Lead-acid storage battery cast-weld production line

A lead-acid battery, battery technology, applied in lead-acid battery, lead-acid battery construction, foundry workshop and other directions, can solve the problems of poor coordination, relying on labor for feeding materials, low production efficiency, etc. Good efficiency, stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

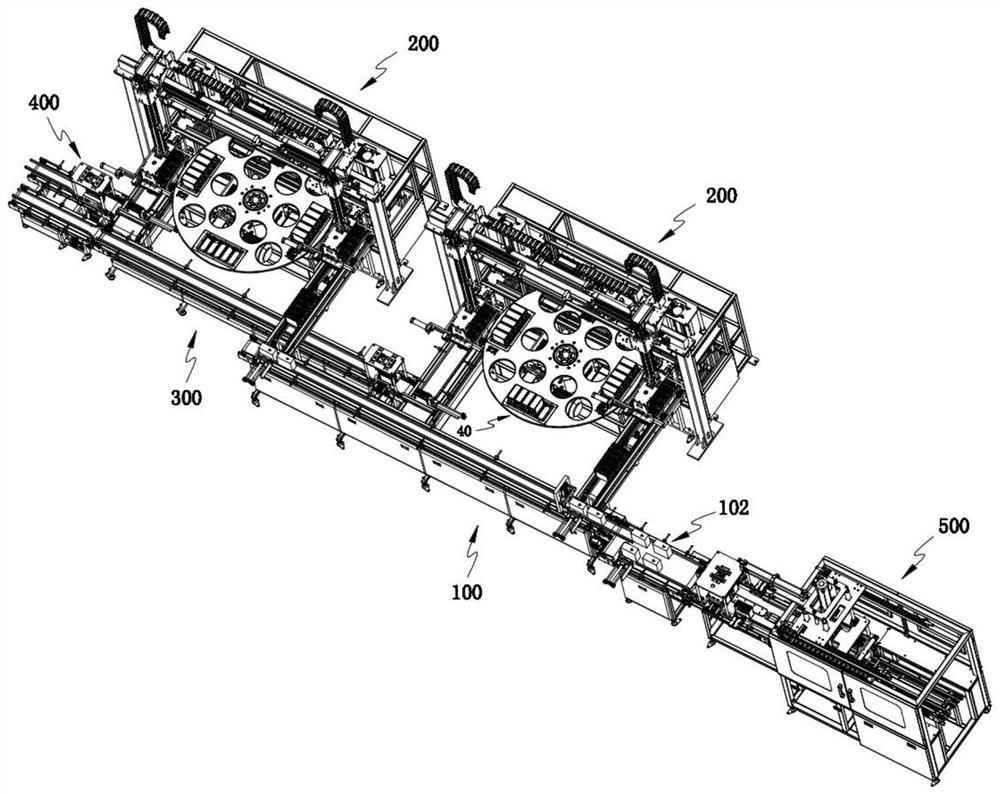

[0056] Such as figure 1 As shown, a lead-acid battery casting and welding production line includes a feed conveying system 100 and at least one group of casting and welding production systems 200 distributed along the conveying direction of the feed conveying system 100; during work, the feed conveying The system 100 distributes the storage batteries 102 in groups to each casting and welding production system 200 for casting and welding;

