Patents

Literature

124 results about "Phosphatase I" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A phosphatase is an enzyme that uses water to cleave a phosphoric acid monoester into a phosphate ion and an alcohol.

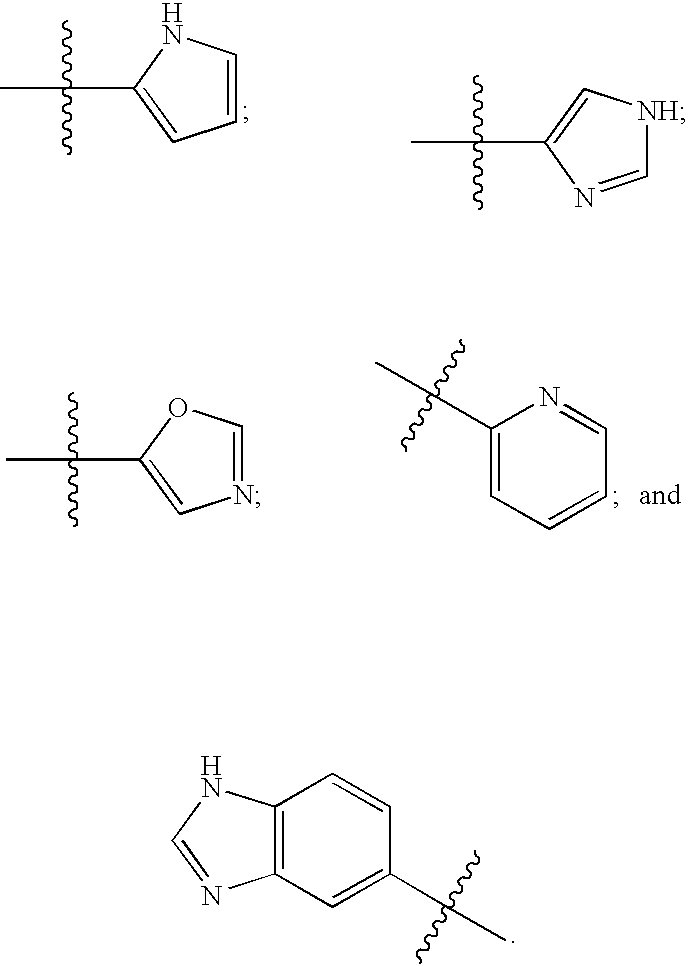

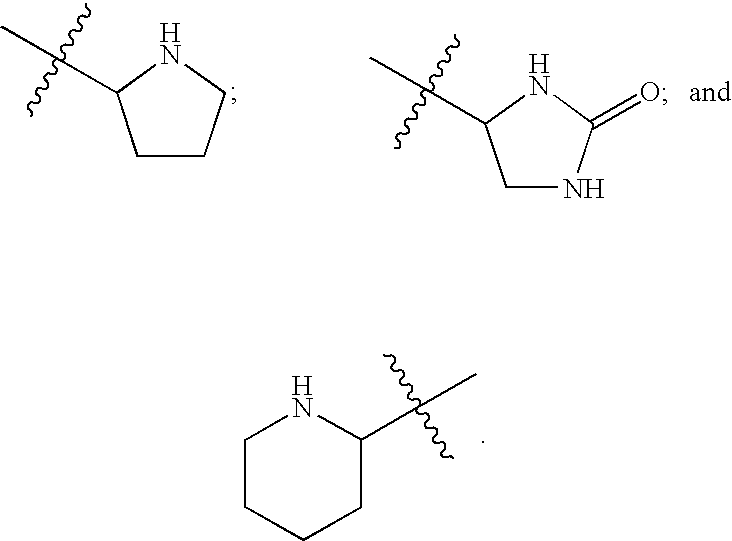

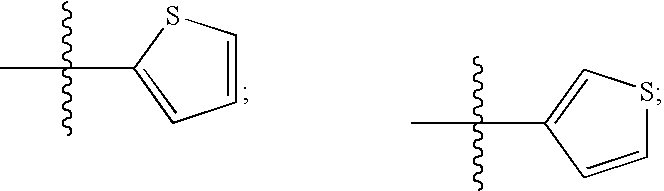

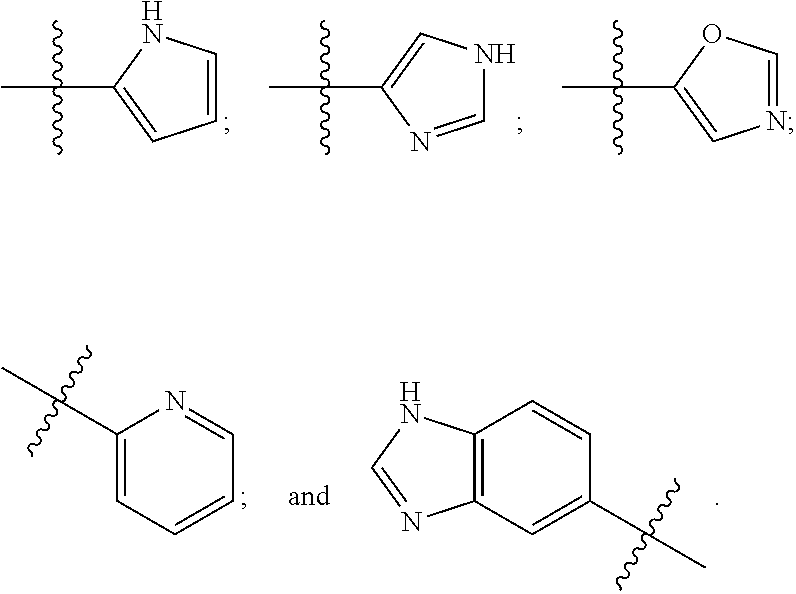

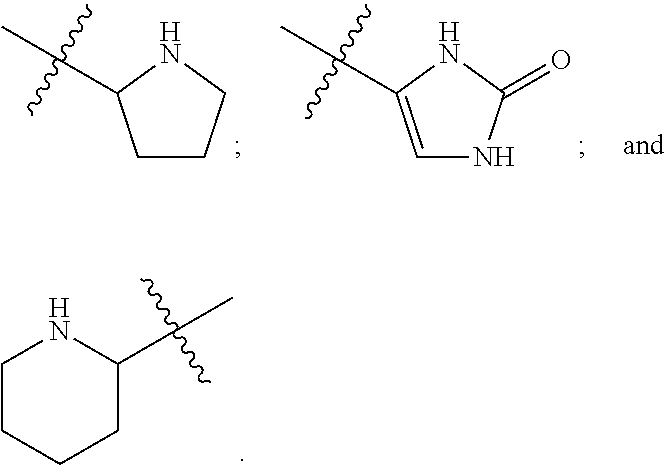

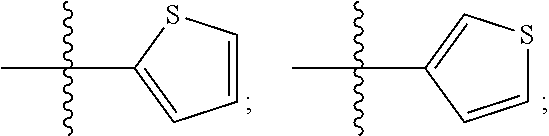

Human protein tyrosine phosphatase inhibitors an methods of use

ActiveUS20080108631A1Regulating angiogenesisAntibacterial agentsBiocidePhosphatase inhibitorTyrosine

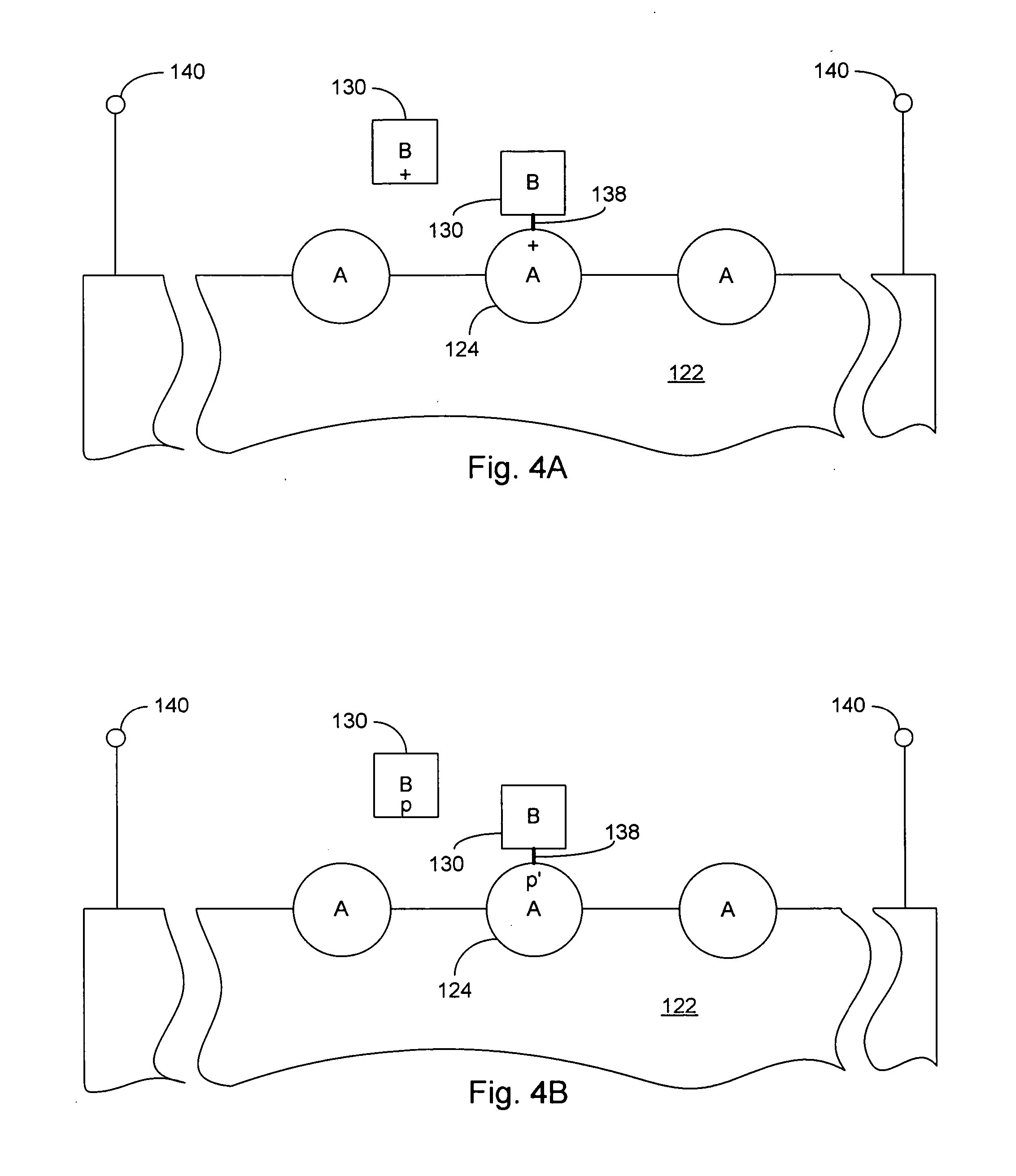

The present disclosure relates to compounds effective as human protein tyrosine phosphatase beta (HPTP-β) inhibitors thereby regulating angiogenesis. The present disclosure further relates to compositions comprising said human protein tyrosine phosphatase beta (HPTP-β) inhibitors, and to methods for regulating angiogenesis.

Owner:EYEPOINT PHARMA INC

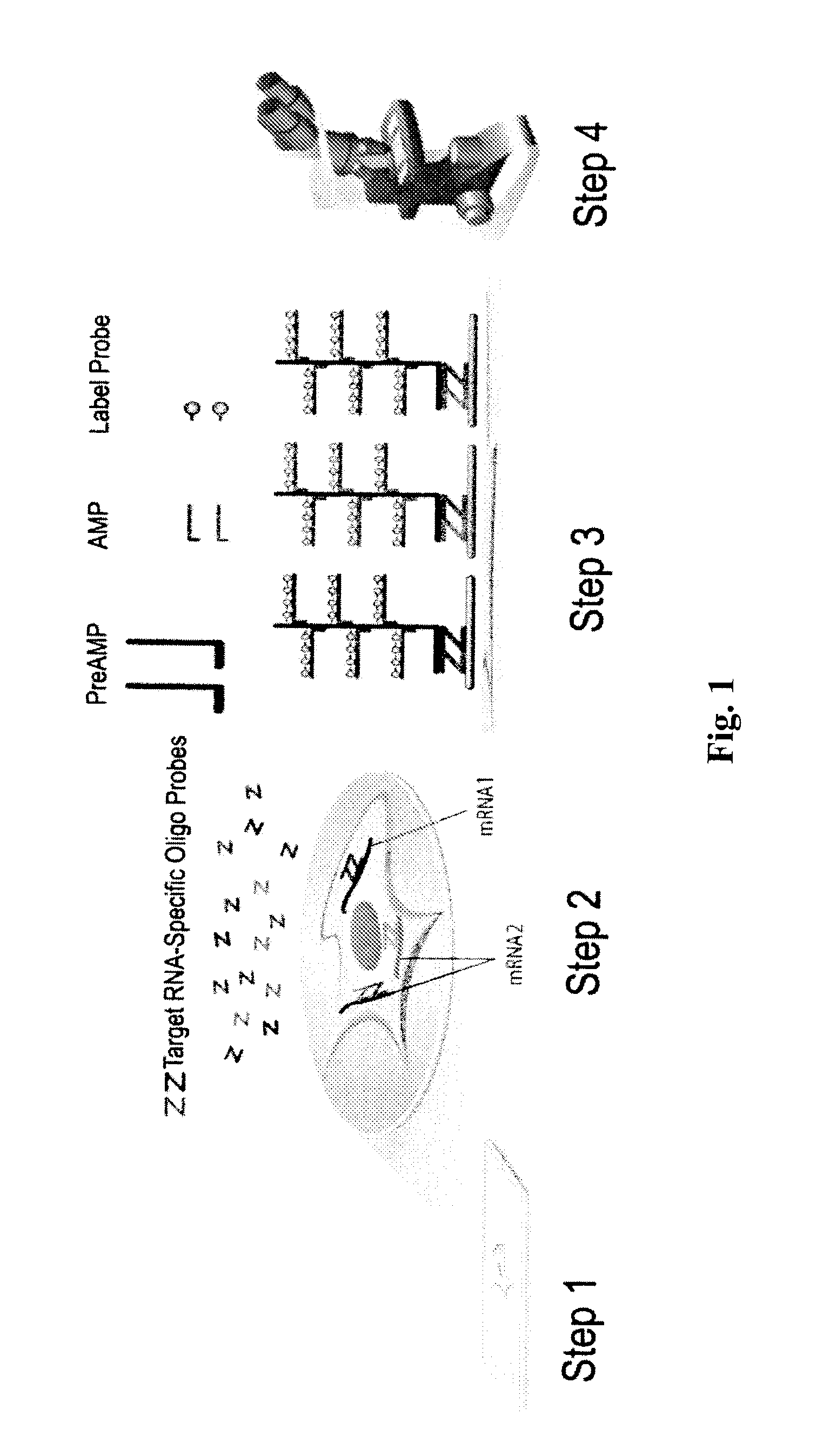

Nucleic acid arrays for monitoring expression profiles of drug target genes

InactiveUS20050221354A1Reagent cost per experimentRobust overall probe set signal valueBioreactor/fermenter combinationsBiological substance pretreatmentsDrug targetPolynucleotide

The present invention provides nucleic acid arrays and methods of using the same for detecting or monitoring expression profiles of drug target genes. Non-limiting examples of drug target genes include kinase genes, phosphatase genes, protease genes, G-protein coupled receptor genes, nuclear hormone receptor genes, and ion channel genes. The present invention also provides methods of using nucleic acid arrays for the identification or validation of drugs or drug targets. In one embodiment, a nucleic acid array of the present invention is concentrated with probes for drug target genes. These probes constitute a substantial portion of all of the polynucleotide probes that are stably attached to the nucleic acid array, and can hybridize under stringent or nucleic acid array hybridization conditions to the tiling sequences selected from Attachment C, or the complements thereof.

Owner:WYETH

Biomarkers for differentiating melanoma from benign nevus in the skin

Disclosed is a method for diagnosing melanoma in a human subject, as well as a method for providing a prognosis to a human subject who is at risk of developing melanoma recurrence, and a method for determining the stage of melanoma in a human subject, comprising the step of determining the level of expression of phosphatase and actin regulator 1 (PHACTR1) gene, or fragments thereof, either alone or in combination with the level of expression of secreted integrin-binding phosphoprotein (SPP1), preferentially expressed antigen in melanoma (PRAME), growth differentiation factor 15 (GDF 15), and chemokine C-X-C motif ligand 10 (CXCL10) genes. Further, the invention relates to a diagnostic kit, comprising at least one substance for detection of the expression of PHACTR1, or fragments thereof, either alone or in combination with the detection of SPP1, PRAME, GDF15, and CXCL10, for the diagnosis or prognosis of melanoma.

Owner:ADVANCED CELL DIAGNOSTICS INC

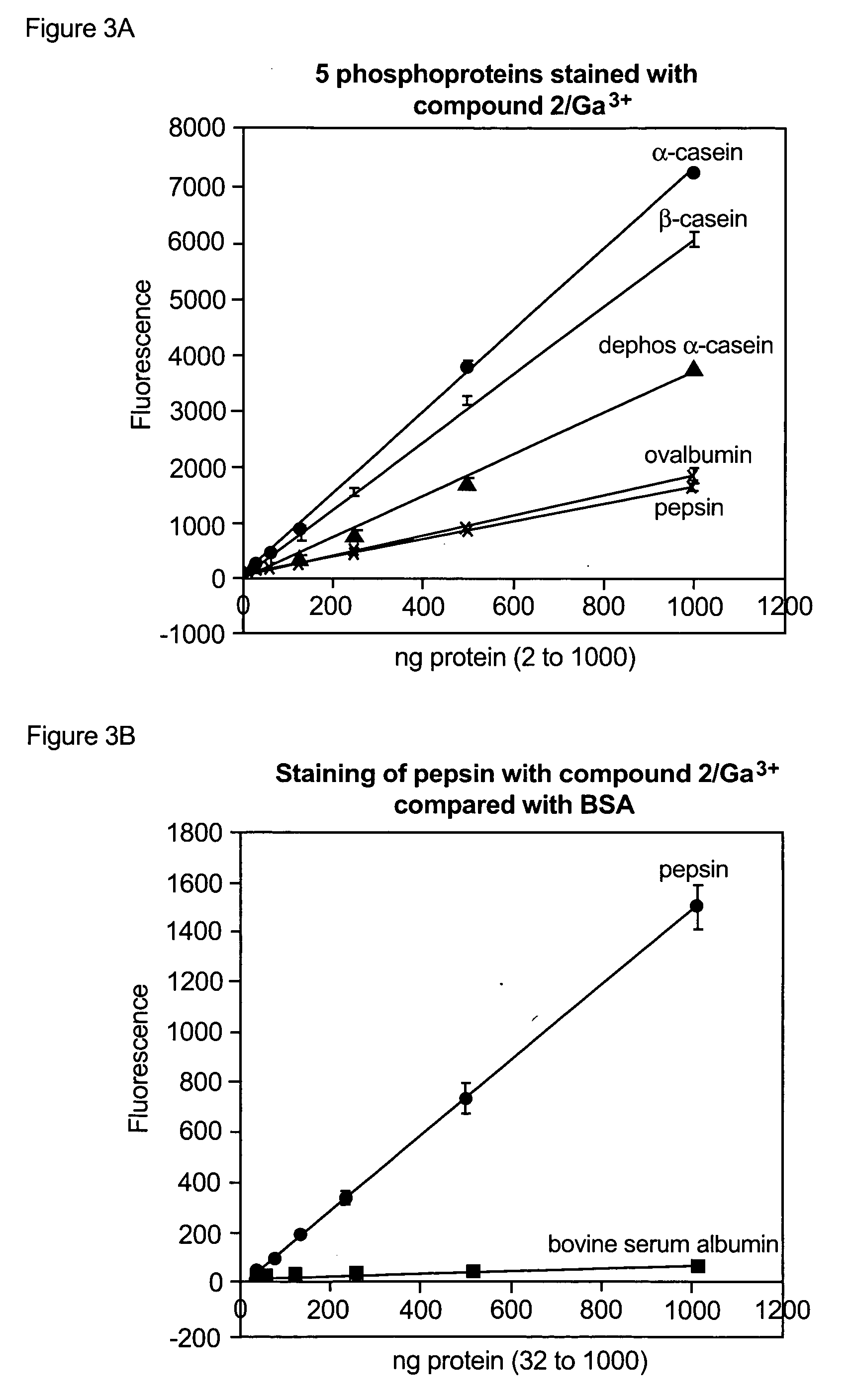

Compositions and methods for detection and isolation of phosphorylated molecules

ActiveUS20050014197A1Simplifies subsequent analysisSugar derivativesPeptide/protein ingredientsTernary complexPhosphorylation

The present invention relates to phosphate-binding compounds that find use in binding, detecting and isolating phosphorylated target molecules including the subsequent identification of target molecules that interact with phosphorylated target molecules or molecules capable of being phosphorylated. A binding solution is provide that comprises a phosphate-binding compound, an acid and a metal ion wherein the metal ion simultaneously interacts with an exposed phosphate group on a target molecule and the metal chelating moiety of the phosphate-binding compound forming a bridge between the phosphate-binding compound and a phosphorylated target molecule resulting in a ternary complex. The binding solution of the present invention finds use in binding and detecting immobilized and solubilized phosphorylated target molecules, isolation of phosphorylated target molecules from a complex mixture and aiding in proteomic analysis wherein kinase and phosphatase substrates and enzymes can be identified.

