Preparation methods of mineralized hydrogel and biomimetic mineralized bone repair material

A mineralized water and hydrogel technology, applied in the fields of biomedical materials and biomedical engineering, can solve the problems of cell incompatibility, inability to simulate the physiological mineralization process well, and inability to achieve cell in situ encapsulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

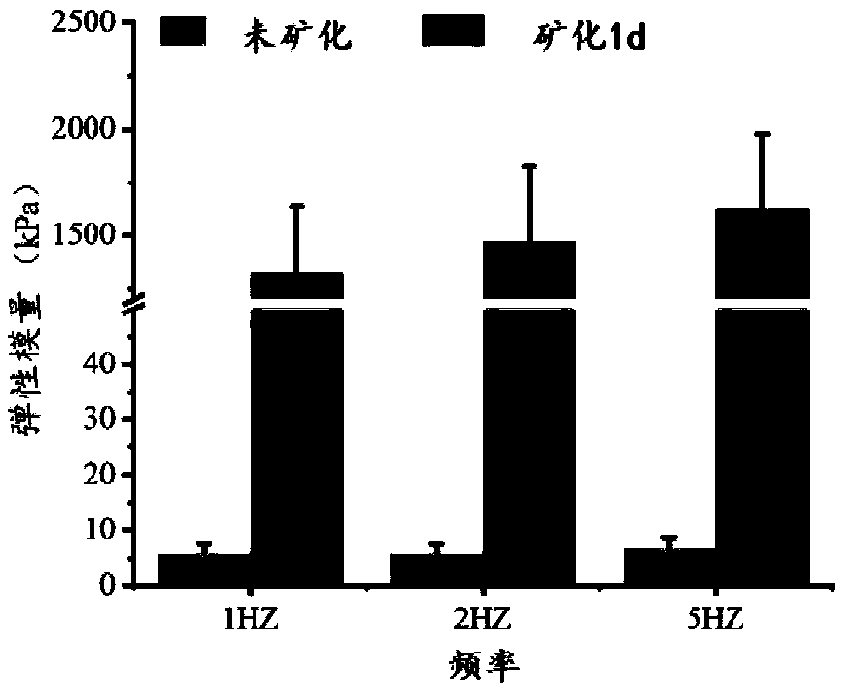

[0075] Example 1 Mineralized Collagen Hydrogel

[0076] The steps of preparing the mineralized collagen hydrogel in this embodiment are as follows:

[0077] (A1) Preparation of Methacrylated Collagen (Col-MA)

[0078] The reaction system formed by mixing the PBS dispersion of medical collagen (pH 7.5) with methacrylic anhydride was reacted at 0°C for 4 hours under stirring conditions, and the obtained product was dialyzed in deionized water for 3 days and then vacuum-dried to obtain methacrylic anhydride. Collagen; 100 parts of reaction system, the final concentration of Chinese collagen is 0.1%; the final concentration of methacrylic anhydride is 0.003%.

