Single-chip optical path module and multi-die semiconductor laser

A single-chip, semiconductor technology, applied in the field of lasers, can solve the problems of inability to guarantee the repeatability and stability of the chip product process, the poor versatility of unit devices, and the consumption of material and manpower, so as to achieve mass production, simplify rework, and save time. and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

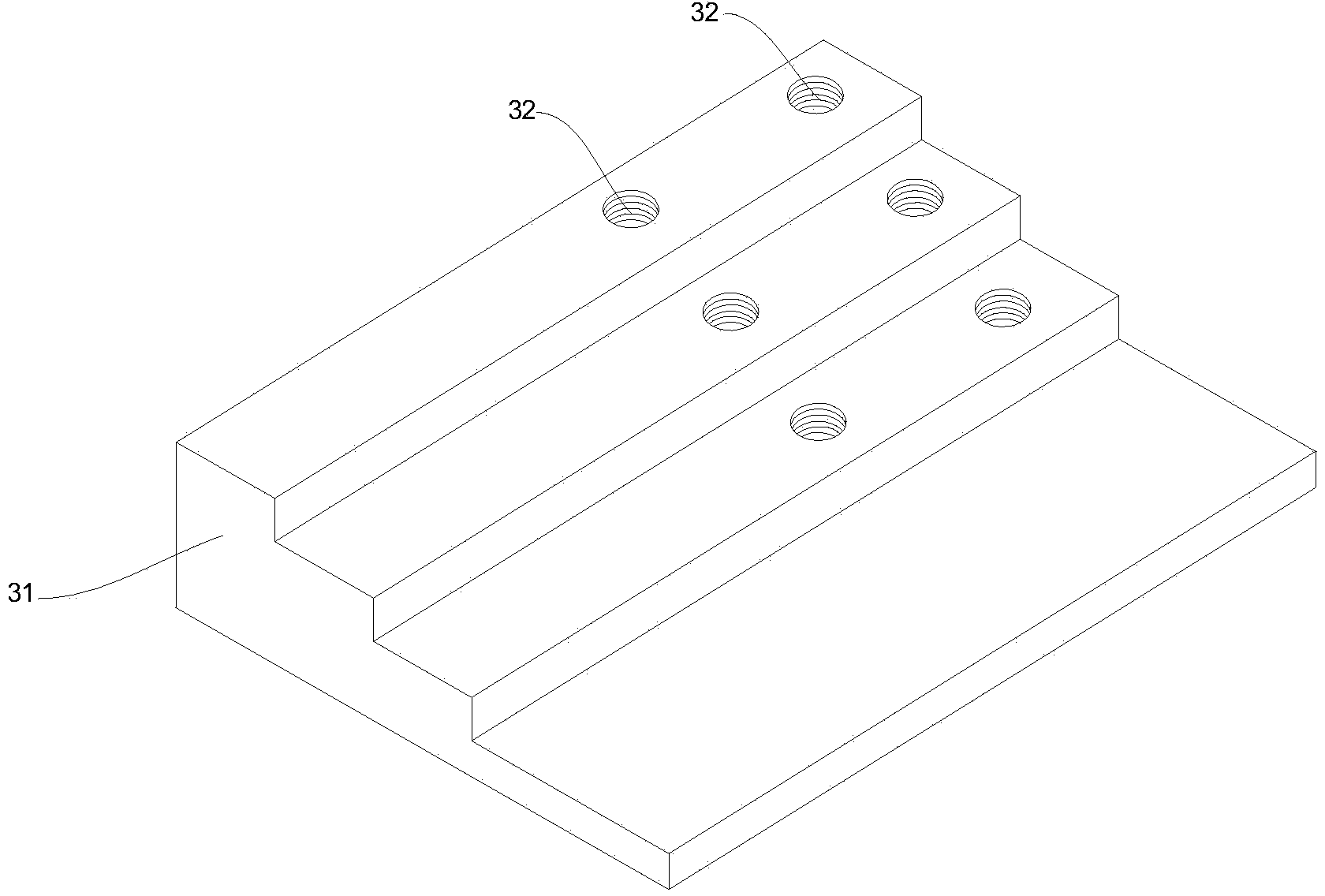

[0041] In the present invention, multiple semiconductor laser unit devices in a multi-die semiconductor laser are respectively modularized to form a plurality of single-chip optical path modules, and the single-chip optical path module is detachably fixed on the stepped bottom plate of the multi-die semiconductor laser. , so as to solve the problem of commonality of components of different multi-chip laser products, and simplify the rework and rework procedures, saving time and cost.