Owner:MOLECULAR PROBES

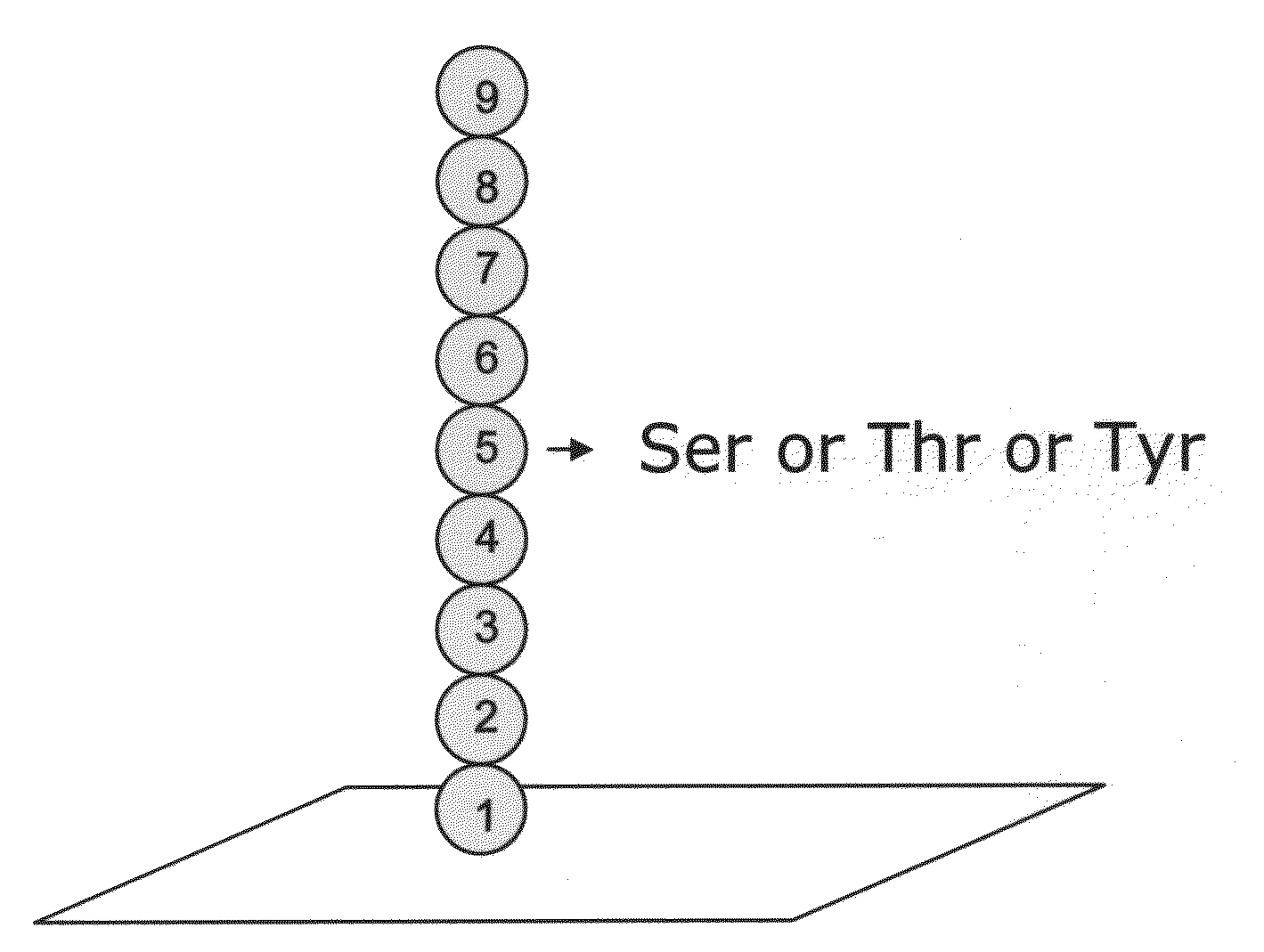

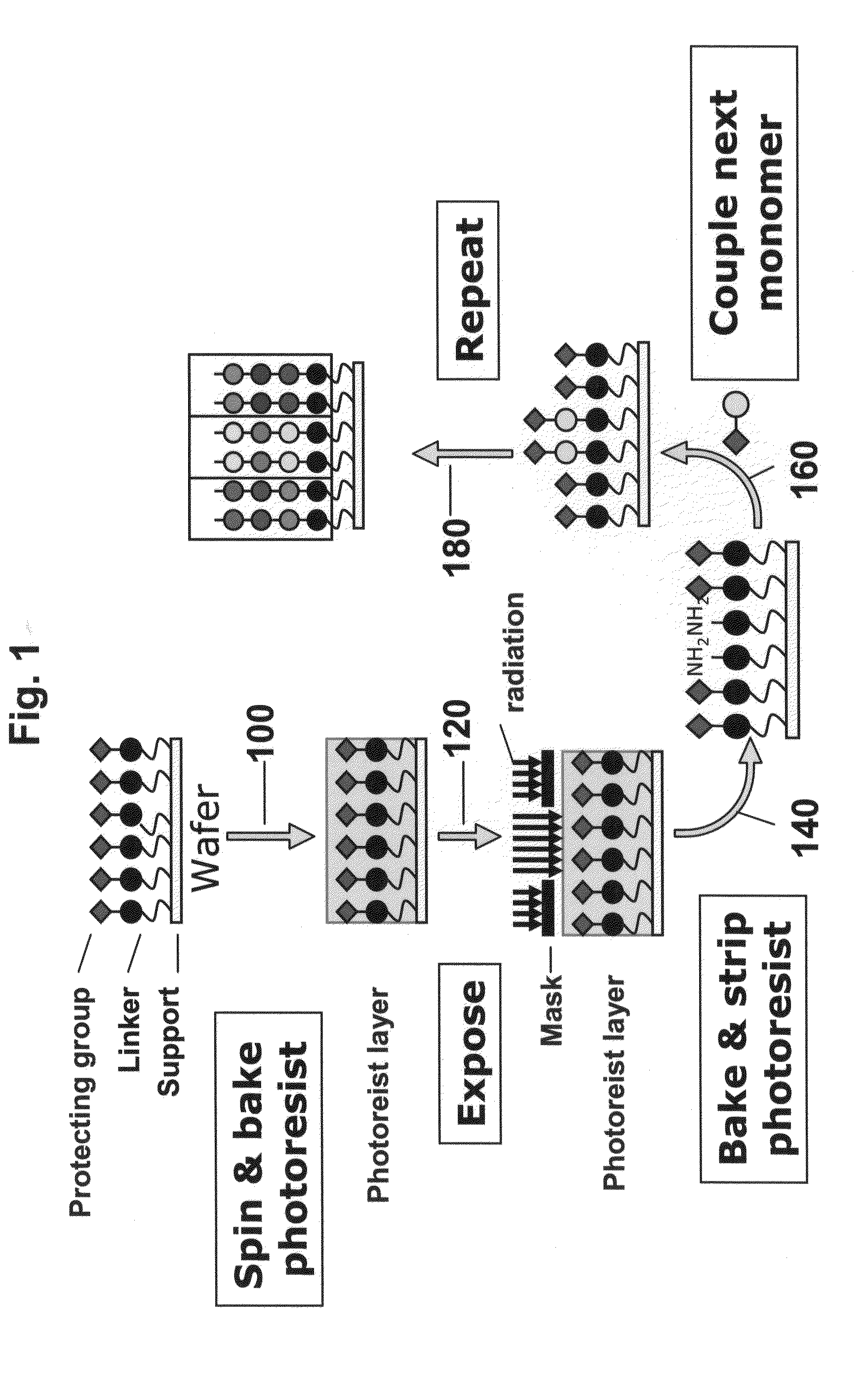

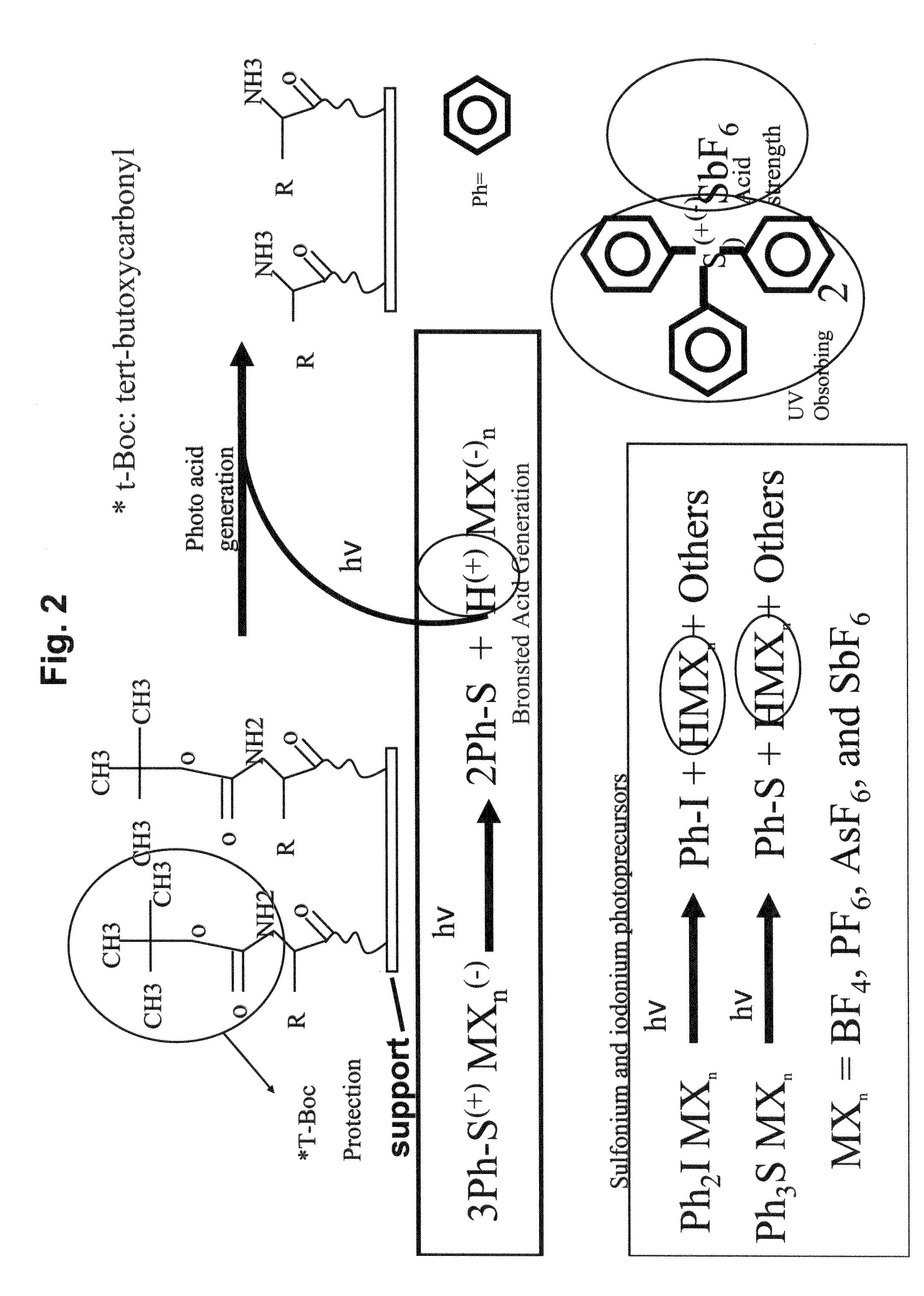

High density peptide arrays containing kinase or phosphatase substrates

Peptide arrays and uses thereof for diagnostics, therapeutics and research. Ultra high density peptide arrays are generated using photolithography, such as using photoresist techniques.

Owner:DIGITAB

Signal amplification method for surface plasmon resonance-based chemical detection

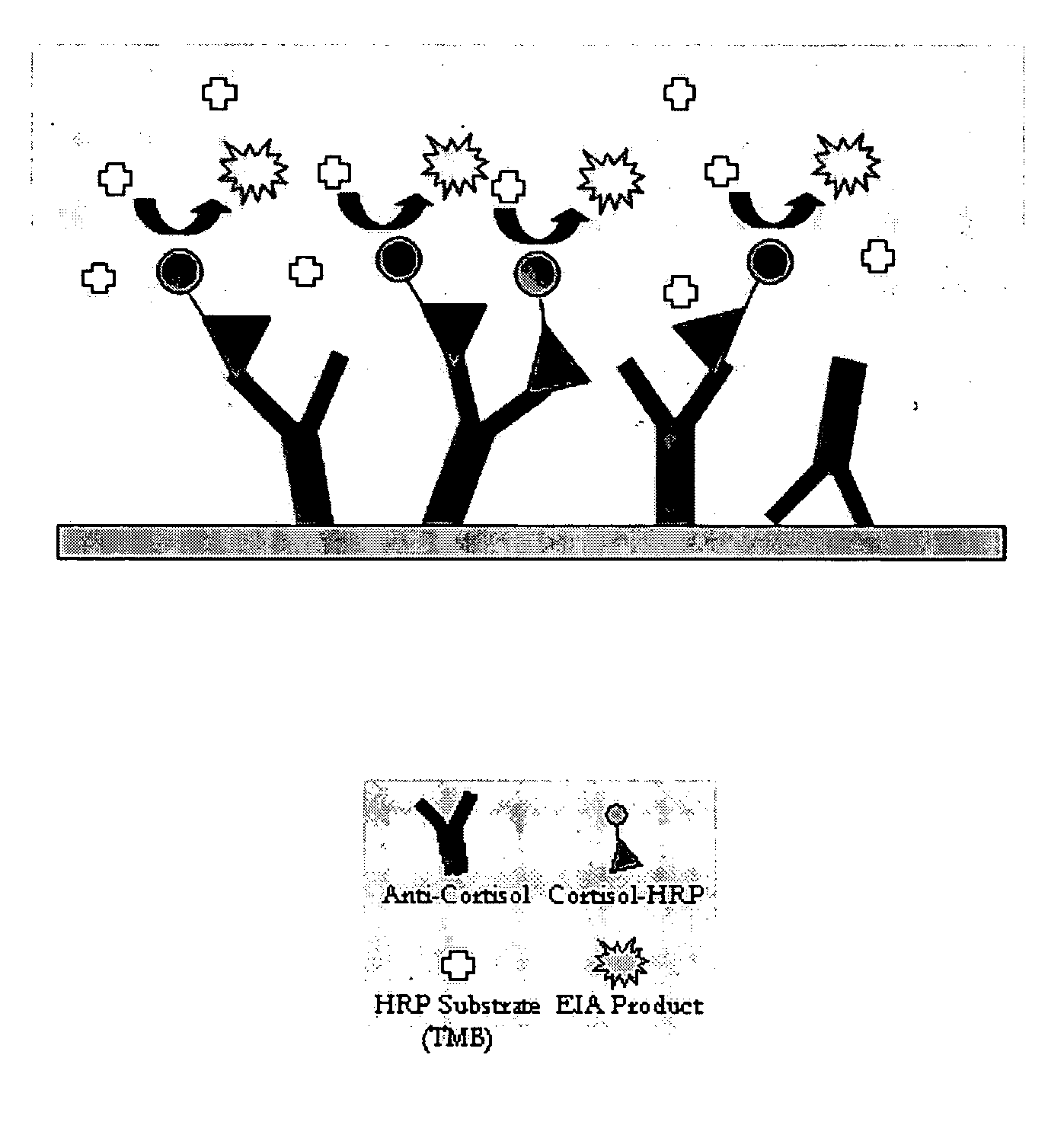

InactiveUS7405054B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPeroxidaseLab-on-a-chip

The present invention provides methods and compositions for amplifying the detection signal in surface plasmon resonance (SPR)-based flow systems. The signal amplification methods comprise the use of well established marker systems that provide a precipitate. The marker systems include, for example, enzyme and nucleation systems. Enzymes suitable for use as a marker system include peroxidases and phosphatases. The amplification system is useful in any SPR-based detection system including microfluidic systems, e.g., “lab on a chip” systems and the like. The methods can comprise any SPR-based assay format, including typical immunoassay formats. The immunoassay formats can include competitive and sandwich assays. Analyte capture agents can include antibodies, lectins, carbohydrates, polynucleotides, receptor proteins, and the like.

Owner:UNIV OF WASHINGTON

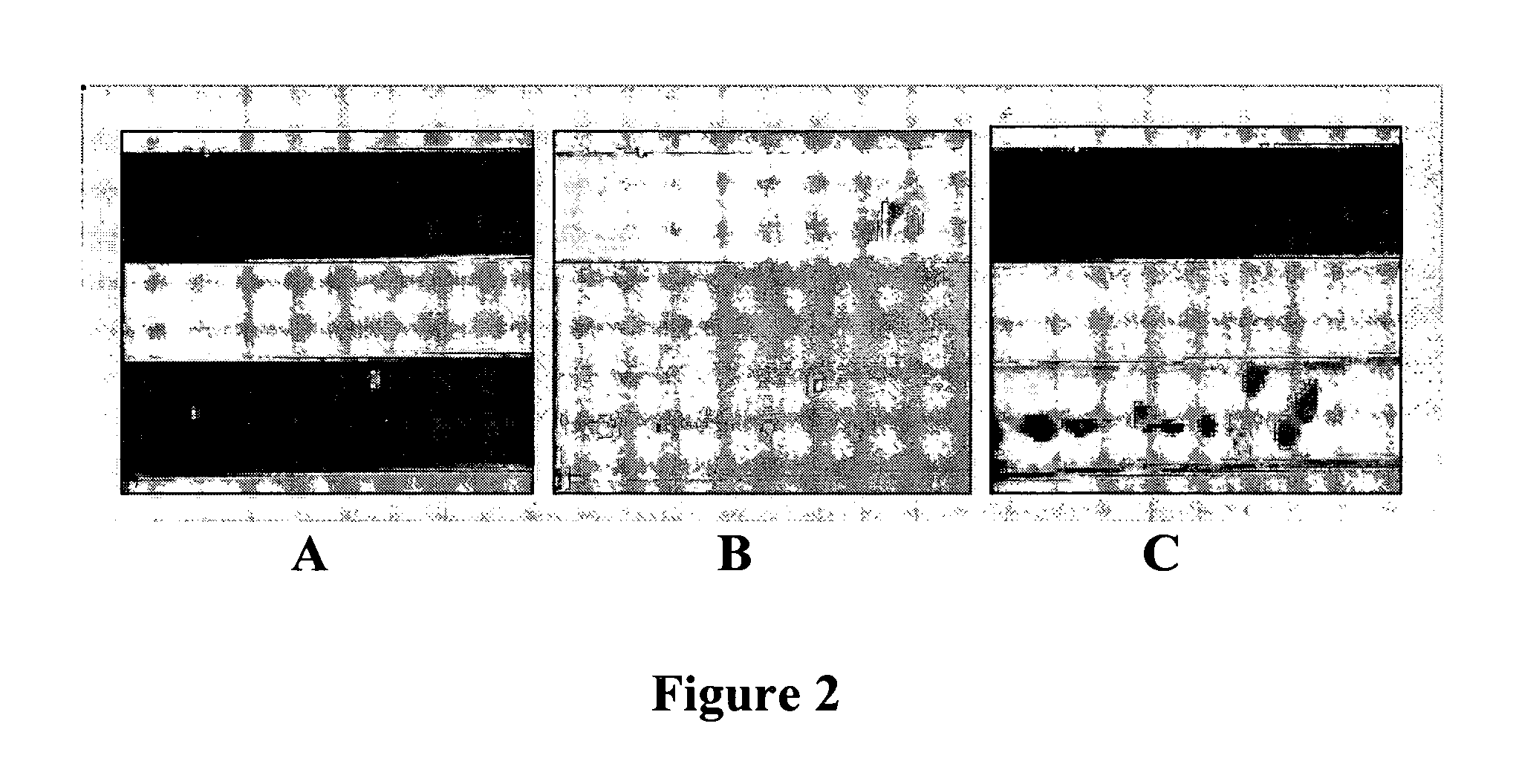

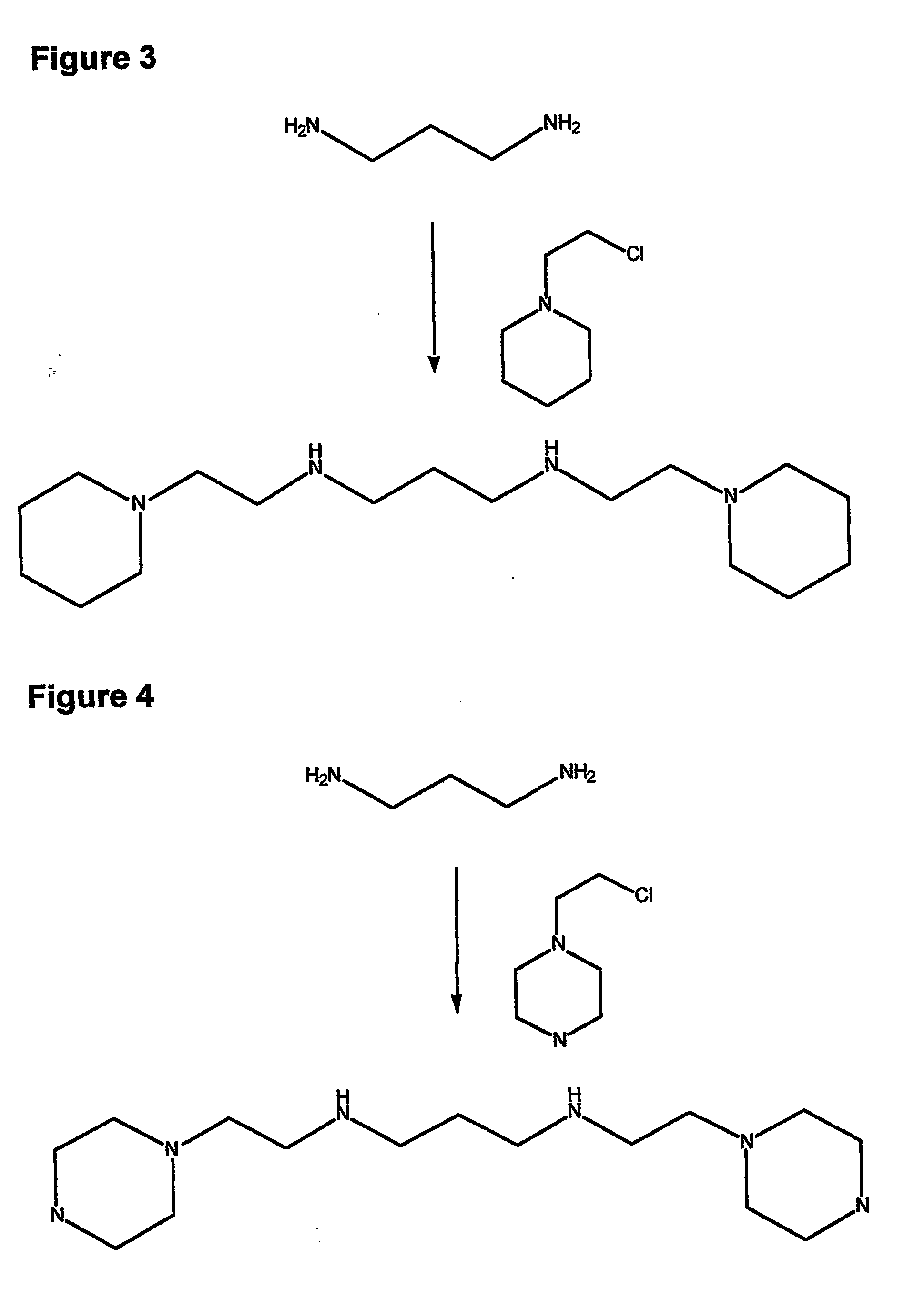

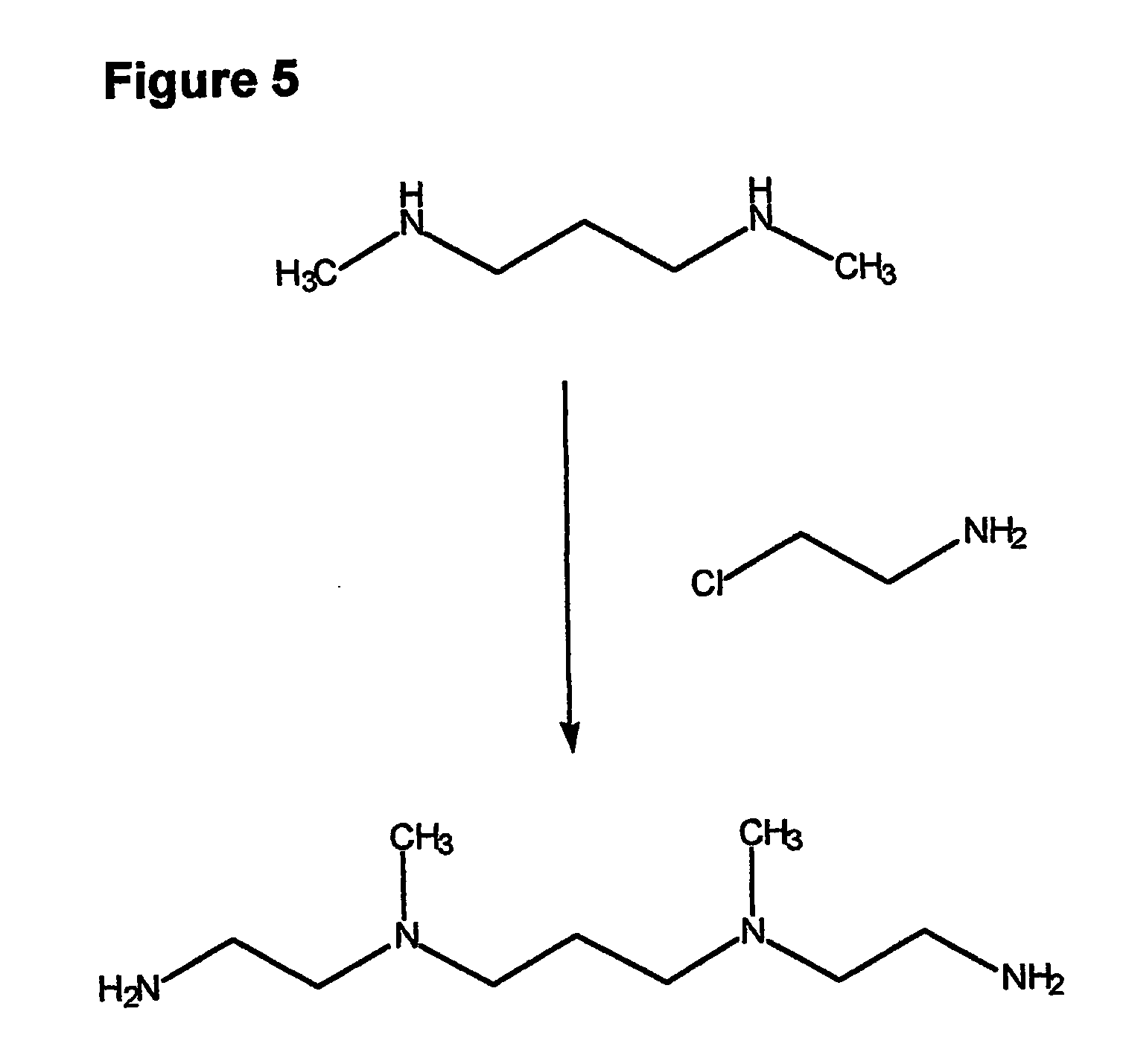

Composition, synthesis and therapeutic applications of polyamines

InactiveUS20050085555A1Chromium concentration were decreasedIncrease excretionBiocideGroup 5/15 element organic compoundsAntidoteRisk stroke

This invention relates to a process of synthesis and composition of open chain (ring), closed ring, linear branched and or substituted polyamines, polyamine derived tyrosine phosphatase inhibitors and PPAR partial agonists / partial antagonists via a series of substitution reactions and optimizing the bioavailability and biological activities of the compounds. Polyamines prevent the toxicty of neutoxins and diabetogenic toxins including paraquat, methyphenyl pyridine radical, rotenone, diazoxide, streptozotocin and alloxan. These polyamines can be to treat neurological, cardiovascular, endocrine acquired and inherited mitochondrial DNA damage diseases and other disorders in mammalian subjects, and more specifically to the therapy of Parkinson's disease, Alzheimer's disease, Lou Gehrig's disease, Binswanger's disease, Olivopontine Cerebellar Degeneration, Lewy Body disease, Diabetes, Stroke, Atherosclerosis, Myocardial Ischemia, Cardiomyopathy, Nephropathy, Ischemia, Glaucoma, Presbycussis, Cancer, Osteoporosis, Rheumatoid Arthritis, Inflammatory Bowel Disease, Multiple Sclerosis and as Antidotes to Toxin Exposure.

