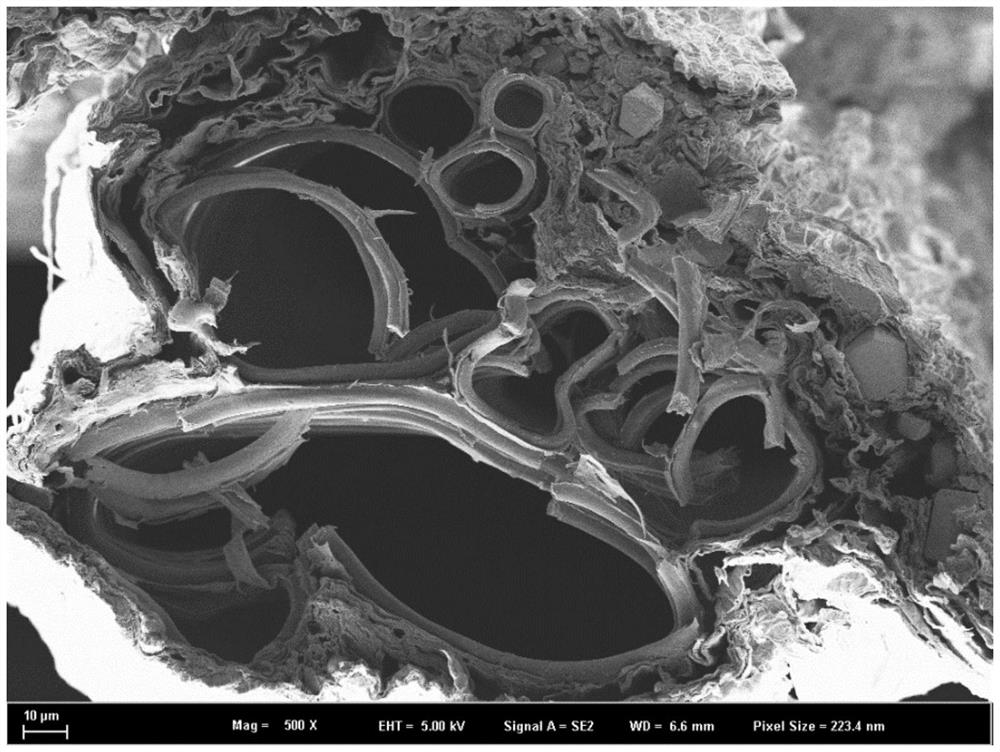

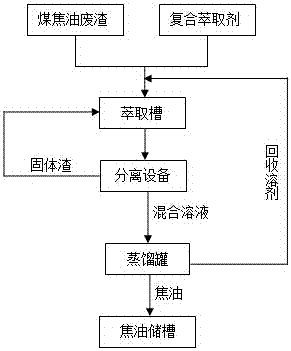

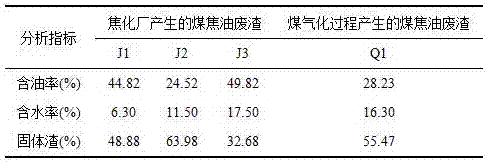

A kind of coal tar waste residue extraction and separation method

ActiveCN105018124BReduce the risk of contaminationReduce energy consumptionSolid waste disposalTar working-up by solvent extractionSludgeDistillation

The invention relates to a method for extracting and separating coal tar waste residue. The purpose of the present invention is to solve the technical problems existing in the existing method of solvent extraction and separation of coal tar waste residue, which easily cause secondary environmental pollution, expensive extraction agent, high operating cost and complicated process. The technical solution adopted in the present invention is, under normal temperature and pressure, using a composite extractant composed of furfural and ester solvents, through the steps of extraction, separation, distillation and washing, the tar, coal powder, and coke in the coal tar waste residue are extracted. In the process of extraction, the amount of the composite extractant used is 1 to 3 times the mass of the coal tar waste residue. The composition of the composite extractant of the invention is cheap and easy to obtain, all of which have low toxicity and high separation efficiency. The whole extraction and separation operation process is carried out under normal temperature and pressure conditions, the process is simple, and the energy consumption and operation cost are low.

