A kind of high-efficiency lead-acid battery casting welding production process

A high-efficiency lead-acid and production technology technology, applied in the direction of lead-acid battery, lead-acid battery construction, manufacturing tools, etc., can solve the problems of low production efficiency of the production line, to improve production efficiency, shorten production time, good stability and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

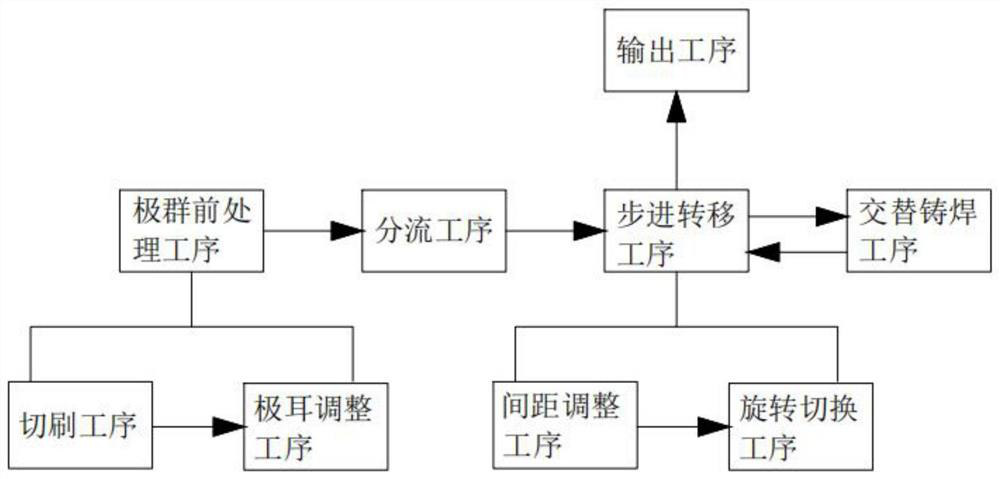

[0076] like figure 1 , 2 , shown in 3, a kind of high-efficiency lead-acid battery casting welding production process, is characterized in that, comprises the following steps:

[0077] S1, the diversion process, the lead-acid battery is automatically transported forward by the feeding conveying system 100, a plurality of casting welding production systems 200 are arranged on the side of the feeding conveying system 100, and a diverting mechanism 9 is arranged on the feeding conveying system 100 to drive a single or multiple each battery 102 is distributed to its corresponding casting and welding production system 200 as a group;

[0078] S2, alternate casting and welding processes. The casting and welding production system 200 includes a casting and welding mechanism 10, a plurality of groups of lead soaking mechanisms 20, and the lead soaking mechanisms 20 are provided in a one-to-one correspondence and can be installed in the casting welding mechanism 10 and the correspondi...