Owner:MURPHY MICHAEL A

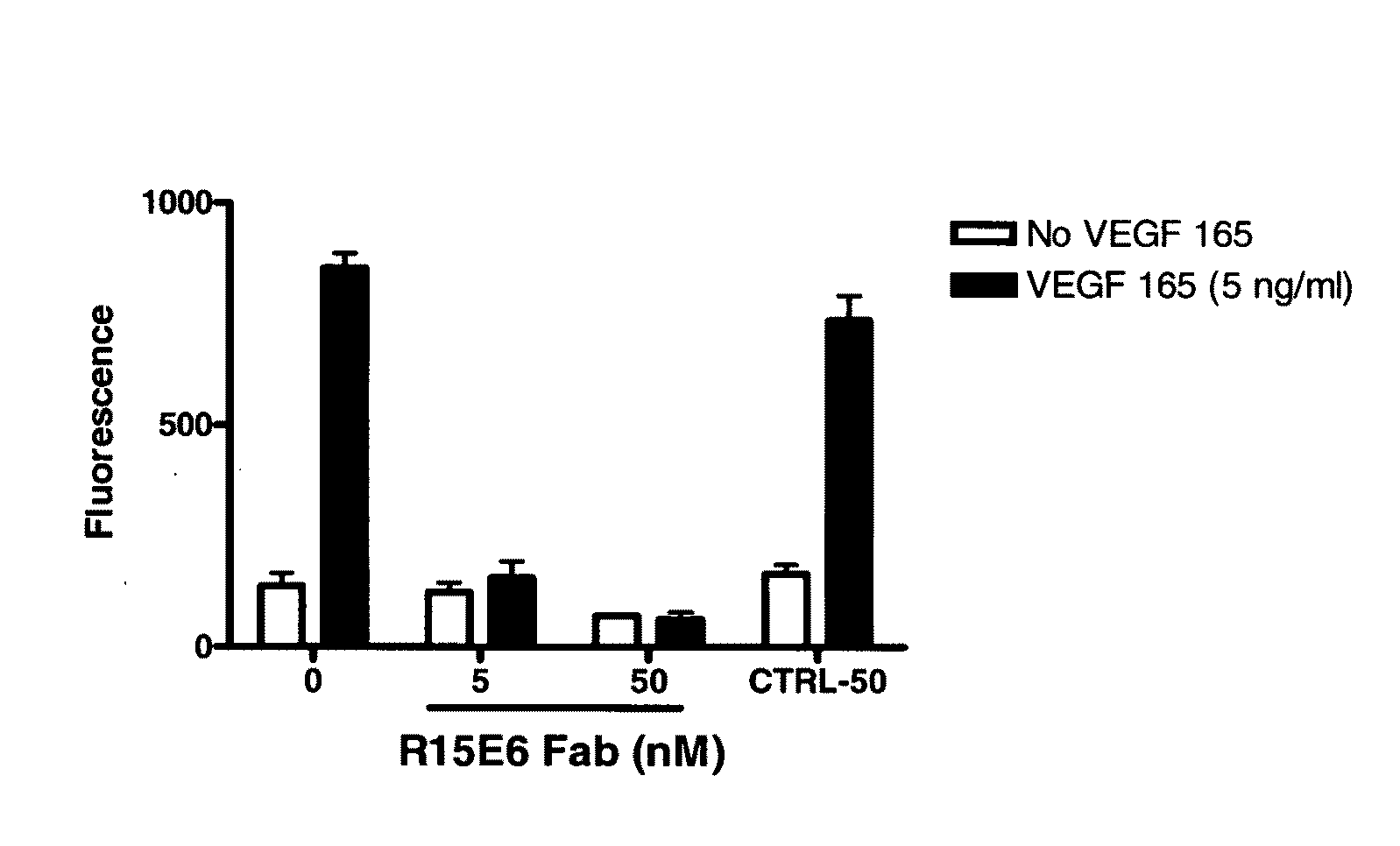

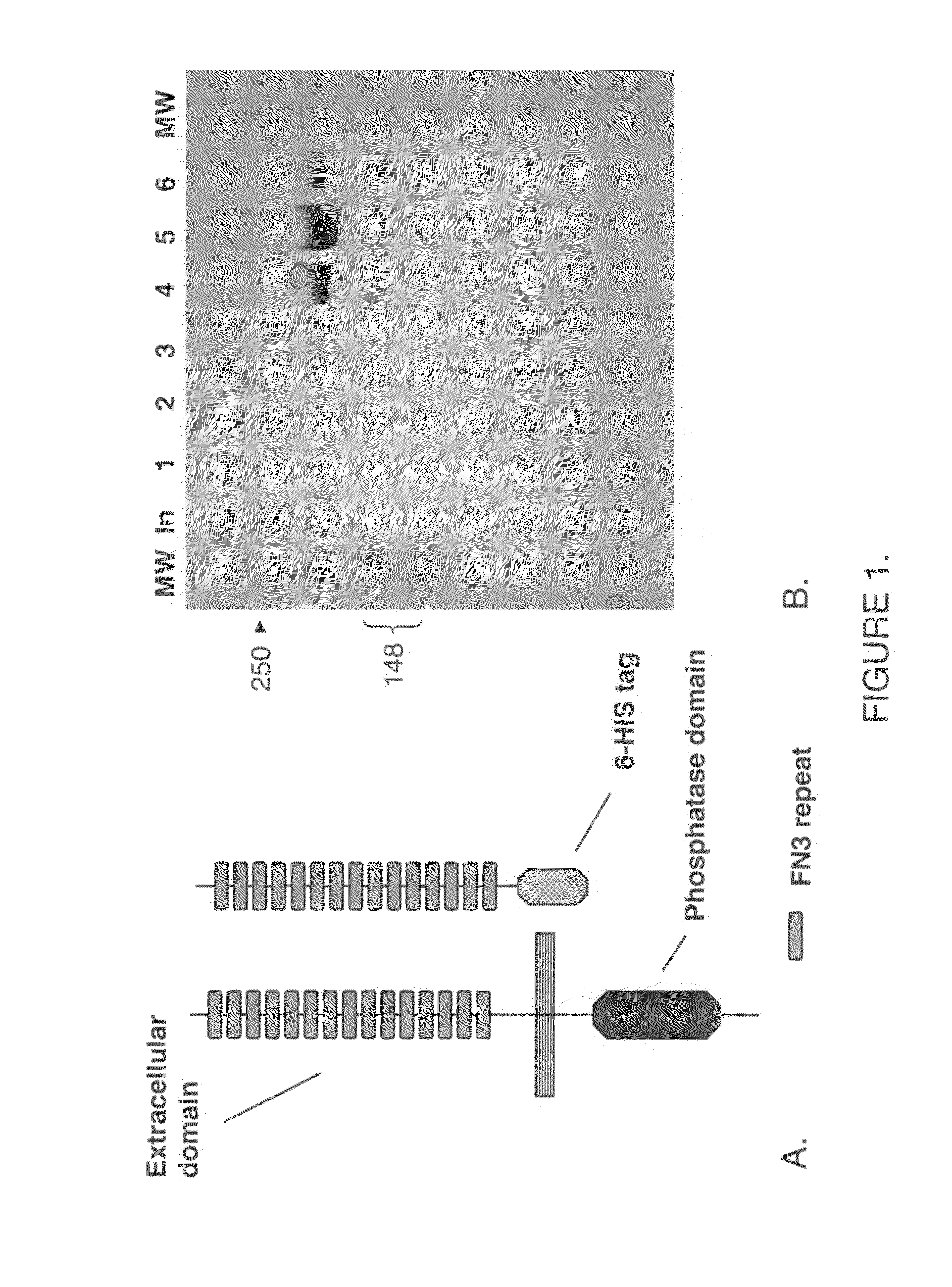

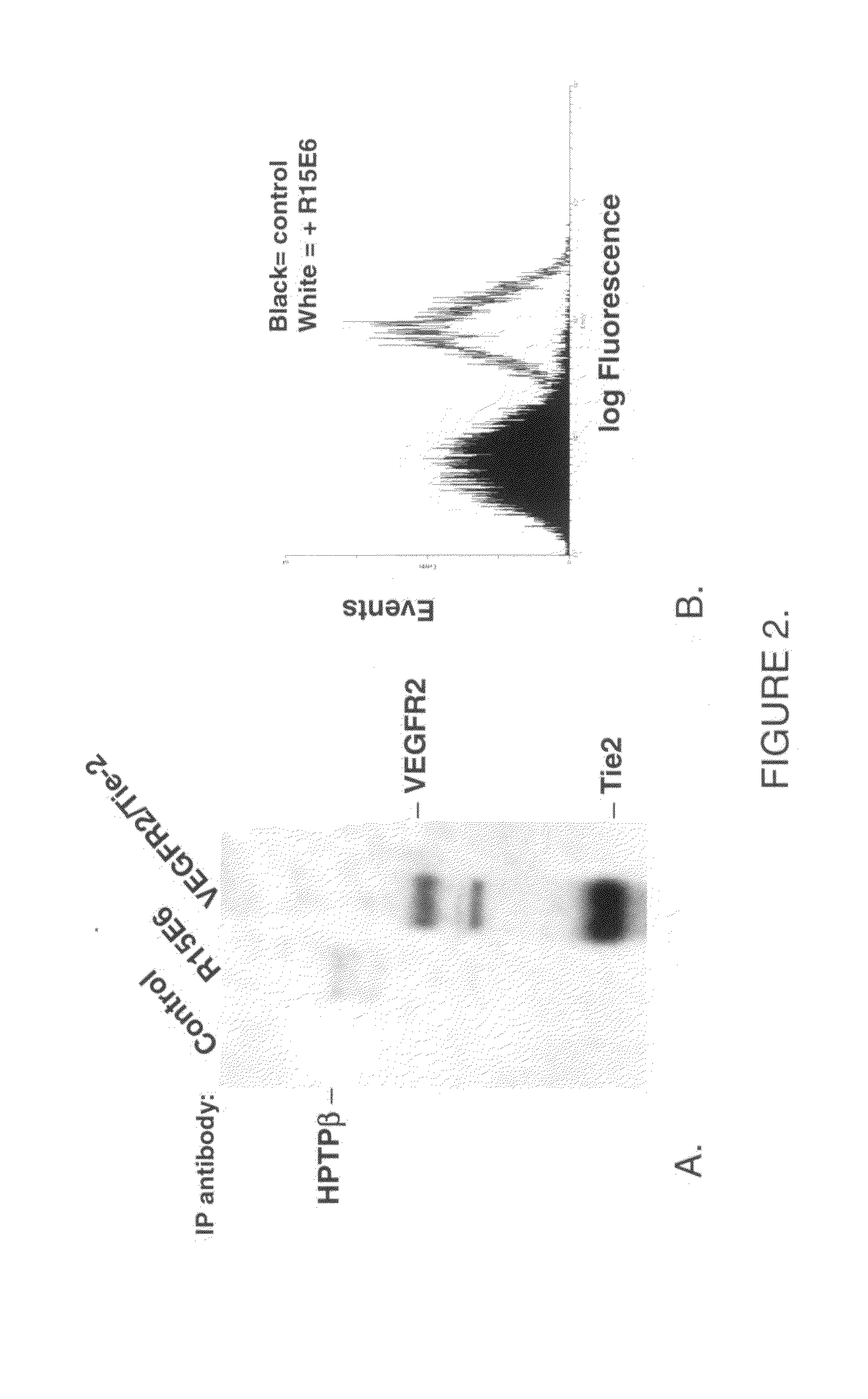

Antibodies that bind human protein tyrosine phosphatase beta (HPTPbeta) and uses thereof

Antibodies and antigen binding fragments thereof that bind to human protein tyrosine phosphatase beta (HPTPβ), and uses thereof.

Owner:EYEPOINT PHARMA INC

Human protein tyrosine phosphatase inhibitors and methods of use

ActiveUS20130023543A1Inhibit angiogenesisOrganic active ingredientsBiocidePhosphatase inhibitorAngiogenesis growth factor

The present disclosure relates to compounds effective as human protein tyrosine phosphatase beta (HPTP-β) inhibitors thereby regulating angiogenesis. The present disclosure further relates to compositions comprising said human protein tyrosine phosphatase beta (HPTP-β) inhibitors, and to methods for regulating angiogenesis.

Owner:EYEPOINT PHARMA INC

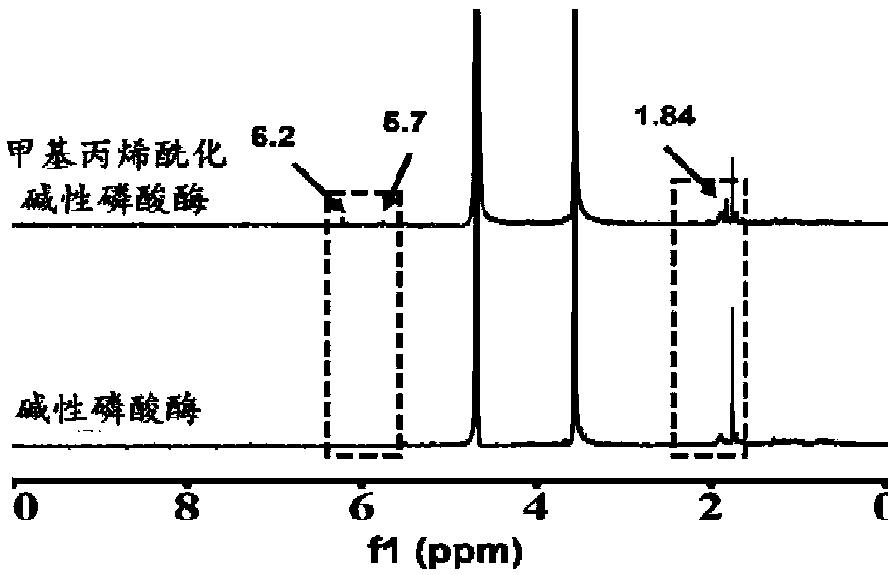

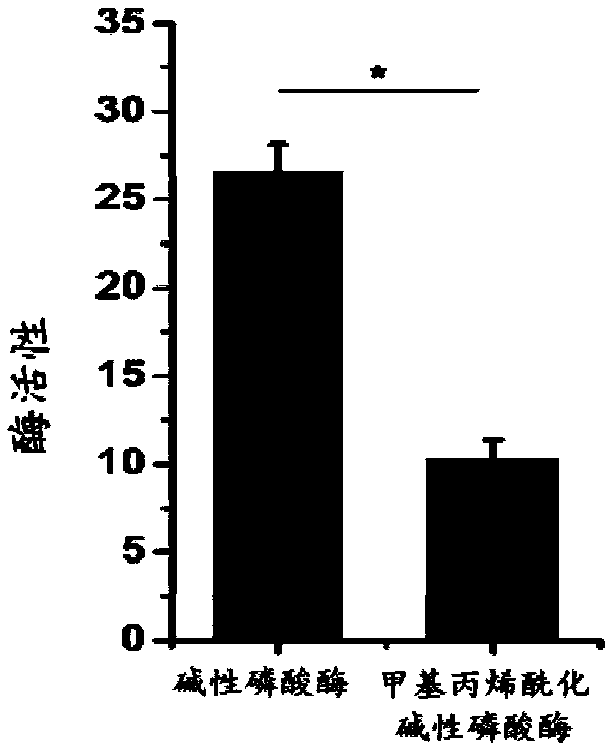

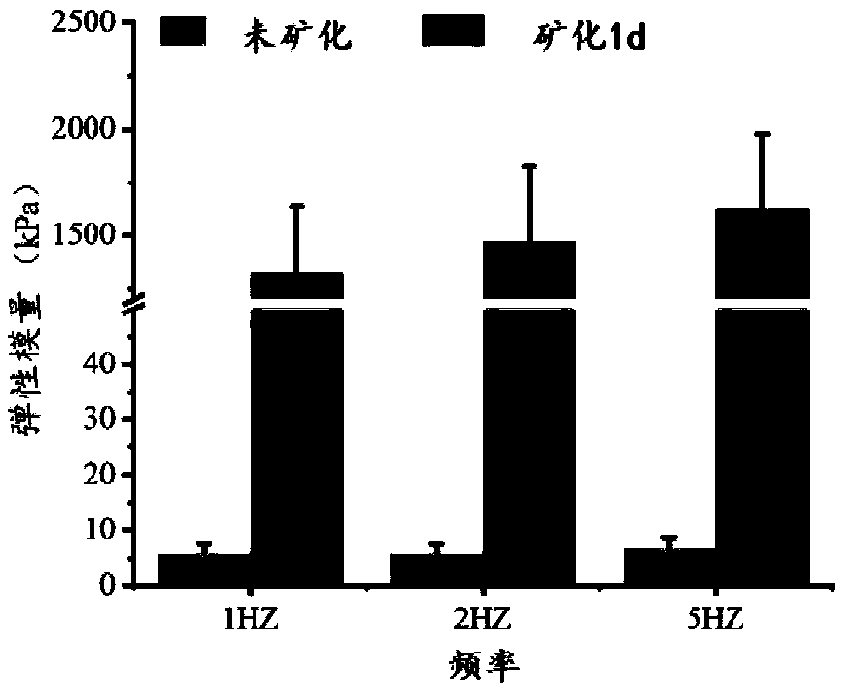

Preparation methods of mineralized hydrogel and biomimetic mineralized bone repair material

The invention discloses preparation methods of mineralized hydrogel and a biomimetic mineralized bone repair material. The mineralized hydrogel is prepared by using a photoactivated biomacromoleculesand a photoactivated phosphatase as raw materials; hydrogel is formed by initiating cross-linking by means of light irradiation or initiating polymerization cross-linking by means of a radical initiator; when the hydrogel is put into mineralized liquid, phosphatase can promote the uniform deposition of phosphate in the gel, so that the uniformly mineralized hydrogel is obtained. Phosphoprotein-like molecules are added during the preparation of the hydrogel; the phosphoprotein-like molecules can promote the uniform deposition of phosphate along a molecular network of biomacromolecules, so thatthe high-strength mineralized hydrogel can be obtained. When the phosphoprotein-like molecules and cells are added during the preparation of the hydrogel, the in-situ loading of the cells can be realized, and the enzyme in a process of bone physiological mineralization can be simulated so as to promote a phosphate mineralization process, so that the biomimetic mineralized bone repair material withhigh strength can be obtained, and the personalized customization of the bionic mineralized bone repair material can be realized; therefore, the preparation methods have a broad application prospectin the field of bone tissue engineering.

Owner:SICHUAN UNIV

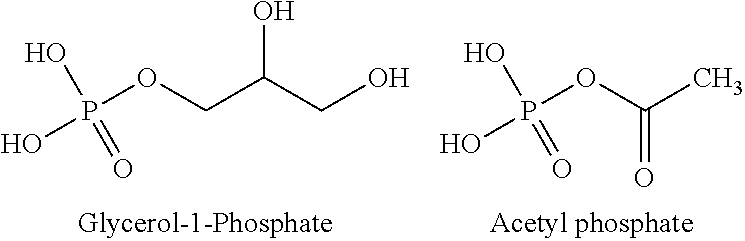

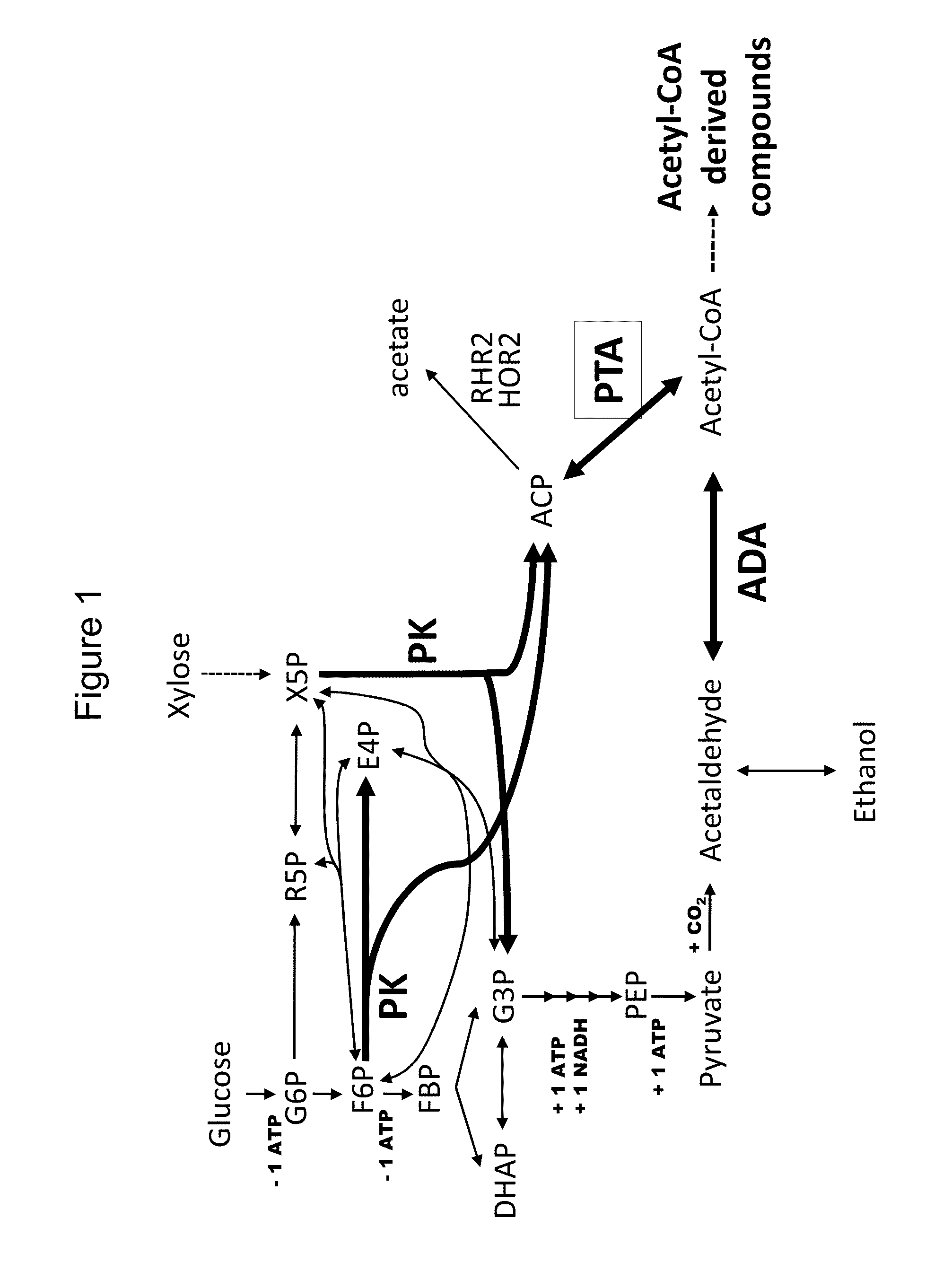

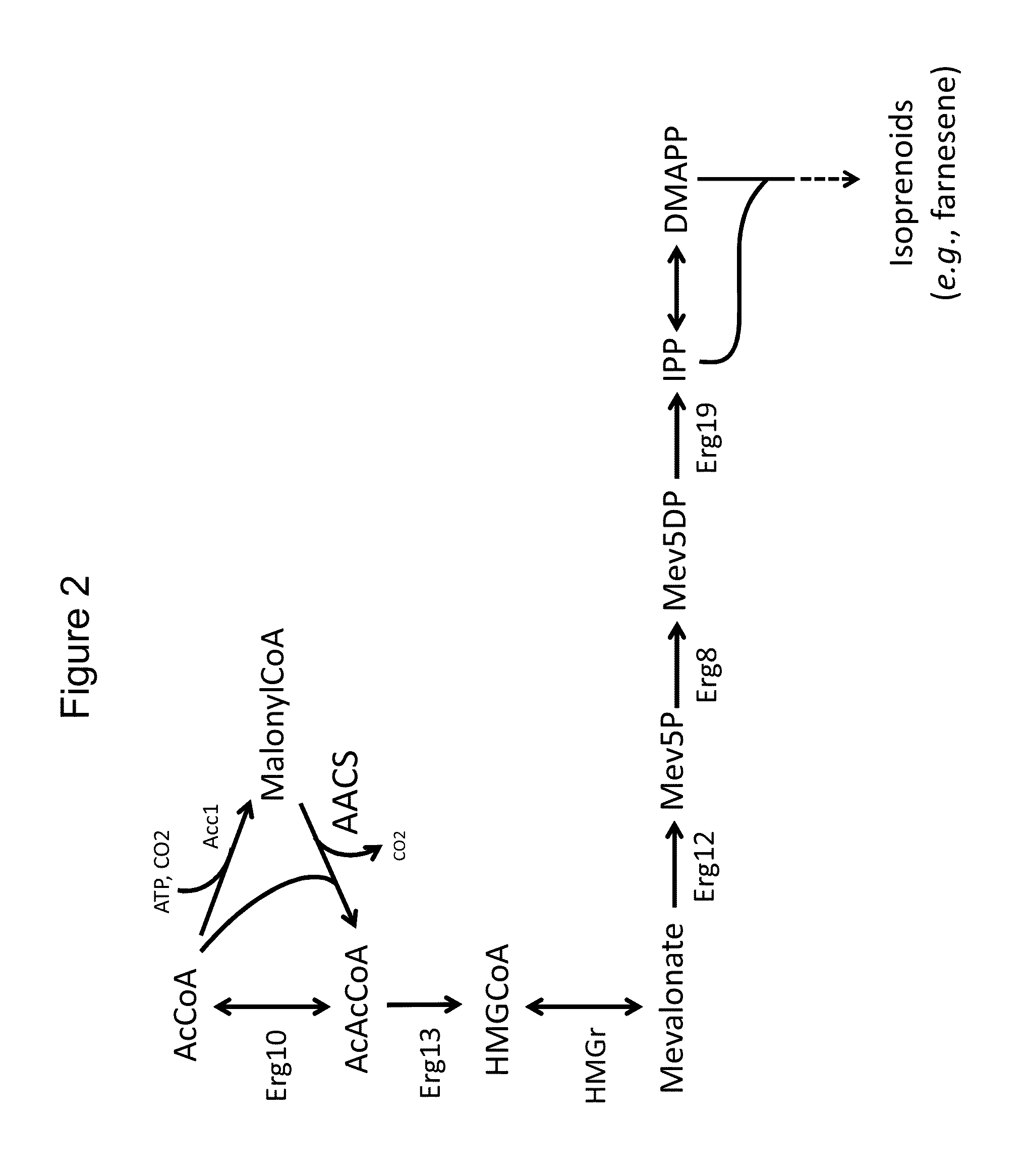

Use of phosphoketolase and phosphotransacetylase for production of acetyl-coenzyme a derived compounds

Provided herein are compositions and methods for improved production of acetyl-CoA and acetyl-CoA derived compounds in a host cell. In some embodiments, the host cell is genetically modified to comprise a heterologous nucleotide sequence encoding a phosphoketolase (PK), and a functional disruption of an endogenous enzyme that converts acetyl phosphate to acetate. In some embodiments, the host cell further comprises a heterologous nucleotide sequence encoding a phosphotransacetylase (PTA). In some embodiments, the enzyme that converts acetyl phosphate to acetate is a glycerol-1-phosphatase. In some embodiments, the glycerol-1-phosphatase is GPP1 / RHR2. In some embodiments, the glycerol-1-phosphatase is GPP2 / HOR2. The compositions and methods described herein provide an efficient route for the heterologous production of acetyl-CoA-derived compounds, including but not limited to, isoprenoids, polyketides, and fatty acids.

