Separation method and equipment of protein from starch sugar liquefied solution

A technology for protein separation and separation equipment, which is applied in the field of separation and removal of proteins in starch sugar liquefaction liquid, can solve problems such as no disclosure, and achieve the effects of reducing damage, improving equipment life, and saving the consumption of decolorization and filtering auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

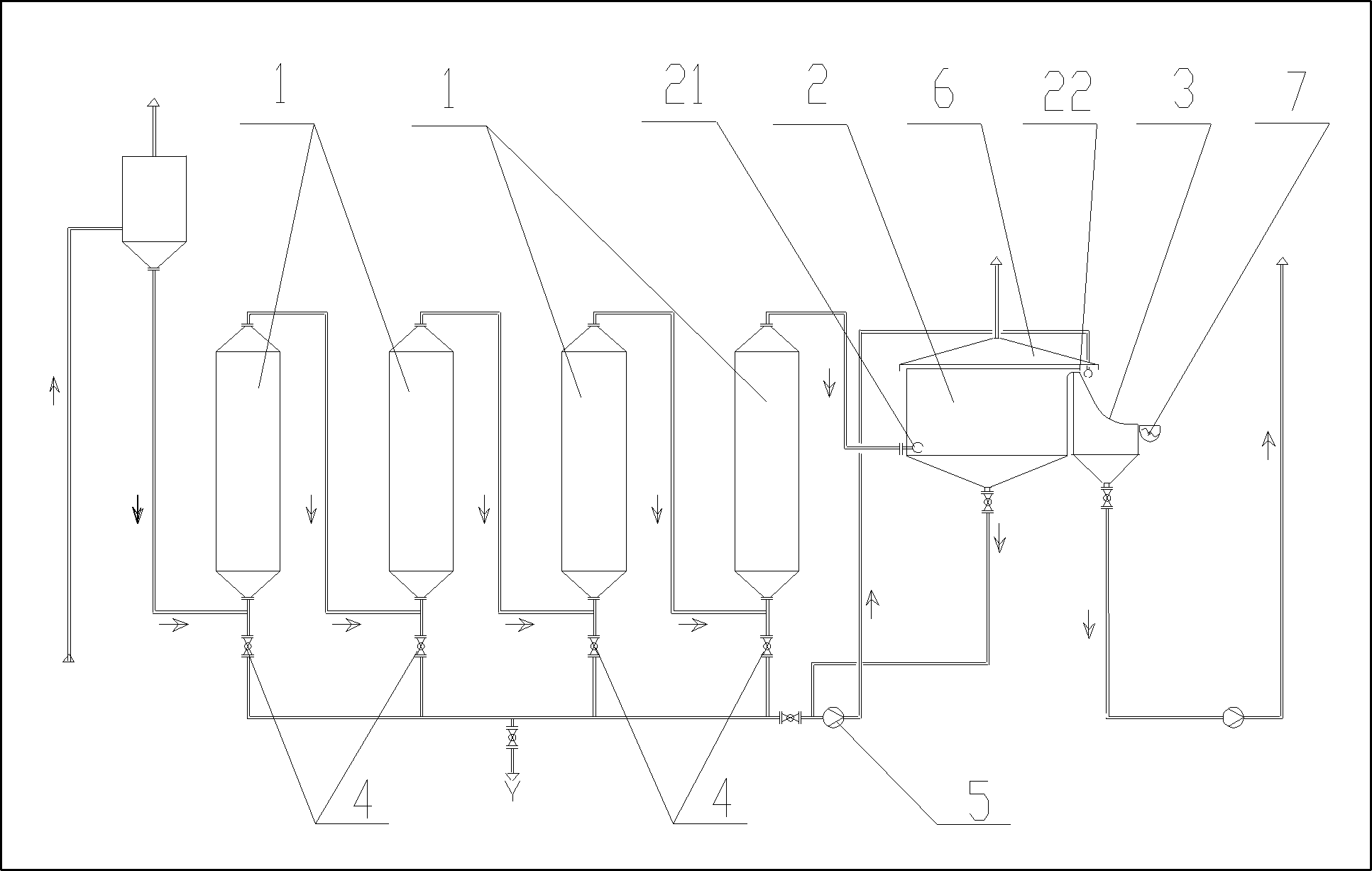

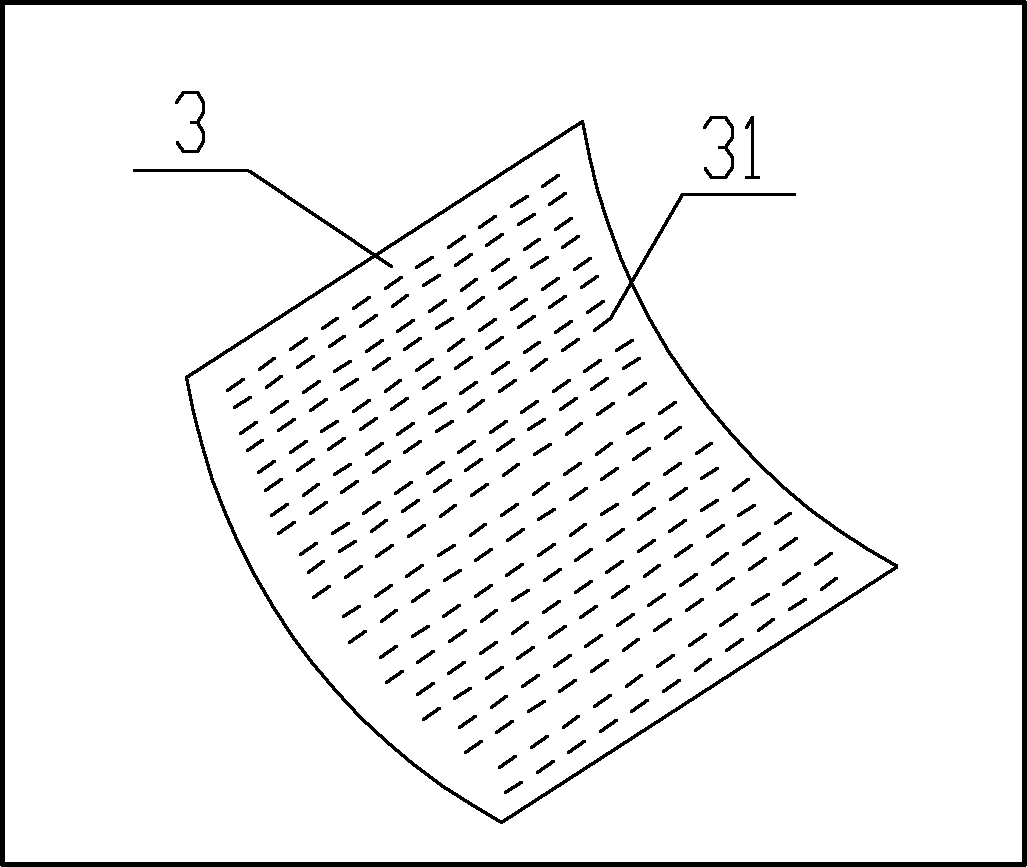

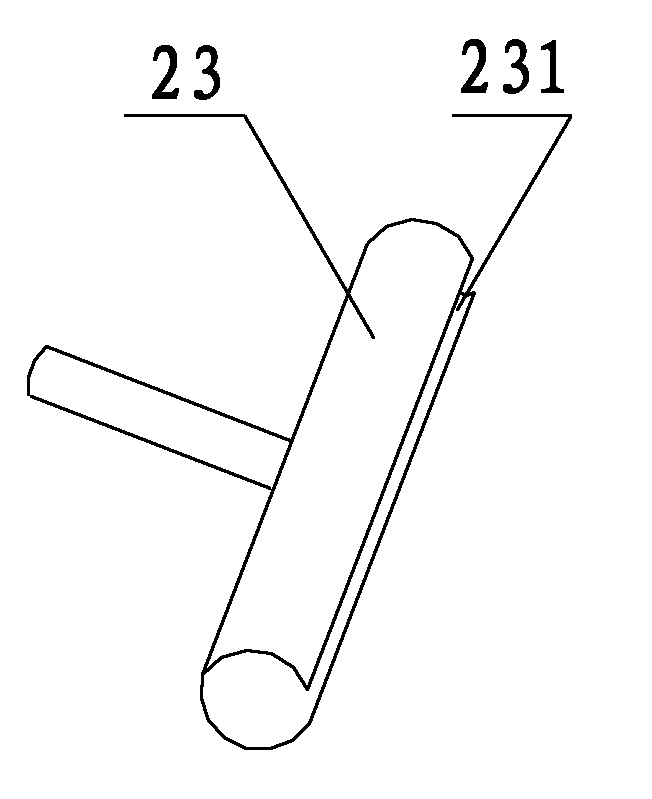

[0051] Referring to the accompanying drawings, the protein separation equipment in the starch sugar liquefaction liquid of the present invention comprises successively connected laminar flow tank systems, protein separation storage tanks 2 and protein separation screens 3 in its structure; the laminar flow tank system includes 4 sequentially connected According to the flow of the feed liquid, the top of the front laminar flow tank 1 is connected with the bottom end of the rear laminar flow tank 1 through a pipeline; The feed port 21 is connected, the top of the protein separation storage tank 2 is provided with an overflow port 22, the overflow port 22 is set opposite to the feed port 21, and the protein separation screen 3 is arranged below the overflow port 22 to accept the Feed liquid; the volume of the protein separation storage tank 2 is not less than the 10-minute flow rate of the feed liquid, and the protein separation storage tank 2 is equal to the protein separation sc...

Embodiment 2

[0057] Referring to accompanying drawing, utilize above-mentioned equipment to carry out the method for protein separation in starch sugar liquefaction liquid, its step comprises:

[0058] A, the preparation of starch gelatinization liquid: starch slurry is adjusted to 19.5 Baume degree, regulate pH value 5.5-5.8 with edible sodium carbonate simultaneously, then add the BiotherMosizeFC α-amylase that Biother Green Company produces, the addition amount is every Add 425 ml of α-amylase to 1 ton of starch dry matter, and then liquefy the starch milk at 105-110°C through a high-temperature jet liquefier to obtain starch gelatinization liquid;

[0059] B. The starch gelatinization liquid is processed by the laminar flow tank system to obtain a primary liquefaction liquid: the starch gelatinization liquid flows through four serially connected laminar flow tanks 1 in sequence, and the starch gelatinization liquid flows from the bottom end of each laminar flow tank 1 to the top Outflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com