Embodiment 2

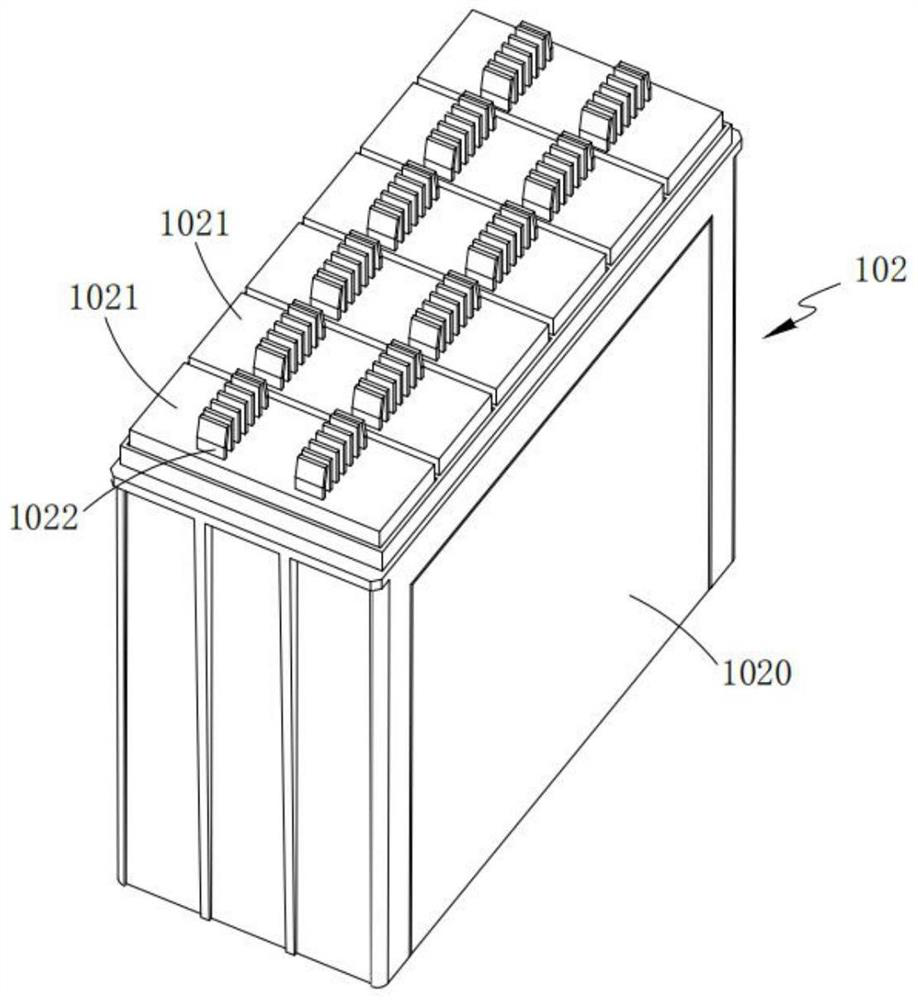

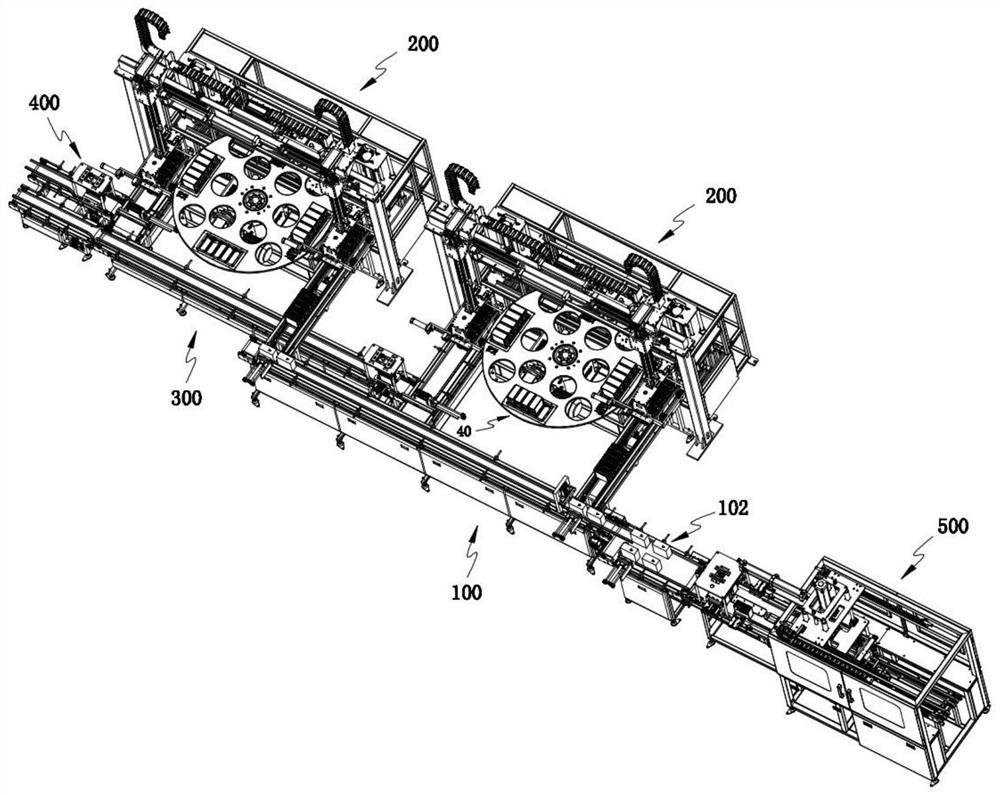

[0094] like Figure 4 As shown, a lead-acid battery casting and welding production line includes a feed conveying system 100 and at least one group of casting and welding production systems 200 distributed along the conveying direction of the feed conveying system 100; during operation, the feed conveying The system 100 distributes the batteries 102 to each casting and welding production system 200 in groups for casting and welding;

[0095] like Figure 2-3 As shown, the casting and welding production system 200 includes a casting and welding station 202, and the casting and welding station 202 is provided with a casting and welding mechanism 10, a plurality of groups of lead immersion mechanisms 20 disposed on the side of the casting and welding mechanism 10, and a plurality of groups The casting and welding molds 30 provided in a one-to-one correspondence with the lead immersion mechanisms 20 and the transfer unit 50 for transferring the casting and welding molds 30 betwee...

Embodiment 3

[0142] For the sake of simplicity, only the difference between the third embodiment and the second embodiment is described below; the difference between the third embodiment and the second embodiment is:

[0143] Preferably, the rotating mechanism 11 is configured as a disc structure 111 , and N number of bearing positions 12 for receiving the battery pack 101 are provided on the disc structure 111 equidistantly along the circumferential direction. The disc structure 111 every turn

[0144] Preferably, N=4.

[0145] In this embodiment, as Figure 4 As shown, the disc structure 111 is provided with four bearing positions 12 equidistantly along the circumferential direction. During operation, the disc structure 111 is rotated by 90° in accordance with the rhythm of casting and welding, so that three of the bearing positions 12 are respectively Correspondingly, it is transferred to the loading station 201 , the casting and welding station 202 and the blanking station 203 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com