Owner:TOTALENERGIES ONETECH +1

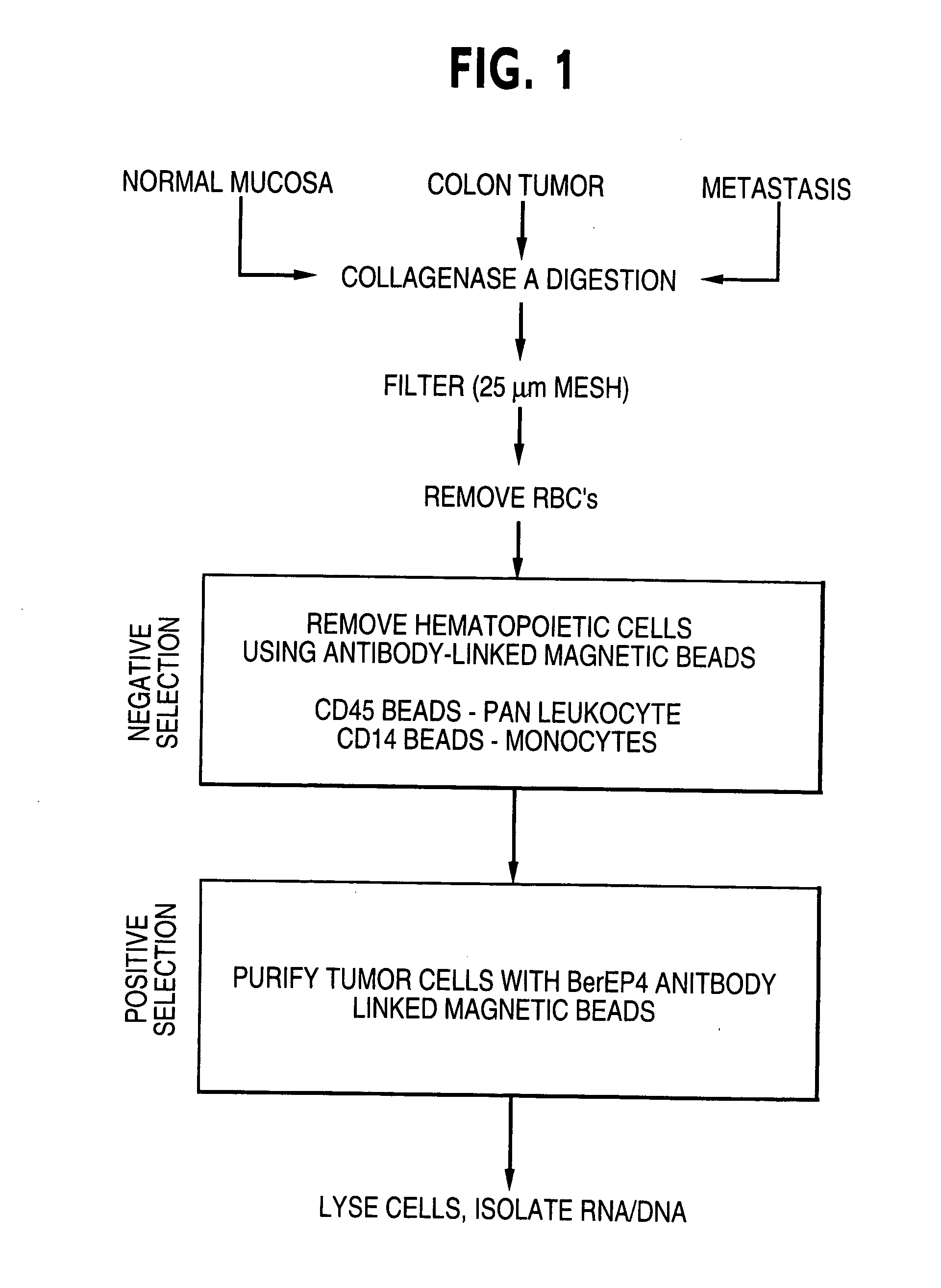

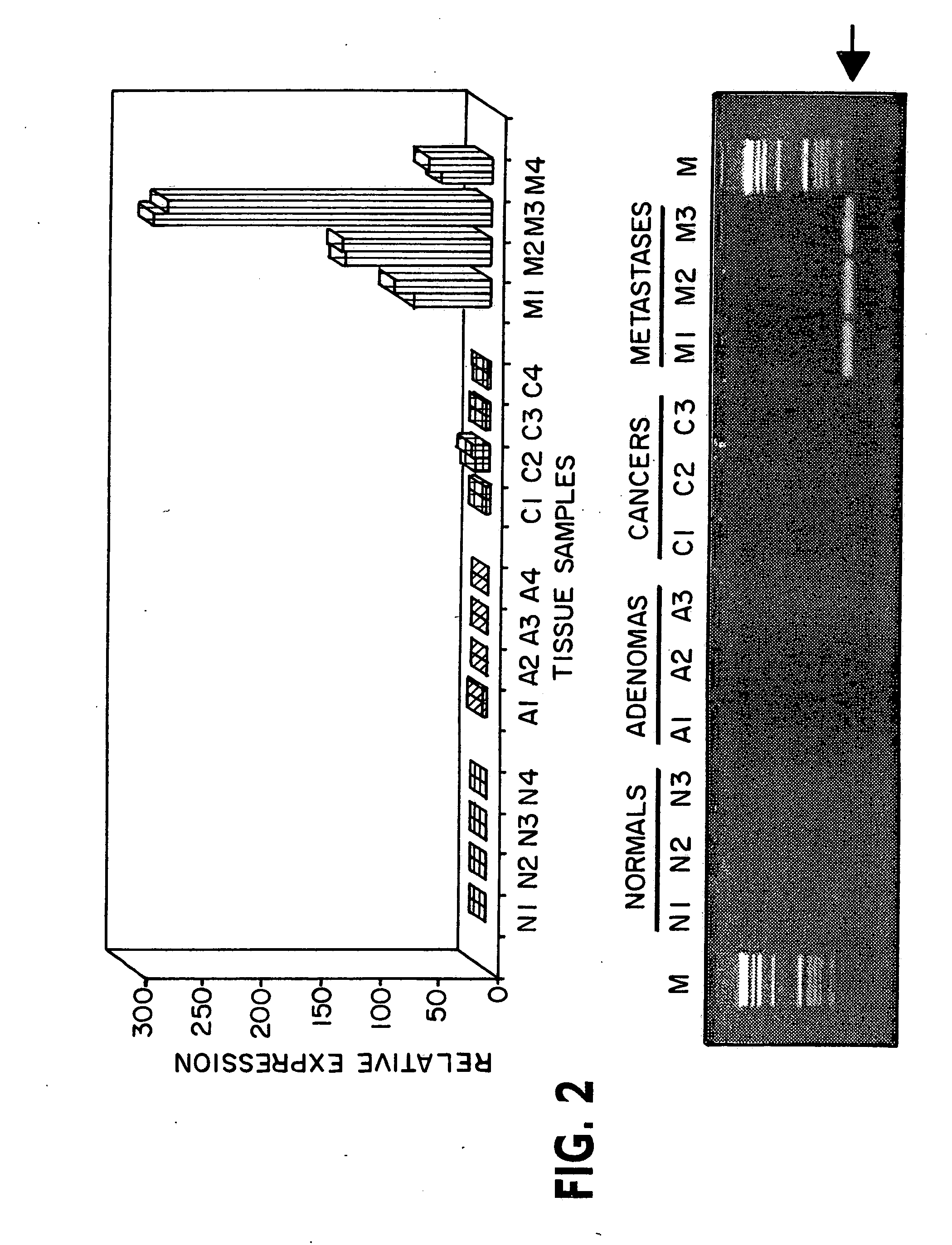

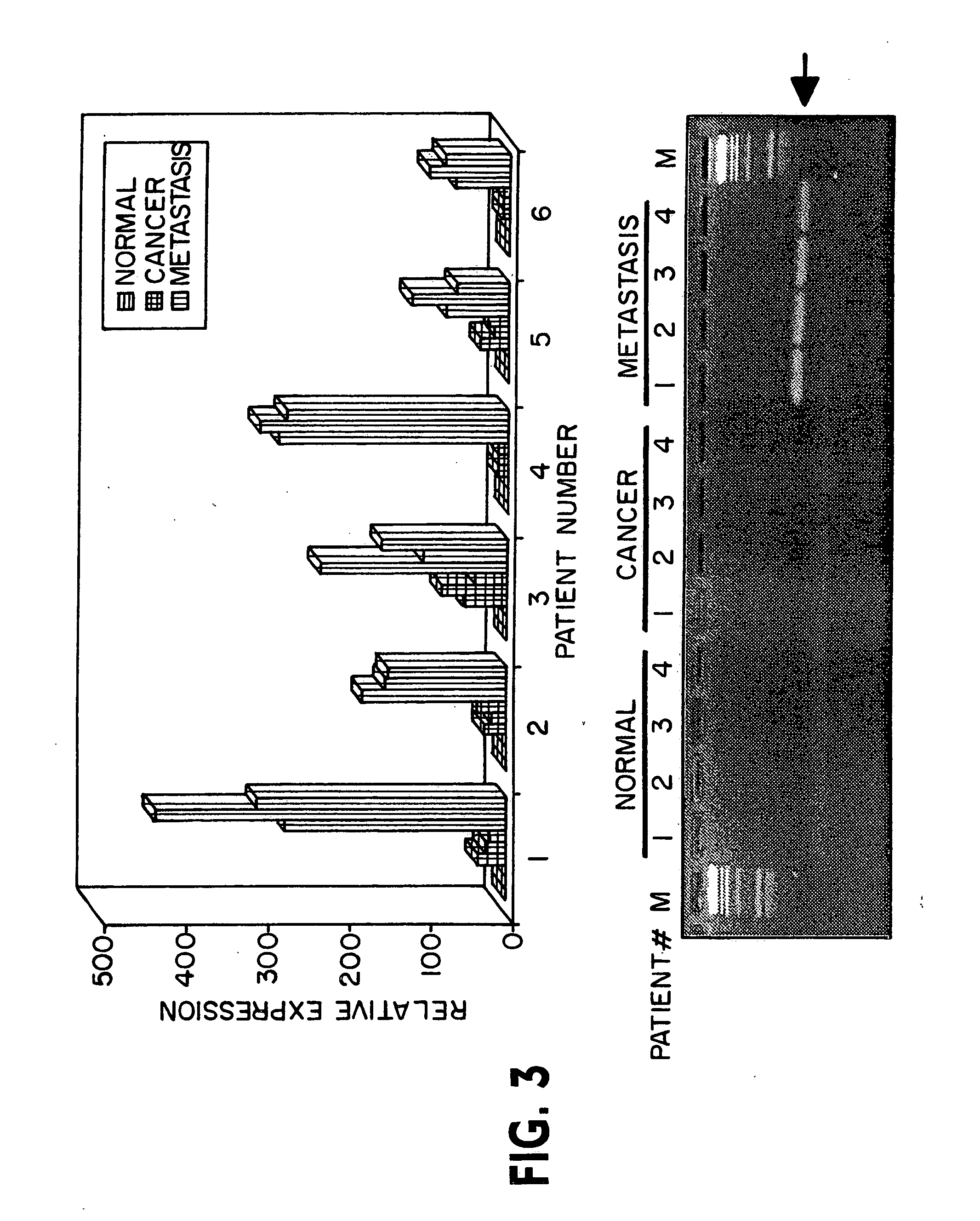

Phosphatase associated with metastasis

ActiveUS20050047996A1Propensity of the tissue to metastasizeIn-vivo radioactive preparationsHydrolasesAbnormal tissue growthEpithelium

Among the genes identified, in a comparison of the global gene expression profile of metastatic colorectal cancer to that of primary cancers, benign colorectal tumors, and normal colorectal epithelium, the PRL-3 protein tyrosine phosphatase gene was of particular interest. It was expressed at high levels in each of 18 cancer metastases studied but at lower levels in non-metastatic tumors and normal colorectal epithelium. In three of twelve metastases examined, multiple copies of the PRL-3 gene were found within a small amplicon located at chromosome 8q24.3. These data suggest that the PRL-3 gene is important for colorectal cancer metastasis and provides a new therapeutic target for these intractable lesions.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

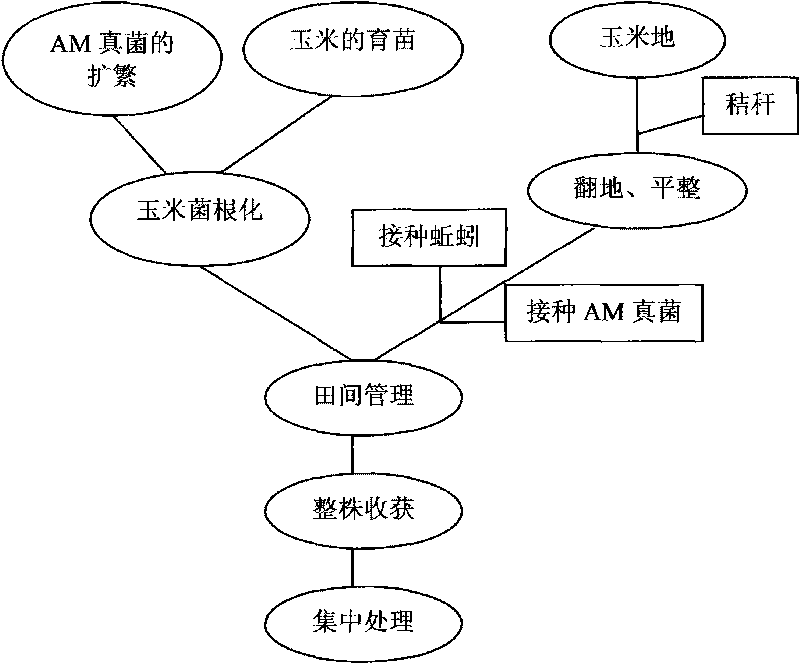

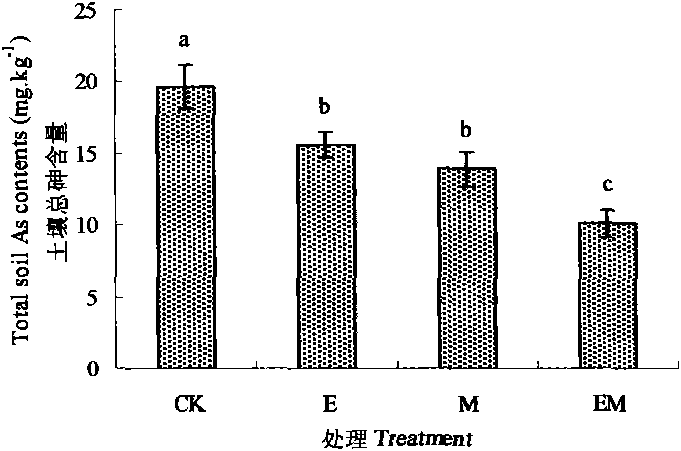

Method for improving phytoremediation efficiency of low-concentration arsenic-contaminated soil

InactiveCN101704015APromote repairPromote growthContaminated soil reclamationHorticulture methodsArbuscular mycorrhizal fungiPhytoremediation

The invention discloses a method for improving the phytoremediation efficiency of low-concentration arsenic-contaminated soil, which comprises the steps of: planting corns in an arsenic-contaminated farmland, inoculating arbuscular mycorrhizal fungi and earthworms, pulling up the corns with roots after the growth season of the corn is over, harvesting the corns wholly, and performing centralized treatment. The method fully exploits the potentials of arsenic remediation of plants, microorganisms and animals, and inoculates the AM fungi and the earthworms to promote the plant absorption and dissipation of arsenic by promoting the growth of the plants, improving the activity of phosphatase of the soil and activating the arsenic in the soil to further achieve the aim of improving the phytoremediation efficiency of the low-concentration arsenic-contaminated soil. The method combines the microorganisms, the animals and the plants together for the in-situ remediation of the arsenic-contaminated farmland, has simple and convenient operation and friendly operating environment, cannot cause secondary pollution, reduces the treatment cost, and has good environmental effect.

Owner:吴江市土壤肥料技术指导站

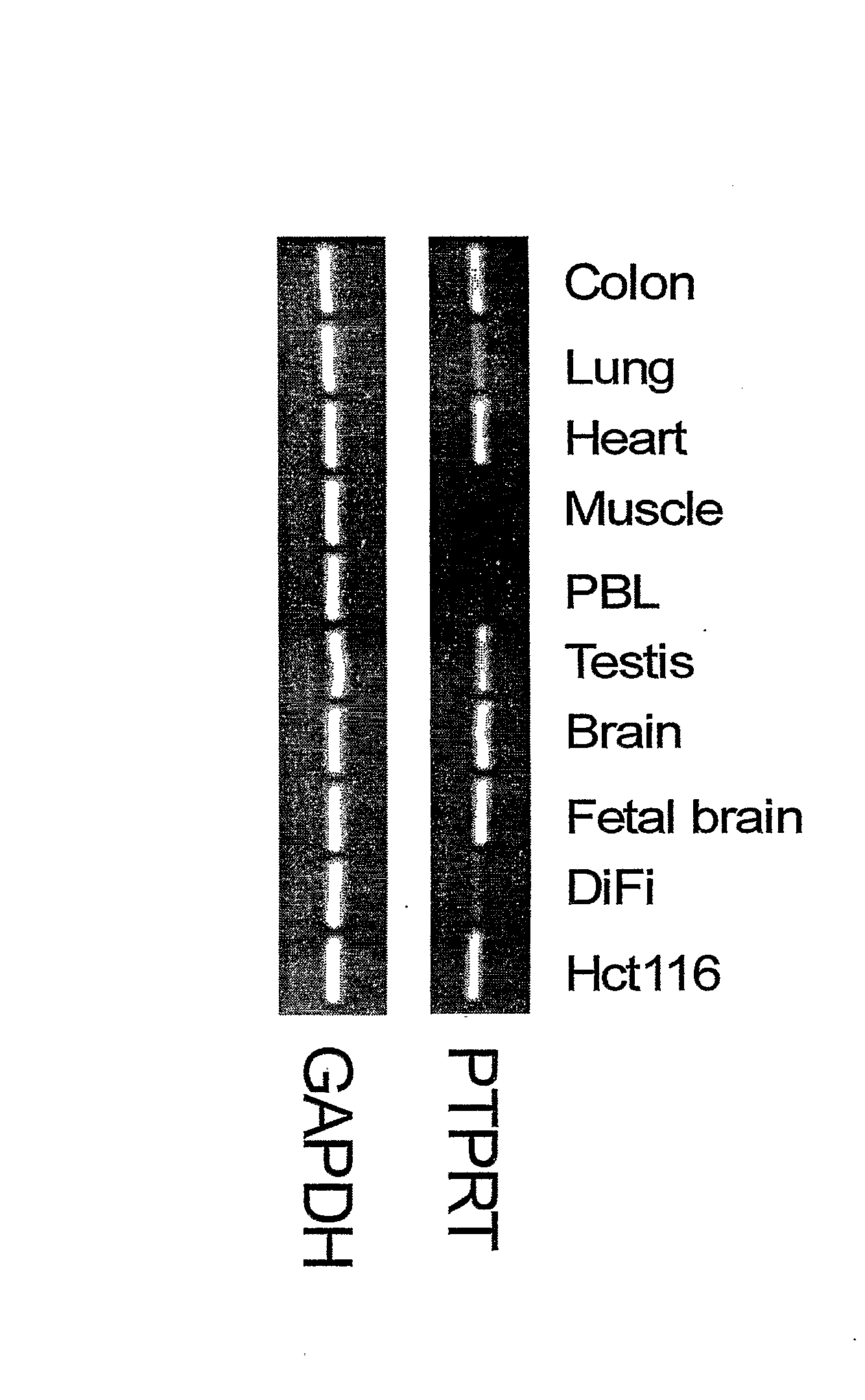

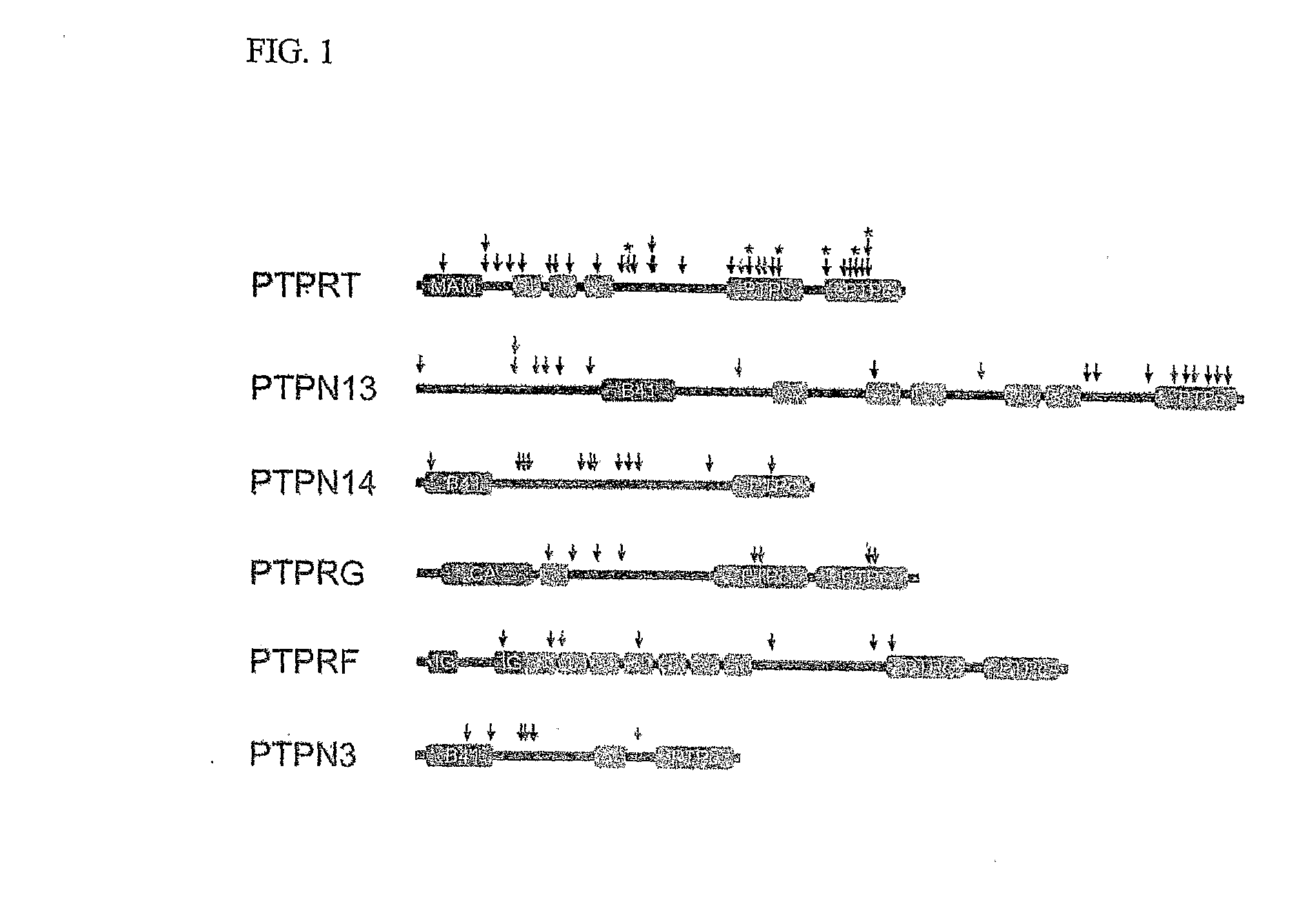

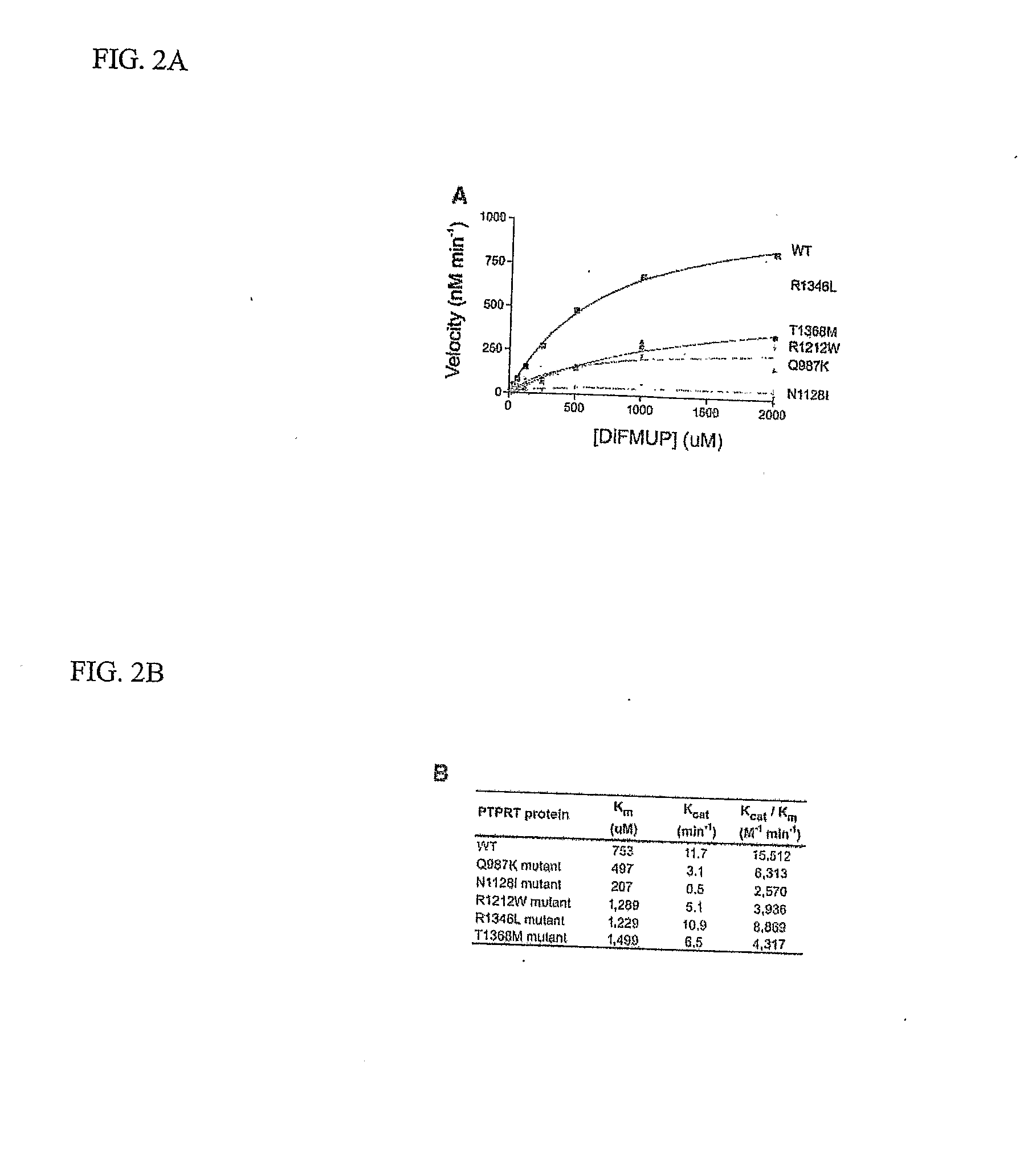

Protein Tyrosine Phosphate Mutations in Cancers

ActiveUS20080039417A1Growth inhibitionOrganic active ingredientsSugar derivativesAbnormal tissue growthCellular pathways