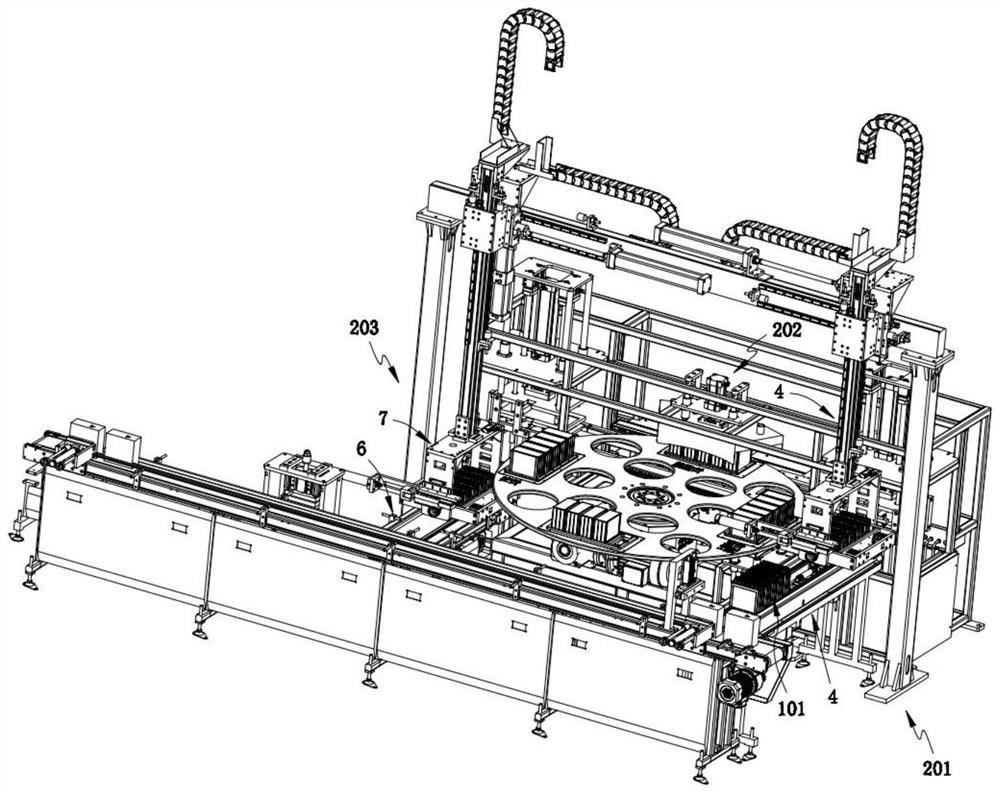

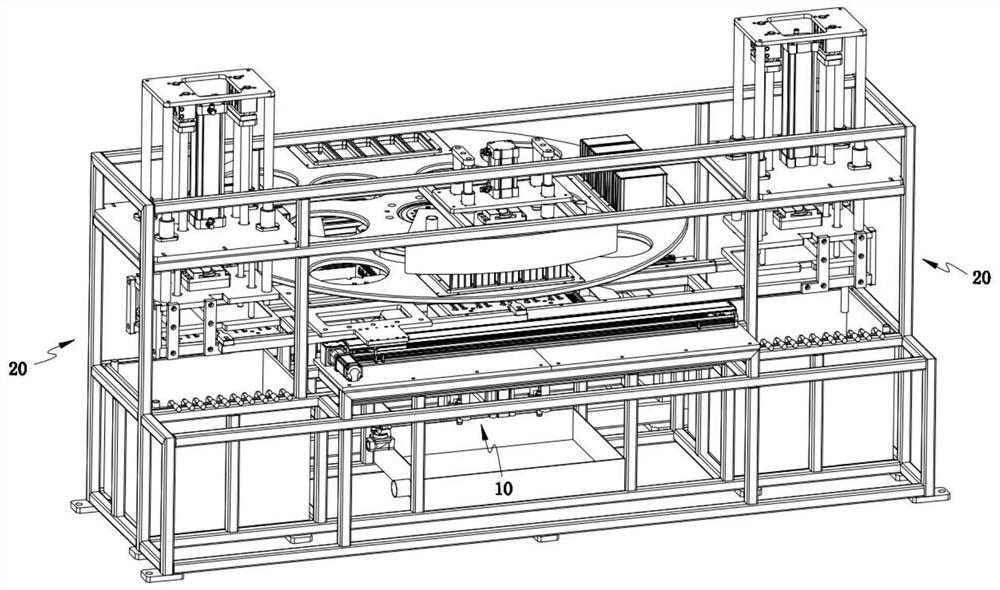

[0057] Such as Figure 2-3 As shown, the casting and welding production system 200 includes a casting and welding station 202, and the casting and welding station 202 is provided with a casting and welding unit 10, a plurality of sets of lead immersion units 20 arranged on the side of the casting and welding unit 10, and a plurality of sets of The casting mold 30 arranged in one-to-one correspondence with the lead immersion unit 20 and the transfer unit 50 that transfers the casting mold 30 between the casting unit 10 and each corresponding...

Embodiment 2

[0105] For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 is described below; the difference between Embodiment 2 and Embodiment 1 is:

[0106] Preferably, the rotating mechanism 11 is configured as a disc structure 111, and N bearing positions 12 for receiving the battery pack 101 are arranged equidistantly along the circumferential direction on the disc structure 111. The disc structure 111 per rotation

[0107] Preferably, N=4.

[0108] In this example, if figure 2 As shown, the disc structure 111 is equidistantly arranged with four bearing positions 12 along the circumferential direction. During operation, the disc structure 111 cooperates with the rhythm of casting and welding, and rotates 90° each time, so that three of the bearing positions 12 are respectively Correspondingly transfer to the loading station 201 , casting and welding station 202 and unloading station 203 .

[0109] In addition, in this embodiment, N can also be a nat...

Embodiment 3

[0111] For the sake of brevity, only the differences between Embodiment 3 and Embodiment 1 are described below; the differences between Embodiment 3 and Embodiment 1 are:

[0112] Preferably, the rotating mechanism 11 is configured as a cross structure 112, and one bearing position 12 is respectively provided on the four protruding ends 110 of the cross structure 112.

[0113] In this example, if Figure 17 As shown, each rotation of the cross structure 112 by 90° allows three of the carrying positions 12 to be transferred to the loading station 201 , casting and welding station 202 and unloading station 203 respectively.

[0114] work process:

[0115] The accumulators 102 that have completed the pole group pretreatment in the pole group pretreatment system 500 are arranged in two rows on the front-end conveying mechanism 8 for transmission, and are conveyed to the shunt conveying mechanism 9 one by one under the push of the first pushing component 81, With the cooperation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com