Physical-sensible-heat recovery method and device of converter flue gas

A technology of sensible heat recovery and converter flue gas, applied in furnaces, furnace components, waste heat treatment, etc., can solve problems such as energy waste, and achieve the effect of reducing water consumption and cooling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

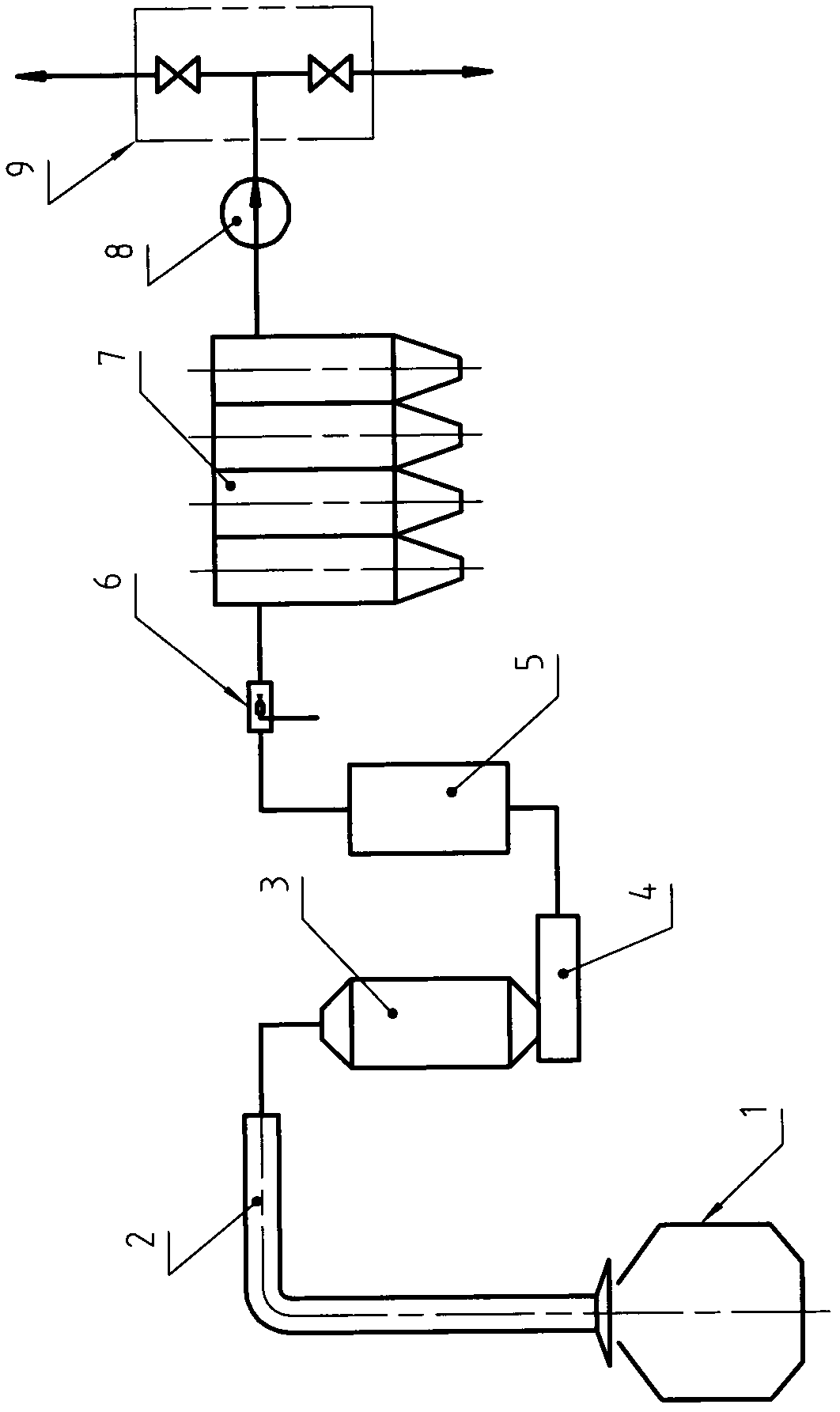

[0023] Example 1, such as figure 1 shown.

[0024] exist figure 1 Among them, 1 is the converter. 2 is the flue heat exchange device of the converter. 3 is an evaporative cooler. 4 is a coarse dust removal device. 5 is a waste heat boiler. 6 is a water mist generator arranged before the dust collector, so as to regulate the temperature and / or humidity of the flue gas entering the fine dust collector when necessary. 7 is a fine dust removal device, specifically, it is a bag filter, of course, it is not ruled out that it is an electric dust collector. 8 is induced draft fan. 9 is a switching station.

[0025] The working process of this embodiment is that after the high-temperature flue gas discharged from the converter 1 passes through the flue heat exchange device 2 of the converter, the temperature drops to 850-950°C, and then passes through the evaporative cooler 3 to further reduce the temperature to 550±30°C, after being dedusted by the coarse dedusting device 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com