Tyrosine phosphorylation, regulated by protein tyrosine phosphatases (PTPs) and kinases (PTKs), is important in signaling pathways underlying tumorigenesis. A mutational analysis of the tyrosine phosphatase gene superfamily in human cancers identified 83 somatic mutations in six PTPs (PTPRF, PTPRG, PTPRT, PTPN3, PTPN13, PTPN14) affecting 26% of colorectal cancers and a smaller fraction of lung, breast and gastric cancers. Fifteen mutations were nonsense, frameshift or splice site alterations predicted to result in truncated proteins lacking phosphatase activity. Five missense mutations in the most commonly altered PTP (PTPRP) were biochemically examined and found to reduce phosphatase activity. Expression of wild-type but not a mutant PTPRT in human cancer cells inhibited cell growth. These observations suggest that the tyrosine phosphatase genes are tumor suppressor genes, regulating cellular pathways that may be amenable to therapeutic intervention.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Compositions and methods for enhancing cognitive function

ActiveUS7923041B2Prevent tau hyperphosphorylationBiocideOrganic active ingredientsTraditional medicinePhosphoprotein phosphatase

Owner:SIGNUM BIOSCIENCES INC +1

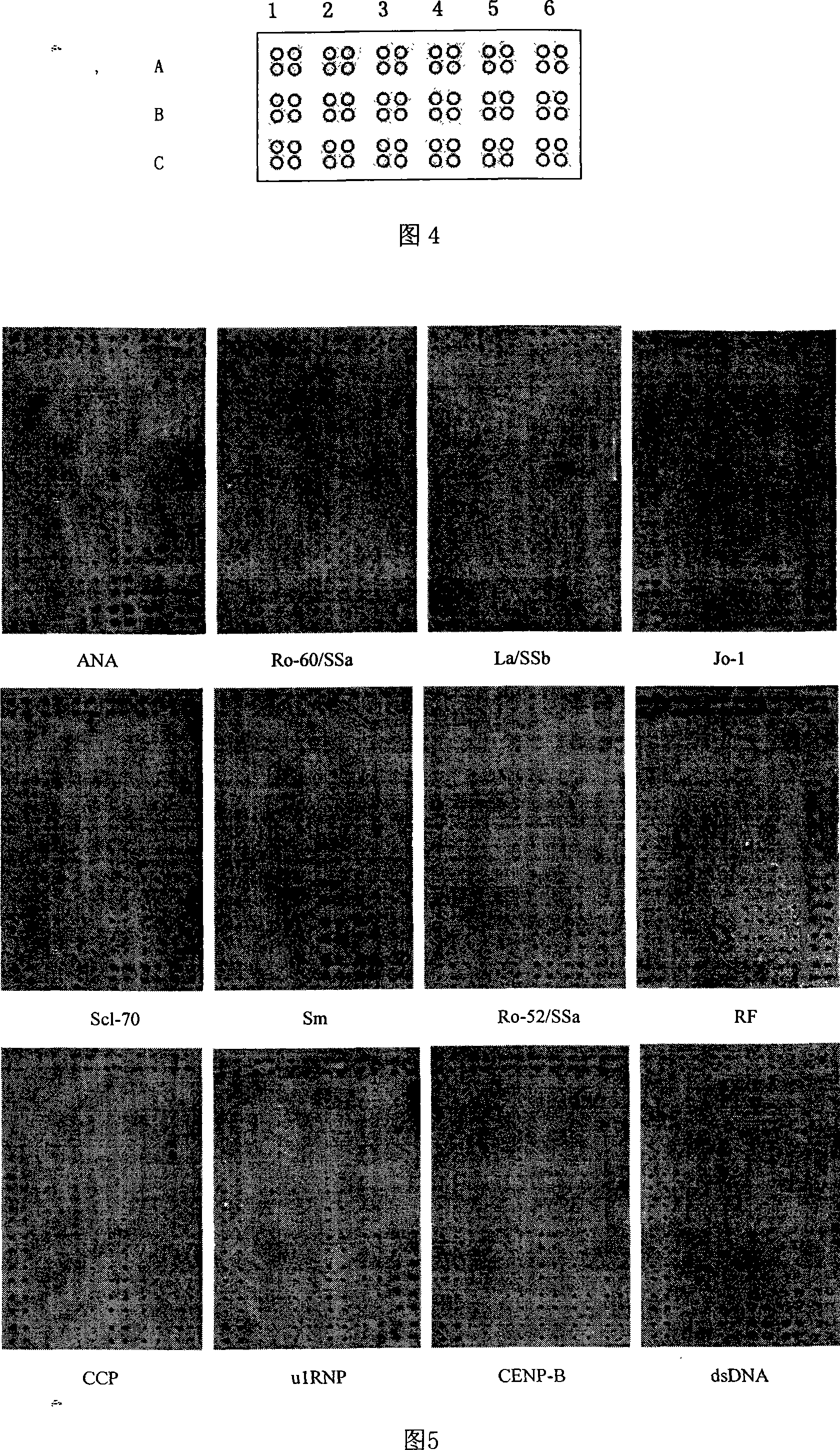

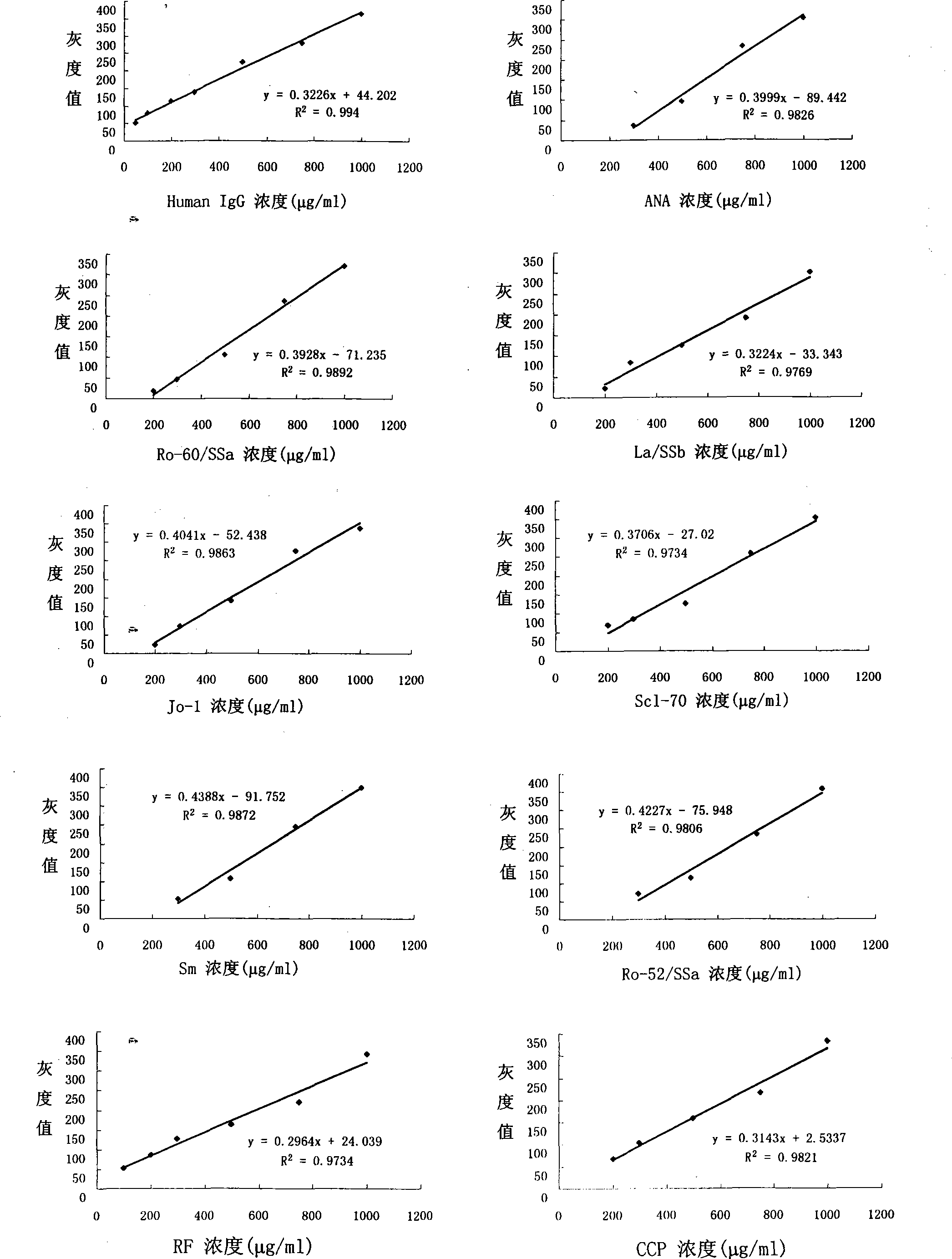

Colour development protein chip using BCIP/NBT as substrate as well as application in detection of autoantibody thereof

InactiveCN101226192AIncreased sensitivityImprove featuresMaterial analysis by observing effect on chemical indicatorBiological testingAntigenAutoantibody production

The invention discloses a color protein chip which substrate is BCIP / NBT. The invention is composed of a substrate, an array, 12 antigens coated on the array, negative contrast, positive contrast and blank contrast, wherein the substrate is a glass slide decorated by APES, the kinds and point sample densities of the 12 antigens are 520ug / ml ANA, 465ug / ml Ro-60, 530ug / ml La / SSb, 530ug / ml Jo-1, 525ug / ml Scl-70, 520ug / ml Sm, 615ug / ml Ro-52 / SSa, 340ug / ml RF, 465ug / ml CCP, 410ug / ml u1RNP, 490ug / ml CENP-B, 580ug / ml dsDNA. The invention uses the alkali phosphatase coloring method whose substrate is BCIP / NBT as the final check signal of protein chip to be widely used for self antibody check, while the check sensitivity has higher coincidence rate than prior art, with reduced check cost and time. The invention can be used in clinical check, sanitary supervision, regular sanitary supervision and scientific research or the like.

Owner:SHANDONG MEDICAL BIO TECH RES CENT

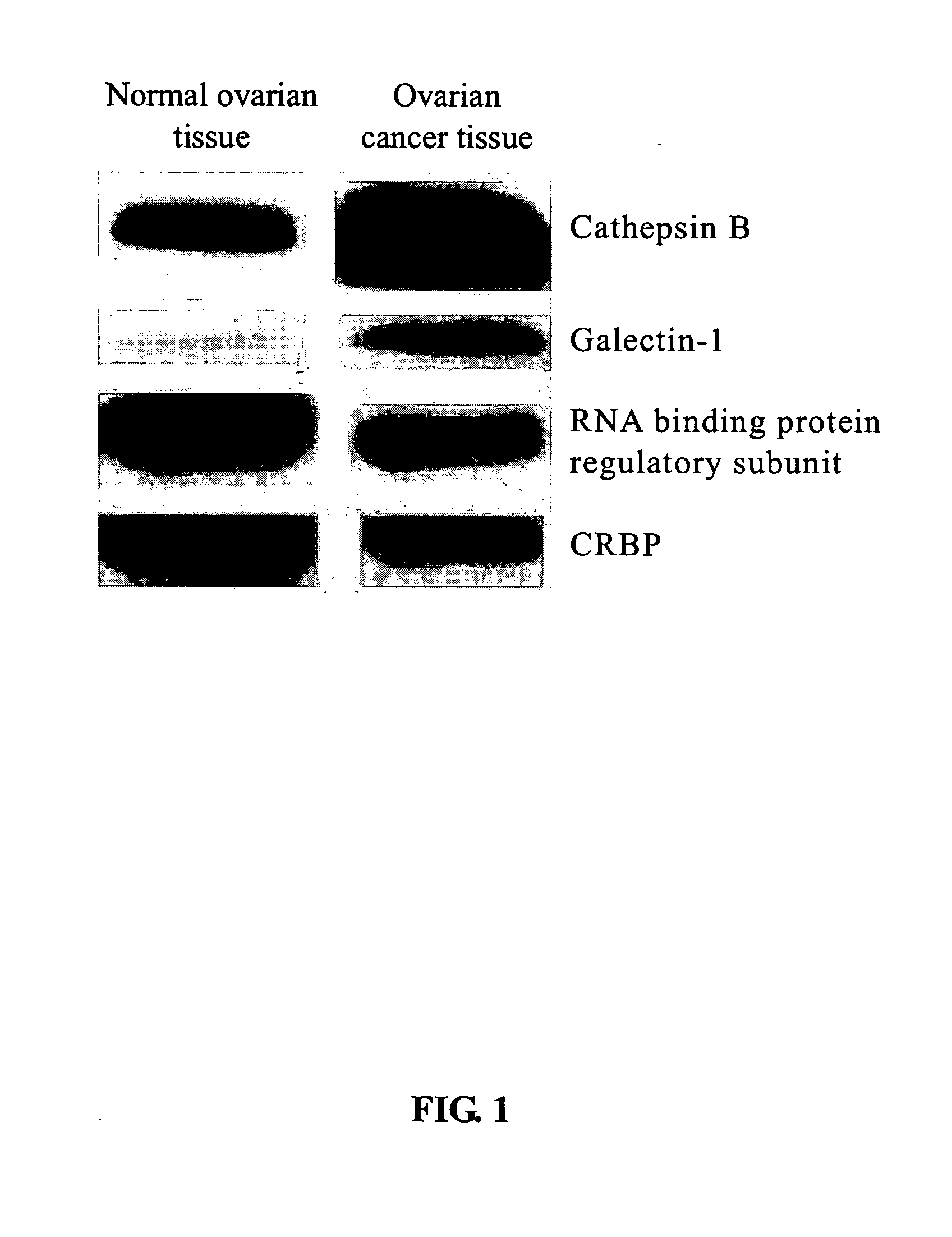

Tumor marker for ovarian cancer diagnosis

InactiveUS20070134689A1Accurate detectionMicrobiological testing/measurementMaterial analysisAbnormal tissue growthCathepsin B

The present invention relates to a tumor marker for diagnosis of ovarian cancer, which is selected from the group consisting of alectin-1, cathepsin B, MHC class I antigen, heat shock protein (HSP) 27, ubiquitin carboxy-termal esterase L1, cellular retinol-binding protein (CRBP), transthyretin, SH3 binding glutamate-rich protein, tubulin-specific chaperone A, RNA binding protein regulatory subunit, γ-actin, tropomyosin and calcium / calmodulin-stimulated cyclic nucleotide phosphatase. The ovarian cancer is diagnosed effectively and efficiently based on detecting the expression levels of the tumor markers in the invention from the ovarian tissue sample of an individual to be diagnosed.

Owner:NAT TAIWAN UNIV

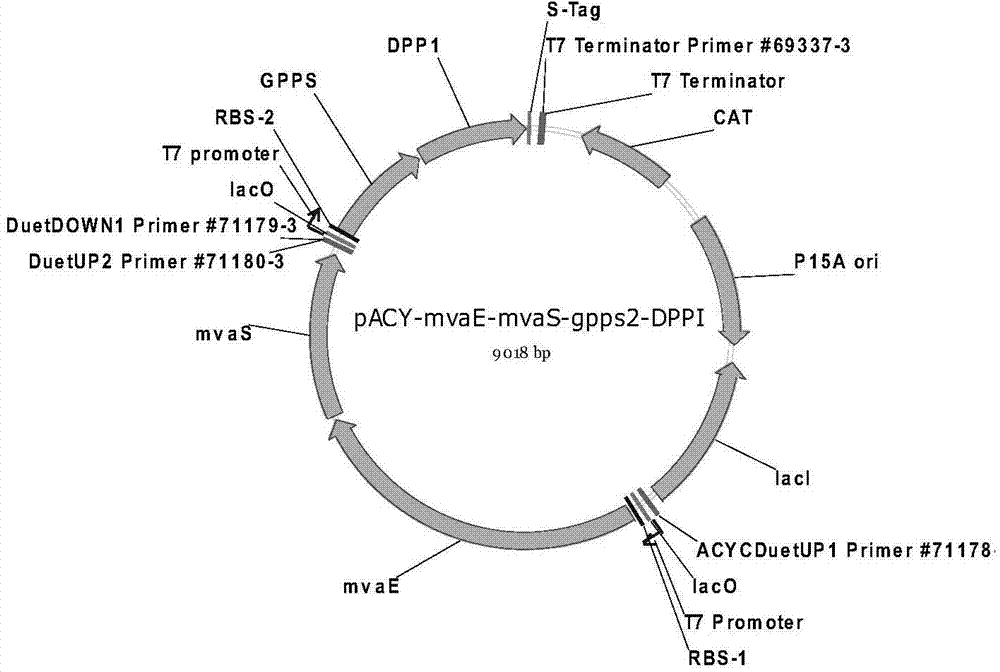

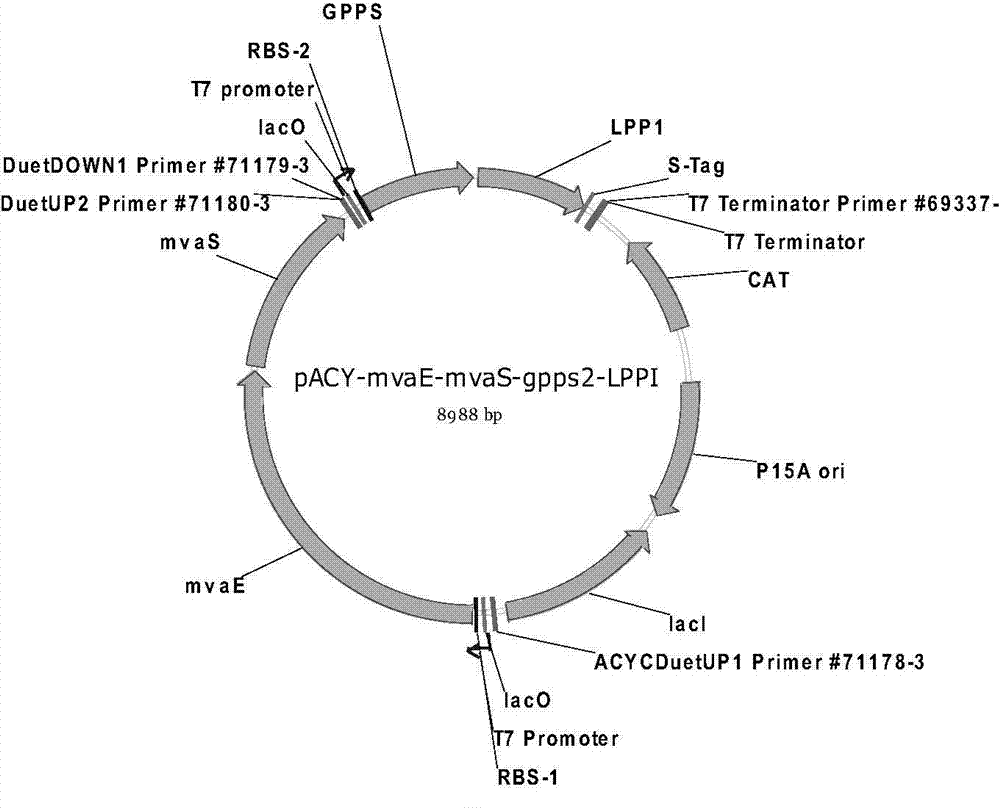

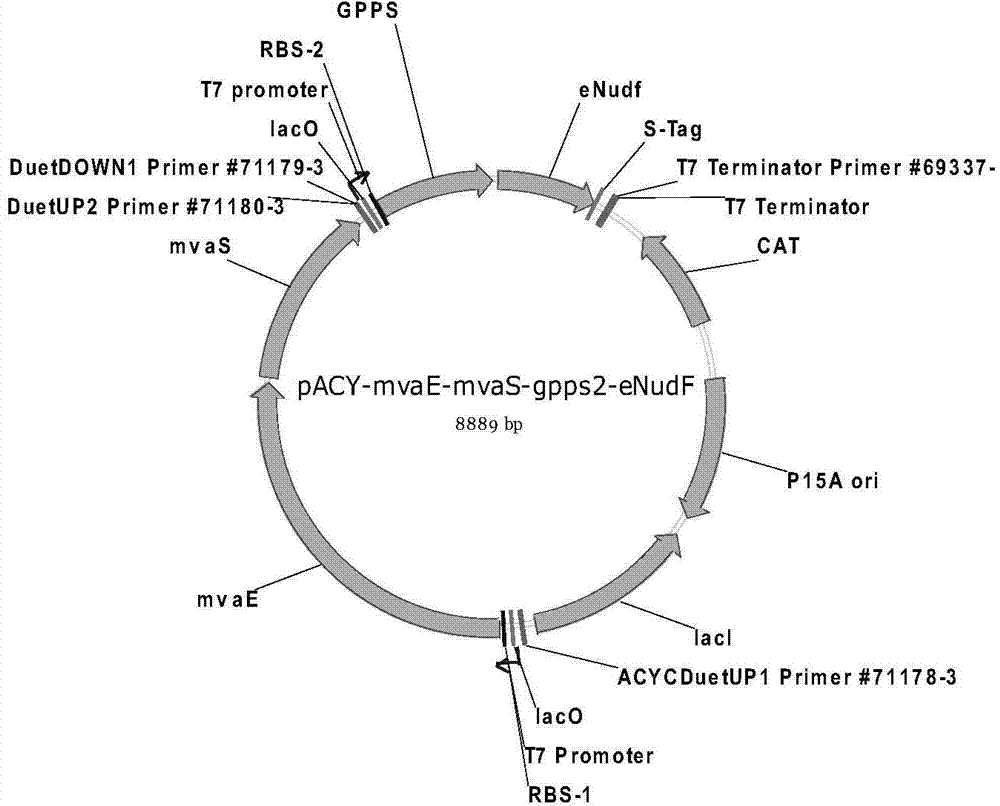

Genetically engineered bacterium co-generating geraniol and nerol and construction method and application thereof

ActiveCN103898037AFast growthShort fermentation cycleBacteriaMicroorganism based processesEscherichia coliGenetically engineered

The invention discloses a genetically engineered bacterium co-generating geraniol and nerol and a construction method and an application thereof, and belongs to the technical field of generic field. According to the genetically engineered bacterium disclosed by the invention, acetyl coenzyme A acyltransferase / hydroxymethyl glutaryl coenzyme A reductase, 3-hydroxyl-3-methyl glutaryl coenzyme A synthase, mevalonic acid kinase, mevalonic acid-5-phosphokinase, mevalonic acid-5-diphosphonic acid decarboxylase, isopentenylpyrophosphate isomerase, geranyl diphosphonic acid synthetase and geraniol synthetase or phosphatase are expressed. The metabolic pathways of geraniol and nerol synthesized in escherichia coli are successfully constructed by genetic engineering means, and glucose is biologically converted into geraniol and nerol.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Compounds and methods of early diagnosis of cervical cancer and genital condyloma with HPV, CHSP60 tumor suppressor h-ras, k-ras and PTEN derived peptides modified

InactiveUS20060154238A1Easy to synthesizeStrong specificityAntibody mimetics/scaffoldsViral antigen ingredientsAbnormal tissue growthHuman papillomavirus

An isolated sequence or peptide isolated from an E2, E4, E6, E7 early or late coding region of human papillomavirus (HPV) that is soluble in aqueous medium, and characterized by a linkage to another protein sequence or peptide isolated from the E2, E4, E6, E7 early or late coding region of HPV by a spacer sequence, wherein the isolated protein sequence or peptide consists of more than 50% hydrophilic amino acids, and is recognized by a specific antibody of HPV. Also disclosed are isolated protein sequences or peptides from Harvey Ras (H-Ras), Kirsten Ras (K-Ras), and phosphatase and tensin homologue (PTEN) tumor suppressor proteins and Chlamydia trachomatis heat shock protein 60 (CHSP60 groEL1) and methods for detecting or diagnosing cancer or cellular abnormalities.