Owner:太原市金浦顺化工有限公司

Post-processing method of polypropylene powder

ActiveCN102453160BEasy to separatePlay a role in removing hydrocarbonsPtru catalystPhysical chemistry

The invention discloses a post-treatment method for polypropylene powder, which belongs to the field of petrochemical industry. For the existing polypropylene post-treatment process, "the polypropylene powder that leaves the polymerization system and undergoes preliminary gas / solid separation or enters the dryer, is indirectly heated by steam and nitrogen, removes hydrocarbons in the powder, and then enters the steam Nitrogen and water vapor are passed into the steamer to deactivate the catalyst; or enter the degassing chamber, and nitrogen containing water vapor is passed into the degassing chamber to improve: instead of passing nitrogen into the dryer, water vapor is passed into the dryer, and the It is transformed into a steam dryer that recovers hydrocarbons and deactivates the catalyst. The polymer after removing hydrocarbons enters the steamer (or degassing chamber, the same below), and nitrogen without water vapor is added into the steamer to deactivate the steam. The steamer is transformed into a dehumidifier for removing water vapor in the powder. The invention can completely recover the hydrocarbons leaving the polymerization system in an economical way, reduce unit consumption and energy consumption, and completely solve the problem of environmental protection.

Owner:高煦

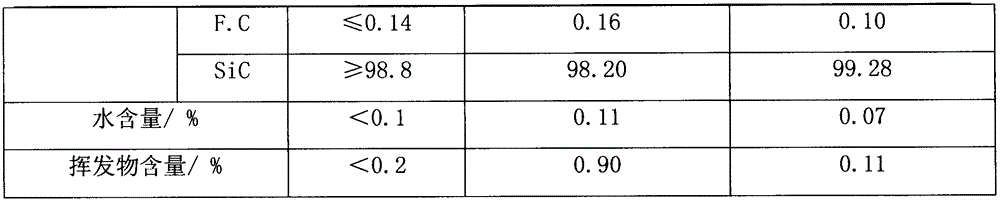

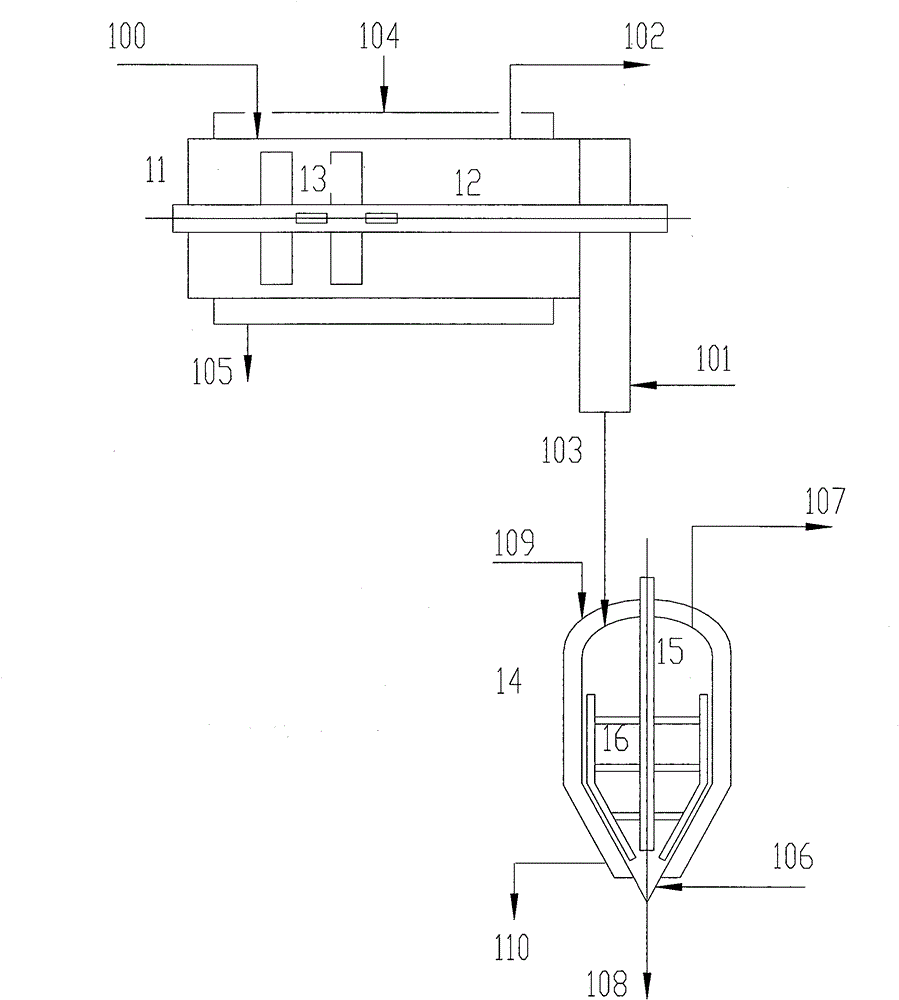

A tube-bundle waste heat recovery system for anti-caking raw gas

