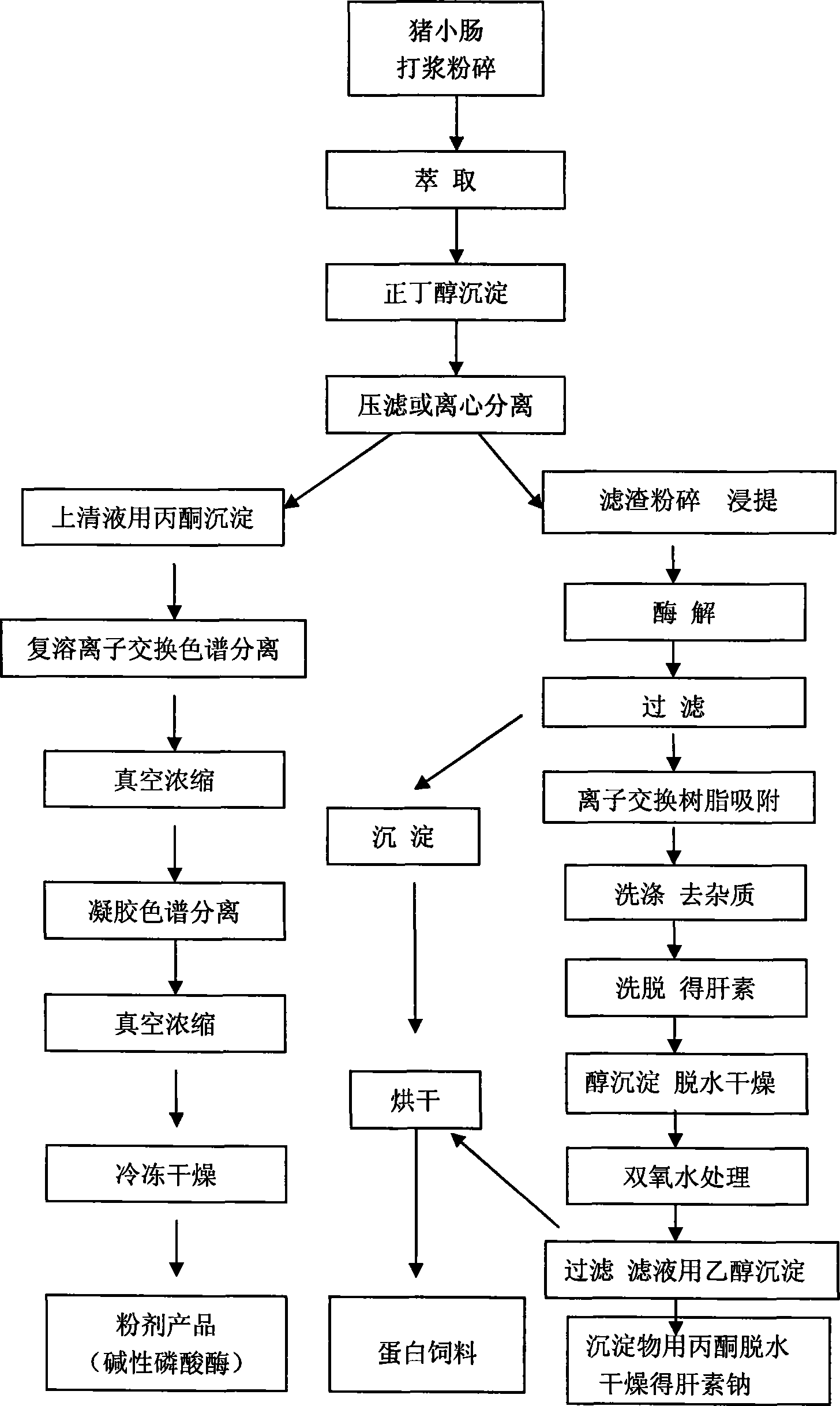

Joint production process joint production producing alkaline phosphatase and heparin sodium with pig small intestine as raw material

A technology of heparin sodium and phosphatase, applied in the field of biomedicine, can solve the problems of unclear precise structure of heparin, complex heparin structure, abnormally complex heparin structure, etc., and achieves the effects of good hydrolysis effect, optimization of enzymolysis parameters and reduction of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the specific preparation methods and processes of each target object, but does not limit the protection scope of the present invention.

[0042] 1. Isolation and purification of alkaline phosphatase

[0043] (1) Clean the small intestine of the pig, cut its mucous membrane into pieces, add 0.05mol / L Tris-HCl buffer (pH7.5, containing 0.01mol / L Magnesium Chloride-0.01mol / L Sodium Chloride-0.01mol / L Zinc Chloride), fully homogenize in a beater, and then place the slurry at a low temperature of 4-10°C for more than 10h.

[0044] (2) Add pre-cooled n-butanol to the homogenate to make the concentration of n-butanol reach 20%-25% (V / V). After fully stirring, keep stirring in a water bath not higher than 37°C for 20-20- 30min, then place at room temperature for 8-10h.

[0045] (3) After pressing with a plate and frame filter press or centrifuging with a centrifuge (3000-5000r / m), the filtrate is colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com