Owner:HU YAO XIONG

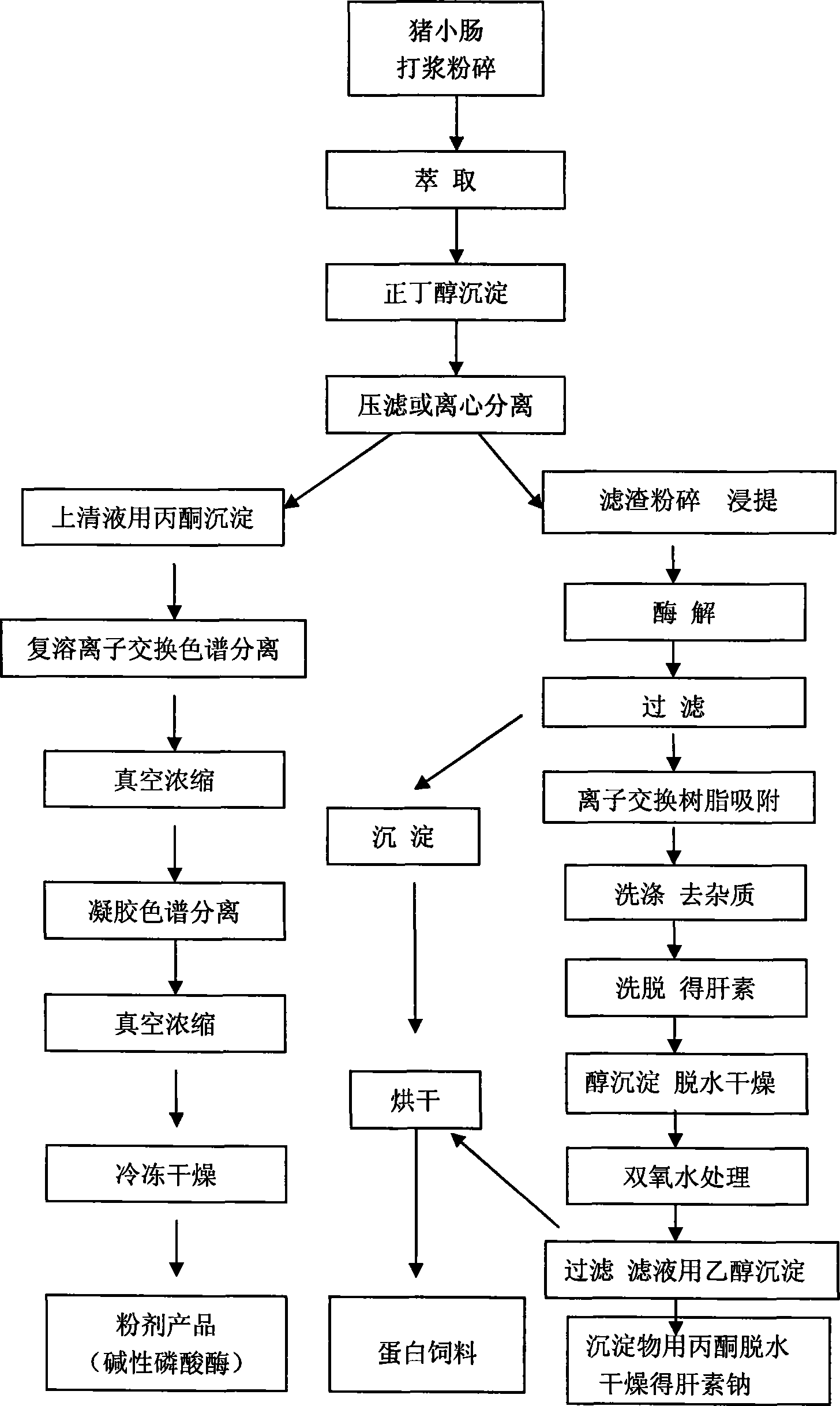

Joint production process joint production producing alkaline phosphatase and heparin sodium with pig small intestine as raw material

ActiveCN101182495AEfficient use ofReduce pollutionTransferasesChromatographic separationFreeze-drying

A co-production process for co-producing alkaline phosphatase and heparin sodium using pig small intestine as raw material, comprising the following steps: ① beating and crushing pig small intestine; ② adding 0.05mol / L Tris-HCl buffer solution for extraction; ③ n-butyl Alcohol precipitation; ④ pressure filtration or centrifugation; ⑤ The supernatant separated in step ④ is precipitated with acetone, and then separated by reconstitution ion exchange chromatography, concentrated, gel chromatographic separation, concentrated, and freeze-dried to obtain alkaline Phosphatase; ⑥ The filter residue separated in step ④ is extracted, enzymatically hydrolyzed, filtered, ion exchange resin adsorbed, washed to remove impurities, eluted to obtain heparin, and then subjected to alcohol precipitation, dehydration and drying to obtain crude heparin sodium, treated with hydrogen peroxide, filtered, The filtrate was precipitated with ethanol, dehydrated and dried with acetone to obtain fine heparin sodium. The process is suitable for industrial production, can not only extract alkaline phosphatase, but also can extract refined heparin sodium, which is beneficial to realize the comprehensive utilization of raw materials, reduce production costs, and reduce environmental pollution caused by leftovers.

Owner:郑州弗博瑞生物技术有限公司

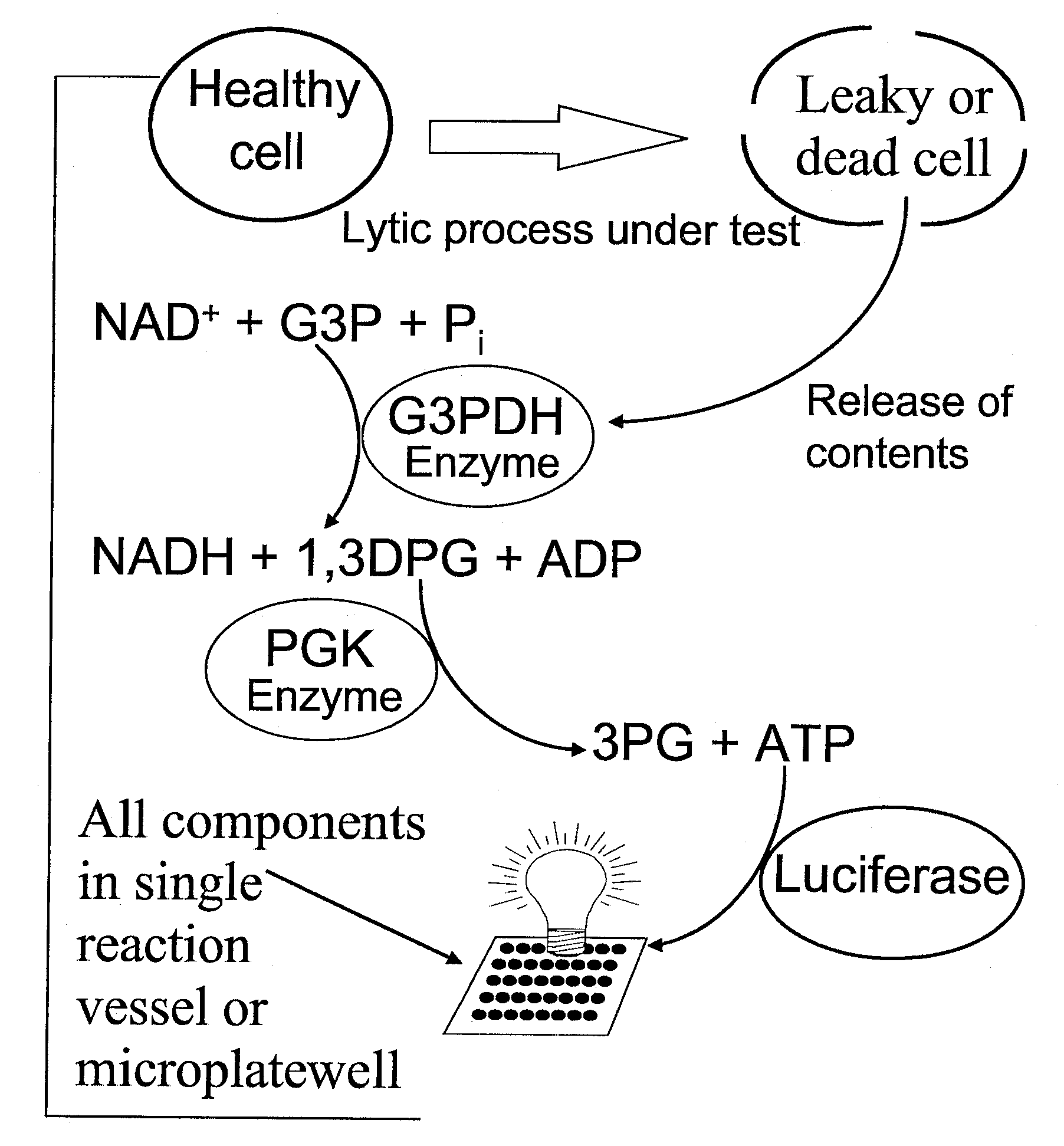

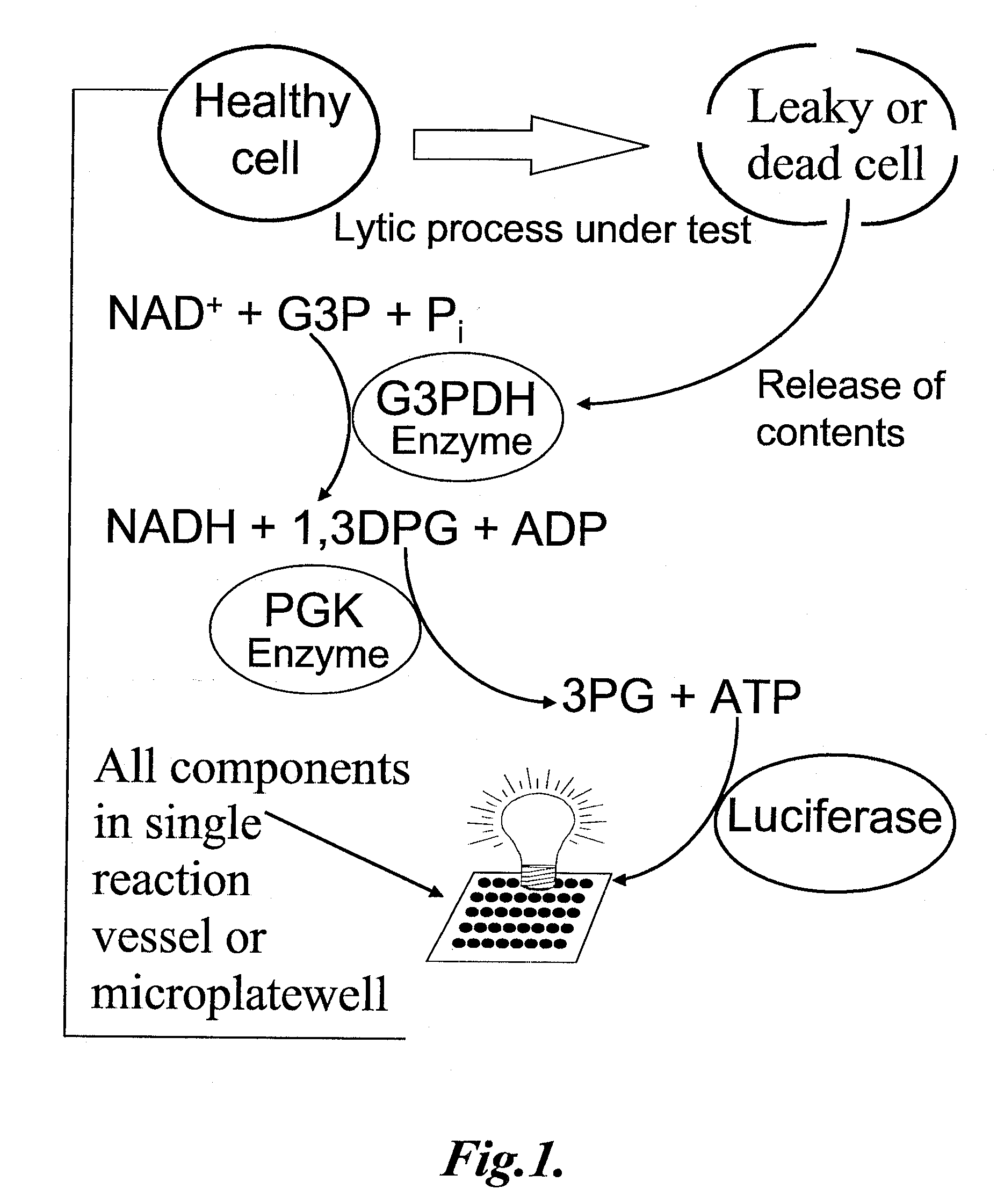

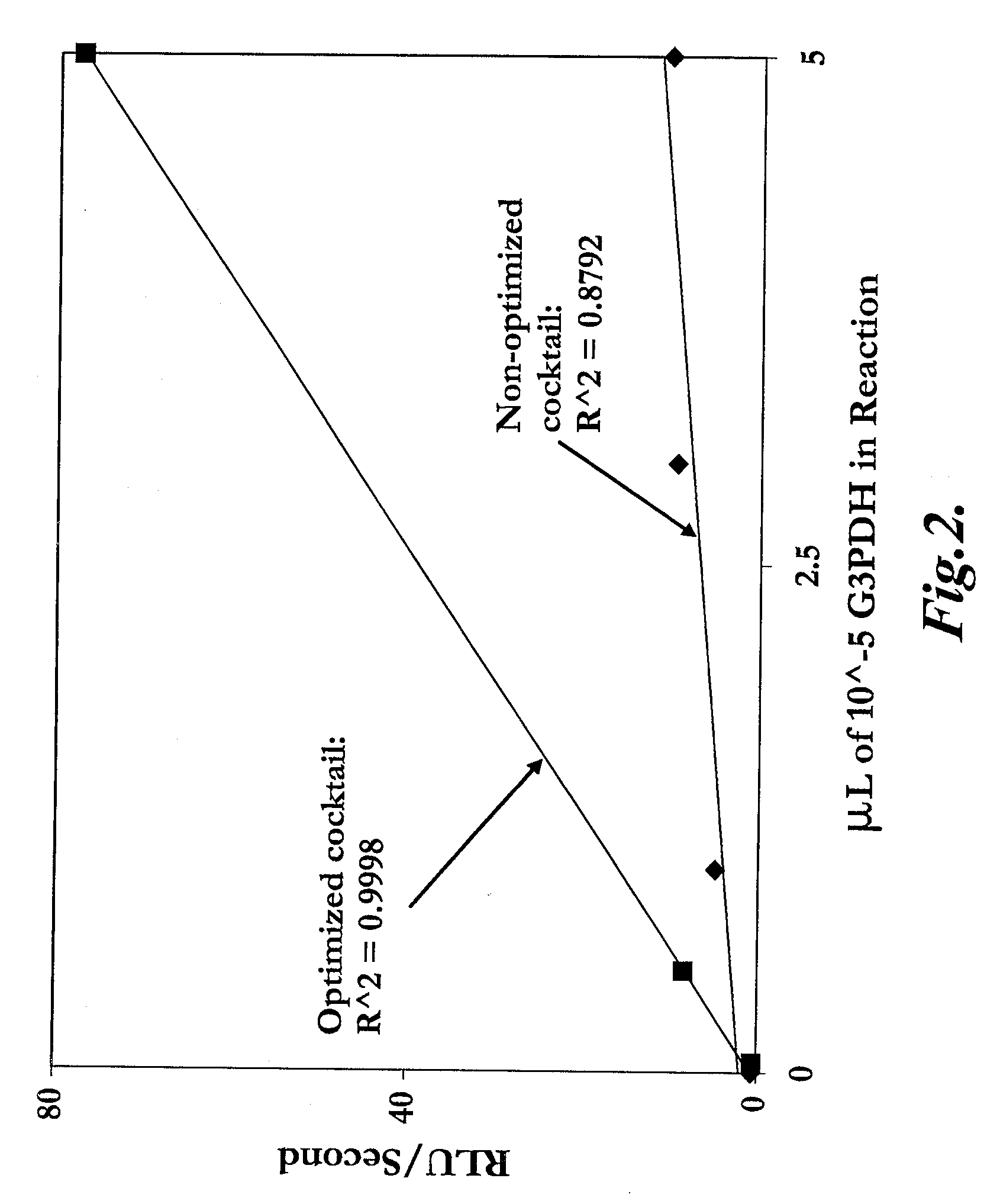

Methods and compositions for coupled luminescent assays

InactiveUS20080050762A1Inadequately sensitiveHigh degree of expertiseMicrobiological testing/measurementBiological material analysisInorganic phosphateHigh energy

The invention provides methods for measuring the amount or activity of a component in a sample using a luminescent assay comprising a luciferase capable of generating light from a high-energy molecule. In one aspect, the invention provides methods for measuring the amount of NAD+ or the activity of an enzyme or enzyme series that results in the interconversion of NDA+ and NADH. In another aspect, the invention provides methods for measuring the amount of a kinase substrate, free inorganic phosphate, and phosphatase activity. In a further aspect, the invention provides methods for measuring the amount of cAMP in a sample.

Owner:COREY MICHAEL J +1

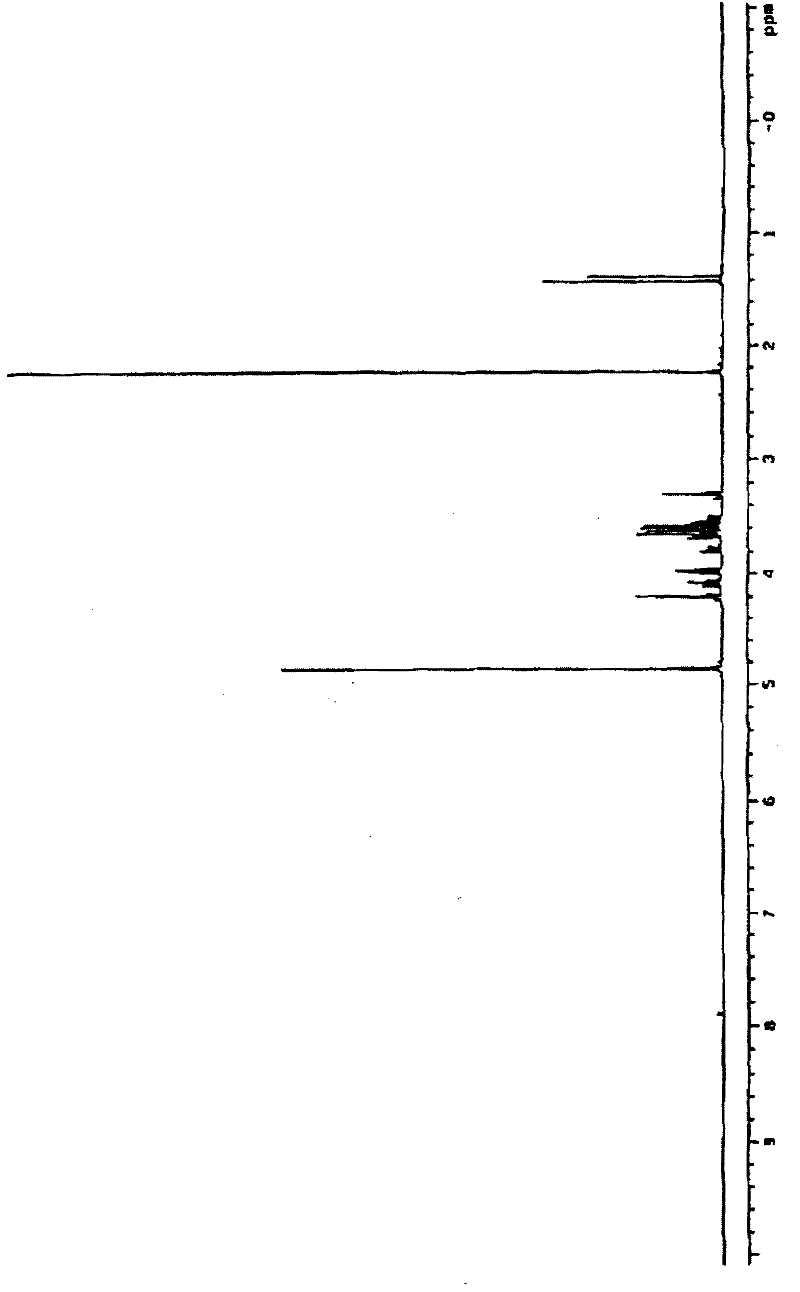

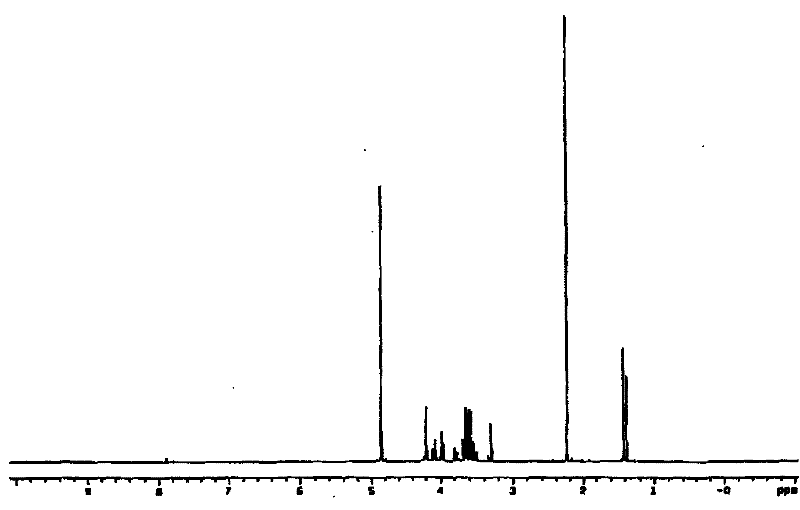

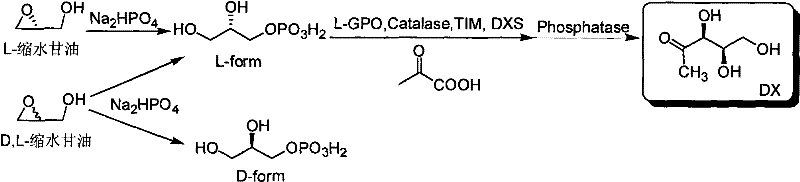

Method for preparing 1-deoxy-D-xylulose with chemical method-enzymatic method

InactiveCN101748170AHigh yieldImprove conversion rateSugar derivativesFermentationPhosphoric acidReaction step

The invention relates to a method for preparing 1-deoxy-D-xylulose with the combination of a chemical method and an enzymatic method, which comprises the steps as follows: in a water phase system under certain temperature, the glycidol can form glycerol 3-phosphate by inorganic phosphate through ring opening, then the generated L-glycerol 3-phosphate is oxidized by L-GPO to form DHAP under the existence of catalase, the DHAP is converted into DXP under the existence of pyruvic acid, TIM enzyme and DXS, and target molecule DX can be obtained by hydrolyzing the compound through phosphatase. The method organically couples the simple method for preparing the DHAP by taking the stable, cheap and easily available compound as raw material with the method for preparing the DX by using the enzymatic method, the target molecule DX can be obtained through one-step reaction, the yield is high, the purification step is simple and feasible, the DX with high purity (more than 95%) can be obtained, the price of the raw material is low, the nature is stable, and the technical problems of expensive and unstable reaction material, complicated reaction steps, longer time consuming and lower overall yield of the method for preparing DX in the background technology are solved.