ActiveCN105602582BSafe recyclingEconomic recyclingEnergy inputIndirect heat exchangersWaste heatAnti adhesive

The invention discloses an anti-bonding pipe bundle type waste heat recycling system for raw coke oven gas, and belongs to the technical field of raw coke oven gas waste heat recycling in the coking technological process. The anti-bonding pipe bundle type waste heat recycling system for the raw coke oven gas comprises a lifting pipe, a pipe bundle heat exchange device and a special-shaped connecting pipe. A lifting pipe extending section is arranged at the top end of the lifting pipe in a vertically upward mode, and communicated with the special-shaped connecting pipe through the pipe bundle heat exchange device. No heat exchange device is arranged in the lifting pipe. The pipe bundle heat exchange device comprises a plurality of single-row assemblies arranged in parallel. The pipe bundle heat exchange device comprises a heat insulation box, an inlet of the insulation box is formed in the side face of the heat insulation box, an outlet of the heat insulation box is formed in the bottom face of the heat insulation box, the inlet and outlet of the heat insulation box are connected through an obliquely-arranged bottom heat insulation plate, and the bottom heat insulation plate is detachably fixed to the bottom face of the heat insulation box. According to the anti-bonding pipe bundle type waste heat recycling system, raw coke oven gas waste heat resources can be recycled more safely, economically and efficiently.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