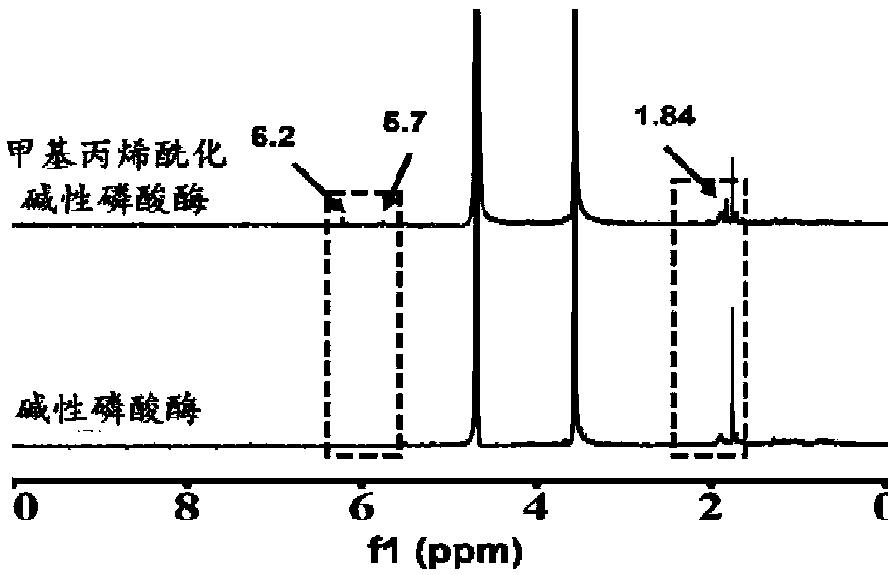

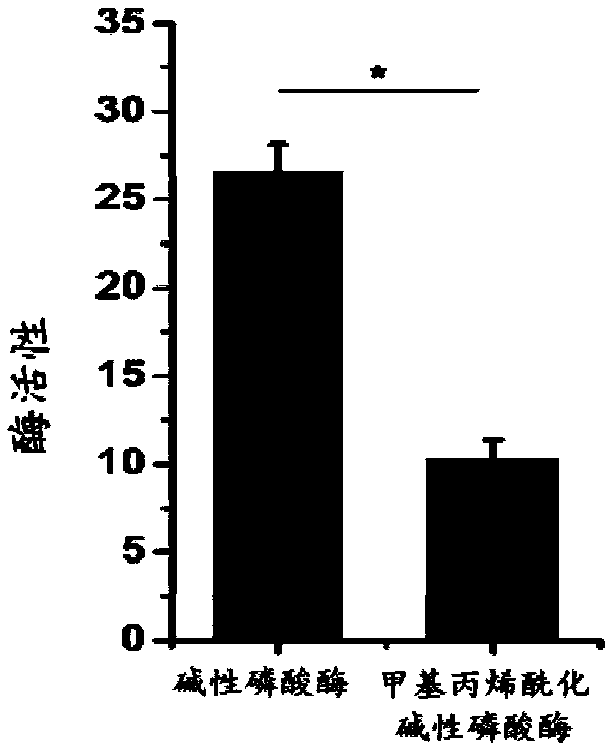

[0079] (A2) Preparation of methacryloyl alkaline phosphatase (ALP-MA)

[0080] The reaction system formed by mixing the PBS dispersion of alkaline phosphatase (pH 7.5) and methacrylic anhydride was reacted at 0°C under stirring conditions for 24 hours, and the obtained product was dialyzed in deionized water for 3 days an...

Embodiment 2

[0085] Example 2 Mineralized Collagen Hydrogel

[0086] The steps of preparing the mineralized collagen hydrogel in this embodiment are as follows:

[0087] (B1) Preparation of Methacrylated Collagen (Col-MA)

[0088] The reaction system formed by mixing the PBS dispersion of medical collagen (pH 7.5) with methacrylic anhydride was reacted for 2 hours at 4°C under stirring conditions, and the obtained product was dialyzed in deionized water for 5 days and then vacuum-dried to obtain methacrylic anhydride. The final concentration of collagen in 100 parts of the reaction system is 0.1%; the final concentration of methacrylic anhydride is 0.01%.

[0089] (B2) Preparation of methacryloyl alkaline phosphatase (ALP-MA)

[0090] The reaction system formed by mixing the PBS dispersion of alkaline phosphatase (pH 7.5) and methacrylic anhydride was reacted at 4°C under stirring conditions for 4 hours, and the obtained product was dialyzed in deionized water for 4 days and then vacuum-...

Embodiment 3

[0095] Example 3 Mineralized gelatin hydrogel

[0096] The steps of preparing mineralized gelatin hydrogel in this embodiment are as follows:

[0097] (B1) Preparation of Acrylylated Gelatin

[0098] The reaction system formed by mixing the sodium acetate buffer dispersion (pH 8.0) of medical gelatin with acrylic anhydride was reacted for 12 hours at 5°C under stirring conditions, and the obtained product was dialyzed in deionized water for 7 days and then vacuum-dried to obtain acrylylated gelatin ; The final concentration of 100 parts of reaction system Chinese medicine gelatin is 2%; the final concentration of acrylic anhydride is 2%.

[0099] (B2) Preparation of methacryloyl alkaline phosphatase

[0100] The reaction system formed by mixing alkaline phosphatase sodium acetate buffer dispersion (pH 8.0) with methacrylic anhydride was reacted for 2 hours at 5°C under stirring conditions, and the obtained product was dialyzed in deionized water for 5 days and then vacuum-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com