Owner:NORTHWEST UNIV(CN)

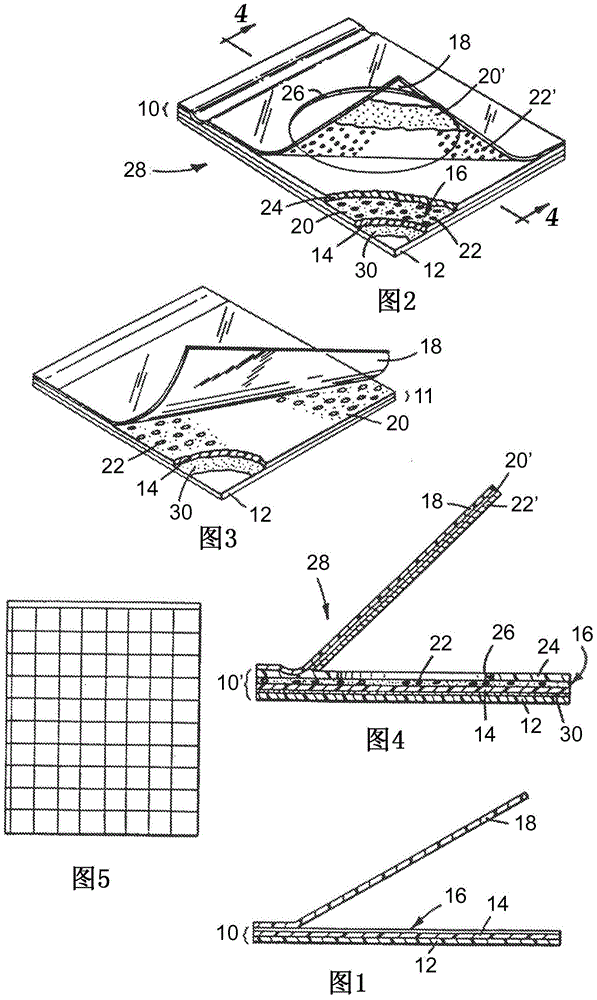

Method and culture device for detecting yeasts and molds

ActiveCN104968778ABioreactor/fermenter combinationsBiological substance pretreatmentsYeastMicroorganism

A thin film culture device for detecting yeast and mold microorganisms in a sample is provided. The culture device comprises a body comprising a self-supporting substrate having a first major surface and a second major surface; a first adhesive composition disposed on a portion of the first major surface of the substrate; a substantially dry, cold-water-soluble first hydrogel-forming composition adhered to the first adhesive composition; and a plurality of indicator agents. The plurality of indicator agents comprises three indicator agents for detecting distinct glycosidase enzyme activities, an indicator agent for detecting an alkyl esterase enzyme activity, and an indicator agent for detecting a phosphatase enzyme activity, wherein each of the plurality of indicator agents comprises a detectable reporter group. A method of using the culture device is also provided.

Owner:3M INNOVATIVE PROPERTIES CO

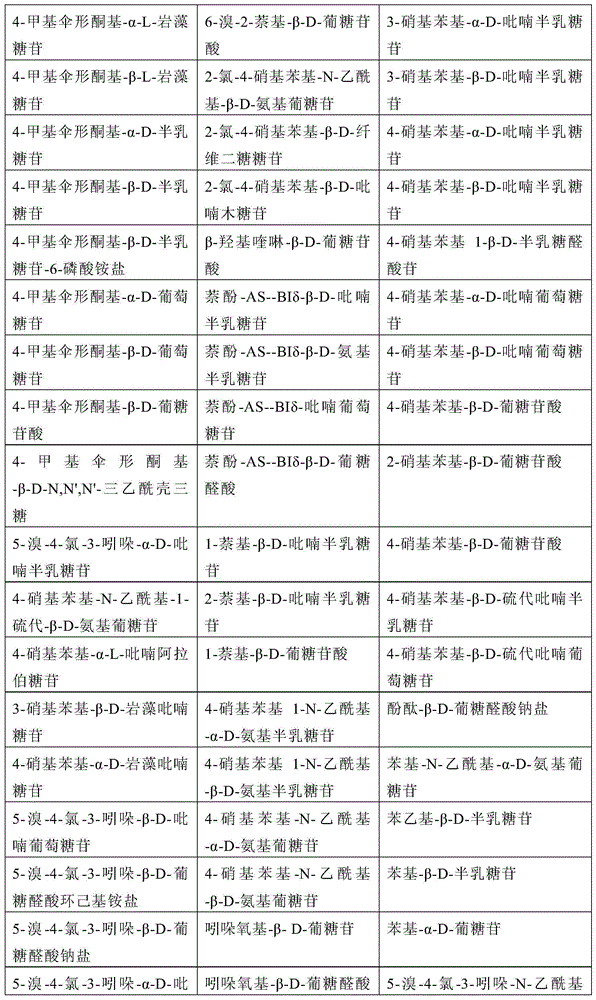

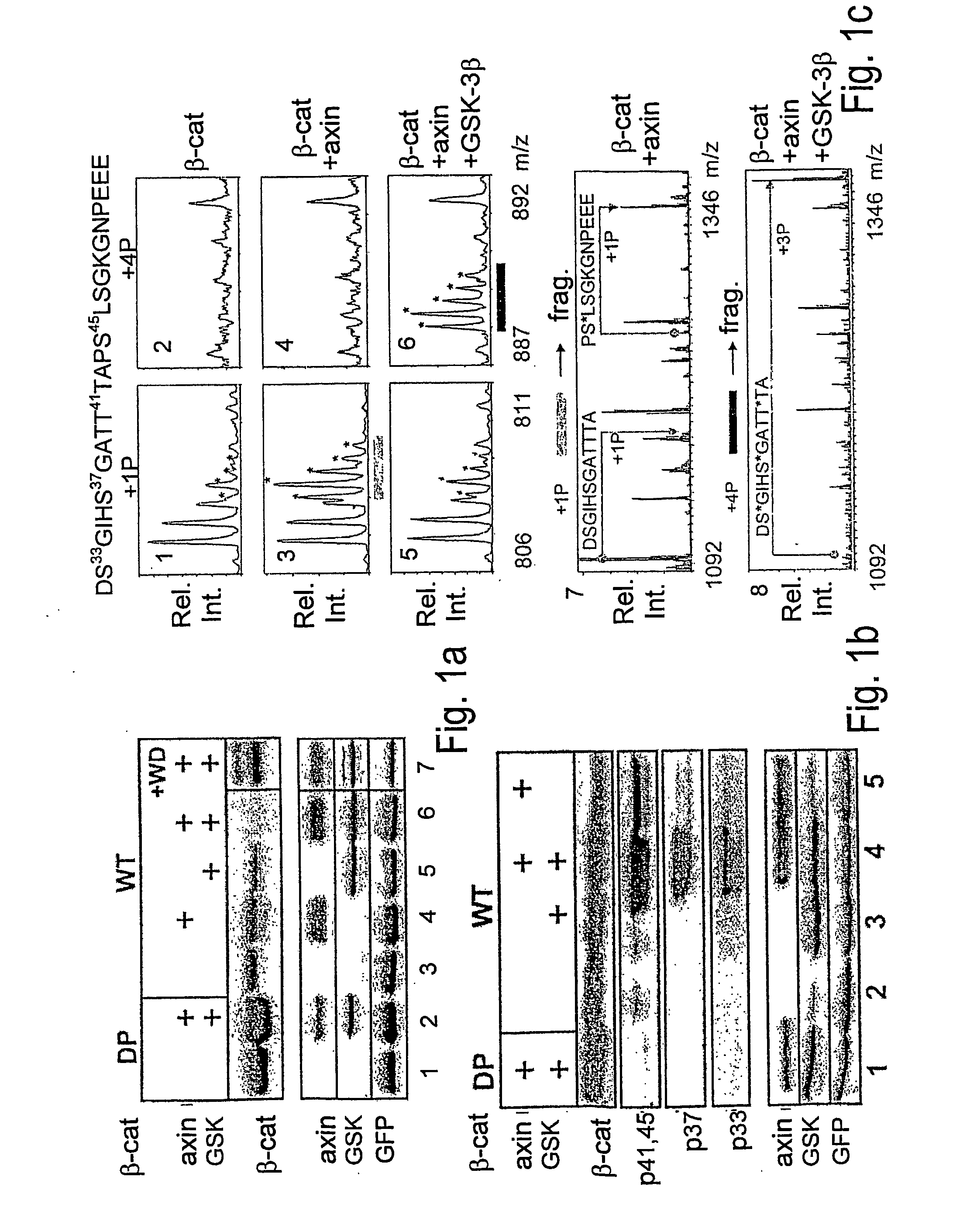

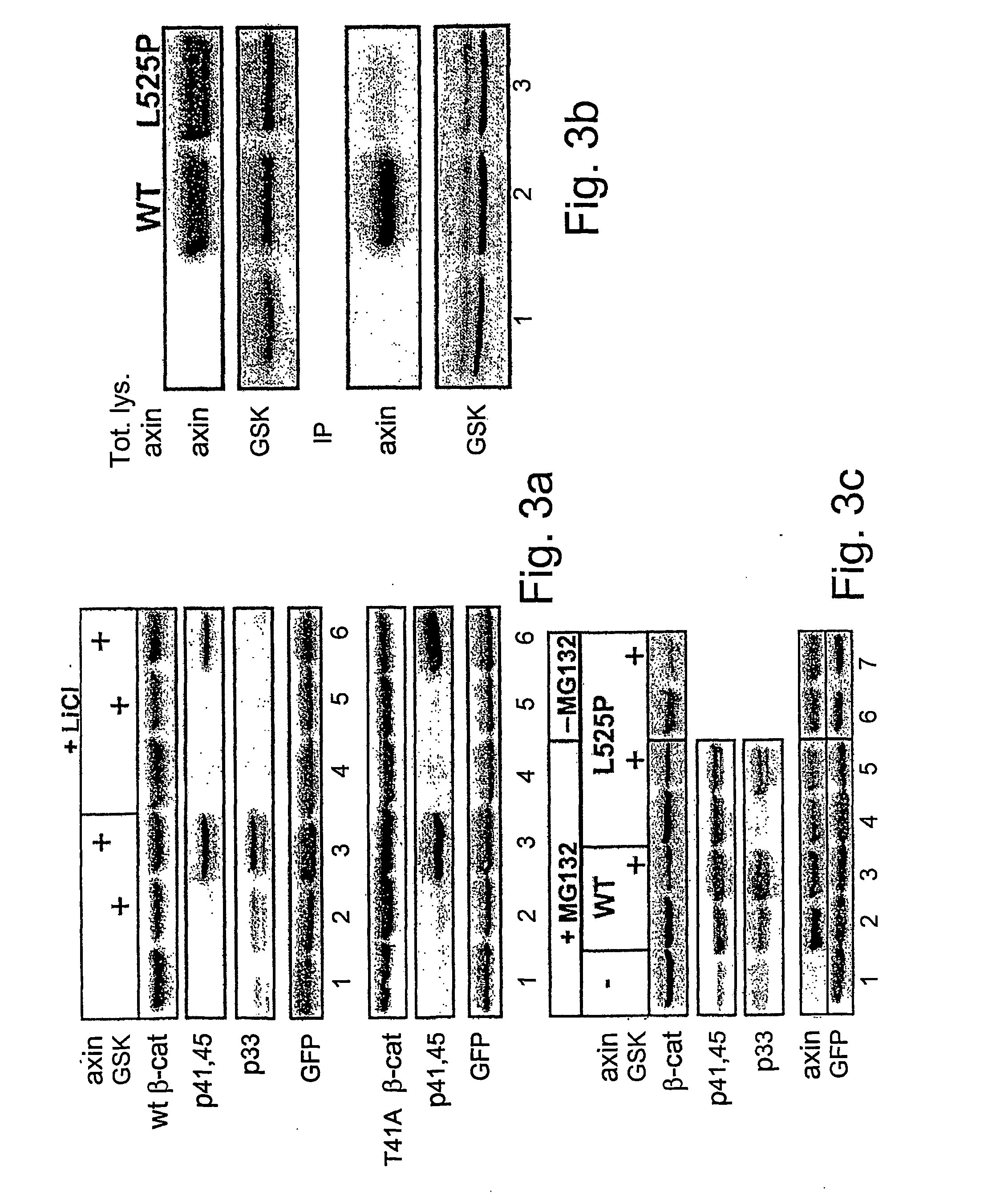

Methods and compositions for modulating beta-catenin phosphorylation

The present invention provides modulators of β-catenin phosphorylation. More specifically, the present invention provides inhibitors and enhancers of β-catenin Serine 45 (S45) phosphorylation. Examples of inhibitors provided by the invention are the proteins Dishevelled (Dvl), Wnt, phosphatase PP2A and CKI7. Examples of enhancers of beta-catenin phosphorylation are phosphatase inhibitors and proteins that promote β-catenin acetylation, like FRAT1. In addition, the present invention provides compositions and uses of the modulators of the invention, specifically for the treatment of cancer, as well as a method for screening such modulators.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

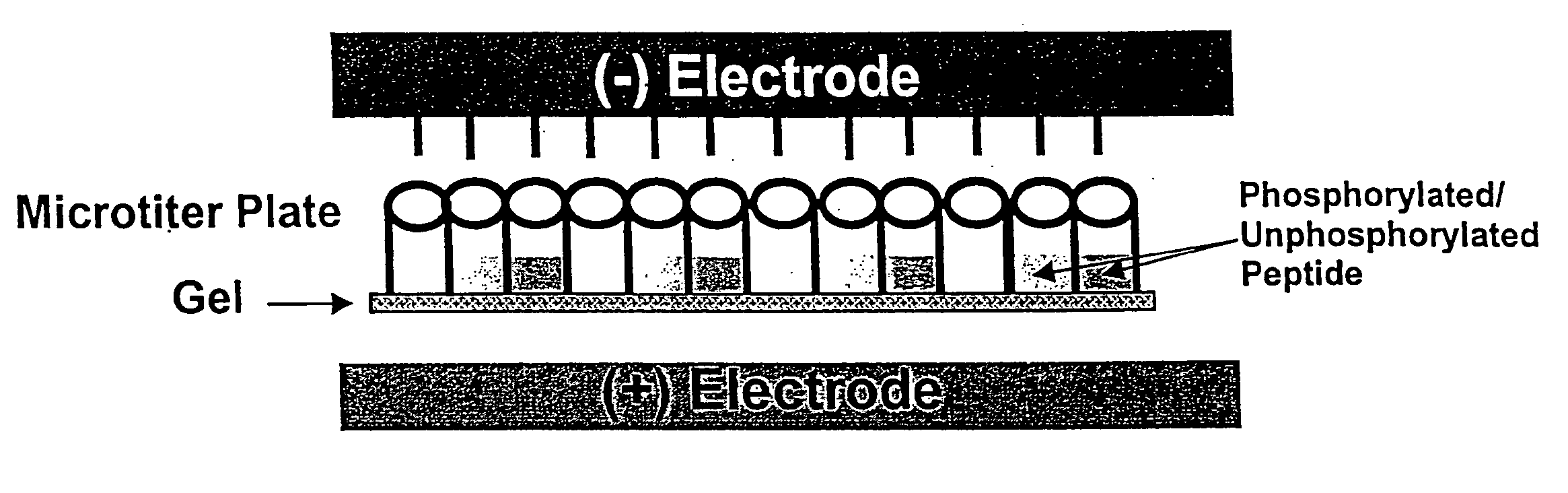

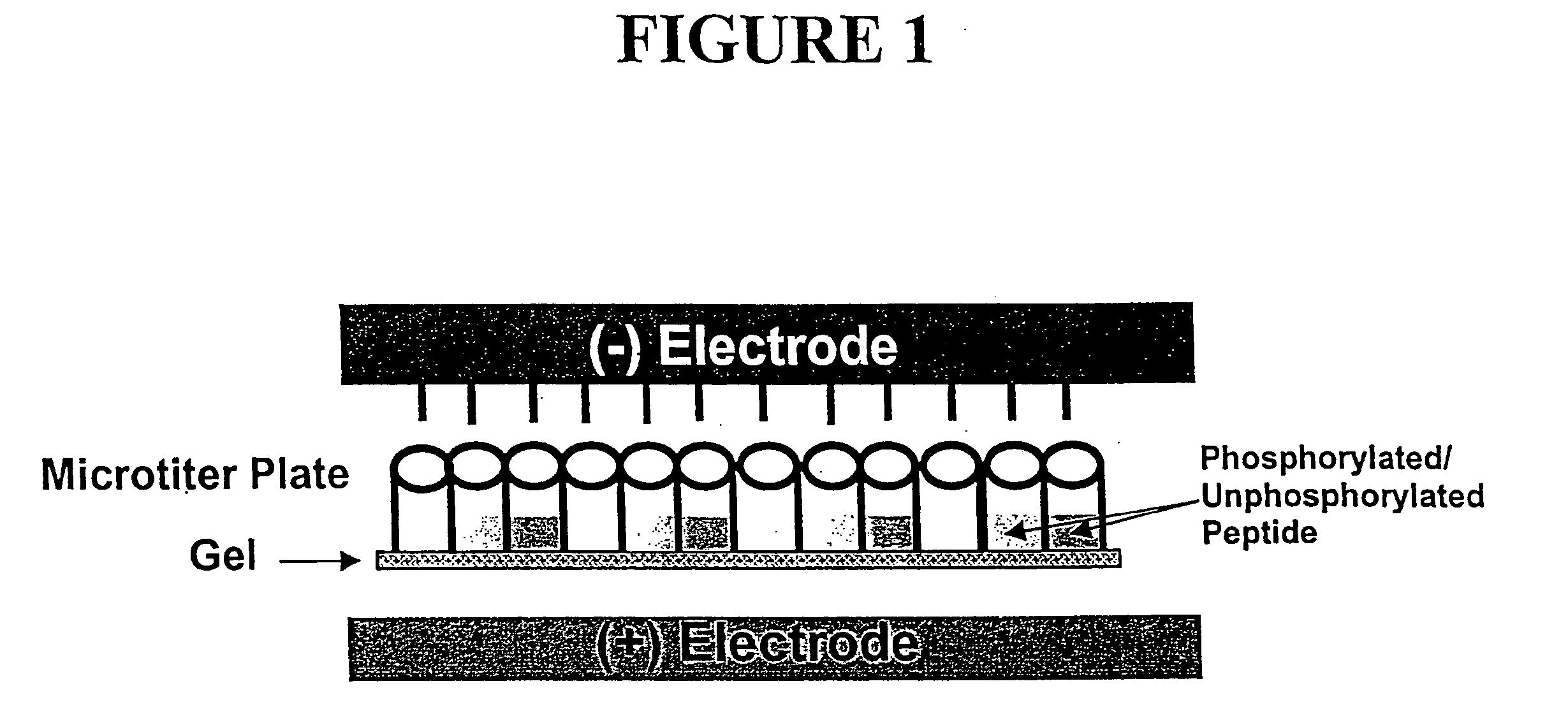

Microtiter plate format device and methods for separating differently charged molecules using an electric field

InactiveUS20050173247A1Easy to adaptSludge treatmentVolume/mass flow measurementHigh-Throughput Screening MethodsProteinase activity