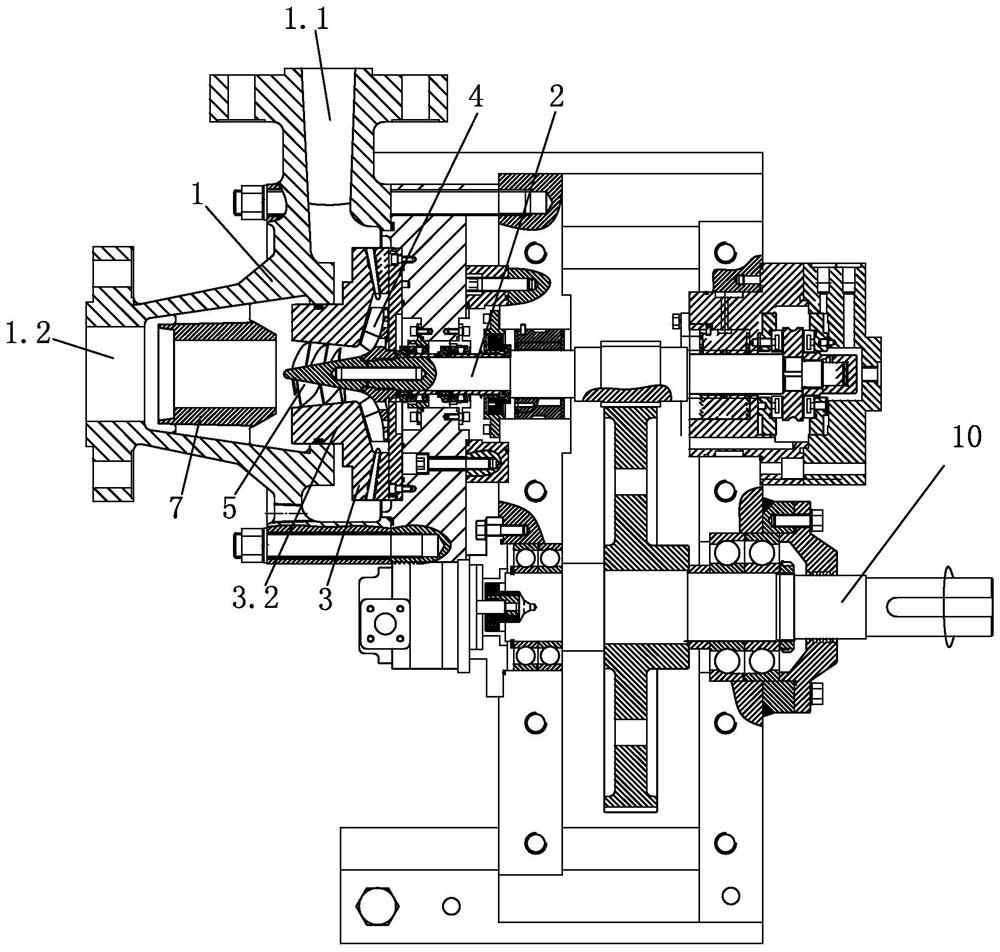

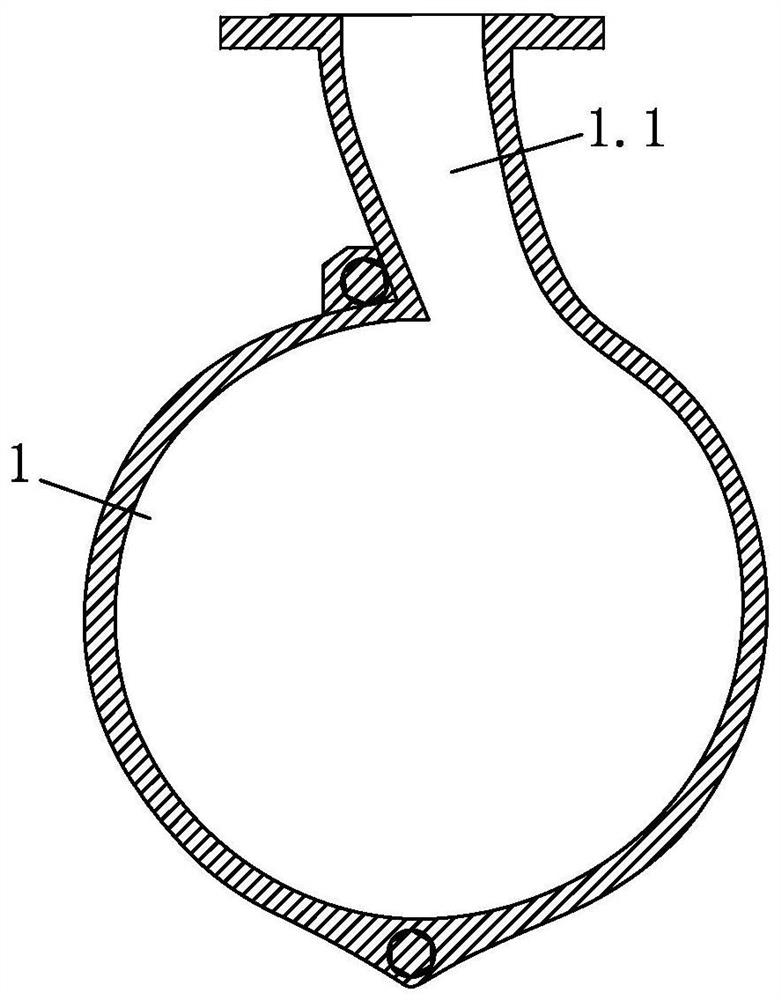

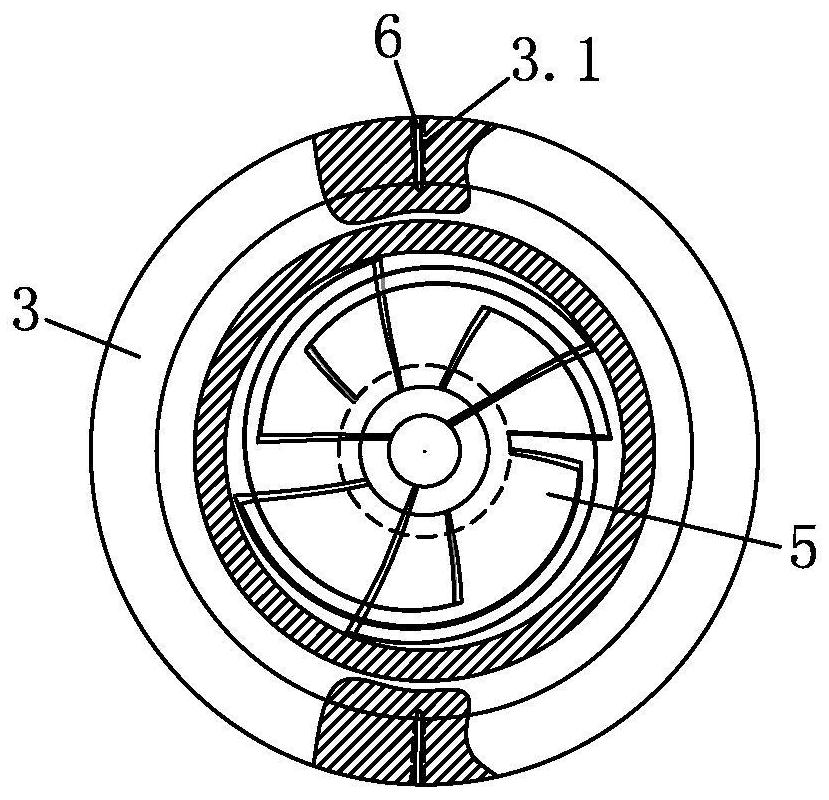

High-speed centrifugal pump reverse rotation hydraulic turbine device

PendingCN111649004AImprove economyReduce energy lossPump componentsHydro energy generationPhysicsCentrifugal pump

The invention belongs to the field of fluid machinery and energy recovery. According to the technical scheme, a high-speed centrifugal pump reverse rotation hydraulic turbine device is characterized by comprising a volute, a turbine shaft, a flow guide shell fixed in an inner cavity of the volute, an impeller rotationally positioned in the flow guide shell and connected with the left end of the turbine shaft, and an inducer fixed at the left end of the impeller, wherein a working medium flows along an inlet section of the volute, the inner cavity of the volute, the impeller and the inducer inan inner cavity of the flow guide shell, and an outlet section of the volute in sequence; a plurality of spraying holes are peripherally distributed in the shell wall of the flow guide shell, and communicate with the inner cavity of the volute and the inner cavity of the flow guide shell; an extension section extending into the outlet section of the volute is arranged on the left side end surfaceof the flow guide shell; the inducer is arranged in the extension section; and the axis of the volute, the axis of the flow guide shell, the rotating axis of the impeller, the rotating axis of the inducer and the rotating axis of the turbine shaft are coaxially arranged. The device can be suitable for the working conditions of low flow and high abundant energy, and is high in energy recovery efficiency and reliable in operation.