[0042] Embodiment 1 of a single-chip optical circuit module

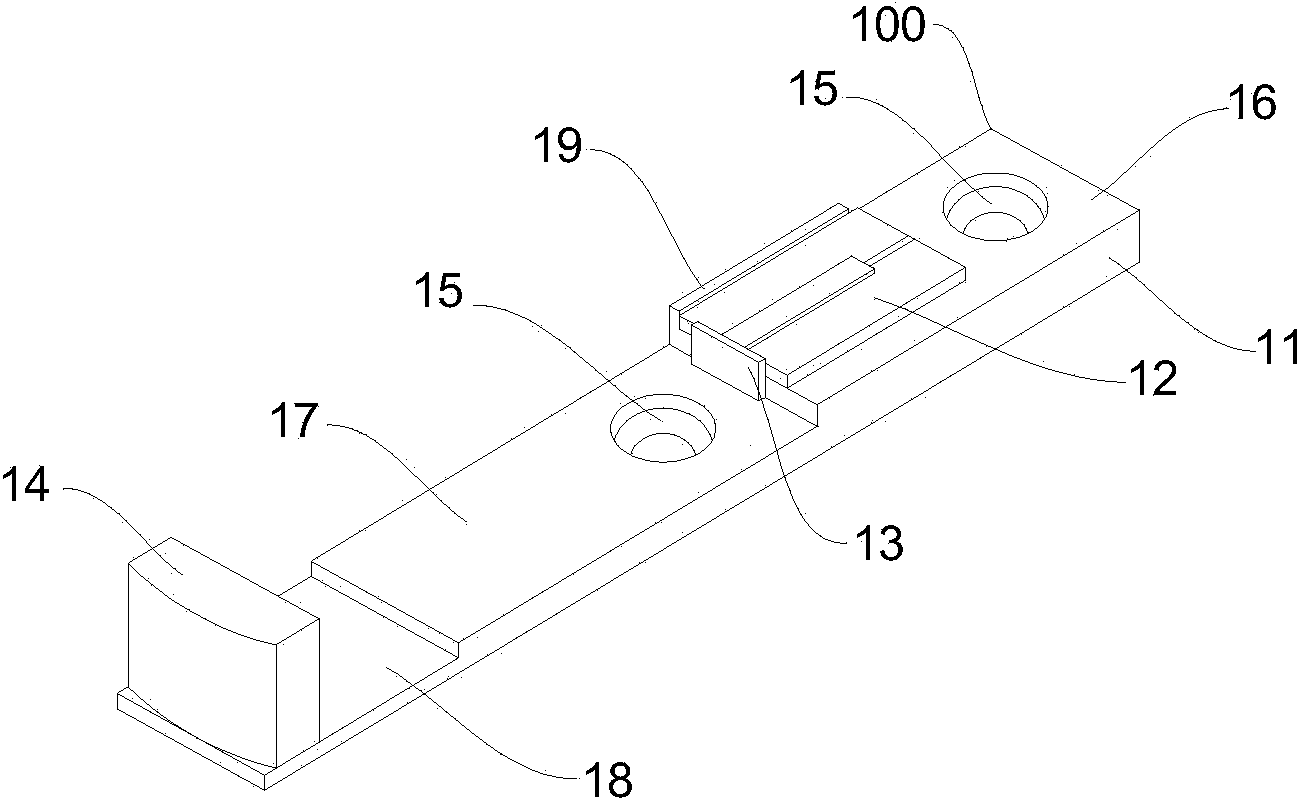

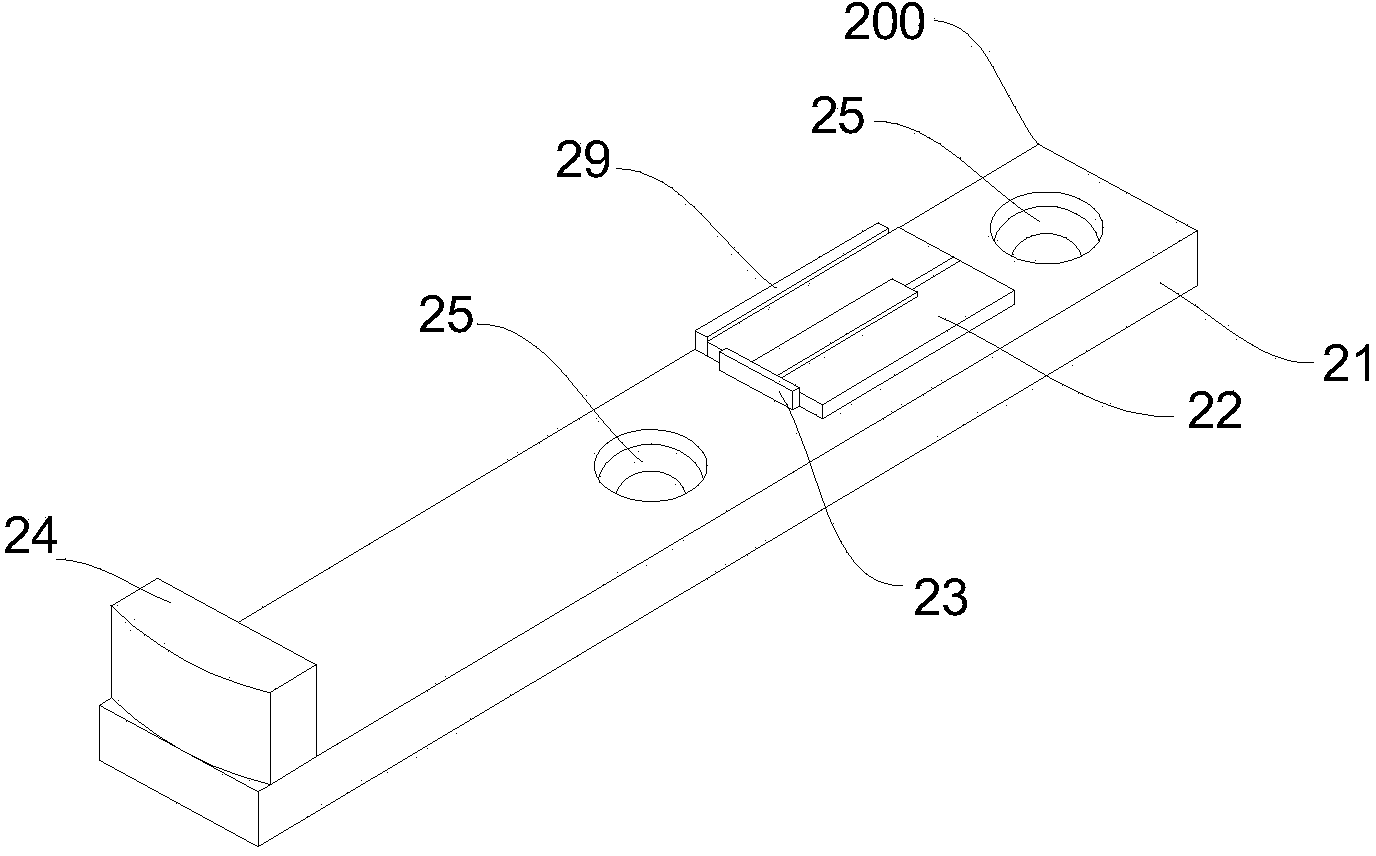

[0043] figure 1 It is a structural schematic diagram of Embodiment 1 of the single-chip optical path module in the present invention. Such as figure 1 As shown, this embodiment discloses a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com