Owner:NANOGEN INC

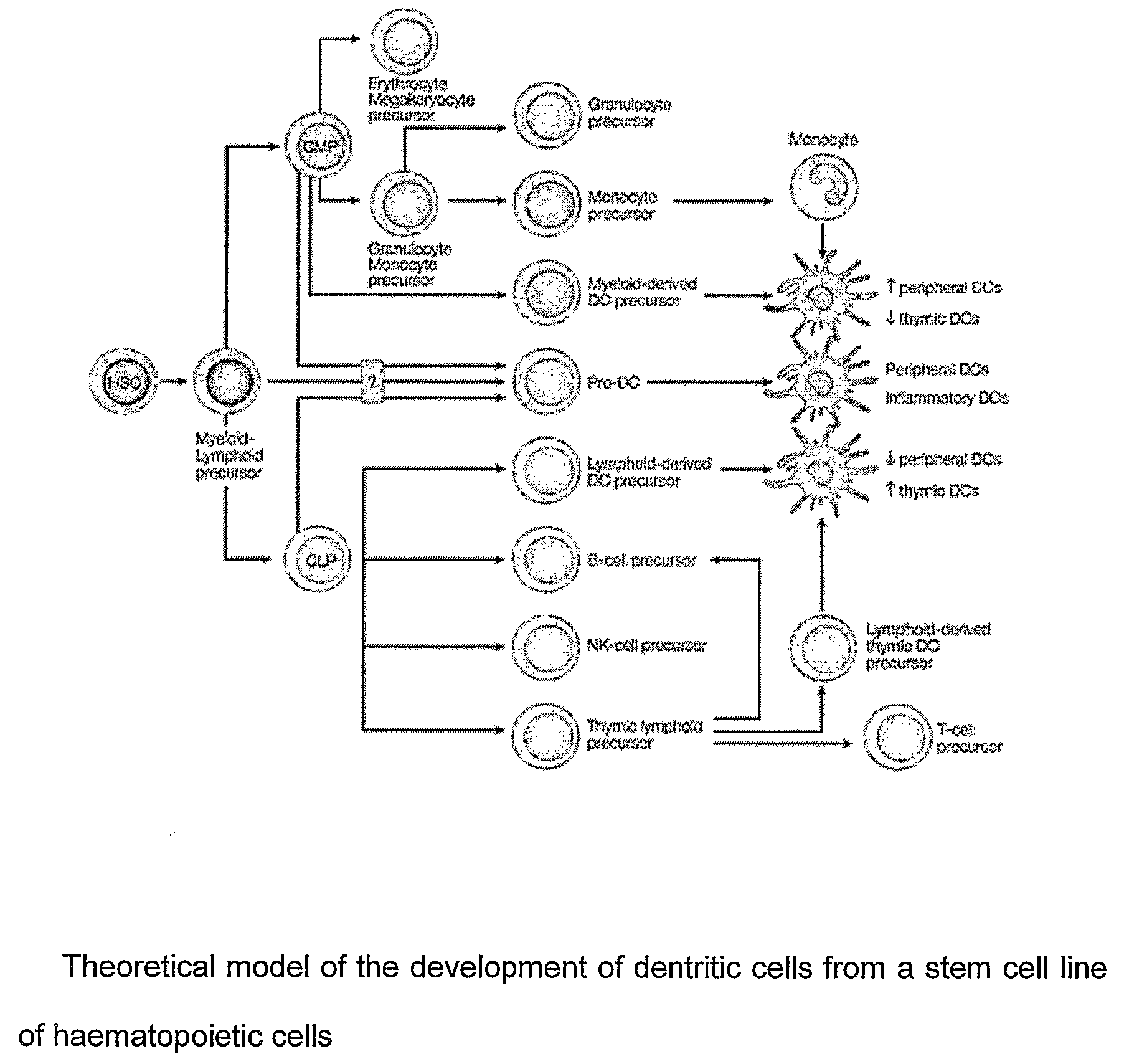

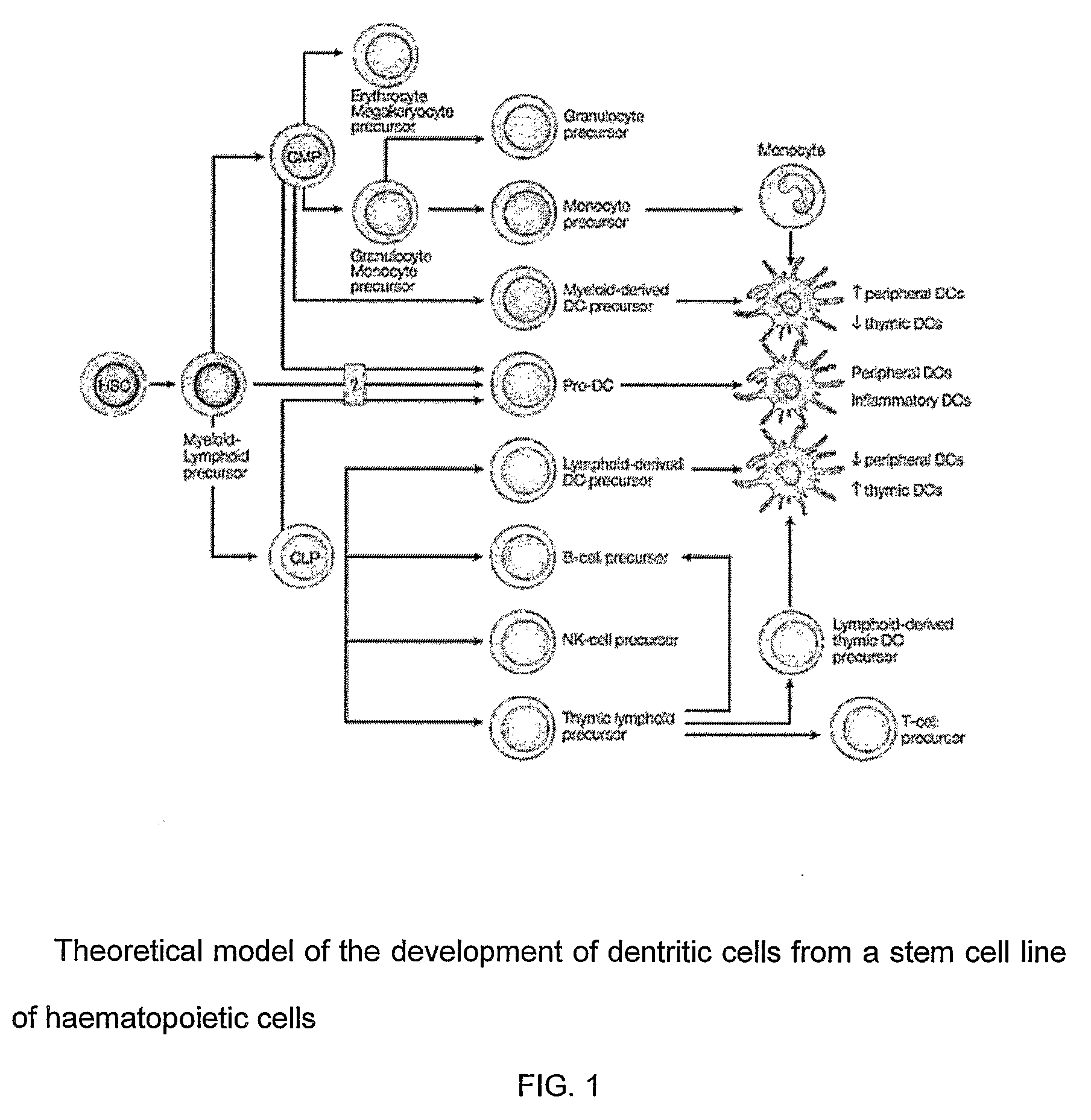

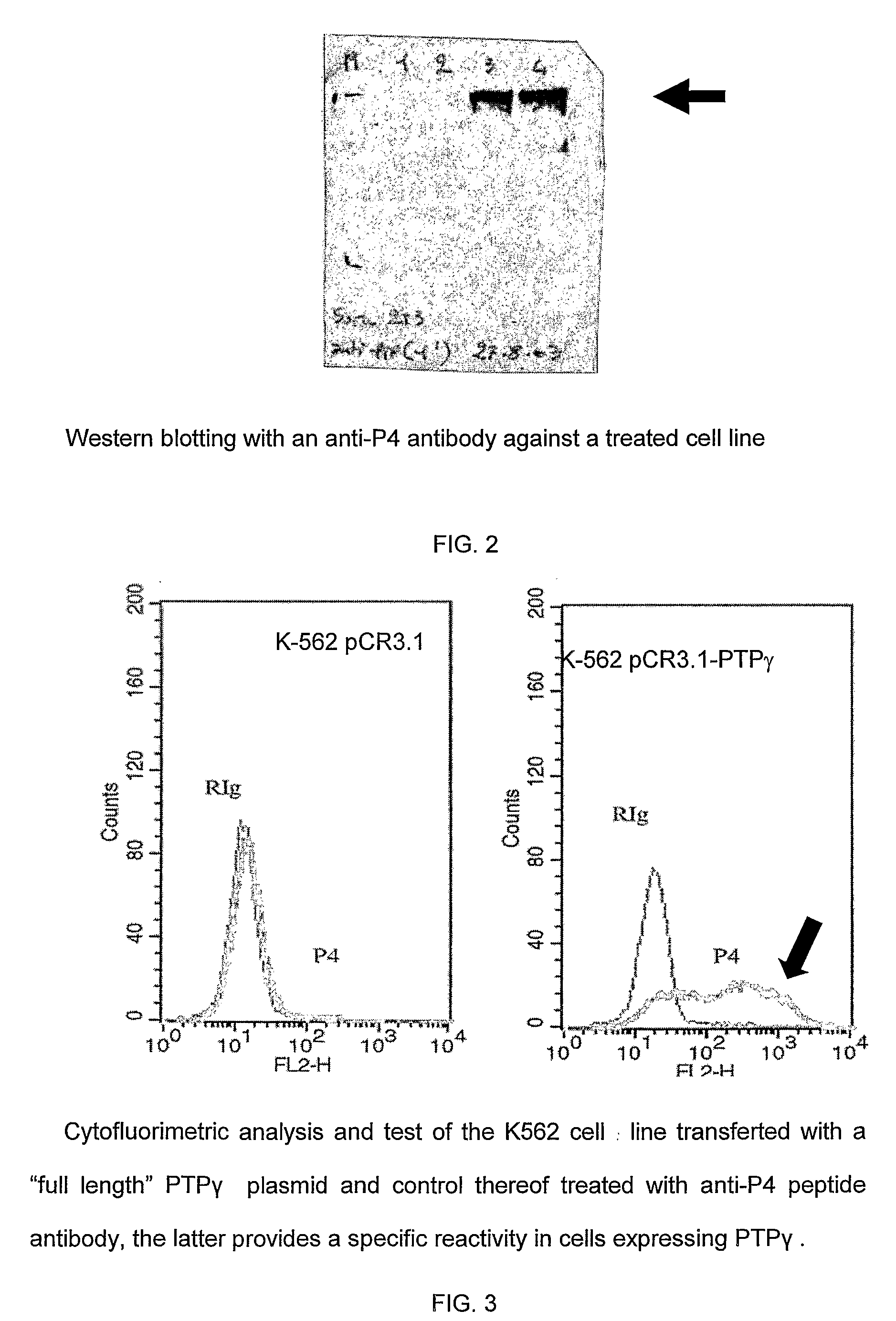

Antibody and method for identification of dendritic cells

InactiveUS20090131346A1Quick and low-cost and effectiveOrganic active ingredientsPeptide librariesPlasmacytoid dendritic cellMammal

Method for identifying myeloid or plasmacytoid dendritic cells provided by a mammal, stimulated or unstimulated, comprising the steps of: a) preparing a cell sample; b) contracting the cell sample myeloid or plasmacytoid dendritic cells to form a complex; c) detecting the complex; characterized in that the phosphatase is the Receptor type Tyrosine Phosphatase Gamma Protein (PTPRG), acting as a specific marker of said dendritic cells, and in that the compound is a polypeptide capable of selectively bind to the PTPRG or to a fragment thereof or to a oligonucleotide complementary to a PTPRG mRNA logonucleotide in such a manner as to allow the selective recognizing of the dendritic cells in the cell sample.

Owner:CONSORZIO PER GLI STUDI UNIVRI & VERONA

Efficient fertilizer and enzyme-assisted method of production

InactiveUS20030145639A1Increase productionPromote formationProductsMagnesium fertilisersBacillus fusiformisMagnesium ammonium phosphate

Slow-release fertilizer is produced by composting animal manure with a magnesium-rich compound The temperature of this mixture is maintained at 20-30° C. and the pH is maintained between 7-10. Urease is added to the mixture. Next, the mixture is inoculated with bacteria of the species Bacillus sphaericus, Bacillus globisporus, or Bacillus fusiformis. The mixture is then allowed to incubate for about 14 days to form magnesium ammonium phosphate. Optionally, phosphatase, an enzyme promoting the formation of phosphate from phosphorus-rich organic compounds, is added with the urease enzyme to increase the yield of magnesium-ammonium phosphate.

Owner:US ARMY CORPS OF ENGINEERS

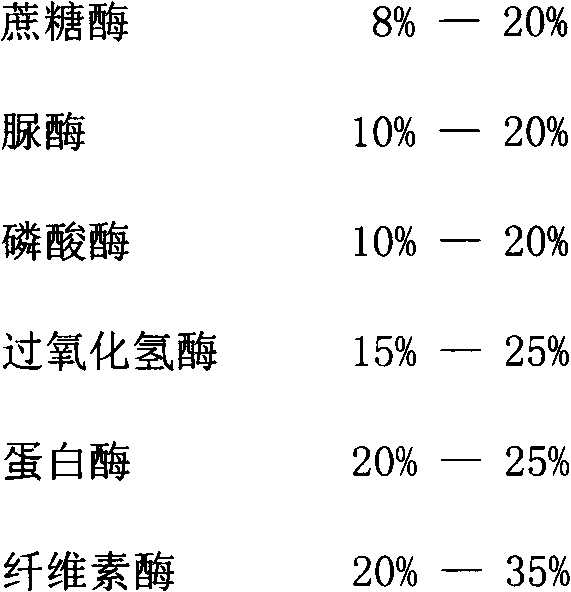

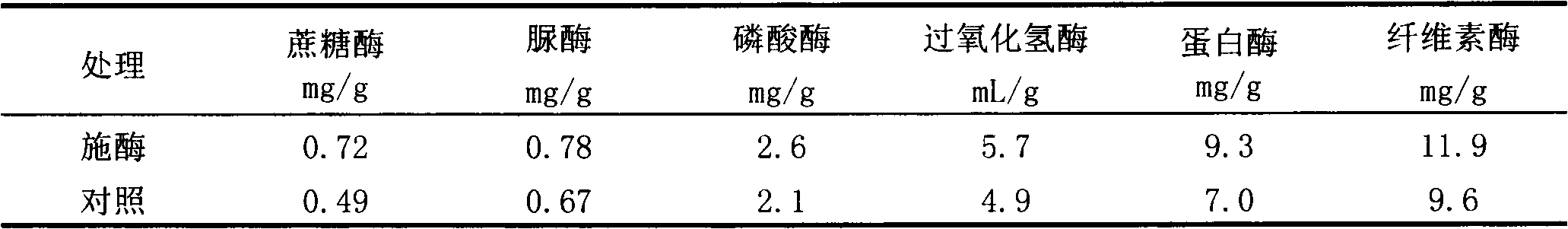

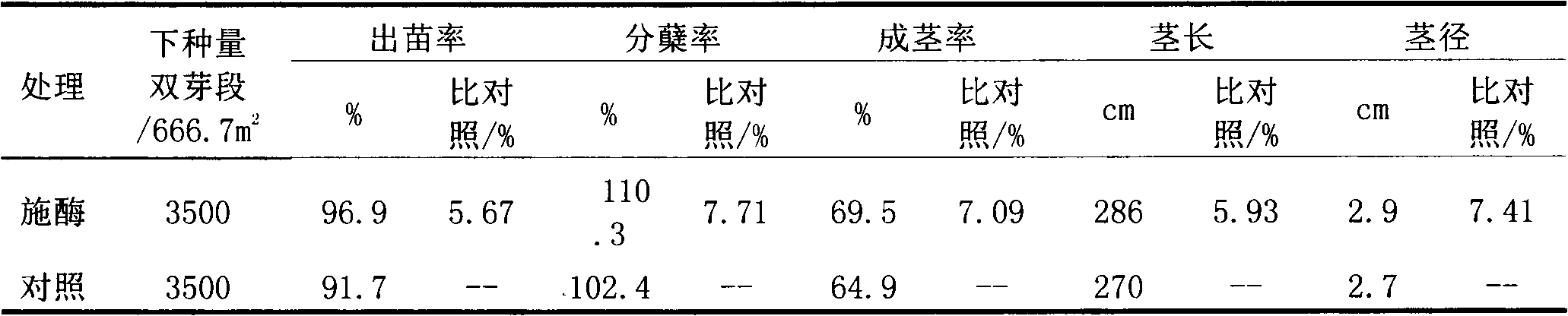

Compound enzyme preparation for improving yield and quality of sugarcane

The invention relates to a compound enzyme preparation for improving the yield and quality of sugarcane, which belongs to the technical field of biological enzyme, and is used for solving the problem of the lower germination rate of the sugarcane in a germination stage and the problem of the deficiency of partial nutrient elements of the sugarcane in a growth process. The compound enzyme preparation is characterized by comprising the following components by weight percentage: 8%-20% of sucrose, 10%-20% of urease, 10%-20% of phosphatase, 15%-25% of catalase, 20%-25% of protease and 20%-35% of cellulose. The compound enzyme preparation can be used for improving the yield and quality of the sugarcane.

Owner:SUZHOU KUNLAN BIOTECH

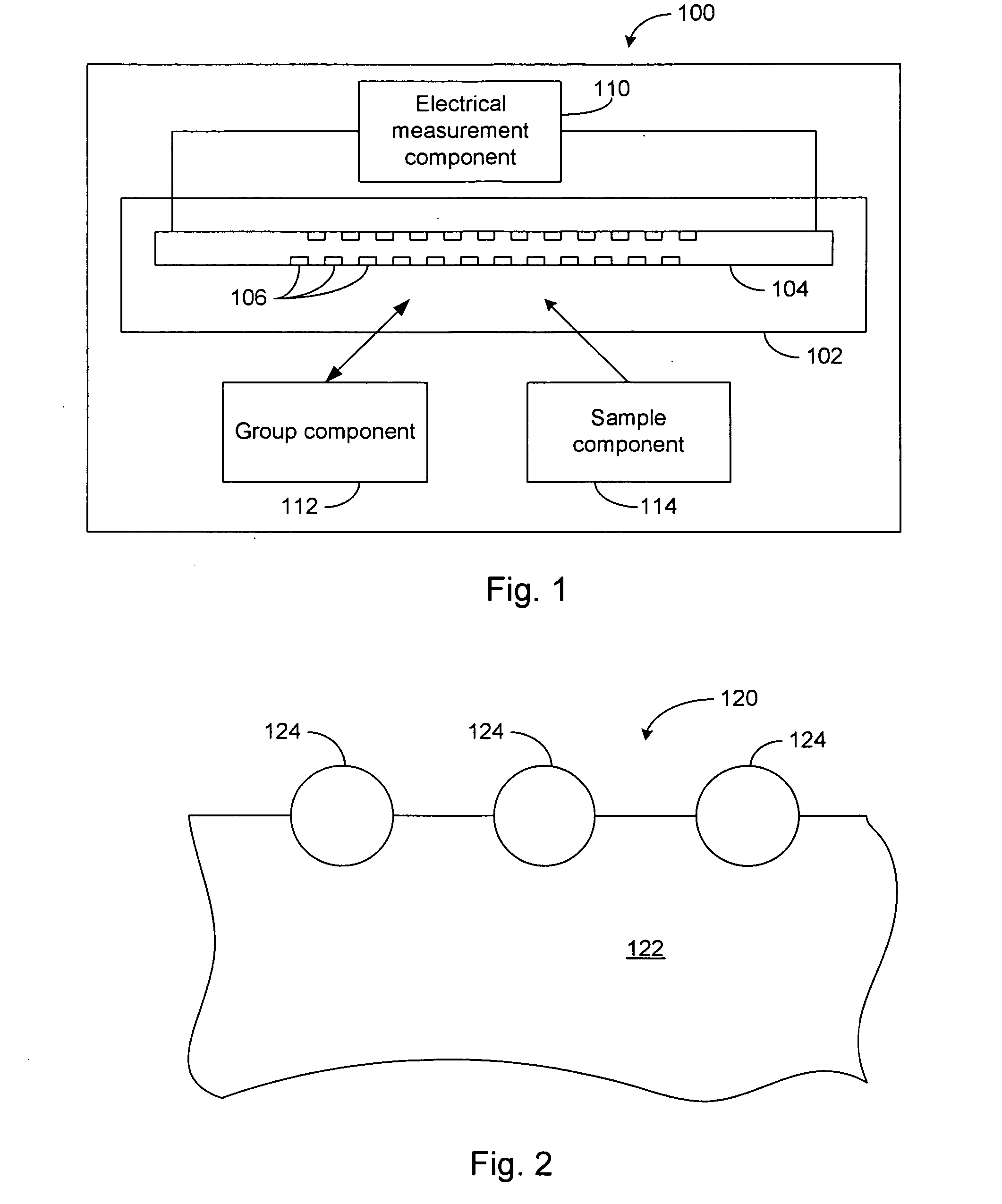

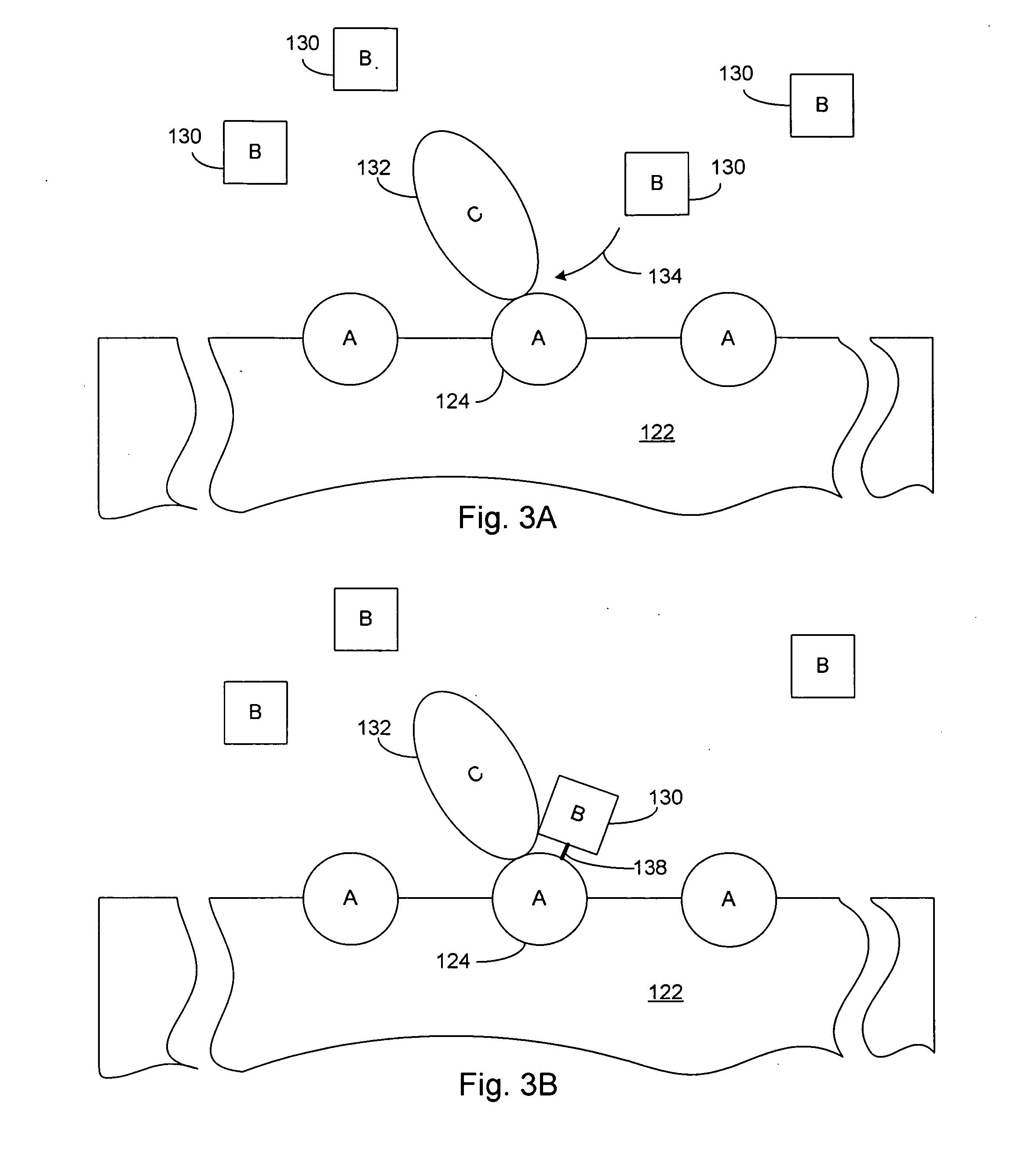

Enzyme assay with nanowire sensor

InactiveUS20060084128A1Bioreactor/fermenter combinationsBiological substance pretreatmentsNanowireEnzyme assay

Systems and methods for enzyme assay using nanowire sensor are disclosed. In some embodiments, a substrate and a group suitable for assaying a target enzyme are identified. The selected substrate is immobilized to a nanowire. The target enzyme introduced to the immobilized substrate modifies the substrate to facilitate addition or removal of the selected group to or from the substrate by formation or breaking of a covalent bond between the group and the substrate. The activity of the target enzyme can be determined by measuring a change in an electrical property of the nanowire due to the addition or removal of the group to or from the immobilized substrate. Kinase and phosphatase are two example reactions that can be assayed by such a method.

Owner:APPL BIOSYSTEMS INC

Anthracene fluorescent dye synthesis and application

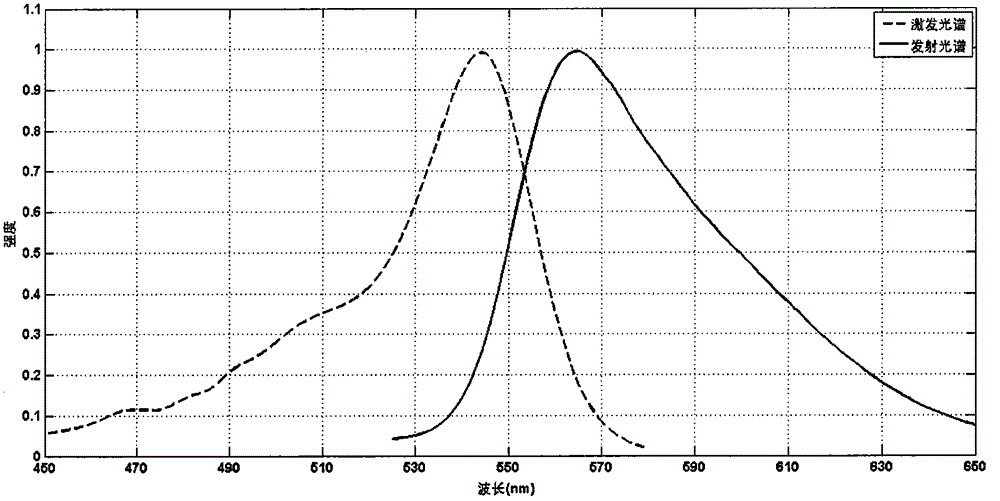

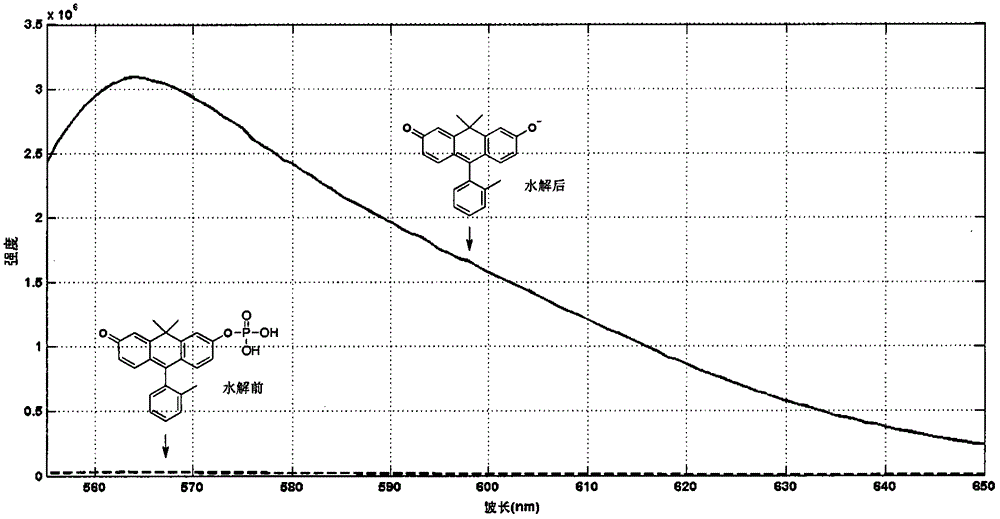

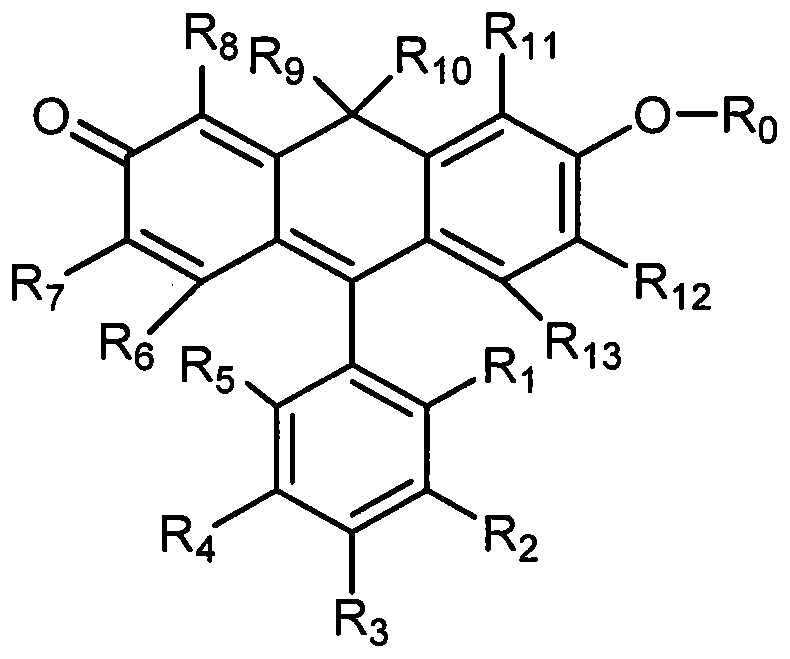

ActiveCN105315698AHigh absorbance coefficientHigh quantum yieldAnthracene dyesLuminescent compositionsQuantum yieldAnthracene

The invention provides a novel fluorescent dye structure and a synthesis method thereof. The anthracene structure fluorescent dye of the type has a high light absorption coefficient similar to that of fluorescein molecules, a high quantum yield and the like and meanwhile has more bathochromic-shift excitation wavelength and emission wavelength. The synthesis method is simple and economical and suitable for large-scale synthesis and group modification of a molecular structure. According to the anthracene fluorescent dye synthesis and application, phosphatase substrate molecules with a fluorescent generation property can be obtained through phosphorylation modification conducted on the molecules, and wide biological application prospect is achieved.

Owner:CYGNUS BIOSCI BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com