Owner:ZHEJIANG SCI-TECH UNIV

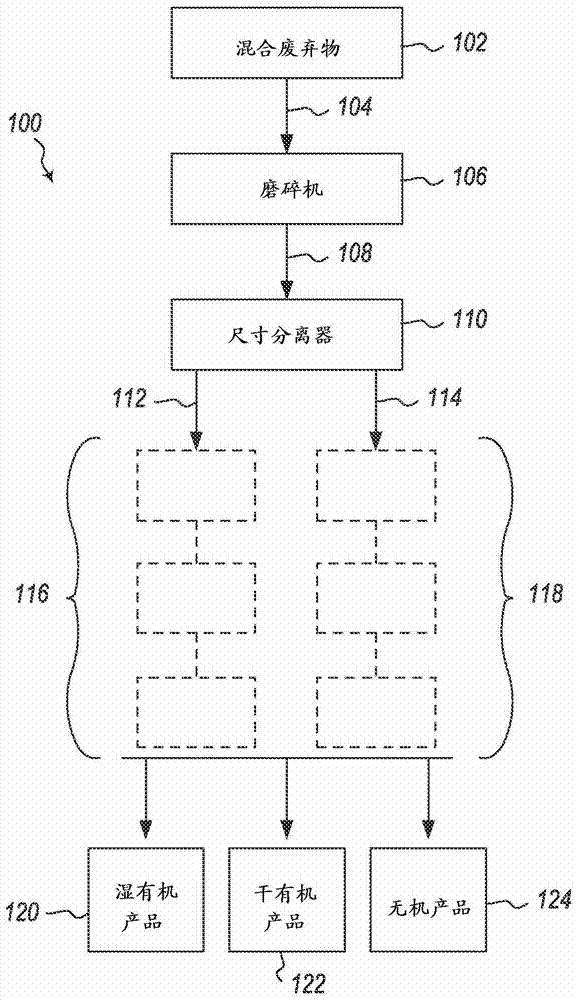

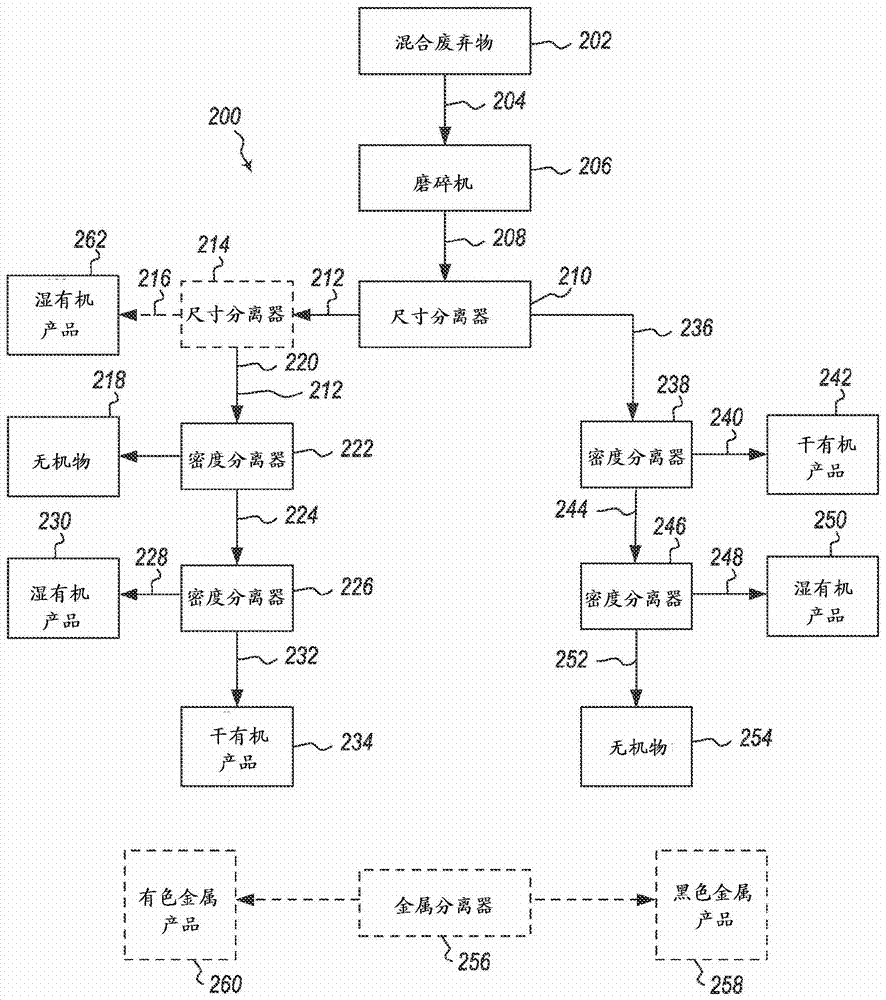

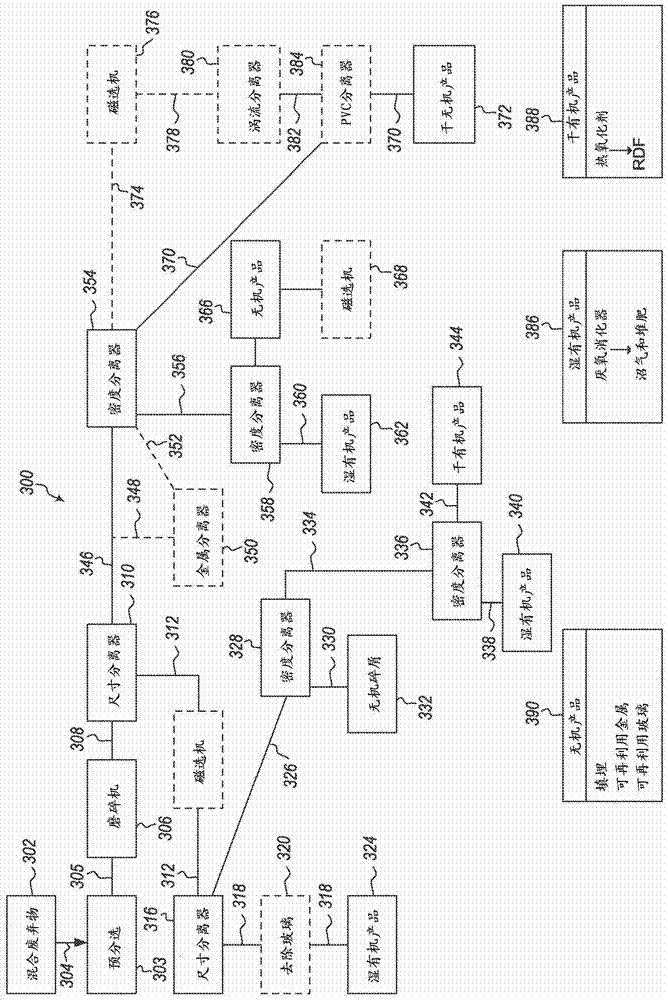

Mechanical separation of wet and dry materials in solid waste streams

ActiveCN103476516BSorting is easier and more efficientEfficient sortingGas current separationSolid waste disposalWaste streamDensity separation

A method and system for separating mixed waste into a wet organic fraction, a dry organic fraction and an inorganic fraction by: (i) shredding the mixed solid waste; (ii) sizing the shredding stream fractionation to produce two or more particle size waste streams; (iii) processing one or more of the particle size waste streams using density separation to produce an intermediate waste stream, and (iv) recovering homogeneous waste streams from the intermediate waste streams Products (for example, reusable materials or organic fuels).

Owner:ORGANIC ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com